FEATURES

LTC4350

Hot Swappable

Load Share Controller

U

DESCRIPTIO

■

Build N + 1 Redundant Supply

■

Hot SwapTM Power Supplies

■

Isolates Supply Failures from Output

■

Eliminates ORing Diodes

■

Identifies and Localizes Output Low, Output High

and Open-Circuit Faults

■

Output Voltages from 1.5V to 12V

■

16-Lead Narrow SSOP Package

U

APPLICATIO S

■

Servers and Network Equipment

■

Telecom and Base Station Equipment

■

Distributed Power Systems

U

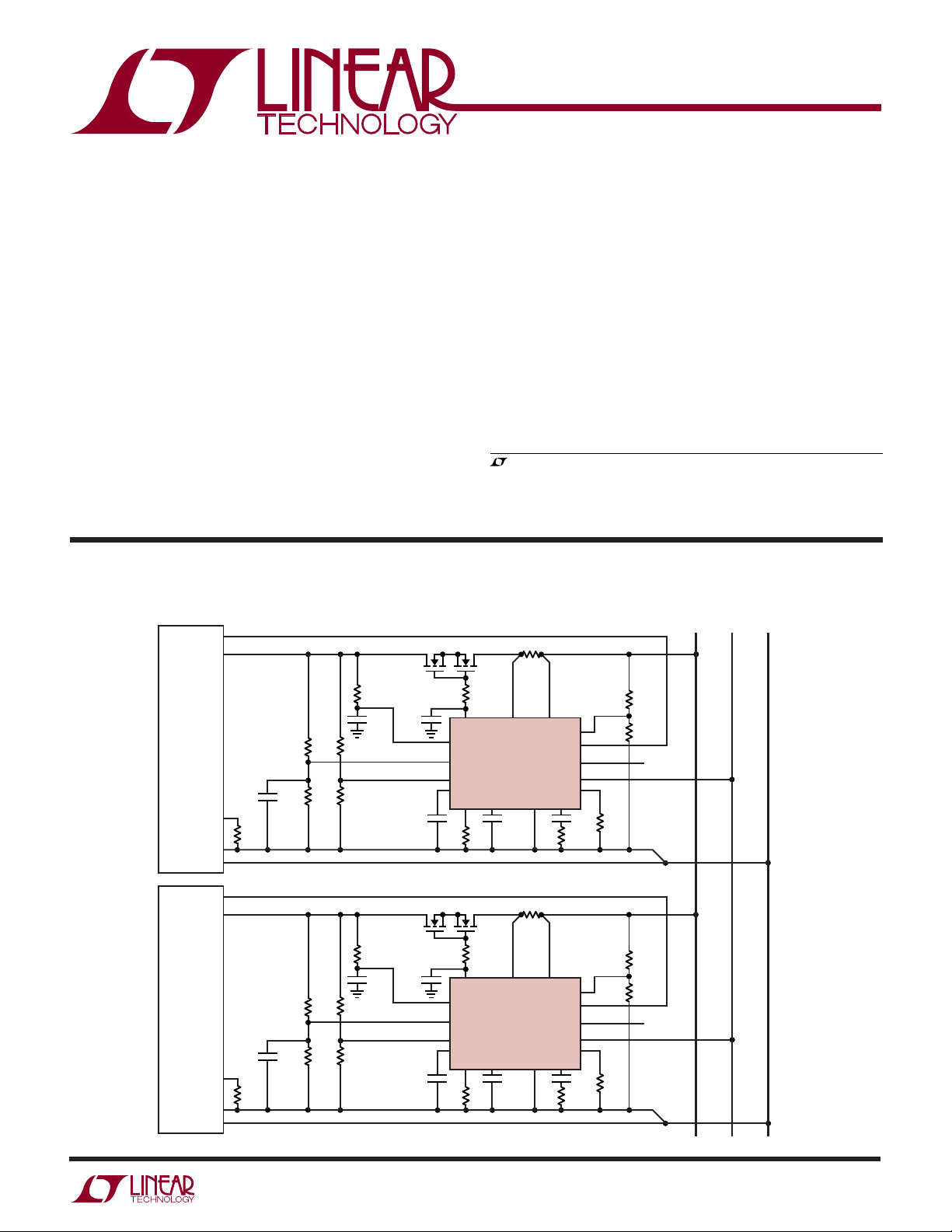

TYPICAL APPLICATIO

5V Load Share (5A per Module)

+

SENSE

+

OUT

SUD50N03-07

The LTC®4350 is a load share controller that allows

systems to equally load multiple power supplies connected in parallel. The output voltage of each supply is

adjusted using the SENSE+ input until all currents match

the share bus. The LTC4350 also isolates supply failures

by turning off the series pass transistors and identifying

the failed supply. The failed supply can then be removed

and replaced with a new unit without turning off the

system power. The LTC4350 is available in a 16-pin

narrow SSOP package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Hot Swap is a trademark of Linear Technology Corporation.

0.010Ω

V

OUT

+

SHARE BUS

–

V

OUT

VICOR*

VI-J30-CY

SENSE

SENSE

VICOR*

VI-J30-CY

SENSE

51Ω 100Ω

0.1µF

0.1µF

43.2k

274k

12.1k

121k

0.1µF

TRIM

470k

–

–

OUT

+

+

OUT

43.2k

274k

0.1µF

TRIM

470k

–

–

OUT

*LOAD SHARING CIRCUIT WORKS WITH MOST POWER SUPPLIES THAT HAVE A SENSE

12.1k121k

0.1µF

SUD50N03-07

51Ω 100Ω

0.1µF

0.1µF

0.1µF

–

34k

34k

R+R

LTC4350

1000pF

0.010Ω

R+R

LTC4350

1000pF

STATUS STATUS

–

STATUS STATUS

+

OR FB PIN

GATE

V

CC

UV

OV

TIMER

GAIN COMP1 GND COMP2

GATE

V

CC

UV

OV

TIMER

GAIN COMP1 GND COMP2

37.4k

FB

I

OUT

SB

R

SET

4.7µF

150Ω

FB

I

OUT

SB

R

SET

4.7µF

150Ω

12.1k

100Ω

37.4k

12.1k

100Ω

4350 TA01

4350fa

1

Note 1: A

LTC4350

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Supply Voltage (VCC) ............................................... 17V

Input Voltage

TIMER .................................................. –0.3V to 1.2V

R+, R– (Note 2) ......................................–0.3V to 17V

FB ........................................................ – 0.3V to 5.3V

OV, UV ....................................................... –0.3V to 17V

Output Voltage

COMP1 ................................................... – 0.3V to 6V

COMP2 ................................................... – 0.3V to 3V

GAIN, SB ............................................. –0.3V to 5.6V

GATE (Note 3) ...........................................– 0.3V to 20V

I

, STATUS ........................................... – 0.3V to 17V

OUT

R

.......................................................................

