Page 1

LINEAR TECHNOLOGY

SERVICE SWITCH

LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

MARCH 2009 VOLUME XIX NUMBER 1

IN THIS ISSUE…

COVER ARTICLE

Battery Stack Monitor

Extends Life of Li-Ion Batteries

in Hybrid Electric Vehicles ..................1

Michael Kultgen and Jon Munson

Linear in the News… ...........................2

DESIGN FEATURES

DC/DC Converter, Capacitor Charger

Takes Inputs from 4.75V to 400V ........9

Robert Milliken and Peter Liu

How to Choose a Voltage Reference ...14

Brendan Whelan

1.2A Monolithic Buck Regulator

Shrinks Supply Size and Cost with

Programmable Output Current Limit

.........................................................20

Tom Sheehan

Boost Converters for Keep-Alive Circuits

Draw Only 8.5μA of Quiescent Current

.........................................................22

Xiaohua Su

Industrial/Automotive Step-Down

Regulator Accepts 3.6V to 36V and

Includes Power-On Reset and Watchdog

Timer in 3mm × 3mm QFN ................24

Ramanjot Singh

Complete APD Bias Solution in 60mm

with On-the-Fly Adjustable Current

Limit and Adjustable V

Xin (Shin) Qi

DESIGN IDEAS

Don’t Want to Hear It? Avoid the Audio

Band with PWM LED Dimming at

Frequencies Above 20kHz ..................30

Eric Young

Eliminate EMI Worries with 2A,

15mm × 9mm × 2.82mm μModule™

Step-Down Regulator ........................33

David Ng

Diode Turn-On Time Induced Failures

in Switching Regulators ....................34

Jim Williams and David Beebe

μModule Regulator Fits a (Nearly)

Complete Buck-Boost Solution in

15mm × 15mm × 2.8mm for

4.5V–36V VIN to 0.8V–34V V

Judy Sun, Sam Young and Henry Zhang

New Device Cameos ...........................41

Design Tools ......................................43

Sales Offices .....................................44

...................27

APD

OUT

2

..........39

Battery Stack Monitor

Extends Life of Li-Ion

Batteries in Hybrid

Electric Vehicles

by Michael Kultgen and Jon Munson

Introduction

The cost of running a car on electricity

is equivalent to paying $0.75/gallon

for gasoline, and if that electricity

comes from carbon neutral sources,

car owners are saving both money

and the environment (gasoline combustion produces 9kg of CO2 per US

gallon). Advancements in battery

technology (see sidebar), especially

with Lithium-based chemistries, hold

the greatest promise for converting

the worldwide fleet of cars to hybrid

or fully electric.

