LTM4604

Low Voltage, 4A DC/DC

µModule

TM

with Tracking

FEATURES

■

Complete Standalone Power Supply

■

Wide Input Voltage Range: 2.375V to 5.5V

■

4A DC, 5A Peak Output Current

■

0.8V to 5V Output

■

Output Voltage Tracking

■

±2% Total DC Error

■

UltraFastTM Transient Response

■

Power Good Indicator

■

Current Mode Control

■

Current Foldback Protection, Parallel/Current Sharing

■

Up to 95% Effi ciency

■

Programmable Soft-Start

■

Micropower Shutdown: IQ ≤ 7μA

■

Overtemperature Protection

■

Small and Very Low Profi le Package:

15mm × 9mm × 2.3mm LGA

APPLICATIONS

■

Telecom and Networking Equipment

■

Servers

■

Storage Cards

■

ATCA Cards

■

Industrial Equipment

DESCRIPTION

The LTM®4604 is a complete 4A switch mode DC/DC power

supply. Included in the package are the switching controller, power FETs, inductor and all support components.

Operating over an input voltage range of 2.375V to 5.5V,

the LTM4604 supports an output voltage range of 0.8V

to 5V, set by a single resistor. This high effi ciency design

delivers up to 4A continuous current (5A peak). Only bulk

output capacitors are needed to complete the design.

The low profi le package (2.3mm) enables utilization of

unused space on the bottom of PC boards for high density

point of load regulation. High switching frequency and

a current mode architecture enable a very fast transient

response to line and load changes without sacrifi cing

stability. The device supports output voltage tracking for

supply rail sequencing.

Fault protection features include foldback current protection, thermal shutdown and a programmable soft-start

function. The LTM4604 is offered in a space saving and

thermally enhanced 15mm × 9mm × 2.3mm LGA package

and is Pb free and RoHS compliant.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

μModule and UltraFast are trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

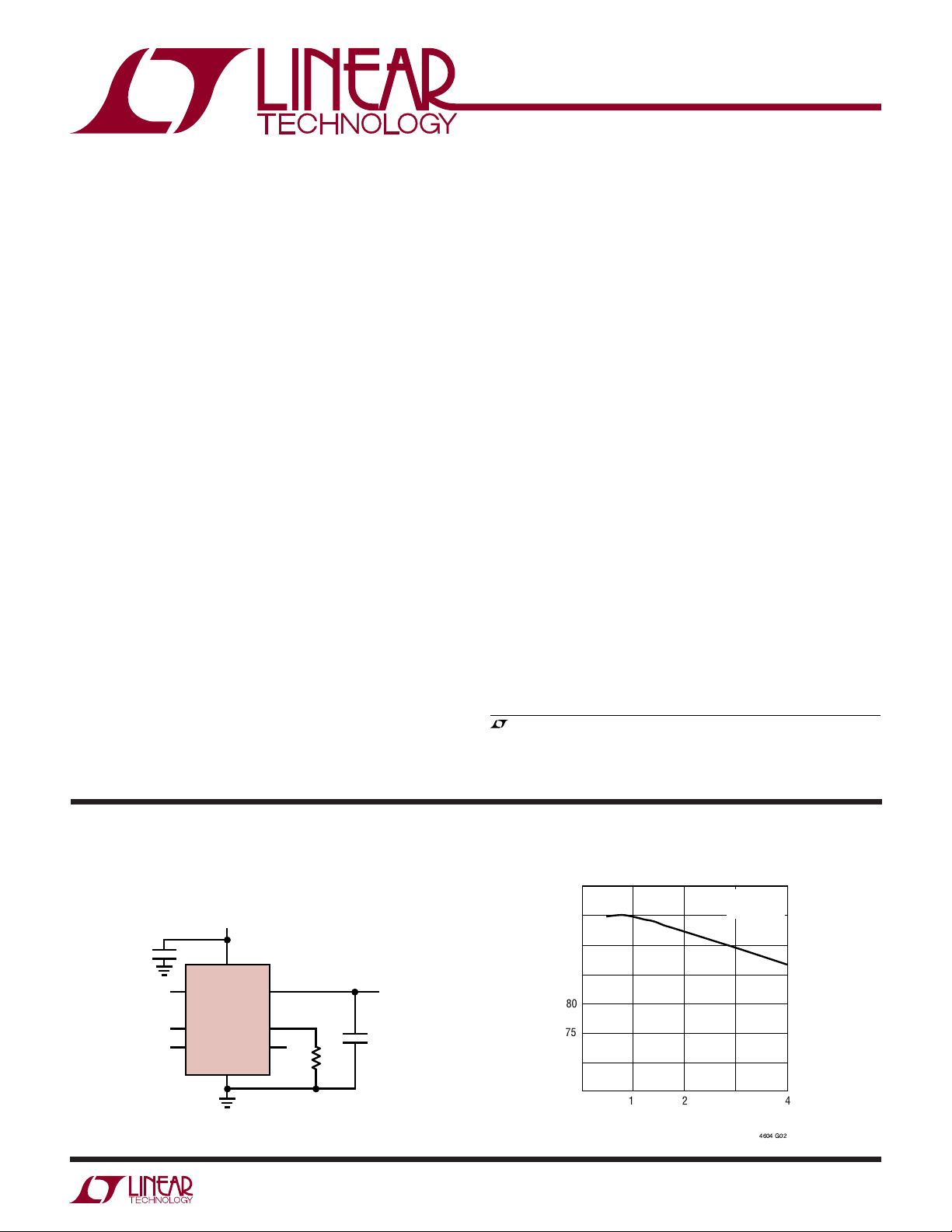

TYPICAL APPLICATION

3.3V to 2.5V/4A μModule Regulator

V

IN

3.3V

10μF

6.3V

PGOOD

LTM4604

COMP

RUN/SS

V

GND

IN

TRACK

V

OUT

FB

V

IN

2.37k

22μF

6.3V

×2

4604 TA01a

V

OUT

2.5V

4A

Effi ciency vs Output Current

100

95

90

85

80

EFFICIENCY (%)

75

70

65

0

VIN = 3.3V

= 2.5V

V

OUT

12 4

OUTPUT CURRENT (A)

3

"$" /

4604f

1

LTM4604

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VIN, PGOOD ................................................. –0.3V to 6V

COMP, RUN/SS, FB, TRACK .........................–0.3V to V

SW, V

........................................–0.3V to (VIN + 0.3V)

