FEATURES

■

Controls –12V, 3.3V, 5V and 12V Supplies

■

±14.4V Absolute Maximum Rating for 12V

IN

and –12VIN Input Pins

■

Insensitive to Supply Voltage Transients

■

Adjustable Foldback Current Limit with Circuit Breaker

■

LOCAL_PCI_RST# Logic On-Chip

■

PRECHARGE Output Biases I/O Pins During Card

Insertion and Extraction

■

LTC4244-1 Designed for Applications without –12V

■

Available in 20-Lead Narrow SSOP Package

U

APPLICATIO S

■ Hot Board Insertion into CompactPCI Bus

, LTC and LT are registered trademarks of Linear Technology Corporation.

Hot Swap is a trademark of Linear Technology Corporation.

CompactPCI is a trademark of the PCI Industrial Computer Manufacturers Group.

LTC4244/LTC4244-1

Rugged, CompactPCI Bus

Hot Swap Controllers

U

DESCRIPTIO

The LTC®4244/LTC4244-1 are Hot SwapTM controllers that

allow a board to be safely inserted into and removed from

a CompactPCITM bus slot. External N-channel transistors

control the 5V and 3.3V supplies while on-chip switches

control the ±12V supplies. The 3.3V and 5V supplies can

be ramped up at an adjustable rate. Electronic circuit

breakers protect all four supplies against overcurrent

faults. After the power-up cycle is complete, the TIMER pin

capacitor serves as auxiliary VCC allowing the LTC4244/

LTC4244-1 to function without interruption in the presence of voltage spikes on the 12VIN supply. The PWRGD

output indicates when all four supplies are within tolerance. The OFF/ON pin is used to cycle board power or reset

the circuit breaker. The PRECHARGE output can be used

to bias the bus I/O pins during card insertion and extraction. PCI_RST# is combined on-chip with HEALTHY# in

order to generate LOCAL_PCI_RST#.

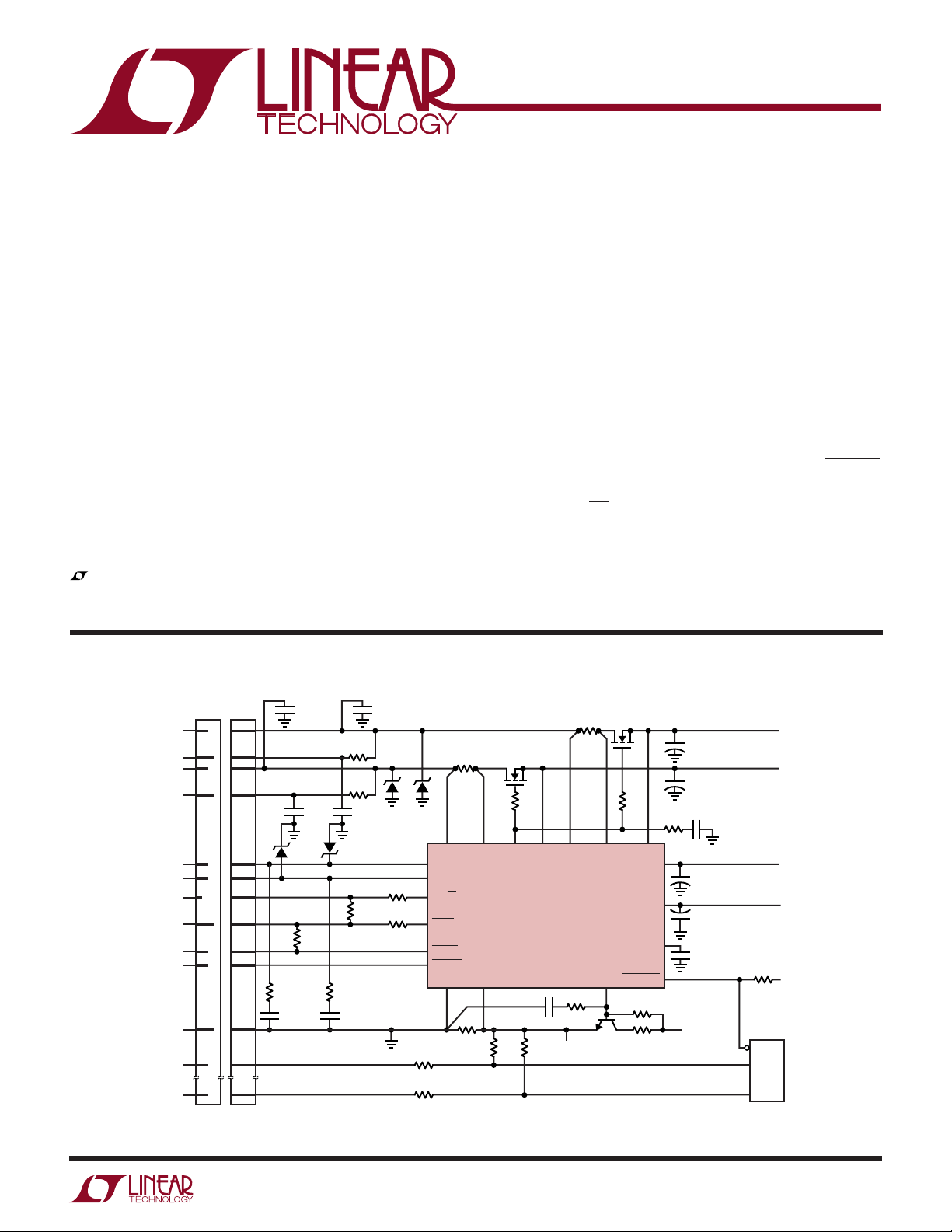

TYPICAL APPLICATIO

5V

LONG 5V

3.3V

LONG 3.3V

12V

–12V

BD_SEL#

LONG V(I/O)

HEALTHY#

PCI_RST#

R15

1Ω

C4

GROUND

I/O PIN 1

I/O PIN 128

•

•

•

0.01µF

I/O DATA LINE 1

I/O DATA LINE 128

Z1, Z2: SMAJ12A Z3, Z4: SMAJ5.0A

U

C8

0.01µF PER

POWER PIN

C6

0.01µF

R17

10k

Z2Z1

R16

1Ω

C5

0.01µF

R22

2.7Ω

R21

1.8Ω

C7

0.01µF

R20

1.2k

C9

0.01µF PER

POWER PIN

R19 1k

R18 10k

•

•

•

3.3V

Z3

5V

IN

IN

Z4

3.3V

12V

V

EEIN

OFF/ON

FAULT

PWRGD

RESETIN

GND PRECHARGE

R13

10Ω

R14

10Ω

0.005Ω

IN

IN

R10 18Ω

R1

Q1

IRF7457

R3

10Ω

3.3V

SENSE

3.3V

GATE 5V

LTC4244

C3 4.7nF

R12

R11

10k

10k

OUT

5V

IN5VSENSE

R9 24Ω

1V

±10%

R2

0.007Ω

DRIVE

MMBT2222A

IRF7457

Q3

Q2

R4

10Ω

12V

V

TIMER

RESETOUT

R8 1k

R7 12Ω

OUT

OUT

EEOUT

•

•

•

+

C

LOAD(5VOUT)

+

C

LOAD(3.3VOUT)

C1

R5

0.33µF

1k

+

C

LOAD(12VOUT)

C

LOAD(VEEOUT)

+

C2

0.082µF

LOCAL_PCI_RST#

V

IN

3.3V

I/O #1

I/O #128

R6

10k

RESET#

PCI

BRIDGE

CHIP

4244 F01

V

OUT

5V

5A

V

OUT

3.3V

7A

V

OUT

12V

500mA

V

EEOUT

–12V

100mA

V

OUT

3.3V

Figure 1. Typical Compact PCI Application

42441f

1

LTC4244/LTC4244-1

WWWU

ABSOLUTE AXI U RATI GS

(Notes 1, 2, 3)

Supply Voltages

12VIN................................................................ 14.4V

V

.............................................................. –14.4V

EEIN

Input Voltages (OFF/ON, RESETIN) ........–0.3V to 13.5V

Output Voltages (FAULT, PWRGD, RESETOUT)

...........................................................–0.3V to 13.5V

Analog Voltages and Currents

5V

, DRIVE, 5VIN, 3.3V

OUT

...........................................................–0.3V to 13.5V

PRECHARGE, GATE ....................................... ±20mA

V

TIMER, 12V

................................................–14.4V to 0.3V

EEOUT

...........................................

OUT

Operation Temperature Range

LTC4244C/LTC4244C-1........................... 0°C to 70°C

LTC4244I/LTC4244I-1 ........................ –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

