Page 1

L DESIGN FEATURES

Ultralow Noise 15mm ×15mm × 2.8mm

µModule Step-Down Regulators Meet

the Class B of CISPR 22 and Yield

High Efficiency at up to 36V

by Judy Sun, Jian Yin, Sam Young and Henry Zhang

Introduction

Power supply designers face many

tradeoffs. Need high efficiency, large

conversion ratios, high power and

good thermal performance? Choose a

switching regulator. Need low noise?

Choose a linear regulator. Need it

all? Compromise. One compromise

is to follow a switcher with a linear

regulator (or regulators). Although this

cleans up the output noise relative to

a switcher-only solution, a good portion of the conducted and radiated

EMI remains—even if ferrite beads,

π filters, and LC filters are used. The

problem can always be traced back to

the switcher, where fast dI/dt transitions and high switching frequencies

Table 1. Feature comparison of ultralow noise µModule regulators

Feature LTM4606 LTM4612

These µModule step-down

regulators are designed

to achieve both high

power density and meet

EMC (electromagnetic

compatibility) standards.

The integrated ultralow

noise feature allows both

devices to pass the Class

B of CISPR 22 radiated

emission limit, thus

eliminating expensive EMI

design and lab testing.

lead to high frequency EMI, but

some applications, especially those

with large conversion ratios, require

a switcher.

Fortunately, the LTM4606 and

LTM4612 µModule regulators offer the

advantages of a switching regulator

while maintaining ultralow conducted

and radiated noise. These µModule

step-down regulators are designed to

achieve both high power density and

meet EMC (electromagnetic compatibility) standards. The integrated

ultralow noise feature allows both

devices to pass the Class B of CISPR

22 radiated emission limit, thus

eliminating expensive EMI design and

IN

V

IN

V

OUT

I

OUT

CISPR 22 Class B Compliant

Output Voltage Tracking and Margining

PLL Frequency Synchronization

±1.5% Total DC Error

Power Good Output

Current Foldback Protection

Parallel/Current Sharing

Low Input and Output Referred Noise

Ultrafast Transient Response

Current Mode Control

Programmable Soft-Start

Output Overvoltage Protection

Package 15mm × 15mm × 2.8mm 15mm × 15mm × 2.8mm

4.5V to 28V 5V to 36V

0.6V to 5V 3.3V to 15V

6A DC Typical, 8A Peak 5A DC Typical, 7A Peak

L L

L L

L L

L L

L L

L L

L L

L L

L L

L L

L L

L L

10

Linear Technology Magazine • January 2009

Page 2

DESIGN FEATURES L

+

INTERNAL

COMP

SGND

COMP

PGOOD

RUN

>1.9V = ON

<1V = OFF

MAX = 5V

MARG1

MARG0

MPGM

FCB

PLLIN

C

SS

INTV

CC

DRV

CC

TRACK/SS

V

FB

f

SET

50k

41.2k

R

FB

19.1k

50k

60.4k

V

OUT

5.1V

ZENER

POWER CONTROL

M1

V

IN

4.5V TO 28V

V

D

V

OUT

2.5V

AT 6A

M2

50k

22µF

1.5µF

C

IN

+

C

OUT

PGND

C

D

10k

4.7µF

INPUT

FILTER

NOISE

CANCEL-

LATION

LOAD CURRENT (A)

0

EFFICIENCY (%)

100

90

70

80

60

50

654321

1.2V

OUT

1.5V

OUT

2.5V

OUT

3.3V

OUT

5V

OUT

LOAD CURRENT (A)

0.0

EFFICIENCY (%)