OUT

Operating Temperature Range (Note 2) ... –40°C to 85°C

Junction Temperature ........................................... 125°C

Storage Temperature Range ................... –55°C to 125°C

IN

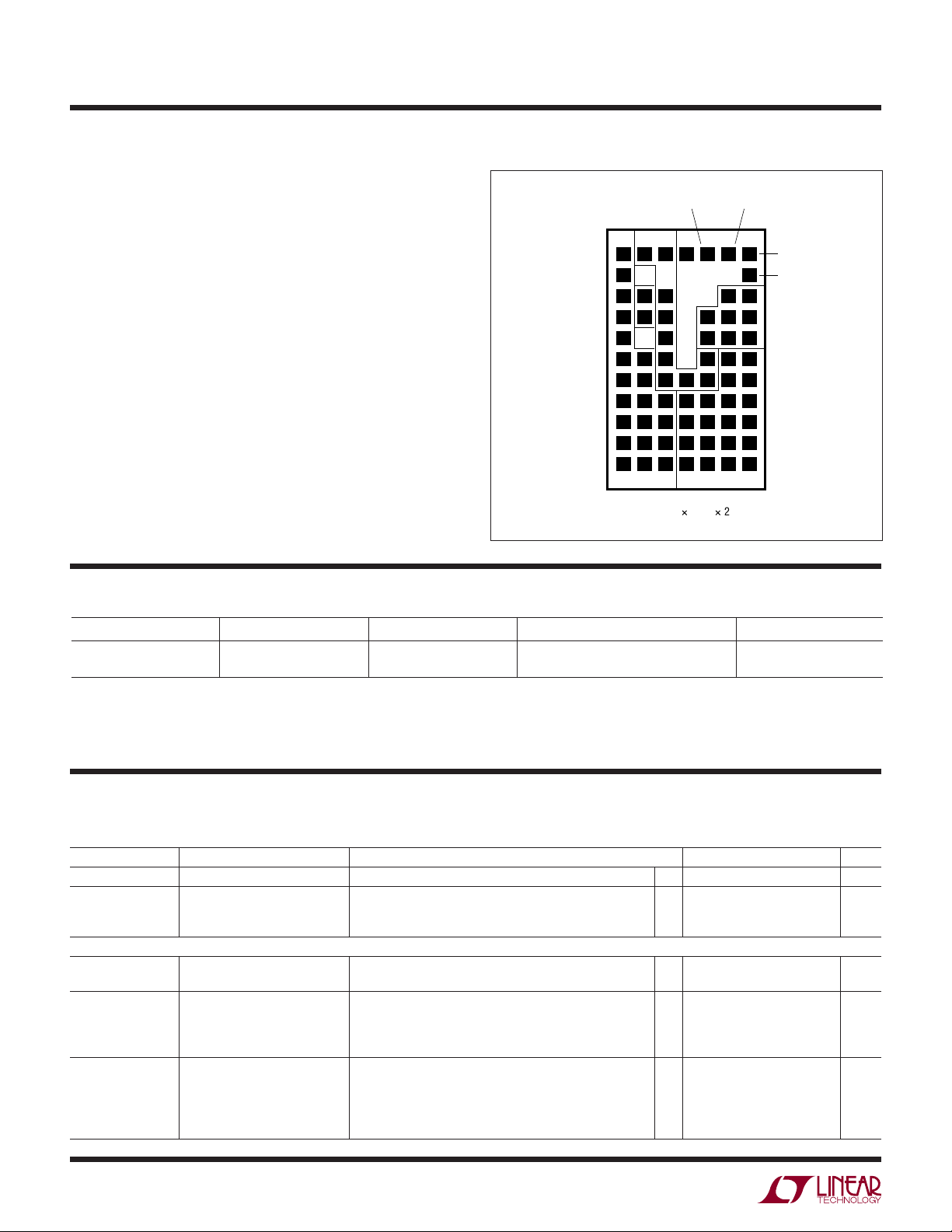

PIN CONFIGURATION

TOP VIEW

TRACK

A

BCDEFG

V

IN

RUN/

SW

GND

66-PIN (15mm ´ 9mm ´ 2.3mm)

= 125°C, θJA = 25°C/W, WEIGHT = 0.86g

SS

GND

LGA PACKAGE

V

OUT

10

11

T

1

2

3

4

5

6

7

8

9

JMAX

PGOOD

COMP

FB

ORDER INFORMATION

LEAD FREE FINISH TRAY PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LTM4604EV#PBF

LTM4604IV#PBF

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. *The temperature grade is identifi ed by a label on the shipping container.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

This product is only offered in trays. For more information go to: http://linear.com/packaging/

ELECTRICAL CHARACTERISTICS

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at TA = 25°C. VIN = 5V unless otherwise noted. See Figure 15.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN(DC)

V

OUT(DC)

Input Specifi cations

V

IN(UVLO)

I

INRUSH(VIN)

I

Q(VIN NOLOAD)

LTM4604EV#PBF

LTM4604IV#PBF

LTM4604V

LTM4604V

Input DC Voltage

Output Voltage, Total Variation

with Line and Load

Undervoltage Lockout

CIN = 10μF × 1, C

V

= 2.375V to 5.5V, I

IN

V

= 2.375V to 5.5V, I

IN

I

= 0A 1.75 2 2.3 V

OUT

Threshold

Peak Input Inrush Current at

Start-Up

I

= 0A, CIN = 10μF, C

OUT

RUN/SS = 0.01μF, V

V

= 3.3V

IN

V

= 5V

IN

Input Supply Bias Current VIN = 3.3V, V

V

= 3.3V, V

IN

V

= 5V, V

IN

V

= 5V, V

IN

Shutdown, RUN = 0, V

15mm × 9mm × 2.3mm LGA

15mm × 9mm × 2.3mm LGA

= 22μF ×3, RFB = 5.69k 0.5%

OUT

= 1.5V, No Switching

OUT

= 1.5V, Switching Continuous

OUT

= 1.5V, No Switching

OUT

= 1.5V, Switching Continuous

OUT

= 0A to 4A, 0°C ≤ TA ≤ 85°C

OUT

= 0A to 4A

OUT

= 22μF ×3,

OUT

= 1.5V

OUT

= 5V

IN

–40°C to 85°C

–40°C to 85°C

●

2.375 5.5 V

1.478

●

1.470

1.5

1.5

1.522

1.522

0.7

0.7

60

28

100

35

7

μA

mA

μA

mA

μA

4604f

V

V

A

A

2

LTM4604

ELECTRICAL CHARACTERISTICS

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

S(VIN)

Output Specifi cations

I

OUT(DC)

ΔV

OUT(LINE)

V

OUT

ΔV

OUT(LOAD)

V

OUT

V

OUT(AC)

f

S

ΔV

OUT(START)

t

START

ΔV

OUT(LS)

t

SETTLE

I

OUT(PK)

Control Section

V

FB

I

FB

V

RUN

I

TRACK

V

TRACK(OFFSET)

V

TRACK(RANGE)

R

FBHI

PGOOD

ΔV

PGOOD

R

PGOOD

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Input Supply Current VIN = 2.5V, V

Output Continuous Current

Range (See Output Current

Derating Curves for Different

V

, V

and TA)

IN

OUT

Line Regulation Accuracy V

Load Regulation Accuracy V

Output Ripple Voltage I

Output Ripple Voltage

Frequency

Turn-On Overshoot C

Turn-on Time C

Peak Deviation for Dynamic

Load Step

Settling Time for Dynamic

Load Step

Output Current Limit C

Voltage at FB Pin I

RUN Pin On/Off Threshold 0.5 0.65 0.8 V

TRACK Pin Current 0.2 μA

Offset Voltage TRACK = 0.4V 30 mV

Tracking Input Range 0 0.8 V

Resistor Between V

OUT

and

FB Pins

PGOOD Range ±7.5 %

PGOOD Resistance Open-Drain Pull-Down 90 150

= 25°C. VIN = 5V unless otherwise noted. See Figure 15.

