Reliable Precision Voltage Reference

OUTPUT VOLTAGE (V)

2.4985

0

NUMBER OF UNITS

40

60

80

180

140

2.5005

20

160

120

2.4995 2.5015

LTC6652A LIMITS

1004 UNITS

DRIFT (ppm/°C)

0 0.5 1.5 2.5 3.5

0

NUMBER OF UNITS

15

20

5

10

30

25

1.0

2.0 3.0

TEMPERATURE (°C)

–50

2.496

V

OUT

(V)

2.500

2.498

2.504

2.502

0

50 100 150

GUARANTEED

with 5ppm/°C Drift is Factory Trimmed

and Tested at –40°C, 25°C and 125°C

Introduction

High precision requirements are no

longer limited to the most exotic and

expensive measurement equipment.

Designers of industrial monitors

and automotive monitor and control

circuits are using precision circuits

to maximize the performance and

uninterrupted operating times of their

products. Improved precision allows

for more accurate assessment of sensor outputs that measure ambient

conditions, equipment position, battery condition, component wear and

many other system indicators. Precise

and consistent measurements are the

key to managing system elements that

change very little over their operating

lives. Recognizing these slight changes

can allow estimation of the remaining

lifetime of lamps, motors, and other

components, or allow control of battery charge and discharge to maximize

operating life. These applications not

only require high accuracy, low drift

and low noise, but also a wide operating temperature range and reasonable

cost.

Factory Calibration Means

Dependable Precision

The LTC6652 reference is a precision

low drift voltage reference that includes

advanced curvature compensation

circuitry and post-package trim. To

guarantee reliable performance, these

parts are tested at –40°C, 25°C and

125°C to verify they meet specification

across the entire temperature range.

