L DESIGN FEATURES

V

IN

SV

IN

SW

RUN

PLLLPF

TRACK

V

OUT

FB

I

TH

I

THM

PGOOD

MGN

CLKOUT GND

CLKIN

4.87k

100μF

10μF

V

OUT

1.8V

8A

V

IN

3V TO 5.5V

LTM4608

SGND

V

IN

V

IN

V

IN

3.3V

PGOOD

COMP

LTM4604

RUN/SS

2.37k

22MF

6.3V

r2

V

OUT

2.5V

4A

10MF

6.3V

V

OUT

FB

TRACK

GND

LOAD CURRENT (A)

0

70

EFFICIENCY (%)

75

80

85

90

95

100

1.0 2.0 3.0 4.0

V

OUT

= 2.5V

VIN = 3.3V

Low Voltage, High Current Step-Down

µModule Regulators Put a (Nearly)

Complete Power Supply in a

15mm × 9mm × 2.8mm Package

by Judy Sun, Sam Young and Henry Zhang

Introduction

Endlessly increasing power density

requirements are a major driving force

behind the continuous need to find

new power supply solutions. Switching

regulators are the top choice for high

current applications because of their

high efficiency and high performance,

but high power density doesn’t come

for free with a switcher. Components

must be carefully chosen and laid

out to maximize efficiency, transient

response and thermal performance.

Making a high density switching power

supply requires significant design and

test time, or does it?

The LTM4604 and LTM4608 LTC

µModule switching regulators make

it possible to create high density

designs with minimal effort. Both

are high density power supplies for

≤5.5V input voltage, high output current, step-down applications. Each

µModule regulator comes in a 15mm

× 9mm LGA surface mount package

and is nearly self-contained—only a

few passive components are required

to complete a power supply design. The

switching controller, MOSFETs, inductor and all support components are

Figure 1. Only a few components are required

for a 2.5V/4A design with LTM4604.

already carefully chosen and laid out

in the package. Low profile packages

(2.3mm and 2.8mm, respectively) allow

them to be easily mounted in unused

space on the bottom of PC boards and

simplify thermal management.

The LTM4604 features a 2.375V

to 5.5V input range and a 0.8V to

5V output range, while the LTM4608

takes a 2.7V to 5.5V input to a 0.6V to

5V output. The LTM4604 can deliver

up to 4A continuous current with up

to 95% efficiency. The slightly higher

profile of the LTM4608 allows it to

deliver up to 8A continuous current

thanks to its high efficiency design and

low thermal impedance package.