SET

Operating Temperature Range

LTC4350C ............................................... 0°C to 70°C

LTC4350I........................................... – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

–0.3V to 1V

U

W

U

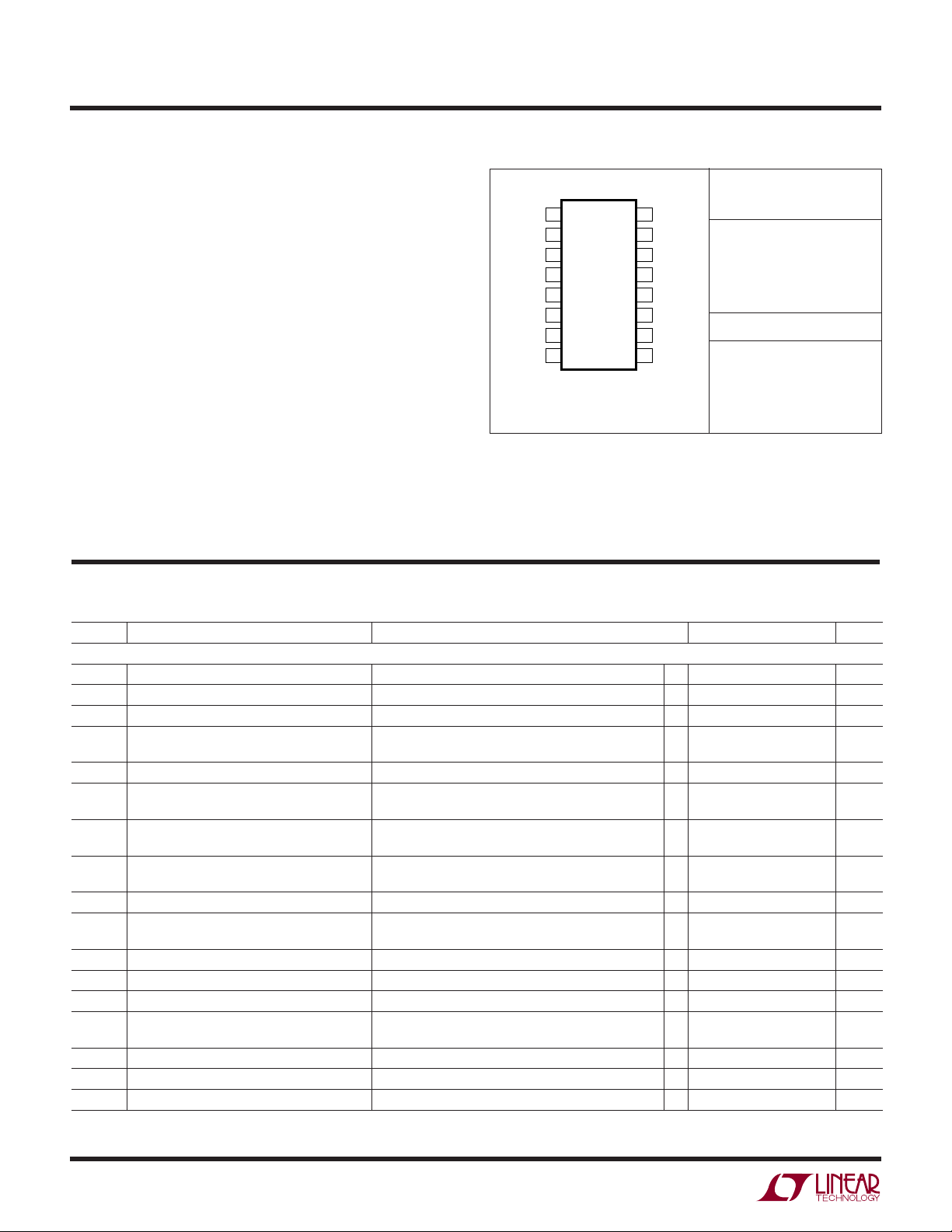

PACKAGE/ORDER INFORMATION

TOP VIEW

1

UV

2

OV

3

TIMER

4

GAIN

5

COMP2

6

COMP1

7

SB

8

GND

GN PACKAGE

16-LEAD PLASTIC SSOP

T

= 150°C, θJA = 135°C/W

JMAX

Consult LTC marketing for parts specified with wider operating temperature ranges.

16

15

14

13

12

11

10

9

V

CC

STATUS

GATE

+

R

–

R

I

OUT

R

SET

FB

ORDER PART

NUMBER

LTC4350CGN

LTC4350IGN

GN PART MARKING

4350

4350I

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DC Characteristics

I

CC

V

LKOH

V

LKOL

V

FB

V

FBLIR

V

FBLOR

V

UVTH

V

OVTH

V

TM

I

TM

V

G

V

GO

V

SB(MIN)

V

SB(MAX)

I

SB(MAX)

R

SB

V

E/A2OFF

VCC Supply Current UV = V

VCC Undervoltage Lockout High ● 2.36 2.45 2.52 V

VCC Undervoltage Lockout Low ● 2.24 2.34 2.44 V

FB Pin Voltage 0°C to 85°C (LTC4350I) or 0°C to 70°C (LTC4350C) 1.208 1.220 1.236 V

FB Line Regulation VCC = 3.3V to 12V, COMP1 = 1.240V 0.02 0.05 %/V

FB Load Regulation COMP1 = 2V ● –0.0008 –0.1 %

UV Pin Threshold High Going Threshold ● 1.215 1.244 1.258 V

OV Pin Threshold High Going Threshold ● 1.203 1.220 1.250 V

TIMER Pin Threshold ● 1.18 1.22 1.26 V

TIMER Pin Current TIMER On, V

GAIN Pin Voltage R

GAIN Pin Offset R

SB Pin Minimum Voltage 28 mV

SB Pin Maximum Voltage VCC = 3.3V ● 2.4 2.7 2.9 V

SB Pin Maximum Current V

SB Pin Resistor Value ● 14 20 33 kΩ

E/A2 Offset VSB – V

CC

–40°C to 85°C (LTC4350I) 1.196 1.220 1.244 V

COMP1 = 0.64V

Low Going Threshold

Low Going Threshold

= 0V ● –1.75 – 2 –2.3 µA

TIMER

TIMER On, V

= 25k, (V

GAIN

= 25k, (V

GAIN

VCC = 12V ● 5.6 7.8 10.5 V

= 0V ● –8 –33 –41 mA

SB

GAIN

= 0V, VOV > V

TIMER

+

– V

R

+

– V

R

–

R

–

R

OVTH

) = 100mV ● 2.3 2.5 2.7 V

) = 0mV ● 0 0.02 0.20 V

● 1.0 1.6 2.0 mA

● 0.003 0.1 %

● 1.205 1.220 1.237 V

● 1.180 1.205 1.229 V

● – 5.30 – 6 – 6.7 µA

● 82550 mV

2

4350fa

LTC4350

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DC Characteristics

V

RSET(MAX)RSET

V

RSET(MIN)RSET

I

RSET(MAX)RSET

V

RCTH

∆V

GATE

I

GATE

V

SOL

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: R

Pin Maximum Voltage VCC = 3.3V, R

V

Pin Minimum Voltage VCC = 5V, R

V

Pin Maximum Current R

Reverse Current Threshold V

External N-Channel Gate Drive V

GATE Pin Current Gate On, V

STATUS Pin Output Low I

+

and R– could be at 17V while VCC = 0V.

OUT

= 100Ω ● 0.94 1 1.03 V

– V

SET

= 100Ω ● 0.94 1 1.03 V

SET

= 1000Ω ● 0.001 0.5 V

SET

= 100Ω ● 0.001 0.5 V

SET

= 1.1V ● 18 20 21 mA

IOUT

+

R

CC

= 0V ● –8 –10 –12 µA

GATE

● 10 30 40 mV

● 10.8 12 12.7 V

= 12V, R

CC

= 5V, R

CC

= 50Ω, V

SET

+

– V

R

GATE

= 3mA ● 0.1 0.3 1.2 V

Note 3: An internal clamp limits the GATE pin to a minimum of 10.8V

above V

. Driving this pin to voltages beyond the clamp may damage the

CC

part.