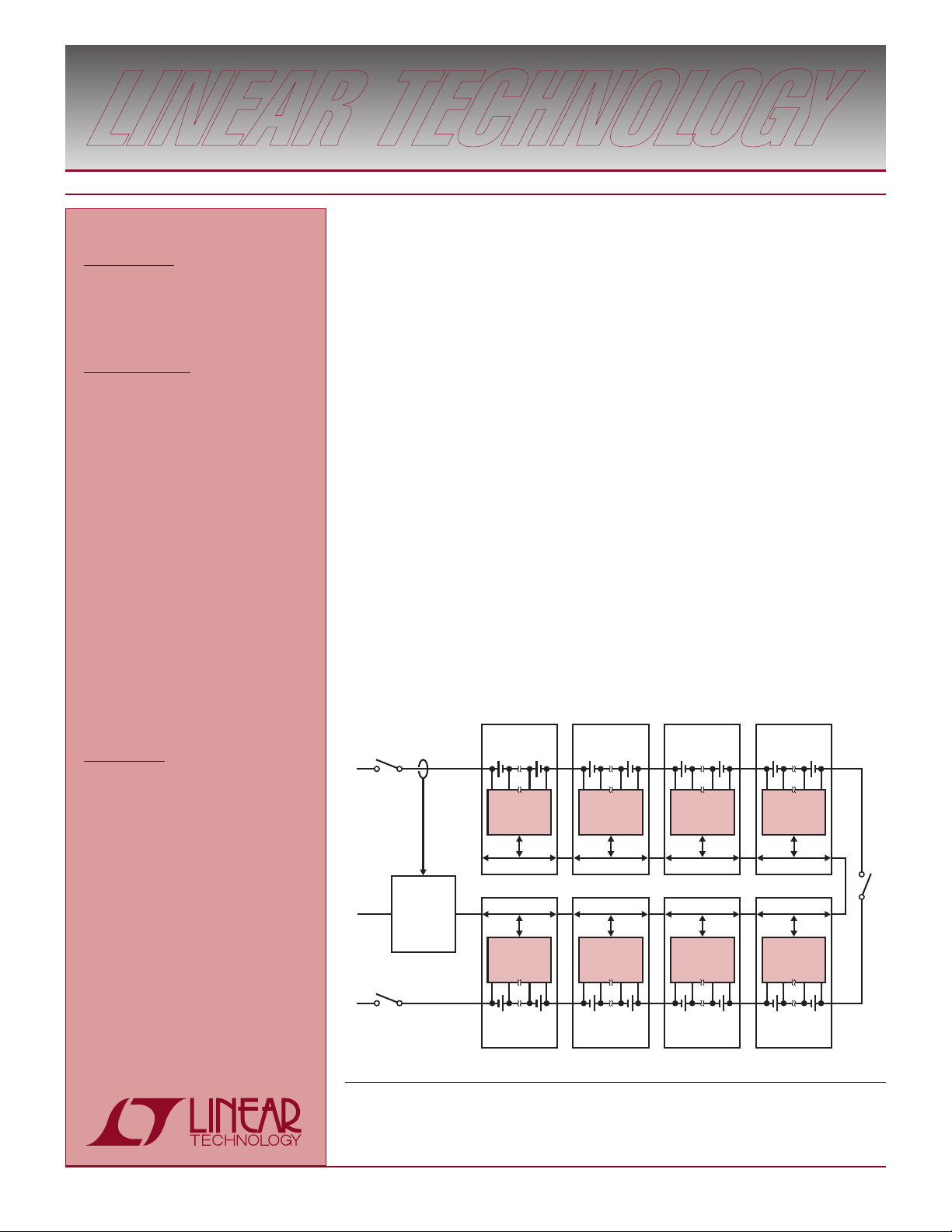

12-CELL BATTERY

MODULE

+

CURRENT

SENSOR

CAN

HOST

CONTROLLER

–

L

, LT, LTC, LTM, Burst Mode, OPTI-LOOP, Over-The-Top and PolyPhase are registered trademarks of Linear Technology

Corporation. Adaptive Power, Bat-Track, BodeCAD, C-Load, DirectSense, Easy Drive, FilterCAD, Hot Swap, LinearView,

µModule, Micropower SwitcherCAD, Multimode Dimming, No Latency ΔΣ, No Latency Delta-Sigma, No R

Filter, PanelProtect, PowerPath, PowerSOT, SmartStart, SoftSpan, Stage Shedding, SwitcherCAD, ThinSOT, TimerBlox, True

Color PWM, UltraFast and VLDO are trademarks of Linear Technology Corporation. Other product names may be trademarks

of the companies that manufacture the products.

+

MONITORING

& BALANCING

SPI

MONITORING

& BALANCING

–

12-CELL BATTERY

BATTERY

DATA BUS

DATA BUS

BATTERY

MODULE

12-CELL BATTERY

MODULE

+

–

BATTERY

MONITORING

& BALANCING

DATA BUS

DATA BUS

BATTERY

MONITORING

& BALANCING

–

+

12-CELL BATTERY

MODULE

Figure 1. 96-cell battery pack

Lithium battery packs offer the

highest energy density of any cur rent battery technology, but high

performance is not guaranteed simply by design. In real world use, a

battery management system (BMS)

makes a significant difference in the

performance and lifetime of Li-Ion

batteries—arguably more so than

the design of the battery itself. The

LTC6802 multicell battery stack

monitor is central to any BMS for the

continued on page 3

–

+

12-CELL BATTERY

MODULE

+

BATTERY

MONITORING

& BALANCING

DATA BUS

DATA BUS

BATTERY

MONITORING

& BALANCING

–

12-CELL BATTERY

MODULE

–

+

12-CELL BATTERY

MODULE

+

BATTERY

MONITORING

& BALANCING

DATA BUS

DATA BUS

BATTERY

MONITORING

& BALANCING

–

12-CELL BATTERY

MODULE

SENSE

–

+

, Operational

Page 2

DESIGN FEATURES L

LTC6802, continued from page 1

large battery stacks common in electric vehicles (EVs) and hybrid electric

vehicles (HEVs). Its robust design and

high accuracy helps guarantee the

performance and lifetime of expensive

battery packs.

lifetime is traded against the need

to use as few kg of batteries as possible—the most expensive component

in any EV. Only a well-designed BMS

can maximize battery performance and

lifetime in the face 200A peak charge

and discharge currents.

For instance, to meet a 15-year,

5000 charge cycle goal, only a portion

(say 40%) of the battery pack’s cellcapacity can be used. Of course, using

only 40% of the capacity essentially

lowers the energy density of the pack.

