FEATURES

Electrical Specifications Subject to Change

LTM4600

10A High Effi ciency

DC/DC µModule

U

DESCRIPTIO

■

Complete Switch Mode Power Supply

■

Wide Input Voltage Range: 4.5V to 20V

■

10A DC, 14A Peak Output Current

■

Parallel Two µModules™ for 20A Output Current

■

0.6V to 5V Output Voltage

■

1.5% Regulation

■

Ultrafast Transient Response

■

Current Mode Control

■

Pb-Free (e4) RoHS Compliant Package

■

Up to 92% Effi ciency

■

Programmable Soft-Start

■

Output Overvoltage Protection

■

Optional Short-Circuit Shutdown Timer

■

Small Footprint, Low Profi le (15mm × 15mm ×

2.8mm) Surface Mount LGA Package

U

APPLICATIO S

■

Telecom and Networking Equipment

■

Servers

■

Industrial Equipment

■

Point of Load Regulation

■

Other General Purpose Step Down DC/DC

, LTC, LT and LTM are registered trademarks of Linear Technology Corporation.

µModule is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners. Protected by U.S. Patents including 5481178,

6100678, 6580258, 5847554, 6304066.

The LTM®4600 is a complete 10A, DC/DC step down power

supply. Included in the package are the switching controller, power FETs, inductor, and all support components.

Operating over an input voltage range of 4.5V to 20V, the

LTM4600 supports an output voltage range of 0.6V to 5V,

set by a single resistor. This high effi ciency design delivers

10A continuous current (14A peak), needing no heat sinks

or airfl ow to meet power specifi cations. Only bulk input

and output capacitors are needed to fi nish the design.

The low profi le package (2.8mm) enables utilization of

unused space on the bottom of PC boards for high density

point of load regulation. High switching frequency and an

adaptive on-time current mode architecture enables a very

fast transient response to line and load changes without

sacrifi cing stability. Fault protection features include

integrated overvoltage and short circuit protection with

a defeatable shutdown timer. A built-in soft-start timer is

adjustable with a small capacitor.

The LTM4600 is packaged in a thermally enhanced, compact

(15mm × 15mm) and low profi le (2.8mm) over-molded

Land Grid Array (LGA) package suitable for automated

assembly by standard surface mount equipment. The

LTM4600 is Pb-free and RoHS certifi ed.

U

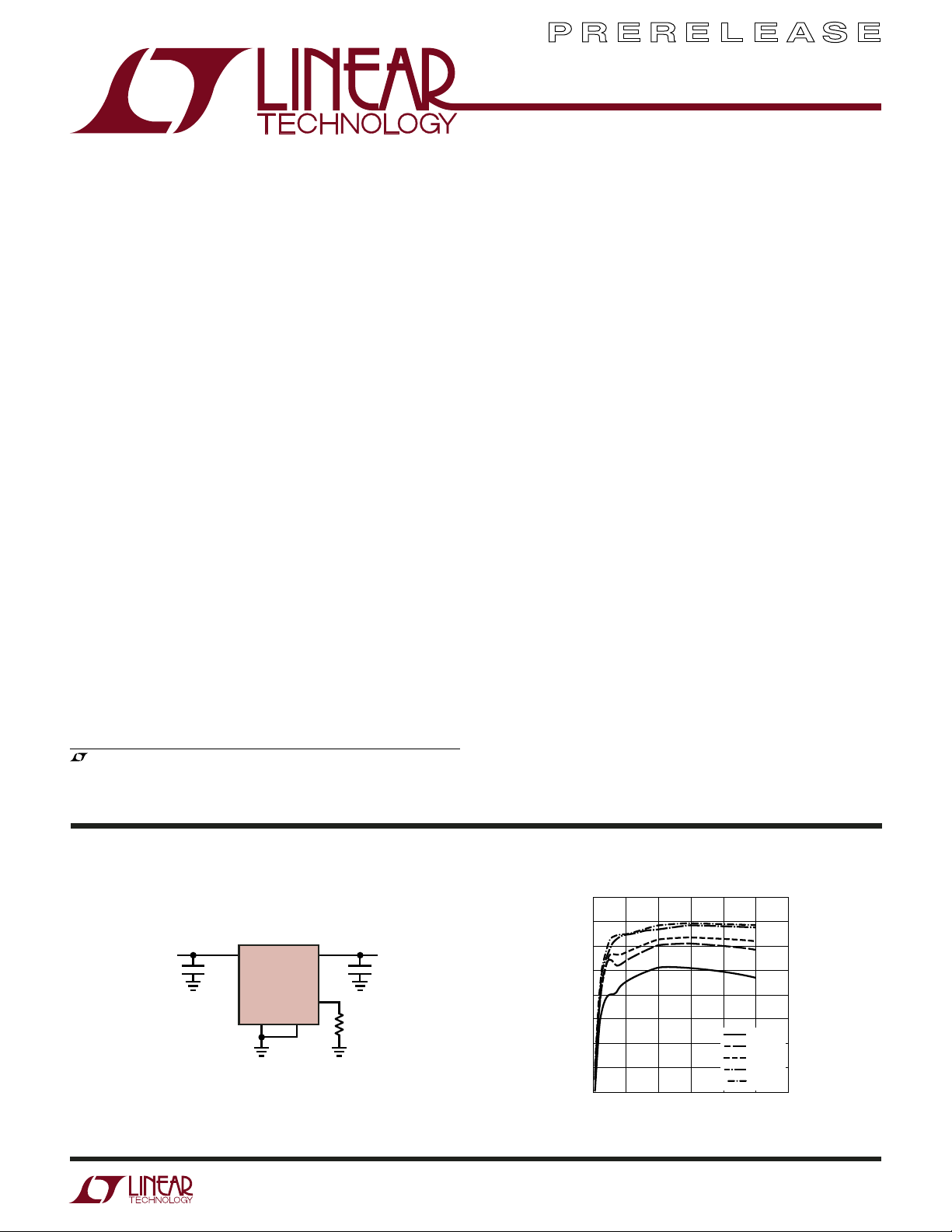

TYPICAL APPLICATIO

10A µModule Power Supply with 4.5V to 20V Input

V

4.5V TO 20V

IN

V

C

IN

V

IN

LTM4600

V

OSET

PGND SGND

OUT

C

OUT

66.5k

4600 TA01a

V

OUT

1.5V

10A

PRERELEASE

Effi ciency vs Load Current

100

90

80

70

60

50

EFFICIENCY (%)

40

30

20

0

with 12V

24 8

LOAD CURRENT (A)

(FCB = 0)

IN

6

0.6V

1.2V

1.5V

2.5V

3.3V

10

OUT

OUT

OUT

OUT

OUT

4600 TA01b

12

4600p

1

LTM4600

WW

W

ABSOLUTE AXI U RATI GS

U

UUW

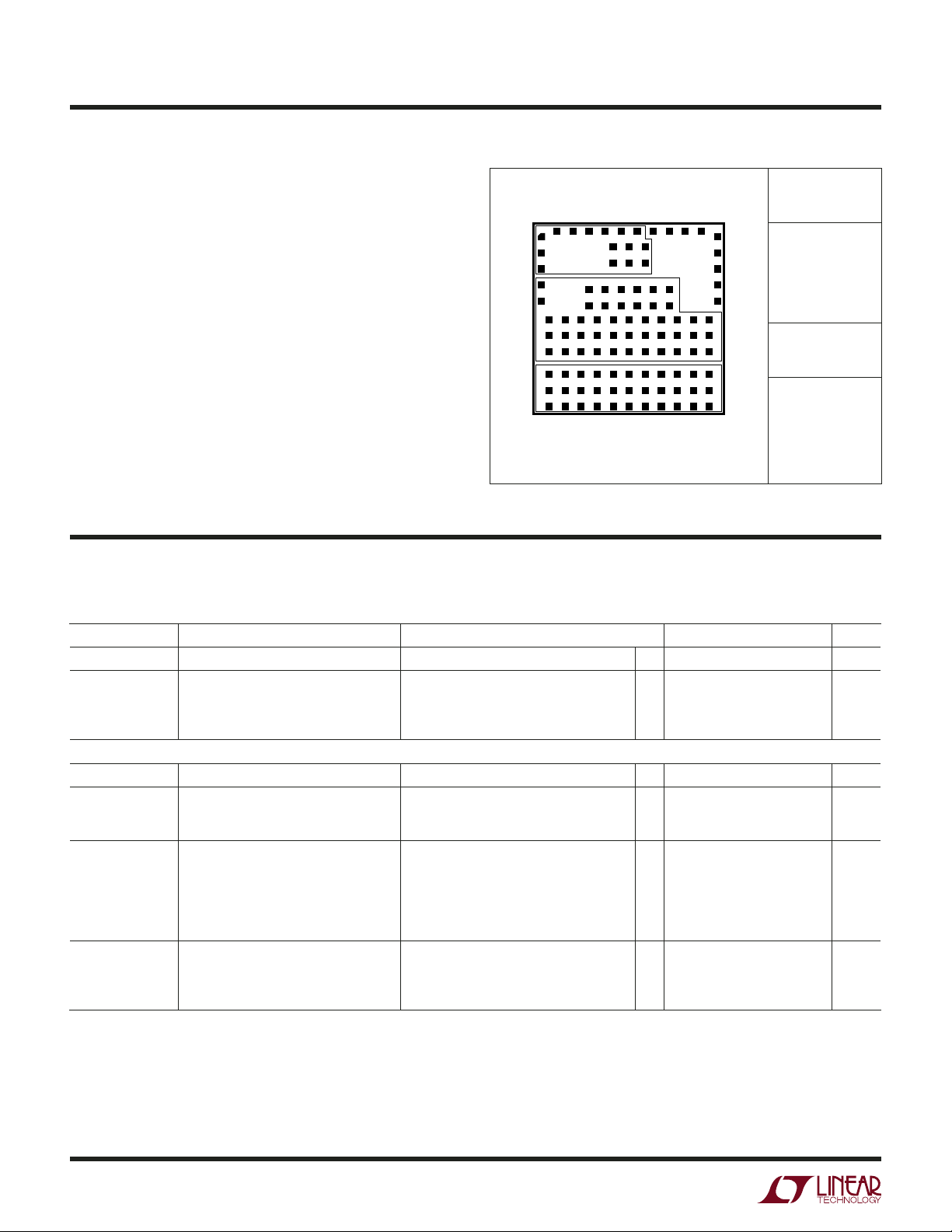

PACKAGE/ORDER I FOR ATIO

(Note 1)