75

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

65

90

70

95

60

55

85

80

24V

IN,

12V

OUT

DCM

CCM

P

GOOD

RUN

V

D

INTV

CC

DRV

CC

f

SET

TRACK/SS

COMP

FCB

MARG0

MARG1

MPGM

V

OUT

V

FB

V

IN

C4

0.01µF

C3

100pF

C

OUT1

22µF

25V

C

OUT2

180µF

16V

V

OUT

12V

4.5A

C1

10µF

50V

C

IN

10µF x 2

50V

V

IN

18V

TO 36V

PLLIN

CLOCK SYNC

ON/OFF

LTM4612

SGND PGND

MARGIN

CONTROL

R4

100k

R

SET

5.23k

R1

392k

5% MARGIN

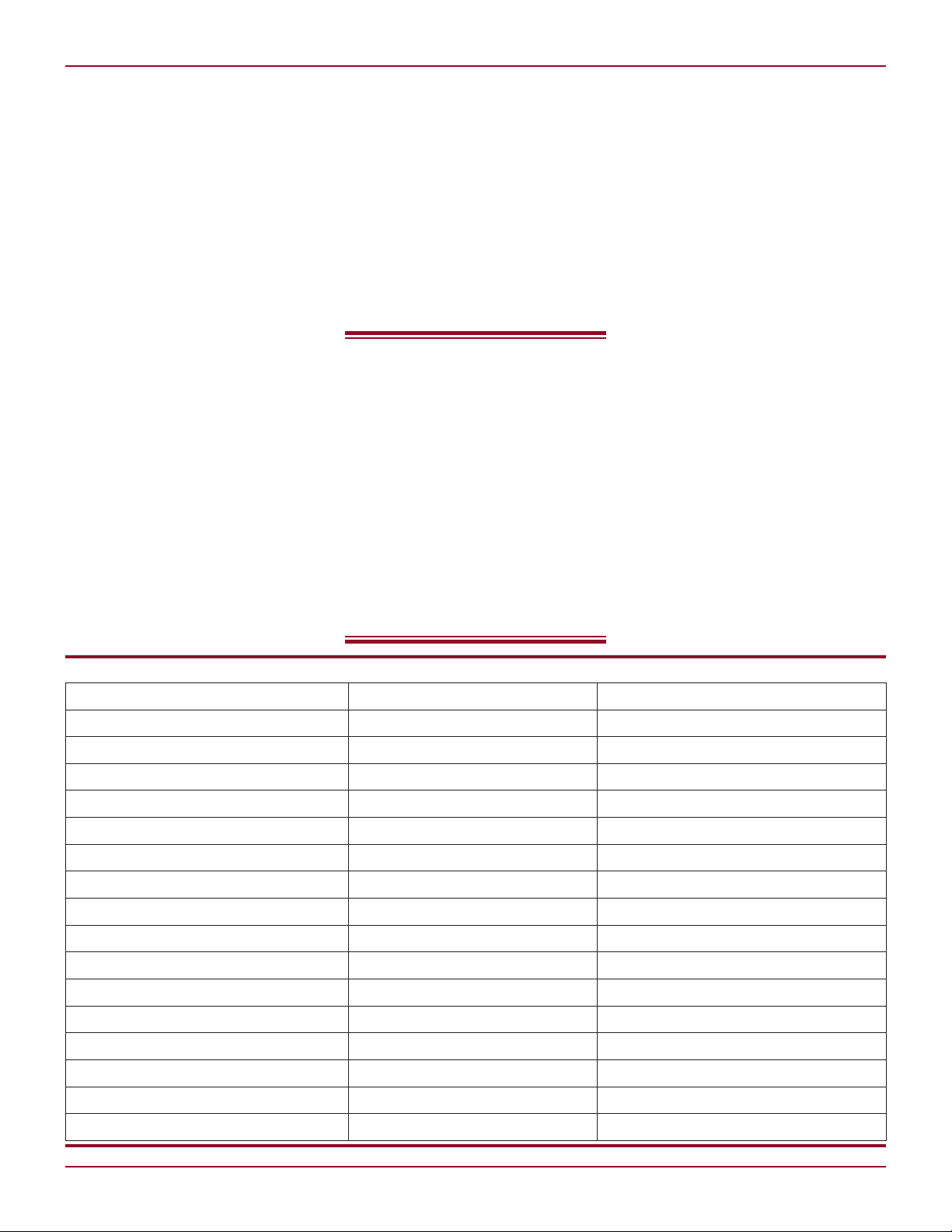

Figure 1. Simplified block diagram of the LTM4606 (LTM4612 is similar). Only a few

capacitors and resistors are required to build a complete wide-input-range regulator.

lab testing. See Table 1 for a feature

comparison of these two parts.