This comprehensive testing ensures

that the LTC6652 can be used with

confidence in demanding applications. One result of this testing is

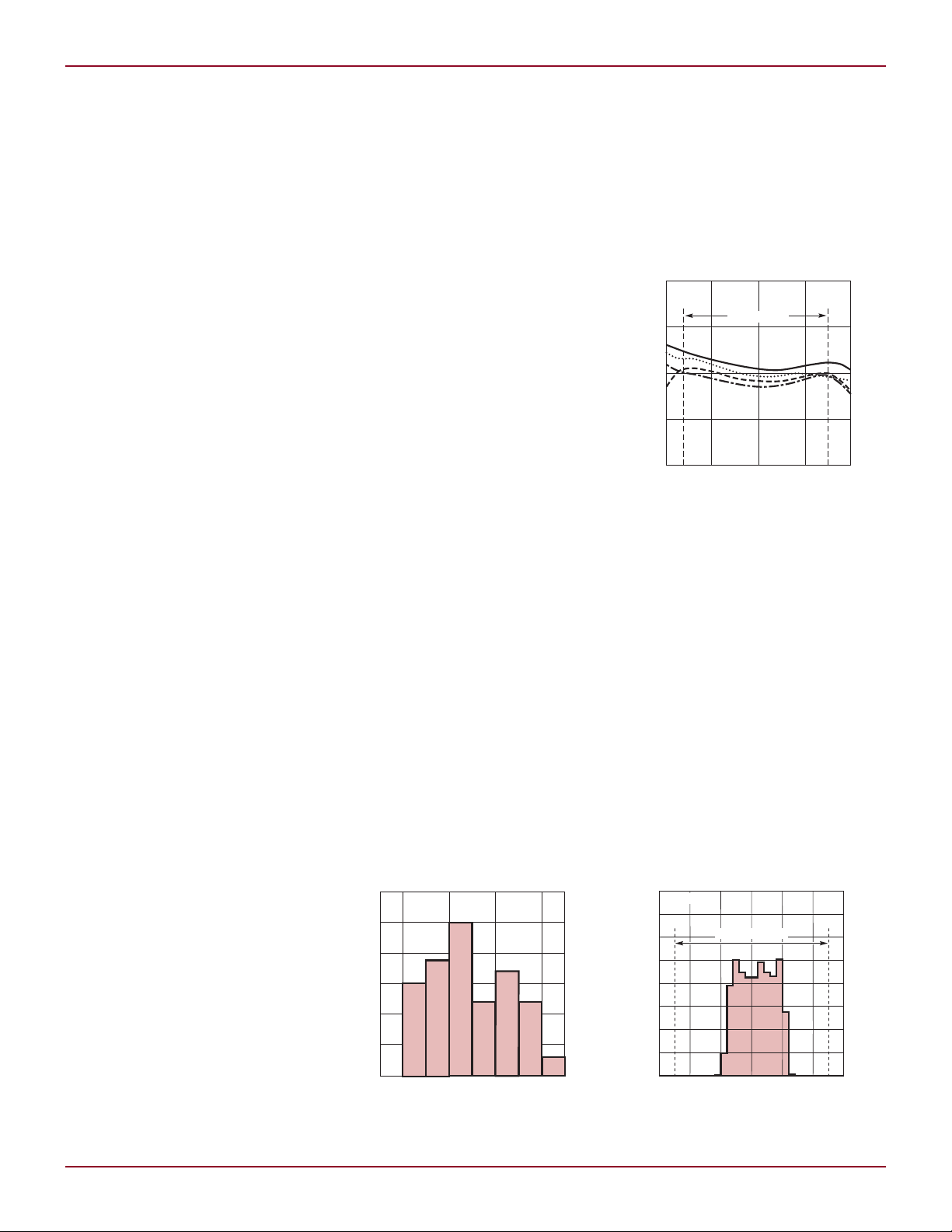

demonstrated in Figure 1. The output

voltage versus temperature for several

randomly chosen parts shows a drift

characteristic that is consistent from

part to part. This is a result of a propri-

Linear Technology Magazine • January 2009

DESIGN FEATURES L

by Michael B. Anderson and Brendan Whelan

etary curvature compensation circuit

that tracks the operating conditions

and the manufacturing process, yielding consistent results. Figure 2 shows

a typical temperature drift distribution of randomly selected production

tested LTC6652s, illustrating how well

the design and testing methodology

works. Finally, the initial accuracy

distribution is tightly controlled, as

shown in Figure 3.

Compare the Real Specs:

Is the Temperature Range

Operating or Functional?

When comparing voltage references for

use in demanding environments, it is

important to know, with confidence,

how the voltage reference performs at

the extremes. When it is important for

the reference to provide precision (not

just survive) in a harsh environment,

the LTC6655 leaves most competing

voltage references behind.

For example, many applications

requiring a precision reference are

designed to work over the industrial

temperature range (–40°C to 85°C).

If the ambient temperature reaches

85°C, the interior of the enclosure and

the temperature of the reference will

Figure 2. Drift distribution (–40°C to 125°C)