FCB, EXTVCC, PGOOD, RUN/SS, V

, SVIN, F

V

IN

, COMP ............................................. –0.3V to 2.7V

V

OSET

........................................... –0.3V to 20V

ADJ

.......... –0.3V to 6V

OUT

Operating Temperature Range (Note 2) ... –40°C to 85°C

Junction Temperature ........................................... 125°C

Storage Temperature Range ................... –65°C to 150°C

V

PGND

TOP VIEW

IN

ADJ

F

IN

OSET

EXTVCCV

SV

COMP

SGND

RUN/SS

FCB

PGOOD

ORDER PART

NUMBER

LTM4600EV

LTM4600IV

LGA PART

MARKING

V

OUT

104-LEAD (15mm × 15mm × 2.8mm)

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

The ● denotes the specifi cations which apply over the –40°C to 85°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at TA = 25°C, VIN = 12V. External CIN = 120µF, C

LGA PACKAGE

T

= 125°C, θJA = 15°C/W

JMAX

= 200µF/Ceramic per typical

OUT

application (front page) confi guration.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN(DC)

V

OUT(DC)

Input Specifi cations

V

IN(UVLO)

I

INRUSH(VIN)

I

Q(VIN)

I

S(VIN)

Input DC Voltage

Output Voltage

V

= 12V, V

IN

V

= 12V, V

IN

V

= 5V, V

IN

Under Voltage Lockout Threshold I

Input Inrush Current at Startup

V

= 5V

IN

V

= 12V

IN

Input Supply Bias Current

V

= 12V, V

IN

V

= 12V, V

IN

VIN = 5V, V

V

= 5V, V

IN

Shutdown, RUN = 0, V

Input Supply Current

V

= 12V, V

IN

V

= 12V, V

IN

V

= 5V, V

IN

= 1.5V, I

OUT

= 1.5V, I

OUT

= 1.5V, I

OUT

= 1.5V, FCB = 5V

OUT

= 1.5V, FCB = 0V

OUT

= 1.5V, FCB = 5V

OUT

= 1.5V, FCB = 0V

OUT

IN

= 1.5V, I

OUT

= 3.3V, I

OUT

= 1.5V, I

OUT

OUT

OUT

= 0A

OUT

= 12V

OUT

OUT

= 10A

OUT

= 0A

= 0A

= 10A

= 10A

FCB = 0

= 0A 3.4 4 V

OUT

= 0A. V

I

OUT

I

= 0A, EXTVCC Open

OUT

= 1.5V, FCB = 0

OUT

●

4.5 20 V

●

1.478 1.50 1.522 V

1.52

3.13

3.64

0.6

0.7

1.2

42

1.0

52

15

LTM4600EV

LTM4600IV

mA

mA

mA

mA

A

A

µA

A

A

A

2

4600p

PRERELEASE

LTM4600

The ● denotes the specifi cations which apply over the –40°C to 85°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Specifi cations

I

OUTDC

ΔV

/ΔVIN Line Regulation Accuracy

OUT

/ΔI

ΔV

OUT

OUT

V

OUT(AC)

Fs Output Ripple Voltage Frequency FCB = 0V, I

t

START

ΔV

OUTLS

t

SETTLE

I

OUTPK

Control Stage

V

OSET

V

RUN/SS

I

RUN(C)/SS

I

RUN(D)/SS

– SV

V

IN

IN

I

EXTVCC

R

FBHI

V

FCB

I

FCB

PGOOD Output

ΔV

OSETH

ΔV

OSETL

ΔV

OSET(HYS)

V

PGL

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTM4600E is guaranteed to meet performance specifi cations

from 0°C to 85°C. Specifi cations over the –40°C to 85°C operating

Output Continuous Current Range

(See Output Current Derating Curves for

Different V

I

OUT

IN

= 0A

, V

OUT

and TA)

Load Regulation Accuracy

V

= 5V

IN

V

= 12V

IN

Output Ripple Voltage

V

IN

V

IN

= 12V, V

= 5V, V

= 1.5V, FCB = 0V

OUT

= 1.5V, FCB = 0V

OUT

Turn-On Time

V

= 12V

IN

V

= 5V

IN

Voltage Drop for Dynamic Load Step

V

= 12V, V

IN

OUT

= 1.5V

Settling Time for Dynamic Load Step

V

= 12V

IN

Output Current Limit

V

= 12V, V

IN

V

= 5V, V

IN

Voltage at V

= 1.5V

OUT

= 1.5V

OUT

Pin I

OSET

RUN ON/OFF Threshold 0.8 1.5 2 V

Soft-Start Charging Current V

Soft-Start Discharging Current V

Current into EXTVCC Pin FCB = 0V, V

Resistor Between V

and FB Pins 100 kΩ

OUT

Forced Continuous Threshold 0.57 0.6 0.63 V

Forced Continuous Pin Current V

PGOOD Upper Threshold V

PGOOD Lower Threshold V

PGOOD Hysteresis V

PGOOD Low Voltage I

= 25°C, VIN = 12V. Per typical application (front page) confi guration.

A

= 12V, V

V

IN

= 1.5V. FCB = 0V

V

OUT

= 1.5V. FCB = 0V

V

OUT

0A to 10A

= 0A

I

OUT

= 1.5V 0 10 A

OUT

● 0.3 %

±1

●

±1

15

20 25

800 kHz

= 5A, VIN = 12V, V

OUT

OUT

●

=

1.5V

V

OUT

= 1.5V, I

OUT

= 10A

0.5

0.7

Load Step: 0A to 5A/µs

C

= 3 • 22µF 6.3V, 470µF 4V Pos Cap,

OUT

36 mV

See Table 2

Load: 10% to 90% to 10% of Full Load 25 µs

17

17

= 0A, V

OUT

RUN/SS

RUN/SS

= 1.5V

OUT

= 0V –0.5 –1.2 –3 µA

= 4V 0.8 1.8 3 µA

●

0.594 0.6 0.606 V

EXTVCC = 0, FCB = 0V 100 mV

= 1.5V, I

OUT

= 0.6V –1 –2 µA

FCB

Rising 7.5 10 12.5 %

OSET

Falling –7.5 –10 –12.5 %

OSET

Returning 1 2.5 %

OSET

= 5mA 0.15 0.4 V

PGOOD

= 0A 16 mA

OUT

temperature range are assured by design, characterization and correlation

with statistical process controls. The LTM4600I is guaranteed and tested

over the –40°C to 85°C temperature range.

mV

mV

P-P

P-P

ms

ms

%

%

A

A

PRERELEASE

4600p

3

LTM4600

w

)

(

)

(

)

(

)

