FEATURES

LTC4258

Quad IEEE 802.3af

Power over Ethernet Controller

with Integrated Detection

U

DESCRIPTIO

■

Controls Four Independent – 48V Powered

Ethernet Ports

■

Each Port Includes:

– IEEE 802

®

.3af Compliant PD Detection and

Classification

– Output Current Limit with Foldback

– Short-Circuit Protection with Fast Gate Pull-Down

– PD Disconnect Using DC Sensing

– Power Good Indication

■

Operates Autonomously or by I2C

■

4-Bit Programmable Digital Address Allows Control

TM

Control

of Up to 64 Ports

■

Programmable INT Pin Eliminates Software Polling

■

Current and Duty Cycle Limits Protect External FETs

■

Available in a 36-Pin SSOP Package

U

APPLICATIO S

■

IEEE 802.3af Compliant Endpoint and Midspan

Power Sources

■

IP Phone Systems

■

DTE Power Distribution

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

Hot Swap is a registered trademark of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

The LTC

®

4258 is a quad –48V Hot SwapTM controller designed for use in IEEE 802.3af compliant Power

Sourcing Equipment (PSE). It consists of four independent

ports, each with output current limit, short-circuit protection, complete Powered Device (PD) detection and classification capability, and programmable PD disconnect using

DC sensing. Used with power MOSFETs and passives as

in Figure 1, the LTC4258 can implement a complete IEEE

802.3af-compliant PSE.

The LTC4258 can operate autonomously or be controlled by

2

an I

C serial interface. Up to 16 LTC4258s may coexist on

the same data bus, allowing up to 64 powered Ethernet ports

to be controlled with only two digital lines. Fault conditions

are optionally signaled with the INT pin to eliminate software

polling.

External power MOSFETs, current sense resistors and diodes allow easy scaling of current and power dissipation

levels and provide protection against voltage and current

spikes and ESD events.

The LTC4258 is available in a 36-pin SSOP package.

Linear Technology also provides solutions for 802.3af PD

applications with the LTC4257, LTC4257-1, and LTC4267.

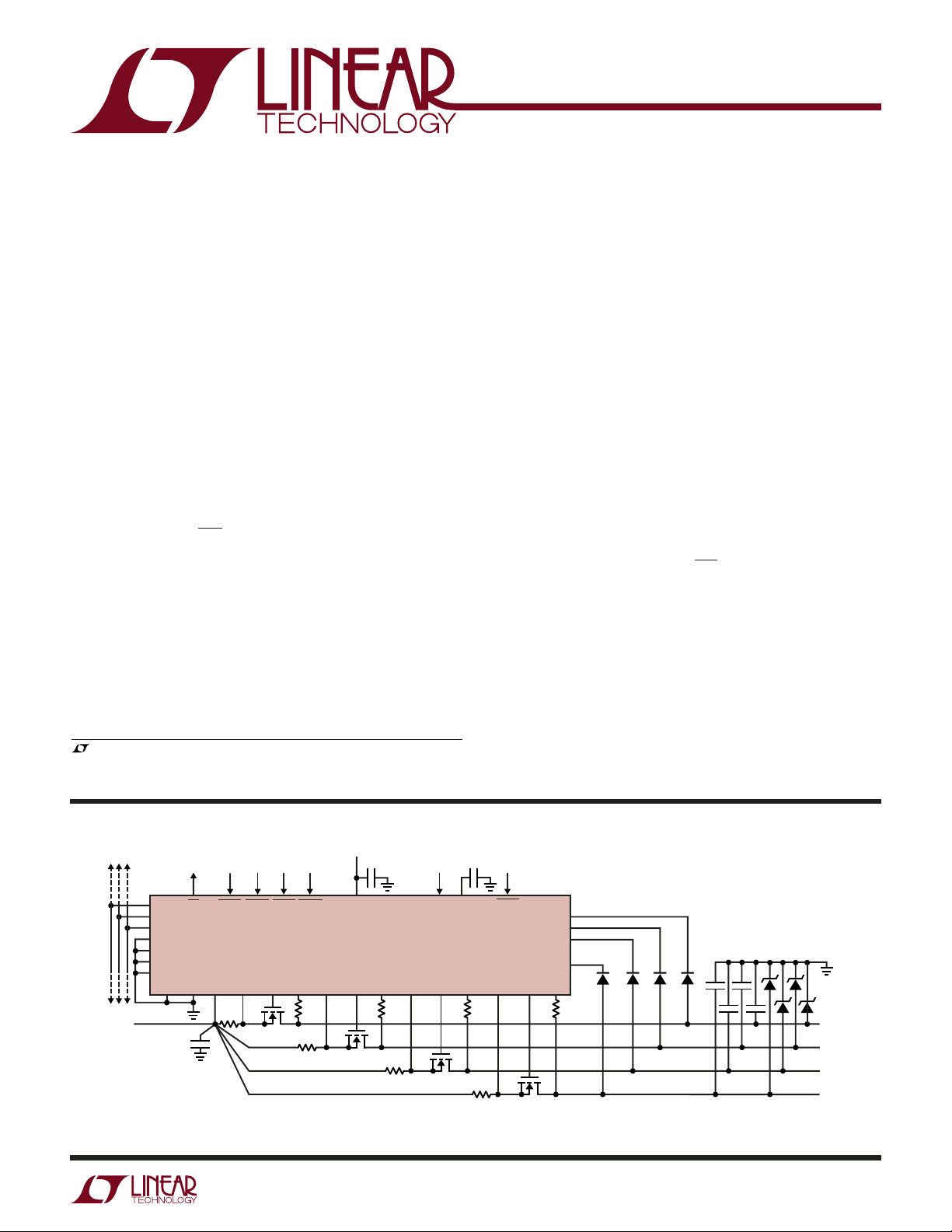

TYPICAL APPLICATIO

INT

SHDN1

SHDN2 SHDN3 SHDN4 V

V

EE

SENSE1

R

S1

RS1 TO RS4: 0.5Ω

Q1 TO Q4: IRFM120A

GATE1

Q1

OUT1 SENSE2 GATE2

–48V

SCL

SDAIN

SDAOUT

AD0

AD1

AD2

AD3

DGND

0.1µF

AGND

U

3.3V

0.1µF

DD

LTC4258

OUT2 SENSE3 GATE3 OUT3 SENSE4 GATE4 OUT4

10k

R

S2

10k 10k 10k

Q2

R

S3

Figure 1. Complete 4-Port Powered Ethernet Power Source

0.1µF

100V X7R

AUTO BYP RESET

Q3

R

S4

DETECT1

DETECT2

DETECT3

DETECT4

Q4

CMPD3003

×4

0.1µF 100V

×4

SMAJ58A

×4

4258 F01

PORT1

PORT2

PORT3

PORT4

4258fb

1

LTC4258

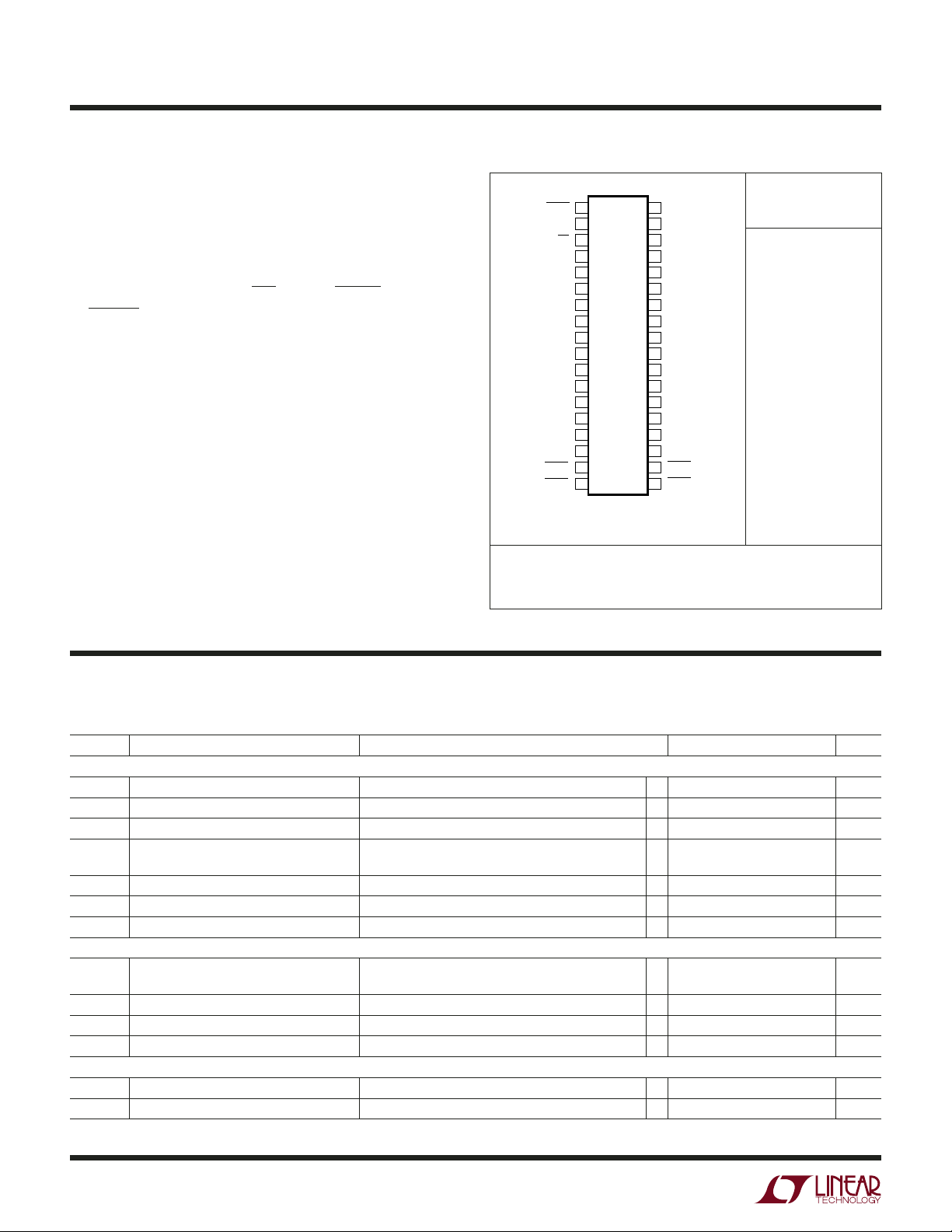

PACKAGE/ORDER I FOR ATIO

UU

W

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

TOP VIEW

GW PACKAGE

36-LEAD PLASTIC SSOP

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

RESET

BYP

INT

SCL

SDAOUT

SDAIN

AD3

AD2

AD1

AD0

DETECT1

DETECT2

DETECT3

DETECT4

DGND

V

DD

SHDN1

SHDN2

NC

AUTO

OUT1

GATE1

SENSE1

OUT2

GATE2

SENSE2

V

EE

OUT3

GATE3

SENSE3

OUT4

GATE4

SENSE4

AGND

SHDN4

SHDN3

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltages

to DGND .......................................... – 0.3V to 5V

V

DD

V

to AGND ......................................... 0.3V to – 70V

EE

DGND to AGND (Note 2) ................................. ±0.3V

Digital Pins

SCL, SDAIN, SDAOUT, INT, AUTO, RESET

n

, AD

SHDN

n .................

Analog Pins

GATE

n

(Note 3) ................... VEE – 0.3V to VEE + 12V

n

DETECT

SENSE

OUT

.................... DGND – 21V to DGND + 0.3V

n .................................

n ....................................

