Page 1

How to Produce Negative Output Voltages from Positive Inputs

Using a µModule Step-Down Regulator

Design Note 1021

Jaino Parasseril

Introduction

Linear Technology’s DC/DC step-down µModule®

regulators are complete switchmode power supplies in a

surface-mount package. They include the DC /DC controller, inductor, power switches and supporting circuitry.

These highly integrated regulators also provide an easy

solution for applications that require negative output

voltages. In other words, these products can operate as

inverting buck-boost regulators. As a result, the lowest

potential in the circuit is not the standard 0V, but –V

OUT

,

which must be tied to the µModule regulator’s GND. All

signals are now referred to –V

For this discussion, the LTM

.

OUT

®

8025 (36V, 3A) is used to

demonstrate how a buck µMo dule regulator c an be altered

to produce a negative output voltage with level-shifting

circuitry for synchronization. This approach can be applied to other µModule regulators, such as the LTM8022

(36V, 1A), LTM8023 (36V, 2A) and LTM8027 (60V, 4A).

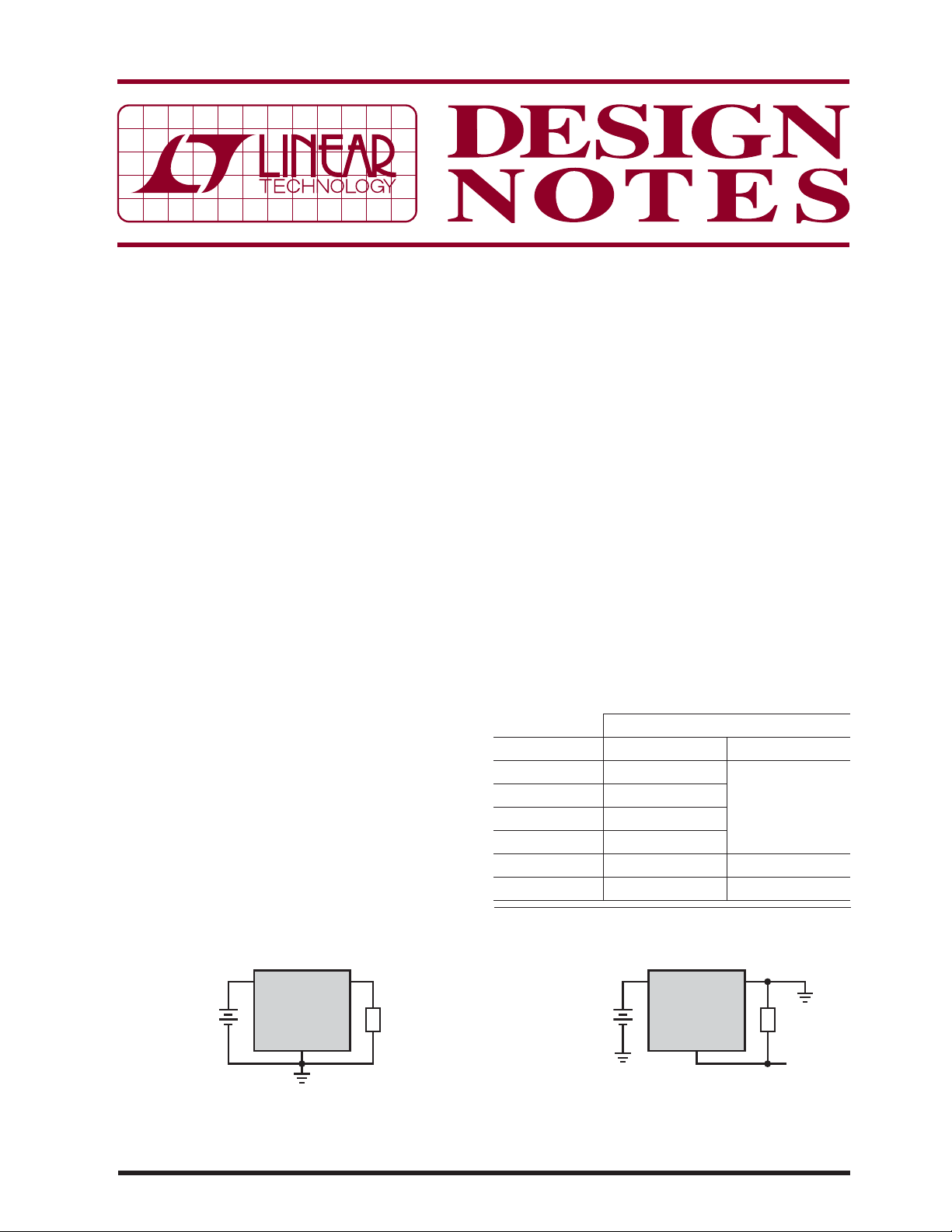

Design Guide

A conventional buck (step-down) µModule regulator

can be easily confi gured to generate negative output

voltages by confi guring it as an inverting buck-boost

c on v er t e r, as i ll u st ra te d i n Fi gu r e 1 . T h e n eg at iv e t e rm in a l

