LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

MARCH 2009 VOLUME XIX NUMBER 1

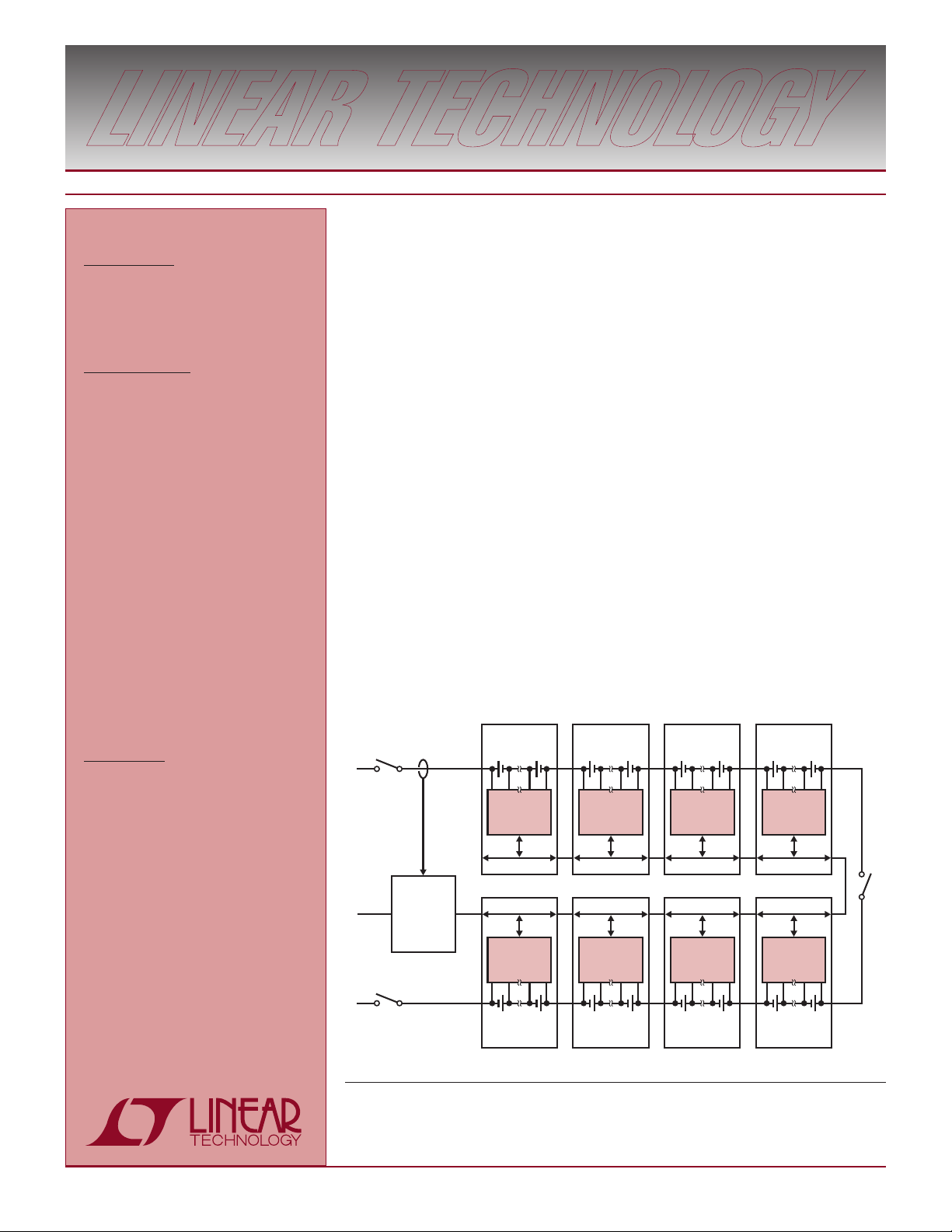

SPI

CURRENT

SENSOR

SERVICE SWITCH

CAN

12-CELL BATTERY

MODULE

–

–

DATA BUS

+

+

BATTERY

MONITORING

& BALANCING

HOST

CONTROLLER

–

+

–

+

–

+

–

+

–

+

–

+

–

+

12-CELL BATTERY

MODULE

DATA BUS

BATTERY

MONITORING

& BALANCING

12-CELL BATTERY

MODULE

DATA BUS

12-CELL BATTERY

MODULE

DATA BUS

12-CELL BATTERY

MODULE

DATA BUS

12-CELL BATTERY

MODULE

DATA BUS

12-CELL BATTERY

MODULE

DATA BUS

12-CELL BATTERY

MODULE

DATA BUS

BATTERY

MONITORING

& BALANCING

BATTERY

MONITORING

& BALANCING

BATTERY

MONITORING

& BALANCING

BATTERY

MONITORING

& BALANCING

BATTERY

MONITORING

& BALANCING

BATTERY

MONITORING

& BALANCING

IN THIS ISSUE…

COVER ARTICLE

Battery Stack Monitor

Extends Life of Li-Ion Batteries

in Hybrid Electric Vehicles ..................1

Michael Kultgen and Jon Munson

Linear in the News… ...........................2

DESIGN FEATURES

DC/DC Converter, Capacitor Charger

Takes Inputs from 4.75V to 400V ........9

Robert Milliken and Peter Liu

How to Choose a Voltage Reference ...14

Brendan Whelan

1.2A Monolithic Buck Regulator Shrinks Supply Size and Cost with Programmable Output Current Limit

.........................................................20

Tom Sheehan

Boost Converters for Keep-Alive Circuits

Draw Only 8.5µA of Quiescent Current

.........................................................22

Xiaohua Su

Industrial/Automotive Step-Down

Regulator Accepts 3.6V to 36V and

Includes Power-On Reset and Watchdog

Timer in 3mm × 3mm QFN ................24

Ramanjot Singh

Complete APD Bias Solution in 60mm

with On-the-Fly Adjustable Current

Limit and Adjustable V

Xin (Shin) Qi

...................27

APD

2

Battery Stack Monitor Extends Life of Li-Ion Batteries in Hybrid Electric Vehicles

by Michael Kultgen and Jon Munson

Introduction

The cost of running a car on electricity

is equivalent to paying $0.75/gallon

for gasoline, and if that electricity

comes from carbon neutral sources,

car owners are saving both money

and the environment (gasoline combustion produces 9kg of CO2 per US

gallon). Advancements in battery

technology (see sidebar), especially

with Lithium-based chemistries, hold

the greatest promise for converting

the worldwide fleet of cars to hybrid

or fully electric.

Lithium battery packs offer the

highest energy density of any cur rent battery technology, but high

performance is not guaranteed simply by design. In real world use, a

battery management system (BMS)

makes a significant difference in the

performance and lifetime of Li-Ion

batteries—arguably more so than

the design of the battery itself. The

LTC6802 multicell battery stack

monitor is central to any BMS for the

continued on page 3

DESIGN IDEAS

Don’t Want to Hear It? Avoid the Audio

Band with PWM LED Dimming at

Frequencies Above 20kHz ..................30

Eric Young

Eliminate EMI Worries with 2A,

15mm × 9mm × 2.82mm µModule™

Step-Down Regulator ........................33

David Ng

Diode Turn-On Time Induced Failures

in Switching Regulators ....................34

Jim Williams and David Beebe

µModule Regulator Fits a (Nearly)

Complete Buck-Boost Solution in

15mm × 15mm × 2.8mm for

4.5V–36V VIN to 0.8V–34V V

Judy Sun, Sam Young and Henry Zhang

New Device Cameos ...........................41

Design Tools ......................................43

Sales Offices .....................................44

..........39

OUT

L

, LT, LTC, LTM, Burst Mode, OPTI-LOOP, Over-The-Top and PolyPhase are registered trademarks of Linear Technology

Corporation. Adaptive Power, Bat-Track, BodeCAD, C-Load, DirectSense, Easy Drive, FilterCAD, Hot Swap, LinearView,

µModule, Micropower SwitcherCAD, Multimode Dimming, No Latency ΔΣ, No Latency Delta-Sigma, No R

Filter, PanelProtect, PowerPath, PowerSOT, SmartStart, SoftSpan, Stage Shedding, SwitcherCAD, ThinSOT, TimerBlox, True

Color PWM, UltraFast and VLDO are trademarks of Linear Technology Corporation. Other product names may be trademarks

of the companies that manufacture the products.

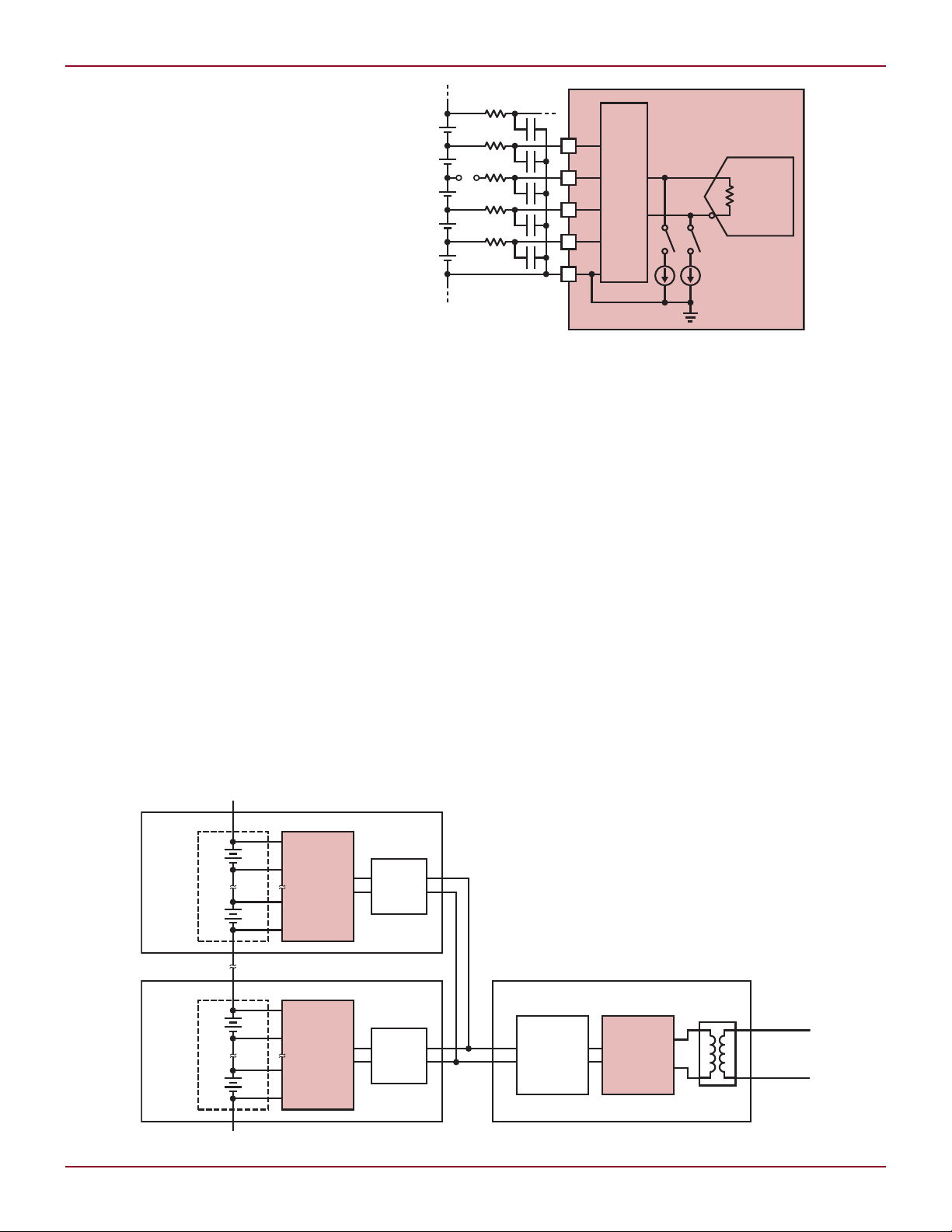

Figure 1. 96-cell battery pack

, Operational

SENSE

L LINEAR IN THE NEWS

Linear in the News…

EDN Highlights Linear for Innovation Awards

EDN magazine in February chose several Linear Technology

products as finalists for their annual Innovation Awards, to

be announced later this month. And the nominees are:

Best Contributed Article—“High Voltage,

Low-Noise DC/DC Converters” by Jim Williams

You can find the article in its entirety on the EDN website

at www.edn.com/jimwilliams.

Battery ICs Category—LTC6802 Battery Stack Monitor

The LTC6802 is a highly integrated multicell battery

monitoring IC capable of precisely measuring the voltages

of up to 12 series-connected battery cells. Using a novel

stacking technique, multiple LTC6802s can be placed in

series without optocouplers or isolators. See the cover

article of this issue for an overview of this part.

Power ICs Category—LTC3642 50mA

Synchronous Step-Down Converter

The LTC3642 uses a unique high voltage synchronous

rectification design, capable of continuous input voltages of 45V and offers transient protection up to 60V. Its

internal synchronous rectification and its programmable

peak current mode control feature enable it to deliver up

to 93% efficiency, maximizing battery run time.

Power ICs: Modules—LTM4606 Ultralow EMI,

6A DC/DC µModule Regulator

The LTM4606 DC/DC µModule™ regulator significantly

reduces switching regulator noise by attenuating conducted

and radiated energy at the source. The µModule device

is a complete DC/DC system-in-a-package, including the

inductor, controller IC, MOSFETs, input and output capacitors and the compensation circuitry, housed in an enclosed

surface-mount plastic package resembling an IC.

The LTM4606 reduces switching regulator noise at the source.

Linear CEO Comments on Growth Markets

Last month in EE Times, Linear Technology CEO Lothar

Maier discussed the challenging market conditions and

the bright spots on the horizon: “In these times our customers will continue to invest in new products and new

product development. Innovation will return growth to the

semiconductor market—specifically to analog. Now is the

time to get new products out, to be first to market and to

have products that target emerging growth markets.” He

discussed several key markets:

q

Automotive. “Automotive manufacturers are

forecasting automotive electronic content to grow 2–3

times over the next few years, so we will continue

to provide new products to the automotive area. In

addition, every major automotive manufacturer in the

world is now working on hybrid vehicles, which will

add even more electronic content in cars. We have

just introduced an innovative device, the LTC6802,

a highly integrated battery stack monitor that

significantly eases the design of battery monitoring

systems for hybrid/electric vehicles.”

q

Green Growth Markets. “Products targeted toward

energy conservation or energy harvesting will

see growth opportunities and are insulated from

the current market conditions. Energy costs and

environmental concerns, as well as the need to

extend battery life for mobile devices, have led to a

focus on power optimization. Our energy-efficient

products enable customers to convert power more

efficiently, consume less power and extend battery

life. Our LED drivers enable a new generation of

low power lighting for a range of applications, from

cars and medical instruments to laptops and office

lighting. Our efficient analog solutions will help drive

innovative cleantech markets such as solar and wind

power systems.”

q

Communications Infrastructure. “Wireless systems

continue to produce significant market opportunities

for products in wireless and network infrastructure.