Figure 1. Typical drift characteristics of

production trimmed and tested parts

likely exceed 85°C. It is not uncommon in this case for the interior of a

circuit enclosure to climb above 100°C

due to the thermal dissipation of its

components. In addition, any comparable voltage reference fully loaded at

5mA with a 13.2V input voltage would

self-heat an additional 18°C, raising its

own internal junction temperature to

118°C. This temperature is well outside the useful range of most voltage

references. The LTC6652, however,

maintains exceptional performance in

these conditions, despite the extreme

environment. By comparison, the drift

of a reference specified only to 85°C will

Figure 3. Typical V

for LTC6652-2.5

distribution

OUT

7

L DESIGN FEATURES

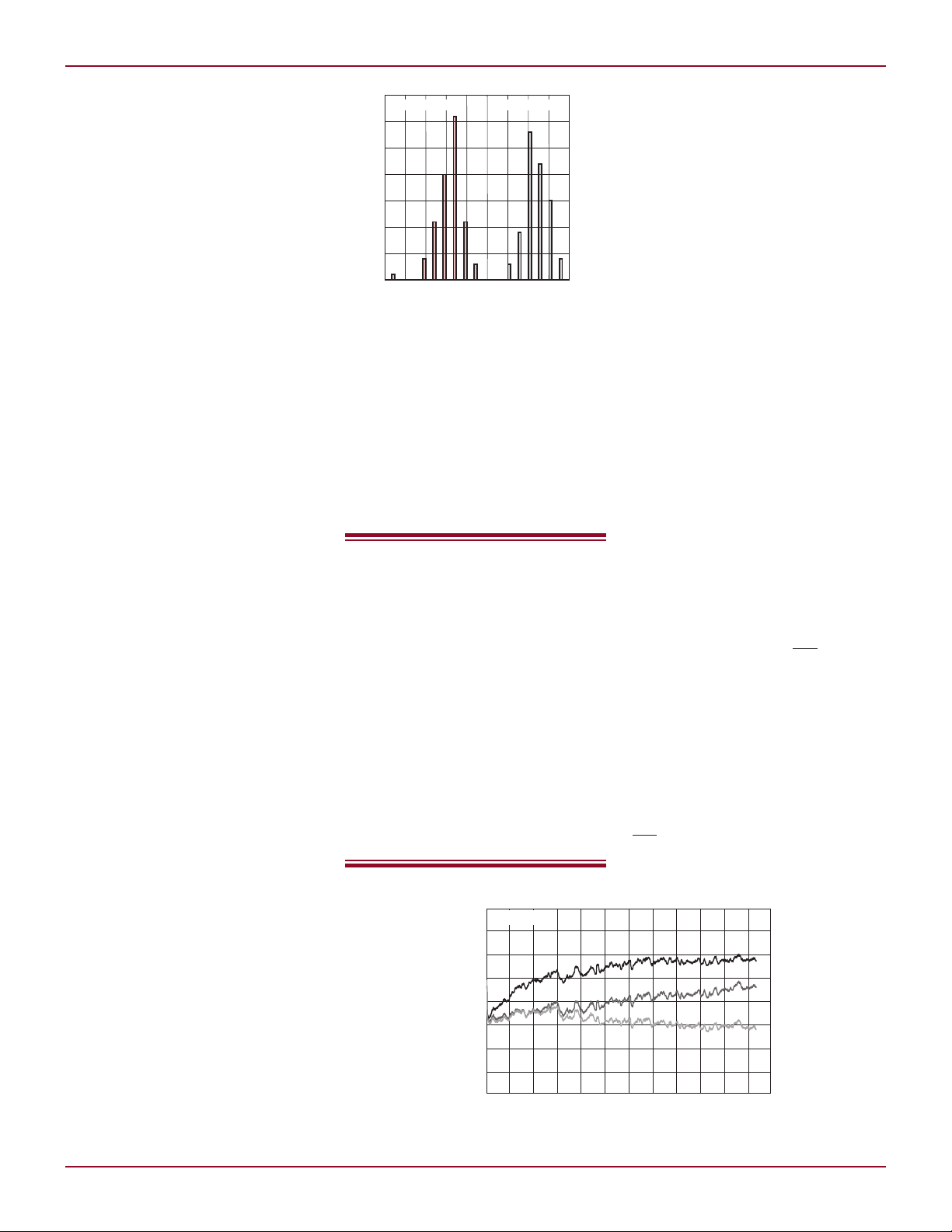

DISTRIBUTION (ppm)

–250 –150 –50

0

NUMBER OF UNITS

5

10

15

35

25

30

20

15050

125°C TO 25°C –40°C TO 25°C

TIME (HOURS)

0

LONG TERM DRIFT (ppm)

160

3000

80

120

–120

–80

40

1000 2000 50004000 6000

–160

–40

0

LTC6652-2.5

likely exhibit substantial additional

error, or it may even fail to operate.

