L DESIGN FEATURES

100k

20Ω

3.01k

1%

27.4k

1%

10µF

39k

1µF

BAS21

1.2k

38.3k

33pF

1.5nF

10µF

100V

0.1µF

t

ON

12k

PGDLYV

NEG

SYNC

R

CLASS

SHDN

V

CMP

R

CMP

ENDLY OSC SFST

LTC4269-1

GND

UVLO

V

PORTP

V

CC

T2P

T2P

FB

C

CMP

+

+

V

PORTN

383k

1%

3.01k

1%

10k

1nF

3.3nF

•

•

•

•

33mΩ

1%

FDS2582

10k

15Ω

150Ω

PE-68386

BAT54

100Ω

2200pF

MMBT3906 MMBT3904

1µF

1µF

16V

T1

PA2369NL

SENSE

–

SENSE

+

SG

PG

L1

0.18µH

22pF

100µF

5.1Ω

•

FDS8880

47µF

5V

5A

+

SMAJ58A

30.9Ω

24k

107k

10k

S1B

B1100 s 8 PLCS

2.2µF

100V

10µH

DO1608C-103

0.1µF

100V

36V

PDZ36B

BSS63LT1

V

PORTP

48V

AUXILIARY

POWER

–54V FROM

DATA PAIR

–54V FROM

SPARE PAIR

+

–

PD Controller ICs with Integrated

Flyback or Forward Controllers Meet

Demands of 25.5W PoE+

Introduction

The IEEE 802.3af Power over Ethernet (PoE) standard allows a powered

device (PD), such as an internet

protocol (IP) telephone, to draw up to

12.95W from an Ethernet cable. When

the 802.3af standard was drafted,

12.95W appeared sufficient to cover

the immediately imaginable range of

PD products (primarily IP phones).

Of course, application developers

are always far more innovative than

standards committees anticipate, so

new power-hungry applications for

PoE immediately started to appear,

such as dual-radio IEEE 802.11a/g

and 802.11n wireless access points,

security cameras with pan/tilt/zoom

motors, and color LCD IP video

phones. 12.95W was suddenly not

enough. The IEEE committee responded with the 802.3at standard,

which raises the available PD power

to 25.5W. The new “at” standard, commonly referred to as PoE+, also adds

a “handshaking” communications

requirement between PDs and power

sourcing equipment (PSEs), while allowing backward compatibility with

the legacy “af” standard.

New power control ICs are required

to take advantage of these expanded

requirements. The DC/DC conversion

and control schemes used for legacy

“af” PDs are not optimized for the increased power capability and feature

requirements of PoE+. For instance,

in both standards the 37V to 57V PoE

voltage is converted to lower voltages

that digital circuitry can tolerate.

This DC/DC conversion is handled

in the lower power 12.95W standard

with a conventionally rectified (i.e.,

diode rectified) flyback converter. The

higher power 25.5W standard is better

by Ryan Huff

served by a synchronously rectified

(i.e. MOSFET rectified) flyback or a

forward power supply topology.

To meet the new performance

requirements of PoE+, including

handshaking, Linear Technology offers

a new family of PD controller ICs that

integrate a front-end PD controller with

a high performance synchronously

rectified flyback (LTC4269-1) or a

forward (LTC4269-2) power supply

controller.

Features

Both parts combine a PD controller—which includes the handshaking

circuitry, Hot Swap™ FET, and input

protection—with a DC/DC power

supply controller. While the power

supply sections of the two parts are

very different, the PD controller in

both is identical.