UW

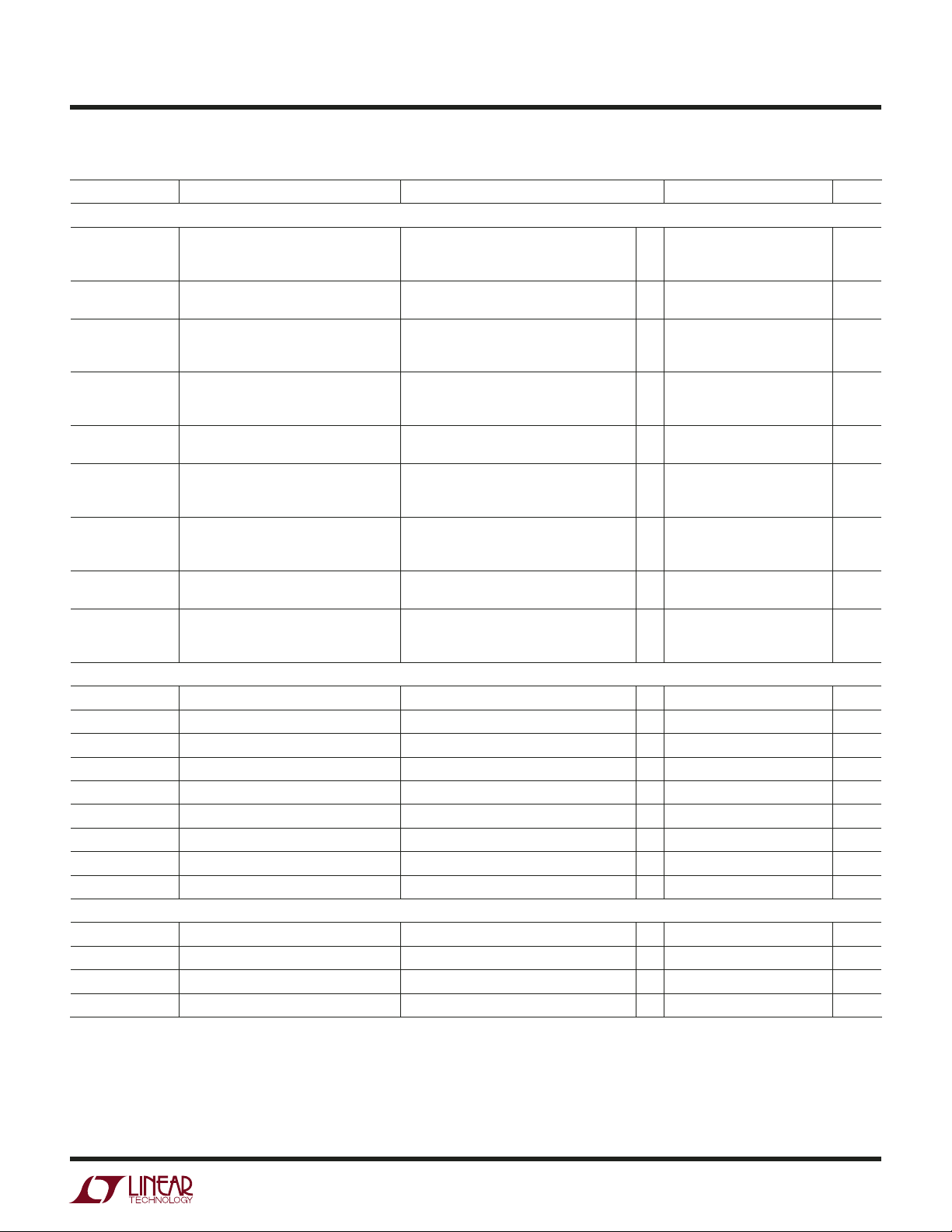

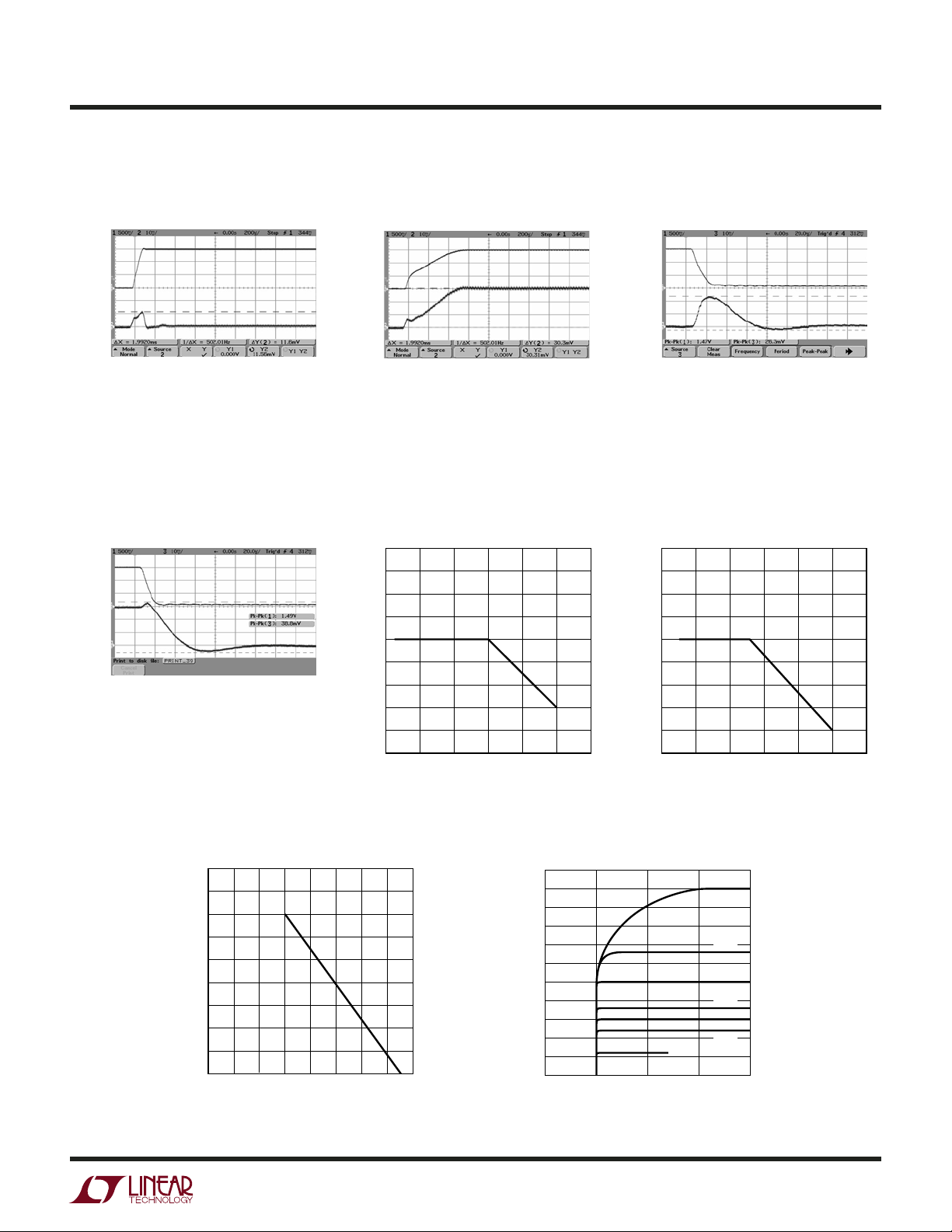

TYPICAL PERFOR A CE CHARACTERISTICS

Effi ciency vs Load Current

ith 5V

100

90

80

70

60

EFFICIENCY (%)

50

40

30

0

(FCB = 0)

IN

24

LOAD CURRENT (A)

Effi ciency vs Load Current

with Different FCB Settings

90

80

70

60

50

EFFICIENCY (%)

40

30

20

0.1

FCB > 0.7V

FCB = GND

LOAD CURRENT (A)

0.6V

OUT

1.2V

OUT

1.5V

OUT

2.5V

OUT

812

610

4600 G01

1

10

4600 G04

Effi ciency vs Load Current

with 12V(FCB = 0

100

90

80

70

60

50

EFFICIENCY (%)

40

30

20

24 8

0

LOAD CURRENT (A)

6

1.2V Transient Response

(See Figure 17)

V

= 50mV/DIV

OUT

I

= 5A/DIV

OUT

25µs/DIV

1.2V AT 5A/µs LOAD STEP

= 3 • 22µF 6.3V CERAMICS

C

OUT

470µF 4V SANYO POS CAP

C3 = 100pF

0.6V

1.2V

1.5V

2.5V

3.3V

10

OUT

OUT

OUT

OUT

OUT

4600 G02

4600 G05

12

Effi ciency vs Load Current

with 18V

100

90

80

70

60

EFFICIENCY (%)

50

40

30

0

(FCB = 0)

IN

24 8

6

LOAD CURRENT (A)

1.5V Transient Response

(See Figure 17)

25µs/DIV

1.5V AT 5A/µs LOAD STEP

= 3 • 22µF 6.3V CERAMICS

C

OUT

470µF 4V SANYO POS CAP

C3 = 100pF

1.5V

1.8V

2.5V

3.3V

10

OUT

OUT

OUT

OUT

4600 G03

4600 G06

12

1.8V Transient Response

See Figure 17

25µs/DIV

1.8V AT 5A/µs LOAD STEP

= 3 • 22µF 6.3V CERAMICS

C

OUT

470µF 4V SANYO POS CAP

C3 = 100pF

4600 G07

4

2.5V Transient Response

See Figure 17

25µs/DIV

2.5V AT 5A/µs LOAD STEP

= 3 • 22µF 6.3V CERAMICS

C

OUT

470µF 4V SANYO POS CAP

C3 = 100pF

4600 G08

PRERELEASE

3.3V Transient Response

See Figure 17

25µs/DIV

3.3V AT 5A/µs LOAD STEP

= 3 • 22µF 6.3V CERAMICS

C

OUT

470µF 4V SANYO POS CAP

C3 = 100pF

4600 G09

4600p

UW

(

)

)

)

TYPICAL PERFOR A CE CHARACTERISTICS

LTM4600

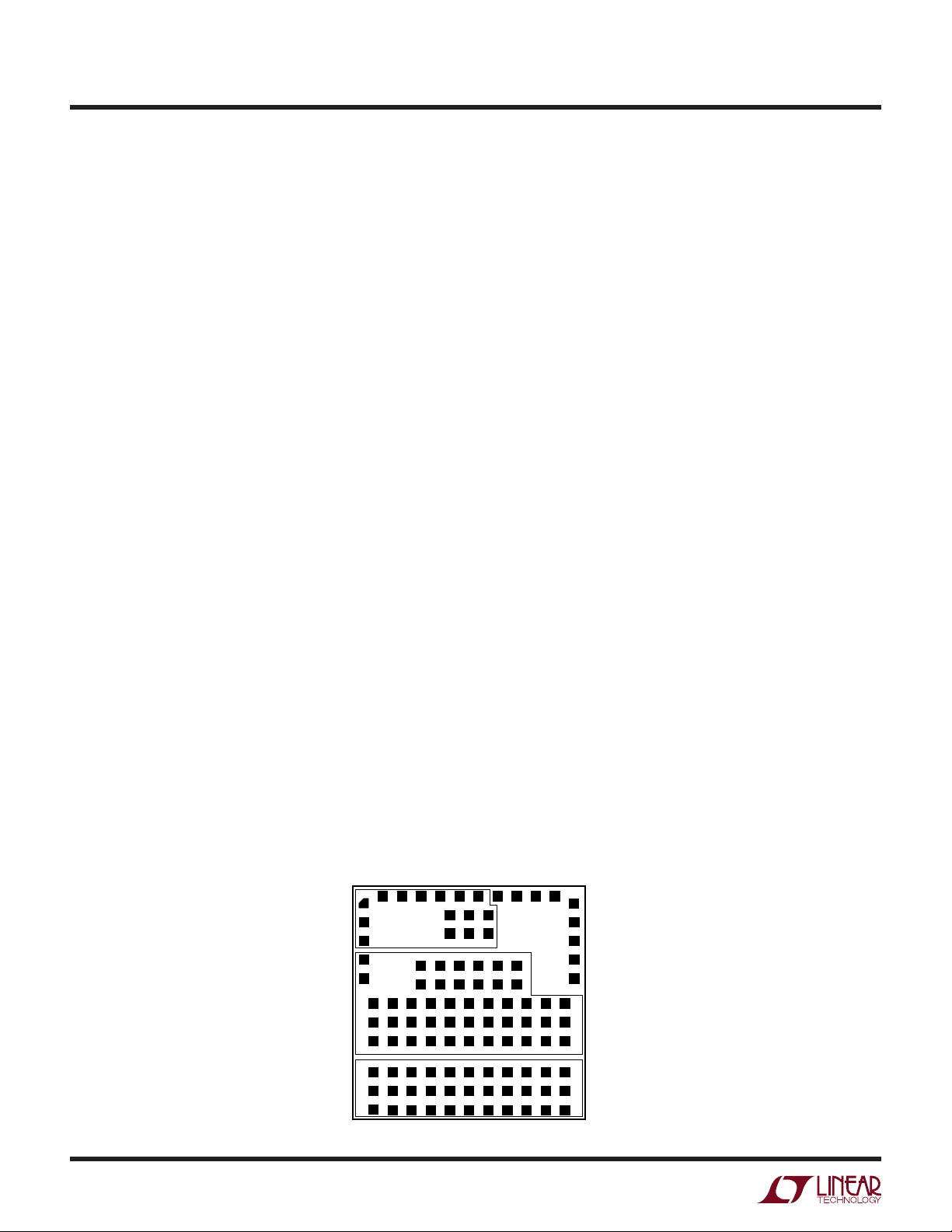

Start-Up, I

OUT

= 0A

(See Figure 17)