of the input supply is connected to the V

µModule regulator and the GND pin is tied to the –V

rail. The actual input voltage (V

’) seen by the µModule

IN

pin of the

OUT

OUT

regulator is the difference between the input supply (V

and the output voltage (–V

). This voltage must be

OUT

within the allowable input range of the part. Additionally,

the absolute value of the output voltage must not exceed

the maximum output voltage rating of the µModule

regulator. Since the part is now operating as an inverting

buck-boost, the switch current is larger than in its buck

counterpar t. Hence, parameters such as output current,

switching frequency, thermal performance, etc. must be

considered to stay within the part’s limits. Refer to Appendix for detailed discussions and calculations. Refer

to Table 1 for a selection guide of example buck µModule

regulators confi gured as inverters.

Table 1. Example of Buck (Step-Down) DC/DC μModule

Regulators Confi gured as Inverters

I

OUT(MAX)

μModule Regulator

LTM8020 0.165A

LTM8021 0.475A

LTM8022 1A

LTM8023 1.6A

LTM8025 2.95A 2.2A

LTM8027 4A 3.65A

L, LT, LTC, LTM, Linear Technology, the Linear logo and µModule are registered

trademarks of Linear Technology Corporation. All other trademarks are the property of

their respective owners.

12V

→ –5V

IN

OUT

24VIN → –12V

See LTM8025

and LTM8027

OUT

IN

)

12/11/1021

V

IN

V

IN

+

–

µModule

REGULATOR

GND

V

OUT

V

OUT

R

LOAD

dn1021 F01

(a) Buck µModule Regulator Confi gured

for Positive Output Voltages

Figure 1. How to Confi gure a Buck Module for Negative Output Voltages

VIN’ = VIN – (–V

VIN’: ACTUAL INPUT

VOLTAGE SEEN BY

µModule REGULATOR

OUT

(b) Buck µModule Regulator Confi gured

for Negative Output Voltages

V

IN

V

)