A

= 1.5V, I

V

= 3.3V, V

IN

V

= 5V, V

IN

= 3.3V, V

V

IN

OUT

OUT

V

IN

V

IN

OUT

V

IN

V

IN

I

OUT

OUT

I

OUT

V

IN

V

IN

OUT

TRACK = V

V

IN

V

IN

OUT

= 1.5V, I

OUT

= 1.5V, I

OUT

= 1.5V 4 A

OUT

= 1.5V, VIN from 2.375V to 5.5V, I

= 1.5V, 0A to 4A

= 3.3V

= 5V

= 0A, C

= 3.3V, V

= 5V, V

= 22μF/X5R/Ceramic ×3

OUT

= 1.5V

OUT

= 1.5V

OUT

= 4A, VIN = 5V, V

= 22μF ×3, V

OUT

= 0A

= 3.3V

= 5V

= 22μF ×3, V

OUT

and RUN/SS = Float

IN

= 3.3V

= 5V

= 4A

OUT

= 4A

OUT

= 4A

OUT

= 0A

OUT

= 1.5V 1.25 MHz

OUT

= 1.5V, RUN/SS = 10nF,

= 1.5V, I

= 1A Resistive Load,

OUT

Load: 0% to 50% to 0% of Full Load,

C

= 22μF ×3 Ceramic

OUT

V

= 5V, V

IN

= 1.5V 25 mV

OUT

Load: 0% to 50% to 0% of Full Load

V

V

V

I

IN

OUT

IN

IN

OUT

OUT

= 5V, V

= 22μF ×3

= 3.3V, V

= 5V, V

= 0A, V

= 0A, V

= 1.5V 10 μs

OUT

= 1.5V

OUT

= 1.5V

OUT

= 1.5V, 0°C ≤ TA ≤ 85°C

OUT

= 1.5V

OUT

Note 2: The LTM4604E is guaranteed to meet performance specifi cations

from 0°C to 85°C. Specifi cations over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls. The LTM4604I is guaranteed over the full

–40°C to 85°C temperature range.