BYP Current ................................................. ±0.1mA

Operating Ambient Temperature Range ...... 0°C to 70°C

Junction Temperature (Note 4)............................ 150°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

DGND – 0.3V to DGND + 5V

VEE – 0.3V to VEE + 1V

VEE – 70V to VEE + 70V

ORDER PART

NUMBER

LTC4258CGW

T

= 150°C, θJA = 80°C/W

JMAX

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

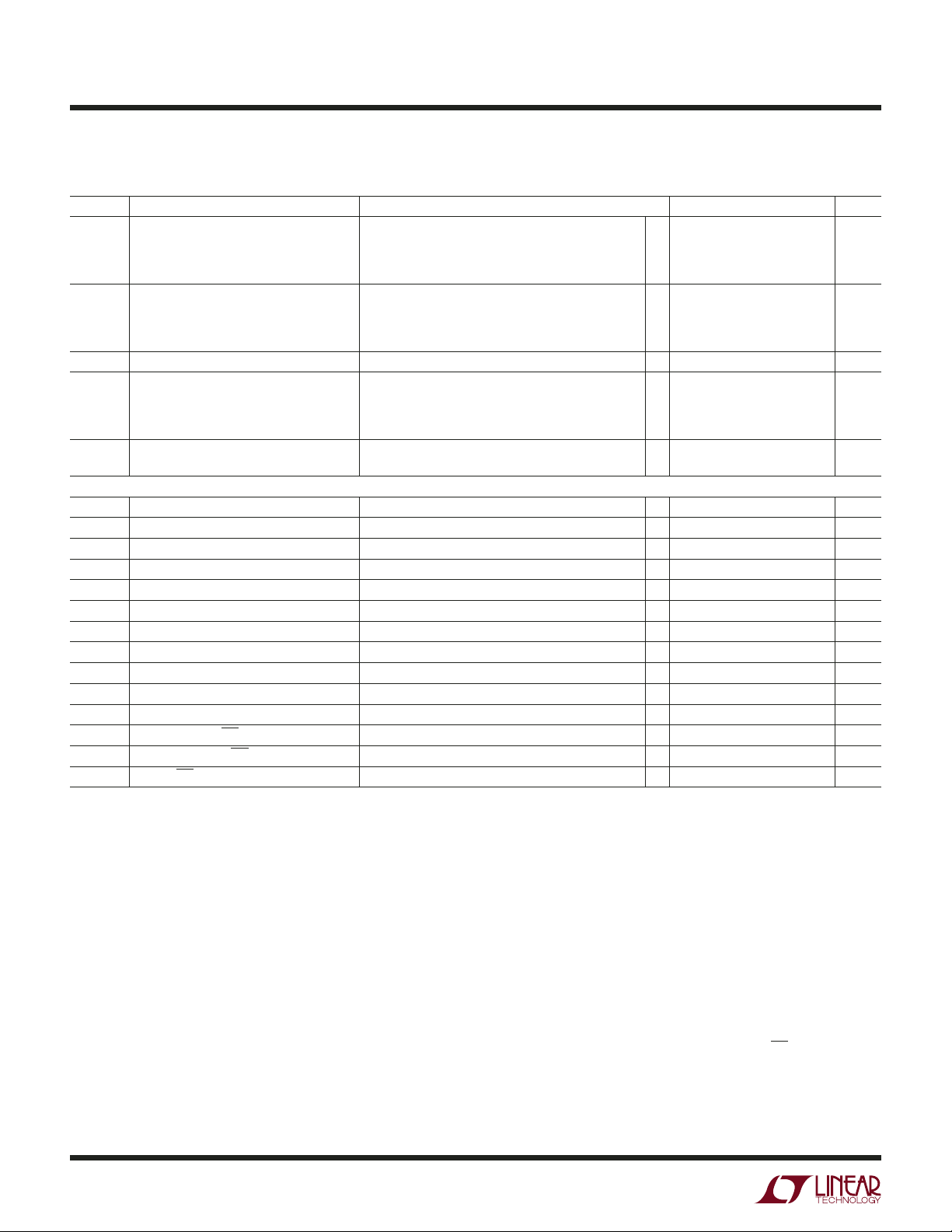

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

(Note 5).

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supplies

V

DD

V

EE

I

DD

I

EE

V

DDMIN

V

EEMINONVEE

V

EEMINOFFVEE

Detection

I

DET

V

DET

R

DETMIN

R

DETMAX

Classification

V

CLASS

I

CLASS

2

VDD Supply Voltage

VEE Supply Voltage To Maintain IEEE Compliant Output (Note 6)

VDD Supply Current

VEE Supply Current Normal Operation

VDD UVLO Voltage 2.7 V

UVLO Voltage (Turning On) VEE – AGND –31 V

UVLO Voltage (Turning Off) VEE – AGND –28 V

Detection Current First Point, V

Detection Voltage Compliance Open Circuit, Measured at DETECTn Pin

Minimum Valid Signature Resistance

Maximum Valid Signature Resistance

Classification Voltage 0mA < I

Classification Current Compliance Into Short (V

The ● denotes the specifications which apply over the full operating

= 25°C. AGND = DGND = 0V, VDD = 3.3V, VEE = –48V unless otherwise noted

A

●

3 3.3 4 V

●

–47 –57 V

Classification Into a Short (V

= –10V

DETECT

Second Point, V

CLASS

DETECT

< 31mA

DETECT

n

n

= 0V)

= –3.5V

DETECT

= 0V) (Note 8)

n

●

●

●

●

235 300 µA

●

145 190 µA

●

●

15.2 17 19 kΩ

●

26.7 29 33 kΩ

●

–16.4 –21 V

●

55 75 mA

2.5 5 mA

–2 –5 mA

100 mA

–20 –23 V

4258fb

LTC4258

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes the specifications which apply over the full operating

= 25°C. AGND = DGND = 0V, VDD = 3.3V, VEE = –48V unless otherwise noted

A

(Note 5).

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

TCLASS

Gate Driver

I

GON

I

GOFF

I

GPD

∆V

GATE

Output Voltage Sense

V

PG

I

VOUT

Current Sense

V

CUT

V

LIM

V

MIN

V

SC

I

SENSE

Digital Interface

V

OLD

V

ILD

V

IHD

R

PU

R

PD

AC Characteristics

t

DETDLY

t

DET

t

CLSDLY

t

CLASS

t

PON

Classification Threshold Current Class 0-1

Class 1-2

Class 2-3

Class 3-4

Class 4-Overcurrent

GATE Pin Current Gate On, V

GATE Pin Current Gate Off, V

GATE Pin Short-Circuit Pull-Down V

External Gate Voltage (V

– VEE)I

GATE

n

Power Good Threshold Voltage V

Out Pin Bias Current 0V > V

Overcurrent Detection Sense Voltage V

Current Limit Sense Voltage V

DC Disconnect Sense Voltage V

= VEE + 2V 50 mA

GATE

n

= –1µA (Note 3)

GATE

n

– V

OUT

n

OUT

–10V > V

V

V

V

OUT

= –48V –20 µA

OUT

n

– VEE, V

SENSE

n

– VEE, V

SENSE

n

– VEE, V

SENSE

n

– VEE, V

SENSE

n

– V

SENSE

n

GATE

GATE

EE

> –10V

n

> –30V

n

EE

= V

n

EE

= VEE + 5V

n

= V

OUT

OUT

OUT

OUT

(Note 7) 166 187.5 199 mV

EE

= V

n

EE

= AGND – 30V 201 224 mV

n

= AGND – 10V 30.2 mV

n

●

5.5 6.5 7.5 mA

●

13 14.5 16 mA

●

21 23 25 mA

●

31 33 35 mA

●

45 48 51 mA

●

–20 –50 –70 µA

●

30 300 µA

●

10 13 15 V

●

123 V

●

●

–6 µA

–18 µA

201 212.5 224 mV

2.52 3.75 4.97 mV

Short-Circuit Sense Voltage 275 mV

SENSE Pin Bias Current V

Digital Output Low Voltage I

Digital Input Low Voltage SCL, SDAIN, RESET, SHDNn, AUTO, AD

Digital Input High Voltage SCL, SDAIN, RESET, SHDNn, AUTO, AD

Pull-Up Resistor to V

DD

= V

SENSE

n

EE

= 3mA, I

SDAOUT

I

SDAOUT

= 5mA, I

INT

INT

ADn, RESET, SHDN

= 3mA

= 5mA

n

–50 µA

●

●

n

n

●

●

2.4 V

0.4 V

0.7 V

0.8 V

50 kΩ

Pull-Down Resistor to DGND AUTO 50 kΩ

Detection Delay From Detect Command or Application of PD to Port

●

170 590 ms

to Detect Complete (Figure 2)

Detection Duration Time to Measure PD Signature Resistance (Figure 2)

Classification Delay From Successful Detect in Auto or Semiauto Mode

●

170 230 ms

●

10.1 52 ms

to Class Complete

●

From Classify Command in Manual Mode (Figure 2)

Classification Duration (Figure 2)

Power On Delay, Auto Mode From Valid Detect to Port On in Auto Mode (Figure 2)

From Port On Command to GATE Pin Current = I

GON

10.1 420 ms

●

10.1 13 ms

●

●

130 ms

1ms

(Note 9)

4258fb

3

LTC4258

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes the specifications which apply over the full operating

= 25°C. AGND = DGND = 0V, VDD = 3.3V, VEE = –48V unless otherwise noted

A

(Note 5).

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

t

START

t

ICUT

DC

CLMAX

t

DIS

t

VMIN

I2C Timing

f

SCLK

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

r

t

f

t

FLTINT

t

STOPINT

t

ARAINT

Maximum Current Limit Duration During t

Port Start-Up t

Maximum Current Limit Duration After t

Port Start-Up t

START1

START1

t

START1

t

START1

ICUT1

ICUT1

t

ICUT1

t

ICUT1

= 0, t

= 0, t

= 1, t

= 1, t

= 0, t

= 0, t

= 1, t

= 1, t

START0

START0

START0

START0

= 0 (Figure 3)

ICUT0

= 1 (Figure 3)

ICUT0

= 0 (Figure 3)

ICUT0

= 1 (Figure 3)

ICUT0

= 0 (Figure 3)

= 1 (Figure 3)

= 0 (Figure 3)

= 1 (Figure 3)

Maximum Current Limit Duty Cycle Reg16h = 00h

Disconnect Delay t

DC Disconnect Minimum Pulse V

DIS1

t

DIS1

t

DIS1

t

DIS1

SENSE

= 0, t

= 0, t

= 1, t

= 1, t

= 0 (Figure 4)

DIS0

= 1 (Figure 4)

DIS0

= 0 (Figure 4)

DIS0

= 1 (Figure 4)

DIS0

– VEE > 5mV, V

n

Width Sensitivity (Note 9)

Clock Frequency (Note 9)

Bus Free Time Figure 5 (Notes 9, 10)

Start Hold Time Figure 5 (Notes 9, 10)

SCL Low Time Figure 5 (Notes 9, 10)

SCL High Time Figure 5 (Notes 9, 10)

Data Hold Time Figure 5 (Notes 9, 10)

Data Set-Up Time Figure 5 (Notes 9, 10)

Start Set-Up Time Figure 5 (Notes 9, 10)

Stop Set-Up Time Figure 5 (Notes 9, 10)

SCL, SDAIN Rise Time Figure 5 (Notes 9, 10)

SCL, SDAIN Fall Time Figure 5 (Notes 9, 10)

Fault Present to INT Pin Low (Notes 9, 10, 11)

Stop Condition to INT Pin Low (Notes 9, 10, 11)

ARA to INT Pin High Time (Notes 9, 10)

= –48V (Figure 4)

OUT

n

●

50 60 70 ms

●

25 30 35 ms

●

100 120 140 ms

●

200 240 280 ms

●

50 60 70 ms

●

25 30 35 ms

●

100 120 140 ms

●

200 240 280 ms

●

5.8 6.3 6.7 %

●

300 360 400 ms

●

75 90 100 ms

●

150 180 200 ms

●

600 720 800 ms

●

●

●

1.3 µs

●

600 ns

●

1.3 µs

●

600 ns

●

150 ns

●

200 ns

●

600 ns

●

600 ns

●

20 300 ns

●

20 150 ns

●

20 150 ns

●

60 200 ns

●

20 300 ns

0.02 1 ms

400 kHz

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: DGND and AGND should be tied together in normal operation.