IN

+

REGULATOR

–

µModule

GND

V

OUT

R

LOAD

–V

OUT

Page 2

5V

0V

750kHz

0.01µF

V

–7V

–12V

100k

750kHz

20V TO 24V

CMDSH2-3

IN

4.7µF

63.4k

V

IN

RUN/SS

LTM8025

SHARE

SYNC

RT ADJ

PGOOD

GND

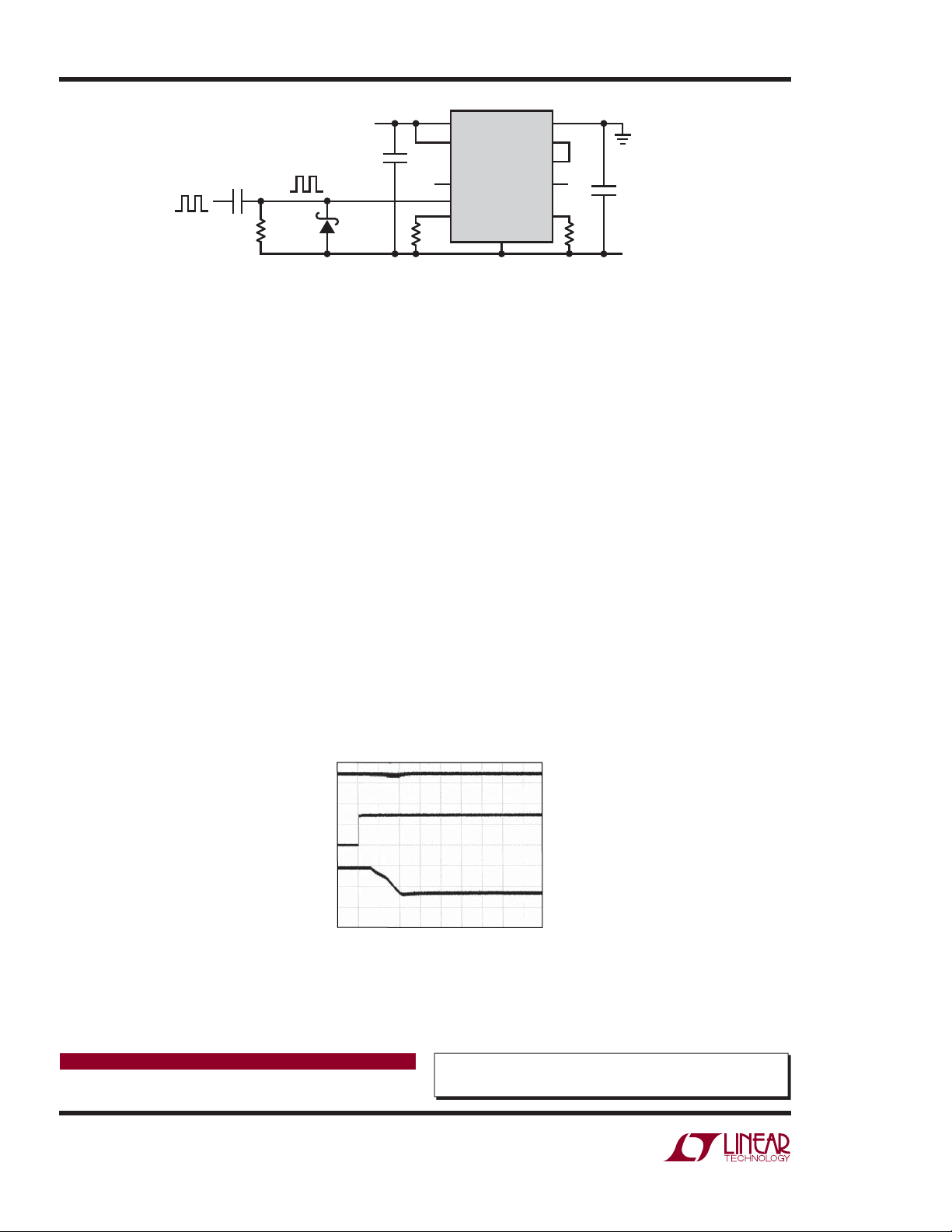

Figure 2. LTM8025 Schematic for –12V Output

V

OUT

AUX

BIAS

34.8k

dn1021 F02

22µF

–V

OUT

–12V AT 2A

–12V Output Application

The LTM8025 is a 36VIN, 3A step-down µModule

converter that can support output voltages up to 24V.

With minimal design effort, it can be easily confi gu r e d t o g e n e r a t e n e g a t i v e o u t p u t v o l t a g e s . F i g u r e 2 s h o w s

an LTM8025 schematic generating –12V at 2A from an

input range of 20V to 24V. The actual input volt age seen by

the LTM8025 is V

= 20V, V

’ = 20V – (–12V) = 32V. Because the maximum

IN

IN

’ = V

IN

– (–V

). For instance, if VIN

OUT

input rating of the LTM8025 is 36V, the input supply in

this specifi c application is limited to 24V.

Additionally, the internal oscillator of the LTM8025 can

b e s y n c h r o n i z e d b y a p p l y i n g a n e x t e r n a l 2 5 0 k H z t o 2 M H z

clock signal to the SYNC pin. For negative output voltages, the clock must be level-shifted to account for the

lower potential. This example has a 0V to 5V, 750kHz

input clock signal. By adding a few passive components,

the input clock is level-shifted to produce a –12V to

–7V signal, which is then applied to the SYNC pin of

V

IN

10V/DIV

the LTM8025. Figure 3 shows the start-up waveforms

for the –12V output application.

Run/Shutdown

The LTM8025 has a RUN/SS pin that provides shutdown

along with soft-start functions. In order to shut down

the part, the RUN/SS pin must be pulled below 0.2V. For

negative output applications, the LTM8025 GND is tied

to –V

above –V

to 2.5V above –V

. So, the RUN/SS voltage must be below 0.2V

OUT

to turn off the part, whereas it must be tied

OUT

for normal operation.

OUT

Conclusion

Step-down µModule regulators, such as the LTM8025,

can be easily confi gured for negative output voltages. For

negative outputs, the LTM8025 operates as an inverting

buck-boost, so the maximum allowable output current is

lower than typical buck topologies. If synchronization is

desired, proper level-shifting circuitry is required. For a

complete description of the LTM8025, including operation and applications information, refer to the data sheet.

RUN/SS

2V/DIV

V

OUT

10V/DIV

Figure 3. LTM8025 Start-Up Waveforms for –12V Output

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

200µs/DIV

dn1021 F03

For applications help,

call (408) 432-1900, Ext. 3747

dn1021 LT/TP 1211 REV A 305K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2011

Page 3

APPENDIX

Level-Shifting the Run Pin in a Negative Output

Application

Step-down Module regulators are equipped with a Run

pin to enable and shut down the part. For negative output

applications, the Run voltage must be level-shifted to

properly turn of f the part. Using just a single PNP transistor and a few resistors, level-shifting can be achieved to

utilize the shutdown feature, as seen in Figure 4. When

the logic input is high, the Run voltage increases by an

amount determined by the voltage divider resistors R2

and R3. Once the Run voltage exceeds the shutdown

threshold, the Module regulator will turn on; as a result,

the output will drop to the programmed negative voltage.