2.9

2.2

1.45

●

●

●

0.1 0.2 %

0.3

0.3

0.6

0.6

10

12

20

20

1.5

1.0

8

8

0.792

●

0.788

0.8

0.8

0.808

0.812

0.2 μA

4.975 4.99 5.025 kΩ

mV

mV

P-P

P-P

mV

mV

ms

ms

A

A

A

%

%

A

A

V

V

Ω

4604f

3

LTM4604

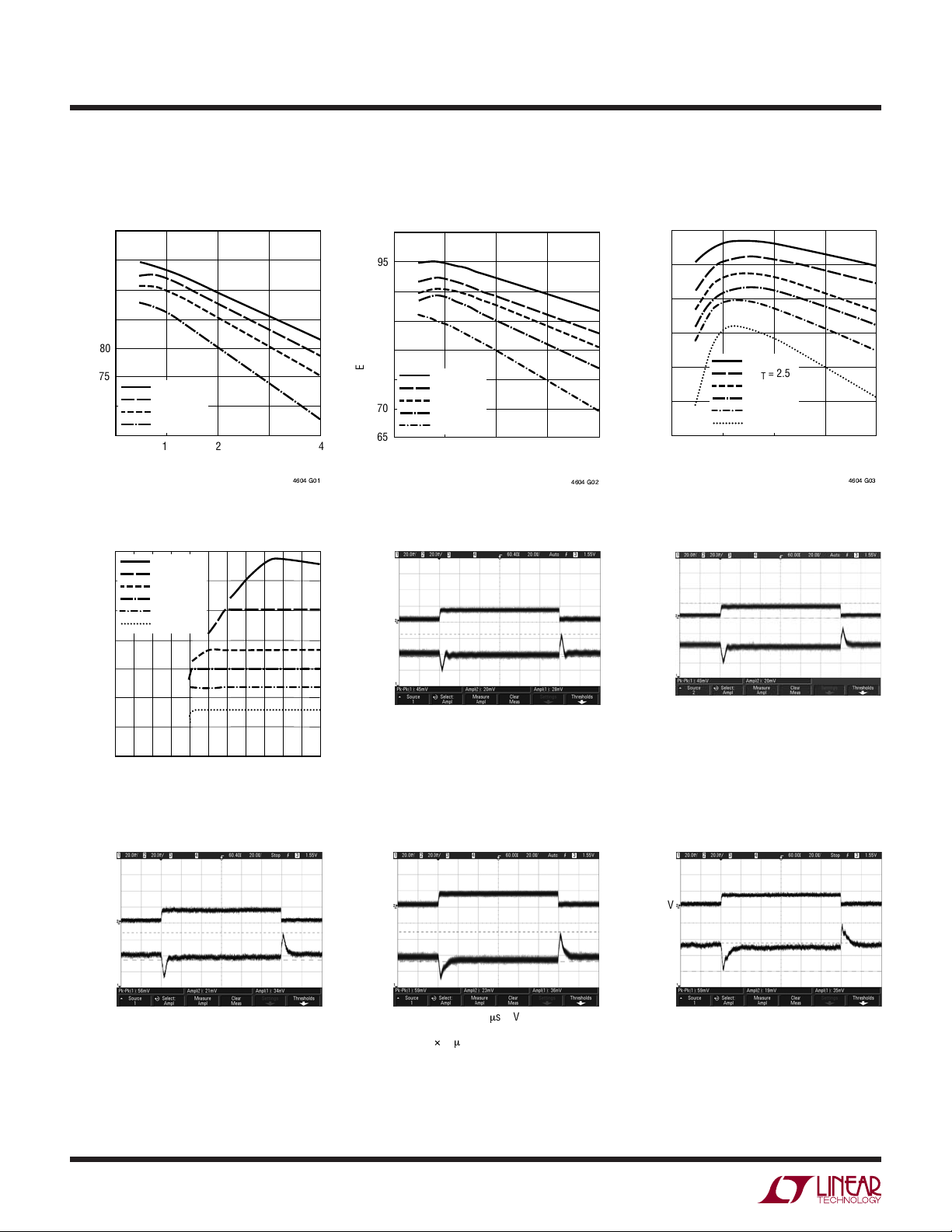

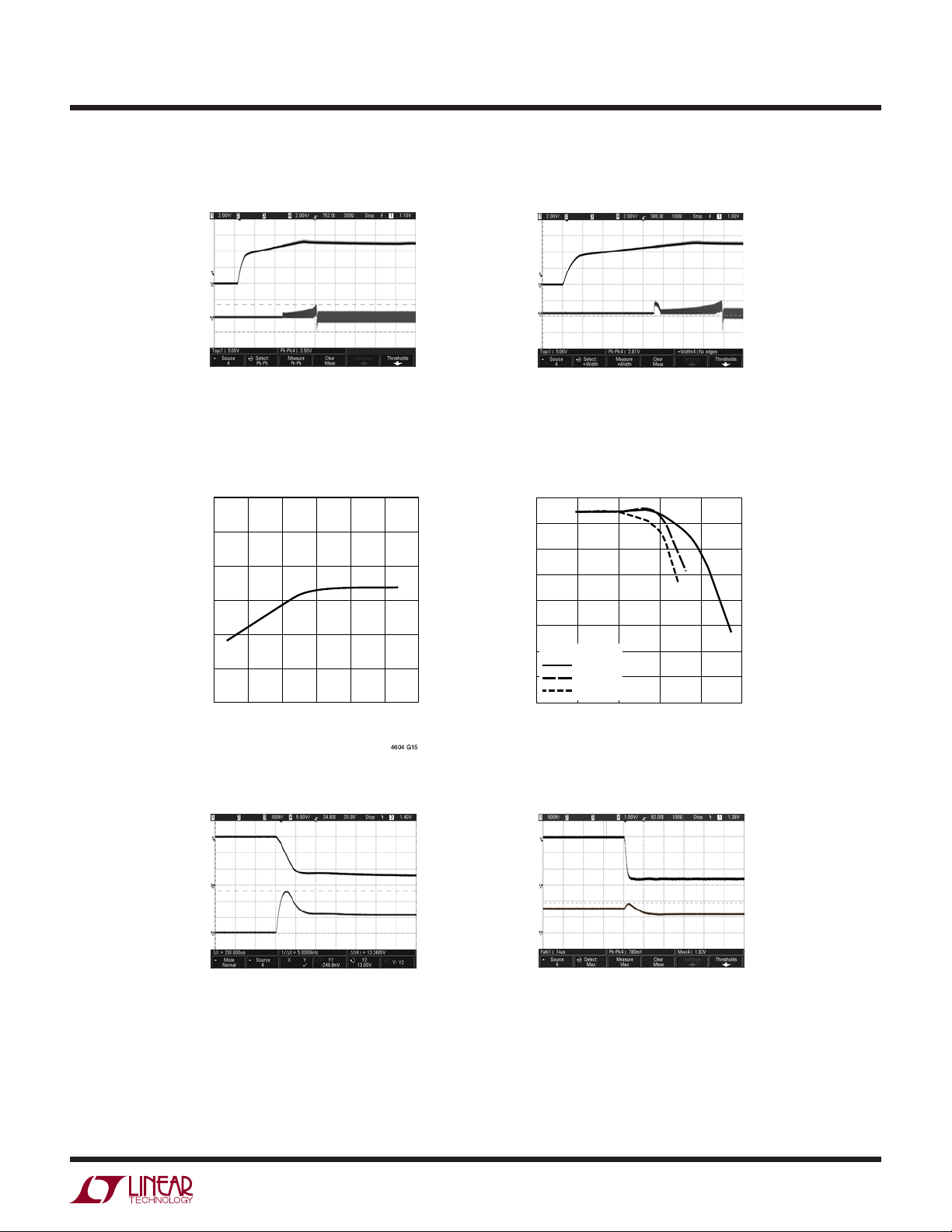

TYPICAL PERFORMANCE CHARACTERISTICS

Effi ciency vs Output Current

V

= 2.5V

IN

100

95

90

85

80

EFFICIENCY (%)

75

70

65

V

= 1.8V

OUT

= 1.5V

V

OUT

= 1.2V

V

OUT

= 0.8V

V

OUT

0

12 4

OUTPUT CURRENT (A)

Minimum Input Voltage

at 4A Load

(V)

OUT

V

3.5

3.0

2.5

2.0

1.5

V

= 3.3V

OUT

= 2.5V

V

OUT

= 1.8V

V

OUT

= 1.5V

V

OUT

= 1.2V

V

OUT

= 0.8V

V

OUT

Effi ciency vs Output Current

VIN = 3.3V

100

95

90

85

80

EFFICIENCY (%)

75

70

3

"$" /

65

V

= 2.5V

OUT

= 1.8V

V

OUT

= 1.5V

V

OUT

= 1.2V

V

OUT

= 0.8V

V

OUT

0

12 4

OUTPUT CURRENT (A)

3

"$" /

Load Transient Response

I

LOAD

2A/DIV

V

OUT

20mV/DIV

Effi ciency vs Output Current

VIN = 5V

95

90

85

80

EFFICIENCY (%)

75

70

65

0

V

V

V

V

V

V

12 34

OUTPUT CURRENT (A)

Load Transient Response

I

LOAD

2A/DIV

V

OUT

20mV/DIV

OUT

OUT

OUT

OUT

OUT

OUT

= 3.3V

= 2.5V

= 1.8V

= 1.5V

= 1.2V

= 0.8V

"$" /!

1.0

0.5

I

LOAD

2A/DIV

V

OUT

20mV/DIV

0

0

0.5

1.5

2.5

34

2

1

VIN (V)