, 3.3VIN, 3.3V

SENSE

, 5V

OUT

SENSE

–0.3V to 14.4V

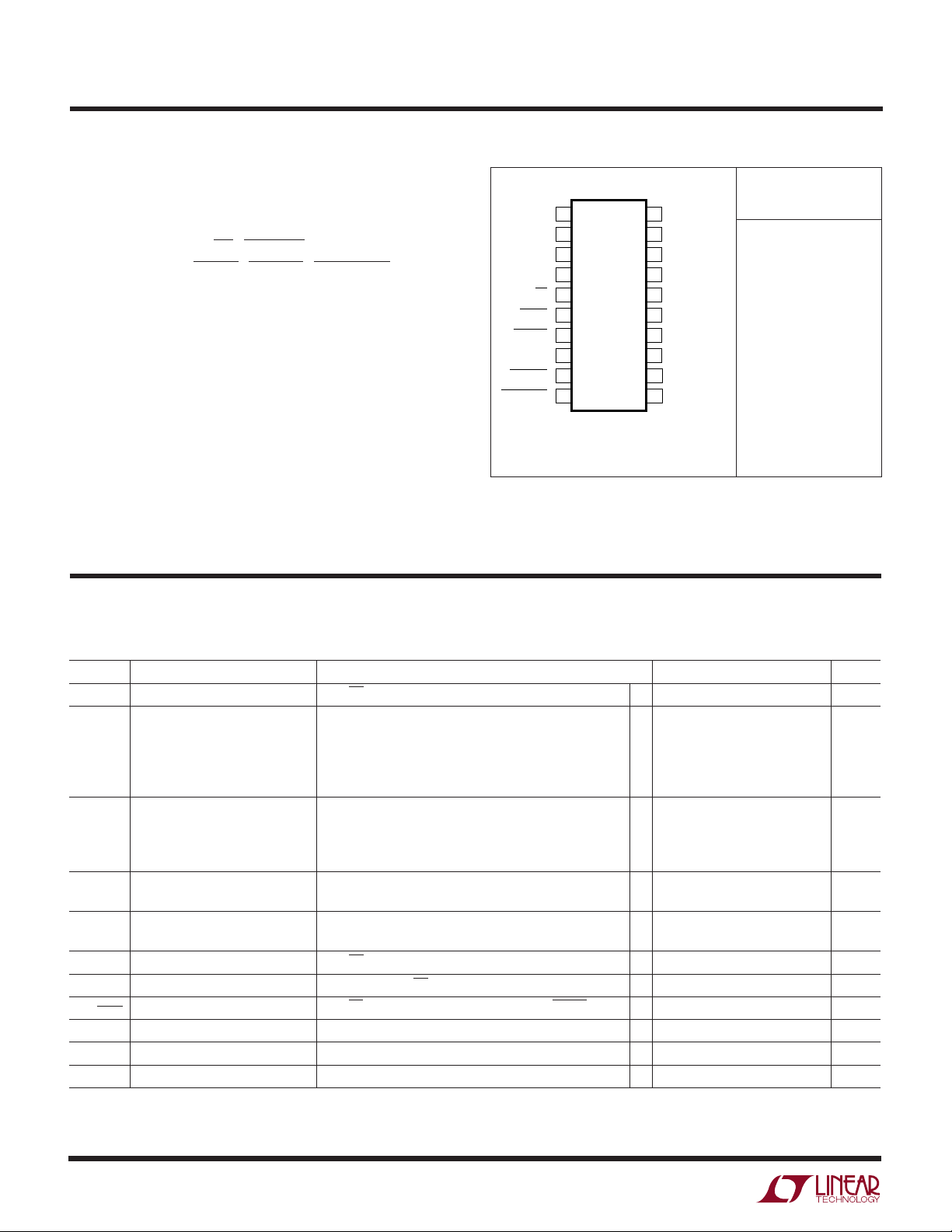

UU

W

PACKAGE/ORDER I FOR ATIO

TOP VIEW

1

12V

V

EEIN

5V

OUT

TIMER

OFF/ON

FAULT

PWRGD

GND

RESETIN

RESETOUT

IN

2

3

4

5

6

7

8

9

10

GN PACKAGE

20-LEAD PLASTIC SSOP

T

= 140°C, θJA = 135°C/W

JMAX

12V

20

V

19

3.3V

18

3.3V

17

3.3V

16

GATE

15

5V

14

13

5V

12

PRECHARGE

11

DRIVE

OUT

EEOUT

OUT

IN

SENSE

SENSE

IN

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ORDER PART

NUMBER

LTC4244CGN

LTC4244CGN-1

LTC4244IGN

LTC4244IGN-1

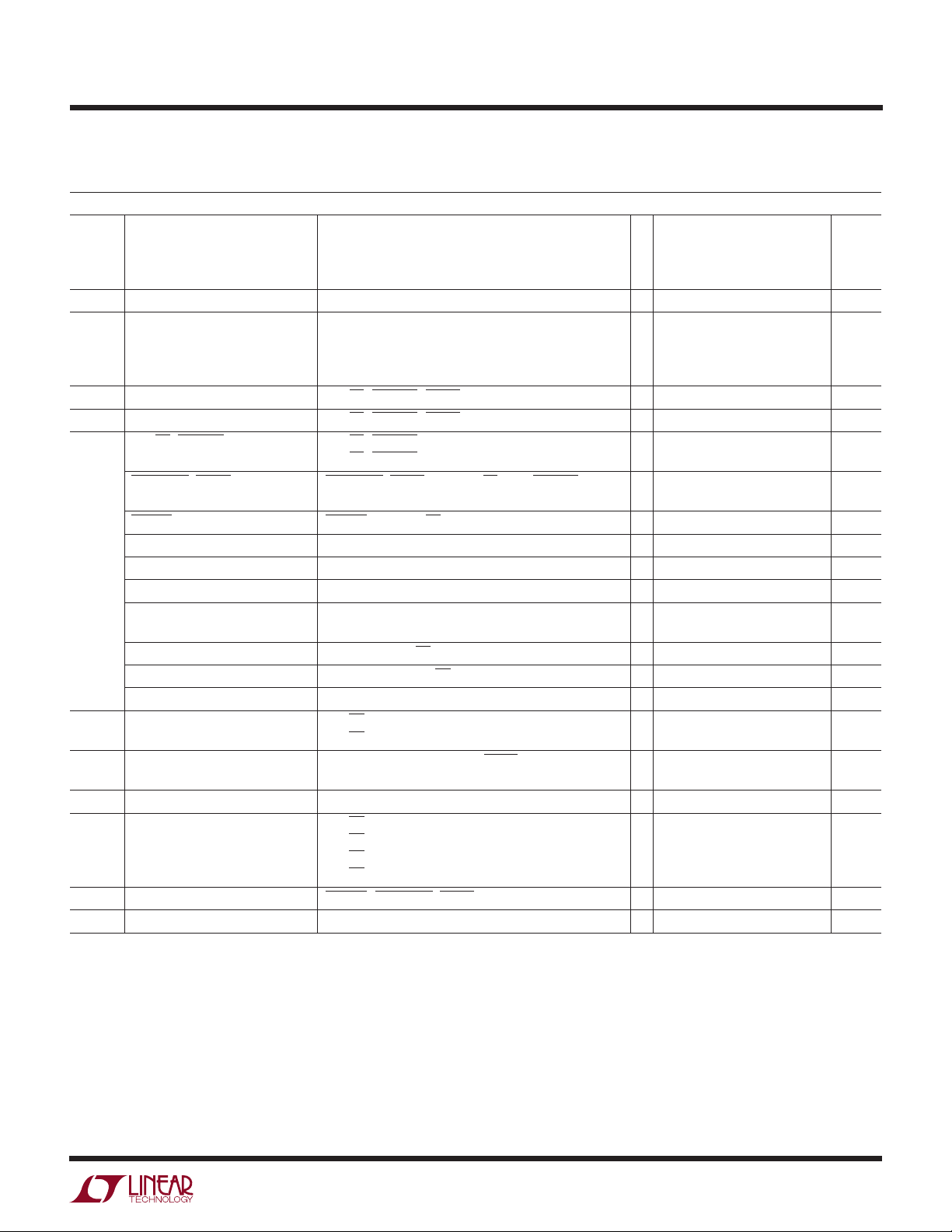

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. V

The ● denotes the specifications which apply over the full operating

12VIN

= 12V, V

= –12V, V

EEIN

3.3VIN

= 3.3V, V

= 5V, unless

5VIN

otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

DD

V

LKO

V

FB

V

CB

t

OC

I

GATE(UP)

I

GATE(DN)

I

GATE(FAULT)

∆V

GATE

∆V

12V

∆V

VEE

V

Supply Current OFF/ON = 0V ● 410 mA

12VIN

Undervoltage Lockout 12VIN, Ramping Down ● 8 9 10 V

, Ramping Down ● 4 4.25 4.5 V

5V

IN

3.3V

, Ramping Down ● 2.25 2.5 2.75 V

IN

, Ramping Up (LTC4244 Only) ● –8.25 –9.25 –10.25 V

V

EEIN

TIMER, Ramping Down, V

Foldback Current Limit Voltage VFB = (V

V

FB

V

FB

V

FB

Circuit Breaker Trip Voltage VCB = (V

V

CB

Overcurrent Fault Response Time (V

(V

5VIN

3.3VIN

= (V

= (V

= (V

= (V

– V

– V

5VIN

5VIN

3.3VIN

3.3VIN

5VIN

3.3VIN

5VSENSE

3.3VSENSE

– V

– V

– V

– V

– V

– V

GATE Pin Output Current OFF/ON = 0V, V

V

= 5V, OFF/ON = 4V ● 20 60 100 µA

GATE

OFF/ON = 0V, V

External Gate Voltage ∆V

Internal Switch Voltage Drop ∆V

∆V

GATE

12V

VEE

= (V

= (V

= (V

12VIN

12VIN

EEOUT

5VSENSE

5VSENSE

3.3VSENSE

3.3VSENSE

5VSENSE

3.3VSENSE

) = 100mV, TIMER = FLOAT ● 17 25 35 µs

) = 100mV, TIMER = FLOAT ● 17 25 35 µs

= 2V, TIMER = 0V ● –20 –67 –100 µA

GATE

= 2V, TIMER = FLOAT, FAULT = 0V ● 4 8 16 mA

GATE

– V

GATE

– V

12VOUT

– V

EEIN

= 6V ● 8.25 9.25 10.25 V

12VIN

), V

), V

= 0V, TIMER = 0V ● 11 16 21 mV

5VOUT

= 3V, TIMER = 0V ● 46 51 56 mV

5VOUT

), V

), V

= 0V, TIMER = 0V ● 11 16 21 mV

3.3VOUT

= 2V, TIMER = 0V ● 46 51 56 mV

3.3VOUT

), TIMER = FLOAT ● 45 52 57 mV

), TIMER = FLOAT ● 45 52 57 mV

), I

= –1µA ● 0.6 1 V

GATE

), I = 500mA ● 225 600 mV

), IEE = 100mA ● 110 250 mV

2

42441f

LTC4244/LTC4244-1

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. V

The ● denotes the specifications which apply over the full operating

12VIN

= 12V, V

= –12V, V

EEIN

3.3VIN

= 3.3V, V

= 5V, unless

5VIN

otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

CL

T

TS

V

TH

V

IL

V

IH

I

IN

I

TIMER

V

TIMER

∆V

R

DIS

V

OL

V

PXG

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Current Foldback 12VIN = 12V, 12V

