Page 1

LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

MARCH 2008 VOLUME XVIII NUMBER 1

IN THIS ISSUE…

COVER ARTICLE

Complete IF Receiver Has

16-Bit, 130Msps ADC, Fixed-Gain

Amplifier and Antialias Filter in

11.25mm × 11.25mm

µModule™ Package .............................1

Todd Nelson

Linear in the News… ...........................2

DESIGN FEATURES

Voltage and Current Monitoring from

7V to 80V in 3mm × 3mm DFN-10 ........5

Zhizhong Hou

Increase I2C or SMBus Data Rate and

Reduce Power Consumption with

Low Power Bus Accelerator .................8

Sam Tran

6-Input Supervisors Offer Accurate

Monitoring and 125°C Operation ......10

Shuley Nakamura and Al Hinckley

High Power, Single Inductor,

Surface Mount Buck-Boost µModule

Regulators Handle 36VIN, 10A Loads

.........................................................16

Manjing Xie

1.5% Accurate Single-Supply

Supervisors Simplify Part Selection

and Operate to 125°C ........................20

Bob Jurgilewicz and Roger Zemke

Versatile Current Sense Amplifiers

Offer Rail-to-Rail Input, 150°C

Operating Temperature ....................24

William Jett and Glen Brisebois

Compact Hot Swap™ Solution

Simplifies Advanced Mezzanine

Card Design ......................................27

Chew Lye Huat

DESIGN IDEAS

....................................................

(complete list on page 31)

New Device Cameos ...........................37

Design Tools ......................................39

Sales Offices .....................................