Our high speed data converters and high frequency

products are designed into the next generation of

cellular basestations. And our Hot Swap™ and Power

over Ethernet products are proliferating in networks.”

q

Industrial. “The broad industrial market continues

to provide a solid core of business and is somewhat

more insulated from market swings. Linear’s analog

products are used in a broad range of industrial

systems, including factory automation, industrial

process control, medical, instrumentation and

security.”

Lothar Maier concluded, “Finally, I believe that Linear’s

strategy of customer, market and geographic diversity will

be a hedge against the current market conditions and will

provide the conduit to future growth.”

L

2

2

Linear Technology Magazine • March 2009

DESIGN FEATURES L

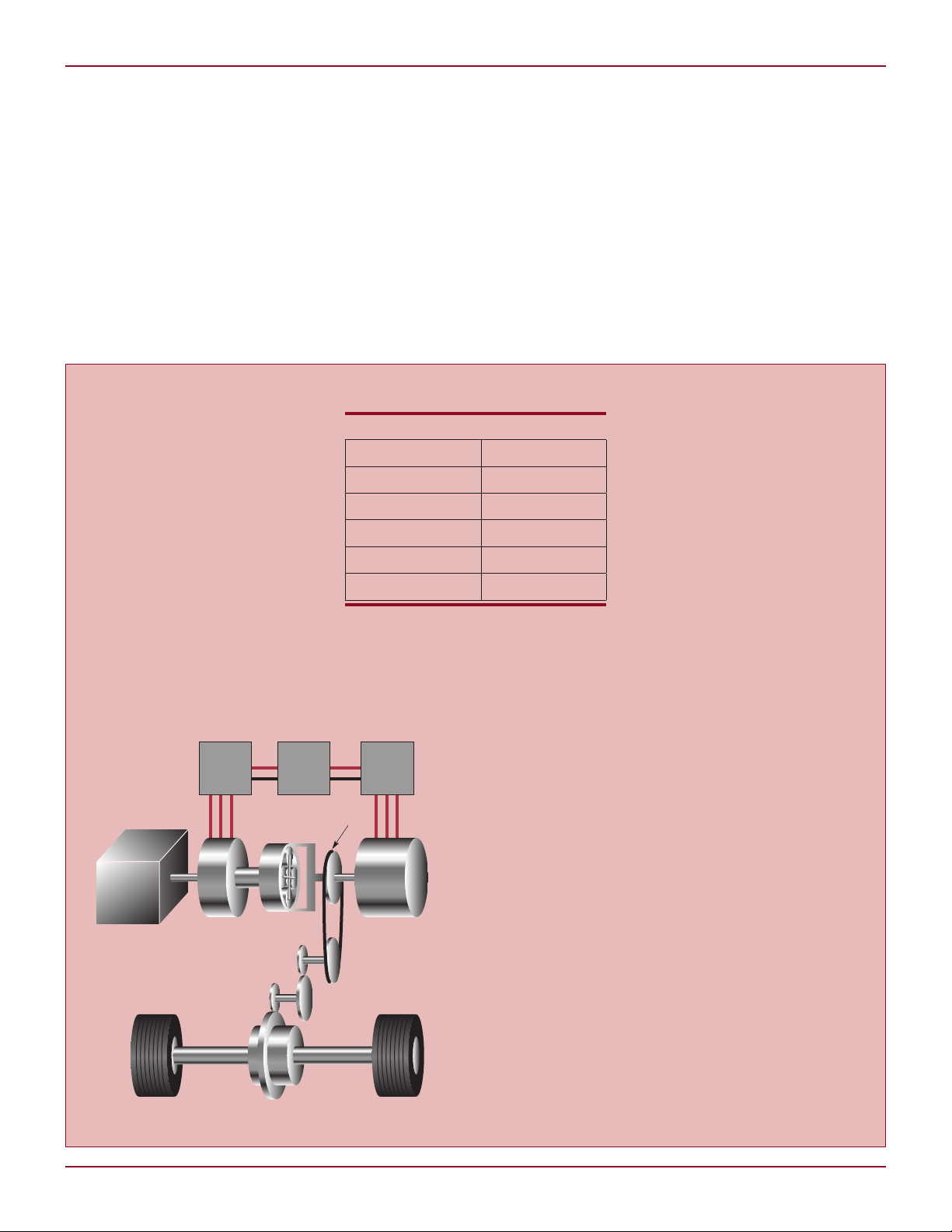

MG1 INVERTER MG2 INVERTERBATTERY

AXLES

DIFFERENTIAL

GASOLINE

ENGINE

ELECTRIC MOTOR/

GENERATOR 1 (MG1)

ELECTRIC MOTOR/

GENERATOR 2 (MG2)

POWER SPLIT

DEVICE

FRONT

WHEELS

REDUCTION

GEARS

SILENT

CHAIN

LTC6802, continued from page 1

large battery stacks common in electric vehicles (EVs) and hybrid electric

vehicles (HEVs). Its robust design and

high accuracy helps guarantee the

performance and lifetime of expensive

battery packs.

lifetime is traded against the need

to use as few kg of batteries as possible—the most expensive component

in any EV. Only a well-designed BMS

can maximize battery performance and

lifetime in the face 200A peak charge

and discharge currents.

For instance, to meet a 15-year,

5000 charge cycle goal, only a portion

(say 40%) of the battery pack’s cellcapacity can be used. Of course, using

only 40% of the capacity essentially

lowers the energy density of the pack.

This is the problem: increasing battery

Battery Management System

Optimizes Li-Ion Run Time

and Lifetime

In any battery stack, the more accurately you know state of charge (SOC)

of each cell, the more cell capacity you

Li-ion Batteries in Electric Vehicles and Hybrids

So why aren’t all cars electric? One

reason is energy density. Gasoline

holds 80 times the energy per kg as

Li-ion batteries (Table 1) and refuels

in three minutes, essentially allowing

indefinite driving. Even a big lithium

pack only gives a passenger car

about a 100-miles after an 8-hour

charging cycle. To drive a passenger

car further than 100 miles you still

need a gasoline engine, but even

so, batteries improve gas mileage in

hybrid electric vehicles (HEVs). The peak efficiency of

the Otto cycle engine is only 30% at high RPMs and the

average efficiency is about 12%. Using batteries to supply torque during acceleration and recover joules during

Figure 2. Toyota Prius “split power” hybrid drive train

Table 1. Energy density comparison

Medium Wh/kg

Diesel Fuel 12,700

Gasoline 12,200

Li-Ion Battery 150

NiMh Battery 100

Lead Acid Battery 25

Li-ion batteries take energy density another step forward,

by offering another 50% improvement. The safety of Liion was a concern, but new battery technologies like the

A123 nanophosphate cell, the EnerDel Spinel-Titanate

chemistry, the GS Yuasa EH6 design and others are as

safe as NiMh, offer extremely high power (200A peak discharge rates), and last 10 to 15 years with proper charge

management. By model year 2012, the majority of hybrid

cars and trucks will use lithium battery technology.

Figure 1 shows a shows a block diagram of the battery pack with a BMS, and Figure 2 shows a typical HEV

power train. The battery pack building block is a 2.5V

to 3.9V, 4Ahr to 40Ahr Li-ion cell. 100 to 200 cells are

connected in series to bring the battery pack voltage into

the hundreds of volts. This DC power source drives a

30kW to 70kW electric motor. The pack voltage is high

so that the average current is low for a given power level.

Lower current reduces I2R power losses, so cables can

be smaller, thus reducing weight and cost. The pack

should be able to deliver 200A under peak conditions

and be quickly rechargeable. In other words, the battery

needs to offer high energy density and high power density, specifications that can be met by Li-ion batteries.

Systems for busses and tractor-trailers use up to four

parallel packs of 640V each.

can use while still maximizing cell life.

In a laptop computer, gas gauging

comes from monitoring cell voltage

and counting coulombs in and out of

the stack of four to eight cells. Voltage, current, time and temperature

are combined in a robust algorithm

to give an indication of the SOC. Unfortunately, it’s nearly impossible to

count coulombs in a car. The battery

drives an electric motor, not a motherboard, so it must handle current

spikes of 200A, followed by low level

idling. Furthermore, you have from 96

regenerative braking means the gas

engine runs less often and runs at a

higher efficiency, effectively doubling

the mpg.

In the 1970s the only available high

power battery chemistry was lead

acid, too heavy to reasonably power

anything larger than a golf cart. Then

came NiMh batteries, which improved

energy density enough to enable the

first commercially successful HEVs,

like the Toyota Prius and Ford Escape.

L

Linear Technology Magazine • March 2009

3

L DESIGN FEATURES

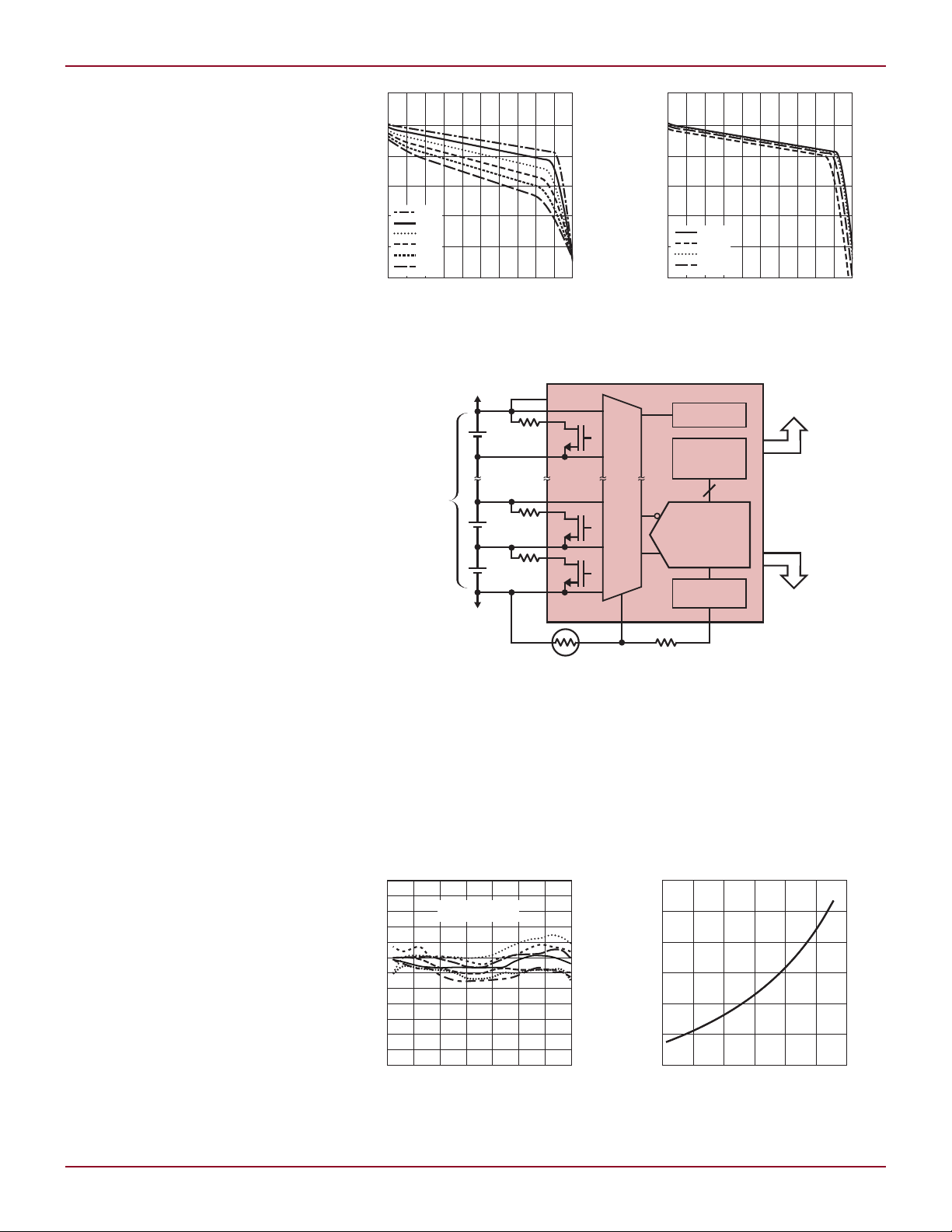

DISCHARGE (%)

0

CELL VOLTAGE (V)

3.5

4.0

70

3.0

2.5

20 40

10 90

30 508060 100

2.0

1.5

4.5

1C

2C

5C

10C

20C

50C

DISCHARGE (%)

0

CELL VOLTAGE (V)

3.5

4.0

70

3.0

2.5

20 40

10 90

30 508060 100

2.0

1.5

4.5

–20°C

0°C

30°C

60°C

MEASUREMENT ERROR (%)

TEMPERATURE (°C)

125–50

0.30

–0.30

–25 0 25 50 75 100

–0.20

–0.25

–0.10

0.10

0

0.20

–0.15

–0.05

0.15

0.05

0.25

7 REPRESENTATIVE

UNITS

COST OF TYPICAL BATTERY PACK ($)

MEASUREMENT ERROR (mV)