= 12V, 12V

12V

IN

V

= –12V, V

EEIN

= –12V, V

V

EEIN

= 0V, TIMER = 0V ● –100 –360 –1000 mA

OUT

= 10V, TIMER = 0V ● –550 –850 –1500 mA

OUT

= 0V, TIMER = 0V ● 50 225 350 mA

EEOUT

= –10V, TIMER = 0V ● 350 610 870 mA

EEOUT

Thermal Shutdown Temperature Junction Temperature, Ramping Up 150 °C

Power Good Threshold Voltage 12V

, Ramping Down ● 10.8 11.1 11.4 V

OUT

, Ramping Down ● 4.50 4.61 4.75 V

5V

OUT

3.3V

, Ramping Down ● 2.80 2.90 3.00 V

OUT

, Ramping Up, LTC4244 Only ● –10.8 –11.1 –11.4 V

V

EEOUT

Logic Input Low Voltage OFF/ON, RESETIN, FAULT ● 0.8 V

Logic Input High Voltage OFF/ON, RESETIN, FAULT ● 2V

OFF/ON, RESETIN Input Current OFF/ON, RESETIN = 0V ● ±10 µA

OFF/ON, RESETIN = 12V

● ±10 µA

RESETOUT, FAULT Leakage RESETOUT, FAULT = 5V, OFF/ON = 0V, RESETIN = 3.3V ● ±10 µA

Current

PWRGD Output Current PWRGD = 5V, OFF/ON = 4V ● ±10 µA

5V

Input Current 5V

SENSE

3.3V

Input Current 3.3V

SENSE

SENSE

SENSE

= 5V, 5V

OUT

= 3.3V, 3.3V

= 0V ● 57 100 µA

= 0V ● 56 100 µA

OUT

5VIN Input Current 5VIN = 5V, TIMER = 0V ● 0.8 1.5 mA

3.3VIN Input Current 3.3VIN = 3.3V, TIMER = FLOAT ● 510 700 µA

= 3.3V, TIMER = 0V ● 400 550 µA

3.3V

IN

5V

Input Current 5V

OUT

3.3V

Input Current 3.3V

OUT

PRECHARGE Input Current V

TIMER Pin Current OFF/ON = 0V, V

TIMER Threshold Voltage TIMER_HI, (V

External Timer Voltage ∆V

TIMER

12V

Discharge Resistance OFF/ON = 4V ● 440 1000 Ω

OUT

5V

Discharge Resistance OFF/ON = 4V ● 200 500 Ω

OUT

Discharge Resistance OFF/ON = 4V ● 200 500 Ω

3.3V

OUT

Discharge Resistance OFF/ON = 4V ● 390 1000 Ω

V

EEOUT

= 5V, OFF/ON = 0V, TIMER = 0V ● 107 200 µA

OUT

= 3.3V, OFF/ON = 0V, TIMER = 0V ● 170 300 µA

OUT

PRECHARGE

OFF/ON = 5V, V

TIMER_LO, V

= 1V ● 0.1 10 µA

= 0V ● 16 21 26 µA

TIMER

= 5V ● 25 45 70 mA

TIMER

TIMER

= (V

– V

12VIN

, Ramping Down ● 0.5 0.8 1.1 V

TIMER

– V

12VIN

), FAULT = 0V, Ramping Up ● 1.3 1.6 1.9 V

TIMER

), I

TIMER

= –1µA ● 1V

TIMER

Output Low Voltage PWRGD, RESETOUT, FAULT, I = 1mA ● 0.4 V

PRECHARGE Reference Voltage V

= 2V ● 0.95 1 1.05 V

DRIVE

Note 3: The 12VIN and V

pins will withstand transient surges up to

EEIN

±15V, respectively, upon hot insertion.

42441f

3

LTC4244/LTC4244-1

VOLTAGE (V)

0

CURRENT (A)

–2 –4 –6 –10–8

4244 G03

–12

–0.6

–0.5

–0.3

–0.4

–0.2

–0.1

0

TEMPERATURE (°C)

–50

VOLTAGE (V)

–25 0 25 7550

4244 G06

100

0.30

0.25

0.15

0.20

0.10

0.05

0

I

12VOUT

= 550mA

TEMPERATURE (°C)

–50

VOLTAGE (mV)