This is the problem: increasing battery

Battery Management System

Optimizes Li-Ion Run Time

and Lifetime

In any battery stack, the more accurately you know state of charge (SOC)

of each cell, the more cell capacity you

Li-ion Batteries in Electric Vehicles and Hybrids

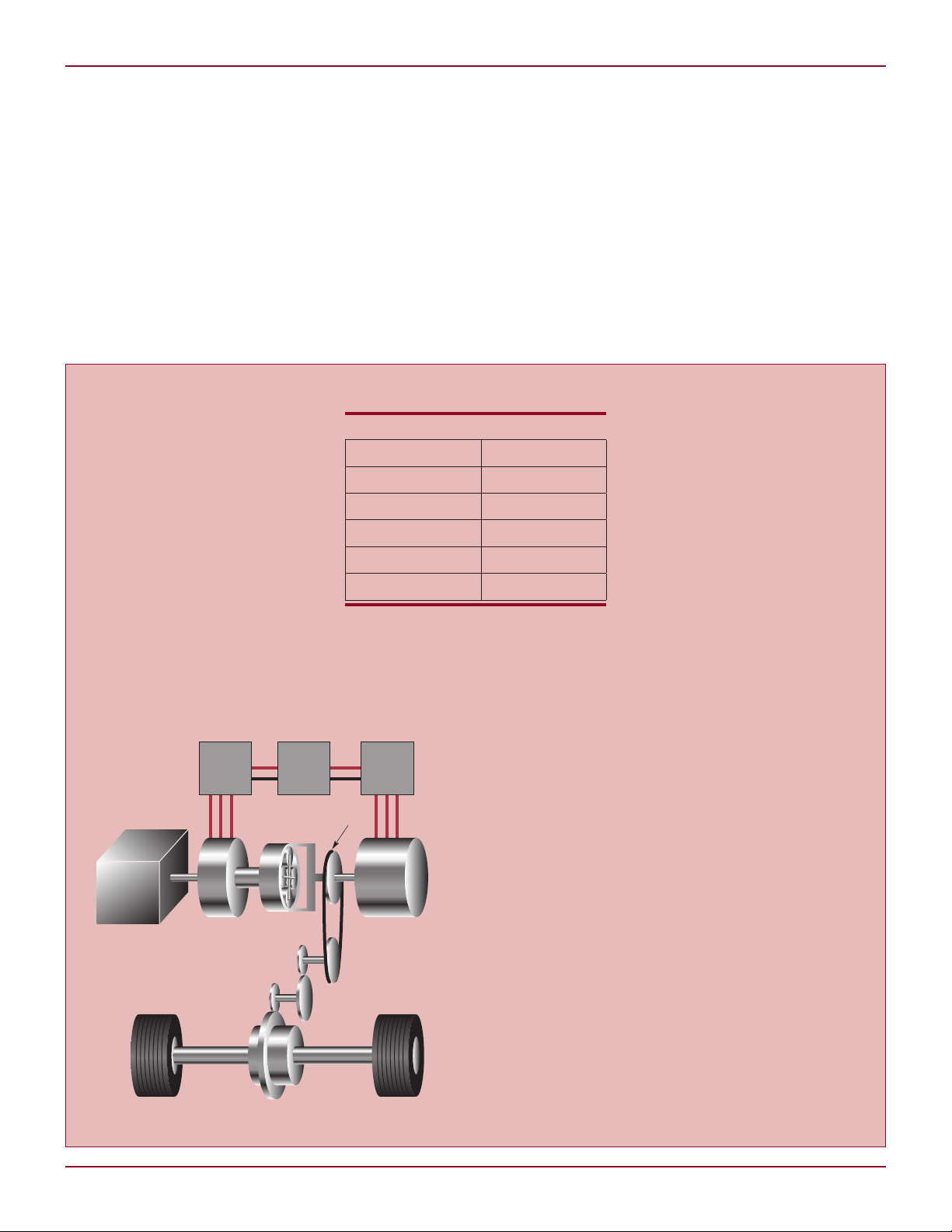

So why aren’t all cars electric? One

reason is energy density. Gasoline

holds 80 times the energy per kg as

Li-ion batteries (Table 1) and refuels

in three minutes, essentially allowing

indefinite driving. Even a big lithium

pack only gives a passenger car

about a 100-miles after an 8-hour

charging cycle. To drive a passenger

car further than 100 miles you still

need a gasoline engine, but even

so, batteries improve gas mileage in

hybrid electric vehicles (HEVs). The peak efficiency of

the Otto cycle engine is only 30% at high RPMs and the

average efficiency is about 12%. Using batteries to supply torque during acceleration and recover joules during

MG1 INVERTER MG2 INVERTERBATTERY

GASOLINE

FRONT

WHEELS

ENGINE

ELECTRIC MOTOR/

GENERATOR 1 (MG1)

AXLES

REDUCTION

GEARS

POWER SPLIT

DEVICE

DIFFERENTIAL

Table 1. Energy density comparison

Medium Wh/kg

Diesel Fuel 12,700

Gasoline 12,200

Li-Ion Battery 150

NiMh Battery 100

Lead Acid Battery 25

Li-ion batteries take energy density another step forward,

by offering another 50% improvement. The safety of Liion was a concern, but new battery technologies like the

A123 nanophosphate cell, the EnerDel Spinel-Titanate

chemistry, the GS Yuasa EH6 design and others are as

safe as NiMh, offer extremely high power (200A peak discharge rates), and last 10 to 15 years with proper charge

management. By model year 2012, the majority of hybrid

cars and trucks will use lithium battery technology.