Note 3: An internal clamp limits the GATE pins to a minimum of 12V above

. Driving this pin beyond the clamp may damage the part.

V

EE

Note 4: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may impair device reliability.

Note 5: All currents into device pins are positive; all currents out of device

4

pins are negative. All voltages are referenced to ground (AGND and DGND)

unless otherwise specified.

Note 6: The LTC4258 is designed to maintain a port voltage of –46.6V to

–57V. The V

supply voltage range accounts for the drop across the

EE

MOSFET and sense resistor.

Note 7: The LTC4258 implements overload current detection per IEEE

802.3af. The minimum overload current (I

voltage; I

CUT_MIN

= 15.4W/V

PORT_MIN

) is dependent on port

CUT

. An IEEE compliant system using the

LTC4258 should maintain port voltage above –46.6V.

Note 8: V

by measuring the DETECT

supply current while classifying a short is measured indirectly

EE

n

pin current while classifying a short.

Note 9: Guaranteed by design, not subject to test.

Note 10: Values measured at V

Note 11: If fault occurs during an I2C transaction, the INT pin will not be

pulled down until a stop condition is present on the I

ILD

and V

IHD

.

2

C bus.

4258fb

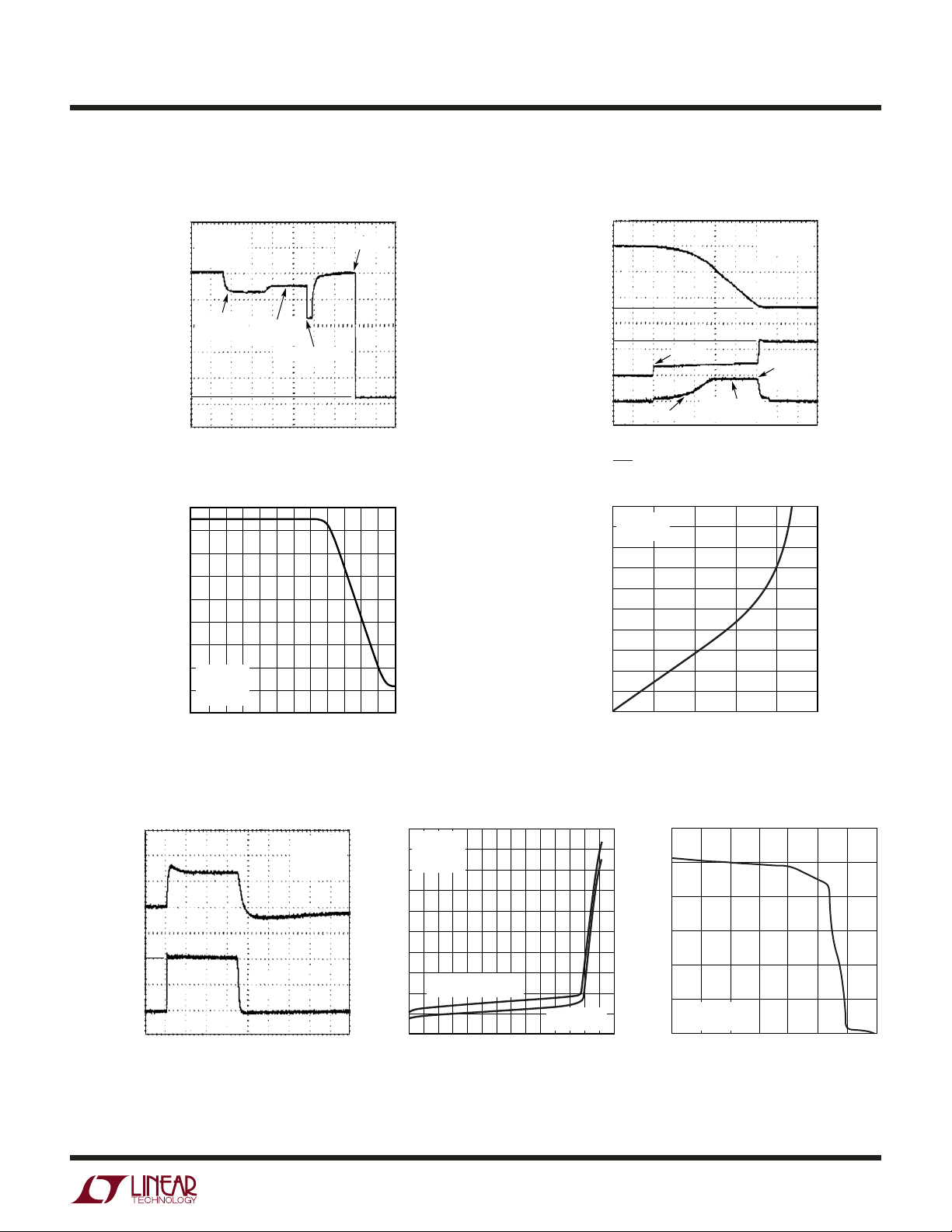

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC4258

PORT

VOLTAGE

10V/DIV

Power On Sequence in Auto Mode

GND

V

EE

PORT 1

= 3.3V

V

DD

= –48V

V

EE

DETECTION

PHASE 1

DETECTION

PHASE 2

CLASSIFICATION

50ms/DIV

POWER ON

Current Limit Foldback

225

200

175

150

125

(mV)

n

100

SENSE

V

75

50

VDD = 3.3V

= –48V

V

EE

25

= 25°C

T

A

0

–48 0

–40

–24–32 –16 –8

V

OUTn-AGND

(V)

4258 G01

4258 G03

450

400

350

300

250

200

150

100

50

0

I

LIMIT

WITH R

SENSE

= 0.5Ω (mA)

PORT

VOLTAGE

20V/DIV

GATE

VOLTAGE

10V/DIV

PORT

CURRENT

500mA/DIV

Powering On a 180µF Load

GND

V

EE

V

EE

+14V

V

0mA

EE

FET ON

FOLDBACK

CURRENT LIMIT

5ms/DIV

INT and SDAOUT Pull Down

Voltage vs Load Current

2.0

VDD = 3.3V

1.8

= 25°C

T

A

1.6

1.4

1.2

1.0

0.8

0.6

PULL-DOWN VOLTAGE (V)

0.4

0.2

0

5

0

10

LOAD CURRENT (mA)

425mA

15

VDD = 3.3V

= –48V

V

EE

LOAD

FULLY

CHARGED

4258 G02

20

4258 G06

25

PORT

VOLTAGE

1V/DIV

PORT

CURRENT

20mA/DIV

Classification Transient Response

to 40mA Load Step Classification Current Compliance

0

VDD = 3.3V

–2

= –48V

V

EE

= 25°C

T

A

–4

–6

–8

–10

–12

–14

PORT VOLTAGE WITH

TYPICAL CMPD3003

–16

CLASSIFICATION VOLTAGE (V)

–18

–20

0 10203040506070

CLASSIFICATION CURRENT (mA)

PIN VOLTAGE

–18V

40mA

0mA

50µs/DIV

VDD = 3.3V

= –48V

V

EE

= 25°C

T

A

4258 G07

DETECT

n

4258 G08

VEE DC Supply Current vs

Supply Voltage

3.0

2.5

2.0

1.5

1.0

SUPPLY CURRENT (mA)

0.5

VDD = 3.3V

REG 12h = 00h

0

–70

–60 –50

–40 –20

VEE SUPPLY VOLTAGE (V)

–30 –10 0

4258 G09

4258fb

5

LTC4258

WU

TEST TI I G

PORT

n

PD

INSERTED

0VV

t

DET

V

SENSE

PORT

TURN ON

(AUTO MODE)