Other references that claim similar

performance to the LTC6652 often are

only “functional”, meaning they don’t

fail, but they don’t meet specification

either at temperatures exceeding 85°C

or below 0°C. These competing parts

are rarely tested across their entire

specified temperature range. The reality of industrial circuit design is that

in many cases, component specifications over “industrial” temperatures

are woefully inadequate.

In contrast, every LTC6652 is fully

tested at 25°C, –40°C and again at

125°C for every device, not just a

small sample. This extensive testing

proves the consistently high quality

of the LTC6652 over its entire wide

temperature range.

Further, the LTC6652 was designed

from the ground up to accommodate

a wide temperature range. Figure 1

clearly illustrates its consistent performance over the entire range. There

is no need to question or derate the

performance of a system that uses

the LTC6652 at its temperature extremes. The consistent, guaranteed

performance makes it easy to design,

specify and calibrate a high performance system. This is not the case

with some competing products.

Eliminate Field Calibration

After any precision reference is soldered onto a printed circuit board,

thermal hysteresis will likely shift the

output from its factory trimmed value.

Further temperature cycling will also

contribute to a shift in the output voltage. Over time, the output will tend to

drift slightly as well due to aging of the

circuit. The circuit design, fabrication

process and mechanical design of the

LTC6652 is optimized for low thermal

hysteresis and excellent long-term

stability, reducing the need for field

calibration. Thermal hysteresis is

caused by differing rates of expansion

and contraction of materials within

a packaged semiconductor device as

the device experiences temperature

changes. As the package material and

the semiconductor die expand and

contract at different rates, mechani-

8

Figure 4. Hysteresis plot (–40°C to 125°C)

cal force changes device parameters

(ever so slightly) and cause the output

voltage to change. This change is

measured in parts per million (ppm)

and is shown in Figure 4.

The LTC6652 boasts a typical

thermal hysteresis value of 105ppm

over its full temperature range. What

this means is that when a device goes

The LTC6652 reference

family is designed and

factory trimmed to yield

exceptional drift and

accuracy performance. The

entire family is guaranteed

and production tested at

–40°C, 25°C and 125°C

to ensure dependable

performance in demanding

applications. Low thermal

hysteresis and low long-term

drift reduce or eliminate the

need for field calibration.

Figure 5. Example of long-term drift

from room temperature to 125° and

back again to room temperature, the

output will typically shift 105ppm.

For a 2.5V voltage option, the output

would shift –260µV. A cold excursion

would shift the most recent room temperature measurement +260µ. Typical

hysteresis of 105ppm is equivalent to

0.0105%; just a small fraction of the

initial accuracy.

It may be convenient to compare

typical values for thermal hysteresis

when choosing a voltage reference.

It is important to remember that

these numbers do not tell the whole

story. It is the distribution of expected

hysteresis that must be used to determine the expected error caused

by temperature cycling. Referring to

Figure 4, some parts will have better

or worse hysteresis. This chart helps

to estimate a realistic error budget.

This is something our competitors

don’t always include, yet is critically

important when specifying precision

systems.