Both µModule regulators are offered in space saving, low profile and

thermally enhanced 15mm × 15mm ×

2.8mm LGA packages, so they can be

placed on the otherwise unused space

at the bottom of PC boards for highaccuracy point-of-load regulation. This

is not possible with linear regulators

Figure 2. Efficiency of the

LTM4606 with a 12V input.

that require a bulky cooling system.

Almost all support components are

integrated into the µModule package,

so layout design is relatively simple,

Figure 3. A few capacitors and resistors complete an 18V–36V input, 12V/4.5A output design.

Linear Technology Magazine • January 2009

requiring only a few input and output

capacitors.

For more output power, both parts

can be easily paralleled, where output

currents are automatically shared

due to the current mode control

structure.

Easy Power Supply Design

with Ultralow Noise

µModule Regulators

With a few external input and output capacitors, the LTM4612 can

deliver 4.5A of DC output current

Figure 4. Efficiency for the circuit in Figure 3.

11

Page 3

L DESIGN FEATURES

V

IN

50mV/DIV

97mV

P–P

13.8mV

P–P

V

OUT

5mV/DIV

2µs/DIVVIN = 5V

V

OUT

= 1.2V

I

LOAD

= 5A

CIN = 3×10µF/25V CERAMIC AND 1×150µF/25V ELECTROLITIC

C

OUT

= 1×100µF/25V AND 3×22µF/25V CERAMIC

SCOPE BW = 300MHz

V

IN

5mV/DIV

10.6mV

P–P

4.4mV

P–P

V

OUT

2mV/DIV

2µs/DIVVIN = 5V

V

OUT

= 1.2V

I

LOAD

= 5A

CIN = 3×10µF/25V CERAMIC AND 1×150µF/25V ELECTROLITIC

C

OUT

= 1×100µF/25V AND 3×22µF/25V CERAMIC

SCOPE BW = 300MHz

+

LT4606 OR LTC4612

V

D

V

IN

V

IN

L1

C3

10µF

C2

10µF

×3

C1

150µF

FREQUENCY (MHz)

0.15

0

SIGNAL AMPLITUDE (dBµV)