Load Transient Response

= 5V

V

IN

= 1.8V

V

OUT

= 3 × 22μF, 6.3V CERAMICS

C

OUT

20μs/DIV

3.5

4.5

4604 G04

4604 G07

V

= 5V

V

= 5V

IN

= 1.2V

V

OUT

= 4 × 22μF, 6.3V CERAMICS

C

OUT

5.55

20μs/DIV

4604 G05

IN

= 1.5V

V

OUT

= 4 × 22μF, 6.3V CERAMICS

C

OUT

20μs/DIV

4604 G06

Load Transient Response Load Transient Response

I

LOAD

2A/DIV

V

OUT

20mV/DIV

V

= 5V

IN

= 2.5V

V

OUT

= 3 ´ 22mF, 6.3V CERAMICS

C

OUT

20ms/DIV

4604 G08

I

LOAD

2A/DIV

V

OUT

20mV/DIV

V

= 5V

IN

= 3.3V

V

OUT

= 2 × 22μF, 6.3V CERAMICS

C

OUT

20μs/DIV

4604 G09

4604f

4

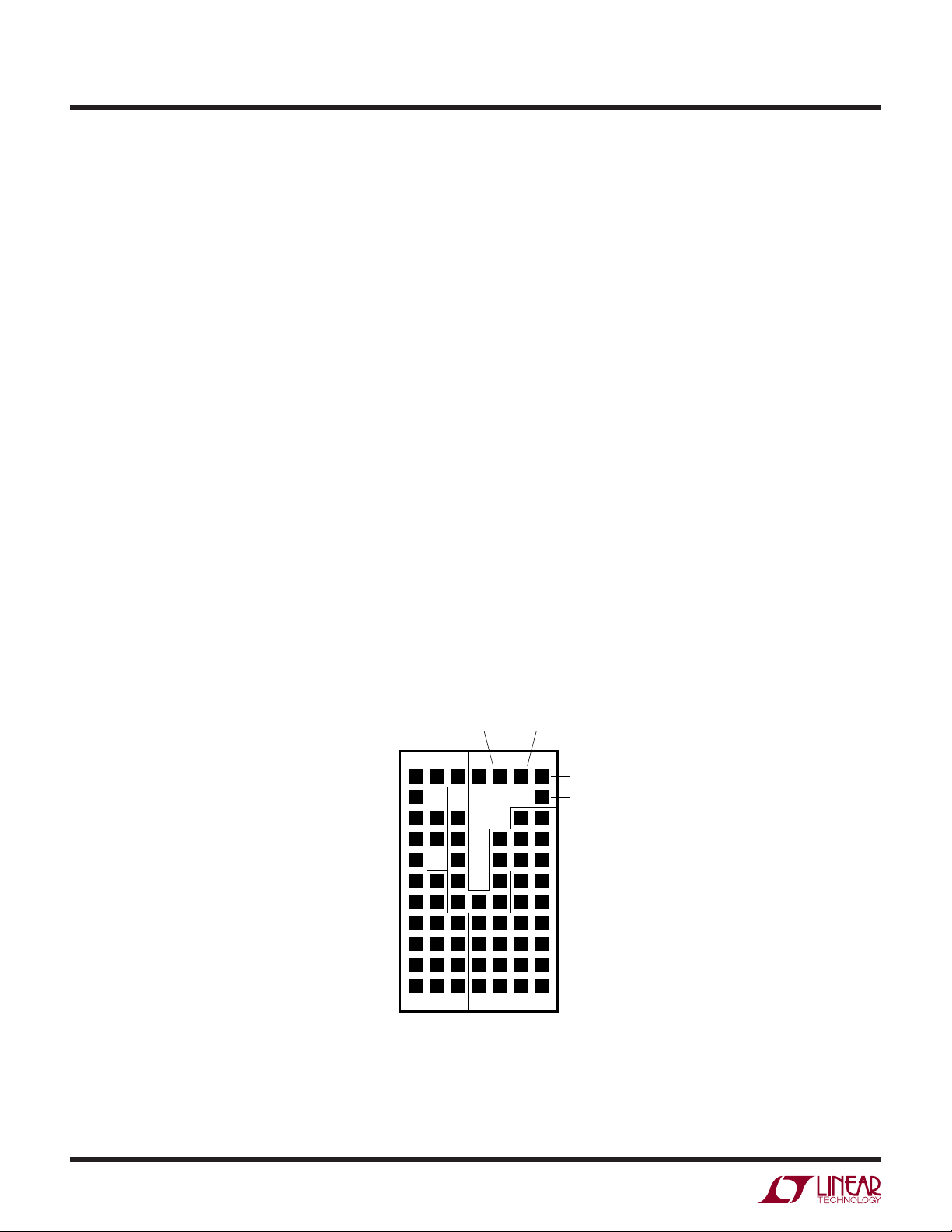

TYPICAL PERFORMANCE CHARACTERISTICS

Start-Up Start-Up

LTM4604

V

OUT

1V/DIV

I

IN

1A/DIV

= 5V

V

IN

= 2.5V

V

OUT

= 4 × 22μF

C

OUT

NO LOAD

(0.01μF SOFT-START CAPACITOR)

VFB vs Temperature

806

804

802

800

(mV)

FB

V

798

796

794

-50

-25 500 25 10075

Temperature (C)

200μs/DIV

4604 G10

"$" /#

V

OUT

1V/DIV

I

IN

1A/DIV

= 5V

V

IN

= 2.5V

V

OUT

= 4 × 22μF

C

OUT

4A LOAD

(0.01μF SOFT-START CAPACITOR)

Current Limit Foldback

1.6

1.4

1.2

1.0

(V)

0.8

OUT

V

0.6

V

0.2

= 1.5V

OUT

VIN = 5V

= 3.3V

V

IN

= 2.5V

V

0

IN

45 7

3

OUTPUT CURRENT (A)

0.4

200μs/DIV

4604 G11

6

8

4604 G12

Short-Circuit Protection

1.5V Short, No Load

V

OUT

0.5V/DIV

I

IN

4A/DIV

20μs/DIV

4604 G13

Short-Circuit Protection

1.5V Short, 4A Load

V

OUT

0.5V/DIV

I

IN

1A/DIV

100μs/DIV

4604 G14

4604f

5

LTM4604

PIN FUNCTIONS

VIN (B1, C1, C3-C7, D7, E6 and E7): Power Input Pins.

Apply input voltage between these pins and GND pins.

Recommend placing input decoupling capacitance directly

between V

(D8-D11, E8-E11, F6-F11, G6-G11): Power Output

V

OUT

pins and GND pins.

IN

Pins. Apply output load between these pins and GND pins.

Recommend placing output decoupling capacitance directly

between these pins and GND pins. Review Table 4.

GND (G3-G5, F3-F5, E4-E5, A1-A11, B6-B11, C8-C11):

Power Ground Pins for Both Input and Output Returns.

TRACK (E1): Output Voltage Tracking Pin. When the module

is confi gured as a master output, then a soft-start capacitor is placed on the RUN/SS pin to ground to control the

master ramp rate. Slave operation is performed by putting

a resistor divider from the master output to ground, and

connecting the center point of the divider to this pin on

the slave regulator. If tracking is not desired, then connect

the TRACK pin to V

. Load current must be present for

IN

tracking. See Applications Information section.

FB (G2): The Negative Input of the Error Amplifi er. Internally, this pin is connected to V

with a 4.99k precision

OUT

resistor. Different output voltages can be programmed

with an additional resistor between FB and GND pins.

Two power modules can current share when this pin is

connected in parallel with the adjacent module’s FB pin.

See Applications Information section.

COMP (G1): Current Control Threshold and Error Amplifi er

Compensation Point. The current comparator threshold

increases with this control voltage. Two power modules

can current share when this pin is connected in parallel

with the adjacent module’s COMP pin.

PGOOD (F1): Output Voltage Power Good Indicator. Opendrain logic output that is pulled to ground when the output

voltage is not within ±7.5% of the regulation point.

RUN/SS (D1): Run Control and Soft-Start Pin. A voltage

above 0.8V will turn on the module, and below 0.5V will

turn off the module. This pin has a 1M resistor to V

IN

and

a 1000pF capacitor to GND. See Application Infomation

section for soft-start information.

SW (B3 and B4): Switching Node of the circuit is used for

testing purposes. This can be connected to copper on the

board to improve thermal performance. Make sure not to

connect it to other output pins.

TOP VIEW

TRACK

A

BCDEFG

V

SW

GND

IN

RUN/

1

2

3

4

5

6

7

8

9

10

11

PGOOD

COMP

SS

GND

V

OUT

FB

4604f

6

BLOCK DIAGRAM

LTM4604

TRACK

SUPPLY

4.99k

5.76k

PGOOD

RUN/SS

C

SSEXT

TRACK

COMP

C

SS

1000pF

INTERNAL

COMP

R

SS

1M

CONTROL,

DRIVE

FB SW

R

FB

5.76k

10μF

6.3V

×2

M1

M2

L

R1

C2

4.99k

470pF

0.5%

10μF

6.3V

V

IN

V

OUT

GND

4604 BD

10μF

6.3V

22μF

6.3V

×3

V

IN

2.375V TO 5.5V

V

OUT

1.5V

4A

Figure 1. Simplifi ed LTM4604 Block Diagram

DECOUPLING REQUIREMENTS

T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

C

IN

C

OUT

External Input Capacitor Requirement

(V

= 2.375V to 5.5V, V

IN

OUT

= 1.5V)

External Output Capacitor Requirement

(V

= 2.375V to 5.5V, V

IN

OUT

= 1.5V)

= 25°C. Use Figure 1 Confi guration.

A

= 4A 10 μF

I

OUT

= 4A 22 100 μF

I

OUT

4604f

7

LTM4604

OPERATION

Power Module Description

The LTM4604 is a standalone non-isolated switch mode

DC/DC power supply. It can deliver up to 4A of DC output

current with few external input and output capacitors.

This module provides a precise regulated output voltage

programmable via one external resistor from 0.8V DC to

5.0V DC over a 2.375V to 5.5V input voltage. A typical

application schematic is shown in Figure 15.

The LTM4604 has an integrated constant frequency current mode regulator with built-in power MOSFETs with

fast switching speed. The typical switching frequency is

1.25MHz. With current mode control and internal feedback

loop compensation, the LTM4604 module has suffi cient

stability margins and good transient performance under a

wide range of operating conditions and with a wide range

of output capacitors, even all ceramic output capacitors.

Current mode control provides cycle-by-cycle fast current

limit. In addition, foldback current limiting is provided

in an overcurrent condition while V

overvoltage and undervoltage comparators pull the open-

drops. Internal

OUT

drain PGOOD output low if the output feedback voltage exits

a ±7.5% window around the regulation point. Furthermore,

in an overvoltage condition, internal top FET M1 is turned

off and bottom FET M2 is turned on and held on until the

overvoltage condition clears.

Pulling the RUN pin below 0.5V forces the controller into its

shutdown state, turning off both M1 and M2. At low load

current, the module works in continuous current mode by

default to achieve minimum output voltage ripple.

The TRACK pin is used for power supply tracking. See the

Applications Information section.

The LTM4604 is internally compensated to be stable over

a wide operating range. Table 4 provides a guideline for

input and output capacitance for several operating conditions. An excel loop analysis tool is provided for transient

and stability analysis.

The FB pin is used to program the output voltage with a

single resistor connected to ground.

