µModule Buck-Boost Regulators Offer a Simple and Effi cient

Solution for Wide Input and Output Voltage Range Applications

Design Note 438

Jian Yin and Eddie Beville

Introduction

An increasing number of applications require DC/DC

converters that produce an output that falls somewhere

within the input voltage range. The problem is that

conventional buck-boost converter topologies, such as

SEPIC or boost followed by buck, are complex, ineffi cient

and consume a relatively large board area. Linear Technology offers 4-switch-topology buck-boost regulators

that signifi cantly improve effi ciency and save space, but

a complete regulator design still requires a number of

external components and meticulous board layout decisions related to electrical and thermal considerations.

The next clear step to simplify the design is a modular

approach—a buck-boost regulator system in an IC form

factor. The LTM4605 and LTM4607 μModule™ buck-boost

regulators take that approach. Each requires only one

external inductor and a single sensing resistor to produce

a compact, high perfor mance, high effi ciency buck-boost

regulator with exceptional thermal performance.

High Effi ciency

The LTM4605 and LTM4607 are high effi ciency switch

mode buck-boost power supply modules. The LTM4605

can operate over an input voltage range of 4.5V to 20V

and support any output voltage within the range of 0.8V

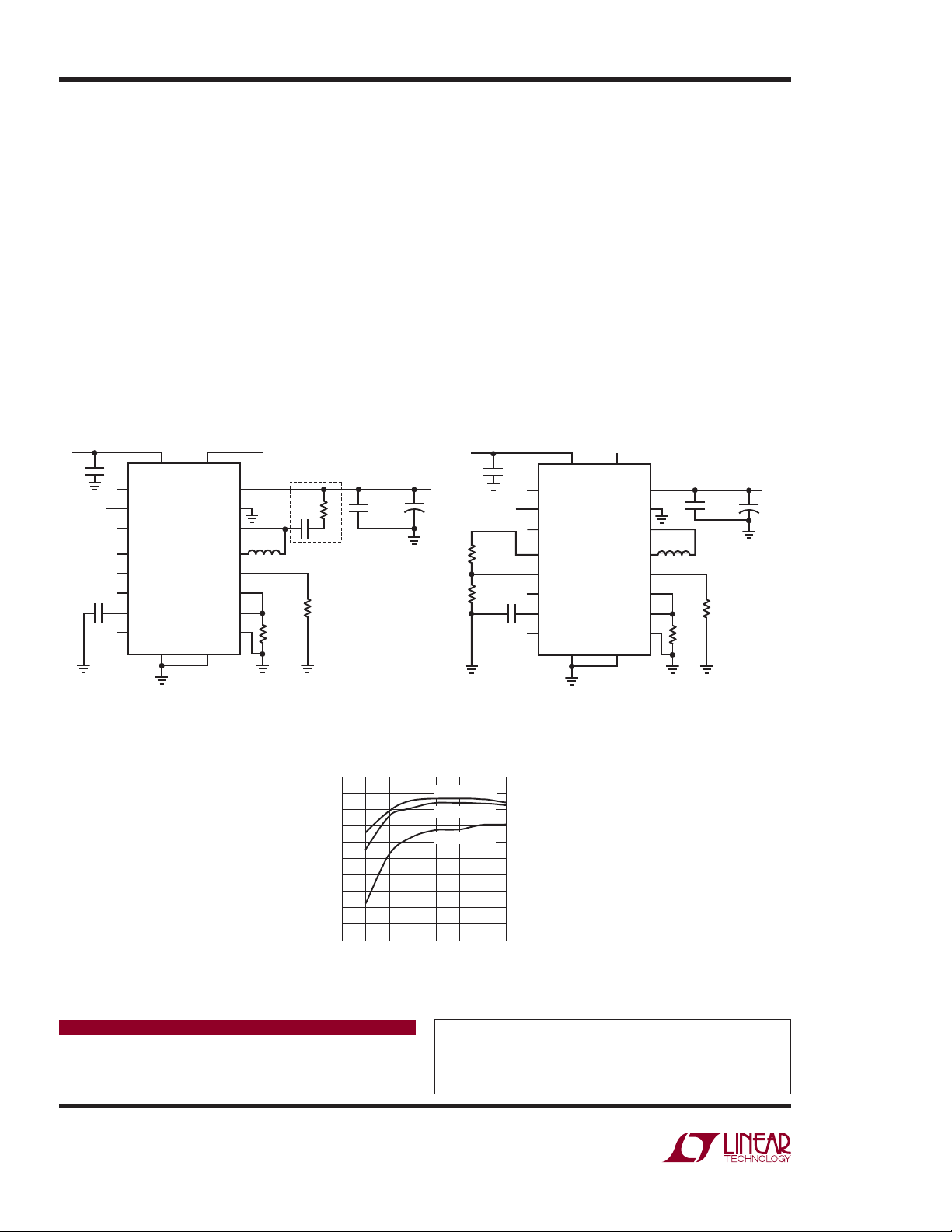

to 16V, set by a single resistor. As shown in Figure 1, the

LTM4607 support s 4.5V to 36V inputs and output s of 0.8V

to 16V. Both can prov ide 92% to 98% ef fi ciency over the

w i d e i n p u t r a n g e . T h i s h i g h e f fi c i e n c y d e s i g n d e l i v e r s u p t o

5A continuous current in boost mode (12A in buck mode).