SILENT

CHAIN

Figure 1 shows a shows a block diagram of the battery pack with a BMS, and Figure 2 shows a typical HEV

power train. The battery pack building block is a 2.5V

to 3.9V, 4Ahr to 40Ahr Li-ion cell. 100 to 200 cells are

connected in series to bring the battery pack voltage into

the hundreds of volts. This DC power source drives a

ELECTRIC MOTOR/

GENERATOR 2 (MG2)

30kW to 70kW electric motor. The pack voltage is high

so that the average current is low for a given power level.

Lower current reduces I2R power losses, so cables can

be smaller, thus reducing weight and cost. The pack

should be able to deliver 200A under peak conditions

and be quickly rechargeable. In other words, the battery

needs to offer high energy density and high power density, specifications that can be met by Li-ion batteries.

Systems for busses and tractor-trailers use up to four

parallel packs of 640V each.

can use while still maximizing cell life.

In a laptop computer, gas gauging

comes from monitoring cell voltage

and counting coulombs in and out of

the stack of four to eight cells. Voltage, current, time and temperature

are combined in a robust algorithm

to give an indication of the SOC. Unfortunately, it’s nearly impossible to

count coulombs in a car. The battery

drives an electric motor, not a motherboard, so it must handle current

spikes of 200A, followed by low level

idling. Furthermore, you have from 96

regenerative braking means the gas

engine runs less often and runs at a

higher efficiency, effectively doubling

the mpg.

In the 1970s the only available high

power battery chemistry was lead

acid, too heavy to reasonably power

anything larger than a golf cart. Then

came NiMh batteries, which improved

energy density enough to enable the

first commercially successful HEVs,

like the Toyota Prius and Ford Escape.

L

Figure 2. Toyota Prius “split power” hybrid drive train

Linear Technology Magazine • March 2009

3

Page 3

L DESIGN FEATURES

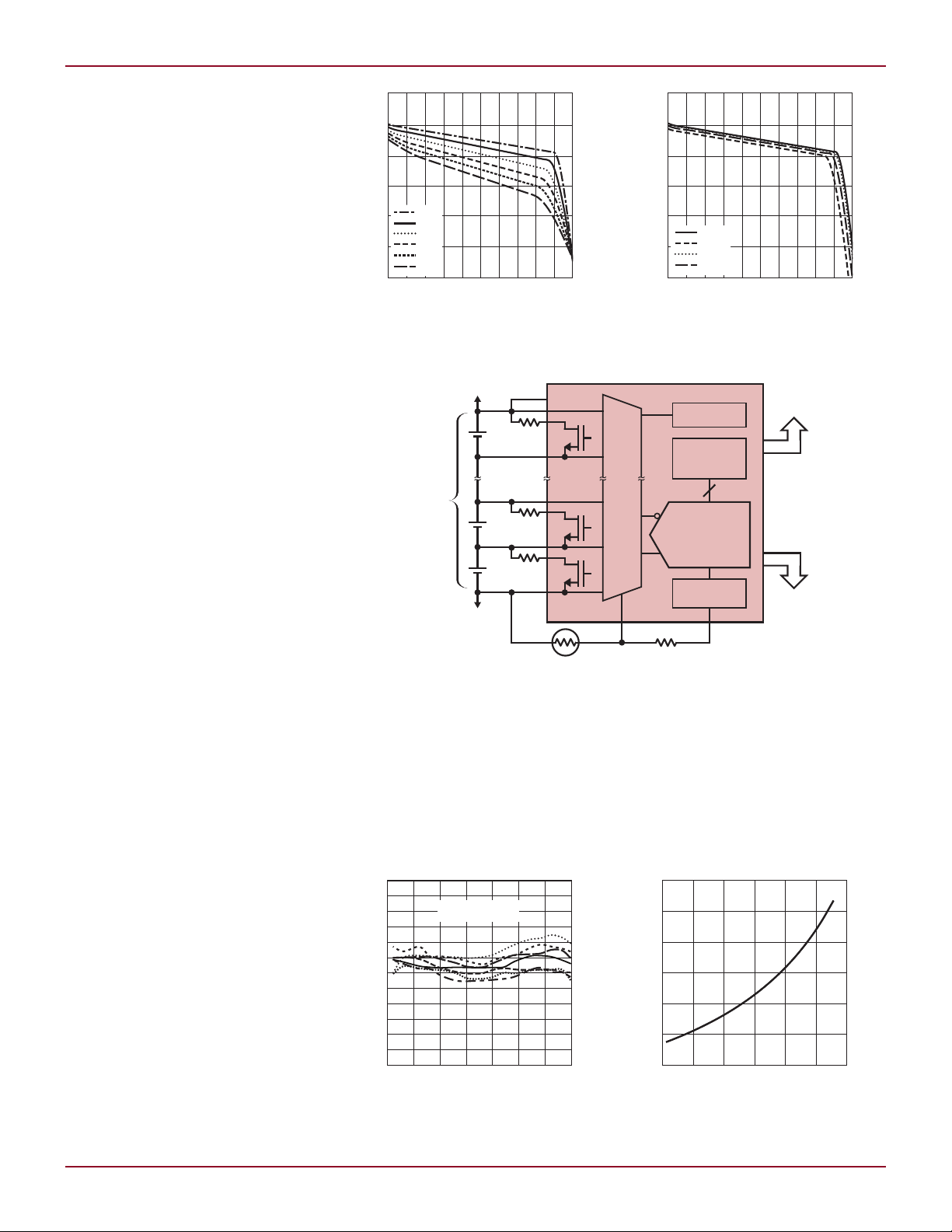

CELL VOLTAGE (V)