V

GATE

V

CLASS

V

n

EE

V

T

INT

t

DETDLY

t

CLSDLY

t

PON

t

CLASS

4258 F02

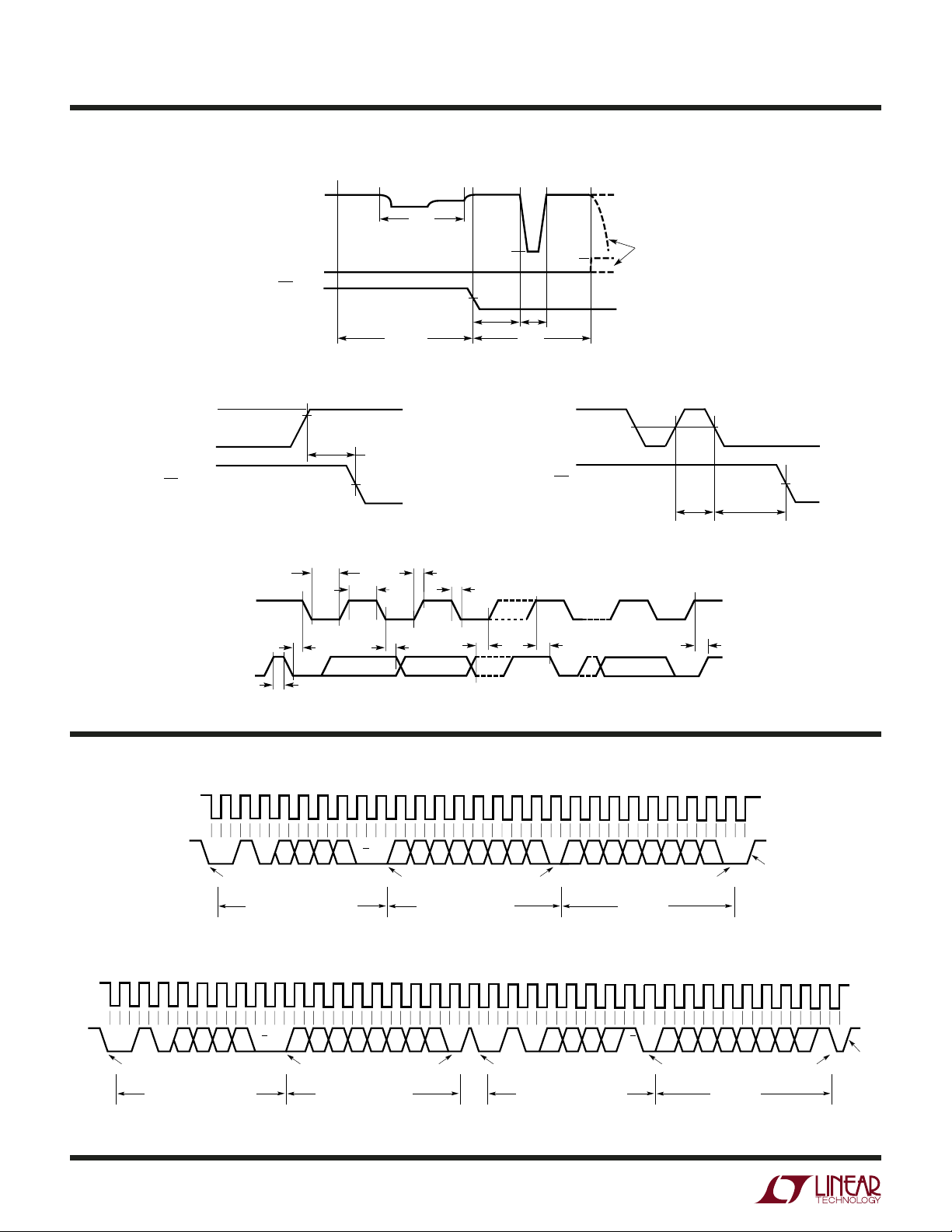

Figure 2. Detect, Class and Turn-On Timing in Auto or Semiauto Modes

V

TO V

n

LIM

EE

0V

INT

V

CUT

t

START

, t

ICUT

V

SENSE

TO V

n

V

EE

MIN

INT

t

4258 F03

VMIN

Figure 3. Current Limit Timing Figure 4. DC Disconnect Timing

SCL

SDA

t

3

t

4

t

2

t

1

t

r

t

f

t

5

t

6

t

7

t

8

4258 F05

Figure 5. I2C Interface Timing

t

DIS

4258 F04

WUW

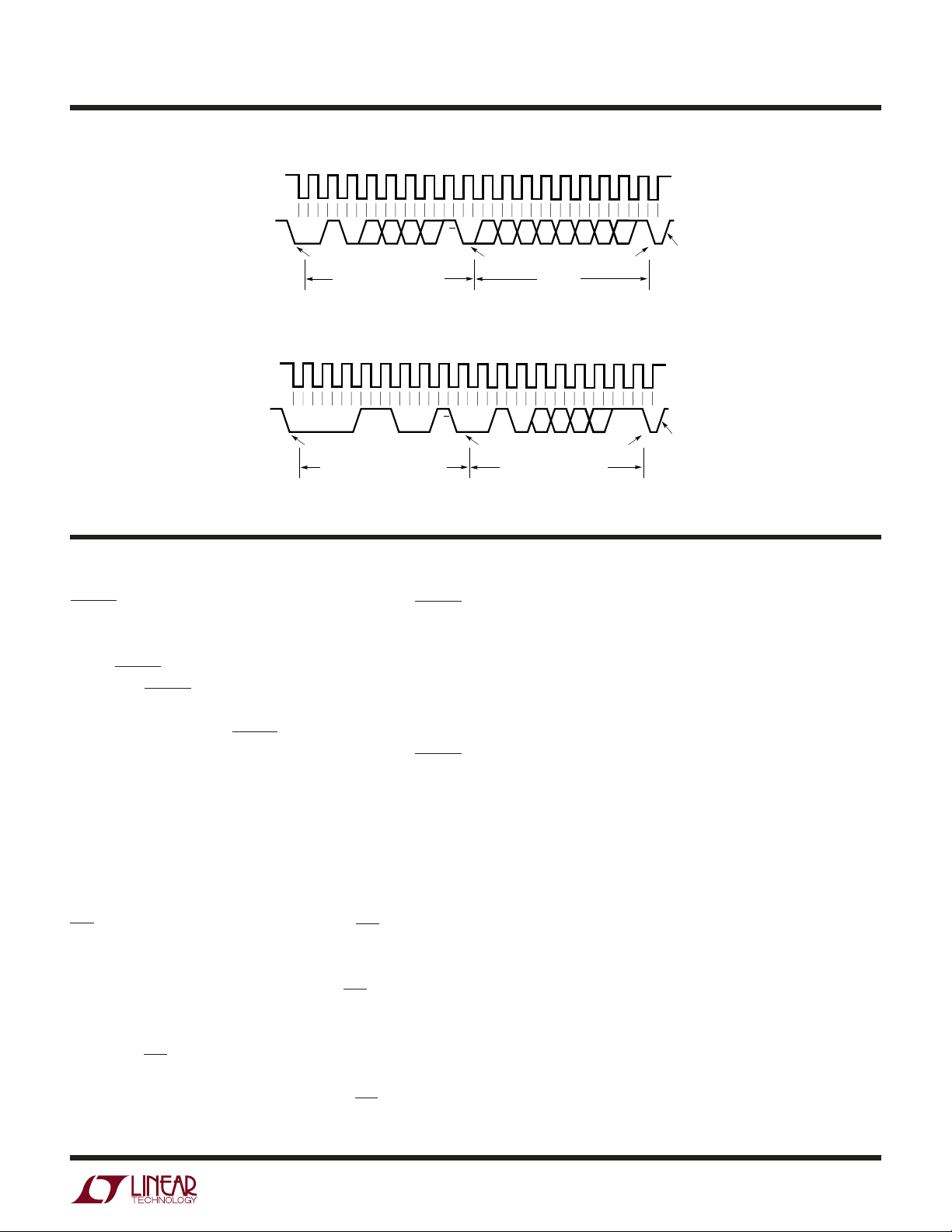

TI I G DIAGRA S

SCL

SCL

SDA

SDA

001

START BY

MASTER

AD3 AD2 AD1 AD0 A7 A6 A5 A4 A3 A2 A1 A0

SERIAL BUS ADDRESS BYTE

FRAME 1

001

START BY

MASTER

AD3 AD2 AD1 AD0 A7 A6 A5 A4 A3 A2 A1 A0

SERIAL BUS ADDRESS BYTE

ACK

R/W

6

FRAME 1

ACK BY

SLAVE

REGISTER ADDRESS BYTE

ACK

R/W

ACK BY

SLAVE

FRAME 2

REGISTER ADDRESS BYTE

ACK BY

SLAVE

Figure 6. Writing to a Register

ACK

001

REPEATED

START BY

MASTER

SERIAL BUS ADDRESS BYTE

FRAME 2

ACK BY

SLAVE

Figure 7. Reading from a Register

ACK ACK

D7 D6 D5 D4 D3 D2 D1 D0

4258 F06

FRAME 2

DATA BYTE

STOP BY

MASTER

NO ACK BY

MASTER

ACK BY

SLAVE

FRAME 3

DATA BYTE

AD3 AD2 AD1 AD0 D7 D6 D5 D4 D3 D2 D1 D0

FRAME 1

R/W

ACK

ACK BY

SLAVE

ACK

4258 F07

STOP BY

MASTER

4258fb

WUW

TI I G DIAGRA S

SCL

LTC4258

SDA

01

START BY

MASTER

AD3 AD2 AD1 AD0 D7 D6 D5 D4 D3 D2 D1 D0

0

SERIAL BUS ADDRESS BYTE

FRAME 1

R/W

ACK

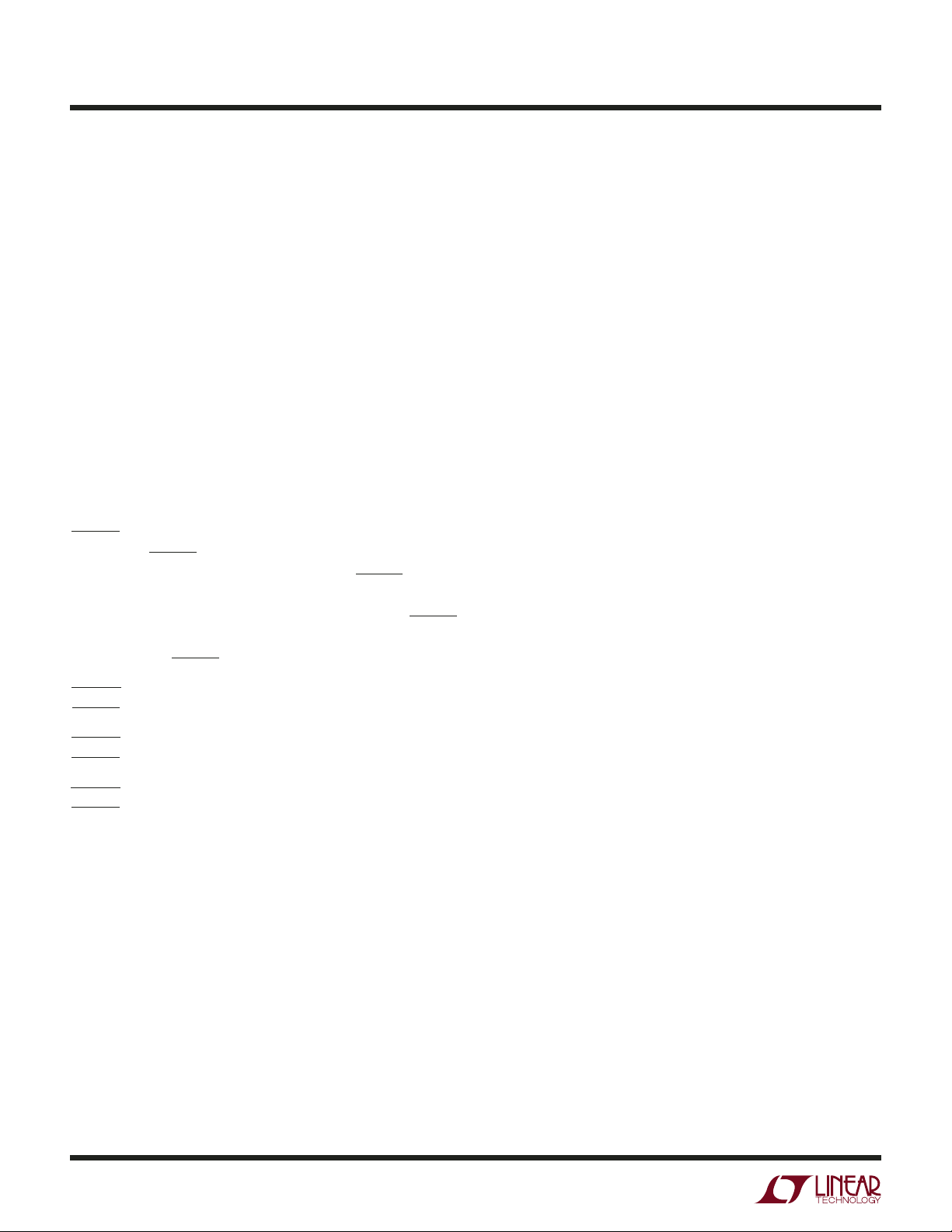

Figure 8. Reading the Interrupt Register (Short Form)

SCL

SDA

00 11

0

START BY

MASTER

FRAME 1

ALERT RESPONSE ADDRESS BYTE

R/W

ACK

Figure 9. Reading from Alert Response Address

U

UU

PI FU CTIO S

RESET (Pin 1): Chip Reset, Active Low. When the RESET

pin is low, the LTC4258 is held inactive with all ports off

and all internal registers reset to their power-up states.

When RESET is pulled high, the LTC4258 begins normal

operation. RESET can be connected to an external capacitor or RC network to provide a power turn-on delay.

Internal filtering of the RESET pin prevents glitches less

than 1µs wide from resetting the LTC4258. Pull RESET

high with ≤10k or tie to V

BYP (Pin 2): Bypass Output. The BYP pin is used to

connect the internally generated –20V supply to an external 0.1µF bypass capacitor. Use a 100V rated 0.1µF, X7R

capacitor. Do not connect the BYP pin to any other external

circuitry.

INT (Pin 3): Interrupt Output, Open Drain. INT will pull low

when any one of several events occur in the LTC4258. It

will return to a high impedance state when bits 6 or 7 are

set in the Reset PB register (1Ah). The INT signal can be

used to generate an interrupt to the host processor,

eliminating the need for continuous software polling.

Individual INT events can be disabled using the Int Mask

register (01h). See Register Functions and Applications

Information for more information. The INT pin is only

2

updated between I

C transactions.

DD

.

ACK

ACK BY

SLAVE

ACK BY

SLAVE

FRAME 2

DATA BYTE

AD30000 1 AD2 AD1 AD0

FRAME 2

SERIAL BUS ADDRESS BYTE

NO ACK BY

MASTER

NO ACK BY

MASTER

STOP BY

MASTER

4258 F08

ACK1

STOP BY

MASTER

4258 F09

SCL (Pin 4): Serial Clock Input. High impedance clock

input for the I

be connected directly to the I

2

C serial interface bus. The SCL pin should

2

C SCL bus line.