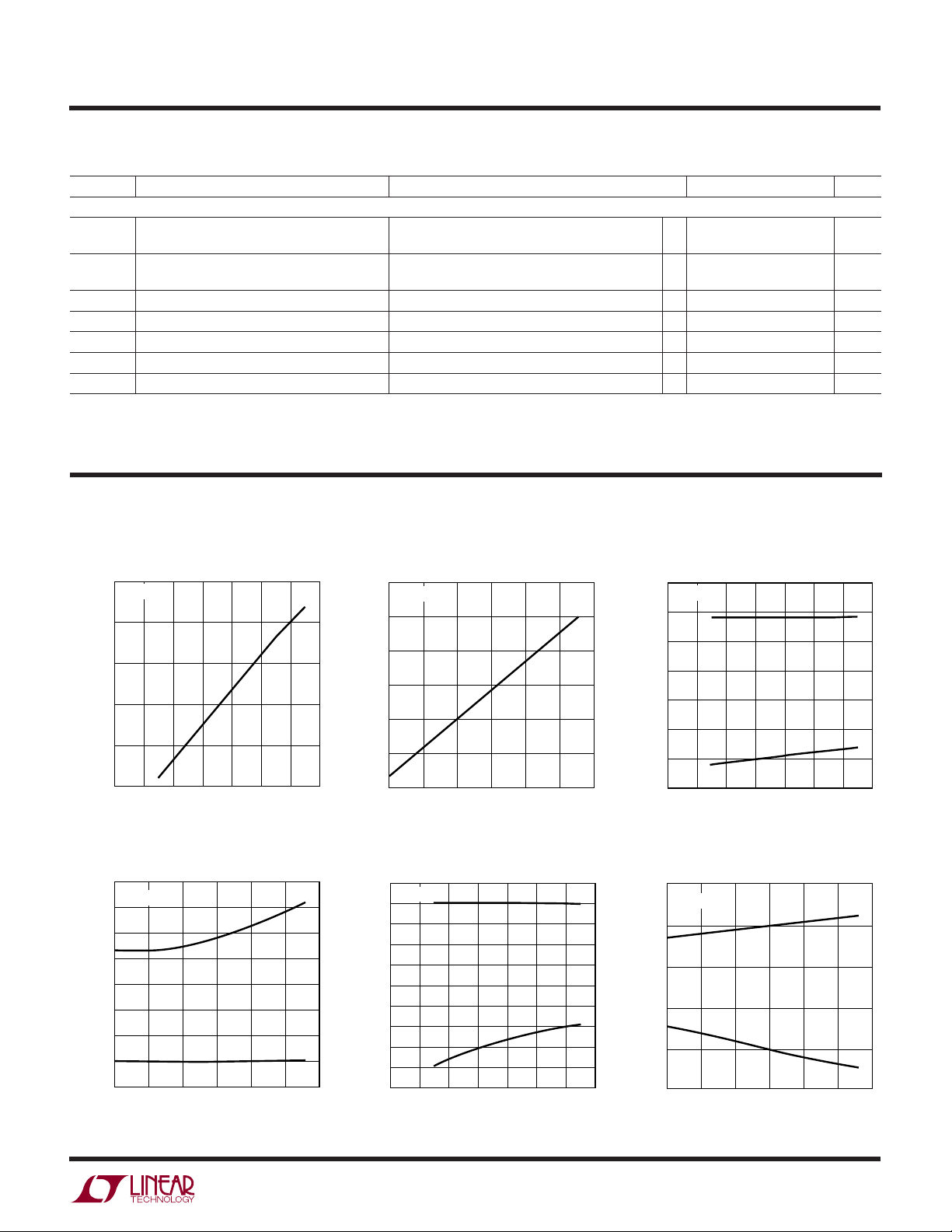

UW

TYPICAL PERFOR A CE CHARACTERISTICS

3.5

3.0

2.5

(mA)

CC

I

2.0

1.5

ICC vs V

TA = 25°C

CC

ICC vs Temperature UV Threshold vs V

1.66

1.64

1.62

1.60

(mA)

CC

I

1.58

1.56

VCC = 5V

1.250

TA = 25°C

1.245

1.240

1.235

1.230

UV THRESHOLD (V)

1.225

1.220

CC

1.0

02

4

VCC (V)

10

8

6

12

14

4350 G01

1.54

–50

–25 0

UV Threshold vs Temperature OV Threshold vs V

1.255

VCC = 5V

1.250

1.245

1.240

1.235

1.230

UV THRESHOLD (V)

1.225

1.220

1.215

–50

–25

02550

TEMPERATURE (°C)

75 100

4350 G04

1.222

TA = 25°C

1.220

1.218

1.216

1.214

1.212

1.210

OV THRESHOLD (V)

1.208

1.206

1.204

1.202

02

25 75

TEMPERATURE (°C)

CC

8

6

4

VCC (V)

50 100

4350 G02

12

14

4350 G05

10

1.215

02

6

4

VCC (V)

OV Threshold vs Temperature

1.225

VCC = 5V

1.220

1.215

1.210

OV THRESHOLD (V)

1.205

1.200

–50

02550

–25

TEMPERATURE (°C)

