OUTPUT

V

REG

IC REGULATOR

REF

GND

VINSWITCH PIN

SWITCH

CONTROL

FEEDBACK NODE

+V

OUTPUT

V

REG

IC REGULATOR

REF

GND

V

IN

SWITCH

PIN

SWITCH

CONTROL

FEEDBACK NODE

+V

STEP-UP STEP-DOWN

AN122 F02

DIODE TURN-ON TIME

DIODE ON VOLTAGE

IC BREAKDOWN LIMIT

AN122 F03

DIODE

UNDER

TEST

5Ω

MEASUREMENT POINT

PULSE IN

t

RISE

≤ 2ns

AMPLITUDE = 5V + V

FWD

L DESIGN IDEAS

Diode Turn-On Time Induced

Failures in Switching Regulators

Never Has So Much Trouble Been Had

by So Many with So Few Terminals

by Jim Williams and David Beebe

This article is excerpted from the Linear

Technology Application Note AN122

with the same title.

Introduction

Most circuit designers are familiar with

diode dynamic characteristics such

as charge storage, voltage dependent

capacitance and reverse recovery

time. Less commonly acknowledged

and manufacturer specified is diode

forward turn-on time. This parameter

describes the time required for a diode

to turn on and clamp at its forward voltage drop. Historically, this extremely

short time, units of nanoseconds, has

been so small that user and vendor

alike have essentially ignored it. It

is rarely discussed and almost never

specified. Recently, switching regulator clock rate and transition time have

become faster, making diode turn-on

time a critical issue. Increased clock

rates are mandated to achieve smaller

magnetics size; decreased transition

times somewhat aid overall efficiency

but are principally needed to minimize

IC heat rise. At clock speeds beyond

about 1MHz, transition time losses are

the primary source of die heating.

A potential difficulty due to diode

turn-on time is that the resultant

Figure 2. Diode forward turn-on time permits transient excursion above

nominal diode clamp voltage, potentially exceeding IC breakdown limit.