8

4604f

APPLICATIONS INFORMATION

LTM4604

A typical LTM4604 application circuit is shown in Figure 15.

External component selection is primarily determined by

the maximum load current and output voltage. Refer to

Table 4 for specifi c external capacitor requirements for a

particular application.

to V

V

IN

There are restrictions in the maximum V

Step-Down Ratios

OUT

and V

IN

OUT

stepdown ratio that can be achieved for a given input voltage.

The LTM4604 is 100% duty cycle, but the V

IN

to V

OUT

minimum dropout is a function of the load current. A typical 0.5V minimum is suffi cient (see Typical Performance

Characteristics).

Output Voltage Programming

The PWM controller has an internal 0.8V reference voltage.

As shown in the Block Diagram, a 4.99k, 0.5% internal

feedback resistor connects the V

and FB pins together.

OUT

The output voltage will default to 0.8V with no feedback

resistor. Adding a resistor R

from the FB pin to GND

FB

programs the output voltage:

kR

499

VV

=+08

OUT

.•

.

Table 1. FB Resistor vs Output Voltage

V

OUT

R

0.8V 1.2V 1.5V 1.8V 2.5V 3.3V

Open 10k 5.76k 4.02k 2.37k 1.62k

FB

FB

R

FB

Input Capacitors

The LTM4604 module should be connected to a low acimpedance DC source. Two 10μF ceramic capacitors are

included inside the module. Additional input capacitors

are only needed if a large load step is required up to a

full 4A level. An input 47μF bulk capacitor is only needed

if the input source impedance is compromised by long

inductive leads or traces.

For a buck converter, the switching duty cycle can be

estimated as:

V

OUT

D

=

V

IN

Without considering the inductor current ripple, the RMS

current of the input capacitor can be estimated as:

I

OUT MAX

()

%

η

DD

••–=

1

()

I

CIN RMS

()

In the above equation, η% is the estimated effi ciency of

the power module. The bulk capacitor can be a switcherrated electrolytic aluminum capacitor, OS-CON capacitor

for bulk input capacitance due to high inductance traces

or leads. If a low inductance plane is used to power the

device, then no input capacitance is required. The two

internal 10μF ceramics are typically rated for 2A to 3A of

RMS ripple current. The worst-case ripple current for the

4A maximum current is 2A or less.

Output Capacitors

The LTM4604 is designed for low output voltage ripple.

The bulk output capacitors defi ned as C

are chosen

OUT

with low enough effective series resistance (ESR) to meet

the output voltage ripple and transient requirements. C

OUT

can be a low ESR tantalum capacitor, a low ESR polymer

capacitor or an X5R/X7R ceramic capacitor. The typical

output capacitance range is 22μF to 100μF. Additional

output fi ltering may be required by the system designer

if further reduction of output ripple or dynamic transient

spike is required. Table 4 shows a matrix of different

output voltages and output capacitors to minimize the

voltage droop and overshoot during a 2A/μs transient.

The table optimizes the total equivalent ESR and total

bulk capacitance to maximize transient performance. The

Linear Technology μModule Power Design Tool can be for

further optimization.

Fault Conditions: Current Limit and Overcurrent

Foldback

The LTM4604 has current mode control, which inherently limits the cycle-by-cycle inductor current not only

in steady-state operation, but also in transient.

To further limit current in the event of an overload condition, the LTM4604 provides foldback current limiting as

the output voltage falls. The LTM4604 device has overtemperature shutdown protection that inhibits switching

operation around 150°C.

4604f

9

LTM4604

APPLICATIONS INFORMATION

Run Enable and Soft-Start

The RUN/SS pin provides dual functions of enable and

soft-start control. The RUN/SS pin is used to control

turn on of the LTM4604. While this pin is below 0.5V, the

LTM4604 will be in a 7μA low quiescent current state. A

0.8V threshold will enable the LTM4604. This pin can be

used to sequence LTM4604 devices. The soft-start control

is provided by a 1M pull-up resistor (R

capacitor (C

) as drawn in the Block Diagram. An external

SS

capacitor can be applied to the RUN/SS pin to increase the

soft-start time. A typical value is 0.01μF. The approximate

equation for soft-start is:

t

SOFTSTART

⎛

=

V

⎜

VV

–.•18

⎝

IN

⎞

IN

⎟

⎠

where RSS and CSS are shown in the Block Diagram of

Figure 1, 1.8V is the soft-start upper range, and C

is the additional capacitance for further soft-start contol.

The soft-start function can also be used to control the

output ramp-up time, so that another regulator can be

easily tracked. An independent ramp control signal can

be applied to the master ramp, otherwise, connect the

TRACK pin to V

to disable tracking.

IN

) and a 1000pF

SS

RC C

SS SS SSE

+ln

()

XXT

SSEXT

X5R OR X7R

C

SSEXT

X5R OR X7R

C

IN1

10μF

6.3V

C

IN2

10μF

6.3V

PGOOD

LTM4604

COMP

RUN/SS

PGOOD

LTM4604

COMP

RUN/SS

V

5V

V

GND

V

5V

V

GND

IN

IN

TRACK

IN

IN

TRACK

V

MASTER

4604 F02

3.3V

4A

V

SLAVE

1.5V

4A

V

OUT

C

OUT1

FB3

FB

22μF

6.3V ×3

X5R OR

X7R

C

OUT2

22μF

6.3V ×3

X5R OR

X7R

FB

RAMP

CONTROL

OR V

V

OUT

FB

R

FB2

5.76k

R

IN

1.62k

R

5.76k

R

FB1

4.99k

Output Voltage Tracking

Output voltage tracking can be programmed externally

using the TRACK pin. The output can be tracked up and

down with another regulator. The master regulator’s

output is divided down with an external resistor divider

that is the same as the slave regulator’s feedback divider

to implement coincident tracking. The LTM4604 uses a

very accurate 4.99k resistor for the top feedback resistor.

Figure 2 shows an example of coincident tracking.

R

2

V

TRACK

=

V

V

is the track ramp applied to the slave’s TRACK pin.

TRACK

applies the track reference for the slave output up

TRACK

to the point of the programmed value at which V

proceeds beyond the 0.8V reference value. The V

499.

FB

kR

+

FB

2

V

•

MASTER

TRACK

TRACK

pin must go beyond 0.8V to ensure the slave output has

reached its fi nal value. Load current must be present for

proper tracking.

OUTPUT VOLTAGE (V)

Figure 2

TIME

Figure 3

MASTER OUTPUT

SLAVE OUTPUT

4604 F03

4604f

10

APPLICATIONS INFORMATION

LTM4604

Ratio metric modes of tracking can be achieved by selecting

different resistor values to change the output tracking ratio.

The master output must be greater than the slave output

for the tracking to work. Linear Technology Tracker Cad26

can be used to implement different tracking scenarios. The

Master and Slave data inputs can be used to implement

the correct resistor values for coincident or ratio tracking.

The master and slave regulators require load current for

tracking down.

Power Good

The PGOOD pin is an open-drain pin that can be used to

monitor valid output voltage regulation. This pin monitors

a ±7.5% window around the regulation point.

COMP Pin

The pin is the external compensation pin. The module

has already been internally compensated for all output

voltages. Table 4 is provided for most application requirements. A spice model will be provided for other control

loop optimizations.

Parallel Operation

The LTM4604 device is an inherently current mode controlled device. Parallel modules will have very good current

sharing. This will balance the thermals on the design.

Figure 16 shows a schematic of the parallel design. The

voltage feedback changes with the variable N as more

modules are paralleled. The equation:

k

499

VV

=+08

OUT

.•

.