8

10

14

12

4350 G03

75 100

4350 G06

4350fa

3

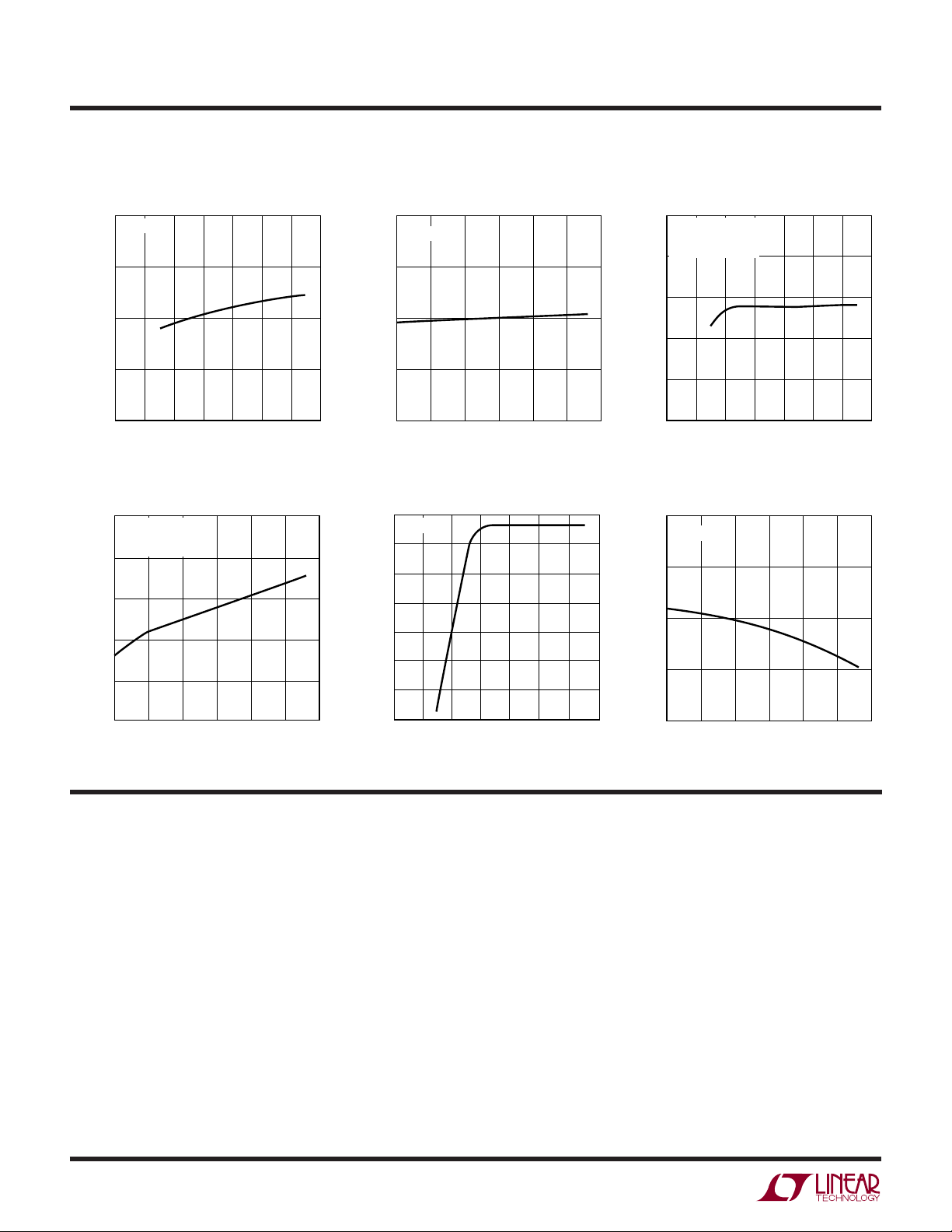

LTC4350

VCC (V)

02

2.2

GAIN (V)

2.4

2.7

4

8

10

4350 G09

2.3

2.6

2.5

6

12

14

R

GAIN

= 25k

(V

R

+

– V

R

–

) = 100mV

T

A

= 25°C

UW

TYPICAL PERFOR A CE CHARACTERISTICS

FB vs V

CC

1.230

TA = 25°C

1.225

1.220

FB (V)

1.215

1.210

02

4

VCC (V)

10

8

6

12

14

4350 G07

Gain Pin Voltage vs Temperature ∆V

2.7

R

= 25k

GAIN

+

–

– V

) = 100mV

(V

R

R

= 5V

V

CC

2.6

2.5

GAIN (V)

2.4

2.3

FB vs Temperature Gain PIn Voltage vs V

1.230

VCC = 5V

1.225

1.220

FB (V)

1.215

1.210

(V)

GATE

∆V

13

12

11

10

9

8

7

–50

GATE

TA = 25°C

02550

–25

TEMPERATURE (°C)

vs V

CC

75 100

4350 G08

(V)

GATE

∆V

13.0

12.5

12.0

11.5

∆V

vs Temperature

GATE

VCC = 5V

CC

2.2

–50

U

02550

–25

TEMPERATURE (°C)

75 100

4350 G10

UU

6

0

24

PI FU CTIO S

UV (Pin 1): Undervoltage Pin. The threshold is set at

1.244V with a 24mV hysteresis. When the UV pin is pulled

high, the charge pump ramps the GATE pin. When the UV

pin is pulled low, the GATE pin will be pulled low.

OV (Pin 2): Overvoltage Pin. The threshold is set at 1.220V

with a 15mV hysteresis. When the OV pin is pulled high,

the GATE pin is pulled low. After a timer cycle, the STATUS

pin is pulled low until the OV pin is pulled low.

TIMER (Pin 3): Analog System Timing Generator Pin. This

pin is used to set the delay before the load sharing turns

on after the UV pin goes high. The other use for the TIMER

pin is to delay the indication of a fault on the STATUS pin.

81214

610

VCC (V)

4350 G11

11.0

–50

02550

–25

TEMPERATURE (°C)

75 100

4350 G12

When the timer is off, an internal N-channel shorts the

TIMER pin to ground. When the timer is turned on, a 2µA

or 6µA timer current (I

) from VCC is connected to the

TIMER

TIMER pin and the voltage starts to ramp up with a slope

given by: dV/dt = I

TIMER/CT

. When the voltage reaches the

trip point (1.220V), the timer will be reset by pulling the

TIMER pin back to ground. The timer period is given by:

(1.220V • CT)/I

TIMER

.

GAIN (Pin 4): Analog Output Pin. The voltage across the

R+ and R– pins is divided by a 1k resistor and sourced as

a current from the GAIN pin. An external resistor on the

GAIN pin determines the voltage gain from the current

sense resistor to the GAIN pin.

4350fa

4

LTC4350

U

UU

PI FU CTIO S

COMP2 (Pin 5): Analog Output Pin. This pin is the output

of the share bus error amplifier E/A2. (A compensation

capacitor between this pin and ground sets the crossover

frequency for the power supply adjustment loop.) In most

cases, this pin operates between 0.5V to 1.5V and represents a diode voltage up from the voltage at the R

It is clamped at 3V. During start-up, this pin is clamped to

ground. After a timer cycle (and if the GATE pin is high), the

COMP2 pin is released.

COMP1 (Pin 6): Analog Output Pin. This pin is the output

of the voltage regulating error amplifier E/A1. A compensation capacitor between this pin and ground sets the

crossover frequency of the share bus loop. This pin

operates a diode voltage up from the voltage at the SB pin

and is clamped at 8.4V.

SB (Pin 7): Analog Output Pin. This pin drives the share

bus used to communicate the value of shared load current

between several power supplies. There is an amplifier that

drives this pin a diode below the COMP1 pin using an

internal NPN as a pull-up and a 20k resistor as a pull-down.

GND (Pin 8): Chip Ground.

FB (Pin 9): Analog Error Amplifier Input (E/A1). This pin is

used to monitor the output supply voltage with an external

resistive divider. The FB pin voltage is compared to 1.220V

reference. The difference between the FB pin voltage and

the reference is amplified and output on the COMP1 pin.

R

(Pin 10): Analog Output Pin. The I

SET

OUT

converts the voltage at the COMP2 pin (down a diode

voltage) to the R

external resistor (R

ground is (COMP2 – V

pin. Therefore, the current through the

SET

) placed between the R

SET

DIODE

)/R

. This current is used to

SET

SET

adjust the output voltage.

I

(Pin 11): Analog Output Pin. The current flowing into

OUT

the I

pin that was set by the external resistor R

pin is equal to the current flowing out of the R

OUT

. This current

SET

is used to adjust the output supply voltage by modifying

the voltage sensed by the power supply’s internal voltage

feedback circuitry.

pin.

SET

amplifier

pin and

SET

R– (Pin 12): Analog Input Pin. With a sense resistor placed

in the supply path between the R+ and R– pins, the power

supply current is measured as a voltage drop between R

and R–. This voltage is measured by the I

SENSE

block and

+

multiplied at the GAIN pin.

+

(Pin 13): Analog Input Pin. With a sense resistor placed

R

in the supply path between the R

supply current is measured as a voltage drop between R

and R–. This voltage is measured by the I

+

and R– pins, the power

block and

SENSE

+

multiplied at the GAIN pin.

GATE (Pin14): The high side gate drive for the external

N-Channel power FET. An internal charge pump provides

the gate drive necessary to drive the FETs. The slope of the

voltage rise or fall at the GATE is set by an external

capacitor connected between GATE and GND, and the

10µA charge pump output current. When the undervoltage

lockout circuit monitoring V

trips, the OV pin is pulled

CC

high or the UV pin is pulled low, the GATE pin is immediately pulled to GND.