CELL VOLTAGE (V)

MEASUREMENT ERROR (%)

0.30

COST OF TYPICAL BATTERY PACK ($)

9k

NEXT 12-CELL

TO LTC6802-1

TO LTC6802-1

to 200 cells in series, in groups of 10

or 12. The cells age at different rates,

were manufactured from multiple lots,

and vary in temperature. Their capacities diverge constantly. Different cells

with the same coulomb count can have

wildly different charge levels.

That’s why the BMS focuses on

cell voltage. If you can accurately

measure the voltage of every cell, you

can know the cell’s SOC with reasonable accuracy (Figure 3). The trick is

to improve the accuracy of the voltage

measurement by taking into account

temperature effects on battery ESR

and capacity. By constantly measuring

each cell’s voltage, you keep a running

estimation of each cell’s charge level.

If some cells are overcharged and

some under, they can be balanced by

bleeding off charge (passive balancing) or redistributing charge (active

balancing).

Accurate Monitoring is Key to

Raising Battery Performance

while Lowering Costs

The LTC6802 (Figure 4) is a precision data acquisition IC optimized for

measuring the voltage of every cell in

a large string series-connected batteries. In the BMS, the LTC6802 does the

heavy lifting analog function, passing

digital voltage and temperature measurements to the host processor for

SOC computation. The LTC6802’s high

accuracy, excellent noise rejection,

high voltage tolerance, and extensive

self-diagnostics make it robust and

easy-to-use. The high level of integration means a substantial cost savings

for customers when compared to

discrete component data acquisition

designs.

Increasing measurement accuracy

reduces battery cost, as illustrated

by the following example. Figure 5

shows the typical performance of the

LTC6802, where 0.1% total error from

–20°C to 60°C translates to 4mV precision for a 3.7V cell. Suppose that to

achieve a 15-year battery lifetime, you

are limited to 40% of a cell’s capacity

per charge cycle, and assume the cell

voltage vs charge level of the battery

is very flat, e.g., 1.25mV/%SOC. A

measurement error of 4mV means the

4

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1C

2C

5C

10C

20C

50C

20 40

0

30 508060 100

10 90

DISCHARGE (%)

Figure 3. State of charge vs current and temperature for a typical Li-ion cell

PACK ABOVE

12-CELL

BATTERY

STRING

NEXT 12-CELL

PACK BELOW

70

+

V

MUX

–

V

100k NTC

Figure 4. Simplified block diagram of the LTC6802

estimation of SOC is accurate to 3%.

The BMS must charge cells to no more

than 37% (40% – 3%) of their capacity

to guarantee the 15-year lifetime.

Now consider a monitor IC with

10mV error over similar conditions.

In this case, the BMS can only use

0.25

0.20

0.15

0.10

0.05

0

–0.05

–0.10

–0.15

–0.20

–0.25

–0.30

Figure 5. Typical measurement accuracy

vs temperature of seven samples

7 REPRESENTATIVE

UNITS

–25 0 25 50 75 100

TEMPERATURE (°C)

125–50

4.5

4.0

3.5

3.0

2.5

–20°C

2.0

1.5

EXTERNAL

TEMP

0°C

30°C

60°C

20 40

0

100k

30 508060 100

10 90

DISCHARGE (%)

LTC6802-1

DIE TEMP

REGISTERS

AND

CONTROL

12-BIT

∆∑ ADC

VOLTAGE

REFERENCE

SERIAL DATA

SERIAL DATA

70

ABOVE

BELOW

32% (40% – 10mV • 1%/1.25mV) of

the cells’ capacity and still guarantee a

15-year life. This seemingly negligible

increase in measurement error results

in a significant 14% reduction in the

usable capacity. That is, a vehicle

requires least 14% more batteries, or

8k

7k

6k

5k

4k

3k

Figure 6. High BMS accuracy is important to

keeping battery costs in check, as shown in

this cost vs measurement error model.

10 15

5

MEASUREMENT ERROR (mV)

Linear Technology Magazine • March 2009

20 25

300

Page 4

DESIGN FEATURES L

0

REJECTION (dB)

0

REJECTION (db)

10M

CELL12

CELL1

100Ω

LTC6802-1

TP0610K

0 = REF_EN

GPIO2

0 = CELL1

GPIO1

WDTB

1M

V

REG

−

V

C1

TP0610K

Figure 7. Improving accuracy with calibration

1µF

1M

2N7002

150Ω

100nF

TP0610K

2.2M

1M 10M

2N7002

TP0610K

at least 14% more weight, cost and

electronics to travel an equivalent

distance as a vehicle with the more

accurate BMS. Batteries are expensive. It takes about $4000 worth of

batteries to drive 50 miles, so the

increased measurement error means

$560 in additional cells. This is why

BMS designers scrutinize every 0.01%

of measurement error. Figure 6 shows

a simple battery cost model as a function of BMS accuracy.