Easy Design with

Few Components

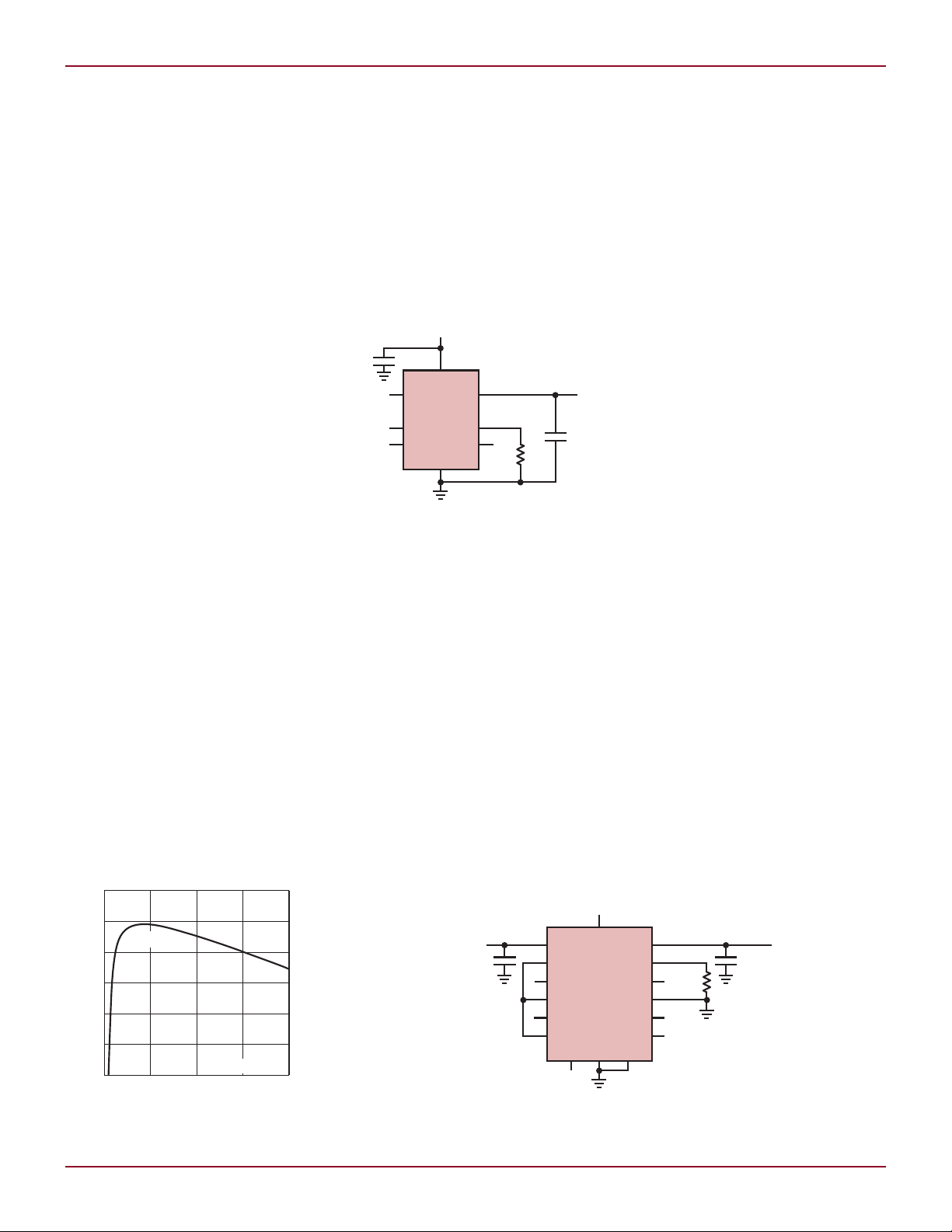

Figure 1 shows a typical 2.5V/4A

design with LTM4604 and Figure 2

shows the resulting efficiency. Ceramic

input capacitors are integrated into

the µModule package—additional

input capacitors are only required if

a load step is expected up to the full

4A level. Additional required output

capacitance is typically in the range

of 22µF to 100µF. A single resistor on

the FB pin sets the output voltage.

For applications needing more

output current, the LTM4608 fits the

bill. Figure 3 shows a 1.8V/8A design

with LTM4608 and Figure 4 shows

its efficiency. As with the LTM4604,

the number of necessary external

components has been reduced to a

minimum, significantly simplifying

the design effort. Nevertheless, a very

fast transient response to the line and

load changes is guaranteed by the optimized design of the µModule’s high

switching frequency and current mode

control architecture. Furthermore, a

number of features can be enabled on

the LTM4604 and LTM460408 to suit

the needs of various applications.

Figure 2. High efficiency is achieved with the

LTM4604 in the application of Figure 1

28

Figure 3. Only a few components are required for a 1.8V/8A design with the LTM4608.