V

OUT

(0.5V/DIV)

I

IN

(0.5A/DIV)

200µs/DIV

VIN = 12V

= 1.5V

V

OUT

= 200µF

C

OUT

NO EXTERNAL SOFT-START CAPACITOR

4600 G10

Short-Circuit Protection,

I

= 10A (See Figure 17

V

OUT

(0.5V/DIV)

I

IN

(0.5A/DIV)

20µs/DIV

VIN = 12V

= 1.5V

V

OUT

= 2× 200µF/X5R

C

OUT

NO EXTERNAL SOFT-START CAPACITOR

4600 G13

Start-Up, I

OUT

= 10A

Resistive Load) (See Figure 17

V

OUT

(0.5V/DIV)

I

IN

(0.5A/DIV)

200µs/DIV

VIN = 12V

= 1.5V

V

OUT

= 200µF

C

OUT

NO EXTERNAL SOFT-START CAPACITOR

Current Limit with 12V

18

16

14

12

10

8

6

CURRENT LIMIT (A)

4

2

0

0

OUTPUT VOLTAGE (V)

4600 G11

4600 G14

Short-Circuit Protection,

I

= 0A (See Figure 17

V

OUT

(0.5V/DIV)

I

IN

(0.2A/DIV)

20µs/DIV

VIN = 12V

= 1.5V

V

OUT

= 2× 200µF/X5R

C

OUT

NO EXTERNAL SOFT-START CAPACITOR

4600 G12

Current Limit with 9V

18

16

14

12

10

8

6

CURRENT LIMIT (A)

4

2

654321

0

0

OUTPUT VOLTAGE (V)

654321

4600 G15

Current Limit with 5V

18

16

14

12

10

8

6

OUTPUT CURRENT (A)

4

2

0

0

OUTPUT VOLTAGE (V)

IN

4.03.53.02.52.01.00.5 1.5

4600 G16

PRERELEASE

(V)

OUT

V

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0

VIN to V

Stepdown Ratio

OUT

5V

3.3V

2.5V

1.8V

1.5V

1.2V

0.6V

515

10 20

VIN (V)

4600 G17

4600p

5

LTM4600

PI FU CTIO S

UUU

(See Package Description for Pin Assignment)

VIN (Bank 1): Power Input Pins. Apply input voltage

between these pins and GND pins. Recommend placing

input decoupling capacitance directly between V

pins

IN

and GND pins.

(Pin A15): An internal resistor from VIN to this pin

F

ADJ

sets the one-shot timer current, thereby setting the switching frequency.

(Pin A17): Supply Pin for Internal PWM Controller.

SV

IN

Leave this pin open or add additional decoupling capacitance.

EXTV

(Pin A19): External 5V supply pin for controller.

CC

If left open, the internal 5V linear regulator will power the

controller and MOSFET drivers. For high input voltage

applications, connecting this pin to an external 5V will

reduce the power loss in the power module. The EXTV

voltage should never be higher than V

(Pin A21): The Negative Input of The Error Am-

V

OSET

plifi er. Internally, this pin is connected to V

IN

.

with a

OUT

CC

100k precision resistor. Different output voltages can be

programmed with additional resistors between the V

OSET

and SGND pins.

COMP (Pin B23): Current Control Threshold and Error

Amplifi er Compensation Point. The current comparator

threshold increases with this control voltage. The voltage

ranges from 0V to 2.4V with 0.8V corresponding to zero

sense voltage (zero current).

SGND (Pin D23): Signal Ground Pin. All small-signal

components should connect to this ground, which in turn

connects to PGND at one point.

RUN/SS (Pin F23): Run and Soft-Start Control. Forcing

this pin below 0.8V will shut down the power supply.

Inside the power module, there is a 1000pF capacitor

which provides approximately 0.7ms soft-start time with

200µF output capacitance. Additional soft-start time can

be achieved by adding additional capacitance between

the RUN/SS and SGND pins. The internal short-circuit

latchoff can be disabled by adding a resistor between this

pin and the V

pin. This resistor must supply a minimum

IN

5µA pull up current.

FCB (Pin G23): Forced Continuous Input. Grounding this

pin enables forced continuous mode operation regardless

of load conditions. Tying this pin above 0.63V enables

discontinuous conduction mode to achieve high effi ciency

operation at light loads. There is an internal 4.75K resistor

between the FCB and SGND pins.

PGOOD (Pin J23): Output Voltage Power Good Indicator.

When the output voltage is within 10% of the nominal

voltage, the PWRGD is open drain output. Otherwise, this

pin is pulled to ground.

PGND (Bank 2): Power ground pins for both input and

output returns.

(Bank 3): Power Output Pins. Apply output load

V

OUT

between these pins and GND pins. Recommend placing

High Frequency output decoupling capacitance directly

between these pins and GND pins.

6

TOP VIEW

2

1

V

8

IN

BANK 1

12

25

32

39

PGND

BANK 2

BANK 3

50

61

72

V

83

OUT

94

1 23

24

26 27 28 29 30 31

33 34 35 36 37 38

42 43 44 45 46 47

41

40

52 53 54 55 56 57 58

51

62

63 64 65 66 67 68 69

73

74 75 76 77 78 79 80

84 85 86 87 88 89 90 91

95 96 97 98

35

79

68

11109

13 14 15

99 100 101 102 103

11 13

10 12

14 16

PRERELEASE

ADJ

F

15 17

IN

EXTVCCV

SV

1918171676543

48

59

70

81

92

19 21

18 20 22

OSET

49

60

71

82

93

104

A

20

B

COMP

C

21

D

SGND

E

22

F

RUN/SS

23

G

FCB

H

24

J

PGOOD

K

L

M

N

P

R

S

4600 PN01

4600p

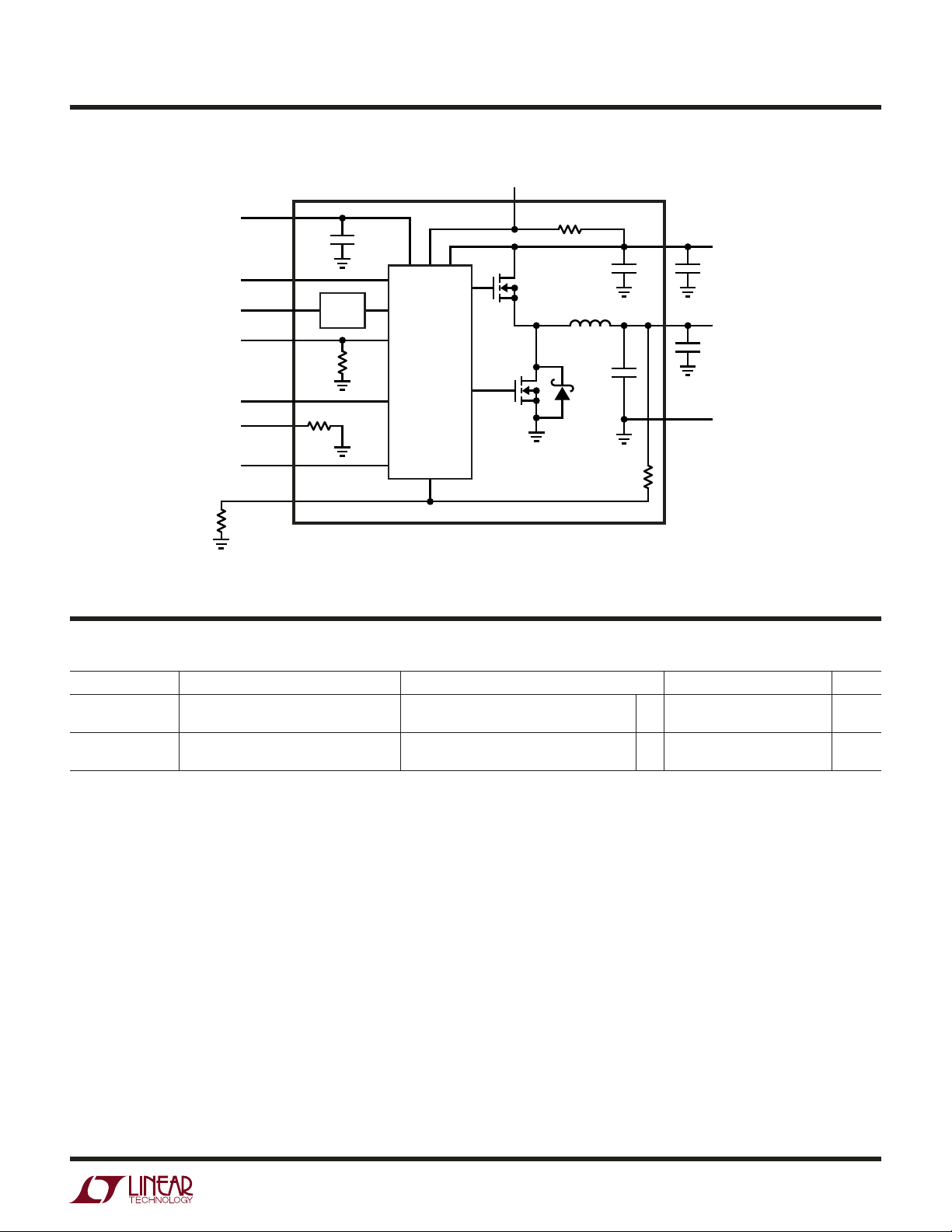

SI PLIFIEDWBLOCK DIAGRA

W

LTM4600

SV

IN

R6

66.5k

RUN/SS

PGOOD

COMP

FCB

F

ADJ

SGND

EXTV

V

OSET

1000pF

Q1

INT

COMP

4.75k

10Ω

CC

CONTROLLER

Q2

1.5µF

15µF

6.3V

LTM4600

100k

0.5%

4600 F01

V

4.5V TO 20V

IN

V

1.5V/10A MAX

OUT

PGND

C

IN

C

OUT

Figure 1. Simplifi ed LTM4600 Block Diagram

U

DECOUPLI G REQUIRE E TS

T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

C

IN

C

OUT

External Input Capacitor Requirement

(V

= 4.5V to 15V, V

IN

OUT

= 1.5V)

External Output Capacitor Requirement

(V

= 4.5V to 15V, V

IN

OUT

= 1.5V)

WU

= 25°C, VIN = 12V. Use Figure 1 confi guration.