20

40

60

80

10

30

50

70

1 3010

CIS25QP

VIN = 24V

V

OUT

= 12V

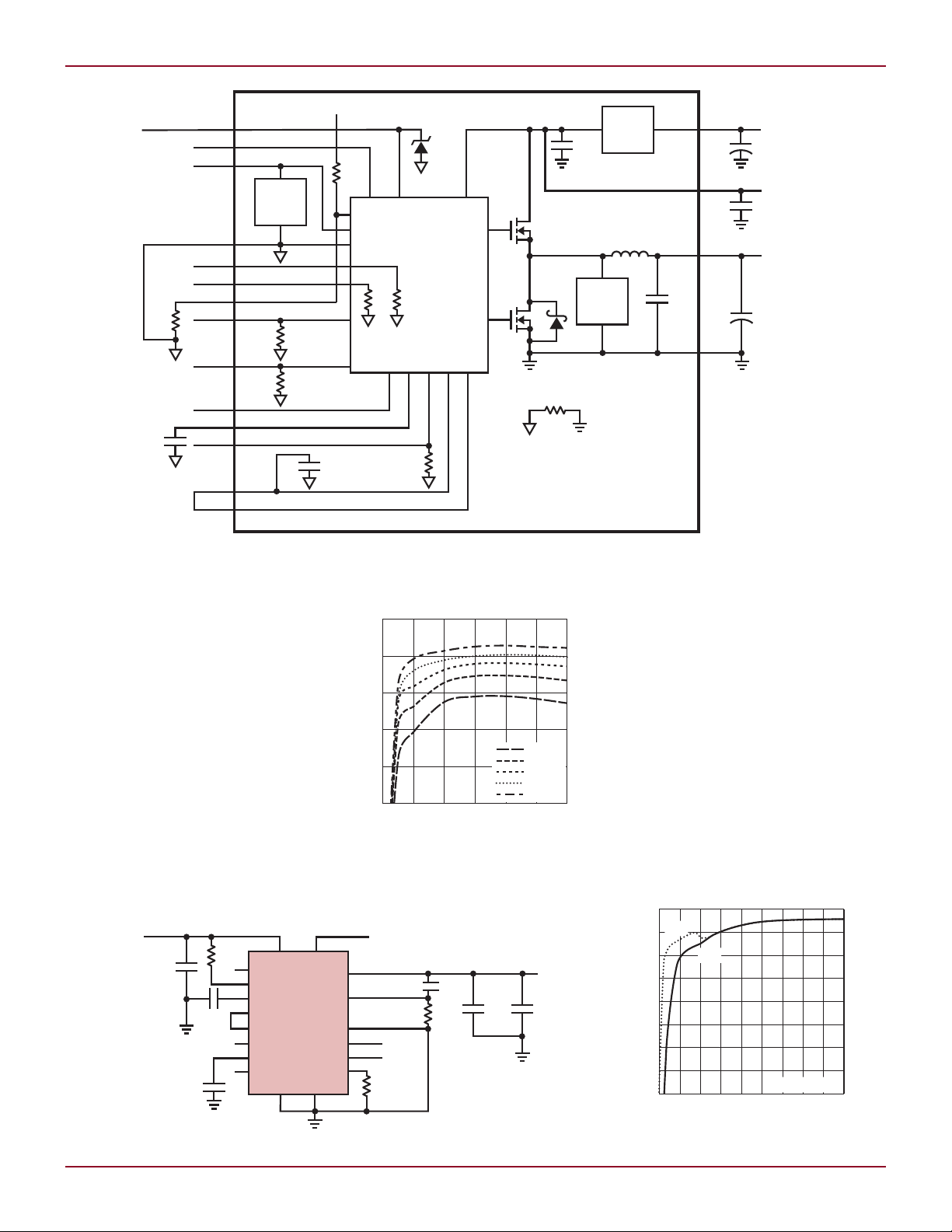

Figure 5. Thermal image of an LTM4606

with 24V input and 3.3V output at 6A

Figure 6. Input π filter reduces

high frequency input noise.

Figure 3 shows a complete 18V–36V

VIN, 12V/4.5A V

LTM4612. Figure 4 shows the ef

design with the

OUT

-

ficiency.

Both parts offer good thermal performance with a large output load

current. Figure 5 shows the LTM4606

thermal image with 24V input and

3.3V output at 6A load current. The

maximum case temperature is only

73.5oC with the 20W output power.

Both include a number of built-in

features, such as controllable softstart, RUN pin control, output voltage

tracking and margining, PGOOD

indicator, frequency adjustment and

external clock synchronization. Efficiency can be further improved by

applying an external gate driver voltage

to the DRVCC pin, especially in high

VIN applications. Discontinuous mode

operation can be enabled to increase

the light load efficiency.

Figure 7. Input and output noise of comparable

µModule regulator without low noise feature

Figure 9. The conducted EMI test of the LTM4612 passes EMI standard CISPR 25 level 5.

and the LTM4606 can deliver 6A. The

LTM4612’s programmable output can

be precisely regulated in a 3.3V-to-15V

range from a 4.5V-to-36V input; the

LTM4606 can produce 0.6V to 5V from

a 4.5V-to-28V range. With current

mode control and optimized internal

compensations, both offer stable

output even in the face of significant

load transients.

12

Figure 8. Input and output noise of LTM4606

µModule regulator is significantly lower than

the regulator in Figure 7.

Figure 1 shows the simplified block

diagram of the LTM4606 with an input

from 4.5V to 28V and 2.5V/6A output.

Figure 2 shows the efficiency test

curves with 12V input voltage under

CCM mode. About 92% efficiency is

achieved at full load with LTM4606,

running at 900kHz switching frequency.

Reduce Conducted EMI

Conducted input and output noise of

switching regulators (aka ripple) is

usually a problem when the regulator

operates at high frequency, which is

common in space-constrained applications. The LTM4606 and LTM4612

reduce peak-to-peak ripple at the

input by integrating a high frequency

inductor as shown in Figure 6. The

external input capacitors at the VD

and VIN pins form a high frequency

input π filter. This effectively reduces

conductive EMI coupling between the

module and the main input bus.