To shut down the part, apply a logic low input to force the

Run voltage to the same potential as the negative output.

LOGIC

LOGIC INPUT

HIGH

0V

Q1

R2

R1

TO RUN PIN

OF µMODULE

REGULATOR

R3

External Schottky Diode for Start-Up Protection

When confi guring a Module regul ator for negative output

voltages, the combination of input and output capacitors

creates an AC voltage divider at the output. During startup, the output (–V

) will initially go positive for a short

OUT

period of time before dropping down to the intended negative potential. The positive voltage peak is dependent on

both the capacitance values and the input voltage step. To

li mi t t he am ou nt of po si ti ve vo lt a ge , a n e x te rn al Sc ho t tk y

diode between –V

and the input supply ground may be

OUT

required. Figure 6 shows a simplifi ed Module regulator

schematic with the Schottky diode protection.

V

IN

–

+

µModule

GND

V

OUT

dn1021 F06

SCHOTTKY

DIODE

C

OUT

(OPTIONAL)

–V

OUT

V

IN

C

IN

REGULATOR

Figure 6. Step-Down Module Regulator with

Schottky Diode Protection for Negative Output

–V

OUT

dn1021 F04

Figure 4. Run Level-Shift Circuit for Negative

Output Confi guration

The shutdown threshold varies with each Module regulator and is listed in their respective data sheet tables.

Scale the resistors R2 and R3 according to the logic high

input voltage and the Module regulator’s shutdown

threshold. Figure 5 shows an example of an LTM8027

–12V output application with the level-shifting circuitry.

In this example, the LTM8027 has a 5V logic input and a

Run pin resistor divider for about 2.5V, enough to exceed

the part’s 1.4V shutdown threshold.

V

IN

LOGIC INPUT

20V TO 48V

5V

2N3906

0V

20k

20k

20k

4.7µF

×2

48.7k

Design Considerations for Negative Output

Applications

For negative ou tput applications, the input volt age seen by

′

the Module regula tor (V

input supply volt age (V

′

V

= VIN – (–V

IN

OUT

As a result, the maximum input voltage (V

) is the dif ference between the

IN

) and the output volt age (–V

IN

OUT

) (Equation 1)

′

IN(MAX)

) must

be below the Module regulator’s abs max input voltage

(V

IN_MODULE(MAX)

V

IN

RUN

SS

SYNC

RT ADJ

LTM8027

GND

V

OUT

BIAS1

BIAS2

AUX

).

56.2k

dn1021 F05

22µF

×4

SCHOTTKY

DIODE

(OPTIONAL)

V

OUT

–12V

3A

):

Figure 5. LTM8027 with Run Level-Shift Circuitry for –12V Output

Page 4

Additionally, the switch current is higher for inverting applications compared to the positive output confi guration.

Hence, the maximum output current (I

OUT(NEG)

) must

be derated from the Module regulator’s typical rating

(I

OUT(POS)

I

) according to the following equation:

OUT(NEG)

≤ (I

OUT(POS)

) • (1 – DC

) (Equation 2)

MAX

where the max duty cycle,

V

DC

MAX

=

V

IN(MIN)

OUT

+ V

(Equation 3)

OUT

Equation 2 is only an approx imation. The following paramete rs nee d to be c ons ider ed to g et a mor e ac cur at e va lue:

switching frequency, inductor current ripple, effi ciency,

switch current limit derating at high duty cycle, etc.

Design Example:

Inverting power supply requirements:

V

= 15V nominal (range: 12V to 18V)

IN

V

I

= –5V

OUT

OUT(NEG)

= 2A

Selected Module regulator: LTM8025

LTM8025 data sheet ratings:

V

IN_MODULE(MAX)

I

OUT(POS)

= 3A

= 36V

Calculations:

Using Equations 1 to 3, the following values were

determined:

V

IN(MAX)

DC

(I

OUT(POS)

MAX

= V

=

V

IN(MIN)

) • (1 – DC

IN(MAX)

V

OUT

– (V

+ V

MAX

) = 18 – (–5) = 23V

OUT

5

=

OUT

= 0.294

12+ 5

) = (3A) • (1 – 0.294) = 2.12A

′

The above calculations determined that the LTM8025

is a good candidate for this inverting application. The

maximum input voltage across the Module regulator

is 23V, well below the 36V maximum operating voltage.

With a max duty cycle of 29.4%, the maximum output

current is approximately 2.12A—suffi cient for the 2A

requirement of this application.

Loading...

Loading...