6

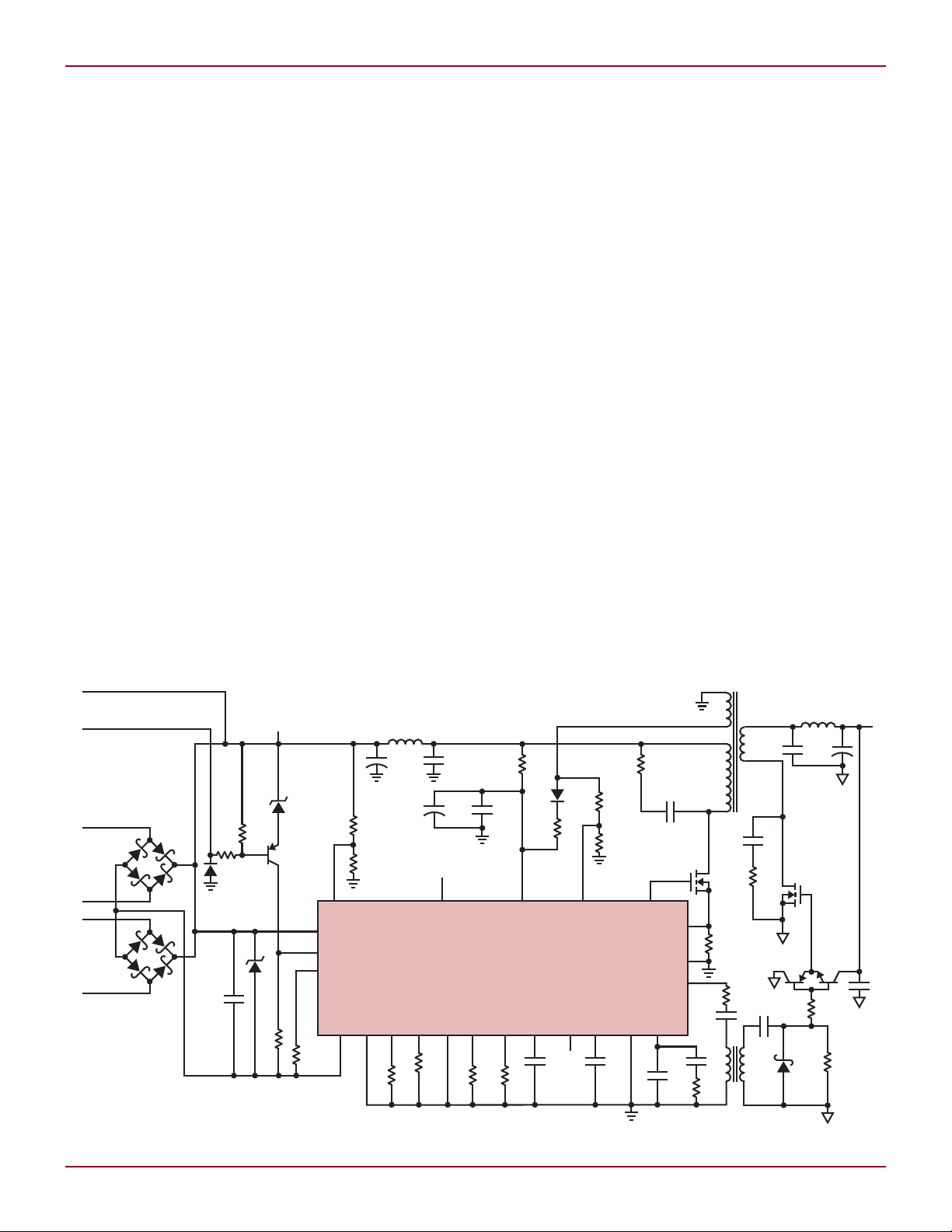

Figure 1. LTC4269-1-based synchronous flyback converter

Linear Technology Magazine • September 2009

+

T2P

T2P

V

NEG

V

PORTN

SHDN

SMAJ58A

R

CLASS

V

PORTP

PGND GND BLANK DELAY

82k

30.9Ω24k

158k 332k

133Ω

BAS516

BAS516

PA2431NL

BAS516

10k

IRF6217

FDS8880

FDS8880

5.1Ω

158k

22.1k

33k

1.5k

50mΩ

2k

5.1Ω

1.2k

TLV431A

PS2801-1-L

V

CC

11.3k

3.65k

22k

0.22µF

0.1µF

R

OSC

V

REF

FB

COMP

I

SENSE

OC

SS_MAXDC

FDS2582

SD_V

SEC

V

IN

S

OUT

LTC4269-2

0.1µF

18V

PDZ18B

10µF

16V

V

CC

33k

237k

107k

10.0k

S1B

B1100 s 8 PLCS

2.2µF

100V

+

10µF

100V

10µH

DO1608C-103

1mH

DO1608C-105

6.8µH

PG0702.682

10.0k

OUT

4.7nF

1nF

5.1Ω

1nF

0.1µF

100V

4.7nF

250V

10nF

+

220µF

6.3V

PSLVOJ227M(12)A

5V

5A

36V

PDZ36B

BSS63LT1

V

PORTP

–48V

AUXILIARY

POWER

–54V FROM

DATA PAIR

–54V FROM

BC857BF

•

•

•

EFFICIENCY (%)

LOAD CURRENT (A)