STATUS (Pin 15): Open-Drain Digital Output. The STATUS pin has an open-drain output to GND. This pin is

pulled low to indicate a fault has occurred in the system.

There are three types of faults. The first is a undervoltage

lockout on VCC or the UV pin is low while the output

voltage is active. The second is when the COMP2 pin is

above 1.5V or below 0.5V and the voltage on the GAIN pin

is greater than 100mV. The final failure is when the OV pin

is high. The three faults will activate the pull-down on the

STATUS pin after a timing cycle.

VCC (Pin 16): The Positive Supply Input, Ranging from

3.3V to 12V for Normal Operation. ICC is typically 1.6mA.

An undervoltage lockout circuit disables the chip until the

voltage at VCC is greater than 2.47V. A 0.1µF bypass

capacitor is required on the VCC pin. If the VCC pin is tied

to the same power supply output that is being adjusted,

then a 51Ω decoupling resistor is needed to hold up the

supply during a short to ground on the supply output. V

CC

must be greater than or equal to the supply that is

connected to the R+ and R– pins.

4350fa

5

LTC4350

BLOCK DIAGRA

W

6

9

1

COMP1

FB

–

R

UV

V

CC

REF

+

–

+

–

REVERSE CURRENT

+

R

30mV

+

–

+

–

–

E/A1

E/A2

1416

GATE

CHARGE

PUMP

OVER/UNDER

CURRENT

13

12

+

–

R

R

+

I

OUT

+

I

SENSE

20k

–

gm = 1m

Ω

GAIN

COMP2

I

OUT

4

SB

7

5

11

–

R

SET

10

6

REF

OV

2

REF

+

+

2µA/6µA

LOGIC

–

GND

8

TIMER

STATUS

3

15

4350 BD

4350fa

WUUU

APPLICATIO S I FOR ATIO

LTC4350

INTRODUCTION

Many system designers find it economically feasible to

parallel power supplies to achieve redundancy. The second trend is providing some load sharing between the

many supplies. In some cases, a failure in any one supply

will trigger a sequence that disconnects the faulty supply

and sends a flag to the system. Then, a service technician

will swap in a good supply. For systems that are continuously powered, there is Hot Swap circuitry to prevent

glitches on the power buses when power cards are

swapped. A block diagram of this system is shown in

Figure 1.

By combining the features of a load share and a Hot Swap

controller into one IC, the LTC4350 simplifies the design

of redundant power supplies. A complete redundant power

supply is a combination of a power module and the

LTC4350 as shown in Figure 2. Note that the power

CONNECTOR

LOAD

HOT

SWAP

CONNECTOR

HOT

SWAP

OUTPUT

SHARE

BUS

Figure 1. Redundant Power Card System

INPUT BUS

OUTPUT BUS

SHARE BUS

INPUT

BUS

BUS

POWER

MODULE

+

OUT

+

SENSE

–

SENSE

–

OUT

Figure 2. Redundant Power Supply

LOAD

SHARE

LOAD

SHARE

LTC4350

4350 F02

POWER

SUPPLY

POWER

SUPPLY

4350 F01

module must have accessible feedback network or a

remote sensing pin (SENSE+) to interface to the LTC4350.

The LTC4350 provides a means for paralleling power

supplies. It also provides for load sharing, fault isolation

and power supply hot insertion and removal. The power

supply current is accurately measured and then compared

to a share bus signal. The power supply’s output voltage

is adjusted until the load current matches the share bus,

which results in load sharing. There are two optional

power FETs in series with the load that provide a quick

disconnect between a load and a failed power supply.

These same power FETs allow a power supply to be

connected into a powered backplane in a controlled manner or removed without disruption.

CURRENT SHARING

The current sharing components will now be discussed.

Figure 3 shows a simplified block diagram of these components. The I

block measures the power supply

SENSE

current by amplifying the voltage drop across the sense

resistor. An external resistor on the GAIN pin determines

the gain of the I

block. The voltage drop across the

SENSE

sense resistor is divided by a precision 1k resistor to

produce a current at the GAIN pin. For example, a 10mV

sense voltage translates to a 10µA current. If a 10k resistor

is on the GAIN pin, then the voltage gain is 10k/1k or 10.

The voltage at the GAIN pin is compared to the current

share bus using the E/A2 block. The output of E/A2 is used

to adjust the output voltage of the power supply using the

I

block. The objective of the E/A2 block is forcing the

OUT

GAIN pin voltage to equal the SB pin voltage. When the

GAIN pin voltages of all the LTC4350s in the system equal

the SB pin voltage, the load current is shared.

VOLTAGE MONITOR

Unique to the LTC4350 is tight output voltage regulation.

This is handled by the LTC4350’s error amplifier and

reference and not the power supply’s error amplifier and

reference. The E/A1 amplifier monitors the output voltage

via the feedback divider connected to the FB pin. The FB pin

is compared to the internal reference of the LTC4350. If the

FB pin is at or below the reference, then the output of E/A1

4350fa

7

LTC4350

WUUU

APPLICATIO S I FOR ATIO

PASS-FET USED TO

DISCONNECT A BAD POWER

SUPPLY AND TO HOT-SWAP A

+

OUT

THE POWER SUPPLY CURRENT

POWER SUPPLY

C

G

GATE

DRIVE

THIS VOLTAGE REPRESENTS

MEASURED USING A SENSE

3

+

RESISTOR

R

I

SENSE

SENSE

21

–

gm = 1m

R

GAIN

R

OUT

+

SENSE

4

FB PIN

Ω

–

E/A1

+

REF

+

E/A2

–

THIS VOLTAGE REPRESENTS

THE

REFERENCE CURRENT

(i.e., SHARE BUS)

VALUE

NEEDED TO FORCE THE OUTPUT

VOLTAGE TO EQUAL THE REF

COMP1 PIN

20k

COMP2 PIN

+

I

OUT

SHARE BUS

I

OUT

PIN

–

THIS AMPLIFIER FORCES THE POWER

SUPPLY CURRENT TO EQUAL THE

REFERENCE CURRENT VALUE

(i.e., SHARE BUS)

+–

I

ADJ

LOAD

THIS RESISTOR CONVERTS I

TO A VOLTAGE TO MODIFY THE

REMOTE SENSE INPUT OF THE

POWER SUPPLY (SENSE

CREATES AN ARTIFICIAL

+

VOLTAGE THAT

SENSE

ADJUSTS THE POWER

SUPPLY’S OUTPUT VOLTAGE

UP OR DOWN

THIS AMPLIFIER CONVERTS

THE E/A2 VOLTAGE OUTPUT TO

A CURRENT OUTPUT (I

R

PIN

SET

R

SET

4350 F03

ADJ

ADJ

+

). IT

)

Figure 3. Simplified Block Diagram

drives the SB pin (or share bus). If the FB pin is above the

reference, the COMP1 pin is grounded and the SB pin is

disconnected from the COMP1 pin using the series diode.

The LTC4350 with the highest reference will drive the SB

pin and the 20k loads connected to the SB pin. All of the

other LTC4350’s COMP1 pins are pulled low because their

FB pins are at a higher voltage than their references. The

series diode between the COMP1 pin and the SB pin is

actually a low impedance buffer amplifier with a diode in

the output stage. Therefore, the master LTC4350’s E/A1

drives the share bus to the proper value that keeps the

output voltage tightly regulated. The buffer amplifier is

capable of driving at least fifty 20k loads (each 20k load

represents an LTC4350).