–25 0 25 7550

4244 G09

100

60

50

30

40

20

10

0

3.3V

OUT

= 2V

3.3V

OUT

= 0V

UW

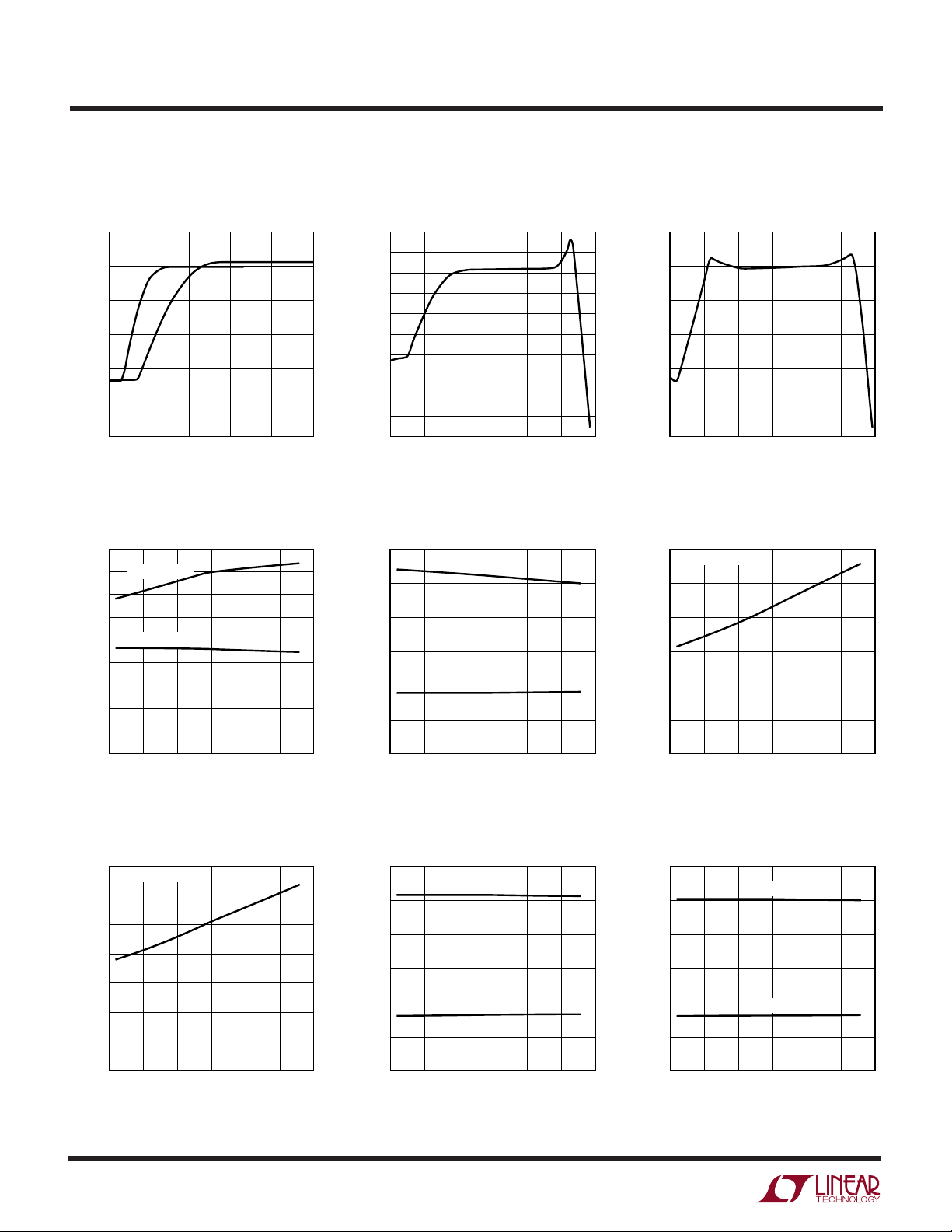

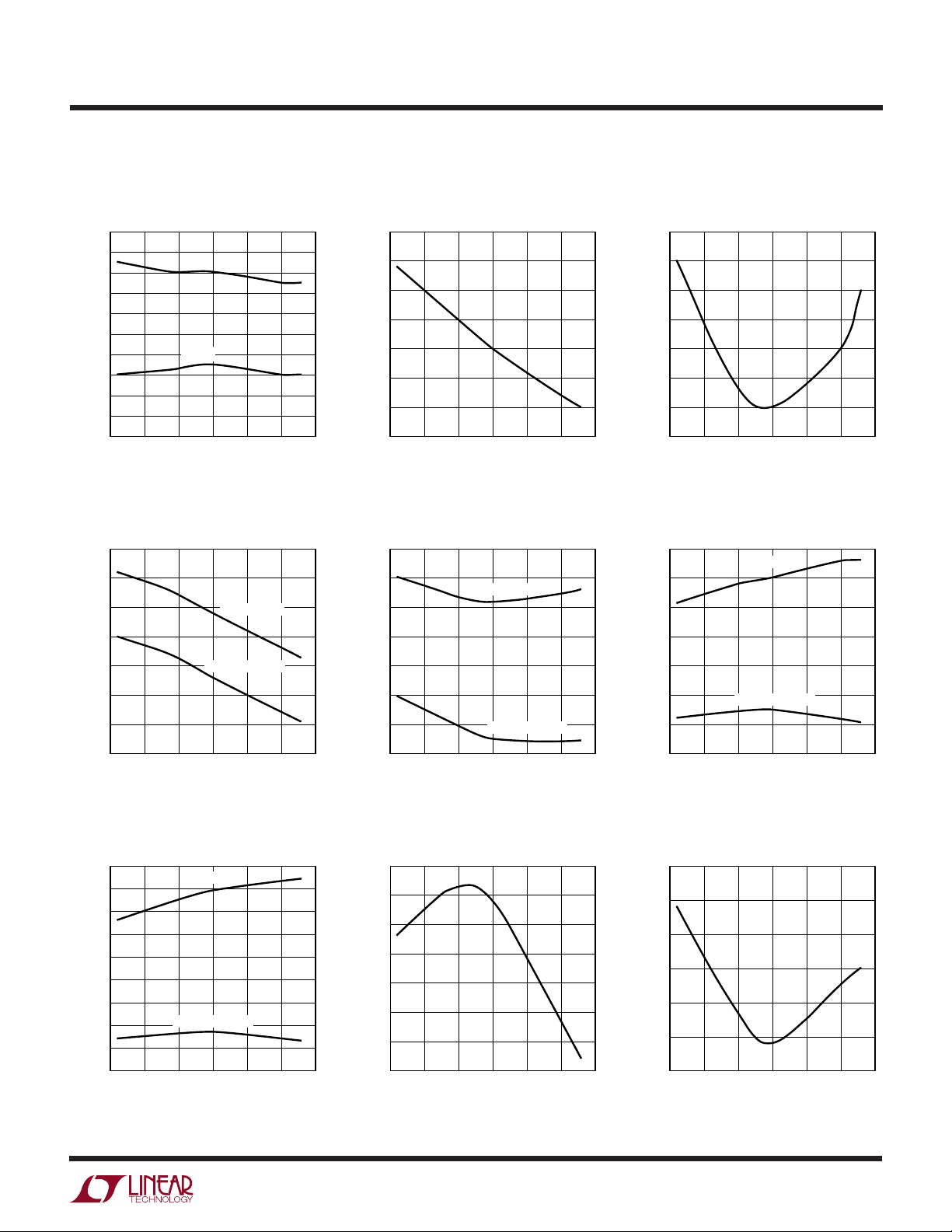

TYPICAL PERFOR A CE CHARACTERISTICS

3.3V and 5V Current Foldback

Profile

60

50

3.3V

40

30

VOLTAGE (mV)

20

10

0

0

5V

234

1

VOLTAGE (V)

12V Foldback Current Limit vs

Temperature

0.9

12V

0.8

0.7

0.6

0.5

0.4

CURRENT (A)

0.3

0.2

0.1

0

–50

= 10V

OUT

12V

= 0V

OUT

–25 0 25 7550

TEMPERATURE (°C)

4244 G01

4244 G04

100

12V

Current vs 12V

OUT

Voltage

1.0

0.9

0.8

0.7

0.6

0.5

0.4

CURRENT (A)

0.3

0.2

0.1

5

0

246 108

0

VOLTAGE (V)

VEE Foldback Current Limit vs

Temperature

0.6

0.5

0.4

0.3

CURRENT (A)

0.2

0.1

0

–50

V

EEOUT

V

EEOUT

–25 0 25 7550

TEMPERATURE (°C)

= 10V

= 0V

OUT

4244 G02

4244 G05

12

100

V

Current vs V

EEOUT

EEOUT

Voltage

12V Internal Switch Voltage Drop

vs Temperature

VEE Internal Switch Voltage Drop

vs Temperature

0.14

I

= 100mA

VEEIN

0.12

0.10

0.08

0.06

VOLTAGE (V)

0.04

0.02

4

0

–25 0 25 7550

–50

TEMPERATURE (°C)

4244 G07

100

5VIN Foldback Current Limit

Voltage vs Temperature

60

5V

= 3V

50

40

30

VOLTAGE (mV)

20

10

0

–50

–25 0 25 7550

OUT

5V

= 0V

OUT

TEMPERATURE (°C)

3.3VIN Foldback Current Limit

Voltage vs Temperature

100

4244 G08

42441f

UW

TEMPERATURE (°C)

–50

CURRENT (mA)

–25 0 25 7550

4244 G12

100

3.94

3.93

3.92

3.90

3.91

3.89

3.88

3.87

TEMPERATURE (°C)

–50

VOLTAGE (V)

–25 0 25 7550

4244 G15

100

4.34

4.32

4.30

4.26

4.28

4.24

4.22

4.20

RAMPING-UP

RAMPING-DOWN

TEMPERATURE (°C)

–50

VOLTAGE (V)

–25 0 25 7550

4244 G18

100

–11.050

–11.055

–11.060

–11.070

–11.065

–11.075

–11.080

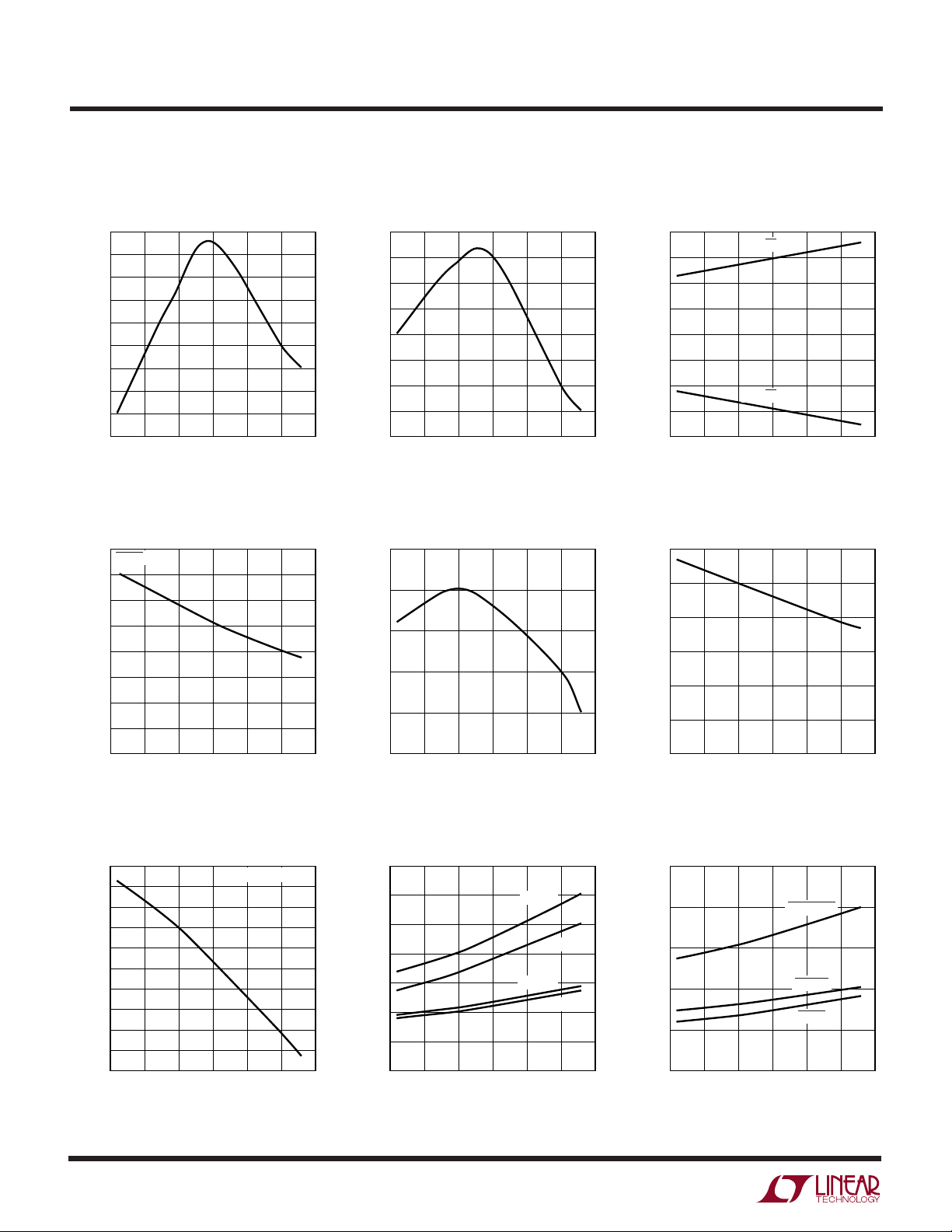

TYPICAL PERFOR A CE CHARACTERISTICS

LTC4244/LTC4244-1

3.3VIN and 5VIN Circuit Breaker

Trip Voltage vs Temperature

52.0

51.8

51.6

51.4

51.2

51.0

50.8

VOLTAGE (mV)

50.6

50.4

50.2

50.0

–50

–25 0 25 7550

5V

IN

3.3V

IN

TEMPERATURE (°C)

12VIN Undervoltage Lockout vs

Temperature

9.30

9.25

9.20

9.15

RAMPING-UP

4244 G10

100

3.3VIN and 5VIN Circuit Breaker

Trip Filter Time vs Temperature

25.0

24.5

24.0

23.5

23.0

TIME (µs)

22.5

22.0

21.5

–25 0 25 7550

–50

V

EEIN

TEMPERATURE (°C)

Undervoltage Lockout vs

Temperature

–9.22

–9.24

–9.26

–9.28

RAMPING-UP

12VIN Supply Current vs

Temperature

100

4244 G11

5VIN Undervoltage Lockout vs

Temperature

9.10

VOLTAGE (V)

9.05

9.00

8.95

–50

–25 0 25 7550

RAMPING-DOWN

TEMPERATURE (°C)

3.3VIN Undervoltage Lockout vs

Temperature

2.54

2.53

2.52

2.51

2.50

2.49

VOLTAGE (V)

2.48

2.47

2.46

2.45

–50

RAMPING-UP

RAMPING-DOWN

–25 0 25 7550

TEMPERATURE (°C)

4244 G13

4244 G16

100

100

–9.30

VOLTAGE (V)

–9.32

–9.34

–9.36

–25 0 25 7550

–50

12V

TEMPERATURE (°C)

Powergood Threshold

OUT

Voltage vs Temperature

11.090

11.085

11.080

11.075

11.070

VOLTAGE (V)

11.065

11.060

11.055

–25 0 25 7550

–50

TEMPERATURE (°C)