Since most input RMS current flows

into capacitor C3 at the VD pin, C3

should have enough capacity to handle

the RMS current. A 10µF ceramic capacitor is recommended. To effectively

attenuate EMI, place C3 as close as

possible to the VD pin. The ceramic

capacitors C2 mainly determine the

ripple noise attenuation, so the capacitor value can be varied to meet the

different input ripple requirements.

C1 is only needed if the input source

impedance is compromised by long

inductive leads or traces.

Since these µModule regulators

are used in a buck circuit topology,

the lowpass filter formed by the output inductor L and capacitor C

Linear Technology Magazine • January 2009

OUT

Page 4

FREQUENCY (MHz)

0

EMISSIONS LEVEL (dBµV/m)

10

30

50

90

70

10009008007006005004003002001000

CISPR22, CLASS B

FREQUENCY (MHz)

0

EMISSIONS LEVEL (dBµV/m)

10

30

50

90

70

10009008007006005004003002001000

CISPR22, CLASS B

VIN = 12V

V

OUT

= 2.5V

I

LOAD

= 6A

FREQUENCY (MHz)

0

EMISSIONS LEVEL (dBµV/m)

10

30

50

90

70

10009008007006005004003002001000

CISPR22, CLASS B

VIN = 12V

V

OUT

= 2.5V

I

LOAD

= 6A

FREQUENCY (MHz)

0

EMISSIONS LEVEL (dBµV/m)

10

30

50

90

70

10009008007006005004003002001000

CISPR22, CLASS B

VIN = 24V

V

OUT

= 12V

I

LOAD

= ??A

RESISTIVE LOAD

LTM4606 µMODULE

REGULATOR

DC POWER SUPPLY

DESIGN FEATURES L

Figure 10. Setup of the radiated emission scan

can similarly reduce the conducted

output EMI.

To show the relative noise attenuation of these µModule regulators, a

similar module without the low noise

feature is compared to the LTM4606

for input and output noise, as shown in

Figure 7 and Figure 8. Both modules

are tested from 5V input to 1.2V output

at 5A with resistive loads. The same

board layout and I/O capacitors are

used in the comparison. The results

show that the LTM4606 produces

much lower input and output noise,

with a nearly 10× reduction of the

peak-to-peak input noise and better

than 3× reduction of the output noise

compared to the similar module in

Figure 7.

Figure 9 shows the conducted EMI

testing results for the LTM4612 with

a 24V VIN, 12V/5A V

, which ac-

OUT

commodates the EMI standard CISPR

25 level 5. The input capacitance for

this test comes from 4 × 10µF/50V

ceramics plus a single 150µF/50V

electrolytic.

Reduce Radiated EMI

Switching regulators also produce

radiated EMI, caused by the high dI/

dt signals inherent in high efficiency

regulators. The input π filter helps to

limit radiated EMI caused by high dI/dt

loops in the immediate module area,

but to further attenuate radiated EMI,

the LTM4606 and LTM4612 include an

optimized gate driver for the MOSFET

and a noise cancellation network.

To test radiated EMI, several setups are tested in a 10-meter shielded

chamber as shown in Figure 10. To

ensure a low baseline radiated noise,

Linear Technology Magazine • January 2009

Figure 11. Radiated emission scan of baseline noise (no switching regulator module)

Figure 12. Radiated emission peak scan of a typical module without the low noise features.

Figure 13. The radiated EMI test of the LTM4606 passes EMI standard CISPR 22 Class B.

Figure 14. The radiated EMI test of the LTM4612 passes EMI standard CISPR 22 Class B.