Linear Technology Magazine • September 2008

LOAD CURRENT (A)

0

70

EFFICIENCY (%)

75

80

85

90

95

100

2 4 6 8

10

V

OUT

= 1.8V

V

IN

= 5V

VIN = 3.3V

TOTAL LOAD CURRENT (A)

0 2 4 6 8 10 12 14 16 18

0

1

2

3

4

5

6

7

8

9

OUTPUT CURRENT OF EACH LTM4608 (A)

I

OUT1

I

OUT2

V

IN

SV

IN

SW

RUN

PLLLPF

TRACK

MODE

PHMODE

V

OUT

FB

I

TH

I

THM

PGOOD

BSEL

MGN

CLKOUT GND

CLKIN

100µF

6.3V

X5R

100pF

10µF

3.32k

V

OUT

1.5V

16A

V

IN

3V TO 5.5V

LTM4608

SGND

V

IN

SV

IN

SW

RUN

PLLLPF

TRACK

MODE

PHMODE

V

OUT

FB

I

TH

I

THM

PGOOD

BSEL

MGN

CLKOUT GND

CLKIN

10µF

100µF

6.3V

X5R

LTM4608

SGND

Figure 4. High efficiency is achieved with the

LTM4608 in the application of Figure 3.

Wealth of Features

Both LTM4604 and LTM4608 feature RUN pin control, output voltage

tracking selections and power good

indicators. For systems requiring

voltage sequencing between different

power supplies, the sequencing function can be implemented by controlling

the RUN pins and the PGOOD signals

with a few additional components.

Fault protection features include

overvoltage protection, over current

protection and thermal shutdown.