Over time a reference is likely to

shift on its own even if it’s kept at a

constant temperature. This is known

as long-term drift. Long-term drift

is measured in ppm/√khr and has

a logarithmic characteristic where

the change in output voltage decays

as time passes. Figure 5 shows the

long-term drift of the LTC6652. Note

that most of the drift occurs within

the first 1,000 or 2,000 hours as the

PCB and package settle. Afterward

the drift tends to settle, and the slope

is reduced over time as a function of

khr. Direct measurement on soldered

√

down parts is the only way to determine

Linear Technology Magazine • January 2009

DESIGN FEATURES L

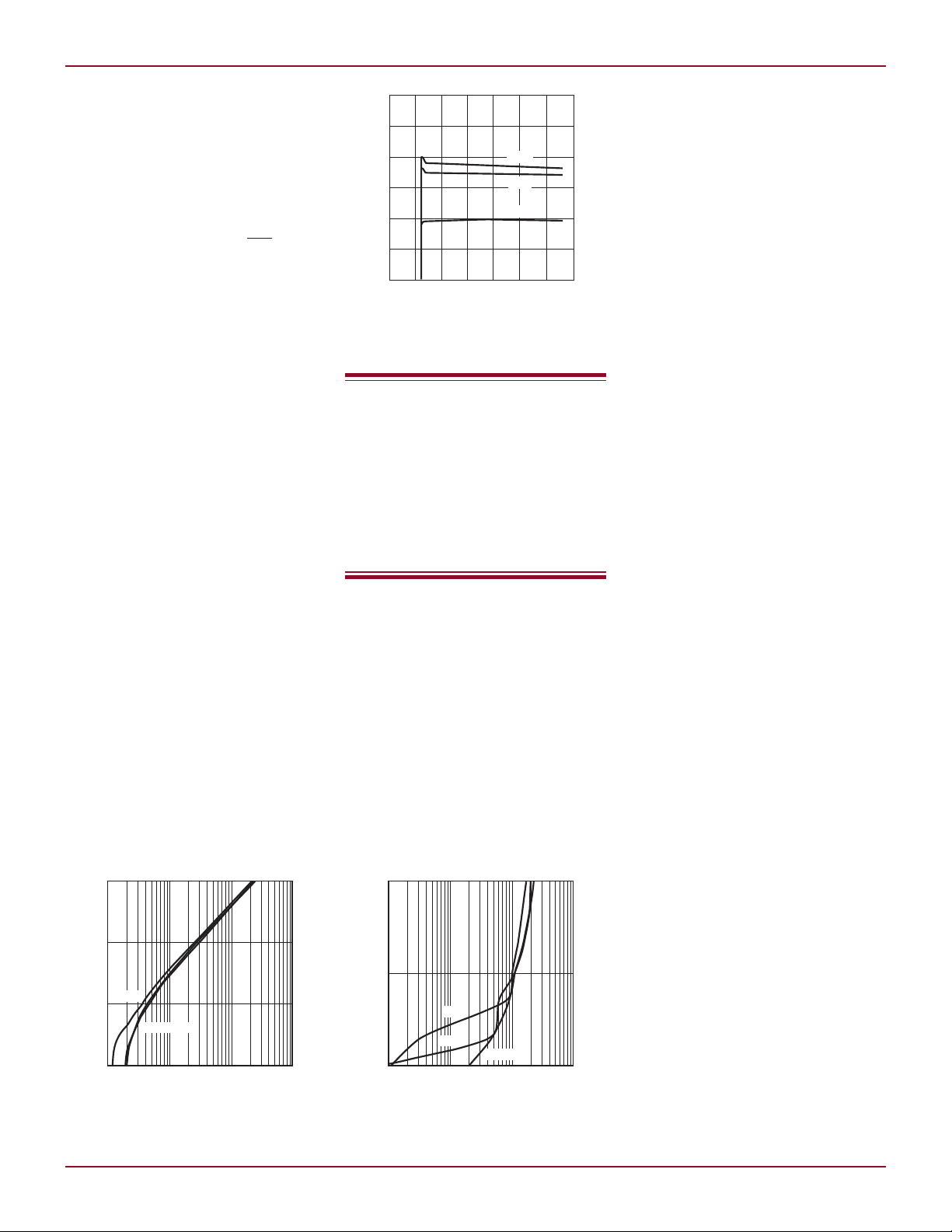

INPUT VOLTAGE (V)

0

OUTPUT VOLTAGE (V)