RAMPING-DOWN

4244 G14

4244 G17

100

100

V

Powergood Threshold

EEIN

Voltage vs Temperature

42441f

5

LTC4244/LTC4244-1

TEMPERATURE (°C)

–50

CURRENT (µA)

–25 0 25 7550

4244 G21

100

80

60

40

0

20

–20

–40

–80

–60

OFF/ON = 0V

OFF/ON = 4V

TEMPERATURE (°C)

–50

CURRENT (mA)

–25 0 25 7550

4244 G24

100

60

50

40

20

30

10

0

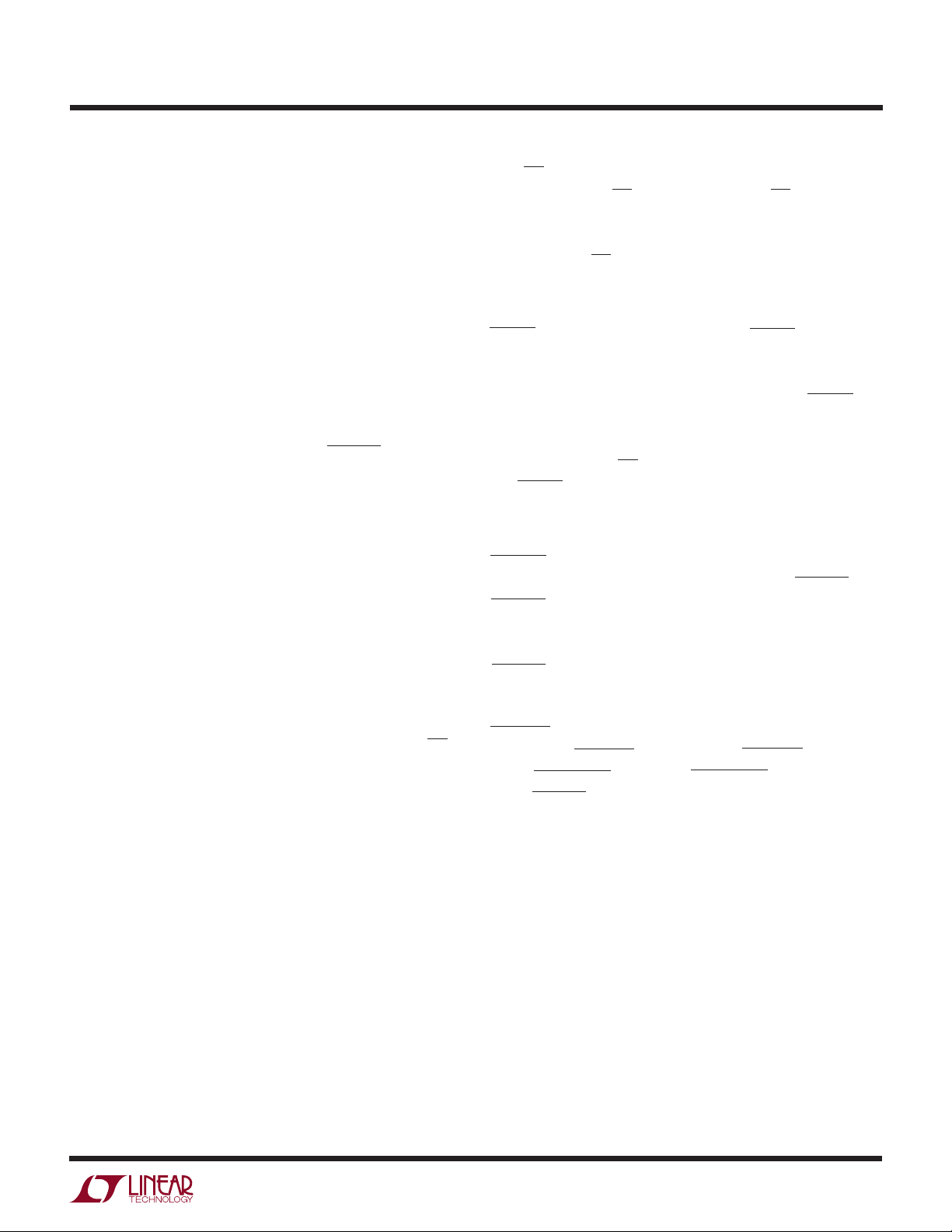

UW

TYPICAL PERFOR A CE CHARACTERISTICS

5V

Powergood Threshold

OUT

Voltage vs Temperature

4.603

4.602

4.601

4.600

4.599

4.598

VOLTAGE (V)

4.597

4.596

4.595

4.594

–25 0 25 7550

–50

TEMPERATURE (°C)

100

4244 G19

3.3V

Powergood Threshold

OUT

Voltage vs Temperature

2.902

2.901

2.900

2.899

2.898

VOLTAGE (V)

2.897

2.896

2.895

2.894

–25 0 25 7550

–50

TEMPERATURE (°C)

Gate Pin Current vs Temperature

100

4244 G20

Gate Pin Fault Current vs

Temperature

16

FAULT = 0V

14

12

10

8

6

CURRENT (mA)

4

2

0

–25 0 25 7550

–50

TEMPERATURE (°C)

Timer Threshold Voltage vs

Temperature

1.66

1.64

1.62

1.60

1.58

1.56

1.54

VOLTAGE (V)

1.52

1.50

1.48

1.46

6

–25 0 25 7550

–50

TEMPERATURE (°C)

12VIN – V

4244 G22

TIMER

4244 G25

100

100

Timer Pin On Current vs

Temperature

20.30

20.25

20.20

20.15

CURRENT (µA)

20.10

20.05

–25 0 25 7550

–50

TEMPERATURE (°C)

100

4244 G23

Timer Pin Off Current vs

Temperature

Discharge Resistance vs

Temperature VOL vs Temperature

700

600

500

400

300

RESISTANCE (Ω)

200

100

0

–25 0 25 7550

–50

TEMPERATURE (°C)

12V

3.3V

OUT

OUT

V

EEOUT

5V

OUT

100

4244 G26

250

200

150

100

RESISTANCE (Ω)

50

0

–25 0 25 7550

–50

RESETOUT

PWRGD

FAULT

100

TEMPERATURE (°C)

4244 G27

42441f

LTC4244/LTC4244-1

U

UU

PI FU CTIO S

12VIN (Pin 1): 12V Supply Input. A 0.5Ω switch is con-

nected between 12VIN and 12V

limit. An undervoltage lockout circuit prevents the switches

from turning on while the 12VIN pin voltage is less than 9V.

12VIN also provides power to the LTC4244’s internal V

node.

V

(Pin 2): –12V Supply Input. A 1Ω switch is con-

EEIN

nected between V

limit. An undervoltage lockout circuit prevents the switches

from turning on while the V

–9.25V. The V

abled for the LTC4244-1.

5V

(Pin 3): 5V Output Sense. The PWRGD pin will not

OUT

pull low until the 5V

active pull-down discharges 5V

power switches are turned off.

TIMER (Pin 4): Current Fault Inhibit Timing Input and

Auxiliary VCC. Connect a capacitor from TIMER to GND.

When the LTC4244 is turned on, a 21µA pull-up current

source is connected to TIMER. Current limit faults will be

ignored until the voltage at the TIMER pin rises to within

1.6V of 12VIN. After the TIMER pin has completed ramping up, the TIMER capacitor serves as an auxiliary charge

reservoir for VCC in the event the 12VIN pin voltage

momentarily drops below the undervoltage lockout threshold voltage. When the LTC4244 is turned off (OFF/ON >

2V), the TIMER pin is pulled down to GND. After the TIMER

pin voltage drops to within 0.8V of GND, the TIMER latch

is reset and the part is ready for another power cycle.

EEIN

and V

EEIN

EEIN

undervoltage lockout function is dis-

pin voltage exceeds 4.61V. A 200Ω

OUT

with a foldback current

OUT

with a foldback current

EEOUT

pin voltage is greater than

to ground when the

OUT

CC

OFF/ON (Pin 5): Digital Input. Connect the CPCI BD_SEL#

signal to the OFF/ON pin. When the OFF/ON pin is pulled

low, the GATE pin is pulled high by a 67µ A current source

and the internal 12V and –12V switches are turned on.

When the OFF/ON pin is pulled high, the GATE pin will be

pulled to ground by a 60µ A current source and the 12V and

–12V switches turn off.

FAULT (Pin 6): Open-Drain Digital I/O. FAULT is pulled low

when a current limit fault is detected. Current limit faults

are ignored until the voltage at the TIMER pin is within 1.6V

of 12VIN. Once the TIMER cycle is complete, FAULT will

pull low and the LTC4244 latches off in the event of an

overcurrent fault. The part will remain in the latched off

state until the OFF/ON pin is cycled high then low. Forcing

the FAULT pin low with an external pull-down will cause

the part to latch into the off state after a 25µs deglitching

time.

PWRGD (Pin 7): Open-Drain Digital Power Good Output.

Connect the CPCI HEALTHY# signal to the PWRGD pin.

PWRGD remains low while V

2.9V, V

the supplies falls below its power good threshold voltage,

PWRGD will go high after a 14µs deglitching time.

GND (Pin 8): Device Ground.

RESETIN (Pin 9): Digital Input. Connect the CPCI PCI_RST#

signal to the RESETIN pin. Pulling the RESETIN pin low will

cause RESETOUT to pull low. RESETOUT will also pull low

when PWRGD is high.

≥ 4.61V, and V

5VOUT

12VOUT

EEOUT

≥ 11.1V, V

≤ –11.1V. When any of

3.3VOUT

≥

42441f

7

LTC4244/LTC4244-1

U

UU

PI FU CTIO S

RESETOUT (Pin 10): Open-Drain Digital Output. Connect

the CPCI_LOCAL_RST# signal to the RESETOUT pin.

RESETOUT is the logical combination of the RESETIN and

PWRGD.

DRIVE (Pin 11): Precharge Base Drive Output. Provides

base drive for an external NPN emitter-follower that in turn

biases the PRECHARGE node.