Adding a low drift reference, an initial factory calibration, and a periodic

self-calibration routine can improve

the measurement accuracy of the

LTC6802 to 0.03%. For example, in

Figure 7 the LT1461A-4 is periodically

applied to channel C1. The temperature stable LT1461 measurement is

used to correct temperature drift in

the LTC6802. The initial error of the

LTC6802 and LT1461A is corrected by

measuring and storing a calibration

reference after board assembly.

Inverter noise can seriously interfere with cell voltage measurements.

When a 100-cell stack is loaded by an

electric motor it can have a 370V open

circuit voltage and up to 100V switching transients (Figure 8). Spreading

the transient equally over the 100 cells

means the top cell has 370V of common mode voltage, 100V of common

mode transients, 1V of differential

transients and an average DC value

1M

V

STACK12

LT1461A-4

DNC

DNC

V

DNC

90.9k

IN

V

SD

OUT

GND

DNC

+

LT1636

SD

–

1M

2.2µF

4.096V

DD

SELCH1CH0V

TC4W53FU

VSSVEEINHCOM

of 3.7V, which we need to measure

to 4mV. Breaking the battery stack

into 12-cell modules further reduces

The LTC6802’s 0.1% total

measurement error from

–20°C to 60°C translates to

4mV precision for a 3.7V cell.

Batteries are expensive. It

takes about $4000 worth

of batteries to drive 50

miles, so just increasing

measurement error to 10mV

means $560 in additional

cells. This is why BMS

designers scrutinize every

0.01% of measurement error.

V

= 5V

CM(IN)

72dB REJECTION

–10

CORRESPONDS TO

LESS THAN 1 BIT

AT ADC OUTPUT

–20

–30

–40

–50

–60

–70

10 10k

P-P

1M100k1k100

FREQUENCY (Hz)

Figure 9. Cell measurement

common mode rejection

370V

Figure 8. Inverter noise example

6µs

270V

10kHz

the common mode voltage. In a pack

like Figure 2, each LTC6802 (one

per module) sees up to 12V common

mode transients and 1V differential

transients per cell. The transients

are at the PWM frequency of 10kHz

to 20kHz. The LTC6802 has excellent

common mode rejection (Figure 9) to

eliminate this error term. The SINC2

filter inherent in the delta-sigma ADC

attenuates the differential noise by

40dB (Figure 10). External filtering or

measurement averaging can be used to

further reduce the differential noise.

Diagnostic Features of the

LTC6802 Improve Robustness

Automotive systems require that “no

bad cell reading be misinterpreted

as a good cell reading.” Two of the

more common faults that can cause

false readings are open circuits and

IC failures. If there is an open circuit

in the wiring harness and if there is

a filter capacitor on the ADC input

(Figure 11), the capacitor will tend

to hold the input voltage at a point

midway between the adjacent cells.

Some type of open wire detection or

cell resistance measuring function

is necessary. The LTC6802 includes

100µA current sources to load the cell

inputs. The current source will cause

large changes in cell readings if there

is an open circuit in the harness.

–10

–20

–30

–40

–50

–60

–70

10 10k 100k1k100

Figure 10. Cell measurement filtering

FREQUENCY (Hz)

Linear Technology Magazine • March 2009

5

Page 5

L DESIGN FEATURES

The host controller must be able

to run diagnostics on all the modules

during normal operation to detect IC

failures. If these periodic self-tests fail,

then the control algorithm is suspect

and the battery pack must be taken off

line. The LTC6802 includes a built-in

self-test in combination with external

support circuits to allow the BMS to

completely verify the data acquisition

system. See the LTC6802 data sheets

for more details.

The LTC6802 Isolates

Communications from

Swings in Ground Potential

Breaking a ~100 cell pack into modules makes it easier to integrate the

analog circuits. Unfortunately, we are

left with the task of getting the data

from measurement IC to the host controller when the difference in ground

potential exceeds 300V. The LTC6802

can solve this problem in a number of

ways, depending on the specific needs

of the application.

The LTC6802 comes in two flavors,

depending on the desired data communication scheme. The LTC6802-1

offers a built-in stackable serial

peripheral interface (SPI) solution

designed for easy daisy chaining of the

interface. The addressable LTC6802-2

is designed for bus-oriented (parallel)

SPI communication, but it can also be

used in a parallel-addressable, daisy

chained interface for a robust and rela-

C4

B4

B3

C

F4

C

F3

Figure 11. Current sources help detect open circuits.

C3

C2

C1

–

V

tively inexpensive solution. All three

schemes are described below.