300

9k

3k

5

10 15

20 25

4k

5k

7k

6k

8k

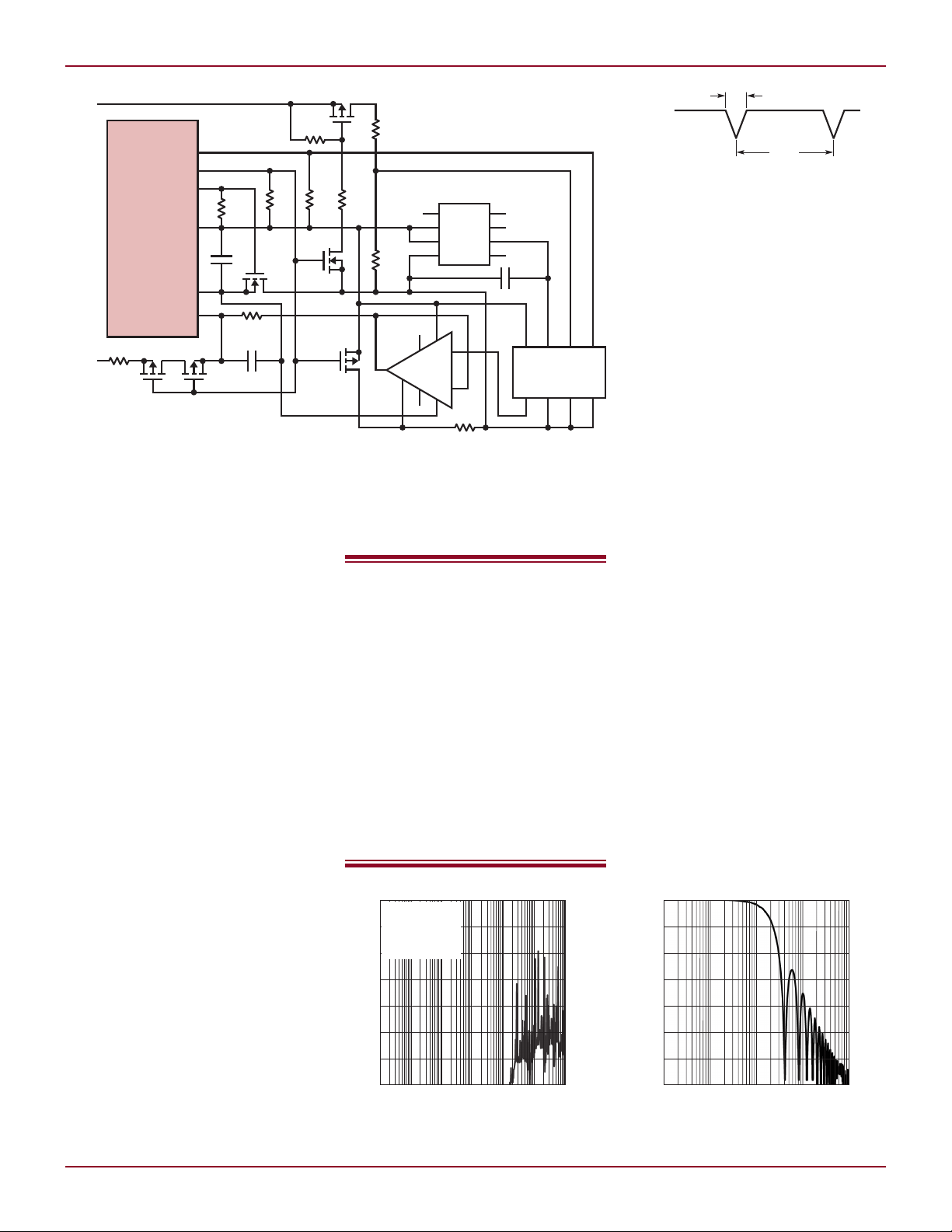

MUX

DIE TEMP

12-CELL

BATTERY

STRING

NEXT 12-CELL

PACK ABOVE

NEXT 12-CELL

PACK BELOW

V

+

V

–

100k NTC

100k

EXTERNAL

TEMP

SERIAL DATA

TO LTC6802-1

ABOVE

SERIAL DATA

TO LTC6802-1

BELOW

LTC6802-1

VOLTAGE

REFERENCE

REGISTERS

AND

CONTROL

12-BIT

∆∑ ADC

to 200 cells in series, in groups of 10

or 12. The cells age at different rates,

were manufactured from multiple lots,

and vary in temperature. Their capacities diverge constantly. Different cells

with the same coulomb count can have

wildly different charge levels.

That’s why the BMS focuses on

cell voltage. If you can accurately

measure the voltage of every cell, you

can know the cell’s SOC with reasonable accuracy (Figure 3). The trick is

to improve the accuracy of the voltage

measurement by taking into account

temperature effects on battery ESR

and capacity. By constantly measuring

each cell’s voltage, you keep a running

estimation of each cell’s charge level.

If some cells are overcharged and

some under, they can be balanced by

bleeding off charge (passive balancing) or redistributing charge (active

balancing).

Figure 3. State of charge vs current and temperature for a typical Li-ion cell

Accurate Monitoring is Key to

Raising Battery Performance

while Lowering Costs

The LTC6802 (Figure 4) is a precision data acquisition IC optimized for

measuring the voltage of every cell in

a large string series-connected batteries. In the BMS, the LTC6802 does the

heavy lifting analog function, passing

digital voltage and temperature measurements to the host processor for

SOC computation. The LTC6802’s high

accuracy, excellent noise rejection,

high voltage tolerance, and extensive

self-diagnostics make it robust and

easy-to-use. The high level of integration means a substantial cost savings

for customers when compared to

discrete component data acquisition

designs.

Increasing measurement accuracy

reduces battery cost, as illustrated

by the following example. Figure 5

shows the typical performance of the

LTC6802, where 0.1% total error from

–20°C to 60°C translates to 4mV precision for a 3.7V cell. Suppose that to

achieve a 15-year battery lifetime, you

are limited to 40% of a cell’s capacity

per charge cycle, and assume the cell

voltage vs charge level of the battery

is very flat, e.g., 1.25mV/%SOC. A

measurement error of 4mV means the

4

Figure 4. Simplified block diagram of the LTC6802

estimation of SOC is accurate to 3%.

The BMS must charge cells to no more

than 37% (40% – 3%) of their capacity

to guarantee the 15-year lifetime.

Now consider a monitor IC with

10mV error over similar conditions.

In this case, the BMS can only use

Figure 5. Typical measurement accuracy

vs temperature of seven samples

32% (40% – 10mV • 1%/1.25mV) of

the cells’ capacity and still guarantee a

15-year life. This seemingly negligible

increase in measurement error results

in a significant 14% reduction in the

usable capacity. That is, a vehicle

requires least 14% more batteries, or

Figure 6. High BMS accuracy is important to

keeping battery costs in check, as shown in

this cost vs measurement error model.

Linear Technology Magazine • March 2009

LTC6802-1

GPIO2

V

−

C1

V

REG

GPIO1

0 = REF_EN

0 = CELL1

V

STACK12

CELL1

CELL12

1M

1M

2N7002

2N7002

TP0610K

TP0610K

TP0610K

TP0610K

1µF

WDTB

LT1461A-4

DNC

DNC

V

OUT

DNC

DNC

V

IN

SD

GND

1M 10M

1M

90.9k

150Ω

100Ω

2.2M

1M

100nF

2.2µF

4.096V

+

–

TC4W53FU

LT1636

SD

SELCH1CH0V

DD

VSSVEEINHCOM

0

–10

–30

–50

–20

–40

–60

–70

FREQUENCY (Hz)

REJECTION (dB)

10 10k 100k1k100

0

–10

–30

–50

–20

–40

–60

–70

FREQUENCY (Hz)

REJECTION (db)

10 10k 10M1M100k1k100

V

CM(IN)

= 5V

P-P

72dB REJECTION

CORRESPONDS TO

LESS THAN 1 BIT

AT ADC OUTPUT

370V

270V

10kHz

6µs

Figure 7. Improving accuracy with calibration

at least 14% more weight, cost and

electronics to travel an equivalent

distance as a vehicle with the more

accurate BMS. Batteries are expensive. It takes about $4000 worth of

batteries to drive 50 miles, so the

increased measurement error means

$560 in additional cells. This is why

BMS designers scrutinize every 0.01%

of measurement error. Figure 6 shows

a simple battery cost model as a function of BMS accuracy.

Adding a low drift reference, an initial factory calibration, and a periodic

self-calibration routine can improve

the measurement accuracy of the

LTC6802 to 0.03%. For example, in

Figure 7 the LT1461A-4 is periodically

applied to channel C1. The temperature stable LT1461 measurement is

used to correct temperature drift in

the LTC6802. The initial error of the

LTC6802 and LT1461A is corrected by

measuring and storing a calibration

reference after board assembly.

Inverter noise can seriously interfere with cell voltage measurements.

When a 100-cell stack is loaded by an

electric motor it can have a 370V open

circuit voltage and up to 100V switching transients (Figure 8). Spreading

the transient equally over the 100 cells

means the top cell has 370V of common mode voltage, 100V of common

mode transients, 1V of differential

transients and an average DC value

Linear Technology Magazine • March 2009

of 3.7V, which we need to measure

to 4mV. Breaking the battery stack

into 12-cell modules further reduces

The LTC6802’s 0.1% total

measurement error from

–20°C to 60°C translates to

4mV precision for a 3.7V cell.

Batteries are expensive. It

takes about $4000 worth

of batteries to drive 50

miles, so just increasing

measurement error to 10mV

means $560 in additional

cells. This is why BMS

designers scrutinize every

0.01% of measurement error.

Figure 9. Cell measurement

common mode rejection

DESIGN FEATURES L

Figure 8. Inverter noise example

the common mode voltage. In a pack

like Figure 2, each LTC6802 (one

per module) sees up to 12V common

mode transients and 1V differential

transients per cell. The transients

are at the PWM frequency of 10kHz

to 20kHz. The LTC6802 has excellent

common mode rejection (Figure 9) to

eliminate this error term. The SINC2

filter inherent in the delta-sigma ADC

attenuates the differential noise by

40dB (Figure 10). External filtering or

measurement averaging can be used to

further reduce the differential noise.

Diagnostic Features of the

LTC6802 Improve Robustness

Automotive systems require that “no

bad cell reading be misinterpreted

as a good cell reading.” Two of the

more common faults that can cause

false readings are open circuits and

IC failures. If there is an open circuit

in the wiring harness and if there is

a filter capacitor on the ADC input

(Figure 11), the capacitor will tend

to hold the input voltage at a point

midway between the adjacent cells.

Some type of open wire detection or

cell resistance measuring function

is necessary. The LTC6802 includes

100µA current sources to load the cell

inputs. The current source will cause

large changes in cell readings if there

is an open circuit in the harness.

Figure 10. Cell measurement filtering

5

L DESIGN FEATURES

MUX

C4

C3

C

F4

C

F3

C2

C1

V

–

100µA

B4

B3

LTC6802-1

LTC6802

BATTERY

MONITOR

12 Li-Ion

SERIES

BATTERIES

BATTERY MODULE 8

CAN

TRANSCEIVER

SPI

µCONTROLLER

GALVANIC

ISOLATOR

TO VEHICLE

CAN BUS

CONTROL MODULE

CAN

LTC6802

BATTERY

MONITOR

DIGITAL

ISOLATOR

DIGITAL

ISOLATOR

12 Li-Ion

SERIES

BATTERIES

BATTERY MODULE 1

The host controller must be able

to run diagnostics on all the modules

during normal operation to detect IC

failures. If these periodic self-tests fail,

then the control algorithm is suspect

and the battery pack must be taken off

line. The LTC6802 includes a built-in

self-test in combination with external

support circuits to allow the BMS to

completely verify the data acquisition

system. See the LTC6802 data sheets

for more details.

The LTC6802 Isolates

Communications from

Swings in Ground Potential

Breaking a ~100 cell pack into modules makes it easier to integrate the

analog circuits. Unfortunately, we are

left with the task of getting the data

from measurement IC to the host controller when the difference in ground

potential exceeds 300V. The LTC6802

can solve this problem in a number of

ways, depending on the specific needs

of the application.

The LTC6802 comes in two flavors,

depending on the desired data communication scheme. The LTC6802-1

offers a built-in stackable serial

peripheral interface (SPI) solution

designed for easy daisy chaining of the

interface. The addressable LTC6802-2

is designed for bus-oriented (parallel)

SPI communication, but it can also be

used in a parallel-addressable, daisy

chained interface for a robust and rela-

Figure 11. Current sources help detect open circuits.

tively inexpensive solution. All three

schemes are described below.

SPI Bus Communication with

the Addressable LTC6802-2

and Digital Isolators

The most straightforward approach is

to use a bus communications scheme,

with a digital isolator between each

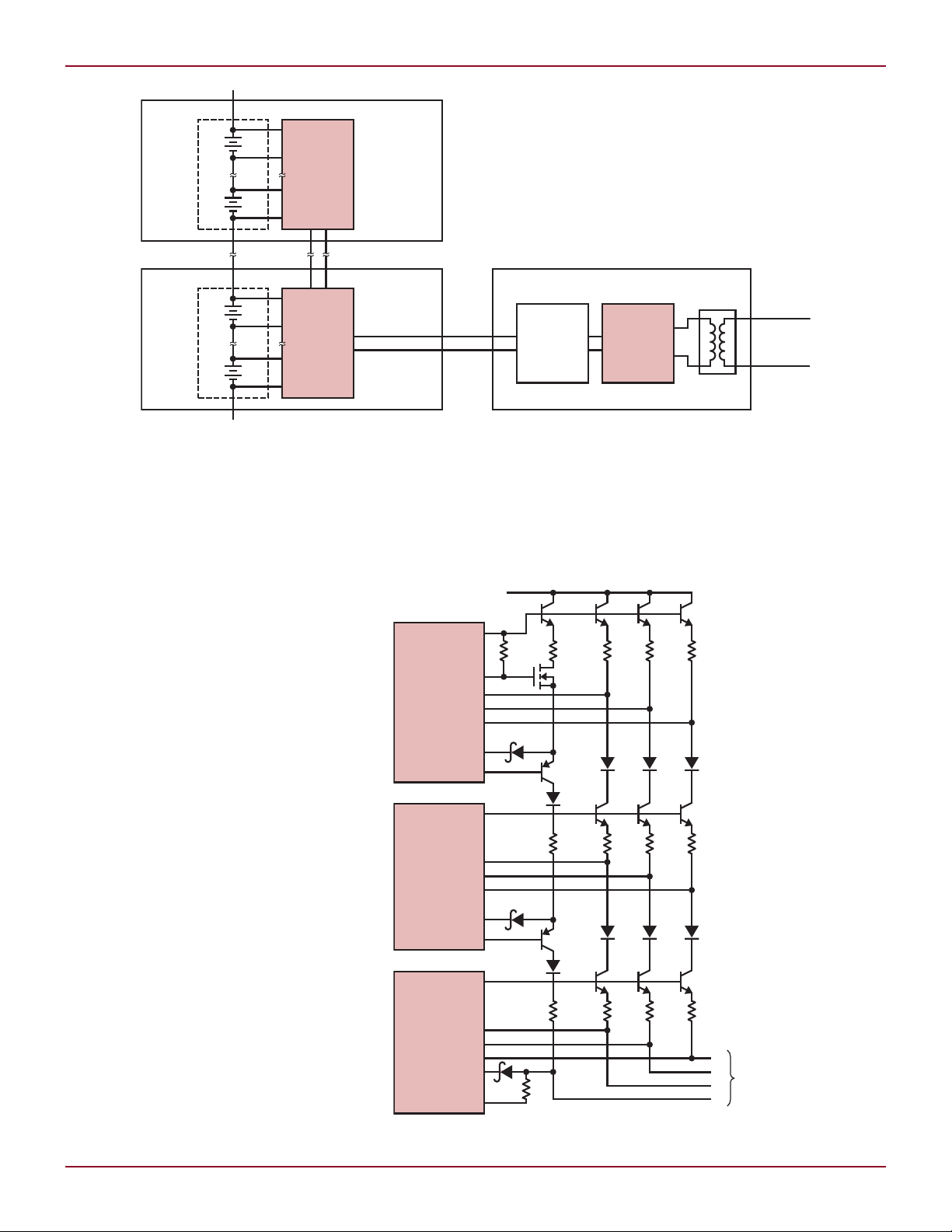

module and the host controller. Figure 12 shows a 96-cell pack using

eight multicell modules monitored

by the LTC6802. The physical layer

is a 4-wire SPI bus. An addressing

scheme allows the control module to

talk to the battery modules separately

or in unison. The data buses on the

modules are isolated from one another.