PRECHARGE (Pin 12): Precharge Monitor Input. An internal error amplifier servos the DRIVE pin voltage to keep the

PRECHARGE node at 1V. See Applications Information for

generating voltages other than 1V. If not used, tie the

PRECHARGE pin to ground.

5VIN (Pin 13): 5V Supply Sense Input. An undervoltage

lockout circuit prevents the switches from turning on

when the voltage at the 5VIN pin is less than 4.25V.

5V

resistor placed in the supply path between 5VIN and

5V

a constant 51mV across the sense resistor and a constant

current through the switch while the TIMER pin is low. A

foldback feature makes the current limit decrease as the

voltage at the 5V

TIMER pin is high, the circuit breaker function is enabled.

If the voltage across the sense resistor exceeds 52mV, the

circuit breaker is tripped after a 25µs time delay. In the

event of a short-circuit or large overcurrent transient

condition, the GATE pin voltage will be adjusted to maintain a constant 150mV across the sense resistor and a

constant current through the switch.

(Pin 14): 5V Current Limit Sense. With a sense

SENSE

, the GATE pin voltage will be adjusted to maintain

SENSE

pin approaches GND. When the

OUT

GATE (Pin 15): High Side Gate Drive for the External 3.3V

and 5V N-Channel Pass Transistors. An external series RC

network is required for current limit loop compensation

and setting the minimum ramp-up time. During power-up,

the slope of the voltage rise at the GATE is set by the 67µ A

current source connected through a Schottky diode to

12VIN and the external capacitor connected to GND (C1 in

Figure 1) or by the 3.3V or 5V current limit and the bulk

capacitance in the 3.3V

power down, the slew rate of the GATE voltage is set by the

60µ A current source connected to GND and the external

GATE capacitor (C1 in Figure 1).

The voltage at the GATE pin will be modulated to maintain

a constant current when either the 5V or 3.3V supplies go

into current limit. In the event of an overcurrent fault, the

GATE pin is immediately pulled to GND.

3.3V

sense resistor placed in the supply path between 3.3V

and 3.3V

maintain a constant 51mV across the sense resistor and a

constant current through the switch while the TIMER pin

is low. A foldback feature makes the current limit decrease

as the voltage at the 3.3V

the TIMER pin is high, the circuit breaker function is

enabled. If the voltage across the sense resistor exceeds

52mV, the circuit breaker is tripped after a 25µ s time delay.

In the event of a short-circuit or large overcurrent transient

condition, the GATE pin voltage will be adjusted to maintain a constant 150mV across the sense resistor and a

constant current through the switch.

(Pin 16): 3.3V Current Limit Sense. With a

SENSE

, the GATE pin voltage will be adjusted to

SENSE

or 5V

OUT

pin approaches GND. When

OUT

supply lines. During

OUT

IN

8

If no 3.3V input supply is available, short the 3.3V

to the 5VIN pin.

SENSE

pin

42441f

LTC4244/LTC4244-1

U

UU

PI FU CTIO S

3.3VIN (Pin 17): 3.3V Supply Sense Input. An undervoltage lockout circuit prevents the switches from turning on

when the voltage at the 3.3VIN pin is less than 2.5V. If no

3.3V input supply is available, short the 3.3VIN pin to the

5VIN pin.

3.3V

Output Supply Voltage. The PWRGD pin cannot pull low

until the 3.3V

supply is available, tie the 3.3V

200Ω active pull-down discharges 3.3V

when the power switches are turned off.

(Pin 18): Analog Input Used to Monitor the 3.3V

OUT

pin voltage exceeds 2.9V. If no 3.3V input

OUT

pin to the 5V

OUT

OUT

to ground

OUT

pin. A

V

connected between V

than –11.1V before the PWRGD pin pulls low. The V

power good comparator is disabled for the LTC4244-1. A

390Ω active pull-up discharges V

the power switches are turned off.

12V

connected between 12VIN and 12V

exceed 11.1V before the PWRGD pin can pull low. A 440Ω

active pull-down discharges 12V

power switches are turned off.

(Pin 19): -12V Supply Output. A 1Ω switch is

EEOUT

and V

EEIN

(Pin 20): 12V Supply Output. A 0.5Ω switch is

OUT

. V

EEOUT

EEOUT

to ground when the

OUT

must be less

EEOUT

to ground when

. 12V

OUT

OUT

EEOUT

must

42441f

9

LTC4244/LTC4244-1

W

BLOCK DIAGRA

3.3V

IN

17

3.3V

SENSE

16

GATE

15

5V

SENSE

14

5V

IN

13

–

5V

CURRENT

FAULT

UVL

MONITOR

V

EEIN

REF

8µs

RISING

EDGE

DELAY

+

50mV

+

–

TIMER_LO ≥ 50mV

TIMER_HI ≥ 150mV

5V

+

+

OUT

GND

8

V

CC

–

–

+

–

12V

IN

CP_OFF

V

67µA

60µA

CC

3.3V

OUT

–

+

+

–

+

–

TIMER_LO ≥ 50mV

TIMER_HI ≥ 150mV

50mV

+

–

3.3V

+

–

CURRENT FAULT

FAULT

6

OFF/ON

5

PWRGD

7

RESETOUT

10

RESETIN

9

CP_OFF

THERMAL FAULT

12V

IN

1

CP_OFF

V

CC

UVL

V

CC

RESET

12V SWITCH

CONTROL

CHARGE

PUMP

46µs

FALLING

EDGE

DELAY

12V CURRENT FAULT

CP_OFF

21µA

14µs

FALLING

EDGE

DELAY

REF

TIMER_HI

POWER GOOD

MONITOR

TIMER

4

3.3V CURRENT FAULT

5V CURRENT FAULT

CURRENT FAULT

V

EE

12V CURRENT FAULT

SQ

RQ

V

CC

THERMAL

SHUTDOWN

V

CC

REFERENCE

THERMAL

FAULT

TIMER_LO

THERMAL

FAULT

REF

TIMER_HI

25µs

RISING

EDGE

DELAY

5V

IN

4R

–

R

+

V

CC

SQ

R

CP_OFF

Q

DRIVE

PRECHARGE

12V

OUT

5V

OUT

3.3V

OUT

11

12

20

3

18

V

EEIN

2

THERMAL FAULT

10

CP_OFF

VEE SWITCH

CONTROL

CURRENT FAULT

V

EE

V

EEOUT

19

4244 BD

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

Hot Circuit Insertion

When a circuit board is inserted into a live CompactPCI

(CPCI) bus, the supply bypass capacitors can draw huge

inrush currents from the CPCI power bus as they charge

up. These transient currents can create glitches on the

power bus, causing other boards in the system to reset.

The LTC4244 is designed to turn a board’s back-end

supply voltages on and off in a controlled manner, allowing the board to be safely inserted or removed from a live

CPCI connector without glitching the system power supplies. It also protects the system supplies from shorts,

precharges the bus I/O connector pins during hot insertion

and extraction, and monitors the supply voltages.

The LTC4244 is specifically designed for CPCI applications where the Hot Swap controller resides on the plugin board.

LTC4244 Feature Summary

• Allows safe insertion and removal from a CPCI backplane.

• Controls all four CPCI supplies: -12V, 12V, 3.3V and 5V.

• Current limit during power up: the supplies are allowed

to power up in current limit. This allows the LTC4244 to

power up boards with widely varying capacitive loads

without tripping the circuit breaker. The maximum

allowable power-up time is adjustable using the TIMER

pin capacitor.

• Internal 12V and –12V power switches.

• PWRGD output: monitors the voltage status of the four

back-end supply voltages.

• PCI_RST# combined on chip with HEALTHY# to create

LOCAL_PCI_RST# output. Simply connect the

PCI_RST# signal to the RESETIN pin and the

LOCAL_PCI_RST# signal to the open-drain RESETOUT

pin.

• Precharge output: on-chip reference and error amplifier

provide 1V for biasing bus I/O connector pins during

CPCI card insertion and extraction.

• TIMER/AUX. VCC: After power-up, the TIMER pin capacitor serves as auxiliary VCC, thus enabling the

LTC4244 to ride out large voltage spikes on the 12V

supply without interruption.

IN

• Adjustable foldback current limit for the 5V and 3.3V

supplies: an adjustable analog current limit with a value

that depends on the output voltage. If the output is

shorted to ground the current limit drops to keep power

dissipation and supply glitches to a minimum.

• 12V and –12V circuit breakers: if either supply remains

in analog foldback current limit for more than 25µ s, the

circuit breakers will trip, the supplies are turned off and

the FAULT pin is pulled low.

• Adjustable 5V and 3.3V circuit breakers: if either supply

exceeds its current limit for more than 25µ s, the circuit

breaker will trip, the supplies will be turned off and the

FAULT pin is asserted low. In the event of a short circuit

on either supply, an analog current limit will prevent the

supply current from exceeding three times the circuit

breaker threshold current.

• Undervoltage lockout: All four input voltages are protected by undervoltage lockouts.

• Space saving 20-pin SSOP package.

LTC4244 vs LTC1644

The LTC4244 is pin-for-pin compatible with the LTC1644.

There are, however, some important differences between

the two parts:

• TIMER: The LTC4244’s TIMER pin threshold voltage is

1.6V below V

up, the LTC4244’s TIMER pin also doubles as auxiliary

VCC.

•V

UVL: The LTC4244 has a –9.5V UVL threshold

EEIN

protecting the V

UVL feature.

vs 1V for the LTC1644. After power-

12VIN

supply. The LTC1644 has no V

EEIN

EEIN

42441f

11

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

•5VIN UVL Threshold Voltage: The LTC4244’s 5VIN UVL

threshold voltage is 4.25V vs. 2.5V for the LTC1644.

•V

power good threshold voltage is –11.1V vs –10.5V for

the LTC1644.

• Absolute Maximum Ratings: The LTC4244’s absolute

maximum ratings for the 12VIN and V

±14.4V, respectively, vs ±13.2V for the LTC1644.