SPI Bus Communication with

the Addressable LTC6802-2

and Digital Isolators

The most straightforward approach is

to use a bus communications scheme,

with a digital isolator between each

module and the host controller. Figure 12 shows a 96-cell pack using

eight multicell modules monitored

by the LTC6802. The physical layer

is a 4-wire SPI bus. An addressing

scheme allows the control module to

talk to the battery modules separately

or in unison. The data buses on the

modules are isolated from one another.

This is a robust scheme, but it has

one major drawback: digital isolators

are expensive and require an isolated

LTC6802-1

MUX

100µA

power supply so that the battery cells

don’t have to provide the power to the

cell side of the isolator.

Daisy Chaining the SPI Interface

with the LTC6802-1

The LTC6802-1 provides fixed 1mA

signaling between stacked devices to

enable easy implementation a daisy

chained SPI interface with inexpensive

support circuitry. The digital isolators

are eliminated as shown in Figure 13.

The interface exploits the fact that the

positive supply of module “N” is the

same voltage as the ground of module

“N+1.” A 1mA current is used to transmit data between adjacent modules.

Like the analog circuits, the modular

approach means the data bus has to

deal with a fraction of the total pack

voltage.

BATTERY MODULE 8

LTC6802

12 Li-Ion

SERIES

BATTERIES

12 Li-Ion

SERIES

BATTERIES

6

BATTERY

MONITOR

LTC6802

BATTERY

MONITOR

Figure 12. Using digital isolators to communicate to the LTC6802

DIGITAL

ISOLATOR

BATTERY MODULE 1

DIGITAL

ISOLATOR

CONTROL MODULE

µCONTROLLER

SPI

CAN

CAN

TRANSCEIVER

GALVANIC

ISOLATOR

TO VEHICLE

CAN BUS

Linear Technology Magazine • March 2009

Page 6

LTC6802

V

500kbps MAX DATA RATE

ALL SCHOTTKY: CMD5H2-3

DESIGN FEATURES L

BATTERY MODULE 8

12 Li-Ion

SERIES

BATTERIES

12 Li-Ion

SERIES

BATTERIES

BATTERY

MONITOR

LTC6802

BATTERY

MONITOR

Figure 13. Using the daisy chained SPI to eliminate digital isolators

The disadvantage of any pure daisy

chain is that a fault in one module

results in a loss of communications

with all the modules above it in the

stack. Also, since there is no galvanic

isolation between modules, the interface needs to handle large voltages

that occur during fault conditions.

For example if the “service switch” in

Figure 1 is open and there is a load

on the pack then the data bus connection between modules 4 and 5 will

see a reverse voltage equal to the total

pack voltage (–300V to –400V). The

LTC6802 interface relies on external

discrete diodes to block the reverse

voltage during fault conditions.

BATTERY MODULE 1

CONTROL MODULE

µCONTROLLER

SPI

CAN

TRANSCEIVER

4mA to energize low power auxiliary

circuitry.

Figure 14 shows a complete stacked

LTC6802-2 SPI interface for a 36cell application. The stack can be

increased in size by replicating the

BATT

LTC6802-2

IC #3

V

WDT

SCKI

CSBI

SDO

REG

SDI

NDC7002N

−

V

GALVANIC

ISOLATOR

CAN

TO VEHICLE

CAN BUS

circuit of the middle IC. In Figure 14,

the V

REG

and V

–

pins of each stacked

IC are used to bias common-base

connected transistors to form a signal

translation current for each SPI data

line. Each LTC6802 can monitor up

2.2k2.2k1.8k1M

2.2k

ALL NPN: CMPT8099

ALL PNP: CMPT8599

ALL PN: RS07J

The Best of Both Worlds:

Daisy Chained, Addressable

Interface with the LTC6802-2

With inexpensive external circuitry,

the LTC6802-2 can also be used in

a stacked SPI configuration like the

LTC6802-1, but with more flexibility

in the operating parameters.

The SPI port of the LTC6802-2 is

a 4-wire connection: chip select in

(CSBI), clock in (SCKI), data in (SDI),

and data out (SDO). The inputs are

conventional CMOS levels and the

output is an open-drain NMOS. The

SDO pin must have an external pull-up

current or added resistance suitable

for the intended data rate. The IC also

provides a versatile always-on 5V output (V

Linear Technology Magazine • March 2009

), which can produce up to

REG

LTC6802-2

IC #2

LTC6802-2

IC #1

Figure 14. Inexpensive SPI daisy chain for parallel-addressed LTC6802-2

V

SCKI

CSBI

SDO

V

SCKI

CSBI

SDO

REG

SDI

REG

SDI

2.2k2.2k100Ω

2.2k

−

V

100Ω

R12

−

V

2.2k

2.2k2.2k

2.2k

CS

CK

HOST µP

DI

DO

7

Page 7

L DESIGN FEATURES

to 12 cell-potentials, which could sum

to 60V in certain instances, so the

transistors selected for the SPI translation need to have a V

over 60V, but

CBO

they should be the highest available fT

to prevent undue slowing of the logic

signals. A suitable NPN candidate is

the CMPT8099, while the CMPT8599

is its PNP complement, both from

Central Semiconductor. These are fast

80V devices (fT > 150MHz).