34

34

transitory “overshoot” voltage across

the diode, even when restricted to

nanoseconds, can induce overvoltage

stress, causing switching regulator

IC failure. As such, careful testing is

required to qualify a given diode for a

particular application to insure reliability. This testing, which assumes

low loss surrounding components

and layout in the final application,

measures turn-on overshoot voltage

due to diode parasitics only. Improper

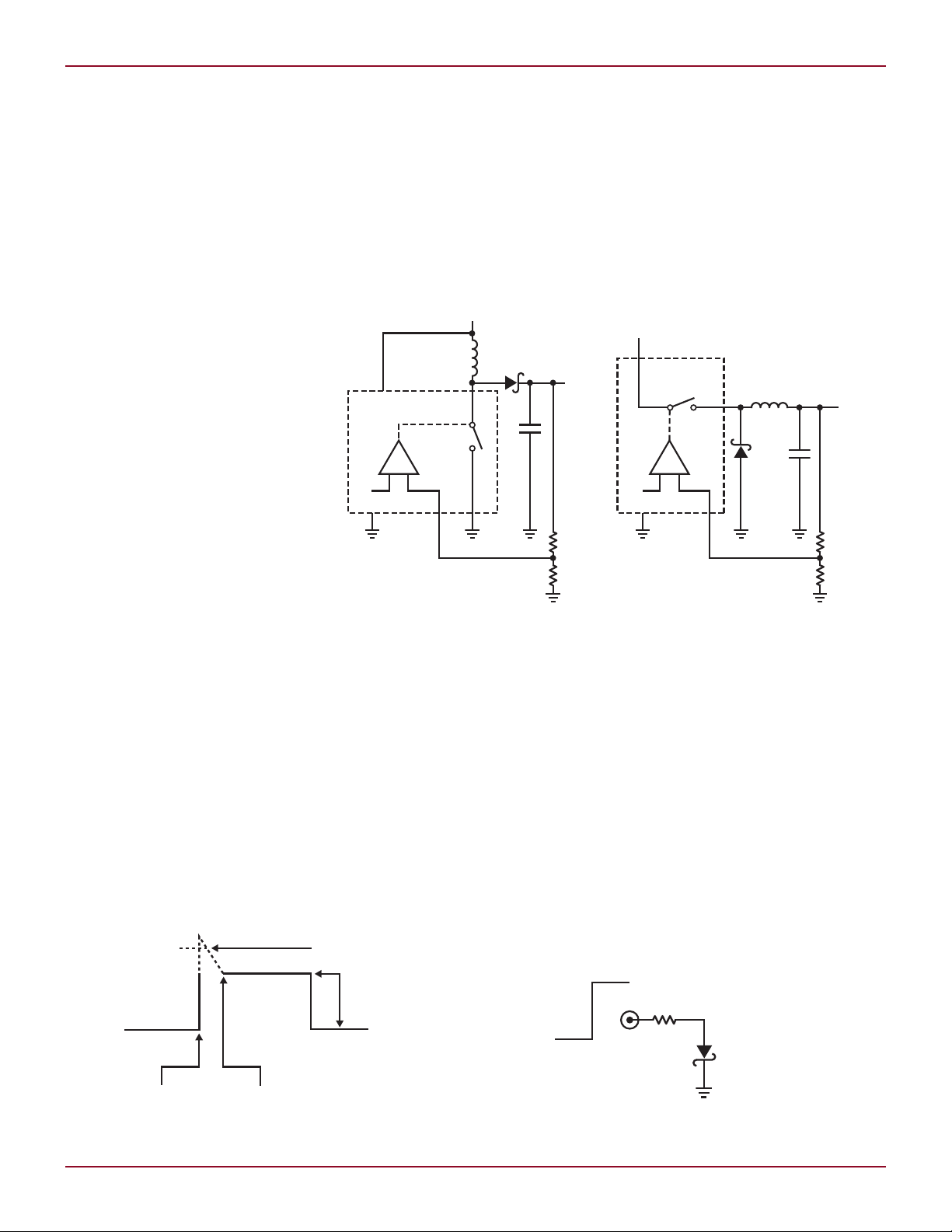

Figure 1. Typical voltage step-up/step-down converters. Assumption

is diode clamps switch pin voltage excursion to safe limits.

associated component selection and

layout will contribute additional overstress terms.

Diode Turn-On Time

Perspectives

Figure 1 shows typical step-up and

step-down voltage converters. In both

cases, the assumption is that the diode

clamps switch pin voltage excursions

to safe limits. In the step-up case, this

limit is defined by the switch pins

Figure 3. Conceptual method tests diode turn-on time at 1A. Input

step must have exceptionally fast, high fidelity transition.

Linear Technology Magazine • March 2009

DESIGN IDEAS L

AN122 F05

LT1086

22µF22µF

120Ω

1k

1k

+V ADJUST (RISE TIME TRIM)