A

= 10A 20 µF

I

OUT

= 10A, Refer to Table 2 in the

I

OUT

Applications Information Section

100 200 µF

PRERELEASE

4600p

7

LTM4600

OPERATIO

U

µModule Description

The LTM4600 is a standalone non-isolated synchronous

switching DC/DC power supply. It can deliver up to 10A of

DC output current with only bulk external input and output

capacitors. This module provides a precisely regulated

output voltage programmable via one external resistor from

0.6V

The input voltage range is 4.5V to 20V. A simplifi ed block

diagram is shown in Figure 1 and the typical application

schematic is shown in Figure 17.

The LTM4600 contains an integrated LTC constant on-time

current-mode regulator, ultra-low R

switching speed and integrated Schottky diode. The typical

switching frequency is 800kHz at full load. With current

mode control and internal feedback loop compensation,

the LTM4600 module has suffi cient stability margins and

good transient performance under a wide range of operating conditions and with a wide range of output capacitors,

even all ceramic output capacitors.

Current mode control provides cycle-by-cycle fast current

limit. In addition, foldback current limiting is provided in an

over-current condition while V

has defeatable short circuit latch off. Internal overvoltage and undervoltage comparators pull the open-drain

PGOOD output low if the output feedback voltage exits a

to 5.0VDC, not to exceed 80% of the input voltage.

DC

FETs with fast

DS(ON)

drops. Also, the LTM4600

FB

±10% window around the regulation point. Furthermore,

in an overvoltage condition, internal top FET Q1 is turned

off and bottom FET Q2 is turned on and held on until the

overvoltage condition clears.

Pulling the RUN/SS pin low forces the controller into its

shutdown state, turning off both Q1 and Q2. Releasing the

pin allows an internal 1.2µA current source to charge up

the softstart capacitor. When this voltage reaches 1.5V,

the controller turns on and begins switching.

At low load current the module works in continuous current mode by default to achieve minimum output voltage

ripple. It can be programmed to operate in discontinuous

current mode for improved light load effi ciency when the

FCB pin is pulled up above 0.8V and no higher than 5V.

The FCB pin has a 4.25k resistor to ground, so a resistor

can set the voltage on the FCB pin.

to V

IN

When EXTV

regulator powers the controller and MOSFET gate drivers.

If a minimum 4.7V external bias supply is applied on the

EXTV

internal switch connects EXTV

This eliminates the linear regulator power loss with high

input voltage, reducing the thermal stress on the controller.

The maximum voltage on EXTV

voltage should never be higher than the V

EXTV

pin, the internal regulator is turned off, and an

CC

must be sequenced after VIN.

CC

pin is grounded, an integrated 5V linear

CC

to the gate driver voltage.

CC

pin is 6V. The EXTVCC

CC

voltage. Also

IN

8

4600p

PRERELEASE

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

The typical LTM4600 application circuit is shown in Figure

20. External component selection is primarily determined

by the maximum load current and output voltage.

Output Voltage Programming and Margining

The PWM controller of the LTM4600 has an internal

0.6V±1% reference voltage. As shown in the block diagram,

a 100k/0.5% internal feedback resistor connects V

FB pins. Adding a resistor R

SET

from V

pin to SGND

OSET

pin programs the output voltage:

kR

VV

=+06

O

100

.•

Table 1 shows the standard vaules of 1% R

R

SET

SET

SET

for typical output voltages:

Table 1.

R

SET

Open 100 66.5 49.9 43.2 31.6 22.1 13.7

(kΩ)

V

O

0.6 1.2 1.5 1.8 2 2.5 3.3 5

(V)

Voltage margining is the dynamic adjustment of the output

voltage to its worst case operating range in production

testing to stress the load circuitry, verify control/protection functionality of the board and improve the system

reliability. Figure 2 shows how to implement margining

function with the LTM4600. In addition to the feedback

resistor R

Turn off both transistor Q

margining. When Q

, several external components are added.

SET

UP

is on and Q

UP

and Q

DOWN

to disable the

DOWN

is off, the output

voltage is margined up. The output voltage is margined

V

LTM4600

100k

PGND SGND

OUT

V

OSET

Figure 2.

R

DOWN

Q

2N7002

R

SET

R

UP

2N7002

Q

4600 F02

OUT

resistor

DOWN

UP

and

down when Q

voltage V

needs to be margined up/down by ±M%, the

O

resistor values of R

is on and Q

DOWN

UP

and R

is off. If the output

UP

can be calculated from

DOWN

the following equations:

()••(%)

RR V M

SET UP O

()

RR k

SET UP

RV M

••(–%)

SET O

RkR

()

100

+Ω

SET DOWN

1

+

100

+Ω

1

=

=

.

06

.

06

V

V

Input Capacitors

The LTM4600 µModule should be connected to a low

ac-impedance AC source. High frequency, low ESR input

capacitors are required to be placed adjacent to the module. In Figure 20, the bulk input capacitor C

is selected

IN

for its ability to handle the large RMS current into the

converter. For a buck converter, the switching duty-cycle

can be estimated as:

V

O

D

=

V

IN

Without considering the inductor current ripple, the RMS

current of the input capacitor can be estimated as:

I

OMAX

()

%

η

DD

••()=−

1

I

CIN RMS

()

In the above equation, η% is the estimated effi ciency of

the power module. C1 can be a switcher-rated electrolytic

aluminum capacitor, OS-CON capacitor or high volume

ceramic capacitors. Note the capacitor ripple current

ratings are often based on only 2000 hours of life. This

makes it advisable to properly derate the input capacitor,

or choose a capacitor rated at a higher temperature than

required. Always contact the capacitor manufacturer for

derating requirements.

In Figure 16, the input capacitors are used as high frequency input decoupling capacitors. In a typical 10A

output application, 1-2 pieces of very low ESR X5R or

X7R, 10µF ceramic capacitors are recommended. This

decoupling capacitor should be placed directly adjacent

PRERELEASE

4600p

9

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

the module input pins in the PCB layout to minimize the

trace inductance and high frequency AC noise.

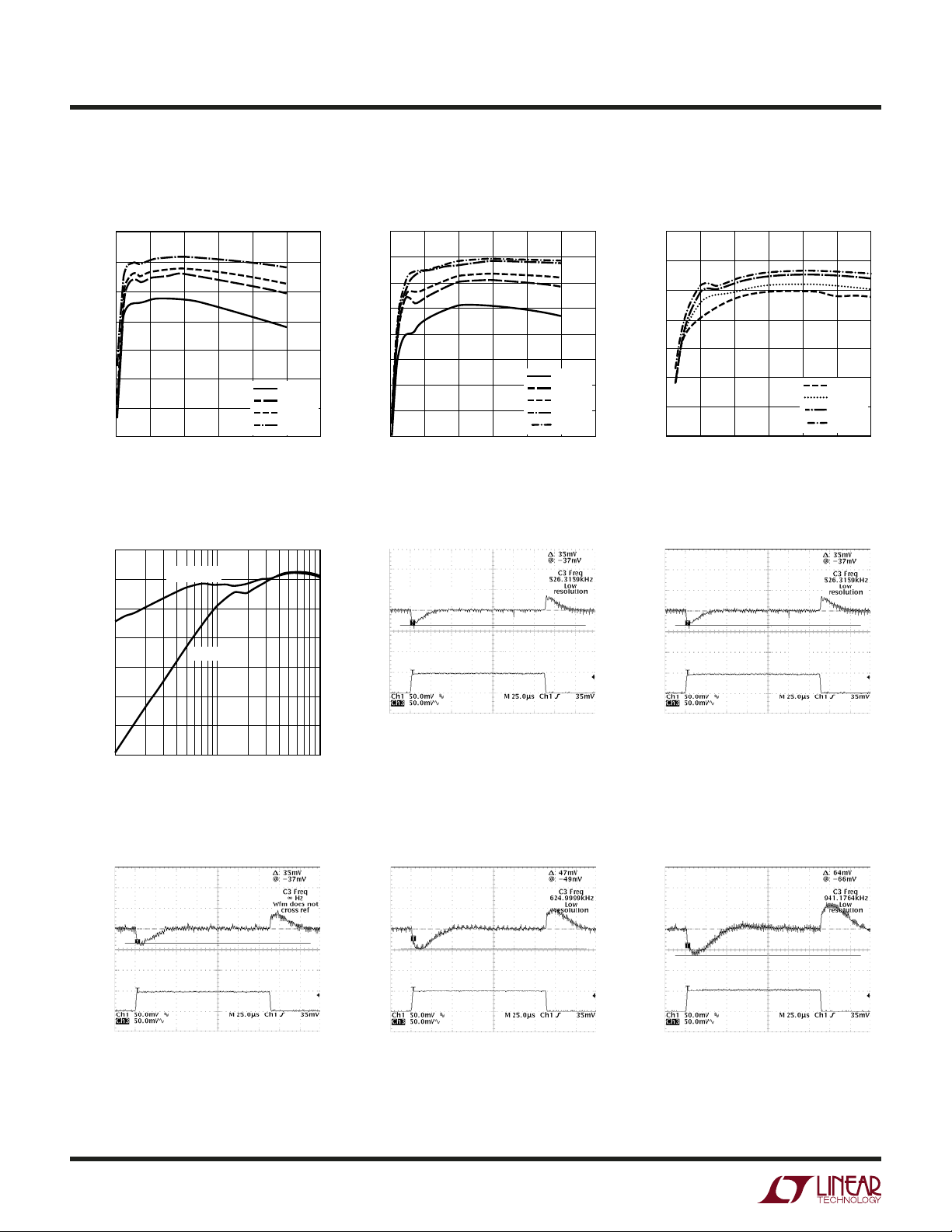

Output Capacitors

The LTM4600 is designed for low output voltage ripple.

The bulk output capacitors C

effective series resistance (ESR) to meet the output voltage

ripple and transient requirements. C

tantalum capacitor, low ESR polymer capacitor or ceramic

capacitor. The typical capacitance is 200µF if all ceramic

output capacitors are used. The internally optimized loop

compensation provides suffi cient stability margin for all

ceramic capacitors applications. Additional output fi ltering may be required by the system designer, if further

reduction of output ripple or dynamic transient spike is

required. Refer to Table 2 for an output capacitance matrix

for each output voltage Droop, peak to peak deviation and

recovery time during a 5A/µs transient with a specifi c

output capacitance.