OUTPUT VOLTAGE ADJUSTMENT

The LTC4350 is designed to work with supplies featuring

remote sense. The output voltage of each power supply

needs to be adjusted below the final output voltage at the

common load. For example, a 5V system would require the

power supply output be set to 4.90V or some value below

5V. This is normally done using the trim pin of the module.

The power supply output is then increased by artificially

reducing the positive sense voltage by a small amount.

The LTC4350 would then adjust the output voltage to 5V,

an increase of 2%. The maximum range of adjustment can

be set from 2% to 5% to compensate for voltage drops in

the wiring, but no more than 300mV.

In most power supplies, the voltage sense is tied directly

to the output voltage. If a small valued resistor, R

OUT

, is

placed in series with the power supply sense line, a voltage

drop across R

appears as a lower sensed voltage. This

OUT

requires the power supply to increase its output voltage to

compensate. Thus, the LTC4350 exercises complete control of the final output voltage.

The I

a current that flows through R

voltage at COMP2 increases, the current in R

block converts the E/A2 output (COMP2 pin) to

OUT

(see Figure 3). As the

OUT

OUT

4350fa

8

WUUU

APPLICATIO S I FOR ATIO

LTC4350

increases. The output voltage will then increase by an

amount equal to the voltage drop across R

external resistor, R

tionship in the I

as I

ADJ

= (V

OUT

COMP2

, sets the voltage to current rela-

SET

block. The current in R

– 0.58V)/R

SET

.

OUT

The maximum voltage that can be applied across R

. The

OUT

is defined

is

SET

1V. The range of the output voltage adjustment is set to be

V

MAXADJ

voltage if the share bus is accidentally shorted to V

= R

OUT/RSET

. This sets the worst-case output

. As

CC

mentioned previously, this range is set to be 2% to 10%

in value.

The compensation elements, C

CP1

and C

, are used to

CP2

set the crossover frequencies of the two error amplifiers

E/A1 and E/A2. In the Design Example section, the

calculations for choosing all of the components will be

discussed.

Output Adjust Soft-Start

In the LTC4350, there is soft-start circuitry that holds the

COMP2 pin at ground until both the GATE pin is 4V above

the VCC pin and a timer cycle is completed following the

UV pin becoming active.

In cases where the power FETs are turned on but the

power supply is still ramping up, the load voltage may

overshoot. For these cases, the COMP2 pin is clamped to

ground during one timing cycle. If the UV pin is greater

than 1.244V, the chip begins the timer cycle. The timer

cycle uses a 2µA current source into an external capacitor

on the TIMER pin. As soon as the voltage at the TIMER pin

exceeds 1.220V, the timer cycle is over. The time-out is

defined as t = C

• 1.220V/2µA. At the end of the timer

T

cycle, the power supply ramping should be complete.

Faults

There are several types of power supply output faults.

Shorts from the output to ground or to a positive voltage

greater than the normal output voltage are considered

“hard faults.” These faults require the bad power supply to

be immediately disconnected from the load in order to

prevent disruption of the system. “Soft faults” include

power supply failed open-circuit or load current sharing

failure where the output voltage is normal but load sharing

between several supplies is not equal. The LTC4350 can

isolate soft and hard faults and signal a system controller

using the STATUS pin.

Upon power-up, most of the circuitry is active including

the circuits that monitor and adjust the output voltage.

The external power FETs are initially open circuit when

power is applied. It takes about 10ms to 100ms for the

FETs to transition from the off to the fully on state (as

discussed in the following Hot Swapping section). During this time the FB pin is near ground which forces the

SB to the positive rail. The COMP2 pin is then forced to

the positive rail, which forces the R

pin to 1V. The

SET

voltage at the output of the power supply is now adjusted

to its maximum adjusted value, which can be 10% above

nominal. Once the power FETs are turned on, the load will

see this adjusted output voltage. This appears to be a

voltage overshoot at the load that exists until the loop can

correct itself. The dominant pole in the loop exists on the

COMP2 pin. Therefore, the overshoot duration is determined by the discharge time of the COMP2 pin.

In order to eliminate this overshoot, the COMP2 pin is

clamped at ground until the GATE pin is 4V above the V

CC

pin (power FETs are turned on). Now, the COMP2 pin will

begin to charge up until the FB pin regulates at 1.220V.

HARD FAULTS

The LTC4350 can identify faults in the power supply and

isolate them from the load if optional external power FETs

are included between the power supply and the load. In the

case of a power supply output short to ground, the reverse

current block will sense that the voltage across the current

sense resistor has changed directions and has exceeded

30mV for more than 5µs. The gate of the external power

FETs is immediately pulled low disconnecting the short

from the load. The gate is allowed to ramp-up and turn-on

the power FETs as soon as the reverse voltage across the

sense resistor is less than 30mV.

The condition where a power supply output shorts to a

high voltage is referred to as an overvoltage fault. In this

case, the gate of the power FETs is pulled low disconnecting the overvoltage from the load. This feature uses the OV

pin to monitor the power supply output voltage. Once the

voltage on the OV pin exceeds the 1.220V threshold, the

gate of the external power FETs is pulled low.

4350fa

9

LTC4350

WUUU

APPLICATIO S I FOR ATIO

A timer is started as soon as the OV pin exceeds 1.220V.

The timer consists of a 6µA current source into an external

capacitor on the TIMER pin. As soon as the voltage on the

TIMER pin exceeds 1.220V, the STATUS pin is pulled low.

There are two external power FETs in Figure 3. The FET

with its drain on the power supply side (left) and its source

on the load side (right) is used to block high voltage faults

from the load. If overvoltage protection is not needed, this

FET is omitted. Likewise, the FET with its drain on the load

side (right) can be eliminated if protection from a ground

short is not needed. The other use for the power FETs is to

allow hot swapping of the power supply. Hot swapping will

be discussed in a later section.

SOFT FAULTS

The existence of a share bus that forces tight regulation of

the system output voltage allows the system to detect if

the load current is not sharing properly. As mentioned

previously, the output of E/A2 will adjust until the measured current equals the share bus value. If the power

supply output fails to share properly, the E/A2 output will

hit the plus or minus supply. The LTC4350 uses the over/

under current block to monitor the E/A2 output. This block

signals the logic that a soft fault has occurred if the E/A2

output goes out of the normal 0.5V to 1.5V range where the

I

block is active. After a timer cycle, the STATUS pin

OUT

indicates a soft fault. The timer consists of a 2µA current

source into an external capacitor on the TIMER pin. As

soon as the voltage on the TIMER pin exceeds 1.220V, the

STATUS pin is pulled low.

The fault indication at the STATUS pin is disabled under

one condition. The E/A2 output can be less than 0.5V when

the load currents are low. In this case, it is desired to

disable the soft fault indication until the current is higher.

Higher current is defined as when the GAIN pin is greater

than 100mV.

The most common situations for soft faults are a disconnected power supply and the share bus shorts to VCC or

ground.

HOT SWAPPING

The LTC4350 controls external power FETs to allow power

supplies to be hot swapped in and out of the powered

system without disturbing the power buses. The gate of

the power FETs are slowly ramped up. This slowly charges

the power supply input and output capacitors, preventing

the large inrush currents associated with capacitors being

hot plugged into power buses.

When power is first applied to the V

power FET is pulled low. As soon as V

pin, the gate of the

CC

rises above the

CC

undervoltage lockout threshold, the chip’s UV pin is functional. A 0.1µF bypass capacitor is required on the VCC pin.

If the VCC pin is tied to the same power supply output that

is being adjusted, then a 51Ω decoupling resistor is

needed to hold up the supply during a short to ground on

the supply output.