2.5000

2.5005

2.5010

6 10

2.4995

2.4990

2 4

8 12 14

2.4985

2.4980

125°C

–40°C

25°C

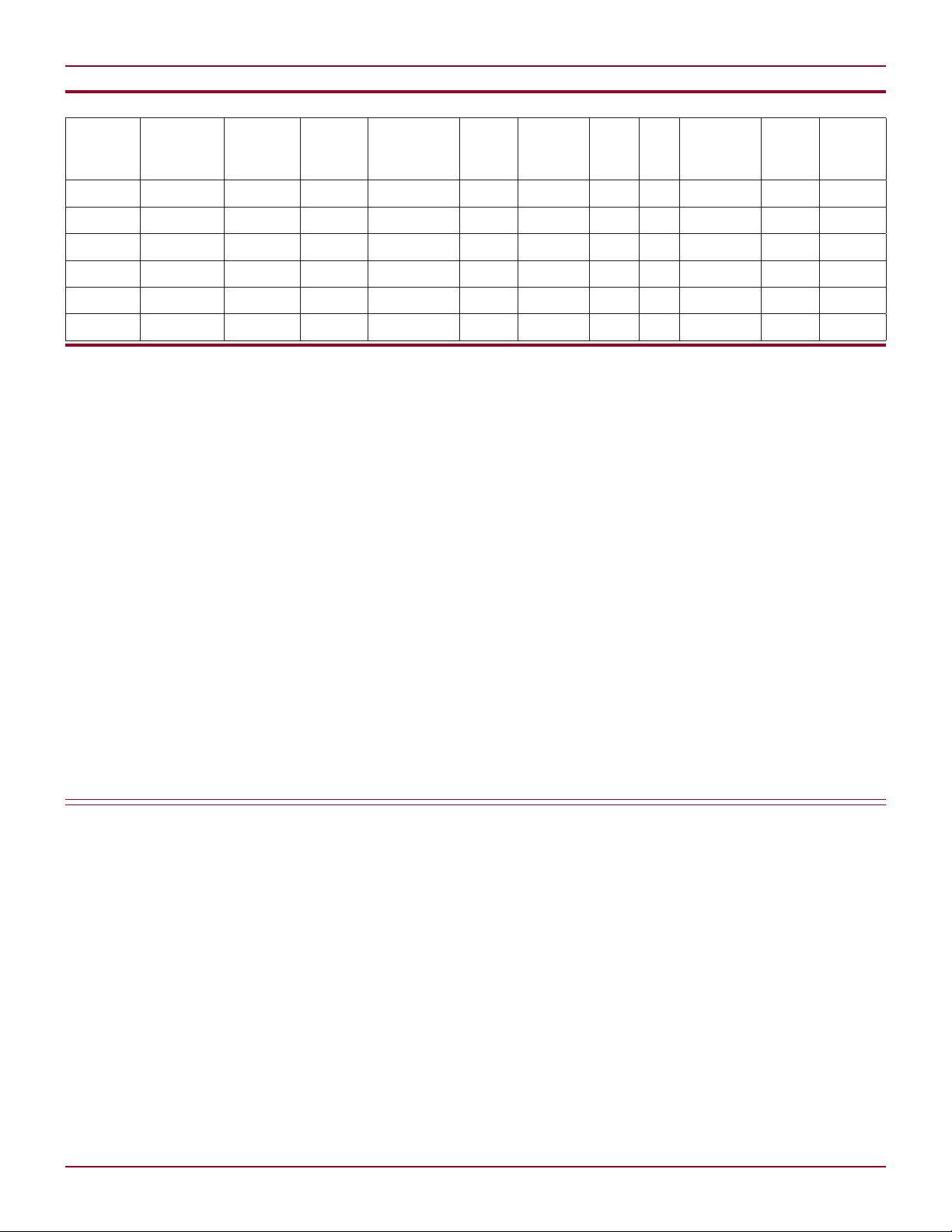

OUTPUT-INPUT VOLTAGE (V)

0.001

OUTPUT CURRENT (mA)

10

0.01 0.1 1

1

0.1

25°C

–40°C

125°C

INPUT-OUTPUT VOLTAGE (V)

0.001

0.01

OUTPUT CURRENT (mA)

1

10

0.01 0.1 1

0.1

25°C

125°C, –40°C

long-term drift. Accelerated testing

does not work. Some users burn in

their boards, which helps eliminate

this initial slope, further reducing the

effect of long-term drift.