This is a robust scheme, but it has

one major drawback: digital isolators

are expensive and require an isolated

power supply so that the battery cells

don’t have to provide the power to the

cell side of the isolator.

Daisy Chaining the SPI Interface

with the LTC6802-1

The LTC6802-1 provides fixed 1mA

signaling between stacked devices to

enable easy implementation a daisy

chained SPI interface with inexpensive

support circuitry. The digital isolators

are eliminated as shown in Figure 13.

The interface exploits the fact that the

positive supply of module “N” is the

same voltage as the ground of module

“N+1.” A 1mA current is used to transmit data between adjacent modules.

Like the analog circuits, the modular

approach means the data bus has to

deal with a fraction of the total pack

voltage.

6

Figure 12. Using digital isolators to communicate to the LTC6802

Linear Technology Magazine • March 2009

DESIGN FEATURES L

LTC6802

BATTERY

MONITOR

12 Li-Ion

SERIES

BATTERIES

BATTERY MODULE 8

CAN

TRANSCEIVER

SPI

µCONTROLLER

GALVANIC

ISOLATOR

TO VEHICLE

CAN BUS

CONTROL MODULE

CAN

LTC6802

BATTERY

MONITOR

12 Li-Ion

SERIES

BATTERIES

BATTERY MODULE 1

2.2k2.2k1.8k1M

NDC7002N

2.2k

LTC6802-2

IC #3

V

REG

V

BATT

WDT

SDI

SCKI

CSBI

SDO

V

−

2.2k2.2k100Ω

100Ω

2.2k

LTC6802-2

IC #2

V

REG

SDI

SCKI

CSBI

SDO

V

−

2.2k2.2k

R12

2.2k

2.2k

LTC6802-2

IC #1

V

REG

SDI

SCKI

CSBI

SDO

CS

CK

DI

DO

HOST µP

500kbps MAX DATA RATE

ALL NPN: CMPT8099

ALL PNP: CMPT8599

ALL PN: RS07J

ALL SCHOTTKY: CMD5H2-3

V

−

Figure 13. Using the daisy chained SPI to eliminate digital isolators

The disadvantage of any pure daisy

chain is that a fault in one module

results in a loss of communications

with all the modules above it in the

stack. Also, since there is no galvanic

isolation between modules, the interface needs to handle large voltages

that occur during fault conditions.

For example if the “service switch” in

Figure 1 is open and there is a load

on the pack then the data bus connection between modules 4 and 5 will

see a reverse voltage equal to the total

pack voltage (–300V to –400V). The

LTC6802 interface relies on external

discrete diodes to block the reverse

voltage during fault conditions.

The Best of Both Worlds:

Daisy Chained, Addressable

Interface with the LTC6802-2

With inexpensive external circuitry,

the LTC6802-2 can also be used in

a stacked SPI configuration like the

LTC6802-1, but with more flexibility

in the operating parameters.

The SPI port of the LTC6802-2 is

a 4-wire connection: chip select in

(CSBI), clock in (SCKI), data in (SDI),

and data out (SDO). The inputs are

conventional CMOS levels and the

output is an open-drain NMOS. The

SDO pin must have an external pull-up

current or added resistance suitable

for the intended data rate. The IC also

provides a versatile always-on 5V output (V

REG

Linear Technology Magazine • March 2009

), which can produce up to

4mA to energize low power auxiliary

circuitry.

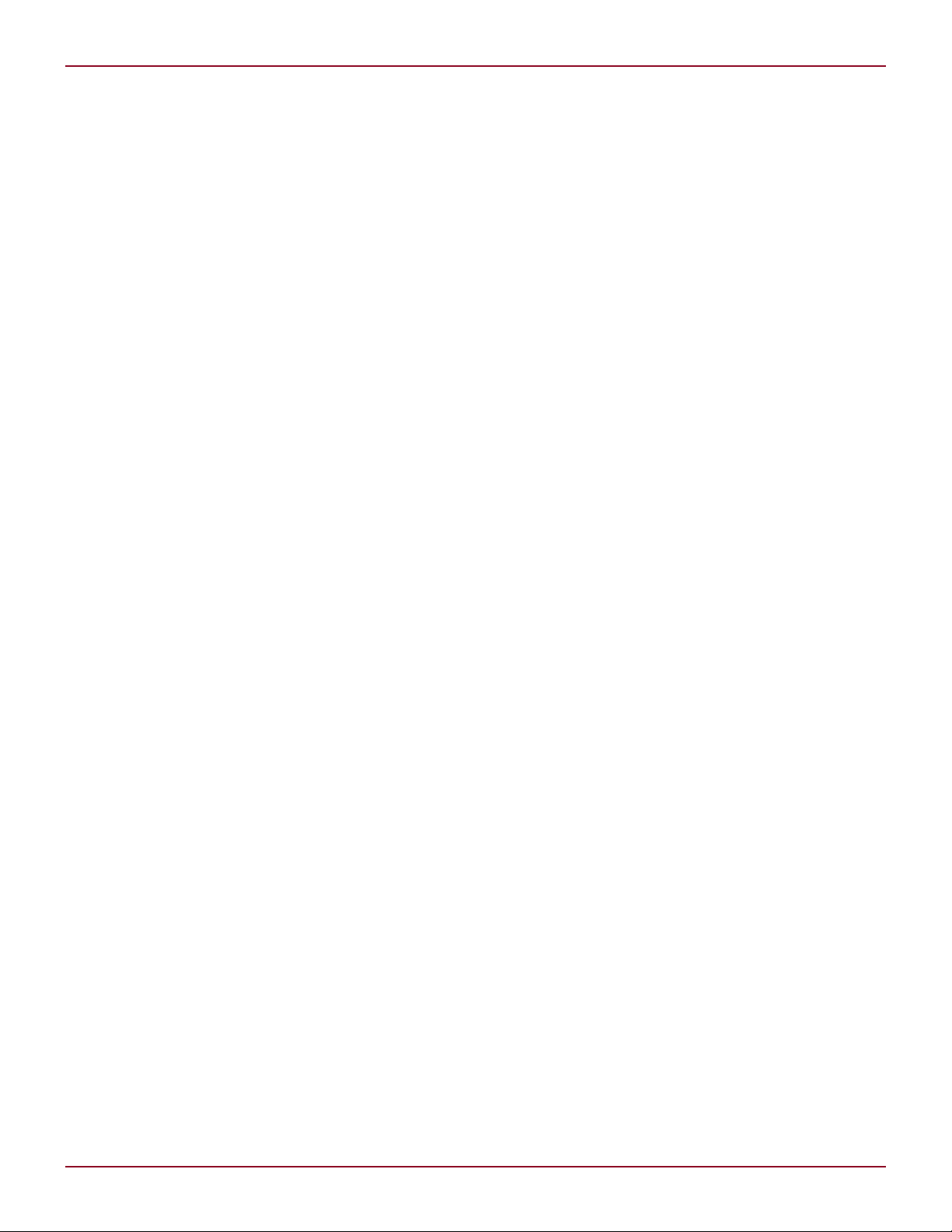

Figure 14 shows a complete stacked

LTC6802-2 SPI interface for a 36cell application. The stack can be

increased in size by replicating the

Figure 14. Inexpensive SPI daisy chain for parallel-addressed LTC6802-2

circuit of the middle IC. In Figure 14,

the V

REG

and V

–

pins of each stacked

IC are used to bias common-base

connected transistors to form a signal

translation current for each SPI data

line. Each LTC6802 can monitor up

7

L DESIGN FEATURES

to 12 cell-potentials, which could sum

to 60V in certain instances, so the

transistors selected for the SPI translation need to have a V

over 60V, but

CBO

they should be the highest available fT

to prevent undue slowing of the logic

signals. A suitable NPN candidate is

the CMPT8099, while the CMPT8599

is its PNP complement, both from

Central Semiconductor. These are fast

80V devices (fT > 150MHz).

Sending Signals Upwards

At the bottom-of-stack IC, the logic

signal is furnished by the host connection, be it a microprocessor or an

SPI isolation device. By simply pulling

down the emitter leg of an NPN having

a V

base potential through a known

REG

resistance, a specific current is formed

for a logic low input signal. In the case

of the component values shown, the

current is about 2mA for a logic low,

and conversely, the transistor is essentially turned off with a logic high

(~0mA for 5V logic).

Since the collector current is nearly

identical to the emitter current, the

same current pulls on the next higher

cascode circuit. Since that next circuit

is the same as the first, the voltage on

the upper emitter resistor reproduces

that of the bottom circuit logic level for

the upper IC. This continues up the

daisy chain, eventually terminating at

the top potential of the battery stack.

Since each IC is provided the same input waveforms, this structure forms a

parallel bus from a logical perspective,

even though each IC is operating at a

different potential in the stack.

The NPN transistors at the top IC

source the logic current directly from

the battery stack. Only small base

currents flow from any V

output.

REG

The 600V collector diodes provide reverse-voltage protection in the event a

battery group interconnection is lost,

perhaps during service (these are not

required for functionality and could

be omitted in some situations).

Bringing Data Down the Stack

The SDO cascode chain is similar in

concept, except the current starts at

the top of the stack and flows downward. At the top IC, a PNP transistor

with its base connected to the local

–

V

pin has current injected into its

emitter by a pullup resistor. Here

again, the collector current is essentially identical to the emitter current,

and so current flows downward

through each successive PNP and terminates into a resistor at the bottom

of stack. In this case, the presence of

the current in the termination resistor,

about 2mA for the component values

shown, forms a logic high potential

for the host interface.

A Schottky diode is connected from

each SDO pin to the emitter of a local

PNP thereby allowing any LTC6802

on the stack to divert the pullup current to the local V

–

when outputting

a logic low. This effectively turns off

the emitter current to the local PNP

transistor and all points lower in the

stack, so the voltage on the bottom

termination resistor then drops to a

logic low level. Since each SDO pin

can force a low level, this forms a

wire-OR function that is equivalent

to paralleled connections as far as

the host interface is concerned. Note

the bottom of stack SDO diode is connected slightly differently; it forms a

direct wire-OR at the host interface.

Since the LTC6802-2 is designed to

use addressed readback commands,

this line is properly multiplexed and

no inter-IC contention occurs.

To eliminate the pull-up current

during standby, a general purpose

N-channel MOSFET is used to interrupt the top PNP emitter current when

the watchdog timer bit goes low. The

watchdog timeout will release when

clock activity is present, so the SDO

line will reactivate as needed. Here

again, an NPN is used at the top of

stack to ensure the pull-up current

comes directly from the battery, rather

than loading V

REG

.

Collector diodes are added here as

well to provide a high reverse voltage

protection capability, plus some added

series resistance is included to protect

the lower transistor emitters from

transient energy (once again, these

protection parts don’t add any other

functionality to the data transmission and could be omitted in some

circumstances).

External SPI Advantages

Since the LTC6802-2 uses a parallel

addressable SPI protocol, the conventional method of connecting multiple

devices in a stack is to provide isolation

for each SPI connection, then parallel

the signals on the host side. Isolators

are relatively expensive and often need

extra power circuitry, thus adding significantly to the total solution cost. The

transistor circuitry shown here is quite

inexpensive and offers the option to

make certain design tradeoffs as well.

With the propagation delays involved

and desire to keep power fairly low, this

circuit as shown still communicates

at over 500kbps. Lower SPI currents

could be chosen in applications that

don’t demand the high data rate by

simply raising the resistance values

accordingly.

The main feature of the transistorized SPI bus is the wide compliance

range that is afforded by the unconstrained collector -base operating

range of the transistors. In normal

operation the VCB ranges from just

less than the cells connected to the

LTC6802, to some five volts below that,

depending on the logic level transmitted. This becomes important since

voltage fluctuations on the battery,

due to load dynamics or switching

transients, affect the VCB of the transistors even though the V+ and ADC cell

inputs may be filtered. Some vehicle

manufacturers are requiring that a

BMS tolerate 1V steps with 200ns

rise/fall time per cell in the stack, so

this is a 12V waveform edge as seen by

the transistors in a typical application.

With the low collector capacitance and

2mA logic level of the transistor chain,

SPI transmissions remain error free

with even this high level of noise.

Conclusion

EVs and HEVs are here to stay. Inherently safe lithium batteries, which

combine energy density, power density, and cycle life, will continue to

evolve to improve the performance of

these vehicles. Battery management

systems using the LTC6802 extract

the most driving distance and lifetime

from the battery pack while lowering

system cost.

L

8

Linear Technology Magazine • March 2009

DESIGN FEATURES L

GND

0

V

OUT

100V/DIV

I

IN(AVG)

2A/DIV

20ms/DIV

VIN = 24V

C

OUT

= 100µF

2V/DIV

250ns/DIV

GND

CHARGE

CLAMP

V

CC

DONE

FAULT

UVLO1

OVLO1

UVLO2

OVLO2

RDCM

RV

OUT

HVGATE

LVGATE

CSP

CSN

FB

RV

TRANS

T1*

1:10

D1

V

OUT

50V TO 450V

V

TRANS

10V TO 24V

V

CC

TO µP

V

CC

LT3751

GND RBG

R6

40.2k

OFF ON

C3

680µF

C2

2.2µF

s5

C1

10µF

•

•

R7

18.2k

R8

40.2k

M1

R5

6mΩ

1W

D2

+

+

C4

100µF

R9

V

TRANS

R1,

154k

R2, 475k

DANGER HIGH VOLTAGE! OPERATION BY HIGH VOLTAGE TRAINED PERSONNEL ONLY

C5

0.47µF

ALL RESISTORS ARE 0805,

1% RESISTORS UNLESS

OTHERWISE NOTED

D1,D2: VISHAY MURS260

M1: IRF3710Z

T1: WURTH 750310349

LIMIT OUTPUT POWER TO

40W FOR 65°C T1 MAX

AMBIENT OPERATION

*

4.7nF

Y RATED

DC/DC Converter, Capacitor Charger

Takes Inputs from 4.75V to 400V

Introduction

High voltage power supplies and capacitor chargers are readily found in

a number of applications, including

professional photoflashes, security

control systems, pulsed radar systems,

satellite communication systems, and

explosive detonators. The LT3751

makes it possible for a designer to

meet the demanding requirements

of these applications, including high

reliability, relatively low cost, safe

operation, minimal board space and

high performance.