31–36

40

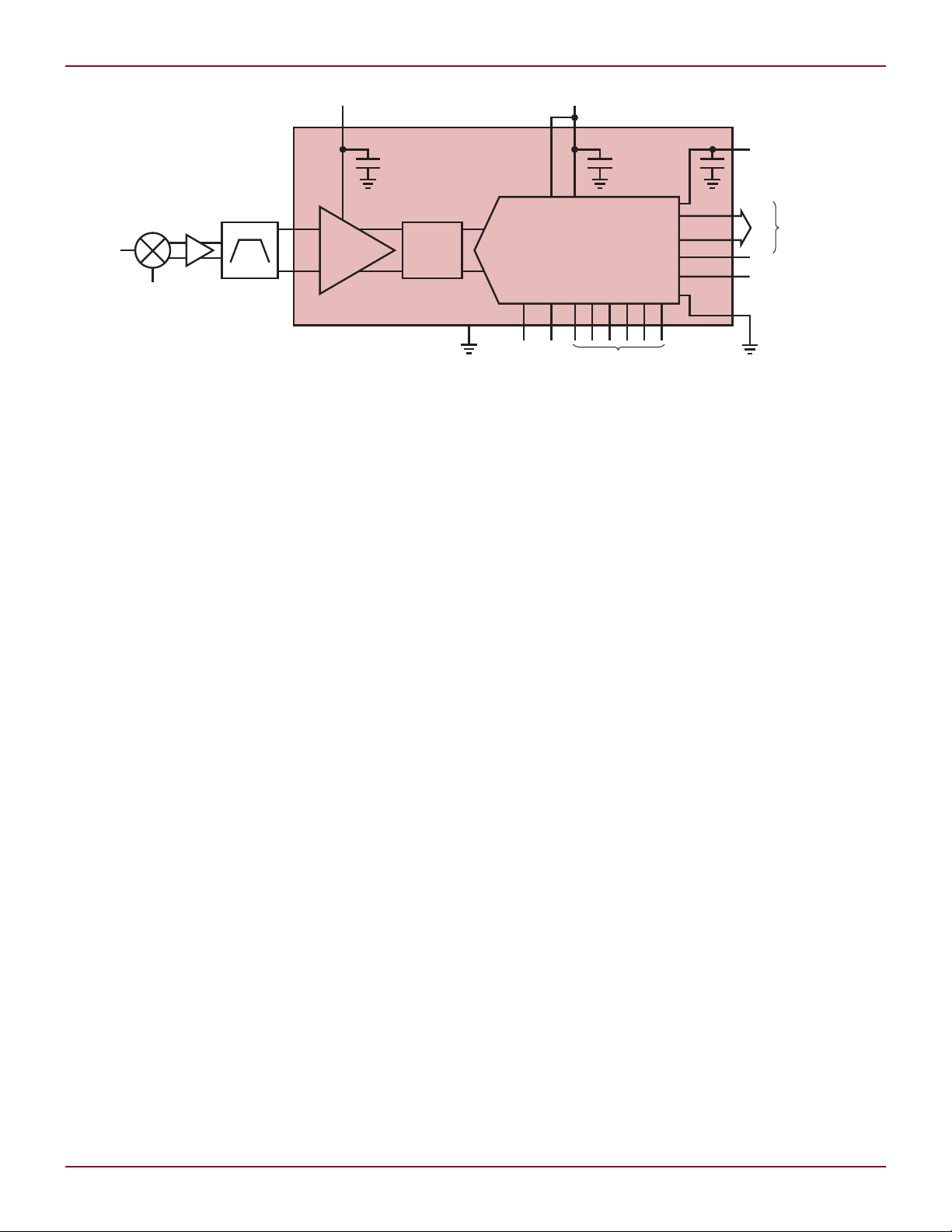

Complete IF Receiver

Has 16-Bit, 130Msps ADC,

Fixed-Gain Amplifier

and Antialias Filter in

11.25mm × 11.25mm

µModule Package

by Todd Nelson

Introduction

In the design of high speed receivers for communications, test or

instrumentation equipment, several

specialized disciplines converge in

one place—the analog-to-digital converter (ADC). Unfortunately, the ADC

is not a simple black box where an

RF designer applies the signal and a

digital designer retrieves the accurate

output. Careful design of the signal

conditioning circuitry to drive the ADC

is critical. Something as seemingly

straightforward as board layout can

degrade the downstream signal by a

few precious decibels. The problem

is that the disciplines required for

the engineering on either side of the

ADC, namely RF/IF design and digital

design, do not include mastery of the

art of ADC interface design. Someone

has to put in the effort to properly drive

the ADC. But who? Instead of adding

more work to either designer’s plate,

what if the ADC were really a black

box, already loaded with integrated

signal conditioning components in an

optimized layout? Now, that would be

a better solution.

The LTM9001 is built using

Linear Technology’s µModule

technology to create an IC

form factor System-in-a-

Package (SiP) that includes

a high speed 16-bit ADC,

antialiasing filter and a low

noise, differential amplifier

with fixed gain. It can

digitize wide dynamic range

signals with an intermediate

frequency (IF) range

up to 300MHz.

The LTM9001 is exactly that black

box. It is built using Linear Technology’s µModule™ technology to create

an IC form factor System-in-a-Package

(SiP) that includes a high speed 16bit ADC, antialiasing filter and a low

noise, differential amplifier with fixed

gain. It can digitize wide dynamic range

continued on page 3

L

, LT, LTC, LTM, Burst Mode, OPTI-LOOP, Over-The-Top and PolyPhase are registered trademarks of Linear Technology

Corporation. Adaptive Power, Bat-Track, BodeCAD, C-Load, DirectSense, Easy Drive, FilterCAD, Hot Swap, LinearView,

µModule, Micropower SwitcherCAD, Multimode Dimming, No Latency ΔΣ, No Latency Delta-Sigma, No R

Filter, PanelProtect, PowerPath, PowerSOT, SmartStart, SoftSpan, Stage Shedding, SwitcherCAD, ThinSOT, True Color PWM,

UltraFast and VLDO are trademarks of Linear Technology Corporation. Other product names may be trademarks of the

companies that manufacture the products.

, Operational

SENSE

Page 2

CLKOUT

OF

LO

V

CC

= 3.3V V

DD

= 3.3V

ENC+ENC

–

ADC CONTROL PINS

DIFFERENTIAL

FIXED GAIN

AMPLIFIER

16-BIT

130Msps ADC

RF

IN

–

IN

+

LTM9001

SENSE

GND

D15

•

•

•

D0

0VDD = 0.5V TO 3.6V

OGND

CMOS

OR

LVDS

SAW

ANTI-ALIAS

FILTER

LTM9001, continued from page 1

DESIGN FEATURES L

Figure 1. A typical application and simplified block diagram of the LTM9001

signals with an intermediate frequency

(IF) range up to 300MHz. Figure 1

shows a typical application.