SDAOUT (Pin 5): Serial Data Output, Open Drain Data

Output for the I

2

C Serial Interface Bus. The LTC4258 uses

two pins to implement the bidirectional SDA function to

2

simplify optoisolation of the I

C bus. To implement a standard bidirectional SDA pin, tie SDAOUT and SDAIN together.

See Applications Information for more information.

SDAIN (Pin 6): Serial Data Input. High impedance data input

2

for the I

C serial interface bus. The LTC4258 uses two pins

to implement the bidirectional SDA function to simplify

optoisolation of the I

2

C bus. To implement a standard

bidirectional SDA pin, tie SDAOUT and SDAIN together.

See Applications Information for more information.

AD3 (Pin 7): Address Bit 3. Tie the address pins high or low

2

to set the I

sponds. This address will be (010A

C serial address to which the LTC4258 re-

3A2A1A0)b

. Pull AD3

high or low with ≤10k or tie to VDD or DGND.

AD2 (Pin 8): Address Bit 2. See AD3.

AD1 (Pin 9): Address Bit 1. See AD3.

AD0 (Pin 10): Address Bit 0. See AD3.

4258fb

7

LTC4258

U

UU

PI FU CTIO S

DETECT1 (Pin 11): Detect Sense, Port 1. The LTC4258

Powered Device (PD) detection and classification hardware monitors port 1 with this pin. Connect DETECT1 to

the output port via a low leakage diode (see Figure 1). If the

port is unused, the DETECT1 pin can be tied to AGND or

allowed to float.

DETECT2 (Pin 12): Detection Sense, Port 2. See DETECT1.

DETECT3 (Pin 13): Detection Sense, Port 3. See DETECT1.

DETECT4 (Pin 14): Detection Sense, Port 4. See DETECT1.

DGND (Pin 15): Digital Ground. DGND should be con-

nected to the return from the 3.3V supply. DGND and

AGND should be tied together.

V

(Pin 16): Logic Power Supply. Connect to a 3.3V

DD

power supply relative to DGND. VDD must be bypassed to

DGND near the LTC4258 with at least a 0.1µF capacitor.

SHDN1 (Pin 17): Shutdown Port 1, Active Low. When

pulled low, SHDN1 shuts down port 1, regardless of the

state of the internal registers. Pulling SHDN1 low is

equivalent to setting the Reset Port 1 bit in the Reset

Pushbutton register (1Ah). Internal filtering of the SHDN1

pin prevents glitches less than 1µs wide from reseting the

LTC4258. Pull SHDN1 high with ≤10k or tie to V

SHDN2 (Pin 18): Shutdown Port 2, Active Low. See

SHDN1.

DD

.

GATE4 (Pin 23): Port 4 Gate Drive. GATE4 should be

connected to the gate of the external MOSFET for port 4.

When the MOSFET is turned on, a 50µA pull-up current

source is connected to the pin. The gate voltage is clamped

to 13V (typ) above V

the voltage at GATE4 will be reduced to maintain constant

current through the external MOSFET. If the fault timer

expires, GATE4 is pulled down with 50µA, turning the

MOSFET off and recording a t

port is unused, float the GATE4 pin or tie it to V

OUT4 (Pin 24): Port 4 Output Voltage Monitor. OUT4

should be connected to the output port through a 10k

series resistor. A current limit foldback circuit limits the

power dissipation in the external MOSFET by reducing the

current limit threshold when the port voltage is within 18V

of AGND. The port 4 Power Good bit is set when the voltage

from OUT4 to V

is connected internally from OUT4 to AGND. If the port is

unused, the OUT4 pin can be tied to AGND or allowed to

float.

SENSE3 (Pin 25): Port 3 Current Sense Input. See SENSE4.

GATE3 (Pin 26): Port 3 Gate Drive. See GATE4.

OUT3 (Pin 27): Port 3 Output Voltage Monitor. See OUT4.

(Pin 28): –48V Supply Input. Connect to a –48V to

V

EE

–57V supply, relative to AGND.

EE

. During a current limit condition,

EE

or t

ICUT

drops below 2V (typ). A 2.5MΩ resistor

event. If the

START

EE

.

SHDN3 (Pin 19): Shutdown Port 3, Active Low. See

SHDN1.

SHDN4 (Pin 20): Shutdown Port 4, Active Low. See

SHDN1.

AGND (Pin 21): Analog Ground. AGND should be connected to the return from the – 48V supply. AGND and

DGND should be tied together.

SENSE4 (Pin 22): Port 4 Current Sense Input. SENSE4

monitors the external MOSFET current via a 0.5Ω sense

resistor between SENSE4 and V

across the sense resistor exceeds the overcurrent detection threshold V

If the voltage across the sense resistor reaches the current

limit threshold V

GATE4 pin voltage is lowered to maintain constant current

in the external MOSFET. See Applications Information for

further details. If the port is unused, the SENSE4 pin must

be tied to VEE.

, the current limit fault timer counts up.

CUT

(typically 25mV/50mA higher), the

LIM

. Whenever the voltage

EE

SENSE2 (Pin 29): Port 2 Current Sense Input. See SENSE4.

GATE2 (Pin 30): Port 2 Gate Drive. See GATE4.

OUT2 (Pin 31): Port 2 Output Voltage Monitor. See OUT4.

SENSE1 (Pin 32): Port 1 Current Sense Input. See SENSE4.

GATE1 (Pin 33): Port 1 Gate Drive. See GATE 4.

OUT1 (Pin 34): Port 1 Output Voltage Monitor. See OUT4.

AUTO (Pin 35): Auto Mode Input. Auto mode allows the

LTC4258 to detect and power up a PD even if there is no

host controller present on the I2C bus. The voltage of the

AUTO pin determines the state of the internal registers

when the LTC4258 is reset or comes out of V

the Register map in Table 1). The states of these register

bits can subsequently be changed via the I

The real-time state of the AUTO pin is read at bit 0 in the

Pin Status register (11h). Pull AUTO high or low with ≤10k

or tie to V

NC (Pin 36): No Internal Connection.

or DGND.

DD

UVLO (see

DD

2

C interface.

4258fb

8

W

TABLE 1. REGISTER AP

Fault 1 0000,0000 0000,0000

Fault 1 0000,0000 0000,0000

ICUT

START

Fault 2 t

Fault 2 t

ICUT

START

Fault 3 t

Fault 3 t

ICUT

START

01

0

A

1

,A

2

A

3

00 00A

0

A

1

,A

2

A

3

0000,0000 0000,0000

DIS0

t

DIS1

t

ICUT0

t

LTC4258

UVLO

EE

supplies are brought up.

EE

UVLO is not set by RESET pin or

and V

DD

DD

reset all pushbutton.

V

V

bit depends on the order in which the

* The start-up state of the V

WO = Write Only

CoR = Clear on Read

R/W = Read/Write

RO = Read Only

Key:

Fault Class Complete Detect Complete Disconnect Pwr Good Event Pwr Enable Event 1000,0000 1000,0000

ICUT

Fault t

START

Fault 4 t

ICUT

Fault 4 t

START

UVLO Reserved Reserved Reserved Reserved 0011,0000* 0011,0000*

EE

UVLO V

DD

ICUT1

t

START0

t

START1

Enable

Interrupts

00h Interrupt RO Global Supply Event t

Interrupts Auto Pin Low Auto Pin High

ADDRESS REGISTER NAME R/W PORT BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 RESET STATE RESET STATE

02h Power Event RO 4321 Pwr Good Pwr Good Pwr Good Pwr Good Pwr Enable Pwr Enable Pwr Enable Pwr Enable 0000,0000 0000,0000

01h Int Mask R/W Global Mask 7 Mask 6 Mask 5 Mask 4 Mask 3 Mask 2 Mask 1 Mask 0 1000,0000 1110,0100

Events

04h Detect Event RO 4321 Class Complete 4 Class Complete 3 Class Complete 2 Class Complete 1 Detect Complete 4 Detect Complete 3 Detect Complete 2 Detect Complete 1 0000,0000 0000,0000

03h Power Event CoR CoR Change 4 Change 3 Change 2 Change 1 Change 4 Change 3 Change 2 Change 1

05h Detect Event CoR CoR

Event CoR CoR

Event RO 4321 Reserved Reserved Reserved Reserved t

START

START

111 Overcurrent 111 Reserved

110 Class 0 110 Open Circuit

101 Undefined—Read as Class 0 101 RHIGH

100 Class 4 100 Detect Good

011 Class 3 011 RLOW 11 Auto Detect, Class and Power Automatically

010 Class 2 010 Reserved 10 Semiauto Detect and Class But Wait to Turn On Power

001 Class 1 001 Short Circuit (<1V) 01 Manual Will Not Advance Between States

0Fh Port 4 Status RO 4 Reserved Class Status 2 Class Status 1 Class Status 0 Reserved Detect Status 2 Detect Status 1 Detect Status 0 0000,0000 0000,0000

11h Pin Status RO Global Reserved Reserved AD3 Pin Status AD2 Pin Status AD1 Pin Status AD0 Pin Status Reserved Auto Pin Status 00A

10h Power Status RO 4321 Power Good 4 Power Good 3 Power Good 2 Power Good 1 Power Enable 4 Power Enable 3 Power Enable 2 Power Enable 1 0000,0000 0000,0000

06h Fault Event RO 4321 Disconnect 4 Disconnect 3 Disconnect 2 Disconnect 1 t

0Bh Supply Event CoR CoR

0Ah Supply Event RO 4321 Over Temp Reserved V

Status

09h t

08h t

07h Fault Event CoR CoR

0Eh Port 3 Status RO 3 Reserved Class Status 2 Class Status 1 Class Status 0 Reserved Detect Status 2 Detect Status 1 Detect Status 0 0000,0000 0000,0000

0Ch Port 1 Status RO 1 Reserved Class Status 2 Class Status 1 Class Status 0 Reserved Detect Status 2 Detect Status 1 Detect Status 0 0000,0000 0000,0000

0Dh Port 2 Status RO 2 Reserved Class Status 2 Class Status 1 Class Status 0 Reserved Detect Status 2 Detect Status 1 Detect Status 0 0000,0000 0000,0000

Configuration

13h Disconnect Enable R/W 4321 Reserved Reserved Reserved Reserved DC Discon En 4 DC Discon En 3 DC Discon En 2 DC Discon En 1 0000,0000 0000,1111

12h Operating Mode R/W 4321 Port 4 Mode 1 Port 4 Mode 0 Port 3 Mode 1 Port 3 Mode 0 Port 2 Mode 1 Port 2 Mode 0 Port 1 Mode 1 Port 1 Mode 0 0000,0000 1111,1111

14h Detect/Class Enable R/W 4321 Class Enable 4 Class Enable 3 Class Enable 2 Class Enable 1 Detect Enable 4 Detect Enable 3 Detect Enable 2 Detect Enable 1 0000,0000 1111,1111

16h Timing Config R/W Global Reserved Reserved t

15h Reserved R/W Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved 0000,0000 0000,0000

17h Misc Config R/W Global Interrupt Pin Reserved Reserved Reserved Reserved Reserved Reserved Reserved 1000,0000 1000,0000

19h Power Enable PB WO 4321 Power Off 4 Power Off 3 Power Off 2 Power Off 1 Power On 4 Power On 3 Power On 2 Power On 1 0000,0000 0000,0000

18h Det/Class Restart PB WO 4321 Restart Class 4 Restart Class 3 Restart Class 2 Restart Class 1 Restart Detect 4 Restart Detect 3 Restart Detect 2 Restart Detect 1 0000,0000 0000,0000

Pushbuttons

1Ah Reset PB WO Global Clear All Clear Interrupt Pin Reserved Reset All Reset Port 4 Reset Port 3 Reset Port 2 Reset Port 1 0000,0000 0000,0000

000 Class Status Unknown 000 Detect Status Unknown 00 Shutdown Power Off, Detection and Class Off

CLASS STATUS DETECT STATUS MODE BIT ENCODING

Encoding

4258fb

9

LTC4258

UU

REGISTER FU CTIO S

Interrupt Registers

Interrupt (Address 00h): Interrupt Register, Read Only. A

transition to logical 1 of any bit in this register will assert

the INT pin (Pin 3) if the corresponding bit in the Int Mask

register is set. Each bit is the logical OR of the corresponding bits in the Event registers. The Interrupt register is Read

Only and its bits cannot be cleared directly. To clear a bit

in the Interrupt register, clear the corresponding bits in the

appropriate Status or Event registers or set bit 7 in the Reset

Pushbutton register (1Ah).