Fault Conditions: Current Limit and Over current

Foldback

The LTM4600 has a current mode controller, which inherently limits the cycle-by-cycle inductor current not only in

steady state operation, but also in transient.

To further limit current in the event of an over load condition, the LTM4600 provides foldback current limiting. If the

output voltage falls by more than 50%, then the maximum

output current is progressively lowered to about one sixth

of its full current limit value.

is chosen with low enough

OUT

can be low ESR

OUT

Soft-Start and Latchoff with the RUN/SS pin

The RUN/SS pin provides a means to shut down the

LTM4600 as well as a timer for soft-start and over-current latchoff. Pulling the RUN/SS pin below 0.8V puts

the LTM4600 into a low quiescent current shutdown (I

≤ 30µA). Releasing the pin allows an internal 1.2µA current source to charge up the timing capacitor CSS. Inside

LTM4600, there is an internal 1000pF capacitor from

RUN/SS pin to ground. If RUN/SS pin has an external

capacitor CSS_EXT to ground, the delay before starting

is about:

V

15

t

DELAY SS EXT

When the voltage on RUN/SS pin reaches 1.5V, the

LTM4600 internal switches are operating with a clamping

of the maximum output inductor current limited by the

RUN/SS pin total soft-start capacitance. As the RUN/SS pin

voltage rises to 3V, the soft-start clamping of the inductor

current is released.

to V

V

IN

OUT

There are restrictions in the maximum V

down ratio that can be achieved for a given input voltage.

These contraints are shown in the Typical Performance

Characteristics curves labeled “V

Ratio”. Note that additional thermal de-rating may apply.

See the Thermal Considerations and Output Current DeRating sections of this data sheet.

.

=

12

.

Stepdown Ratios

CpF

•( )

A

µ

_

+

1000

to V

IN

to V

IN

OUT

Stepdown

OUT

Q

step

10

4600p

PRERELEASE

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

Table 2. Output Voltage Response Verses Component Matrix

TYPICAL MEASURED VALUES

C

VENDORS PART NUMBER C

OUT1

TDK C4532X5R0J107MZ (100UF,6.3V) SANYO POS CAP 6TPE330MIL (330µF, 6.3V)

TAIYO YUDEN JMK432BJ107MU-T ( 100µF, 6.3V) SANYO POS CAP 2R5TPE470M9 (470µF, 2.5V)

TAIYO YUDEN JMK316BJ226ML-T501 ( 22µF, 6.3V) SANYO POS CAP 4TPE470MCL (470µF, 4V)

V

OUT

(V)

1.2 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 12 35 68 25 5

1.2 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 5 35 68 25 5

1.5 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 12 36 75 25 5

1.5 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 5 36 75 25 5

1.8 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 12 40 81 30 5

1.8 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 5 40 81 30 5

2.5 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 12 51 102 30 5

2.5 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 5 57 116 30 5

3.3 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 12 64 129 35 5

3.3 2 × 10µF 25V 150µF 35V 3 × 22µF 6.3V 470µF 4V NONE 100pF 7 82 166 35 5

1.2 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 2.5V NONE 100pF 12 35 70 20 5

1.2 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 2.5V NONE 100pF 5 35 70 20 5

1.5 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 2.5V NONE 100pF 12 37 79 20 5

1.5 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 2.5V NONE 100pF 5 37 79 20 5

1.8 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 2.5V NONE 100pF 12 44 85 20 5

1.8 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 2.5V NONE 100pF 5 44 88 20 5

2.5 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 4V NONE 100pF 12 48 103 30 5

2.5 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 4V NONE 100pF 5 48 103 30 5

3.3 2

3.3 2 × 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 4V NONE 100pF 7 66 132 30 5

1.2 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 12 40 80 20 5

1.2 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 5 40 80 20 5

1.5 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 12 44 89 20 5

1.5 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 5 44 84 20 5

1.8 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 12 44 91 20 5

1.8 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 5 46 91 20 5

2.5 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 12 56 113 30 5

2.5 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 5 56 113 30 5

3.3 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 12 64 126 30 5

3.3 2 × 10µF 25V 150µF 35V 2 × 100µF 6.3V 330µF 6.3V NONE 100pF 7 64 126 30 5

1.2 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 12 49 98 20 5

1.2 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 5 49 98 20 5

1.5 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 12 54 108 20 5

1.5 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 5 61 118 20 5

1.8 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 12 62 125 20 5

1.8 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 5 62 128 20 5

2.5 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 12 70 159 25 5

2.5 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 5 60 115 25 5

3.3 2 ×

3.3 2 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 7 100 200 25 5

52 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 15 188 375 25 5

52 × 10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 20 159 320 25 5

CIN

(CERAMIC)

× 10µF 25V 150µF 35V 1 × 100µF 6.3V 470µF 4V NONE 100pF 12 52 106 30 5

10µF 25V 150µF 35V 4 × 100µF 6.3V NONE NONE 100pF 12 76 144 25 5

CIN

(BULK)

C

OUT1

(CERAMIC)

C

OUT2

(BULK)

C

COMP

VENDORS PART NUMBER

OUT2

C3 VIN

(V)

DROOP

(mV)

PEAK TO PEAK

(mV)

RECOVERY TIME

(µs)

LOAD STEP

(A/µs)

PRERELEASE

4600p

11

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

After the controller has been started and given adequate

time to charge up the output capacitor, CSS is used as a

short-circuit timer. After the RUN/SS pin charges above 4V,

if the output voltage falls below 75% of its regulated value,

then a short-circuit fault is assumed. A 1.8µA current then

begins discharging CSS. If the fault condition persists until

the RUN/SS pin drops to 3.5V, then the controller turns

off both power MOSFETs, shuting down the converter

permanently. The RUN/SS pin must be actively pulled

down to ground in order to restart operation.

The over-current protection timer requires the soft-start

timing capacitor CSS be made large enough to guarantee

that the output is in regulation by the time CSS has reached

the 4V threshold. In general, this will depends upon the

size of the output capacitance, output voltage and load

current characteristic. A minimum external soft-start

capacitor can be estimated from:

3

CpFCVFV

SS EXT OUT OUT S_

•([/])+>1000 10

Generally 0.1µF is more than suffi cient.

Since the load current is already limited by the current

mode control and current foldback circuitry during a

shortcircuit, over-current latchoff operation is NOT always

needed or desired, especially the output has large amount

of capacitance or the load draw huge current during start

up. The latchoff feature can be overridden by a pull-up

current greater than 5µA but less than 80µA to the RUN/SS

pin. The additional current prevents the discharge of CSS

during a fault and also shortens the soft-start period. Using a resistor from RUN/SS pin to V

–

is a simple solution

IN

to defeat latchoff. Any pull-up network must be able to

maintain RUN/SS above 4V maximum latchoff threshold

and overcome the 4µA maximum discharge current. Figure

3 shows a conceptual drawing of V

during startup and

RUN

short circuit.

V

RUN/SS

4V

3V

1.5V

SOFT-START

CLAMPING

RELEASED

OF I

L

SWITCHING

STARTS

Figure 3. RUN/SS Pin Voltage During Startup and

Short-Circuit Protection

Figure 4. Defeat Short-Circuit Latchoff with a Pull-Up

Resistor to V

SHORT-CIRCUIT

LATCH ARMED

V

IN

500k

IN

V

O

V

IN

LTM4600

RUN/SS

PGND SGND

OUTPUT

OVERLOAD

HAPPENS

4600 F04

SHORT-CIRCUIT

LATCHOFF

75%V

O

3.5V

t

t

4600 F03

12

4600p

PRERELEASE

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

Enable

The RUN/SS pin can be driven from logic as shown in

Figure 5. This function allows the LTM4600 to be turned

on or off remotely. The ON signal can also control the

sequence of the output voltage.

RUN/SS

PGND

RAMP

FB1

STATUS

SDO

FB2

LTM4600

SGND

3.3V

4600 F05

V

49.9k

V

66.5k

4600 F06

V

V

LTM4600

OSET

V

V

LTM4600

OSET

IN

IN

V

1.8V

OUT

IN

IN

V

1.5V

OUT

ON

2N7002

Figure 5. Enable Circuit with External Logic

Output Voltage Tracking

For the applications that require output voltage tracking,

several LTM4600 modules can be programmed by the

power supply tracking controller such as the LTC2923.

Figure 6 shows a typical schematic with LTC2923. Coin-

V

GATE

CC

ON

LTC2923

RAMPBUF

TRACK1

TRACK2

Q1

GND

V

IN

DC/DC

5V

R

ONB

R

ONA

R

TB1

R

TA1

TB2

R

TA2

R

Figure 6. Output Voltage Tracking with the LTC2923 Controller

cident, ratiometric and offset tracking for VO rising and

falling can be implemented with different sets of resistor

values. See the LTC2923 data sheet for more details.

EXTV

Connection

CC

An internal low dropout regulator produces an internal 5V

supply that powers the control circuitry and FET drivers.

Therefore, if the system does not have a 5V power rail,

the LTM4600 can be directly powered by V

. The gate

IN

driver current through LDO is about 18mA. The internal

LDO power dissipation can be calculated as:

P

LDO_LOSS

= 18mA • (VIN – 5V)

The LTM4600 also provides an external gate driver voltage pin EXTV

recommended to connect EXTV

rail. Whenever the EXTV

. If there is a 5V rail in the system, it is

CC

pin to the external 5V

CC

pin is above 4.7V, the internal

CC

5V LDO is shut off and an internal 50mA P-channel switch

connects the EXTV

from EXTV

until this pin drops below 4.5V. Do not apply

CC

more than 6V to the EXTV

. The following list summaries the possible connec-

< V

IN

tions for EXTV

1. EXTV

grounded. Internal 5V LDO is always powered

CC

to internal 5V. Internal 5V is supplied

CC

pin and ensure that EXTVCC

CC

:

CC

from the internal 5V regulator.

2. EXTV

connected to an external supply. Internal LDO

CC

is shut off. A high effi ciency supply compatible with the

MOSFET gate drive requirements (typically 5V) can improve overall effi ciency. With this connection, it is always

required that the EXTV

pin voltage.

V

IN

voltage can not be higher than

CC

Discontinuous Operation and FCB Pin

The FCB pin determines whether the internal bottom

MOSFET remains on when the inductor current reverses.