The LT3751 is a general purpose

flyback controller that can be used as

either a voltage regulator or as a capacitor charger. The LT3751 operates in

boundary-mode, between continuous

conduction mode and discontinuous

conduction mode. Boundary-mode

operation allows for a relatively small

transformer and an overall reduced

PCB footprint. Boundary-mode also

reduces large signal stability issues

that could arise from using voltagemode or PWM techniques. Regulation

is achieved with a new dual, overlapping modulation technique using both

by Robert Milliken and Peter Liu

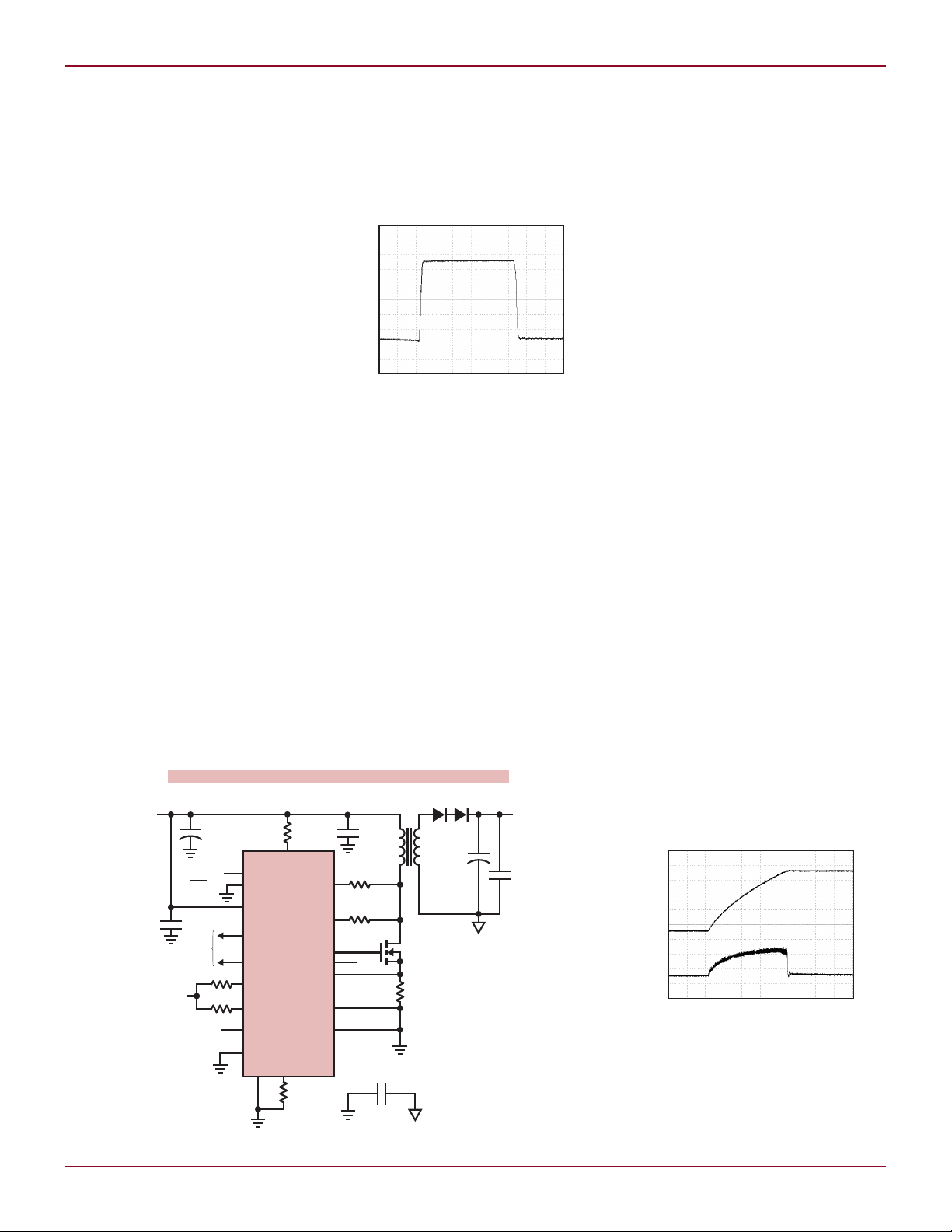

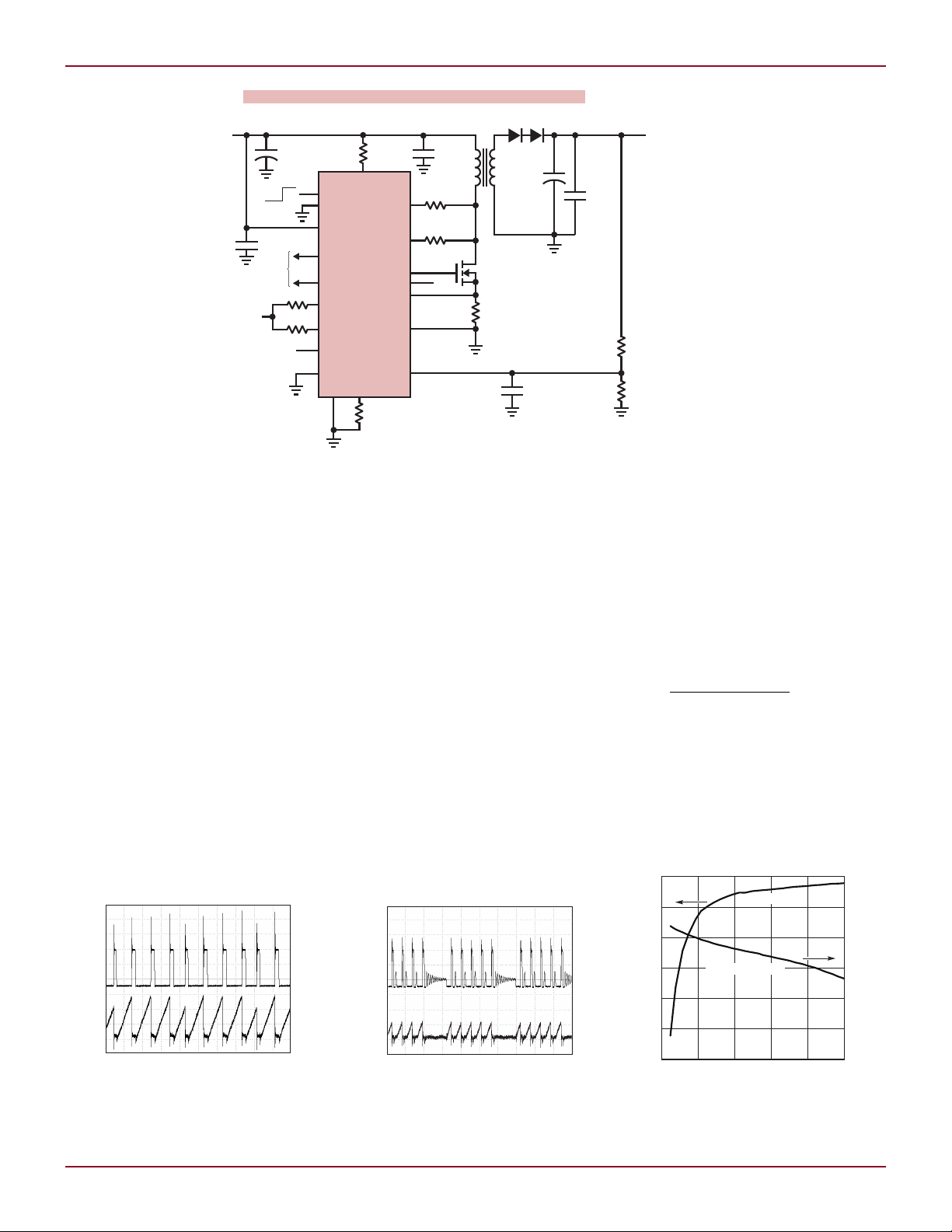

Figure 1. Gate driver waveform

in a typical application

peak primary current modulation and

duty-cycle modulation, drastically reducing audible transformer noise.

The LT3751 features many safety

and reliability functions, including

two sets of undervoltage lockouts

(UVLO), two sets of overvoltage

lockouts (OVLO), no-load operation,

over-temperature lockout (OTLO), internal Zener clamps on all high voltage

pins, and a selectable 5.6V or 10.5V

internal gate driver voltage clamp (no

external components needed). The

LT3751 also adds a start-up/shortcircuit protection circuit to protect

against transformer or external FET

damage. When used as a regulator, the

LT3751’s feedback loop is internally

compensated to ensure stability. The

LT3751 is available in two packages,

either a 20-pin exposed pad QFN or a

20-lead exposed pad TSSOP.

New Gate Driver with Internal

Clamp Requires No External

Components

There are four main concerns when

using a gate driver: output current

drive capability, peak output voltage,

power consumption and propagation

delay. The LT3751 is equipped with a

1.5A push-pull main driver, enough to

drive +80nC gates. An auxiliary 0.5A

PMOS pull-up only driver is also integrated into the LT3751 and is used in

parallel with the main driver for VCC

voltages of 8V and below. This PMOS

driver allows for rail-to-rail operation.

Above 8V, the PMOS driver must be

deactivated by tying its drain to VCC.

Most discrete FETs have a VGS limit

of 20V. Driving the FET higher than

20V could cause a short in the internal gate oxide, causing permanent

Figure 2. Isolated high voltage capacitor charger from 10V to 24V input

Linear Technology Magazine • March 2009

Figure 3. Isolated high voltage capacitor

charger charging waveform

9

L DESIGN FEATURES

R

N

V V

R

OUT TRIP DIODE

9 8

0 98

=

•

+

•

.

( )

0

GND

V

DRAIN

20V/DIV

I

PRIMARY

5A/DIV

10µs/DIV

V

OUT

(V)

EFFICIENCY (%)

LOAD CURRENT (mA)

1000

90

60

20 40 60 80

65

70

80

75

85

402

399

400

401

LOAD REGULATION

EFFICIENCY

0

GND

V

DRAIN

20V/DIV

I

PRIMARY

5A/DIV

10µs/DIV

CHARGE

CLAMP

V

CC

DONE

FAULT

UVLO1

OVLO1

UVLO2

OVLO2

RDCM

RV

OUT

HVGATE

LVGATE

CSP

CSN

FB

RV

TRANS

T1**

1:10

D1

V

OUT

400V

V

TRANS

10V TO 24V

V

CC

TO µP

V

CC

LT3751

GND RBG

R6

40.2k

OFF ON

C3

680µF

R10*

499k

R11

1.54k

C2

2.2µF

s5

C1

10µF

•

•

R7

18.2k

R8

40.2k

M1

R5

6mΩ

1W

D2

+

+

C4

100µF

R9

787Ω

V

TRANS

R1,154k

R2, 475k

DANGER HIGH VOLTAGE! OPERATION BY HIGH VOLTAGE TRAINED PERSONNEL ONLY

C5

0.47µF

C6

10nF

ALL RESISTORS ARE 0805,

1% RESISTORS UNLESS

OTHERWISE NOTED

C4: CDE 380LX101M500J042

C5: TDK CKG57NX7R2J474M

D1,D2: VISHAY MURS260

M1: IRF3710Z

T1: WURTH 750310349

USE TWO SERIES 1206,

1% RESISTORS FOR R10

R10: 249k s2

LIMIT OUTPUT POWER TO

40W FOR 65°C T1 MAX

AMBIENT OPERATION

*

**

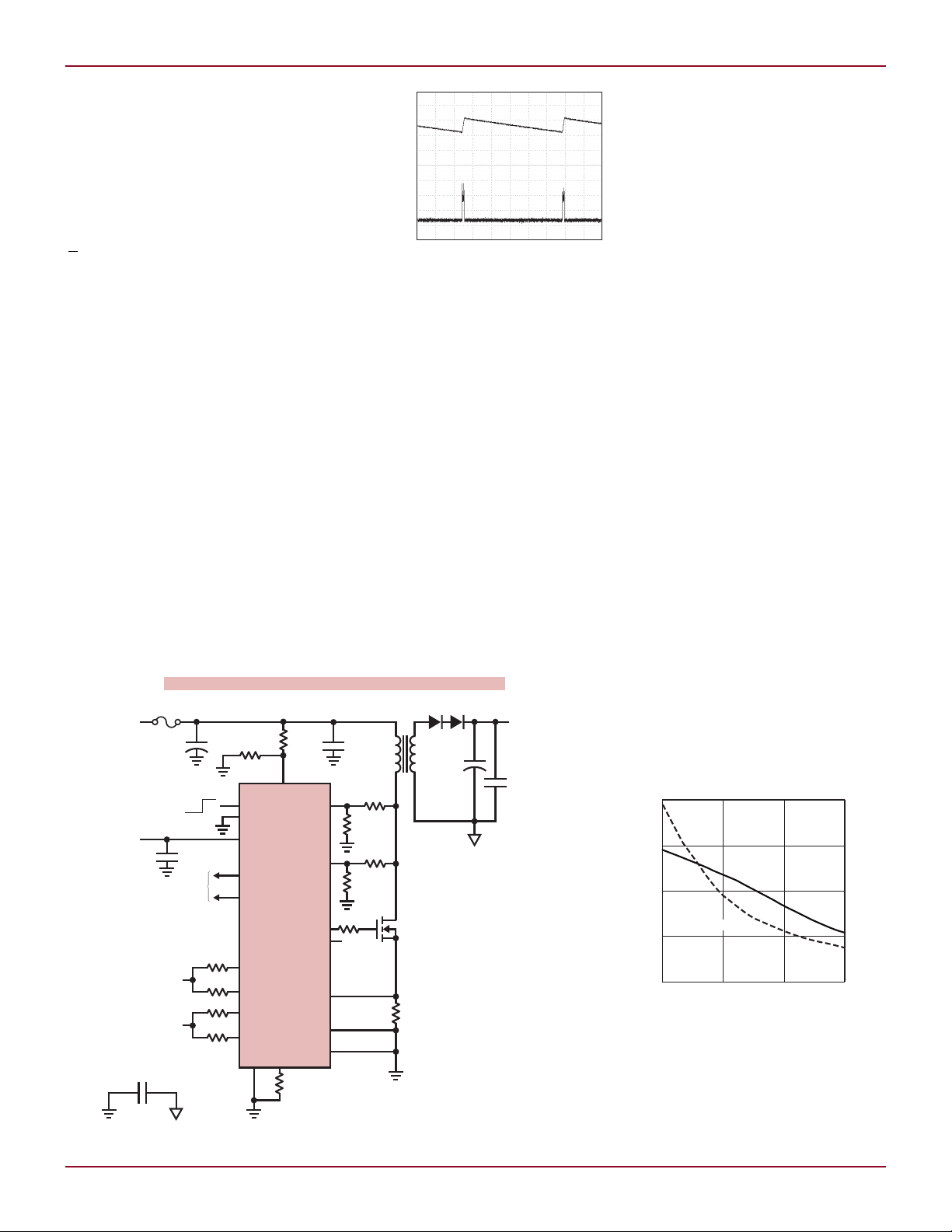

Figure 4. A 10V to 24V input, 400V regulated power supply

damage. To alleviate this issue, the

LT3751 has an internal, selectable

5.6V or 10.5V gate driver clamp. No

external components are needed, not

even a capacitor. Simply tie the CLAMP

pin to ground for 10.5V operation or

tie to VCC for 5.6V operation. Figure

1 shows the gate driver clamping at

10.5V with a VCC voltage of 24V.