+V TYPICAL 17VVIN = 20V

*

+V

Q1

Q4

+V

Q2

Q5

+V

Q3

Q6

1Ω

1Ω

1Ω

5Ω**

OUTPUT

62Ω50Ω

2pF TO 12pF

EDGE

PURITY

EDGE PURITY

100Ω

PULSE

INPUT

MINIMIZE INDUCTANCE IN ALL PATHS

= 2N3866

= 2N3375

** = TEN PARALLELED 50Ω RESISTORS

* = BYPASS EVERY TRANSISTOR WITH

22µF SANYO OSCON PARALLELED WITH

2.2µF MYLAR

+

+

*

*

1V/DIV

2ns/DIV

AN122 F06

AN122 F04

DIODE

UNDER

TEST

5Ω

OSCILLOSCOPE

1GHz BANDWIDTH

t

RISE

= 350ps

PULSE CURRENT

AMPLIFIER

t

RISE

= 2ns

PULSE GENERATOR

t

RISE

< 1ns

Z0 PROBE

≈1A

TYPICALLY

5V TO 6V, 30ns

WIDE

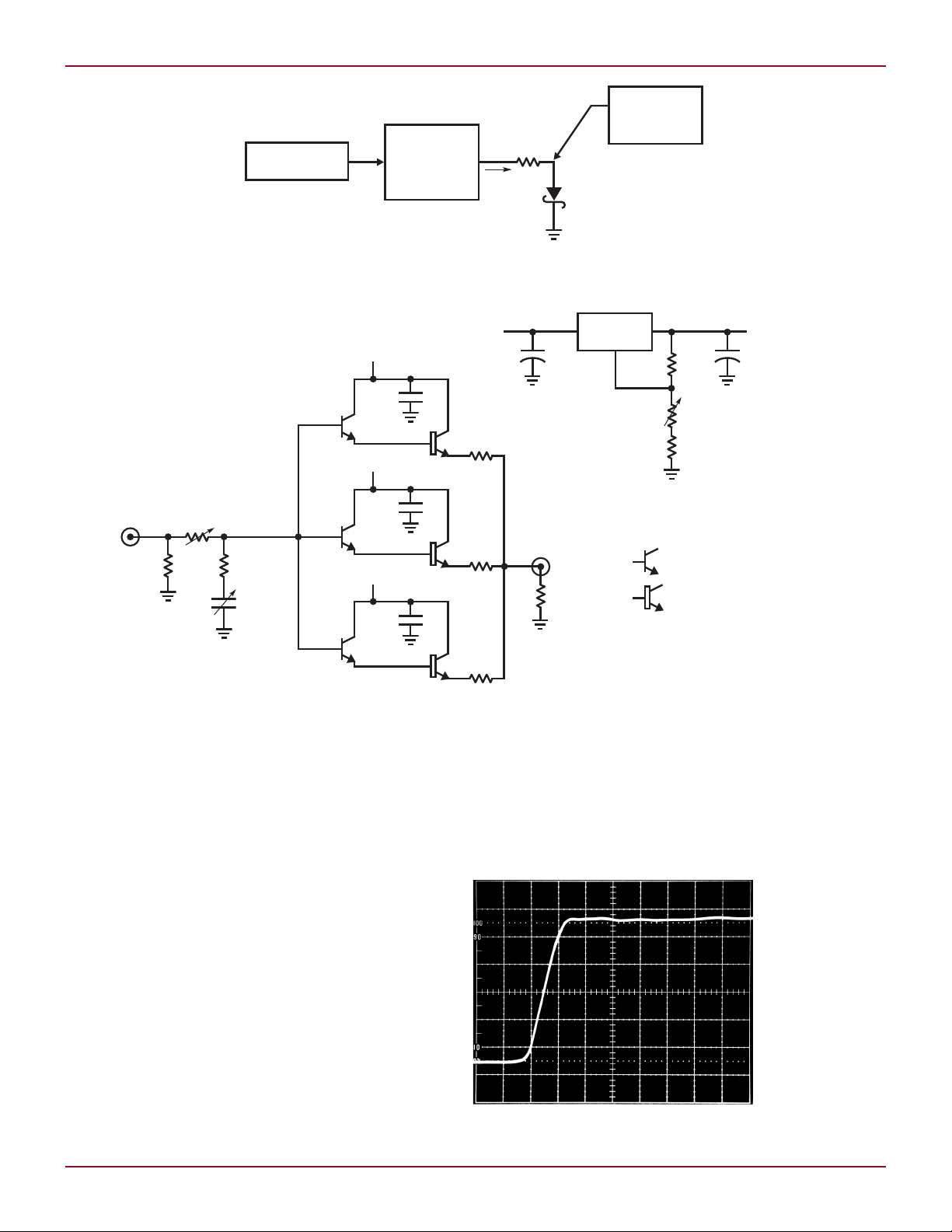

Figure 4. Detailed measurement scheme indicates necessary performance parameters for various elements. Subnanosecond rise time pulse

generator, 1A, 2ns rise time amplifier and 1GHz oscilloscope are required.

maximum allowable forward voltage.

The step-down case limit is set by

the switch pins maximum allowable

reverse voltage.

a finite length of time to clamp at its

forward voltage. This forward turnon time permits transient excursions

above the nominal diode clamp voltage, potentially exceeding the IC’s

breakdown limit. The turn-on time is

typically measured in nanoseconds,

making observation difficult. A further

complication is that the turn-on overshoot occurs at the amplitude extreme

of a pulse waveform, precluding high

resolution amplitude measurement.