There is an internal 4.75k pulling down resistor connecting

this pin to ground. The default light load operation mode

is forced continuous (PWM) current mode. This mode

provides minimum output voltage ripple.

PRERELEASE

4600p

13

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

In the application where the light load effi ciency is important, tying the FCB pin above 0.6V threshold enables

discontinuous operation where the bottom MOSFET turns

off when inductor current reverses. Therefore, the conduction loss is minimized and light load effi cient is improved.

The penalty is that the controller may skip cycle and the

output voltage ripple increases at light load.

Paralleling Operation with Load Sharing

Two or more LTM4600 modules can be paralleled to provide

higher than 10A output current. Figure 7 shows the necessary interconnection between two paralleled modules. The

OPTI-LOOP™ current mode control ensures good current

sharing among modules to balance the thermal stress.

The new feedback equation for two or more LTM4600s

in parallel is:

k

100

VV

=+06

OUT

.•

where N is the number of LTM4600s in parallel.

V

IN

Figure 7. Parallel Two µModules with Load Sharing

OPTI-LOOP is a trademark of Linear Technology Corporation.

V

IN

PGND SGNDCOMP

V

IN

PGND

N

R

SET

R

SET

LTM4600

V

OSET

OSET

LTM4600

V

OUT

R

SET

SGNDCOMP V

V

OUT

4600 F07

V

OUT

(20A

MAX

)

Thermal Considerations and Output Current Derating

The power loss curves in Figures 8 and 13 can be used

in coordination with the load current de-rating curves in

Figures 9 to 12 and Figures 14 to 15 for calculating an

approximate θ

for the module. Each of the load current

JA

de-rating curves will lower the maximum load current

as a function of the increased ambient temperature to

keep the maximum junction temperature of the power

module at 100°C maximum. This 100°C maximum is to

allow for an increased rise of about 15°C to 20°C inside

the module. This will maintain the maximum operating

temperature to below 125°C. Each of the de-rating curves

and the power loss curve that corresponds to the correct

output voltage can be used to solve for the approximate

of the condition. Each Figure has three curves that are

θ

JA

taken at three different air fl ow conditions. For example

in Figure 9, the 10A load current can be achieved up to

60°C ambient temperature with no air fl ow. If this 60°C

is subtracted from the maximum module temperature

of 100°C, then 40°C is the maximum temperature rise.

Now Figure 8 records the power loss for this 5V to 1.5V

at the 10A output. If we take the 40°C rise and divided it

by the 3 watts of loss, then we get an approximate θ

JA

of 13.5°C/W with no heatsink. If we take the next air fl ow

curve in Figure 9 at 200LFM of air fl ow, then the maximum

ambient temperature allowed at 10A load current is 65°C.

This calculates to a 35°C rise, and an approximate θ

JA

of

11.6°C/W with no heatsink. In the next air fl ow curve at

400LFM in Figure 9, the maximum ambient temperature

allowed at 10A load current is 73°C. This calculates to

a 27°C rise, and an approximate θ

of 9°C/W with no

JA

heatsink. Each of the de-rating curves in Figures 9 to

12 or Figures 14 to 15 can be used with the appropriate

power loss curve in either fi gure 8 or fi gure 13 to derive

an approximate θ

for Figures 9 to 12, and Figures 14 to 15. A complete

θ

JA

. Table 3 and 4 provide the approximate

JA

explanation of the thermal characteristics is provided in

the thermal application note for the LTM4600.

14

4600p

PRERELEASE

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

4.5

4.0

3.5

3.0

2.5

2.0

1.5

POWER LOSS (W)

1.0

0.5

0

086

Figure 8. Power Loss vs Load Current

10

9

VIN = 5V

= 1.5V

V

O

12V LOSS

24 10

OUTPUT CURRENT (A)

5V LOSS

4600 F08

10

9

VIN = 5V

= 1.5V

V

O

8

7

6

MAXIMUM LOAD CURRENT (A)

5

0 LFM

200 LFM

400 LFM

4

50 70

60 80 90

AMBIENT TEMPERATURE (°C)

Figure 9. No Heatsink

10

9

8

7

6

MAXIMUM LOAD CURRENT (A)

5

0 LFM

200 LFM

400 LFM

4

50 55 70

60 65 75 80 85 90

AMBIENT TEMPERATURE (°C)

4600 F09

VIN = 12V

= 1.5V

V

O

4600 F11

8

7

6

MAXIMUM LOAD CURRENT (A)

5

0 LFM

200 LFM

400 LFM

4

50

70

60 80 90 100

AMBIENT TEMPERATURE (°C)

Figure 10. BGA Heatsink

10

VIN = 12V

= 1.5V

V

O

9

8

7

6

5

MAXIMUM LOAD CURRENT (A)

0 LFM

4

200 LFM

400 LFM

3

50

70

60

AMBIENT TEMPERATURE (°C)

4600 F10

80 90 100

4600 F12

Figure 11. No Heatsink

PRERELEASE

Figure 12. BGA Heatsink

4600p

15

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

5.0

4.5

4.0

3.5

3.0

2.5

2.0

POWER LOSS (W)

1.5

1.0

0.5

0

086

Figure 13. Power Loss vs Load Current

10

9

8

7

6

5

4

3

2

MAXIMUM LOAD CURRENT (A)

0 LFM

200 LFM

1

400 LFM

0

40 70

6050 80 90

AMBIENT TEMPERATURE (°C)

VIN = 12V

= 3.3V

V

O

4600 F14

12V LOSS

24 10

OUTPUT CURRENT (A)

4600 F13

10

VIN = 12V

= 3.3V

V

O

9

8

7

6

MAXIMUM LOAD CURRENT (A)

5

4

40 50

0 LFM

200 LFM

400 LFM

70

60 80 90 100

AMBIENT TEMPERATURE (°C)

4600 F15

16

Figure 14. No Heatsink

Figure 15. BGA Heatsink

4600p

PRERELEASE

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

Table 3. 1.5V Output

DE-RATING CURVE VIN (V) POWER LOSS CURVE AIR FLOW (LFM) HEATSINK* θJA (°C/W)

Figures 9, 11 5, 12 Figure 8 0 None 13.5

Figures 9, 11 5, 12 Figure 8 200 None 11

Figures 9, 11 5, 12 Figure 8 400 None 9

Figures 10, 12 5, 12 Figure 8 0 BGA Heatsink 9.5

Figures 10, 12 5, 12 Figure 8 200 BGA Heatsink 6.25

Figures 10, 12 5, 12 Figure 8 400 BGA Heatsink 4.5

Table 4. 3.3V Output

DE-RATING CURVE VIN (V) POWER LOSS CURVE AIR FLOW (LFM) HEATSINK* θJA (°C/W)

Figure 14 12 Figure 8 0 None 13.5

Figure 14 12 Figure 8 200 None 11.6

Figure 14 12 Figure 8 400 None 10.4

Figure 15 12 Figure 8 0 BGA Heatsink 9.5

Figure 15 12 Figure 8 200 BGA Heatsink 6

Figure 15 12 Figure 8 400 BGA Heatsink 4.77

*Heatsink manufacturer: Wakefi eld Engineering #CiS20069

PRERELEASE

4600p

17

LTM4600

U

WUU

APPLICATIO S I FOR ATIO

Safety Considerations

The LTM4600 modules do not provide isolation from V

. There is no internal fuse. If required, a slow blow fuse

V

OUT

with a rating twice the maximum input current should be

provided to protect each unit from catastrophic failure.

Layout Checklist/Example

The high integration of the LTM4600 makes the PCB board

layout very simple and easy. However, to optimize its electrical and thermal performance, some layout considerations

are still necessary.

• Use large PCB copper areas for high current path, including V

, PGND and V

IN

. It helps to minimize the

OUT

PCB conduction loss and thermal stress

• Place high frequency ceramic input and output capacitors next to the V

, PGND and V

IN

pins to minimize

OUT

high frequency noise

• Place a dedicated power ground layer underneath the

unit

• To minimize the via conduction loss and reduce module

thermal stress, use multiple vias for interconnection

between top layer and other power layers

IN

to

• Do not put via directly on pad

• Use a separated SGND ground copper area for components connected to signal pins. Connect the SGND

to PGND underneath the unit

Figure 16 gives a good example of the recommended

layout.

V

IN

C

IN

PGND

V

OUT

LOAD

TOP LAYER

Figure 16. Recommended PCB Layout

4600 F16

18

4600p

PRERELEASE

TYPICAL APPLICATIO

V

IN

5V TO 20V

GND

+

C1

150µF

C3

100pF

V

OUT

R1

66.5k

REFER TO

TABLE 2

Figure 17. Typical Application, 5V to 20V Input, 0.6V to 5V Output, 10A Max

U

C4

OPT

C

IN

10µF

2x

EXTV

SV

IN

F

ADJ

V

OSET

COMP

FCB

PGOOD

SGND

CC

V

IN

(MULTIPLE PINS)

(MULTIPLE PINS)

LTM4600

PGND

(MULTIPLE PINS)

V

OUT

RUN/SS

C2

22µF

6.3V

×3

REFER TO

TABLE 2

4600 F20

C

OUT

470µF

REFER TO

TABLE 2

0.6V TO 5V

LTM4600

V

OUT

GND

PRERELEASE

4600p

19

LTM4600

TYPICAL APPLICATIO

U

Parallel Operation and Load Sharing

C8

10µF

25V

RUN/SOFT-START

C3

10µF

25V

C7

10µF

25V

C1

10µF

25V

4.5V TO 20V

EXTV

FCB

RUN

COMP

EXTV

FCB

RUN

COMP

CC

CC

V

IN

LTM4600

V

IN

LTM4600

V

= 0.6V • ([100k/N] + R

OUT

WHERE N = 2

F

SET

V

OUT

FB

SV

IN

PGOOD

PGNDSGND

F

SET

V

OUT

FB

SV

IN

PGOOD

PGNDSGND

4600 F17

2.5V

R4

15.8k

1%

C4

220pF

2.5V

R1

100k

C1, C3, C7, C8: TDK C3216X5R1E106MT

C2, C9: TAIYO YUDEN, JMK316BJ226ML-T501

C5, C10: SANYO POS CAP, 4TPE470MCL

C9

22µF

x3

C2

22µF

x3

SET

)/R

SET

C10

470µF

4V

C5

470µF

4V

2.5V AT 20A

Current Sharing Between Two

LTM4600 Modules

12

12V

IN

2.5V

OUT

20A

10

MAX

8

6

4

INDIVIDUAL SHARE

2

0

0

5

I

OUT2

10 15 20

TOTAL LOAD

I

OUT1

25

4600 F18

4600p

20

PRERELEASE

PACKAGE DESCRIPTIO

LTM4600

U

aaa Z

LGA Package

104-Lead (15mm × 15mm)