The three curves shown in Figure 5

give a general indication of how much

long-term drift to expect. The typical

specification is 60ppm/√khr, which

translates into 150µV drift. Combining the typical thermal hysteresis

and long-term drift numbers yields

165ppm. To put this in perspective,

the LTC6652 temperature coefficient

is typically 2ppm/°C over 165°C temperature range, which yields 330ppm

due to drift alone. The combined thermal hysteresis and long-term drift is

half this number (or just 20% of the

maximum drift specification). The

superior thermal hysteresis and longterm drift performance of the LTC6652

ensures accuracy and reliability over

the product lifetime, virtually eliminating the need for field calibration.

Small Footprint and

Output Capacitor Optional

The performance of the LTC6652

is often only found in larger packages such as an SOIC. However,

the LTC6652 is packaged in a small

8-lead MSOP and does not require

an input or output capacitor. This

minimizes required board space, thus

simplifying the design of applications

with tight PCB constraints such as

small sensor enclosure applications.

Another advantage of not using capacitors is eliminating energy storage

devices tied to sensitive circuits. This

Figure 6. Line regulation

The LTC6652 reference

family has seven output

voltage options, making

it suitable for a variety

of today’s demanding

applications. These options

are 1.25V, 2.048V, 2.5V, 3V,

3.3V, 4.096V, and 5V.

is a useful feature in safety critical

systems, where energy storage must

be minimized. If, however, low noise

is a priority, an input capacitor may

be added to suppress high frequency

transients on the supply line, while an

output capacitor will reduce wideband

noise and improve AC PSRR. Either

way, the LTC6652 offers stable operation. Small size and a range of useful

input and output capacitors allows

the LTC6652 to satisfy the requirements of many different applications.

This includes everything from small,

tight-fitting portable applications to

high precision, low noise measurement

applications.

Output Can Source

and Sink Current

The LTC6652 is a series voltage reference that can source current, but it can

also sink current like a shunt reference. Some series voltage references

can only source output current and

rely on a resistor divider for feedback

and to sink a small amount of current.

These types of devices can experience

long settling times, especially when

charge is kicked back from a switched

capacitor circuit causing the output

voltage to rise. The sink (overvoltage)

settling time on a source only reference is dominated by the RC time

constant of the output capacitor and

the resistive divider. For example, a

2.2µF output capacitor and a 125kΩ

resistive divider will have a 275ms

time constant. Depending on the size

of the perturbation and the system

precision, a source only reference

may not settle in a timely fashion.

The LTC6652 current sink capacity

is 5mA and will dynamically respond

for faster settling.

Shunt references are two terminal

devices that maintain the output voltage by sinking more or less current.

The sinking ability of the LTC6652

allows it to operate in a similar, but

more efficient manner. In fact, for

voltage options of 3V or higher, the

VIN pin can actually go below the V

pin while sinking currents of 100µA

and higher and still maintain good

regulation.

OUT

Linear Technology Magazine • January 2009

a. Sourcing current b. Sinking current

Figure 7. Dropout voltage sourcing and sinking current

Wide Input Range,

Low Dropout, and

Seven Voltage Options

The LTC6652 reference family has

seven output voltage options to choose

from, making it suitable for a variety

of today’s demanding applications.

These options are 1.25V, 2.048V, 2.5V,

3V, 3.3V, 4.096V, and 5V. For low

input voltage requirements, the 1.25V

and 2.048V options work with input

voltages down to 2.7V. The other five

options require only 300mV input-to-

continued on page 14

9

L DESIGN FEATURES

Table 2. Noise margins are good for radiated emission results shown in Figure 13

EUT

Frequency

(MHz)

134.31 H 354 364 1.3 11.428 0 1.532 0 14.26 30 15.74

119.96 V 184 110 3.5 12.694 0 1.456 0 17.65 30 12.35

160.02 H 0 354 0.5 10.499 0 1.793 0 12.792 30 17.208

174.37 H 0 100 1.2 9.638 0 1.944 0 12.782 30 17.218

224.28 V 0 100 –1.87 10.586 0 2.044 0 10.76 30 19.24

263.63 H 0 371 –4.72 12.6 0 2.385 0 10.265 37 26.735

Antenna

Polarization

Azimuth

(Degrees)

a linear DC power supply is used

for the input, and a resistive load is

employed on the output. The baseline

noise is checked with the power supply

providing a DC current directly to the

resistive load. The baseline emission

scan results are shown in Figure 11.