These factors must be considered

when designing a diode turn-on test

method.

Linear Technology Magazine • March 2009

Figure 5. Pulse amplifier includes paralleled, darlington driven RF transistor output stage. Collector voltage adjustment

(“rise time trim”) peaks Q4 to Q6 FT, input RC network optimizes output pulse purity. Low inductance layout is mandatory.

Figure 2 indicates the diode requires

Figure 3 shows a conceptual method

for testing diode turn-on time. Here,

the test is performed at 1A although

other currents could be used. A pulse

Figure 6. Pulse amplifier output into 5Ω. Rise time is 2ns with minimal pulse-top aberrations.

steps 1A into the diode under test via

the 5Ω resistor. Turn-on time voltage excursion is measured directly

at the diode under test. The figure

3535

L DESIGN IDEAS

AN122 F05

LT1086

22µF22µF

120Ω

1k

1k

+V ADJUST (RISETIME TRIM)

+V, TYPICAL 17VV

IN

= 20V

*

+V

Q1

Q4

+V

Q2

Q5

+V

Q3

Q6

1Ω

1Ω

1Ω

5Ω**

DIODE

UNDER

TEST

62Ω50Ω

2pF TO 12pF

EDGE

PURITY

EDGE PURITY

100Ω

HP-215A

PULSE GENERATOR

t

RISE

= 800ps

P

WIDTH

= 30ns

MINIMIZE INDUCTANCE IN ALL PATHS

= 2N3866

= 2N3375

** = TEN PARALLELED 50Ω RESISTORS

* = BYPASS EVERY TRANSISTOR WITH

22µF SANYO OSCON PARALLELED WITH

2.2µF MYLAR

ADJUST PULSE GENERATOR AMPLITUDE FOR 5.5V AMPLITUDE AT 5Ω RESISTOR

Z

0

PROBE = TEKTRONIX

P-6056, 500Ω

215A

≈

6.7V

≈

5.5V

7104

7A29 7B15 7B107A29

TEKTRONIX

7104/7A29/7B10/7B15

1GHz (t

RISE

= 350ps)

OSCILLOSCOPE

+

+

*

*

Figure 7. Complete diode forward turn-on time measurement arrangement includes subnanosecond rise time

pulse generator, pulse amplifier, Z0 probe and 1GHz oscilloscope.

36

36

Linear Technology Magazine • March 2009

DESIGN IDEAS L

200mV/DIV

2ns/DIV

AN122 F08

200mV/DIV

2ns/DIV

AN122 F09

200mV/DIV

5ns/DIV

AN122 F12

200mV/DIV

2ns/DIV

AN122 F10

200mV/DIV

5ns/DIV

AN122 F11

Figure 8. “Diode Number 1” overshoots steady state

forward voltage for ≈3.6ns, peaking 200mV.

Figure 10. “Diode Number 3” peaks 1V above nominal

400mV VFWD, a 2.5x error.

Figure 9. “Diode Number 2” peaks ≈750mV before settling

in 6ns... > 2x steady state forward voltage.

Figure 11. “Diode Number 4” peaks ≈750mV with lengthy

(note horizontal 2.5x scale change) tailing towards VFWD value.

Figure 12. “Diode Number 5” peaks offscale with extended tailing (note

horizontal slower scale compared to Figures 8 thru 10).

Linear Technology Magazine • March 2009

3737

L DESIGN IDEAS

90

70

50

EMISSIONS LEVEL (dBµV/m)

30

10

80

60

40

20

0

–10

0 100 200 300 400 500

FREQUENCY (MHz)

600 700 800 900 1000

EN55022

CLASS B

LIMIT

90

70

50

EMISSIONS LEVEL (dBµV/m)

30

10

80

60

40

20

0

–10

0 100 200 300 400 500

FREQUENCY (MHz)

600 700 800 900 1000

EN55022

CLASS B

LIMIT

Authors can be contacted

at (408) 432-1900

is deceptively simple in appearance.

In particular, the current step must

have an exceptionally fast, high-fidelity

transition and faithful turn-on time

determination requires substantial

measurement bandwidth.