Not only does the internal clamp

protect the FET from damage, it also

reduces the amount of energy injected

into the gate. This increases overall

efficiency and reduces power consumption in the gate driver circuit. The

gate driver overshoot is very minimal,

as seen in Figure 1. Placing the external

FET closer to the LT3751 HVGATE pin

reduces overshoot.

a. Switching waveform for I

10

High Voltage, Isolated

Capacitor Charger from

10V to 24V Input

The LT3751 can be configured as

a fully isolated stand-alone capacitor charger using a new differential

discontinuo us-conductio n-mode

(DCM) comparator—used to sense

the boundary-mode condition—and

a new differential output voltage

(V

) comparator. The differential

OUT

operation of the DCM comparator and

V

comparator allow the LT3751 to

OUT

accurately operate from high voltage

input supplies of greater than 400V.

Likewise, the LT3751’s DCM comparator and V

input supplies down to 4.75V. This

accommodates an unmatched range

of power sources.

= 100mA b. Switching waveform for I

OUT

Figure 5. High voltage regulator performance

OUT

comparator can work with

= 10mA c. Efficiency and load regulation

OUT

Figure 2 shows a high voltage capacitor charger driven from an input

supply ranging from 10V to 24V. Only

five resistors are needed to operate

the LT3751 as a capacitor charger.

The output voltage trip point can be

continuously adjusted from 50V to

450V by adjusting R9 given by:

The LT3751 stops charging the

output capacitor once the programmed

output voltage trip point (V

OUT(TRIP)

) is

reached. The charge cycle is repeated

by toggling the CHARGE pin. The

maximum charge/discharge rate in

Linear Technology Magazine • March 2009

DESIGN FEATURES L

P

C FREQUENCY

V V V

AVG

OUT

OUT TRIP RIPPLE

=

••

•

1

2

2

( )

–

RRIPPLE

W240

(

)

≤

V

CC

R3, 154k

R4, 475k

CHARGE

CLAMP

V

CC

DONE

FAULT

UVLO1

OVLO1

UVLO2

OVLO2

RV

OUT

HVGATE

LVGATE

CSP

CSN

FB

RV

TRANS

T1***

1:3

D1

V

OUT

500V

V

TRANS

100V TO 400V DC

V

CC

10V TO 24V

TO µP

V

CC

LT3751

GND RBG

R6*

625k

OFF ON

C3

100µF

450V

C2

2.2µF

630V

s5

C1

10µF

•

•

R8

137k ×3

R7

88.7k + 7.5k

R10*

208k

R13,20Ω

M1

FQB4N80

R12

68mΩ

1/4W

D2

+

+

C4

220µF

550V

R5

1.11k

V

TRANS

R1**

1.5M

R2**, 9M

DANGER HIGH VOLTAGE! OPERATION BY HIGH VOLTAGE TRAINED PERSONNEL ONLY

C5

0.47µF

630V

RDCM

F1, 1A

R9

66.5k

R11

14.7k +

17.4k

ALL RESISTORS ARE 0805,

1% RESISTORS UNLESS

OTHERWISE NOTED

C4: HITACHI PS22L221MSBPF

C5: TDK CKG57NX7R2J474M

T1: COILCRAFT HA4060-AL

D1,D2: VISHAY US1M

F1: BUSSMANN PCB-1-R

* USE THREE SERIES 1206, 0.1%

RESISTORS FOR R6 & R10

R6: 249k ×2 + 127k

R10: 66.5k ×2 + 75k

** USE TWO SERIES 1206, 1%

RESISTORS FOR R1 & R2

R1: 750k ×2

R2: 4.53M ×2

*** OUTPUT POWER LIMITED TO

20W FOR 65°C T1 AMBIENT

OPERATION

4.7nF

Y RATED

0

V

OUT

AC RIPPLE

10V/DIV

I

IN(AVG)

20mA/DIV

2s/DIV

CHARGE TIME (ms)

V

OUT,TRIP

(V)

INPUT VOLTAGE (V)

400100

530

490

200 300

500

520

510

1000

400

850

550

700

V

OUT,TRIP

CHARGE TIME

the output capacitor is limited by the

temperature rise in the transformer.

Limiting the transformer surface temperature in Figure 2 to 65°C with no

air flow requires the average output

power to be ≤40W given by:

where V

voltage, V

OUT(TRIP)

is the output trip

is the ripple voltage

RIPPLE

on the output node, and frequency is

the charge/discharge frequency. Two

techniques are used to increase the

available output power: increase the

airflow across the transformer, or increase the size of the transformer itself.

Figure 3 shows the charging waveform

and average input current for a 100µF

output capacitor charged to 400V in

less than 100ms (R

= 976Ω).

9

For output voltages higher than

450V, the transformer in Figure 2 must

be replaced with one having higher

primary inductance and a higher

turns ratio. Consult the LT3751 data

Figure 6. The LT3751 protecting the

output during a no-load condition

sheet for proper transformer design

procedures.

High Voltage Regulated Power

Supply from 10V to 24V Input

The LT3751 can also be used to convert

a low voltage supply to a much higher

voltage. Placing a resistor divider from

the output node to the FB pin and

ground causes the LT3751 to operate as a voltage regulator. Figure 4

shows a 400V regulated power supply

operating from an input supply range

of 10V to 24V.

The LT3751 uses a regulation control scheme that drastically reduces

audible noise in the transformer and

the input and output ceramic bulk

capacitors. This is achieved by using

an internal 26kHz clock to synchronize

the primary winding switch cycles.

Within the clock period, the LT3751

modulates both the peak primary

current and the number of switching cycles. Figures 5a and 5b show

heavy-load and light-load waveforms,

respectively, while Figure 5c shows

efficiency over most of the operating

range for the application in Figure 4.

The clock forces at least one switch

cycle every period which would overcharge the output capacitor during a

no-load condition. The LT3751 handles no-load conditions and protects

against over-charging the output node.

Figure 6 shows the LT3751 protecting

during a no-load condition.

Resistors can be added to RV

OUT

and

RBG to add a second layer of protection, or they can be omitted to reduce

component count by tying RV

OUT

and

RBG to ground. The trip level for the

V

comparator is typically set 20%

OUT

higher than the nominal regulation

voltage. If the resistor divider were to

fail, the V

comparator would disable

OUT

switching when the output climbed to

20% above nominal.

Linear Technology Magazine • March 2009

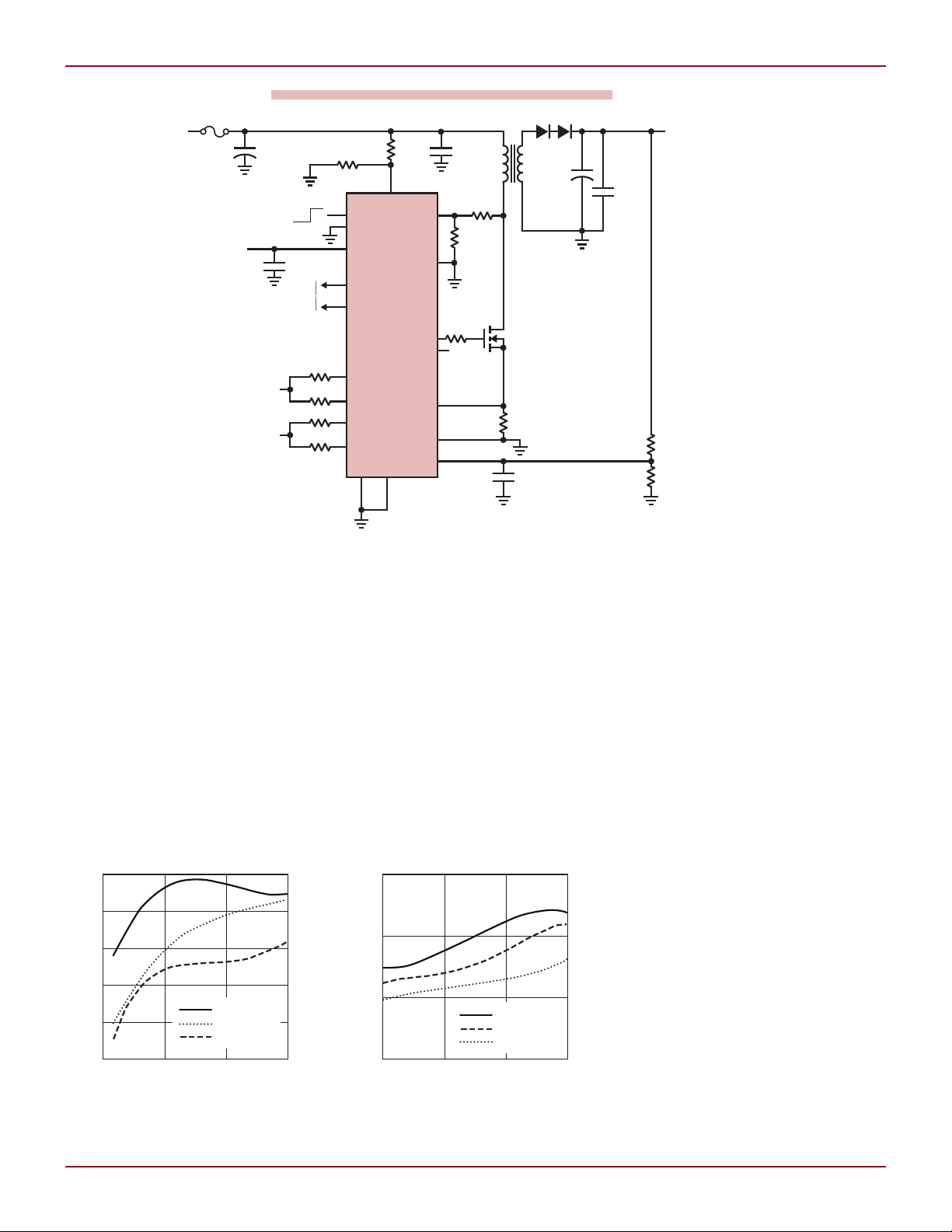

Figure 7. A 100V to 400V input, 500V output, isolated capacitor charger

Figure 8. Isolated capacitor charger V

and charge time with respect to input voltage

OUT(TRIP)

11

L DESIGN FEATURES

OUTPUT VOLTAGE (V)

INPUT VOLTAGE (V)

400100

398

395

200 300

396

397

I

OUT

= 10mA

I

OUT

= 25mA

I

OUT

= 50mA

EFFICIENCY (%)

OUTPUT CURRENT (mA)

750

90

40

50

25 50

60

70

80

VIN = 100V

VIN = 250V

VIN = 400V

V

CC

R3, 154k

R4, 475k

CHARGE

CLAMP

V

CC

DONE

FAULT

UVLO1

OVLO1

UVLO2

OVLO2

RV

OUT

HVGATE

LVGATE

CSP

CSN

FB

RV

TRANS

T1***

1:3

D1

V

OUT

400V

V

TRANS

100V TO 400V DC

V

CC

10V TO 24V

TO µP

V

CC

LT3751

GND RBG

R6*

615k

OFF ON

C3

100µF

C2

2.2µF

s5

C1

10µF

C6

10nF

•

•

R8*

411k

R13,20Ω

M1

FQB4N80

R10

68mΩ

¼W

D2

+

+

C4

100µF

R12

1.54k

R11**

499k

V

TRANS

R1**, 1.5M

R2**, 9M

DANGER HIGH VOLTAGE! OPERATION BY HIGH VOLTAGE TRAINED PERSONNEL ONLY

C5

0.47µF

RDCM

F1, 1A

R9

66.5k

ALL RESISTORS ARE 0805,

1% RESISTORS UNLESS

OTHERWISE NOTED

C4: CDE 380LX101M500J042

C5: TDK CKG57NX7R2J474M

T1: COILCRAFT HA4060-AL

D1,D2: VISHAY US1M

F1: BUSSMANN PCB-1-R

* USE THREE SERIES 1206, 1%

RESISTORS FOR R6 & R8

R6: 205k ×3

R8: 137k ×3

** USE TWO SERIES 1206, 1%

RESISTORS FOR R1, R2 & R11

R1: 750k ×2

R2: 4.53M ×2

R11: 249k ×2

*** OUTPUT POWER LIMITED TO

20W FOR 65°C T1 AMBIENT

OPERATION

R7

95.3k

can also be used for a capacitor

charger. The LT3751 operates as a

capacitor charger until the FB pin

reaches 1.225V, after which the

LT3751 operates as a voltage regulator.

This keeps the capacitor topped-off

until the application needs to use its

energy. The output resistor divider

forms a leakage path from the output

capacitor to ground. When the output

voltage droops, the LT3751 feedback

circuit will keep the capacitor topped-

12

Figure 9. A 100V to 400V input, 400V output, capacitor charger and voltage regulator

Note that the FB pin of the LT3751

a. Overall efficiency b. Line regulation

Figure 10. High voltage input and output regulator performance

off with small, low current bursts of

charge as shown in Figure 6.

High Input Supply Voltage,

Isolated Capacitor Charger

As mentioned above, the LT3751 differential DCM and V

allow the part to accurately work from

very high input supply voltages. An

offline capacitor charger, shown in

Figure 7, can operate with DC input

voltages from 100V to 400V. The transformer provides galvanic isolation from

comparators

OUT

the input supply to output node—no

additional magnetics required.