50.5

95

65

1 1.5 2 2.5 3 3.5 4 4.5

70

75

85

80

90

VIN = 42V

VIN = 50V

VIN = 57V

In the LTC4269, handshaking circuitry, also known as the “High Power

Available,” “Two Finger Detect,” or

“Ping Pong” indicator, allows the PD

to take full advantage of a new PSE’s

full 25.5W of available power. Both

parts include an integrated Hot Swap

MOSFET for a controlled power up of

the PD. The switch has a low 700mΩ

(typical) resistance and a robust 100V

max rating, thus meeting the needs of

a wide range of applications. Auxiliary

power supplies (“wall warts”) can be

accommodated by interfacing to the

SHDN pin to disable the PoE power

path. Setting a programmable classification current allows different

power leveled PDs to be recognized

by the PSE. Achieving this is as easy

as choosing the proper resistor and

placing it from the R

pin. The ICs are chock-full of protection features, including overvoltage,

undervoltage, and overtemperature to

name a few. Finally, complementary

power good indicators signal that the

CLASS

pin to V

PORTN

PD Hot Swap MOSFET is out of the

inrush limit and ready to draw full

power.

The power supply controllers of the

LTC4269s also share some features.

Both offer programmable switching

frequency, which allows the designer

to optimize the trade-off between efficiency and size, or the designer can

choose a specific frequency to meet

application specific EMI requirements. The power supply soft-start

time is also adjustable to prevent

the PSE from dropping out its power

due to excessive inrush current and

virtually eliminate any power supply

DESIGN FEATURES L

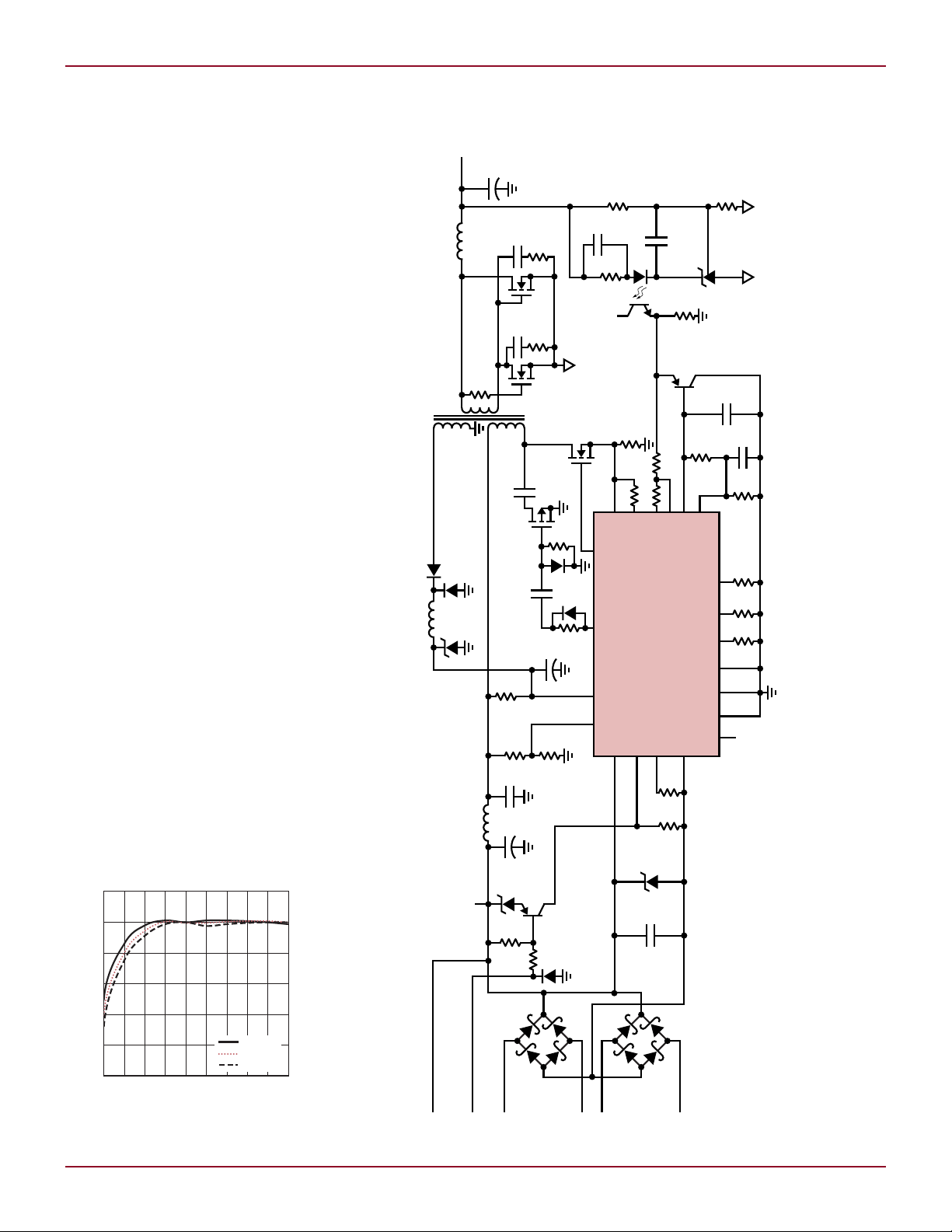

Figure 3. LTC4269-2-based self-driven synchronous forward converter

Figure 2. Efficiency of the circuit in Figure 1

Linear Technology Magazine • September 2009

7

L DESIGN FEATURES

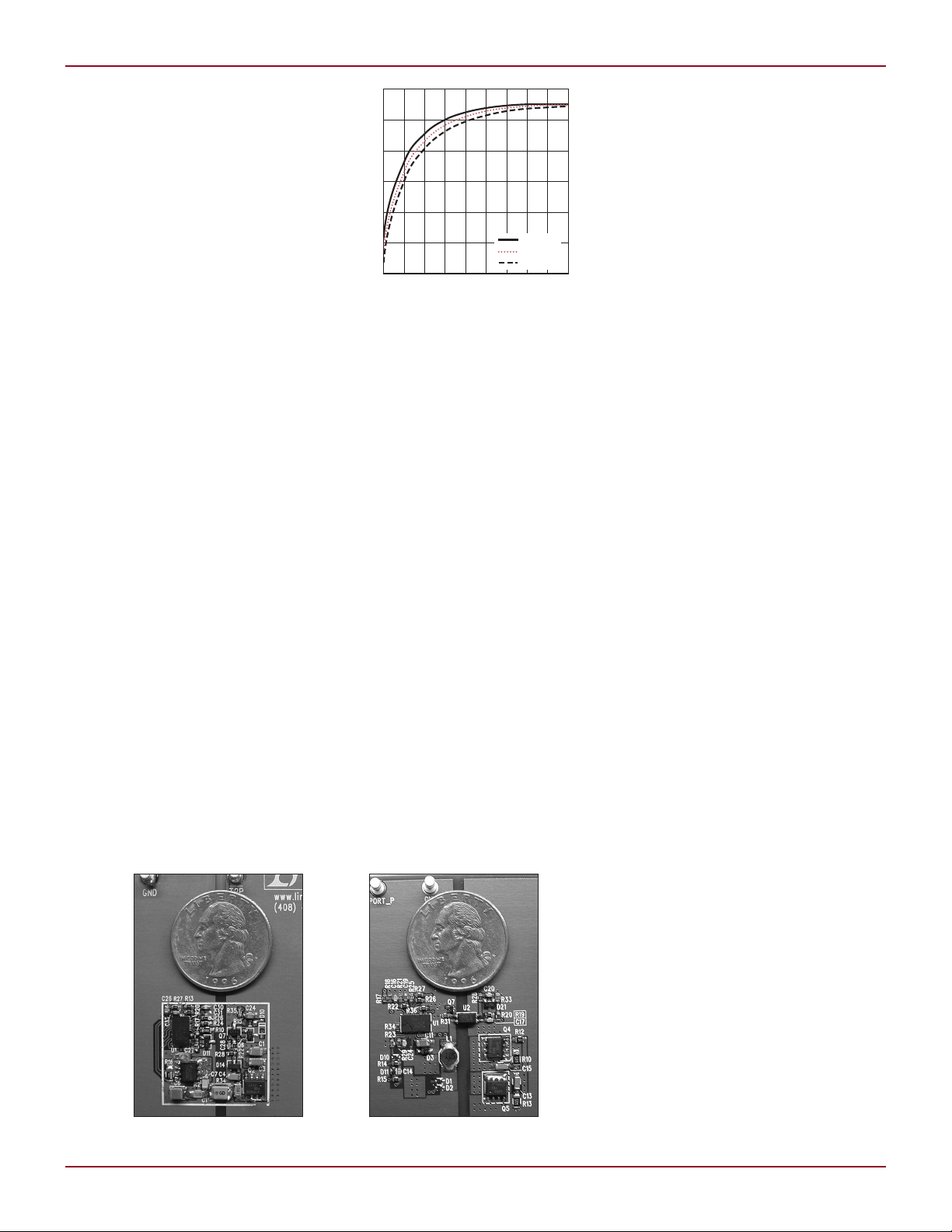

EFFICIENCY (%)

LOAD CURRENT (A)

50.5

95

65

1 1.5 2 2.5 3 3.5 4 4.5

70

75

85

80

90

VIN = 42V

VIN = 50V

VIN = 57V

output voltage overshoot. Both parts

include short circuit protection with

automatic restart.