13

Page 5

L DESIGN FEATURES

Table 2. Noise margins are good for radiated emission results shown in Figure 13

EUT

Frequency

(MHz)

134.31 H 354 364 1.3 11.428 0 1.532 0 14.26 30 15.74

119.96 V 184 110 3.5 12.694 0 1.456 0 17.65 30 12.35

160.02 H 0 354 0.5 10.499 0 1.793 0 12.792 30 17.208

174.37 H 0 100 1.2 9.638 0 1.944 0 12.782 30 17.218

224.28 V 0 100 –1.87 10.586 0 2.044 0 10.76 30 19.24

263.63 H 0 371 –4.72 12.6 0 2.385 0 10.265 37 26.735

Antenna

Polarization

Azimuth

(Degrees)

a linear DC power supply is used

for the input, and a resistive load is

employed on the output. The baseline

noise is checked with the power supply

providing a DC current directly to the

resistive load. The baseline emission

scan results are shown in Figure 11.

There are two traces in the plot, one

for the vertical and horizontal orientations of the receiver antenna.

Figure 12 shows the peak scan re

sults of a µModule buck regulator—not

the LTM4606 or LTM4612—without

the integrated low noise feature. The

scan results show that the noise below

350MHz is produced by the µModule

switching regulator, when compared

to the baseline noise level. Radiated

EMI here does not meet the Class B

of CISPR 22 (quasi-peak) radiated

emission limit.

Antenna

Height

(cm)

Uncorrected

Amplitude

(dBµV)

Pre-Amp

ACF

(dB/m)

In contrast, Figure 13 shows the

peak scan results of the low noise

LTM4606 module. To ensure enough

margin to the quasi-peak limit for

different operation conditions, the

six highest noise points are checked

as shown in the table of Figure 13

using the quasi-peak measurement.

The results show that it has more

than 12dBµV margin below the Class

-

B of CISPR 22(quasi-peak) radiated

emission limit.

Figure 14 shows the results for the

LTM4612 meeting the Class B of CISPR

22 radiated emission limit at 24V VIN,

12V/5A V

OUT

.

Conclusion

The LTM4606 and LTM4612 µModule

regulators offer all of the high performance benefits of switching regulators

minus the noise issues. The ultralow

Gain

(dB)

Corrected

CBL

DCF

(dB)

(dB)

Amplitude

(dBµV)

Limit

(dBµV)

Margin

noise optimized design produces radiated EMI performance with enough

margin below the Class B of CISPR 22

limit to simplify application in noisesensitive environments.

Design is further simplified by

exceptional thermal performance,

which allows them to achieve high

efficiency and a compact form factor. A low profile 15mm × 15mm ×

2.8mm package contains almost all

of the support components—only a

few input and output capacitors are

required to complete a design. Several

µModule regulators can be easily run

in parallel for more output power. The

versatility of these parts is rounded out

by optional features such as soft-start,

RUN pin control, output voltage tracking and margining, PGOOD indicator,

frequency adjustment and external

clock synchronization.

L

(dB)

LTC6652, continued from page 9

output headroom while fully loaded,

and they require less headroom with a

reduced load or while sinking current.

Popular application requirements,

such as a 2.5V reference operating

on a 3V supply, or a 4.096V reference

operating on a 5V supply, are easily

accommodated. For high input voltage requirements, all voltage options

work up to 13.2V. Regardless of input

voltage the LTC6652 maintains its

excellent accuracy as shown in the

line regulation plot in Figure 6. A plot

of the dropout voltage for both sourcing and sinking current is shown in

Figures 7a and 7b, respectively.

14

Superior Performance

While many references share some

features of the LTC6652, it’s difficult

to find any that include all the features

at the same level of performance and

reliability. Additional features include

low noise, good AC PSRR, and excellent load regulation (both sourcing and

sinking current). Low power consumption and a shutdown mode round out

the feature list.

Conclusion

The LTC6652 reference family is

designed and factory trimmed to

yield exceptional drift and accuracy

performance. The entire family is

guaranteed and production tested at

–40°C, 25°C and 125°C to ensure dependable performance in demanding

applications. Low thermal hysteresis

and low long-term drift reduce or

eliminate the need for field calibration. The small 8-lead MSOP package

and sparse capacitor requirements

minimize required board space. The

wide input range from 2.7V to 13.2V

and seven output voltage options will

tackle the needs of most precision

reference users.

Linear Technology Magazine • January 2009

L

Loading...

Loading...