Int Mask (Address 01h): Interrupt Mask, Read/Write. A logic

1 in any bit of the Int Mask register allows the corresponding Interrupt register bit to assert the INT pin if it is set. A

logic 0 in any bit of the Int Mask register prevents the corresponding Interrupt bit from affecting the INT pin. The

actual Interrupt register bits are unaffected by the state of

the Int Mask register.

Event Registers

Power Event (Address 02h): Power Event Register, Read

Only. The lower four bits in this register indicate that the

corresponding port Power Enable status bit has changed;

the logical OR of these four bits appears in the Interrupt

register as the Pwr Enable Event bit. The upper four bits

indicate that the corresponding port Power Good status bit

has changed; the logical OR of these four bits appears in

the Interrupt register as the Pwr Good Event bit. The Power

Event bits latch high and will remain high until cleared by

reading from address 03h.

Power Event CoR (Address 03h): Power Event Register,

Clear on Read. Read this address to clear the Power Event

register. Address 03h returns the same data as address 02h

and reading address 03h clears all bits at both addresses.

Detect Event (Address 04h): Detect Event Register, Read

Only. The lower four bits in this register indicate that at least

one detection cycle for the corresponding port has completed; the logical OR of these four bits appears in the Interrupt register as the Detect Complete bit. The upper four

bits indicate that at least one classification cycle for the

corresponding port has completed; the logical OR of these

four bits appears in the Interrupt register as the Class Complete bit. In Manual mode, this register indicates that the

requested detection/classification cycle has completed and

the LTC4258 is awaiting further instructions. In Semiauto

or Auto modes, these bits indicate that the Detect Status

and Class Status bits in the Port Status registers are valid.

The Detect Event bits latch high and will remain high until

cleared by reading from address 05h.

Detect Event CoR (Address 05h): Detect Event Register,

Clear on Read. Read this address to clear the Detect Event

register. Address 05h returns the same data as address 04h,

and reading address 05h clears all bits at both addresses.

Fault Event (Address 06h): Fault Event Register, Read Only.

The lower four bits in this register indicate that a

t

fault has occurred at the corresponding port; the logi-

ICUT

cal OR of these four bits appears in the Interrupt register

as the t

connect event has occurred at the corresponding port; the

logical OR of these four bits appears in the Interrupt register as the Disconnect bit. The Fault Event bits latch high

and will remain high until cleared by reading from address

07h.

Fault Event CoR (Address 07h): Fault Event Register, Clear

on Read. Read this address to clear the Fault Event register. Address 07h returns the same data as address 06h and

reading address 07h clears all bits at both addresses.

t

START

Only. The lower four bits in this register indicate that a t

fault has occurred at the corresponding port; the logical OR

of these four bits appears in the Interrupt register as the

t

START

remain high until cleared by reading from address 09h. The

upper four bits in this register are reserved and will always

read as 0.

t

START

Clear on Read. Read this address to clear the Fault Event

register. Address 09h returns the same data as address 08h

and reading address 09h clears all bits at both addresses.

Supply Event (Address 0Ah): Supply Event Register, Read

Only. Bit 4 indicates that V

UVLO level (typically – 28V). Bit 5 signals that the VDD supply

has dropped below the V

that the LTC4258 die temperature has exceeded its thermal

shutdown limit (see Note 4 under Electrical Characteristics). The logical OR of bits 4, 5 and 7 appears in the Interrupt register as the Supply Fault bit. The remaining bits in

Fault bit. The upper four bits indicate that a Dis-

ICUT

Event (Address 08h): t

Fault bit. The t

Event CoR (Address 09h): t

Event bits latch high and will

START

EE

UVLO threshold. Bit 7 indicates

DD

Event Register, Read

START

Event Register,

START

has dropped below the V

START

EE

4258fb

10

UU

REGISTER FU CTIO S

LTC4258

the register are reserved and will always read as 0. The

Supply Event bits latch high and will remain high until

cleared by reading from address 0Bh.

Supply Event CoR (Address 0Bh): Supply Event Register,

Clear on Read. Read this address to clear the Fault Event

register. Address 0Bh returns the same data as address 0Ah,

and reading address 0Bh clears all bits at both addresses.

Status Registers

Port 1 Status (Address 0Ch): Port 1 Status Register, Read

Only. This register reports the most recent detection and

classification results for port 1. Bits 0-2 report the status

of the most recent detection attempt at the port and bits 4-6

report the status of the most recent classification attempt

at the port. If power is on, these bits report the detection/

classification status present just before power was turned

on. If power is turned off at the port for any reason, all bits

in this register will be cleared. See Table 1 for detection and

classification status bit encoding.

Port 2 Status (Address 0Dh): Port 2 Status Register, Read

Only. See Port 1 Status.

Port 3 Status (Address 0Eh): Port 3 Status Register, Read

Only. See Port 1 Status.

Port 4 Status (Address 0Fh): Port 4 Status Register, Read

Only. See Port 1 Status.

Power Status (Address 10h): Power Status Register, Read

Only. The lower four bits in this register report the switch

on/off state for the corresponding ports. The upper four

bits (the power good bits) indicate that the drop across the

power switch and sense resistor for the corresponding ports

is less than 2V (typ) and power start-up is complete. The

power good bits are latched high and are only cleared when

a port is turned off or the LTC4258 is reset.

Pin Status (Address 11h): External Pin Status, Read Only.

This register reports the real time status of the AUTO

(Pin 35) and AD0-AD3 (Pins 7-10) digital input pins. The

logic state of the AUTO pin appears at bit 0 and the AD0-AD3

pins at bits 2-5. The remaining bits are reserved and will

read as 0. AUTO affects the initial states of some of the

LTC4258 configuration registers at start-up but has no

effect after start-up and can be used as a general purpose

input if desired, as long as it is guaranteed to be in the

appropriate state at start-up.

Configuration Registers

Operating Mode (Address 12h): Operating Mode Configu-

ration, Read/Write. This register contains the mode bits for

each of the four ports in the LTC4258. See Table 1 for mode

bit encoding. At power-up, all bits in this register will be set

to the logic state of the AUTO pin (Pin 35). See Operating

Modes in the Applications Information section.

Disconnect Enable (Address 13h): Disconnect Enable

Register, Read/Write. The lower four bits of this register

enable or disable DC disconnect detection circuitry at the

corresponding port. If the DC Discon Enable bit is set the

port circuitry will turn off power if the current draw at the

port falls below I

, where RS is the sense resistor and should be 0.5Ω for

R

S

for more than t

MIN

DIS

. I

is equal to V

MIN

MIN

/

IEEE 802.3af compliance. If the bit is clear the port will not

remove power due to low current.

Detect/Class Enable (Address 14h): Detection and Classification Enable, Read/Write. The lower four bits of this register enable the detection circuitry at the corresponding port

if that port is in Auto or Semiauto mode. The upper four bits

enable the classification circuitry at the corresponding port

if that port is in Auto or Semiauto mode. In manual mode,

setting a bit in this register will cause the LTC4258 to perform one classification or detection cycle on the corresponding port. Writing to the Detect/Class Restart PB (18h)

has the same effect without disturbing the Detect/Class

Enable bits for other ports.

Timing Config (Address 16h): Global Timing Configuration,

Read/Write. Bits 0-1 program t

, the time duration before

DIS

a port is automatically tuned off after the PD is removed.

Bits 2-3 program t

current can exceed I

current is still above I

dicate a t

t

START

fault and turn the port off. Bits 4-5 program

ICUT

, the time duration before an overcurrent condition

during port power-on is considered a t

port is turned off. Note that using the t

, the time during which a port’s

ICUT

without it being turned off. If the

CUT

CUT

after t

, the LTC4258 will in-

ICUT

fault and the

START

and t

ICUT

START

times

other than the default is not compliant with IEEE 802.3af

and may double or quadruple the energy dissipated by the

external MOSFETs during fault conditions. Bits 6-7 are reserved and should be read/written as 0. See Electrical Characteristics for timer bit encoding. Also see the Applications

Information for descriptions of t

START

, t

and DC discon-

ICUT

nect timing.

4258fb

11

LTC4258

UU

REGISTER FU CTIO S

Misc Config (Address 17h): Miscellaneous Configuration,

Read/Write. Setting bit 7 enables the INT pin. If this bit is

reset, the LTC4258 will not pull down the INT pin in any

condition nor will it respond to the Alert Response Address.

This bit is set by default.

Pushbutton Registers

Note Regarding Pushbutton Registers: “Pushbutton” reg-

isters are specialized registers that trigger an event when

a 1 is written to a bit; writing a 0 to a bit will do nothing. Unlike

a standard read/write register, where setting a single bit

involves reading the register to determine its status, setting the appropriate bit in software and writing back the

entire register, a pushbutton register allows a single bit to

be written without knowing or affecting the status of the

other bits in the register. Pushbutton registers are writeonly and will return 00h if read.

Det/Class Restart PB (Address 18h): Detection/Classification Restart Pushbutton Register, Write Only. Writing a

1 to any bit in this register will start or restart a single

detection or classification cycle at the corresponding port

in Manual mode. It can also be used to set the corresponding bits in the Detect/Class Enable register (address 14h)

for ports in auto or semiauto mode. The lower 4 bits affect

detection on each port while the upper 4 bits affect

classification.

Power Enable PB (Address 19h): Power Enable Pushbutton

Register, Write Only. The lower four bits of this register set

the Power Enable bit in the corresponding Port Status register; the upper four bits clear the corresponding Power

Enable bit. Setting or clearing the Power Enable bits via this

register will turn on or off the power in any mode except

shutdown, regardless of the state of detection or classification. Note that t

enabled) will still turn off power if they occur.

The Power Enable bit cannot be set if the port has turned

off due to a t

yet counted back to zero. See Applications Information for

more information on t

Clearing the Power Enable bits with this register also

clears the detect and fault event bits, the Port Status

register, and the Detection and Classification Enable bits

for the affected port(s).

Reset PB (Address 1Ah): Reset Pushbutton, Write Only.

Bits 0-3 reset the corresponding port by clearing the power

enable bit, the detect and fault event bits, the status register and the detection and classification enable bits for that

port. Bit 4 returns the entire LTC4258 to the power-on

reset state; all ports are turned off, the AUTO pin is reread

and all registers are returned to their power-on defaults,

except V

setting it has no effect. Setting bit 6 releases the Interrupt

pin if it is asserted without affecting the Event registers or

the Interrupt register. When the INT pin is released in this

way, the condition causing the LTC4258 to pull the INT pin

down must be removed before the LTC4258 will be able to

pull INT down again. This can be done by reading and

clearing the event registers or by writing a 1 into bit 7 of

this register. Setting bit 7 releases the Interrupt pin, clears

all the Event registers and clears all the bits in the Interrupt

register.

ICUT

UVLO, which remains cleared. Bit 5 is reserved;

DD

ICUT

or t

, t

START

fault and the t

START

timing.