The LTM4608 offers some additional features. Burst Mode® operation,

pulse-skipping mode or continuous

current mode can be selected to improve light load efficiency. Burst Mode

operation provides the highest efficiency at very light load, while forced

continuous current mode leads to the

lowest output ripple. Pulse-skipping

mode offers a compromise between

Burst Mode operation and continuous

mode, offering good light load efficiency

while keeping output voltage ripple

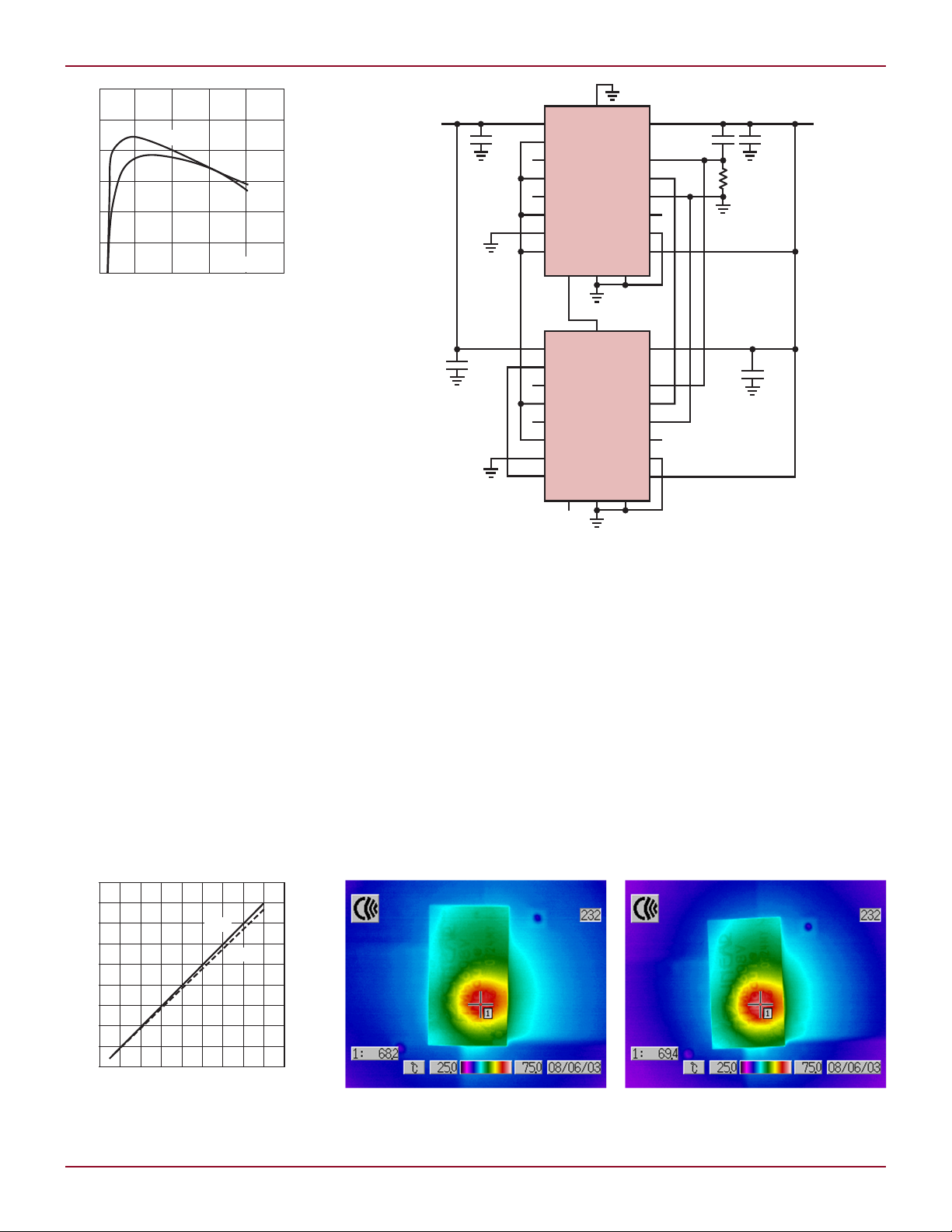

Figure 5. Two LTM4608s are easily paralleled to provide

1.5V/16A output with interleaved switching operation.

down. Programmable output voltage

margining is supported for ±5%, ±10%

and ±15% levels. The LTM4608 also

allows frequency synchronization and

spread spectrum operation to further

reduce switching noise harmonics.

Parallel for More Power

With cycle-by-cycle current mode

control, the LTM4604 and LTM4608

can be easily paralleled to provide

more output power with excellent current sharing. The LTM4608 includes

CLKIN and CLKOUT pins to make it

DESIGN FEATURES L

possible to operate paralleled devices

out of phase of one another to reduce

input and output ripple. A total of 12

phases can be cascaded to run simultaneously with respect to each other

by programming the PHMODE pin of

each LTM4608 to different levels.

Figure 5 shows an example of two

LTM4608s in parallel to provide 16A

output current. Figure 6 shows the

measured current sharing perfor mance of the circuit, illustrating that

the DC current sharing error is less

continued on page 31

Figure 6. Bench test shows excellent current

sharing between two paralleled LTM4608s over

the entire load range.

Linear Technology Magazine • September 2008

Figure 7. Good thermal balance is maintained between two

paralleled LTM4608 boards supplying 16A output current.

29

DESIGN IDEAS L

bias supply. Another boost converter

and an inverter generate VON and

V

, which also use the 5V supply

OFF

as input.

When power is first applied to the

input, the RUN-SS1 capacitor starts

charging. When its voltage reaches

0.8V, Switcher 1 is enabled. The capacitor at the RUN-SS1 pin controls

the ramp rate for the Switcher 1 output, V

and inrush current in L1.

LOGIC

Switchers 2, 3 and 4 are controlled

by the BIAS pin, which is usually

connected to V

. When the BIAS

LOGIC

pin is higher than 2.8V, the capacitors

at the RUNSS-2 and RUN-SS3/4 pin

begin charging to enable Switchers 2,

3 and 4. When AV

reaches 90% of

DD

its programmed voltage, the PGOOD

pin is pulled low. When AV

DD

, V

OFF

and

E3 all reach 90% or their programmed

voltages, the C

timer is enabled and a

T

20µA current source begins to charge

CT. When the C

pin reaches 1.1V, the

T

output PNP turns on, connecting E3

to VON. Figure 2 shows the start up

sequence of the circuit in Figure 1.