If the UV pin is greater than 1.244V, the gate of the external

FETs is charged with a 10µA current source. The voltage

at the GATE pin begins to rise with a slope equal to 10µA/

CG (Figure 4), where CG is the external capacitor connected between the GATE pin and GND. This slow charging

allows the power supply output to begin load sharing in a

nondisruptive manner.

VCC + 10V

V

SLOPE = 10µA/C

CC

t

Figure 4. Supply Turn-On

G

1

t

2

GATE

V

OUT

4350 F04

10

4350fa

WUUU

APPLICATIO S I FOR ATIO

LTC4350

When the power supply is disconnected, the UV pin will

drop below 1.220V if the supply is loaded. The LTC4350

then discharges the gate of the power FET isolating the

load from the power supply.

DESIGN EXAMPLE

Load Share Components

This section demonstrates the calculations involved in

selecting the component values. The design example in

Figure 5 is a 5V output. This design can be extended to

each of the parallel sections.

The first step is to determine the final output voltage and

the amount of adjustment on the output voltage. The

power supply voltage before the load sharing needs to be

lower than the final output voltage. If the load is expecting

to see a 5V output, then all of the shared power supplies

need to be trimmed to 4.90V or lower. This allows 2%

variation in component and reference tolerances so that

the output always starts below 5V.

Now that the output voltage is preset below the desired

output, the LTC4350 will be responsible for increasing the

output utilizing the SENSE+ input to the power supply. If

a SENSE+ line is not available, then the feedback divider at

the module’s error amplifier can be used. The next step is

to determine the maximum positive adjustment needed for

each power supply. This adjustment includes any I • R drops

across sense resistors, power FETs, wiring and connectors in the supply path between the power supply and the

load. For example, if the maximum current is 10A and the

parasitic resistance between the power supply and load is

0.01Ω, then the positive adjustment range for I • R drops

is 0.1V. Since the starting voltage is 4.9V ±0.1V, then the

lowest starting voltage can be 4.8V. This voltage is 0.2V

below the target. The total adjustment range that the

LTC4350 will need for this example is 0.1V + 0.2V = 0.3V.

Note that the lowest starting voltage should not be lower

than 300mV below the target voltage.

The I • R drops should be designed to be low to eliminate

the need for additional bulk capacitance at the load. In

most cases the bulk capacitance exists at the power

supply output before the I • R drops. If a 0.002Ω sense

resistor is used and the FET resistance is below 0.003Ω,

then a total 0.005Ω series resistance is acceptable for

loads to 20A. Obviously, the FB pin compensates for the

DC output impedance, but the AC output impedance is the

I • R drops plus the ESR of the capacitors.

4.9V NOMINAL, 5.3V MAXIMUM

+

OUT

+

SENSE

C

UV

0.1µF

4 × SUD50N03-07

(0.007Ω EACH)

R

OUT

R

GAIN

86.6k

51Ω

GATE

V

CC

I

OUT

R

SET

GAIN

GND

UV

OV

R

R

FB

TIMER

LTC4350

STATUS STATUS

SB

COMP1

COMP2

C

P2

1µF

R

P1

150Ω

R

G

100Ω

+

–

30Ω

0.1µF

R

SET

100Ω

43.2k274k

12.1k121k

Figure 5. 5V Load Share (20A per Module)

C

G

0.1µF

C

T

0.1µF

C

P1

1000pF

3

R

SENSE

0.002Ω

5V

SHARE

BUS

BUS

21

4

37.4k

12.1k

4350 F05

4350fa

11

LTC4350

WUUU

APPLICATIO S I FOR ATIO

The resistors R

voltage on R

ratio of R

OUT/RSET

output voltage will track the voltage at the R

and R

OUT

is translated to a voltage on R

SET

set the adjustment range. The

SET

. Therefore, the adjustment on the

OUT

pin which

SET

by the

is also the voltage on the COMP2 pin minus a diode

voltage. The expression is V

(V

V

RSET

COMP2

– V

DIODE

) • R

OUT/RSET

is limited to 1V. The maximum adjustment on the

output is expressed as V

value for R

If we set R

is in the 50Ω to 100Ω range.

SET

to be 100Ω, then an R

SET

= (V

ADJ

. The maximum voltage at

ADJMAX

= R

) • R

RSET

OUT/RSET

OUT

OUT/RSET

. A normal

of 100Ω allows

=

the output voltage a full 1V adjustment. For the 0.3V range

in this example, the R

is 30Ω. In some power modules,

OUT

there already exists a resistor between the SENSE+ line

and the power output. In this case, the value of R

OUT

is the

parallel combination of two resistors, one in the module

and one placed between the SENSE+ and output terminals

of the module.

The value of the gain setting resistor, R

depends on

GAIN,

the maximum voltage drop across the sense resistor and

the supply voltage VCC for the chip. The highest possible

voltage at the GAIN pin is 1.5V from the VCC voltage. The

maximum voltage on the GAIN pin is expressed as:

V

GAINMAX

expression for R

I

MAX

is 0.002Ω. Therefore, R

= R

SENSE

GAIN

• I

: R

MAX

GAIN

). In this example, V

GAIN

• R

= (VCC – 1.5V) • 1k/(R

is 5V, I

CC

/1k = VCC – 1.5V. The

GAIN

is 20A and R

MAX

SENSE

is 87.5k but using 1% values

•

SENSE

results in 86.6k.

The FB pin divider provides a 1.220V output for a 5V input.

The precision of the FB pin divider resistors will impact the

accuracy of the final output voltage. The UV resistive

divider in this example, turns on the gate when V

CC

increases above 4V. This corresponds to the UV pin at

1.220V. The capacitor CUV prevents false activation during

load steps. The OV set point needs to occur above the

adjustment max for VCC. The power supply output (which

also is VCC), can start as high as 5V and adjust upwards to

5.3V. The OV set point in this example is 5.5V on V

CC

when

the OV pin is at 1.220V.

charge up to 9V before the output can ramp to 5V which

happens in 90ms. In this case, the output adjust soft-start

turns on when the gate ramps above 9V. The soft-start

circuitry releases the COMP2 pin allowing the load sharing

loop to function. A 100Ω resistor RG prevents high frequency oscillations from the power FETs at their turn-on

threshold. A 0.1µF bypass capacitor is required on the V

CC

pin. If the VCC pin is tied to the same power supply output

that is being adjusted, then a 51Ω decoupling resistor is

needed to hold up the supply during a short to ground on

the supply output.

COMPENSATION

The compensation capacitor, CP1, is needed to set the

crossover frequency of the feedback error amplifier E/A1.

The crossover frequency of 200kHz is adequate for most

applications and requires CP1 to be 1000pF (0.001µF).

The design of the other compensation capacitor will

require some knowledge about the power supply’s bandwidth. The bandwidth can be measured easily. First, use

a storage oscilloscope to monitor the power supply

output voltage. Then place a 1A resistive fixed load and

switch in a second resistive load that increases the total

load current close to rated maximum. Tapping the second

resistor (with the correct power rating) to the power

supply output creates this load step. Trigger the scope on

the falling edge of the output voltage as it drops more than

100mV (for example from 5V to 4.8V). The recovery time,

tR, from the step needs to be measured. tR is defined as

the 10% to 90% time measurement (see Figure 6). The

90%

(t)

OUT

V

10%

0.1∆V

0.1∆V

t

r

∆V

The timer capacitor CT is set to be 0.1µF for a 61ms timer

cycle. The expression is t = CT • 1.22V/2µA. The gate

capacitor CG is set to be 0.1µF which sets a slope of 10µA/

CG or 1V every 10ms. In this case, the GATE pin must

12

t

Figure 6. tR Measurement

4350 F06

4350fa

WUUU

APPLICATIO S I FOR ATIO

LTC4350

compensation capacitor CP2 can be looked up in Table 1

using tR. The value for the zero setting resistor, RP1, is

150Ω. This value guarantees the zero is at or above the

crossover frequency.