Input voltages greater than 80V

require the use of resistor dividers

on the DCM and V

comparators

OUT

(charger mode only). The accuracy of

the V

trip threshold is heightened

OUT

by increasing current IQ through R10

and R11; however, the ratio of R6/R7

should closely match R10/R11 with

tolerances approaching 0.1%. A trick

is to use resistor arrays to yield the

desired ratio. Achieving 0.1% ratio accuracy is not difficult and can reduce

the overall cost compared to using

individual 0.1% surface mount resistors. Note that the absolute value of

the individual resistors is not critical,

only the ratio of R6/R7 and R10/R11.

The DCM comparator is less critical

and can tolerate resistance variations

greater than 1%.

The 100V to 400VDC input capacitor charger has an overall V

accuracy of better than 6% over the

entire operating range using 0.1% resistor dividers. Figure 8 shows a typical

performance for V

OUT(TRIP)

and charge

time for the circuit in Figure 7.

Linear Technology Magazine • March 2009

OUT(TRIP)

DESIGN FEATURES L

V

TRANS

100V TO 200V DC

V

CC

V

CC

R11, 84.5k

R12, 442k

UVLO1

OVLO1

UVLO2

OVLO2

DONE

FAULT

CHARGE

CLAMP

V

CC

HVGATE

LVGATE

CSP

CSN

FB

RV

TRANS

TO µP

V

CC

LT3751

LT4430

GND RBG

R3

210k

OFF ON

C3

22µF

350V

s2

C2

1µF

C1

100pF

C4

1µF

250V

s2

C7

400µF

330V

C8

22nF

R17

3.16k

R14

249k

V

OUT

282V

225mA

C6

0.1µF

630V

ISOLATION

BOUNDARY

C5

0.01µF

630V

C9

3.3µF

C10

0.47µF

•

M2

M1

D1

R8

2.49k

R7

475Ω

R18

274Ω

R6

40mΩ

1/4W

V

TRANS

R9, 2.7M

R5, 210k

R13

5.11Ω

R16, 1k

R10, 4.3M

DANGER HIGH VOLTAGE! OPERATION BY HIGH VOLTAGE TRAINED PERSONNEL ONLY

RDCM

RV

OUT

U1

ALL RESISTORS ARE 0805,1% RESISTORS

UNLESS OTHERWISE NOTED

C7: 330FK400M22X38

D1: 12V ZENER

D2: MURS140

D3: P6kE200A

D4, D5: STTH112A

D6: BAT54

D7: BAS516

M1: IRF830

M2: STB11NM60FD

T1: TDK SRW24LQ-UxxH015

(Np:Ns:Npb:Nsb=1:2:0.08:0.08)

U1: PS2801-1

U2: LT4430

R4, 105k

R2, 10ΩD2

D3

D5

D6

D4

Np

Ns

Nsb

U2

VINCOMP

GND

OC FB

OPTO

Npb

T1

D7

R15

221k

R1

49.9k

1/2W

•

•

•

+

+

1

1 1 1

1

11

1

1

1

2

2

2

2

2

2

2

F1, 2A

1 2

4.7nF

Y RATED

0

GND

V

DRAIN

100V/DIV

I

PRIMARY

2A/DIV

20µs/DIV

0

GND

V

DRAIN

100V/DIV

I

PRIMARY

2A/DIV

20µs/DIV

R

V

A

OUT TRIP

11

1 225

50

=

−

( )

.

µ

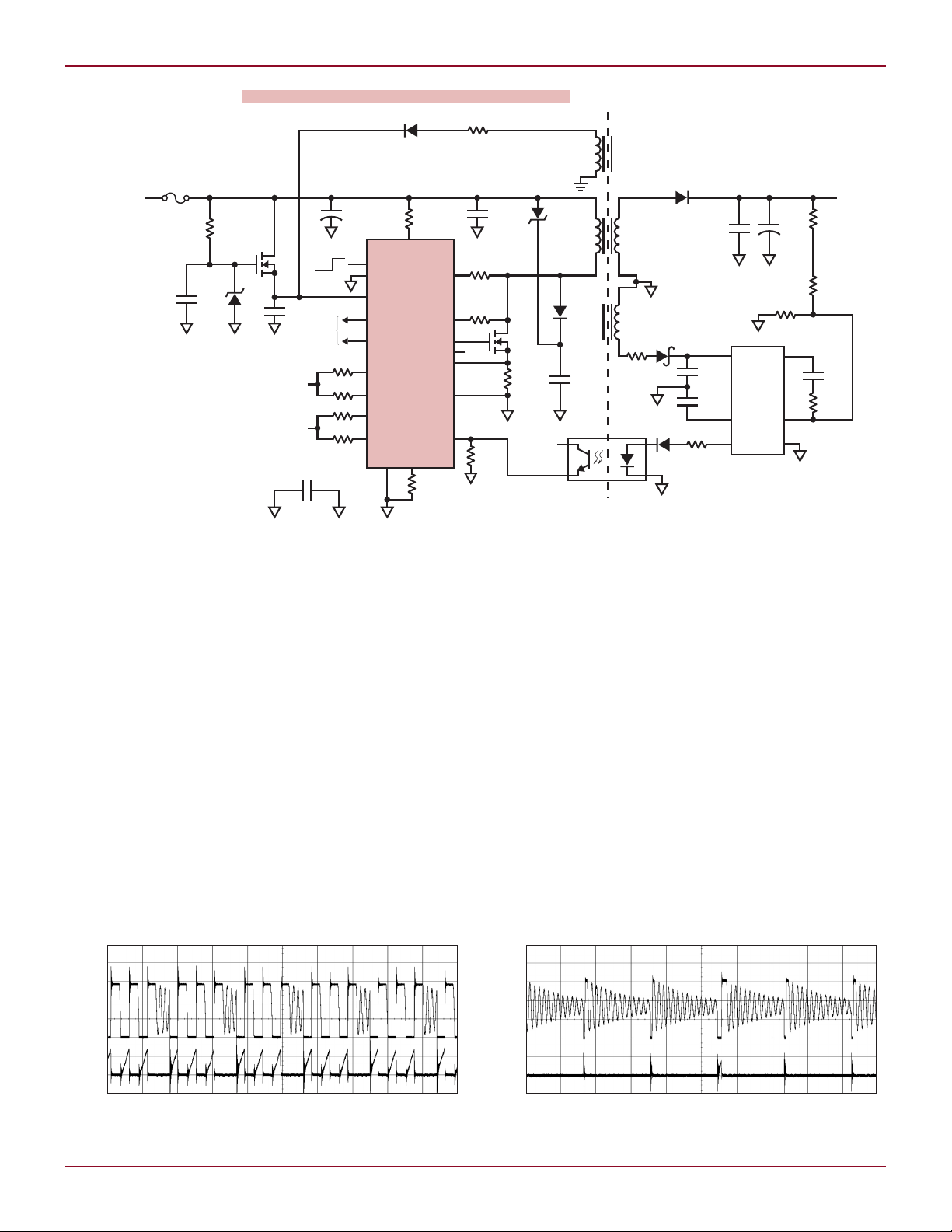

Figure 11. Fully isolated, high output voltage regulator

High Input Supply Voltage,

Non-Isolated Capacitor

Charger/Regulator

The FB pin of the LT3751 can also

be configured for charging a capacitor from a high input supply voltage.

Simply tie a resistor divider from the

output node to the FB pin. The resistor dividers on the R

pins can tolerate 5% resistors, and all

the R

removed. This lowers the number and

and RBG pin resistors are

V(OUT)

the tolerance of required components,

reducing board real estate and overall

design costs. With the output voltage

resistor divider, the circuit in Figure

9 is also a fully functional, high-efficiency voltage regulator with load

Linear Technology Magazine • March 2009

VTRANS

a. I

and R

= 225mA b. I

OUT

DCM

and line regulation better than 1%.

Efficiency and line regulation for the

circuit in Figure 9 are shown in Figure

10a and Figure 10b, respectively.

Alternatively, a resistor can be tied

from V

pin. This mimics the V

to the OVLO1 pin or OVLO2

OUT

compara-

OUT

tor, stopping charging once the target

voltage is reached. The FB pin is tied

to ground. The CHARGE pin must be

toggled to initiate another charge sequence, thus the LT3751 operates as

a capacitor charger only. Resistor R12

is omitted from Figure 9 and resistor

R11 is tied from V

or OVLO2. R11 is calculated using the

following equation:

Figure 12. Switching waveforms

OUT

directly to OVLO1

Note that OVLO1 or OVLO2 will

cause the FAULT pin to indicate a

fault when the target outpaut voltage,

V

OUT(TRIP) ,

is reached.

High Voltage Input/Output

Regulator with Isolation

Using a resistor divider from the output

node to the FB pin allows regulation

but does not provide galvanic isolation.

Two auxiliary windings are added to

the transformer in circuit shown in

Figure 11 to drive the FB pin, the

OUT

= 7.1mA

continued on page 42

13

L DESIGN FEATURES

V

REF

+IN

–IN

GND

8

7

6

5

1

2

3

4

V

CC

CLK

D

OUT

CS/SHDN

LTC1286

V

IN

5V

0.1µF

5V

18k

LT1634-4.096

µC/µP

SERIAL

INTERFACE

0.1µF

How to Choose a Voltage Reference

by Brendan Whelan

Why Voltage References?

It is an analog world. All electronic

devices must in some way interact with

the “real” world, whether they are in

an automobile, microwave oven or cell

phone. To do that, electronics must be

able to map real world measurements

(speed, pressure, length, temperature)

to a measurable quantity in the electronics world (voltage). Of course, to

measure voltage, you need a standard

to measure against. That standard is

a voltage reference. The question for

any system designer is not whether he

needs a voltage reference, but rather,

which one?

A voltage reference is simply that—a

circuit or circuit element that provides

a known potential for as long as the circuit requires it. This may be minutes,

hours or years. If a product requires

information about the world, such

as battery voltage or current, power

consumption, signal size or characteristics, or fault identification, then the

signal in question must be compared

to a standard. Each comparator, ADC,

DAC, or detection circuit must have a

voltage reference in order to do its job

(Figure 1). By comparing the signal of

interest to a known value, any signal

may be quantified accurately.

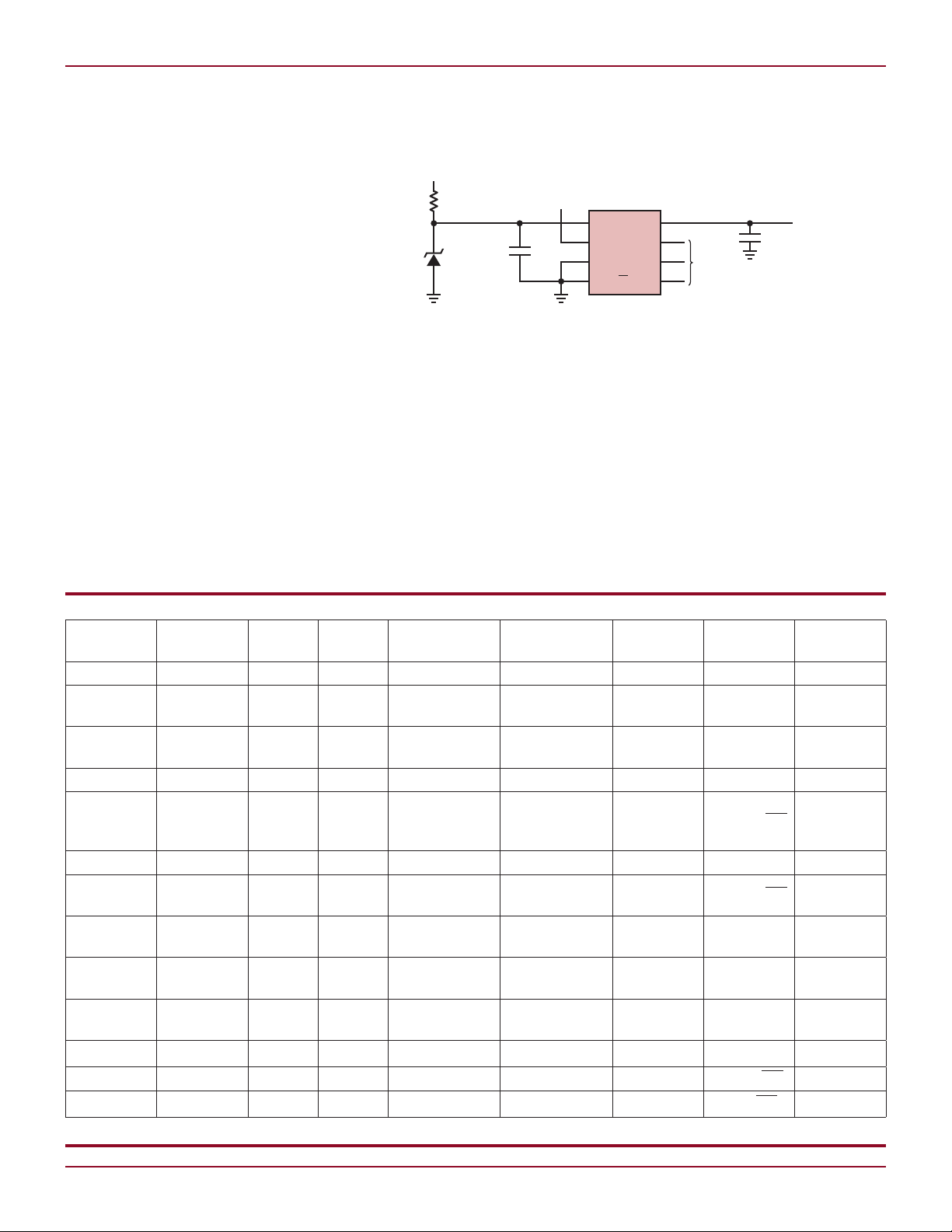

Figure 1. Typical use of a voltage reference for an ADC

Reference Specifications

Voltage references come in many forms

and offer different features, but in

the end, accuracy and stability are

a voltage reference’s most important

features, as the main purpose of the

reference is to provide a known output

voltage. Variation from this known

value is an error. Voltage reference

specifications usually predict the

uncertainty of the reference under

Table 1. Specifications for high performance voltage references

Temperature

Coefficient

Initial

Accuracy

I

S

Architecture V

OUT

Voltage

Noise*

Long-Term

Drift

Package

LT1031 5ppm/°C 0.05% 1.2mA Buried Zener 10V 0.6ppm 15ppm/kHr H

LT1019 5ppm/°C 0.05% 650µA Bandgap

LT1027 5ppm/°C 0.05% 2.2mA Buried Zener 5V 0.6ppm

2.5V, 4.5V,

5V, 10V

2.5ppm SO-8, PDIP

20ppm/

month

SO-8, PDIP

LT1021 5ppm/°C 0.05% 800µA Buried Zener 5V, 7V, 10V 0.6ppm 15ppm/kHr SO-8, PDIP, H