Sending Signals Upwards

At the bottom-of-stack IC, the logic

signal is furnished by the host connection, be it a microprocessor or an

SPI isolation device. By simply pulling

down the emitter leg of an NPN having

a V

base potential through a known

REG

resistance, a specific current is formed

for a logic low input signal. In the case

of the component values shown, the

current is about 2mA for a logic low,

and conversely, the transistor is essentially turned off with a logic high

(~0mA for 5V logic).

Since the collector current is nearly

identical to the emitter current, the

same current pulls on the next higher

cascode circuit. Since that next circuit

is the same as the first, the voltage on

the upper emitter resistor reproduces

that of the bottom circuit logic level for

the upper IC. This continues up the

daisy chain, eventually terminating at

the top potential of the battery stack.

Since each IC is provided the same input waveforms, this structure forms a

parallel bus from a logical perspective,

even though each IC is operating at a

different potential in the stack.

The NPN transistors at the top IC

source the logic current directly from

the battery stack. Only small base

currents flow from any V

output.

REG

The 600V collector diodes provide reverse-voltage protection in the event a

battery group interconnection is lost,

perhaps during service (these are not

required for functionality and could

be omitted in some situations).

Bringing Data Down the Stack

The SDO cascode chain is similar in

concept, except the current starts at

the top of the stack and flows downward. At the top IC, a PNP transistor

with its base connected to the local

–

V

pin has current injected into its

emitter by a pullup resistor. Here

again, the collector current is essentially identical to the emitter current,

and so current flows downward

through each successive PNP and terminates into a resistor at the bottom

of stack. In this case, the presence of

the current in the termination resistor,

about 2mA for the component values

shown, forms a logic high potential

for the host interface.

A Schottky diode is connected from

each SDO pin to the emitter of a local

PNP thereby allowing any LTC6802

on the stack to divert the pullup current to the local V

–

when outputting

a logic low. This effectively turns off

the emitter current to the local PNP

transistor and all points lower in the

stack, so the voltage on the bottom

termination resistor then drops to a

logic low level. Since each SDO pin

can force a low level, this forms a

wire-OR function that is equivalent

to paralleled connections as far as

the host interface is concerned. Note

the bottom of stack SDO diode is connected slightly differently; it forms a

direct wire-OR at the host interface.

Since the LTC6802-2 is designed to

use addressed readback commands,

this line is properly multiplexed and

no inter-IC contention occurs.

To eliminate the pull-up current

during standby, a general purpose

N-channel MOSFET is used to interrupt the top PNP emitter current when

the watchdog timer bit goes low. The

watchdog timeout will release when

clock activity is present, so the SDO

line will reactivate as needed. Here

again, an NPN is used at the top of

stack to ensure the pull-up current

comes directly from the battery, rather

than loading V

REG

.

Collector diodes are added here as

well to provide a high reverse voltage

protection capability, plus some added

series resistance is included to protect

the lower transistor emitters from

transient energy (once again, these

protection parts don’t add any other

functionality to the data transmission and could be omitted in some

circumstances).

External SPI Advantages

Since the LTC6802-2 uses a parallel

addressable SPI protocol, the conventional method of connecting multiple

devices in a stack is to provide isolation

for each SPI connection, then parallel

the signals on the host side. Isolators

are relatively expensive and often need

extra power circuitry, thus adding significantly to the total solution cost. The

transistor circuitry shown here is quite

inexpensive and offers the option to

make certain design tradeoffs as well.

With the propagation delays involved

and desire to keep power fairly low, this

circuit as shown still communicates

at over 500kbps. Lower SPI currents

could be chosen in applications that

don’t demand the high data rate by

simply raising the resistance values

accordingly.

The main feature of the transistorized SPI bus is the wide compliance

range that is afforded by the unconstrained collector -base operating

range of the transistors. In normal

operation the VCB ranges from just

less than the cells connected to the

LTC6802, to some five volts below that,

depending on the logic level transmitted. This becomes important since

voltage fluctuations on the battery,

due to load dynamics or switching

transients, affect the VCB of the transistors even though the V+ and ADC cell

inputs may be filtered. Some vehicle

manufacturers are requiring that a

BMS tolerate 1V steps with 200ns

rise/fall time per cell in the stack, so

this is a 12V waveform edge as seen by

the transistors in a typical application.

With the low collector capacitance and

2mA logic level of the transistor chain,

SPI transmissions remain error free

with even this high level of noise.

Conclusion

EVs and HEVs are here to stay. Inherently safe lithium batteries, which

combine energy density, power density, and cycle life, will continue to

evolve to improve the performance of

these vehicles. Battery management

systems using the LTC6802 extract

the most driving distance and lifetime

from the battery pack while lowering

system cost.

L

8

Linear Technology Magazine • March 2009

Loading...

Loading...