ICUT

and disconnect events (if

timer has not

ICUT

12

4258fb

WUUU

APPLICATIO S I FOR ATIO

LTC4258

OVERVIEW

Over the years, twisted-pair Ethernet has become the most

commonly used method for local area networking. The

IEEE 802.3 group, the originator of the Ethernet standard,

has defined an extension to the standard, known as

802.3af, which allows DC power to be delivered simultaneously over the same cable used for data communication. This promises a whole new class of Ethernet devices,

including IP telephones, wireless access points, and PDA

charging stations, which do not require additional AC

wiring or external power transformers, a.k.a. “wall warts.”

With about 13W of power available, small data devices can

be powered by their Ethernet connections, free from AC

wall outlets. Sophisticated detection and power monitoring techniques prevent damage to legacy data-only devices, while still supplying power to newer, Ethernetpowered devices over the twisted-pair cable.

A device that supplies power is called Power Sourcing

Equipment (PSE); a device that draws power from the

wire is called a Powered Device (PD). A PSE is typically an

Ethernet switch, router, hub, or other network switching

equipment that is commonly found in the wiring closets

where cables converge. PDs can take many forms: digital

IP telephones, wireless network access points, PDA or

notebook computer docking stations, cell phone chargers, and HVAC thermostats are examples of devices that

can draw power from the network.

A PSE is required to provide a nominal 48V DC between

either the signal pairs or the spare pairs (but not both) as

shown in Figure 10. The power is applied as a voltage

between two of the pairs, typically by powering the centertaps of the isolation transformers used to couple the

differential data signals to the wire. Since Ethernet data is

transformer coupled at both ends and is sent differentially,

a voltage difference between the transmit pairs and the

receive pairs does not affect the data. A 10base-T/

100base-TX Ethernet connection only uses 2 of the 4 pairs

in the cable. The unused or spare pairs can be powered

directly, as shown in Figure 10, without affecting the data.

However, 1000base-T uses all 4 pairs and power must

be connected to the transformer center taps for

compatibility.

GND

3.3V

INTERRUPT

I2C

–48V

0.1µF

100V

BYP AGND

DGND

V

DD

INT

SCL

SDAIN

SDAOUT

VEESENSE GATE OUT

0.5Ω

1/4

LTC4258

IRFM120A

DETECT

CAT 5

PSE PD

0.1µF

CMPD3003

10k

Tx

Rx

SMAJ58A

58V

RJ45

4

5

1

2

3

6

7

8

20Ω MAX

ROUNDTRIP

0.05µF MAX

SPARE PAIR

DATA PAIR

DATA PAIR

SPARE PAIR

RJ45

4

5

1

2

3

6

7

8

1N4002

×4

0.1µF

SMAJ58A

58V

Rx

1N4002

Tx

×4

Figure 10. PoE System Diagram

R

CLASS

–48V

GND

LTC4257

–48V

IN

PWRGD

OUT

5µF

MIN

DC/DC

CONVERTER

V

+

OUT

–

4258 F10

4258fb

13

LTC4258

WUUU

APPLICATIO S I FOR ATIO

The LTC4258 provides a complete solution for detection

and powering of PD devices in an IEEE 802.3af compliant

system. The LTC4258 consists of four independent ports,

each with the ability to detect, classify, and provide isolated –48V power to a PD device connected to it. The

LTC4258 senses removal of a PD with IEEE 802.3af

compliant DC method and turns off –48V power when the

PD is removed. An internal control circuit takes care of

2

system configuration and timing, and uses an I

C interface

to communicate with the host system.

OPERATING MODES

Each LTC4258 port can operate in one of four modes:

Manual, Semiauto, Auto or Shutdown. The operating

mode for a port is set by the appropriate bits in the

Operating Mode register. The LTC4258 will power up with

all ports in Shutdown mode if the external AUTO pin is tied

low; if AUTO is high, all ports will wake up in Auto mode.

The operating mode can be changed at any time via the I

2

C

interface, regardless of the state of the AUTO pin.

Regardless of which mode it is in, the LTC4258 will

remove power automatically from any port that generates

a t

START

and t

or t

START

overcurrent fault event (see t

ICUT

ICUT

Timing

Timing sections). It will also automatically

remove power from any port that generates a disconnect

event if the appropriate Disconnect Enable bit is set in the

Disconnect Enable register. The host controller may also

remove power at any time by setting the appropriate

Power Off bit in the Power Enable PB register.

Power-On RESET

At turn-on or any time the LTC4258 is reset (either by

pulling the RESET pin low or writing to the global Reset All

bit), all the ports turn off and all internal registers go to a

predefined state, shown in Table 1.

Several of the registers assume different states based on

the state of the AUTO pin at reset. The default states with

AUTO high allow the LTC4258 to detect and power up a PD

in Automatic mode, even if nothing is connected to the I

2

C

interface.

In Manual mode, a port will wait for instructions from

•

the host system before taking any action. It will run

single detection or classification cycles when commanded, and will report results in the Port Status

registers. When the host system decides it is time to

turn on or off power to a port, it can do so by setting

the appropriate Power On/Off bits in the Power Enable

PB register regardless of the current status of detection or classification.

• In Semiauto mode, the port will repeatedly attempt to

detect and classify a PD device attached to the link. It

will report this information in its Port Status register,

and wait for the host system to set the appropriate

Power On bit in the Power Enable PB register before

applying power to the port.

• In Auto mode, the port will detect and classify a PD

device connected to it, then immediately turn on the

power if detection was successful regardless of the

result of classification.

• In Shutdown mode, the port is disabled and will not detect

or power a PD. Also, the detect and fault event bits, status

bits and enable bits for the port are reset to zero.

SIGNATURE DETECTION

The IEEE defines a specific pair-to-pair PD signature

resistance that identifies a device that can accept

Power over Ethernet in accordance with the 802.3af

specification. When the port voltage is below 10V, an

802.3af compliant PD will have a 25k signature resistance.

Figure 11 illustrates the relationship between the PD

signature resistance (white box from 23.75k to 26.25k)

and required resistance ranges the PSE must accept

(white box) and reject (gray boxes). According to the

802.3af specification, the PSE may or may not accept

resistances in the two ranges of 15k to 19k and 26.5k to

33k. Note that the black box in Figure 11 represents the

150Ω pair-to-pair termination used in legacy 802.3 devices like a computer’s network interface card (NIC) that

cannot accept power.

RESISTANCE

0Ω 10k

150Ω (NIC)

PD

PSE

Figure 11. IEEE 802.3af Signature Resistance Ranges

20k 30k

19k 26.5k

15k

26.25k23.75k

33k

4258 F11

4258fb

14

WUUU

APPLICATIO S I FOR ATIO

LTC4258

The LTC4258 checks for the signature resistance by

forcing two test currents on the port (via the DETECT

n

pins) in sequence and measuring the resulting voltages. It

then subtracts the two V-I points to determine the resistive

slope while removing voltage offset caused by any series

diodes or current offset caused by leakage at the port (see

Figure 12). The LTC4258 will typically accept any PD

resistance between 17k and 29k as a valid PD and report

Detect Good (100 binary) in the Detect Status bits (bits 2

through 0) of the corresponding Port Status register.

Values outside this range, including open and short circuits, are also reported in the Detect Status bits. Refer to

Table 1 for a complete decoding of the Detect Status bits.

The first test point is taken by forcing a test current into

the port, waiting a short time to allow the line to settle and

measuring the resulting voltage. This result is stored

and the second current is applied to the port, allowed to

settle and the voltage measured. Each point takes about

100ms to measure, and an entire detection cycle takes

230ms (max).

The LTC4258 will not report Detect Good if the PD has

more than 5µF in parallel with its signature resistor.

The port’s operating mode controls if and when the

LTC4258 runs a detection cycle. In manual mode, the port

will sit idle until a Restart Detection (register 18h) command is received. It will then run a complete 200ms

detection cycle on the selected port, report the results in

the Detect Status bits in the corresponding Port Status

register and return to idle until another command is

received. In Semiauto mode, the LTC4258 autonomously

tests valid PDs connected to the ports but it will not apply

power until instructed to do so by the host controller. It

repeatedly queries the port every 320ms and updates the

Detect Status bits at the end of each cycle. If a Detect Good

is reported, it will advance to the classification phase and

report that result in the Port Status register. Until instructed to do otherwise, the LTC4258 will continue to

repeat detection on the port. Behavior in Auto mode is

similar to Semiauto; however, after a Detect Good is

reported, the LTC4258 performs the classification phase

and then powers up the port without further intervention.

The signature detection circuitry is disabled when the port

is in Shutdown mode, powered up or the corresponding

275

25kΩ SLOPE

165

CURRENT (µA)

VALID PD

SECOND

DETECTION

POINT

FIRST

DETECTION

POINT

Detect Enable bit is cleared.

CLASSIFICATION

A PD has the option of presenting a “classification signature” to the PSE to indicate how much power it will draw

when powered up. This signature consists of a specific

0V-2V

OFFSET

VOLTAGE

4258 F12

constant current draw when the PSE port voltage is between

15.5V and 20.5V, with the current level indicating the power

class to which the PD belongs. Per the IEEE 802.3af speci-

Figure 12. PD Detection

fication, the LTC4258 identifies the five classes of PD listed

in Table 2. During classification, the LTC4258 controls and

Table 2. IEEE 802.3af Powered Device Classes

IEEE 802.3af CLASSIFICATION MAXIMUM MINIMUM PSE

CLASS CURRENT AT PSE PD POWER OUTPUT POWER CLASS DESCRIPTION

0 0mA to 5mA 12.95W 15.4W PD Does Not Implement Classification, Unknown Power

1 8mA to 13mA 3.84W 4W Low Power PD

2 16mA to 21mA 6.49W 7W Medium Power PD

3 25mA to 31mA 12.95W 15.4W High or Full Power PD

4 35mA to 45mA 12.95W 15.4W Reserved, Power as Class O

4258fb

15

LTC4258

WUUU

APPLICATIO S I FOR ATIO

measures the port voltage through the DETECTn pin. Note

that class 4 is presently specified by the IEEE as reserved

for future use. Figure 13 shows a PD load line, starting with

the shallow slope of the 25k signature resistor below 10V,

then drawing the classification current (in this case, class 3)

between 14.5V and 20.5V. The LTC4258’s load line for classification is also shown in Figure 13. It has low impedance

until current limit is reached at 55mA (min).

The LTC4258 will classify a port immediately after a

successful detection cycle in Semiauto or Auto modes, or

when commanded to in Manual mode. It measures the PD

classification signature current by applying 18V (typ) to

the port and measuring the resulting current. It reports the

detected class in the Class Status bits in the corresponding Port Status register. Note that in Auto mode, the port

will power up regardless of which class is detected.

The classification circuitry is disabled when the port is in

Shutdown mode, powered up, or the corresponding Class

Enable bit is cleared.

60

PSE LOAD LINE

OVER

TYPICAL

CLASS 3

PD LOAD

LINE

VOLTAGE (V

CURRENT

CLASS 4

CLASS 3

CLASS 2

CLASS 1

CLASS 0

CLASS

)

48mA

33mA

23mA

14.5mA

6.5mA

25

4258 F13

50

40

30

CURRENT (mA)

20

10

0

0

Figure 13. PD Classification

5101520

Gate Currents

Once the decision has been made to turn on power to a

port, the LTC4258 uses a 50µA current source to pull up

on the GATE pin. Under normal power-up circumstances,

the MOSFET gate will charge up rapidly to V

(the MOSFET

T

threshold voltage), the MOSFET current will rise quickly to

the current limit level and the GATE pin will be servoed to

maintain the proper I

INRUSH

charging current. When output charging is complete, the MOSFET current will fall and

the GATE pin will be allowed to continue rising to fully

enhance the MOSFET and minimize its on resistance. The

final V

is nominally 13V. When a port is turned off, a

GS

50µA current source pulls down on the GATE pin, turning

the MOSFET off in a controlled manner.