Table 1

t

R

5µs 70kHz 0.1µF

10µs 35kHz 0.22µF

20µs 17.5kHz 0.47µF

40µs 8.8kHz 1µF

60µs 5.8kHz 1.5µF

80µs 4.4kHz 2.2µF

100µs 3.5kHz 2.7µF

150µs 2.3kHz 3.3µF

200µs 1.8kHz 4.7µF

300µs 1.2kHz 6.8µF

400µs 0.9kHz 10µF

500µs 0.7kHz 12µF

fC = 0.35/t

R

C

P2

OTHER APPLICATIONS

The application shown on the first page of this data sheet

assumes that the power supplies and the load reside on

one main board. If the system is a true N + 1 hot swappable

power supply, then the LTC4350 will reside with the power

supply on a daughter card that plugs into the main board.

In this case, the input and output capacitors need to be hot

swapped (see Figure 7). The output capacitors are Hot

Swap protected by the LTC4350. The input capacitors are

®

Hot Swap protected using the LT

4250. Other Hot Swap

parts are described in Table 2.

Table 2

VOLTAGE RANGE PART NUMBER

3.3V to 12V LTC1422 Single Channel

LTC1645 Dual Chanel

3.3V to 15V LTC1642 Overvoltage Protection

2.7V to 16.5V LTC1647 Dual Channel

9V to 80V LT1641 Positive High Voltage

–20V to – 80V LT4250 Negative High Voltage

In some cases, the output voltage is below the undervoltage

lockout of the LTC4350. In this case, an external supply of

3.3V or greater needs to provide for the chip. Figure 8

shows a 1.5V output redundant power supply that uses

24V to 1.5V switching power supplies. The V

pin of the

CC

LTC4350 can be driven from the INTVCC pin of the LTC1629.

4350fa

13

LTC4350

WUUU

APPLICATIO S I FOR ATIO

–48V

LOAD

–48V

3.3V

OUT

GND

STATUS

–48V

3.3V

OUT

GND

STATUS

SB

CONNECTOR

SB

CONNECTOR

RTN–48V RTN–48V RTN

–48V

RTN–48V RTN

–48V

POWER SUPPLY 1

V

PWRGD

EE

EE

DD

LT4250L

21

V

DD

LT4250L

21

DRAIN

GATESENSEV

43

POWER SUPPLY 2

PWRGD

DRAIN

GATESENSEV

43

UV

OV

UV

OV

+

V

IN

ON/OFF

–

V

IN

+

V

IN

ON/OFF

–

V

IN

OUT

SENSE

SENSE

OUT

OUT

SENSE

SENSE

OUT

+

R

OUT

+

–

R

G

–

V

GATE

CC

STATUS

LTC4350

COMP2

CC

STATUS

LTC4350

COMP2

TIMER

COMP1

C

R

P2

GATE

TIMER

COMP1

C

R

P2

+

R

–

R

FB

SB

P2

R

G

+

R

–

R

FB

SB

P2

I

OUT

R

SET

R

SET

R

GAIN

GAIN

GND

UV

C

UV

+

+

–

–

C

UV

OV

R

OUT

V

I

OUT

R

SET

R

SET

R

GAIN

GAIN

GND

UV

OV

R

SENSE

3

C

G

C

T

C

P1

R

SENSE

3

C

G

C

T

C

P1

3.3V

21

4

3.3V

21

4

14

4350 F07

Figure 7. –48V to 3.3V Hot Swap Power Supply

4350fa

PACKAGE DESCRIPTIO

LTC4350

U

GN Package

16-Lead Plastic SSOP (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1641)

.045 ±.005

.254 MIN

RECOMMENDED SOLDER PAD LAYOUT

.007 – .0098

(0.178 – 0.249)

.016 – .050

NOTE:

1. CONTROLLING DIMENSION: INCHES

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.150 – .165

.0250 BSC.0165 ± .0015

.015

(0.38 ± 0.10)

0° – 8° TYP

± .004

× 45°

.229 – .244

(5.817 – 6.198)

.0532 – .0688

(1.35 – 1.75)

.008 – .012

(0.203 – 0.305)

TYP

16

15

12

.189 – .196*

(4.801 – 4.978)

14

12 11 10

13

5

4

3

678

.0250

(0.635)

BSC

(0.229)

9

.150 – .157**

(3.810 – 3.988)

.004 – .0098

(0.102 – 0.249)

GN16 (SSOP) 0204

.009

REF

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

4350fa

15

LTC4350

WUUU

APPLICATIO S I FOR ATIO

V

24V

LOAD

24V

GND

1.5V

OUT

STATUS

24V

IN

SB

CONNECTOR

IN

IN

V

GND

V

IN

VCCSENSE

ON

TIMER GND

IN

GATE

LT1641

C

IN

C

IN

INTV

LTC1629

R

SENSE

C

OUT

R

G

C

R

CC

+

V

OS

C

UV

C

OUT

OUT

V

GATE

CC

I

R

OUT

R

R

SET

R

SET

R

GAIN

GAIN

GND

UV

OV

STATUS

LTC4350

COMP1

COMP2

TIMER

C

R

P1

FB

SB

P2

G

+

–

C

T

C

P1

R

SENSE

1.5V

1.5V

R

G

C

G

+

–

C

T

C

P1

GND GND

V

OUT

SB

STATUS

CONNECTOR

VCCSENSE

LT1641

ON

TIMER GND

GATE

INTV

LTC1629

R

CC

+

V

OS

C

UV

OUT

R

SET

R

GAIN

I

OUT

R

GAIN

GND

UV

OV

V

SET

CC

LTC4350

COMP2

GATE

STATUS

TIMER

COMP1

C

R

P1

R

R

FB

SB

P2

Figure 8. 24V to 1.5V Hot Swap Power Supply

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1421 Hot Swap Controller Multiple Supplies from 3V to 12V and –12V

LT1640AL/LT1640AH Negative Voltage Hot Swap Controllers Negative High Voltage Supplies from –10V to – 80V

LT1641 Positive Voltage Hot Swap Controller Positive High Voltage Supplies from 9V to 90V

LTC1645 2-Channel Hot Swap Controller Operates from 1.2V to 12V, Power Sequencing

LTC1646 Dual CompactPCITM Hot Swap Controller 3.3V/5V Only with Precharge and Local Reset Logic

LTC1647-1/LTC1647-2 Dual Hot Swap Controllers Dual ON Pins, Operates from 2.7V to 16.5V

LTC4211 Hot Swap Controller with Multifunction Circuit Breaker 2.5V to 16.5V Supplies and RESET Output

LTC4251 –48V Hot Swap Controller in ThinSOT

ThinSOT is a trademark of Linear Technology Corporation. CompactPCI is a trademark of the PCI Industrial Computer Manufacturers Group.

Linear Technology Corporation

16

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

TM

Active Current Limiting, –15V to –100V Supplies

LT/TP 1004 1K REV A • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2001

4350fa

Loading...

Loading...