Detailed Measurement

Scheme

A more detailed measurement scheme

appears in Figure 4. Necessary performance parameters for various

elements are called out. A subnanosecond rise time pulse generator, 1A,

2ns rise time amplifier and a 1GHz

oscilloscope are required. These specifications represent realistic operating

conditions; other currents and rise

times can be selected by altering appropriate parameters.

The pulse amplifier necessitates

careful attention to circuit configuration and layout. Figure 5 shows the

amplifier includes a paralleled, Darlington driven RF transistor output

stage. The collector voltage adjustment

(“rise time trim”) peaks Q4 to Q6 FT;

an input RC network optimizes output

pulse purity by slightly retarding input

pulse rise time to within amplifier

passband. Paralleling allows Q4 to Q6

to operate at favorable individual currents, maintaining bandwidth. When

the (mildly interactive) edge purity and

rise time trims are optimized, Figure

6 indicates the amplifier produces a

transcendently clean 2ns rise time

output pulse devoid of ringing, alien

components or post-transition excursions. Such performance makes diode

turn-on time testing practical.

1

Figure 7 depicts the complete diode

forward turn-on time measurement arrangement. The pulse amplifier, driven

by a sub-nanosecond pulse generator,

drives the diode under test. A Z0 probe

monitors the measurement point and

feeds a 1GHz oscilloscope.

2, 3, 4

Diode Testing and

Interpreting Results

The measurement test fixture, properly equipped and constructed,

permits diode turn-on time testing

with excellent time and amplitude

resolution.5 Figures 8 through 12

show results for five different diodes

from various manufacturers. Figure 8

(Diode Number 1) overshoots steady

state forward voltage for 3.6ns, peaking

200mV. This is the best performance

of the five. Figures 9 through 12 show

increasing turn-on amplitude and

time which are detailed in the figure

captions. In the worst cases, turn-on

amplitudes exceed nominal clamp

voltage by more than 1V while turn-on

times extend for tens of nanoseconds.

Figure 12 culminates this unfortunate

parade with huge time and amplitude

errors. Such errant excursions can and

will cause IC regulator breakdown and

failure. The lesson here is clear. Diode

turn-on time must be characterized

and measured in any given application

to insure reliability.

Notes

1

An alternate pulse generation approach appears in

Linear Technology Application Note 122, Appendix

F, “Another Way to Do It.”

2

Z0 probes are described in Linear Technology Ap-

plication Note 122 Appendix C, “About Z0 Probes.”

See also References 27 thru 34.

3

The subnanosecond pulse generator requirement

is not trivial. See Linear Technology Application

Note 122 Appendix B, “Subnanosecond Rise Time

Pulse Generators For The Rich and Poor.”

4

See Linear Linear Technology Application Note

122 Appendix E, “Connections, Cables, Adapters,

Attenuators, Probes and Picoseconds” for relevant

commentary.

5

See Linear Technology Application Note 122 Ap-

pendix A, “How Much Bandwidth is Enough?” for

discussion on determining necessary measurement

bandwidth.

L

LTM8032, continued from page 33

amount of ambient noise in the room.

Figure 3 shows the noise spectrum in

the chamber without any devices running. This can be used to determine the

actual noise produced by the DUT.

Figure 4 shows the worst case

LTM8032 emissions plot, which occurs at maximum power out, 10V at

38

38

2A, from the maximum input voltage,

36V. There are two traces in the plot,

one for the vertical and horizontal

orientations of the test lab’s receiver

antenna. As shown in the figure, the

LTM8032 easily meets the CISPR 22

Conclusion

The LTM8032 switching step-down

regulator is both easy to use and quiet,

meeting the radiated emissions requirements of CISPR22 and EN55022

class B by a wide margin.

L

class B limits, with 20db of margin for

most of the frequency spectrum, with

either antenna orientation.

Figure 3. The baseline measurement of ambient

noise in the 5-meter chamber (no devices operating) Figure 4. The LTM8032 emissions for 20W out, 36V

IN

Linear Technology Magazine • March 2009

Loading...

Loading...