There are two traces in the plot, one

for the vertical and horizontal orientations of the receiver antenna.

Figure 12 shows the peak scan re

sults of a µModule buck regulator—not

the LTM4606 or LTM4612—without

the integrated low noise feature. The

scan results show that the noise below

350MHz is produced by the µModule

switching regulator, when compared

to the baseline noise level. Radiated

EMI here does not meet the Class B

of CISPR 22 (quasi-peak) radiated

emission limit.

Antenna

Height

(cm)

Uncorrected

Amplitude

(dBµV)

Pre-Amp

ACF

(dB/m)

In contrast, Figure 13 shows the

peak scan results of the low noise

LTM4606 module. To ensure enough

margin to the quasi-peak limit for

different operation conditions, the

six highest noise points are checked

as shown in the table of Figure 13

using the quasi-peak measurement.

The results show that it has more

than 12dBµV margin below the Class

-

B of CISPR 22(quasi-peak) radiated

emission limit.

Figure 14 shows the results for the

LTM4612 meeting the Class B of CISPR

22 radiated emission limit at 24V VIN,

12V/5A V

OUT

.

Conclusion

The LTM4606 and LTM4612 µModule

regulators offer all of the high performance benefits of switching regulators

minus the noise issues. The ultralow

Gain

(dB)

Corrected

CBL

DCF

(dB)

(dB)

Amplitude

(dBµV)

Limit

(dBµV)

Margin

noise optimized design produces radiated EMI performance with enough

margin below the Class B of CISPR 22

limit to simplify application in noisesensitive environments.

Design is further simplified by

exceptional thermal performance,

which allows them to achieve high

efficiency and a compact form factor. A low profile 15mm × 15mm ×

2.8mm package contains almost all

of the support components—only a

few input and output capacitors are

required to complete a design. Several

µModule regulators can be easily run

in parallel for more output power. The

versatility of these parts is rounded out

by optional features such as soft-start,

RUN pin control, output voltage tracking and margining, PGOOD indicator,

frequency adjustment and external

clock synchronization.

L

(dB)

LTC6652, continued from page 9

output headroom while fully loaded,

and they require less headroom with a

reduced load or while sinking current.

Popular application requirements,

such as a 2.5V reference operating

on a 3V supply, or a 4.096V reference

operating on a 5V supply, are easily

accommodated. For high input voltage requirements, all voltage options

work up to 13.2V. Regardless of input

voltage the LTC6652 maintains its

excellent accuracy as shown in the

line regulation plot in Figure 6. A plot

of the dropout voltage for both sourcing and sinking current is shown in

Figures 7a and 7b, respectively.

14

Superior Performance

While many references share some

features of the LTC6652, it’s difficult

to find any that include all the features

at the same level of performance and

reliability. Additional features include

low noise, good AC PSRR, and excellent load regulation (both sourcing and

sinking current). Low power consumption and a shutdown mode round out

the feature list.

Conclusion

The LTC6652 reference family is

designed and factory trimmed to

yield exceptional drift and accuracy

performance. The entire family is

guaranteed and production tested at

–40°C, 25°C and 125°C to ensure dependable performance in demanding

applications. Low thermal hysteresis

and low long-term drift reduce or

eliminate the need for field calibration. The small 8-lead MSOP package

and sparse capacitor requirements

minimize required board space. The

wide input range from 2.7V to 13.2V

and seven output voltage options will

tackle the needs of most precision

reference users.

Linear Technology Magazine • January 2009

L

Loading...

Loading...