(Reference LTM DWG # 05-05-1800)

6.9865

4.4442

1.9042

0.0000

1.9058

4.4458

5.7142

3.1742

0.6342

0.6358

3.1758

5.7158

6.9421

Y

X

15

BSC

15

BSC

TOP VIEW

aaa Z

PAD 1

CORNER

4

0.15

0.10

0.15

TOLERANCE

2.72 – 2.92

0.27 – 0.37

SUBSTRATE

CAP

MOLD

20

21

19

1817

16

11

7

10

6

9

13 14 15

5

4

5.7650

4.4950

3

2

1

8

24

23

22

28 29 30 31

27

26

2.3600

32

12

25

38

37

36

35

33 34

1.0900

60

49

59

48

58

47

57

46

56

45

55

44

54

53

42 43

52

41

40

51

39

50

82

71

81

70

68 69

78 79 80

67

77

66

65

64

74 75 76

63

62

73

61

72

Z

DETAIL B

bbb Z

2.45 – 2.55

93

92

89 90 91

88

84 85 86 87

83

6.3500

104

3.8100

1.2700

0.3175

0.3175

99 100 101 102 103

1.2700

3.8100

95 96 97 98

6.3500

94

DETAIL B

3

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M-1994

2. ALL DIMENSIONS ARE IN MILLIMETERS

3

R

T

93

104

92

99 100 101 102 103

5.0800

2.5400

0.0000

12.70

NOTES:

PADS

SEE NOTES

BSC

TOP VIEW

2.5400

SUGGESTED SOLDER PAD LAYOUT

5.0800

84 85 86 87 88 89 90 91

95 96 97 98

94

83

DETAILS OF PAD #1 IDENTIFIER ARE OPTIONAL,

BUT MUST BE LOCATED WITHIN THE ZONE INDICATED.

THE PAD #1 IDENTIFIER IS A MARKED FEATURE OR A

NOTCHED BEVELED PAD

4

LAND DESIGNATION PER JESD MO-222, SPP-010

P

82

81

74 75 76 77 78 79 80

73

72

5. PRIMARY DATUM -Z- IS SEATING PLANE

L

M

N

71

60

49

70

59

48

42 43 44 45 46 47

63 64 65 66 67 68 69

52 53 54 55 56 57 58

41

40

51

62

39

50

61

aaa

eee

bbb

SYMBOL

6. THE TOTAL NUMBER OF PADS: 104

FGH

K

J

24

23

22

26 27 28 29 30 31

33 34 35 36 37 38

32

12

25

ABCDE

20

21

1918171676543

11109

13 14 15

2

1

8

YXeee

4600 02-18

M

23

19 21

18 20 22

15 17

14 16

13.93

11 13

10 12

79

68

35

24

1

BSC

BOTTOM VIEW

6.9888

6.5475

5.2775

4.0075

2.7375

1.4675

0.3175

0.0000

0.3175

1.2700

2.5400

5.7150

4.4450

6.9850

PRERELEASE

0.11 – 0.27

13.97

BSC

PAD 1

C(0.30)

21

4600p

LTM4600

PACKAGE DESCRIPTIO

PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME

A1 - B1 V

A2 - B2 - C2 - D2 - E2 - F2 - G2 - H2 A3 V

IN

A4 - B4 - C4 - D4 - E4 - F4 - G4 - H4 A5 V

IN

A6 - B6 - C6 - D6 - E6 - F6 - G6 - H6 A7 V

IN

A8 - B8 - C8 - D8 - E8 - F8 - G8 - H8 A9 V

IN

A10 - B10 - C10 V

A11 V

IN

A12 - B12 - C12 V

A13 V

IN

A14 - B14 - C14 V

A15 FADJ B15 - C15 - D15 - E15 - F15 - G15 - H15 PGND

A16 - B16 - C16 - D16 - E16 - F16 - G16 - H16 A17 SV

IN

A18 - B18 - C18 - D18 - E18 - F18 - G18 - H18 A19 EXTVCCB19 - C19 - D19 - E19 - F19 - G19 - H19 A20 - B20 - C20 - D20 - E20 - F20 - G20 - H20 A21 V

OSET

A22 - B22 - C22 - D22 - E22 - F22 - G22 - H22 A23 - B23 COMP C23 - D23 SGND E23 - F23 RUN/SS G23 FCB H23 -

IN

B3 - C3 - D3 - E3 - F3 - G3 - H3 -

B5 - C5 - D5 - E5 - F5 - G5 - H5 -

B7 - C7 - D7 - E7 - F7 - G7 - H7 PGND

B9 - C9 - D9 - E9 - F9 - G9 - H9 PGND

B11 - C11 - D11 - E11 - F11 - G11 - H11 PGND

B13 - C13 - D13 - E13 - F13 - G13 - H13 PGND

B17 - C17 - D17 - E17 - F17 - G17 - H17 PGND

B21 - C21 - D21 - E21 - F21 - G21 - H21 -

U

Pin Assignment Tables

(Arranged by Pin Number)

C1 - D1 V

D10 - E10 V

IN

D12 - E12 V

IN

D14 - E14 V

IN

E1 - F1 V

IN

G1 PGND H1 -

IN

F10 - G10 - H10 -

IN

F12 - G12 - H12 -

IN

F14 - G14 - H14 -

IN

PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME PIN NAME

J1 PGND K1 - L1 - M1 - N1 - P1 - R1 - T1 J2 - K2 - L2 PGND M2 PGND N2 PGND P2 V

OUT

R2 V

OUT

T2 V

J3 - K3 - L3 - M3 - N3 - P3 - R3 - T3 J4 - K4 - L4 PGND M4 PGND N4 PGND P4 V

OUT

R4 V

OUT

T4 V

J5 - K5 - L5 - M5 - N5 - P5 - R5 - T5 J6 - K6 - L6 PGND M6 PGND N6 PGND P6 V

OUT

R6 V

OUT

T6 V

J7 - K7 PGND L7 - M7 - N7 - P7 - R7 - T7 J8 - K8 L8 PGND M8 PGND N8 PGND P8 V

OUT

R8 V

OUT

T8 V

J9 - K9 PGND L9 - M9 - N9 - P9 - R9 - T9 J10 - K10 L10 PGND M10 PGND N10 PGND P10 V

OUT

R10 V

OUT

T10 V

J11 - K11 PGND L11 - M11 - N11 - P11 - R11 - T11 J12 - K12 - L12 PGND M12 PGND N12 PGND P12 V

OUT

R12 V

OUT

T12 V

J13 - K13 PGND L13 - M13 - N13 - P13 - R13 - T13 J14 - K14 - L14 PGND M14 PGND N14 PGND P14 V

OUT

R14 V

OUT

T14 V

J15 - K15 PGND L15 - M15 - N15 - P15 - R15 - T15 J16 - K16 - L16 PGND M16 PGND N16 PGND P16 V

OUT

R16 V

OUT

T16 V

J17 - K17 PGND L17 - M17 - N17 - P17 - R17 - T17 J18 - K18 - L18 PGND M18 PGND N18 PGND P18 V

OUT

R18 V

OUT

T18 V

J19 - K19 - L19 - M19 - N19 - P19 - R19 - T19 J20 - K20 - L20 PGND M20 PGND N20 PGND P20 V

OUT

R20 V

OUT

T20 V

J21 - K21 - L21 - M21 - N21 - P21 - R21 - T21 J22 - K22 - L22 PGND M22 PGND N22 PGND P22 V

OUT

R22 V

OUT

T22 V

J23 PGOOD K23 - L23 - M23 - N23 - P23 - R23 - T23 -

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

22

4600p

PRERELEASE

PACKAGE DESCRIPTIO

LTM4600

U

Pin Assignment Tables

(Arranged by Pin Number)

PIN NAME

G1 PGND

H7

H9

H11

H13

H15

H17

PGND

PGND

PGND

PGND

PGND

PGND

J1 PGND

K7

K9

K11

K13

K15

K17

L2

L4

L6

L8

L10

L12

L14

L16

L18

L20

L22

M2

M4

M6

M8

M10

M12

M14

M16

M18

M20

M22

N2

N4

N6

N8

N10

N12

N14

N16

N18

N20

N22

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

P2

P4

P6

P8

P10

P12

P14

P16

P18

P20

P22

R2

R4

R6

R8

R10

R12

R14

R16

R18

R20

R22

T2

T4

T6

T8

T10

T12

T14

T16

T18

T20

T22

PIN NAME

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

PIN NAME

A3

A5

A7

A9

A11

A13

B1 V

C10

C12

C14

D1 V

E10

E12

E14

F1 V

PIN NAME

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

IN

V

IN

V

IN

V

IN

IN

V

IN

V

IN

V

IN

IN

A15 FADJ

A17 SV

A19 EXTV

A21 V

IN

CC

OSET

B23 COMP

D23 SGND

F23 RUN/SS

G23 FCB

J23 PGOOD

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

no responsibility is assumed for its use. Linear Technology Corporation makes no representation that

the interconnection of its circuits as described herein will not infringe on existing patent rights.

PRERELEASE

However,

4600p

23

LTM4600

1.8V, 10A R

TYPICAL APPLICATIO

C2

10µF

25V

U

4.5V AT 20V

C1

10µF

25V

EXTV

FCB

RUN

COMP

CC

V

IN

LTM4600

egulator

C5

F

SET

V

OUT

FB

SV

IN

PGOOD

PGNDSGND

4600 F19

100pF

49.9k

1%

1.8V AT 10A

C3

R1

100k

R2

C1, C2: TDK C3216X5R1E106MT

C3: TAIYO YUDEN, JMK316BJ226ML-T501

C4: SANYO POS CAP, 4TPE470MCL

22µF

x3

PGOOD

C4

470µF

4V

24

This product contains technology licensed from Silicon Semiconductor Corporation.

PRE-RELEASE

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

PRERELEASE

®

4600p

LT 1105 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...