R

N

FB

R

FB

N is the number of paralleled modules.

Thermal Considerations and Output Current Derating

The power loss curves in Figures 4 and 5 can be used

in coordination with the load derating curves in Figures

6 through 13 for calculating an approximate θ

for the

JA

module with and without heat sinking methods with various airfl ow conditions. Thermal models are derived from

several temperature measurements at the bench, and are

correlated with thermal analysis software. Tables 2 and

3 provide a summary of the equivalent θ

conditions. These equivalent θ

parameters are correlated

JA

for the noted

JA

to the measured values and improve with air fl ow. The

maximum junction temperature is monitored while the

derating curves are derived.

2.0

1.8

1.6

1.4

1.2

1.0

WATTS

0.8

0.6

0.4

0.2

0

2.0

1.8

1.6

1.4

1.2

1.0

WATTS

0.8

0.6

0.4

0.2

0

0

234

1

LOAD CURRENT (A)

0

12

LOAD CURRENT (A)

5V TO 1.2V

POWER LOSS

3.3V TO 1.2V

POWER LOSS

34

4604 F04

5

Figure 4. 1.2V Power Loss Figure 5. 2.5V Power Loss

5V TO 2.5V

POWER LOSS

3.3V TO 2.5V

POWER LOSS

5

4604 F05

4604f

11

LTM4604

APPLICATIONS INFORMATION

4.0

3.5

3.0

2.5

4.0

3.5

3.0

2.5

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

0LFM

200LFM

400LFM

0

75 115

70

80

85

AMBIENT TEMPERATURE (°C)

Figure 6. 5VIN to 1.2V

4.0

3.5

3.0

2.5

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

0LFM

200LFM

400LFM

0

75 115

70

80

85

AMBIENT TEMPERATURE (°C)

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

90

95

No Heat Sink Figure 7. 5VIN to 1.2V

OUT

90

95

100

100

105

105

110

110

4606 F08

4606 F06

4.0

3.5

3.0

2.5

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

0LFM

200LFM

400LFM

0

75 115

70

AMBIENT TEMPERATURE (°C)

0LFM

200LFM

400LFM

0

75 115

70

AMBIENT TEMPERATURE (°C)

90

80

80

95

85

85

100

with Heat Sink

OUT

90

95

100

105

105

110

4606 F07

110

4606 F09

12

Figure 8. 3.3VIN to 1.2V

4.0

3.5

3.0

2.5

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

0LFM

200LFM

400LFM

0

75

70

80

85

AMBIENT TEMPERATURE (°C)

Figure 10. 5VIN to 2.5V

No Heat Sink Figure 9. 3.3VIN to 1.2V

OUT

4.0

3.5

3.0

2.5

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

90

95

100

No Heat Sink Figure 11. 5VIN to 2.5V

OUT

105

110

4606 F10

0

70

with Heat Sink

OUT

0LFM

200LFM

400LFM

90

75 115

80

AMBIENT TEMPERATURE (°C)

95

85

OUT

110

100

105

4606 F11

with Heat Sink

4604f

APPLICATIONS INFORMATION

4.0

3.5

3.0

2.5

LTM4604

4.0

3.5

3.0

2.5

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

0LFM

200LFM

400LFM

0

75 115

70

AMBIENT TEMPERATURE (°C)

90

80

85

Figure 12. 3.3VIN to 2.5V

2.0

1.5

LOAD CURRENT (A)

1.0

0.5

95

OUT

110

100

105

4606 F12

No Heat Sink Figure 13. 3.3VIN to 2.5V

0LFM

200LFM

400LFM

0

75 115

70

AMBIENT TEMPERATURE (°C)

90

80

95

85

OUT

110

100

105

4606 F13

with Heat Sink

4604f

13

LTM4604

APPLICATIONS INFORMATION

Table 2. 1.2V Output

DERATING CURVE VIN (V) POWER LOSS CURVE AIR FLOW (LFM) HEAT SINK θJA (°C/W)

Figures 6, 8 3.3, 5 Figure 4 0 None 25

Figures 6, 8 3.3, 5 Figure 4 200 None 22.5

Figures 6, 8 3.3, 5 Figure 4 400 None 21

Figures 7, 9 3.3, 5 Figure 4 0 BGA Heat Sink 21

Figures 7, 9 3.3, 5 Figure 4 200 BGA Heat Sink 20

Figures 7, 9 3.3, 5 Figure 4 400 BGA Heat Sink 18

Table 3. 2.5V Output

DERATING CURVE VIN (V) POWER LOSS CURVE AIR FLOW (LFM) HEAT SINK θJA (°C/W)

Figures 10, 12 3.3, 5 Figure 5 0 None 25

Figures 10, 12 3.3, 5 Figure 5 200 None 21

Figures 10, 12 3.3, 5 Figure 5 400 None 21

Figures 11, 13 3.3, 5 Figure 5 0 BGA Heat Sink 21

Figures 11, 13 3.3, 5 Figure 5 200 BGA Heat Sink 18

Figures 11, 13 3.3, 5 Figure 5 400 BGA Heat Sink 16

Table 4. Output Voltage Response Versus Component Matrix (Refer to Figure 17), 0A to 2A Load Step Typical Measured Values

C

V

(V)

OUT

1.2 10μF 56μF Aluminum 100μF 6.3V None 2.5 21 43 10 2 10

1.2 10μF 56μF Aluminum 22μF ×4 None 3.3 23 45 10 2 10

1.2 10μF 56μF Aluminum 22μF ×4 None 5 24 46 10 2 10

1.5 10μF 56μF Aluminum 100μF 6.3V None 2.5 19 41 10 2 5.76

1.5 10μF 56μF Aluminum 22μF ×4 None 3.3 21 43 10 2 5.76

1.5 10μF 56μF Aluminum 22μF ×4 None 5 21 43 10 2 5.76

1.8 10μF 56μF Aluminum 100μF 6.3V None 2.5 25 50 10 2 4.02

1.8 10μF 56μF Aluminum 22μF ×3 None 3.3 30 60 10 2 4.02

1.8 10μF 56μF Aluminum 22μF ×3 None 5 30 60 10 2 4.02

2.5 10μF 56μF Aluminum 100μF 6.3V None 2.5 22 45 12 2 2.37

2.5 10μF 56μF Aluminum 22μF ×3 None 3.3 25 55 12 2 2.37

2.5 10μF 56μF Aluminum 22μF ×3 None 5 25 55 12 2 2.37

3.3 10μF 56μF Aluminum 100μF 6.3V None 2.5 22 50 15 2 1.62

3.3 10μF 56μF Aluminum 22μF ×3 None 3.3 25 56 15 2 1.62

3.3 10μF 56μF Aluminum 22μF ×3 None 5 25 56 15 2 1.62

IN

(CERAMIC) CIN (Bulk)

C

OUT

(CERAMIC) C

COMP

VIN (V)

DROOP

(mV)

PEAK-TOPEAK(mV)

RECOVERY

(μs)

LOAD STEP

(A/μs)

R

FB

(kΩ)

14

4604f

APPLICATIONS INFORMATION

LTM4604

Safety Considerations

The LTM4604 modules do not provide isolation from V

. There is no internal fuse. If required, a slow blow fuse

V

OUT

IN

to

with a rating twice the maximum input current needs to be

provided to protect each unit from catastrophic failure.

Layout Checklist/Example

The high integration of LTM4604 makes the PCB board

layout very simple and easy. However, to optimize its electrical and thermal performance, some layout considerations

are still necessary.