• 5V/3.3V Circuit Breakers: If a short-circuit occurs after

power-up, the LTC4244 actively limits the voltage

dropped across the external 5V and 3.3V sense resistors to 150mV for 25µs before tripping the circuit

breaker. In the event either the 5V or 3.3V sense resistor

voltage exceeds 150mV, the LTC1644 trips the circuit

breaker without delay.

• 5V/3.3V Circuit Breaker Threshold Voltage: The LTC4244

threshold voltage is 52mV ±5mV vs 55mV ±15mV for

the LTC1644.

• External Gate Voltage: After power-up, the voltage drop

from the 12VIN pin to the GATE pin is 0.6V for the

LTC4244 vs 50mV for the LTC1644.

Hot Plug Power-Up Sequence

The LTC4244 is specifically designed for hot plugging

CPCI boards. The typical application circuit is shown in

Figure 1.

CPCI Connector Pin Sequence

The staggered lengths of the CPCI male connector pins

ensure that all power supplies are physically connected to

the LTC4244 before back-end power is allowed to ramp up

(BD_SEL# asserted low). The long pins, which include 5V,

3.3.V, V(I/O) and GND, mate first. The short BD_SEL# pin

mates last. At least one long 5V power pin must be

connected to the LTC4244 in order for the PRECHARGE

voltage to be available during the insertion sequence.

PWRGD Threshold Voltage: The LTC4244 V

EEOUT

pins are

EEIN

EEOUT

The following is a typical hot insertion sequence:

1. ESD clips make contact.

2. Long power and ground pins make contact and Early

Power is established. The 1V precharge voltage becomes valid at this stage of insertion. Power is also

applied to the pull-up resistors connected to the FAULT,

PWRGD and OFF/ON pins. All power switches are held

off at this stage of insertion.

3. Medium length pins make contact. Both FAULT and

PWRGD continue to be pulled up high at this stage in the

hot plug sequence, and the power switches are still held

off. The 12V and –12V connector pins also make

contact at this stage. Zener clamps Z1 and Z2 plus shunt

RC snubbers R16-C5 and R15-C4 help protect the V

and 12VIN pins, respectively, from large voltage transients during hot insertion.

The signal pins also connect at this point. These include

the HEALTHY# signal (which is connected to the PWRGD

pin), the PCI_RST# signal (which is connected to the

RESETIN pin) and the I/O connector pins (which are

biased at 1V by the LTC4244’s precharge circuit).

4. Short pins make contact. The BD_SEL# signal is connected to the OFF/ON pin. If the BD_SEL# signal is

grounded on the backplane, the plug-in card power-up

cycle begins immediately. System backplanes that do

not ground the BD_SEL# signal will instead have circuitry that detects when BD_SEL# makes contact with

the plug-in board. The system logic can then control the

power up process by pulling BD_SEL# low.

Power-Up Sequence

The back-end 3.3V

lated from the 3.3VIN and 5VIN power planes by external

N-channel pass transistors Q1 and Q2, respectively. Internal pass transistors isolate the back-end 12V

V

planes.

power planes from the 12VIN and V

EEOUT

OUT

and 5V

power planes are iso-

OUT

EEIN

EEIN

and

OUT

power

12

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

Sense resistors R1 and R2 provide current fault detection

and R5 and C1 provide current control loop compensation

as well as ramp rate control for the GATE pin voltage.

Resistors R3 and R4 prevent high frequency oscillations

in MOSFET’s Q1 and Q2.

A power-up sequence begins when the OFF/ON pin is

pulled low (Figure 2). This enables the pass transistors to

turn on and an internal 21µ A current source is connected

to TIMER. Once the pass transistors begin to conduct

current, the supplies will start to power up. Current limit

faults are ignored while the TIMER pin voltage is ramping

up and is less than (12V

– 1.6V). When all four supply

IN

voltages are within tolerance, HEALTHY# will pull low and

LOCAL_PCI_RST# is free to follow PCI_RST#.

TIMER

10V/DIV

GATE

10V/DIV

12V

OUT

10V/DIV

5V

OUT

10V/DIV

3.3V

OUT

10V/DIV

V

EEOUT

10V/DIV

BD_SEL#

10V/DIV

HEALTHY#

10V/DIV

LCL_PCI_RST#

10V/DIV

Power-Down Sequence

When the BD_SEL# signal is pulled high, a power-down

sequence begins (Figure 3).

Internal switches are connected to each of the output

voltage supply pins to discharge the bypass capacitors to

ground. The TIMER pin is immediately pulled low. The

GATE pin is pulled down by a 60µA current source to

prevent the load currents on the 3.3V and 5V supplies from

going to zero instantaneously and glitching the power

supply voltages. When any of the output voltages dips

below its threshold, the HEALTHY# signal pulls high and

LOCAL_PCI_RST# will be asserted low.

TIMER

10V/DIV

GATE

10V/DIV

12V

OUT

10V/DIV

5V

OUT

10V/DIV

3.3V

OUT

10V/DIV

V

EEOUT

10V/DIV

BD_SEL#

10V/DIV

HEALTHY#

10V/DIV

LCL_PCI_RST#

10V/DIV

10ms/DIV

Figure 2. Normal Power-Up Sequence

4244 F02

20ms/DIV

Figure 3. Normal Power-Down Sequence

4244 F03

42441f

13

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

Once the power-down sequence is complete, the CPCI

card may be removed from the slot. During extraction, the

precharge circuit continues to bias the bus I/O connector

pins at 1V until the long 5V and 3.3V connector pin

connections are broken.

GATE Pin Capacitor Selection

Both the load capacitance and the LTC4244’s GATE pin

capacitor (C1 in Figure 1) affect the ramp rate of the 5V

and 3.3V

voltages. The precise relationship can be

OUT

OUT

expressed as:

dV

OUT

dt

I

GATE

=

C

1

I

LIMIT(3.3V)

=

I

LIMIT(5V)

or =

I

–

LOAD V

C

LOAD VOUT

33

(. )

C

I

–

LOAD V

LOAD VOUT

5

()

33

(. )

5

()

or

(1)

whichever is slowest. The power-up time for any of the

LTC4244’s outputs where the inrush current is constrained

by that supply’s foldback current limit can be approximated as:

t

on VOUT

()

n

Where nV

<

OUT

example, if C

I

LOAD(5VOUT)

= 5A, the 5V

••

LOAD OUT

II

LIMIT VOUT LOAD VOUT

() ()

nn

= 5V

LOAD

, 3.3V

OUT

=2000µF, I

OUT

n

–

, 12V

OUT

LIMIT(5VOUT)

OUT

or V

= 6A and

EEOUT

(2)

. For

turn-on time will be less than

CV

2

20ms.

If the value of C1 is large enough that it alone determines

the output voltage ramp rate, then the magnitude of the

inrush current initially charging the load capacitance is:

C

I

INRUSH

LOAD

=

I

•

C

GATE

1

(3)

The maximum power-up time for this condition can be

approximated by:

V V C MAX

()

t

<

ON

where V

+

OUT TH MOSFET MAX

TH,MOSFET(MAX)

,()

I

GATE MIN

()

is the maximum threshold voltage

•( )1

(4)

of the external 5V or 3.3V MOSFET.

In general, the edge rate (dI/dt) at which the back-end 5V

and 3.3V supply currents are turned on can be limited by

increasing the size of C1. Applications that are sensitive to

the edge rate should characterize how varying the size of

C1 reduces dI/dt for the external MOSFET selected for a

particular design.

In the event of a short-circuit or overcurrent condition, the

LTC4244’s GATE pin can be pulled down within 2µ s since

a 1kΩ (R5 in Figure 1) decouples C1 from the gates of the

external MOSFET’s (Q1 and Q2 in Figure 1).

TIMER Pin Capacitor Selection

During a power-up sequence, a 21µA current source is

connected to the TIMER pin and current limit faults are

ignored until the voltage ramps to within 1.6V of 12VIN.

This feature allows the part to power up large capacitive

loads using its foldback current limit. The TIMER inhibit

period can be expressed as:

t

TIMER

CVV

=

•–12

TIMER IN TIMER

()

I

TIMER

(5)

The timer period should be set longer than the duration of

any inrush current that exceeds the LTC4244’s foldback

current limit but yet be short enough not to exceed the

maximum, safe operating area of the external 5V and 3.3V

pass transistors in the event of a short circuit (see Design

Example). As a design aid, the TIMER period as a function

of the timing capacitor using standard values from 0.1µ F

to 0.82µF is shown in Table 1.

14

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

Table 1. t

C

TIMER

vs C

TIMER

(±10%) t

0.1µF 35ms 74ms

0.22µF 77ms 162ms

0.33µF 115ms 243ms

0.47µF 164ms 346ms

0.68µF 238ms 500ms

0.82µF 287ms 603ms

TIMER

TIMER(MIN)

t

TIMER(MAX)

The TIMER pin is immediately pulled low when the BD_SEL#

pin signal goes high.

Thermal Shutdown

The internal switches for the 12V and –12V supplies are

protected by a thermal shutdown circuit. When the junction temperature of the die reaches 150°C, all switches will

be latched off and the FAULT pin will be pulled low.

TIMER

10V/DIV

Short-Circuit Protection

During a normal power-up sequence, if the TIMER pin is

done ramping and any supply is still in current limit all of

the pass transistors will be immediately turned off and

FAULT will be pulled low as shown in Figure 4.

In order to prevent excessive power dissipation in the pass

transistors and prevent voltage spikes on the supplies

during short-circuit conditions, the current limit on each

supply is designed to be a function of the output voltage.

As the output voltage drops, the current limit decreases.

Unlike a traditional circuit breaker function where large

currents can flow before the breaker trips, the current

foldback feature guarantees that the supply current will be

kept at a safe level.