How is a µModule component

different than a traditional IC? The

µModule construction allows the

LTM9001 to mix standard ADC and

amplifier components regardless of

their process technology and match

them with passive components for

a particular application. The result

is a high performance product with

no process technology compromises

and the potential for semi-custom

adaptations.

What’s Inside?

The µModule receiver consists of wirebonded die, packaged components and

passives mounted on a high performance, 4-layer, Bismaleimide-Triazine

(BT) substrate. BT is similar to other

laminate substrates such as FR4 but

has superior stiffness and a lower

coefficient of thermal expansion.

In time, several different versions

of the LTM9001 will be available. The

LTM9001-AA, as the first release, is

configured with a 16-bit, 130Msps

ADC. The amplifier gain is 20dB with

an input impedance of 200Ω and an

input range of ±250mV. The matching network is designed to optimize

the interface between the amplifier

outputs and the ADC inputs under

these conditions. Additionally, there

is a second order bandpass filter

designed for 162.5MHz, ±25MHz to

prevent aliasing and to limit the noise

from the amplifier.

Linear Technology Magazine • March 2008

Extracting the full performance

from 16-bit, high speed ADCs requires

careful layout as well as good circuit

design. The substrate design carefully

shields sensitive analog traces, maximizes thermal conduction through

multiple ground pads and minimizes

coupled noise by including bypass

capacitors inside the module and close

to the ADC. A common problem with

traditional ADC board layouts is long

traces from the bypass capacitors to

the ADC. The bare die construction

with internal bypass capacitors provides the closest possible decoupling

and eliminates the need for external

bypass capacitors.

The passive filter network implements an antialias filter and matches

the amplifier outputs to the ADC inputs. Most communications receiver

applications utilize a highly selective

filter between the mixer and the ADC

driver. The antialias filter between

the ADC driver and the ADC inputs

limits the wideband amplifier noise

and helps preserve the high SNR of

the ADC. Printed circuit board (PCB)

layout has a significant impact on the

performance even if the circuit topology and component values are correct.

The signal paths must be symmetric

and isolated from the clock inputs and

digital outputs.

The low noise, low distortion amplifier stage provides gain without adding

significant noise or distortion to the

signal. Despite the low noise of the

amplifier, the noise is multiplied by the

same gain as the amplifier, so higher

gain unavoidably adds noise to the

system. However, the input range of

the amplifier is proportionately smaller

thanks to the gain and this smaller

input range allows for lower distortion

from the preceding components. The

amplifier inputs present a resistive

200Ω differential input impedance

which is simple to match to most

common, high speed, single-ended or

differential signal paths. This presents

a more straightforward interface than

a switched-capacitor ADC and simplifies the connection to the final stage

of the RF signal chain.

Why 162.5MHz?

The ADC inside the LTM9001 has

a full power bandwidth of 700MHz

and the amplifier is suitable for input frequencies up to 300MHz, so

why was 162.5MHz chosen for this

first version? Nyquist theory tells us

that the minimum sample rate for a

given input frequency is twice that

frequency. Working backwards, an

ADC sampling at 130Msps can capture a frequency range up to 65MHz

wide. Undersampling allows us to

move that frequency range. Hence

the first Nyquist zone is DC – 65MHz,

the second is 65MHz to 130MHz, the

third is 130MHz to 195MHz, and so

on, see Figure 2.

instrumentation applications. In such

applications, the linearity and dynamic

range requirements are extremely

high. Traditional instruments utilize

preselectors and multiple down-con-

The LTM9001-AA is intended for

3

Page 3

L DESIGN FEATURES

FFT BIN NUMBER (32k TOTAL)

0

AMPLITUDE (dBFS)