No External Capacitors

No external capacitors are required on the GATE pins for

active current limit stability, lowering part count and cost.

This also allows the fastest possible turn-off under severe

overcurrent conditions, providing maximum safety and

protection for the MOSFETs, load devices and board traces.

Connecting capacitors to the external MOSFET gates can

adversely affect the LTC4258’s ability to respond to a

shorted port.

Inrush Control

The 802.3af standard lists two separate maximum current

limits, I

LIM

and I

. Because they have identical val-

INRUSH

ues, the LTC4258 implements both as a single current

limit using V

differentiated through the use of t

tively (see t

maintain consistency with the standard, the I

is used when referring to an initial t

(described below). Their functions are

LIM

and t

Timing and t

ICUT

ICUT

Timing sections). To

START

START

START

INRUSH

power-up event.

, respec-

term

POWER CONTROL

The primary function of the LTC4258 is to control the

delivery of power to the PSE port. It does this by controlling the gate drive voltage of an external power MOSFET

while monitoring the current via a sense resistor and the

output voltage at the OUT pin. This circuitry serves to

couple the raw isolated –48V input supply to the port in a

controlled manner that satisfies the PD’s power needs

while minimizing disturbances on the –48V backplane.

16

When the LTC4258 turns on a port, it turns on the MOSFET

by pulling up on the gate. The LTC4258 is designed to

power up the port in current limit, limiting the inrush

current to I

INRUSH

.

The port voltage will quickly rise to the point where the PD

reaches its input turn-on threshold and begins to draw

current to charge its bypass capacitance, slowing the rate

of port voltage increase.

4258fb

WUUU

APPLICATIO S I FOR ATIO

LTC4258

Dual-Level Current Limit

A PD is permitted to draw up to 15.4W continuously and

up to 400mA for 50ms. The LTC4258 has two corresponding current limit thresholds, I

(375mA typ) and I

CUT

LIM

(425mA typ). These are given by the equations:

I

CUT

= V

CUT/RS

, I

LIM

= V

LIM/RS

RS is the sense resistor and should be 0.5Ω for IEEE

802.3af compliance. While the LTC4258 allows the port

current to exceed I

timing below), it does not allow the current to exceed I

for a limited time period (see t

CUT

ICUT

LIM

.

The current limit circuit monitors the port current by

monitoring the voltage across the sense resistor and reduces the MOSFET gate voltage as needed to keep the

current at or below I

I

, the gate voltage is restored to the full value to keep

LIM

. When the current drops below

LIM

the MOSFET resistance to a minimum.

t

Timing

ICUT

Whenever more than I

the port’s sense voltage is above V

counts up. If the sense voltage is still above V

t

timer expires, the LTC4258 will turn off the power to

ICUT

the port immediately and set the appropriate t

in register 06h/07h. The t

CUT

= V

ICUT

CUT/RS

flows through a port,

and the t

CUT

ICUT

when the

CUT

ICUT

timer duration can be pro-

timer

Fault bit

grammed via register 16h, bits 3 and 2 (Table 1).

The t

timer is an up/down counter that is designed to

ICUT

protect the external MOSFET from thermal stress caused

by repeatedly operating in current limit. The counter

counts up whenever the current is above I

and counts

CUT

down at 1/16th the rate when it is not. The counter will

bottom out at zero to prevent underflow. Full count indicates that the t

timer has expired and the port will be

ICUT

turned off.

This count up/count down behavior implements duty cycle

protection, preventing intermittent current limit faults from

causing cumulative thermal stress in the MOSFET. If the port

enters current limit but then exits before the timer expires,

the count will decrease slowly, giving the I

timer the

CUT

ability to turn off sooner in the case of a repetitive fault. If

the overcurrent duty cycle is less than 6.3% the t

ICUT

timer

will be fully reset.

If the t

timer expires and causes the port to shut off, the

ICUT

timer will continue to run, counting down at the slow

1/16th rate and preventing the port from being repowered

until the count returns to zero. This protects the MOSFET

from damage due to a faulty PD that may still have a valid

signature, or from errant software that repeatedly writes to

the Power On bit.

The port will not repower until after the t

ICUT

counter

returns to zero. In manual and semiauto modes the power

enable command must be received after the t

ICUT

counter

reaches zero. In auto mode the LTC4258 must complete a

valid detection cycle after the t

t

Timing

START

counter reaches zero.

ICUT

To distinguish between normal turn-on current limit behavior and current limit faults which occur after power-up

is complete, the LTC4258 starts a timer (the t

START

timer)

whenever a power-up sequence begins.

The t

timer serves three functions. First and fore-

START

most, it allows the user to specify a different current limit

timeout (t

START

instead of t

) during turn-on (current

ICUT

limit duty cycle protection remains functional). Second,

the DC disconnect timer is disabled during this period and

can only begin counting up after the t

START

timer has

expired. Together, these two features let the PD draw the

maximum current I

INRUSH

to charge its input capacitance,

boot up and begin drawing power without triggering a

fault. Finally, if the device is in current limit for the

t

START

entire t

instead of a t

period, a t

START

ICUT

fault will be generated

START

fault. This can be useful for tracking down

the cause of a current fault.

As long as the PD draws less than I

and begins drawing the minimum current within t

t

expires (if DC disconnect is enabled), no faults will

START

at the end of t

CUT

DIS

START

after

be indicated.

The t

tion described under t

timer also implements the duty cycle protec-

START

timing and its duration can be

ICUT

programmed via register 16h, bits 5 and 4 (Table 1).

4258fb

17

LTC4258

WUUU

APPLICATIO S I FOR ATIO

Foldback

Foldback is designed to limit power dissipation in the

MOSFET during power-up and momentary short-circuit

conditions. At low port output voltages, the voltage across

the MOSFET is high, and power dissipation will be large if

significant current is flowing. Foldback monitors the port

output voltage and reduces the V

current limit level

LIM

linearly from its full value (212.5mV typ) at a port voltage

of 18V to approximately 1/7th of the full value (30mV typ)

at a port voltage of 0V. With 0.5Ω sense resistors, this

limits the short-circuit current to 60mA (typ) instead of the

full 425mA (typ) current limit. When the LTC4258 is in

foldback, the t

timer is active.

ICUT

Short-Circuit Protection

If a port is suddenly shorted out, the MOSFET power

dissipation can rise to very high levels, jeopardizing the

MOSFET even before the normal current limit circuit can

respond. A separate short-circuit current limit circuit

watches for significant overcurrent events (V

SENSE

>275mV, >550mA with a 0.5Ω sense resistor) and pulls

the GATE pin down immediately if such an event occurs,

shutting off the MOSFET in less than 1µs (with no external

capacitor on GATE). Approximately 100µs later, GATE is

allowed to rise back up and the normal current limit circuit

will take over, allowing I

timer to count up. During a short circuit, I

t

ICUT

current to flow and causing the

LIM

will be

LIM

reduced by the foldback feature to 1/7th of the nominal

value.

Figures 14 and 15 show the LTC4258 controlling port

current during short circuits. In Figure 14, the MOSFET is

turned off 0.5µs after the port is shorted with 1Ω. The

spike in port voltage and current at the moment the

MOSFET turns off is the response of inductance in the

system, such as the magnetics and the Ethernet cable; see

Surge Suppressors and Circuit Protection for further

details. The 0.1µF port bypass cap (see Figure 1) provides

some port current for 0.25µs after the MOSFET is off. In

Figure 15, the LTC4258 quickly turns the port off and the

spike above ground is again due to inductance. It then

ramps the MOSFET gate up, similar to applying power

after a PD is detected, bringing the port into a controlled

425mA (typ) I

current limit. When the short is removed,

LIM

the port current no longer needs to be limited and LTC4258

ramps up its GATE pin to fully enhance the MOSFET.

Short-circuit protection quickly stops excessive current

and limits the energy delivered to a short or faulty PD. Yet

the LTC4258 only stops current briefly, so momentary

faults typically do not cause the PD to lose power and PDs

receive at least 50ms of 400mA to 450mA peak current as

required by the 802.3af standard.

GND

PORT

VOLTAGE

20V/DIV

V

GATE

VOLTAGE

10V/DIV

PORT

CURRENT

20A/DIV

V

+15V

V

0mA

EE

EE

EE

FAST PULL-DOWN

ACTIVATED

SHORT APPLIED

250ns/DIV

Figure 14. Rapid Response to 1Ω Short

GND

PORT

VOLTAGE

20V/DIV

V

GATE

VOLTAGE

10V/DIV

PORT

CURRENT

500mA/DIV

V

+15V

V

0mA

EE

EE

EE

CURRENT LIMIT

FAST PULL-DOWN

SHORT APPLIED

100µs/DIV

Figure 15. Rapid Response to Momentary 100Ω Short

VDD = 3.3V

V

FET OFF

VDD = 3.3V

V

SHORT REMOVED

= –48V

EE

= –48V

EE

4258 G04

4258 G05

18

4258fb

WUUU

APPLICATIO S I FOR ATIO

LTC4258

Choosing External MOSFETs

Power delivery to the ports is regulated with external

power MOSFETs. These MOSFETs are controlled as previously described to meet the IEEE 802.3af specification.

Under normal operation, once the port is powered and the

PD’s bypass capacitor is charged to the port voltage, the

external MOSFET dissipates very little power. This suggests that a small MOSFET is adequate for the job. Unfortunately, other requirements of the IEEE 802.3af mandate

a MOSFET capable of dissipating significant power. When

the port is being powered up, the port voltage must reach

30V or more before the PD turns on. The port voltage can

then drop to 0V as the PD’s bypass capacitor is charged.

According to the IEEE, the PD can directly connect a 180µF

capacitor to the port and the PSE must charge that

capacitor with a current limit of 400mA to 450mA for at

least 50ms.

An even more extreme example is a noncompliant PD that

provides the proper signature during detection but then

behaves like a low valued resistor, say 50Ω, in parallel with

a 1µF capacitor. When the PSE has charged this

noncompliant PD up to 20V, the 50Ω resistor will draw

400mA (the minimum IEEE prescribed I

keeping the port voltage at 20V for the remainder of t

The external MOSFET sees 24V to 37V V

450mA, dissipating 9.6W to 16.7W for 60ms (typ).

The LTC4258 implements foldback to reduce the current

limit when the MOSFET VDS is high; see the Foldback

section. Without foldback, the MOSFET could see as much

as 25.7W for 60ms (typ) when powering a shorted or a

noncompliant PD with only a few ohms of resistance. With

foldback, the MOSFET sees a maximum of 18W for the

duration of t

The LTC4258’s duty cycle protection enforces 15 times

longer off time than on time, preventing successive attempts to power a defective PD from damaging the MOSFET. System software can enforce even longer wait times.

When the LTC4258 is operated in semiauto or manual

mode—described in more detail under Operating Modes—

START

.

current limit)

LIM

at 400mA to

DS

START

.

it will not power on a port until commanded to do so by the

host controller. By keeping track of t

the host controller can delay turning on the port again after

one of these faults even if the LTC4258 reports a Detect

Good. In this way the host controller implements a MOSFET cooling off period which may be programmed to

protect smaller MOSFETs from repeated thermal cycling.

The LTC4258 has built-in duty cycle protection for t

and t

that is sufficient to protect the MOSFETs shown in

Figure 1.

Before designing a MOSFET into your system, carefully

compare its safe operating area (SOA) with the worst case

conditions (like powering up a defective PD) the device will

face. Using transient suppressors, polyfuses and extended wait times after disconnecting a PD are effective