1.25V, 2.048V,

LTC6652 5ppm/°C 0.05% 350µA Bandgap

2.5V, 3V, 3.3V,

2.1ppm 60ppm/√kHr

MSOP

4.096V, 5V

LT1236 5ppm/°C 0.05% 800µA Buried Zener 5V, 10V 0.6ppm 20ppm/kHr SO-8, PDIP

LT1461 3ppm/°C 0.04% 35µA Bandgap

LT1009 15ppm/°C 0.2% 1.2mA Bandgap 2.5V 20ppm/kHr

LT1389 20ppm/°C 0.05% 700nA Bandgap

LT1634 10ppm/°C 0.05% 7µA Bandgap

2.5V, 3V, 3.3V,

4.096V, 5V

1.25V, 2.5V,

4.096V, 5V

1.25V, 2.5V,

4.096V, 5V

8ppm 60ppm/√kHr

MSOP-8,

SO-8, Z

20ppm SO-8

6ppm

SO-8,

MSOP-8, Z

LT1029 20ppm/°C 0.20% 700µA Bandgap 5V 20ppm/kHr Z

LM399 1ppm/°C 2% 15mA Buried Zener 7V 1ppm 8ppm/√kHr

LTZ1000 0.05ppm/°C 4% Buried Zener 7.2V 0.17ppm 2µV/√kHr H

*0.1Hz–10Hz, Peak-to-Peak

14

Linear Technology Magazine • March 2009

SO-8

H

DESIGN FEATURES L

TEMPERATURE (˚C)

–50

OUTPUT VOLTAGE (NORMALIZED) (V)

1.001

1.002

1.003

25 75

1.000

0.999

–25 0

50 100 125

0.998

0.997

5ppm/oC

0oC TO 70oC “BOX”

LT1019

CURVE

UNCOMPENSATED

“STANDARD” BANDGAP

DRIFT CURVE

10ppm/oC

FULL TEMP RANGE “BOX”

certain conditions using the following

definitions.

Initial Accuracy

The variance of output voltage as

measured at a given temperature,

usually 25°C. While the initial output

voltage may vary from unit to unit, if

it is constant for a given unit, then it

can be easily calibrated.

Temperature Drift

This specification is the most widely

used to evaluate voltage reference

performance, as it shows the change

in output voltage over temperature.

Temperature drift is caused by imperfections and nonlinearities in the

circuit elements, and is often nonlinear

as a result.

For many parts, the temperature

drift, TC, specified in ppm/°C, is the

dominant error source. For parts with

consistent drift, calibration is possible.

A common misconception regarding

temperature drift is that it is linear.

This leads to assumptions such as

“the part will drift a lesser amount

over a smaller temperature range.”

Often the opposite is true. TC is generally specified with a “box method” in

order to give an understanding of the

likely error over the entire operating

temperature range. It is a calculated

value based only on minimum and

maximum values of voltage, and does

not take into account the temperatures

at which these extrema occur.

For voltage references that are very

linear over the specified temperature

range, or for those that are not carefully tuned, the worst-case error can

be assumed to be proportional to the

temperature range. This is because

the maximum and minimum output

voltages are very likely to be found at

the maximum and minimum operating

temperatures. However, for very carefully tuned references, often identified

by their very low temperature drift,

the nonlinear nature of the reference

may dominate.

fied as 100ppm/°C tends to appear

quite linear over any temperature

For example, a reference speci-

range, as the drift due to component

mismatches completely obscures the

Linear Technology Magazine • March 2009

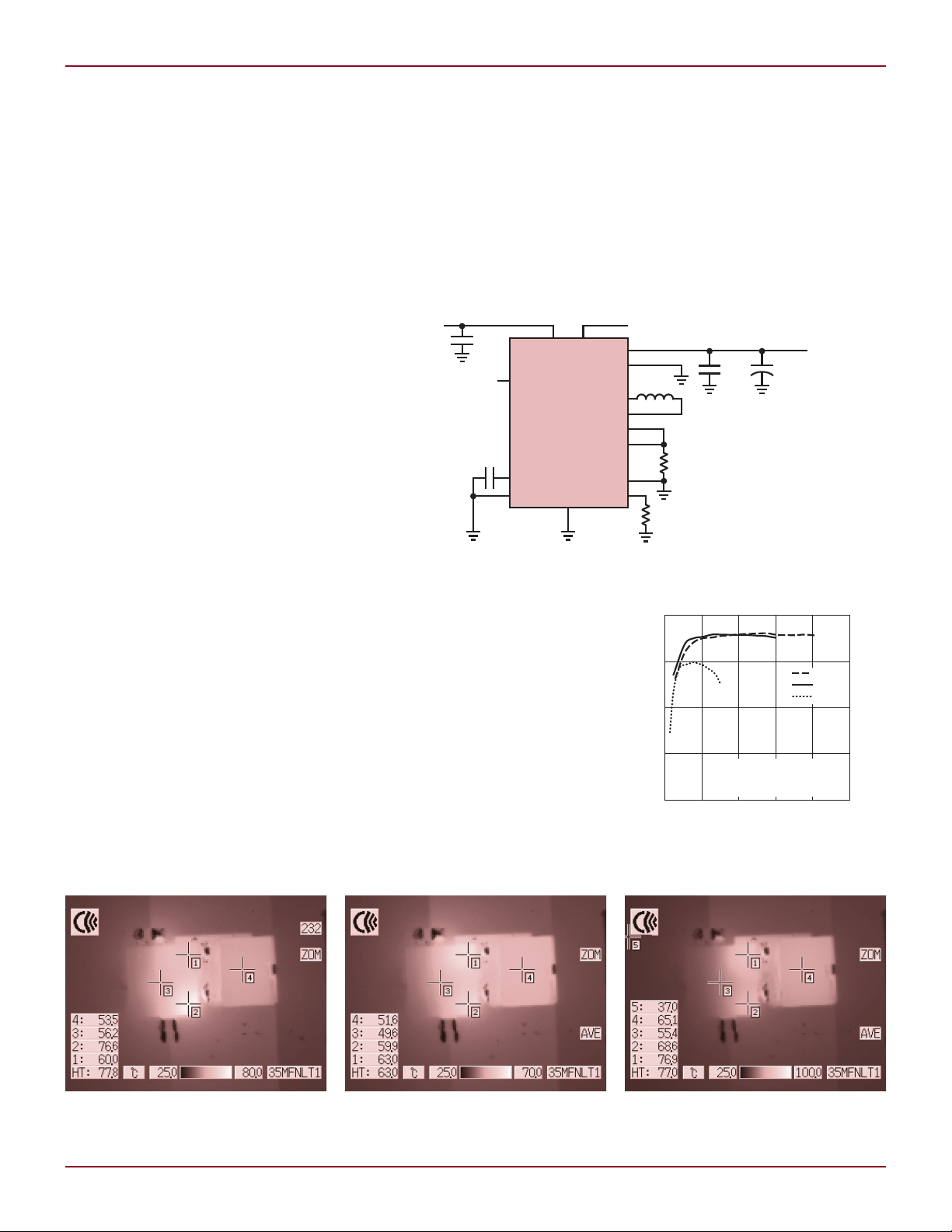

Figure 2. Voltage reference

temperature characteristics

inherent nonlinearity. In contrast, the

temperature drift of a reference specified as 5ppm/°C will be dominated by

the nonlinearities.

Voltage references come

in many forms and offer

different features, but in the

end, accuracy and stability

are a voltage reference’s

most important features,

as the main purpose of

the reference is to provide

a known output voltage.

Variation from this known

value is an error. Voltage

reference specifications

usually predict the

uncertainty of the reference

under certain conditions.

This can be easily seen in the output

voltage vs temperature characteristic

of Figure 2. Note that there are two

possible temperature characteristics

represented. An uncompensated

bandgap appears as a parabola, with

minima at the temperature extrema

and maximum in the middle. A

temperature compensated bandgap,

such as the LT1019, shown here,

appears as an “S” shaped curve, with

greatest slope near the center of the

temperature range. In the latter case,

nonlinearity is exacerbated so that the

aggregate uncertainty over temperature is reduced.

The best use of the temperature drift

specification is to calculate maximum

total error over the specified temperature range. It is generally inadvisable

to calculate errors over unspecified

temperature ranges unless the temperature drift characteristics are well

understood.

Long Term Stability

This is a measure of the tendency of a

reference voltage to change over time,

independent of other variables. Initial

shifts are largely caused by changes

in mechanical stress, usually from the

difference in expansion rates of the

lead frame, die and mold compound.

This stress effect tends to have a large

initial shift that reduces quickly with

time. Initial drift also includes changes

in electrical characteristics of the

circuit elements, including settling

of device characteristics at the atomic

level. Longer-term shifts are caused

by electrical changes in the circuit

elements, often referred to as “aging.”

This drift tends to occur at a reduced

rate as compared to initial drift, and to

further reduce over time. It is therefore

often specified as drift/

khr. Voltage

√

references tend to age more quickly

at higher temperatures.

Thermal Hysteresis

This often-overlooked specification

can also be a dominant source of error. It is mechanical in nature, and is

the result of changing die stress due

to thermal cycling. Hysteresis can be

observed as a change in output voltage

at a given temperature after a large

temperature cycle. It is independent

of temperature coefficient and time

drift, and reduces the effectiveness

of initial voltage calibration.

Most references tend to vary around

a nominal output voltage during

subsequent temperature cycles, so

thermal hysteresis is usually limited

to a predictable maximum value. Each

manufacturer has their own method

for specifying this parameter, so typical

values can be misleading. Distribution

data, as provided in data sheets such

as the LT1790 and LTC6652, is far

more useful when estimating output

voltage error.

15

L DESIGN FEATURES

5V

4.7M

LT1389-1.25

V

OUT

1.25V

0.1MF

2.6V b VINb 18V

1MF

V

OUT

= 2.5V

LT1790-2.5

82.4k135k

14.9k2.8k

2.5k

Q1

Q2

2k

Q1

Q5

20pF

20pF

7.5k

5007500k

60k

300k

50k

200k

V

REF

1.235V, 0mV/°C

240mV, +0.8mV/°C

60mV, +0.2mV/°C

360mV, +1.2mV/°C

575mV, –2.2mV/°C

600k

Q3

Q11

Q10

Q9

Q14

–

+

–

–

–

+

+

+

Q8

Q6

Q4

Q12

Q13

Figure 3. Shunt voltage reference

Other Specifications

Additional specifications that may be

important, depending on application

requirements include:

q

Voltage Noise

q

Line Regulation/PSRR

q

Load Regulation

q

Dropout Voltage

q

Supply Range

q

Supply Current

Reference Types

The two main types of voltage reference

are shunt and series. See Table 2 for

a list of Linear Technology series and

shunt voltage references.

Shunt References

The shunt reference is a 2-terminal

type, usually designed to work over a

specified range of currents. Though

most shunts are of the bandgap type

and come in a variety of voltages, they

can be thought of and are as simple

to use as a Zener diode.

The most common circuit ties one

terminal of the reference to ground and

the other terminal to a resistor. The

remaining terminal of the resistor is

Figure 4. Series voltage reference

then tied to a supply. This becomes, in

essence, a three terminal circuit. The

shared reference/resistor terminal

is the output. The resistor must be

chosen such that the minimum and

maximum currents through the reference are within the specified range

over the entire supply range and load

current range. These references are

quite easy to design with, provided

the supply voltage and load current do

not vary much. If either, or both, may

change substantially, then the resistor must be chosen to accommodate

this variance, often forcing the circuit

to dissipate significantly more power

than required for the nominal case. It

can be considered to function like a

class A amplifier, in that sense.

Advantages of shunt references

include simple design, small packages

and good stability over wide current

and load conditions. In addition, they

are easily designed as negative voltage

references and can be used with very

high supply voltages, as the external

resistor holds off most of the potential,

or very low supplies, as the output can

be as little as a few millivolts below

the supply. Linear Technology offers

shunt products including the LT1004,

LT1009, LT1389, LT1634, LM399 and

LTZ1000. A typical shunt circuit can

be seen in Figure 3.

Series References

Series references are three (or more)

terminal devices. They are more like

low dropout (LDO) regulators, so they

have many of the same advantages.

Most notably, they consume a relatively fixed amount of supply current over

a wide range of supply voltages, and

they only conduct load current when

the load demands it. This makes them

ideal for circuits with large changes in

supply voltage or load current. They

are especially useful in circuits with

very large load currents as there is no

series resistor between the reference

and supply.

Series products available from Linear Technology include the LT1460,

LT1790, LT1461, LT1021, LT1236,

LT1027, LTC6652, LT6660, and many

others. Products such as the LT1021

and LT1019 may be operated either as

a shunt or a series voltage reference.

A series reference circuit is illustrated

in Figure 4.

Figure 5. A bandgap circuit is designed for a theoretically zero temperature coefficient.

16

Figure 6. A 200mV reference circuit

Linear Technology Magazine • March 2009

DESIGN FEATURES L

Reference Circuits

There are many ways to design a voltage reference IC. Each has specific

advantages and disadvantages.

Zener-Based References

The buried Zener type reference is a

relatively simple design. A Zener (or

avalanche) diode has a predictable

reverse voltage that is fairly constant

over temperature and very constant

over time. These diodes are often very

low noise and very stable over time if

held within a small temperature range,

making them useful in applications

where changes in the reference voltage

must be as small as possible.

This stability can be attributed to

the relatively small number of components and die area as compared

to other types of reference circuits,

as well as the careful construction

of the Zener element. However, relatively high variances in initial voltage

and temperature drift are common.

Additional circuitry may be added to

compensate these imperfections, or

to provide a range of output voltages.

Both shunt and series references use

Zener diodes.

Devices like the LT1021, LT1236

and LT1027 use internal current

sources and amplifiers to regulate the

Zener voltage and current to increase

stability, as well as to provide various

output voltages such as 5V, 7V and

10V. This additional circuitry makes

the Zener diode more compatible with

a wide variety of application circuits,

but requires some additional supply

headroom and may cause additional

error.

Alternatively, the LM399 and

LTZ1000 use internal heating elements and additional transistors to

stabilize the temperature drift of the

Zener diode, giving the best combination of temperature and time stability.

In addition, these Zener-based products have extraordinarily low noise,

giving the best possible performance.

The LTZ1000 exhibits 0.05ppm/°C