Only the inductor, sensing resistor, and bulk input and

o u t p u t c a p a c i t o r s a r e n e e d e d t o fi n i s h t h e d e s i g n . F i g u r e 2

shows a typical LTM4605 application with an output

of 12V at 5A. An optional RC snubber is added here to

reduce switching noise for applications where radiated

EMI noise is a concern.

Low Profi le Solution

These power modules are offered in a space saving

and thermally enhanced 15mm × 15mm × 2.8mm LGA

package. This low profi le package can fi t the back side

of PC boards for many high density point-of-load applications. Their high switching frequency and current

mode architecture enable a fast transient response to

line and load changes without sacrifi cing stability. Both

can be frequency synchronized with an external clock to

reduce undesirabl e frequency harmonics. Fault prot ection

comes in the form of over voltage protection and foldback

current protection.

Smooth Transition and Circuit Simplicity

Both the LTM4605 and LTM4607 include the switching

controller, four power FETs, compensation circuitry and

support componen ts. The 4-switch topolog y provides high

effi ciency in all three modes of operation—buck, buckboost and boost— with a smooth transition bet ween each.

L, LT, LTC and LTM are registered trademarks and μModule is a trademark of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

Figure 1. There is No Easier Way to Design a

High Effi ciency, High Power Density Buck-Boost

Regulator than with the LTM4605 or LTM4607

04/08/438

Figure 2 shows an actual buck-boost design with external components chosen to satisfy the boost mode’s 5A

maximum load current. For buck-only applications, the

maximum load current can be 12A at 12V

with the

OUT

same external components. For instance in a buck-only

confi guration, such as in Figure 3, the load current can

be increased up to 7A at 12V

for 168W capability.

OUT

This application can achieve better than 98% effi ciency

as shown in Figure 4.

Excellent Thermal Performance

The low profi le LGA package has a low thermal resistance

from junction to pin (4°C/ W), thus maintaining an acceptable junction temperature even w hen satisfying high power

requirements. Typically, operation in room temperature

ambient conditions requires no special heat sinking or

added airfl ow, but for warmer ambient environments or

high loads, simply add a heat sink to the top of the case

for 2-sided cooling and add air fl ow to signifi cantly lower

the thermal resistance from junction to ambient. The data

sheet provides more details about adding heat sinks and

air fl ow considerations.

Conclusion

There is no easier way to design an effi cient high-density

buck-boost converter than with the LTM4605 or LTM4607

μModule regulator. No design tricks are necessary to

achieve effi ciencies up to 98%—only one inductor, a

single sensing resistor and bulk capacitance are required

to complete a design. Low profi le LGA packages fi t on the

back side of PCBs and have good thermal performance,

enabling a 168W power output in an 8cm × 8.4cm 4-layer

PCB. These devices are ideal for automotive, telecom,

medical, motor drive and battery-powered applications.

5V TO 20V CLOCK SYNC

IN

ON/OFF

0.1μF

22μF

25V

C3

V

IN

PGOOD

RUN

COMP

INTV

CC

PLLFLTR

EXTV

CC

SS

STBYMD

SGND PGND

LTM4605

PLL

IN

V

OUT

FCB

SW1

SW2

V

R

SENSE

SENSE+

SENSE–

dn4eb F02

L1

4.7μH

FB

R2

2x12mΩ

Figure 2. Buck-Boost Converter Produces

12V

at 5A from a 5V to 20V Input Range

OUT

Figure 4. Effi ciency for the 24V

C1

R3

2200pF

2

FDA1254-4R7M

R1

7.15k

100

99

98

97

96

95

94

EFFICIENCY (%)

93

92

91

90

10μF x2

25V

*

*OPTIONAL SNUBBER

0

LOAD CURRENT (A)

24V TO 36V

IN

12V/5A

OUT

+

330μF

25V

28VIN TO 24V

32VIN TO 24V

36VIN TO 24V

426

ON/OFF

R3

4.64k

R4

1.21k

OUT

OUT

OUT

dn4eb F04

Converter in Figure 3

OUT

10μF x2

50V

C3

0.1μF

PGOOD

RUN

COMP

INTV

CC

PLLFLTR

EXTV

SS

STBYMD

PLL

V

IN

U1

LTM4607

CC

SGND PGND

IN

V

OUT

FCB

SW1

SW2

V

R

SENSE

SENSE+

SENSE–

dn4eb F03

10μF x2

50V

L1

8μH

FDA1254-8ROM

FB

R1

3.4k 1%

R2

13mΩ

Figure 3. Buck Converter Produces a

24V Output with 168W Capability

7315

24V/7A

+

OUT

270μF

50V

Data Sheet Download

www.linear.com/micromodule

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

For applications help,

call (408) 432-1900, Ext. 2593

dn438 LT/TP 0408 241K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2008

Loading...

Loading...