–80

–60

–40

–20

0

12288

–100

–120

4096

20480 28672

HD2HD3

NYQUIST ZONE 1

DC TO 65MHz

DC CENTER = 32.5MHz 65MHz

NYQUIST ZONE 2

65MHz TO 130MHz

CENTER = 97.5MHz f

SAMPLE

NYQUIST ZONE 3

130MHz TO 195MHz

CENTER = 162.5MHz 195MHz

NYQUIST ZONE 4

195MHz TO 260MHz

CENTER = 227.5MHz 260MHz

Figure 2. Nyquist zones for 130MHz sample rate

version stages to place the band of

interest at DC. With the advent of high

performance ADCs capable of undersampling, modern instruments are able

to eliminate the final down-conversion

stage without sacrificing performance.

The LTM9001-AA configuration selects the third Nyquist zone with the

bandpass filter set squarely in the

middle of the zone.

More than Just

a Buffered ADC

The sample-and-hold front end of

discrete ADCs presents a complex

charge/discharge profile to the drive

circuitry. Ideally, the input circuitry

should be fast enough to fully charge

the sampling capacitor during the

sampling period (half of the clock

period), but this is not always possible and the incomplete settling may

degrade the SNR and SFDR. Some

manufacturers promote a “buffered”

ADC as a solution but this falls short

of addressing the system-level solution

since a low distortion amplifier is still

required to provide the full-scale input

to the ADC.

From the system view, the ADC

follows the RF and IF portions of the

receiver chain and converts the signal

to a digital format. The signal comes

from the antenna with very little power.

Figure 3. An FFT of the LTM9001 at 160MHz

input frequency with the randomizer on

4

The signal must be filtered and amplified through each stage. Amplification

(gain) increases the total noise and

reduces the headroom, which generally causes more distortion. The added

distortion may be addressed with a

higher supply voltage or a higher power

amplifier, neither of which is preferable. Therefore, from the system-level

point of view, an ADC with a small

input range is better.

The LTM9001 meets these systemlevel criteria. The resistive amplifier

inputs are easily matched and it has

an input range of ±250mV, enabling

the use of low OIP3 components or

higher loss SAW filters. The noise of

the amplifier is low enough that the

SNR of the LTM9001 is good despite

the high gain (see Figure 3).

Working with a

µModule Receiver

The LTM9001 uses a land grid array

(LGA), which provides higher pin density than dual in-line or quad packages

and better thermal conduction than

BGA packages. The high integration

of the LTM9001 makes the PCB board

layout simple. The multilayer substrate

allows greater flexibility in pin placement on the package relative to pin

placement on the die. The LTM9001

has been optimized for a flow-through

layout so that the interaction between

inputs, clock and digital outputs is

minimized. The analog and clock inputs are surrounded by ground pads

and a continuous row of ground pads

further separate the analog and digital

signal lines. However, to optimize its

electrical and thermal performance,

some layout considerations are still

necessary. See the actual evaluation

board in Figure 4.

Use large PCB copper areas for

ground. This helps to dissipate heat

through the board and also helps

to shield sensitive on-board analog

signals. Common ground (GND) and

output ground (OGND) are electrically

isolated on the LTM9001, but for most

digital output configurations should

be connected on the PCB underneath

the part to provide a common return

path.

Use multiple ground vias. Using as

many vias as possible helps to improve

the thermal performance of the board

and creates necessary barriers separating analog and digital traces on the

board at high frequencies. Take care to

separate analog and digital traces as

much as possible, using vias to create

high frequency barriers. This reduces

digital feedback that can reduce the

signal-to-noise ratio (SNR) and dynamic range of the LTM9001.

Conclusion

µModule technology, introduced first

by Linear Technology for DC/DC converters, now brings the advantages of

small size, higher integration and ease

of use for high speed ADC applications.

By integrating fine-line CMOS and

SiGe components with appropriate

passive networks, the challenging

task of matching a fixed gain amplifier to a high speed ADC is done. All is

reduced to an easy-to-use black box:

the LTM9001.

Figure 4. An evaluation board shows the

small overall circuit. Note that no external

components are required.

Linear Technology Magazine • March 2008

L

Loading...

Loading...