• Use large PCB copper areas for high current path,

including V

, GND and V

IN

. It helps to minimize the

OUT

PCB conduction loss and thermal stress.

• Place high frequency ceramic input and output capacitors

next to the V

, GND and V

IN

pins to minimize high

OUT

frequency noise.

• Place a dedicated power ground layer underneath the

unit.

• To minimize the via conduction loss and reduce module

thermal stress, use multiple vias for interconnection

between top layer and other power layers.

• Do not put vias directly on the pads unless they are

capped.

• SW pads can be soldered to board to improve thermal

performance.

Figure14 gives a good example of the recommended

layout.

GND

•

•• ••••

•

V

IN

••

•

•

•••••••••••••••••••••

C

IN

Figure 14. Recommended PCB Layout

V

OUT

C

OUT

C

OUT

C

OUT

••

••

••••

••

SW

••

•

••

••

•••

•••

••••

•••

•••

GND

•

4604 F14

V

IN

2.375V TO 5.5V

C

IN

10μF

6.3V

X5R OR X7R

V

OPEN-DRAIN

PULL UP

C

SSEXT

0.01μF

PGOOD

LTM4604

COMP

RUN/SS

GND

IN

TRACK

V

OUT

FB

R

FB

5.69k

0.5%

4604 F15

V

OUT

1.5V

4A

C

OUT

22μF ×3

6.3V

X5R OR X7R

REFER TO

TABLE 4

Figure 15. Typical 2.375V to 5.5V Input, 1.5V at 4A Design

4604f

15

LTM4604

TYPICAL APPLICATIONS

OPEN-DRAIN PULL UP

10μF

X5R OR X7R

C

SSEXT

0.01μF

10μF

X5R OR X7R

C

6.3V

C

6.3V

IN1

IN2

V

IN

2.375V TO 5V

V

IN

PGOOD

LTM4604

COMP

RUN/SS

GND

V

IN

PGOOD

LTM4604

COMP

RUN/SS

GND

V

OUT

TRACK

V

OUT

TRACK

V

= 0.8V × ((4.99k/N) + RFB)/R

OUT

WHERE N IS THE NUMBER OF PARALLEL DEVICES

C

OUT1

4604 F16

22μF ×3

6.3V

X5R OR X7R

REFER TO

TABLE 4

C

OUT2

22μF ×3

6.3V

X5R OR X7R

REFER TO

TABLE 4

FB

R

FB

2.87k

FB

FB

V

OUT

1.5V

8A

Figure 16. Two LTM4604s in Parallel, 1.5V at 8A Design

4604f

16

TYPICAL APPLICATIONS

OPEN-DRAIN

PULL UP

V

IN

3.3V TO 5V

C

IN

50k

10μF

6.3V

X5R OR X7R

V

IN

C

SSEXT

0.01μF

PGOOD

COMP

RUN/SS

LTM4604

TRACK

GND

V

OUT

FB

R

FB

2.37k

C

OUT

22μF ×3

6.3V

X5R OR X7R

REFER TO

TABLE 4

4604 F17

Figure 17. 3.3V to 5V Input, 2.5V at 4A Design

V

OUT

2.5V

4A

LTM4604

4604f

17

LTM4604

PACKAGE DESCRIPTION

12.70

BSC

0.864 – 0.914

FGE

D

0.864 – 0.914

BSC

7.620

SUBSTRATE

CAP

MOLD

C

0.29 – 0.35

Z

B

1.27

DETAIL A

bbb Z

BSC

A

PADS

PAD 1

56

711 910

PACKAGE BOTTOM VIEW

82143

3

SEE NOTES

Module

m

LTMXXXXXX

PIN “A1”

COMPONENT

LGA 66 0607 REV A

PACKAGE IN TRAY LOADING ORIENTATION

BEVEL

TRAY PIN 1

LGA Package

66-Lead (15mm × 9mm × 2.32mm)

(Reference LTC DWG # 05-08-1807 Rev A)

15.00

aaa Z

2.19 – 2.45

Y

X

BSC

9.00

BSC

1.90 – 2.10

PAD “A1”

4

CORNER

DETAIL A

PACKAGE SIDE VIEW

aaa Z

PACKAGE TOP VIEW

0.15

0.10

TOLERANCE

DETAILS OF PAD #1 IDENTIFIER ARE OPTIONAL,

BUT MUST BE LOCATED WITHIN THE ZONE INDICATED.

THE PAD #1 IDENTIFIER MAY BE EITHER A MOLD OR A

MARKED FEATURE

4

3

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M-1994

2. ALL DIMENSIONS ARE IN MILLIMETERS

LAND DESIGNATION PER JESD MO-222

6.350

5.080

3.810

2.540

1.270

0.4445

0.000

0.4445

1.270

2.540

3.810

5.080

6.350

3.810

2.540

1.270

aaa

bbb

SYMBOL

5. PRIMARY DATUM -Z- IS SEATING PLANE

6. THE TOTAL NUMBER OF PADS: 66

2.540

1.270

0.000

0.4445

0.4445

TOP VIEW

SUGGESTED PCB LAYOUT

3.810

4604f

18

PACKAGE DESCRIPTION

PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME

A1 GND B1 V

A2 GND B2 – C2 – D2 – E2 – F2 – G2 FB

A3 GND B3 SW C3 V

A4 GND B4 SW C4 V

A5 GND B5 – C5 V

A6 GND B6 GND C6 V

A7 GND B7 GND C7 V

A8 GND B8 GND C8 GND D8 V

A9 GND B9 GND C9 GND D9 V

A10 GND B10 GND C10 GND D10 V

A11 GND B11 GND C11 GND D11 V

IN

Pin Assignment Table

(Arranged by Pin Number)

C1 V

D1 RUN/SS E1 TRACK F1 PGOOD G1 COMP

IN

D3 – E3 – F3 GND G3 GND

IN

D4 – E4 GND F4 GND G4 GND

IN

D5 – E5 GND F5 GND G5 GND

IN

D6 – E6 V

IN

D7 V

IN

IN

OUT

OUT

OUT

OUT

E7 V

E8 V

E9 V

E10 V

E11 V

IN

IN

OUT

OUT

OUT

OUT

F6 V

F7 V

F8 V

F9 V

F10 V

F11 V

OUT

OUT

OUT

OUT

OUT

OUT

G6 V

G7 V

G8 V

G9 V

G10 V

G11 V

LTM4604

OUT

OUT

OUT

OUT

OUT

OUT

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

4604f

19

LTM4604

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC2900 Quad Supply Monitor with Adjustable Reset Timer Monitors Four Supplies; Adjustable Reset Timer

LTC2923 Power Supply Tracking Controller Tracks Both Up and Down; Power Supply Sequencing

LTM4600 10A DC/DC μModule Basic 10A DC/DC μModule

LTM4601 12A DC/DC μModule with PLL, Output Tracking/

Margining and Remote Sensing

LTM4602 6A DC/DC μModule Pin Compatible with the LTM4600

LTM4603 6A DC/DC μModule with PLL and Output Tracking/

Margining and Remote Sensing

LTM4608 8A Low Voltage μModule 2.375V ≤ V

Synchronizable, PolyPhase Operation, LTM4601-1 Version has no Remote

Sensing

Synchronizable, PolyPhase Operation, LTM4603-1 Version has no Remote

Sensing, Pin Compatible with the LTM4601

≤ 5V, Parallel for Higher Output Current, 9mm × 15mm × 2.8mm

IN

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

4604f

LT 0807 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...