LTC4269-1 Synchronous

Flyback for Optimized

Combination of Efficiency,

Simplicity, Size and Cost

A synchronous flyback supply utilizing the LTC4269-1 offers the best

combination of efficiency, simplicity,

size and cost. See Figures 1 and 2 for

the schematic and efficiency curves,

respectively, for an LTC4269-1-based

PD power supply capable of a 5V output voltage at 5A.

The flyback parts count is low for a

few reasons. There is no need for the

large output inductor that a forward

converter (see Figure 3) needs, for this

function is rolled into the isolation

transformer (T1). A small, inexpensive

second-stage filter inductor (L1) is

used in the flyback in order to reduce

output voltage ripple, but it should not

be confused with a traditional output

inductor.

In the case of the LTC4269-1, nei

ther a secondary side reference nor an

optocoupler are needed to transmit the

output voltage regulation information

across the isolation boundary. This is

because the IC uses the third (bias)

winding on the transformer, T1, to get

the output voltage information across

the boundary. Finally, the synchronous flyback topology requires half

of the switching MOSFETs (only two)

needed by the forward converter.

Performance, in terms of efficiency, tops out at above 90% for the

-

Figure 4. Efficiency of the circuit in Figure 3

LTC4269-1 synchronous flyback. As

a contrast, typical PoE efficiencies at

the “af” power level for a conventionally rectified flyback were in the lower

half of the 80%’s. This higher efficiency is due to the IC’s well-controlled

implementation of the synchronous

rectifier’s gate drive. This efficiency

is not attainable with an uncontrolled

self-driven synchronous rectification

scheme that is sometimes used.

Regulation over the full PoE+ input

voltage range and 0A to 5A output current range for the LTC4269-1 is better

than ±1%. Output voltage ripple for

the fundamental switching frequency

is less than 30mV peak-to-peak.

LTC4269-2

Synchronous Forward

to Maximize Efficiency

If the efficiency of a PoE+ power supply

is paramount, an LTC4269-2-based

synchronous forward supply is the answer at 92.5% efficiency. The increased

efficiency comes with the trade-off of

increased circuit size and complexity.

Figure 3 shows a complete PD power

supply. Figure 4 shows efficiency,

and Figure 5 compares the physical

size of the flyback (LTC4269-1) versus

the forward (LTC4269-2). The forward

supplies 5V at 5A.

The increase in the forward’s efficiency comes about in part from

decreased RMS currents in the secondary side MOSFETs and in part from

separating the transformer and output

inductor. Both of these changes from

the flyback reduce resistive losses.

The forward supply uses twice the

number of MOSFETs as a flyback so

each switch handles just a portion

of the current that the switches in

the flyback do, thus reducing the I2R

power losses. By separating the isolation transformer and output inductor,

instead of using the transformer for

both as in the flyback, the same power

is processed through two components

instead of one. The net effect is more

copper, thus less resistance and lower

resistive losses.

The cost of the circuit obviously

increases with the addition of larger

and more expensive power path

components. Complexity also goes

up with the need to control twice as

many MOSFETs. Also, the forward

topology does not lend itself to the

third winding feedback method. This

means extra complexity in the design

and compensation of a secondary side

reference and opto-coupler circuitry.

Other than the ultra high efficiency

of the LTC4269-2’s synchronous

forward, the solution has similar performance to the flyback. The output

ripple of the fundamental switching

frequency is about 40mV peak-topeak. The regulation over the entire

input voltage and load current range

is well under ±1%.

8

Figure 5. LTC4269-1 and -2 solutions

Conclusion

Two new highly integrated PD controller ICs are fully compliant with, and

take full advantage of, the upcoming

IEEE 802.3at PoE+ standard. The

LTC4269 family of parts support the

preferred high performance power

supply topologies for use in the new

standard.

Linear Technology Magazine • September 2009

L

Loading...

Loading...