If one of the regulated voltages,

V

LOGIC

, AV

DD

, V

or E3 dips more

OFF

than 10%, the internal PNP turns off

to shut down VON. This action protects

the panels, as V

must be present to

ON

turn on the TFT display. The PGOOD

pin can drive an optional PMOS device

at the output of the boost regulator to

disconnect the load at AV

from the

DD

input during shutdown. The converter

uses all ceramic capacitors. X5R and

X7R types are recommended, as these

materials maintain capacitance over

a wide temperature range.

All four switchers employ a constant frequency, current mode control

scheme. Switching regulator 1 uses a

feedback scheme that senses inductor current, while the other switching

regulators monitor switch current.

The inductor current sensing method

avoids minimum on-time issues and

maintains the switch current limit at

any input-to-output voltage ratio. The

other three regulators have frequency

foldback scheme, which reduces the

switching frequency when its FB pin

is below 0.75V. This feature reduces

the average inductor current during

start up and overload conditions,

minimizing the power dissipation

in the power switches and external

components.

Layout Considerations

Proper PC board layout is important

to achieve the best operating performance. Paths that carry high switching

current should be short and wide to

minimize parasitic inductance. In a

buck regulator, this loop includes

the input capacitor, internal power

switch and Schottky diode. In a boost

regulator, this loop includes the output capacitor, internal power switch

and Schottky diode. Keep all the loop

compensation components and feedback resistors away from the high

switching current paths. The LT3513

pin out was designed to facilitate PCB

layout. Keep the traces from the center

of the feedback resistors to the corresponding FB pins as short as possible.

LT3513 has an exposed ground pad

on the backside of the IC to reduce

thermal resistance. A ground plane

with multiple vias into ground layers

should be placed underneath the part

to conduct heat away from the IC.

Conclusion

The LT3513 is a comprehensive, but

compact, power supply solution for

TFT-LCD panels. Its wide input range

and low power dissipation allow it

to be used in a wide variety of applications. All four of the integrated

switching regulators have a 2MHz

switching frequency and allow the

exclusive use of the ceramic capacitors to minimize circuit size, cost and

output ripple.

L

LTM4604, LTM4608, continued from page 29

than 5% at full load. Excellent cur-

leled LTM4608 boards supplying 16A

output current.

rent sharing results in well balanced

thermal stresses on the paralleled

LTM4608s, which in turn makes

for a more reliable system. Figure 7

demonstrates the small temperature

difference between these two paral-

LTC4352, continued from page 27

generates a 4.1V supply at the VCC

pin. For VIN below 4.1V, VCC follows

approximately 50mV below VIN. The

0.1µF VCC capacitor is still needed for

bypassing and LDO stability.

Conclusion

The LTM4604 and LTM4608 15mm

× 9mm µModule regulators are complete power supply solutions for low

input voltage and high output cur-

trend has been to lower the voltage of

distributed power, which increases the

current to maintain power levels. Given

these constraints, board designers

must scrutinize each diode in a high

current power path for its power and

area consumption.

Conclusion

An ever -present theme in electronic

system design has been to pack more

computation in smaller form factors

and tighter power budgets. Another

Linear Technology Magazine • September 2008

provides the same functionality as a

diode but at higher efficiencies and

cooler temperatures, especially as

currents increase. It also incorporates

The LTC4352 MOSFET controller

rent applications. They significantly

simplify circuit and layout designs

by effortlessly fitting into the tightest

spaces, including the bottom of the

PCB. Despite their compact form,

these µModules are rich in features,

and they can be easily paralleled when

more output current is needed.

L

useful features such as fast switch

control, 0V operation, undervoltage

and overvoltage protection, open

MOSFET detection, ability to allow

reverse current, Hot Swap capability, and fault and status outputs. All

of this functionality comes wrapped

in space-saving 12-pin DFN (3mm ×

3mm) and MSOP packages, making

it possible to produce an ideal diode

solution in a smaller footprint than

conventional diodes.

L

3131

Loading...

Loading...