If either the 12V or –12V supply exceeds current limit

after power-up, the shorted supply’s current will drop

GATE

10V/DIV

3.3V

OUT

10V/DIV

BD_SEL#

10V/DIV

HEALTHY#

10V/DIV

LCL_PCI_RST#

10V/DIV

FAULT

10V/DIV

12V

OUT

5V

OUT

10V/DIV

10V/DIV

V

EEOUT

10V/DIV

20ms/DIV

4244 F04

Figure 4. Power-Up Into a Short on a 3.3V Output

42441f

15

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

immediately to its I

value. If that supply remains in

LIMIT

current limit for more than 25µ s, all of the supplies will be

latched off. The 25µ s prevents quick current spikes—for

example, from a fan turning on—from causing false trips

of the circuit breaker.

After power-up, the 5V and 3.3V supplies are protected

from short circuits by dual-level circuit breakers. In the

event that either supply’s current exceeds the nominal

current limit, an internal timer is started. If the supply is

still overcurrent after 25µ s, the circuit breaker trips and all

the supplies are turned off (Figure 5). An analog current

limit loop prevents the supply current from exceeding 3×

the nominal current limit in the event of a short circuit

(Figure 6). The LTC4244 will stay in the latched off state

until the OFF/ON pin is cycled high then low or the 12V

IN

power supply is cycled low then high.

The current limit and the foldback current level for the 5V

and 3.3V outputs are both a function of the external sense

resistor. As shown in Figure 1, a sense resistor is connected between 5VIN and 5V

for the 5V supply. For

SENSE

the 3.3V supply, a sense resistor is connected between

3.3VIN and 3.3V

. The typical current limit and the

SENSE

foldback current levels are given by Equations 6 and 7:

mV

I

LIMIT VOUT

()

n

I

FOLDBACK VOUT

where nV

OUT

()

n

= 5V

51

=

R

SENSE VOUT

=

R

or 3.3V

OUT

()

n

mV

16

SENSE VOUT

()

n

.

OUT

(6)

(7)

The current limit for the internal 12V switch is set at

850mA folding back to 360mA and the –12V switch at

610mA folding back to 225mA.

5V

IN

100mV/DIV

20V/DIV

10V/DIV

20V/DIV

– 5V

GATE

5V

OUT

FAULT

5V/DIV

TIMER

SENSE

10µs/DIV

Figure 5. Overcurrent Fault on 5V Output

4244 F05

3V

IN

500mV/DIV

GATE

20V/DIV

3.3V

OUT

5V/DIV

FAULT

5V/DIV

TIMER

20V/DIV

– 3V

SENSE

10µs/DIV

Figure 6. Short-Circuit Fault on 3.3V Output

4244 F06

16

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

Calculating R

SENSE

Determining the most appropriate value for the sense

resistor first requires knowing the maximum current needed

by the load under worst-case conditions. Two other parameters affect the value of the sense resistor. First is the

tolerance of the LTC4244’s circuit breaker threshold voltage. The LTC4244’s nominal circuit breaker threshold

voltage is V

CB(NOM)

= 52mV; however it exhibits ±5mV

tolerance over process and temperature. Second is the

tolerance (RTOL) of the sense resistor. Sense resistors are

available in RTOL’s of ±1%, ±2% and ±5% and exhibit

temperature coefficients of resistance (TCR’s) between

±75ppm/°C and ±100ppm/°C. How the sense resistor

changes as a function of temperature depends on the

I2 • R power being dissipated by it. The power rating of the

sense resistor should accommodate steady-state fault

current levels so that the component is not damaged

before the circuit breaker trips.

Table 2 lists I

TRIP(MIN)

gested values of R

and I

TRIP(MAX)

. Table 7 lists manufacturers and

SENSE

versus some sug-

part numbers for these resistor values.

Table 2. I

R

SENSE

vs R

TRIP

(1% RTOL) I

0.005Ω 9.31A 11.5A

0.007Ω 6.6A 8.2A

0.011Ω 4.2A 5.2A

SENSE

TRIP(MIN)

I

TRIP(MAX)

Output Voltage Monitor

The status of all four output voltages is monitored by the

power good function. In addition, the PCI_RST# signal is

logically combined on-chip with the HEALTHY# signal to

create LOCAL_PCI_RST# (see Table 3). As a result,

LOCAL_PCI_RST# will be pulled low whenever HEALTHY#

is pulled high independent of the state of the PCI_RST#

signal.

If any of the output voltages drop below the power good

threshold for more than 14µs, the PWRGD pin will be

pulled high and the LOCAL_PCI_RST# signal will be

asserted low.

Table 3. LOCAL_PCI_RST# Truth Table

PCI_RST# HEALTHY# LOCAL_PCI_RST#

LO LO LO

LO HI LO

HI LO HI

HI HI LO

Precharge

The PRECHARGE input and DRIVE output pins are intended for use in generating the 1V precharge voltage that

is used to bias the bus I/O connector pins during board

insertion and extraction. The LTC4244 is also capable of

generating precharge voltages other than 1V. Figure 7

shows a circuit that can be used in applications requiring

a precharge voltage of less than 1V. The circuit in Figure␣ 8

can be used for applications that need precharge voltages

greater than 1V.

Precharge resistors are used to connect the 1V bias voltage to the I/O lines with minimal disturbance. Figure 1

shows the precharge application circuit for 5V signaling.

The precharge resistor requirements are more stringent

for 3.3V and Universal Hot Swap boards. If the total leakage current on the I/O line is less 2µ A, then a 50k resistor

can be connected directly from the 1V bias voltage to the

I/O line. However, many ICs connected to the I/O lines can

have leakage currents up to 10µ A. For these applications,

a 10k resistor is used but must be disconnected when the

board is seated as determined by the state of the BD_SEL#

signal. Figure 9 shows a precharge circuit that uses a bus

switch to connect the individual 10k precharge resistors to

the LTC4244’s 1V PRECHARGE pin. The electrical connection is made (bus switches closed) when the voltage on the

BD_SEL# pin of the plug-in card is pulled-up to 5VIN,

which occurs just after the long pins have made contact.

The bus switches are electrically disconnected when the

short, BD_SEL# connector pin makes contact and the

42441f

17

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

LTC4244*

128

R10A

DRIVEPRECHARGE

11

Q3

MMBT2222A

• 1V

1k

5%

12Ω

5%

3.3V

GND

18Ω

4.7nF

5%

R10BR10A

PRECHARGE OUT

V

PRECHARGE

*ADDITIONAL DETAILS OMITTED FOR CLARITY

=

R10A + R10B

Figure 7. Precharge Voltage <1V Application Circuit

5V

LONG 5V

BD_SEL#

GROUND

I/O PIN 1

• • •

I/O PIN 128

BACKPLANE

CONNECTOR

PCB EDGE

BACKPLANE

CONNECTOR

Z4: SMAJ5.0A

*ADDITIONAL DETAILS OMITTED FOR CLARITY

R22

2.7Ω

C7

0.01µF

DATA BUS

C9

0.01µF PER

POWER PIN

Z4

5V

IN

4244 F07

IN

R23

51.1k 5%

R20

1.2k

5%

R24

75k

5%

R19

1k 5%

100Ω

Q2

MMBT3906

LTC4244*

18Ω

5%

R10A

DRIVEPRECHARGE

11

Q3

MMBT2222A

• 1V

1k

5%

12Ω

5%

GND

128

4.7nF

R10BR10A

PRECHARGE OUT

V

PRECHARGE

*ADDITIONAL DETAILS OMITTED FOR CLARITY

R10A + R10B

=

Figure 8. Precharge Voltage >1V Application Circuit

13

5V

IN

LTC4244*

5

OFF/ON

GND

PRECHARGE DRIVE

• • •

R8

1k 5%

R7

12Ω 5%

I/O

I/O

0.1µF

R13

10Ω

5%

R14

10Ω

5%

8

R10

18Ω 5%

12 11

R9

24Ω

IN

V

DD

BUS SWITCH

OE

OUT OUT

R11

R12

10k

10k

5%

5%

• • •

UP TO 128 I/O LINES

C3 4.7nF

MMBT2222A

PRECHARGE OUT

I

OUT

Q3

1V ±10%

= ±55mA

3.3V

4244 F08

PCI

BRIDGE

CHIP

IN

3V

4244 F09

IN

18

Figure 9. Precharge Bus Switch Application Circuit for 3.3V and Universal Hot Swap Boards

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

BD_SEL# voltage drops below 4.4V thus causing the bus

switch OE to be pulled high by Q2.

The CompactPCI specification assumes that there is a

diode to 3.3V on the circuit that is driving the BD_SEL# pin.

The 1.2k resistor pull-up to 5VIN on the plug-in card will be

clamped by the diode to 3.3V. If the BD_SEL# pin is being

driven high, the actual voltage on the pin will be approximately 3.9V. This is still above the high TTL threshold of

the LTC4244 OFF/ON pin, but low enough for Q2 to disable

the bus switches and thus disconnect the 10k precharge

resistors from the I/O lines. Since the power to the bus

switch is derived from a front-end power plane, a 100Ω

resistor should be placed in series with the power supply

of the bus switch.

When the plug-in card is removed from the connector, the

BD_SEL# connection is broken first, and the BD_SEL#

voltage pulls up to 5VIN. This causes Q2 to turn off, which

re-enables the bus switch, and the precharge resistors are

again connected to the LTC4244 PRECHARGE pin for the

remainder of the extraction process.

TIMER/Auxiliary V

CC

Once the TIMER pin voltage has ramped to within 1.6V of

12VIN, the auxiliary VCC function is enabled. In the event

the 12VIN supply voltage collapses, the LTC4244 will

continue to draw power from the charge stored on the

TIMER pin capacitor until the internal VCC node drops

below its undervoltage lockout threshold or the 12V

IN

supply voltage recovers, whichever happens first.

Other CompactPCI Applications

The LTC4244-1 is designed for CompactPCI designs

where the –12V supply is not being used on the plug-in

board. The V

and VEE circuit breaker functions are disabled. The V

pin should be connected to GND and the V

power good comparator, V

EEOUT

EEIN

EEOUT

UVL,

EEIN

pin left

floating if a –12V output is not needed.

If no 3.3V supply input is required, Figure 10 illustrates

how the LTC4244 should be configured: 3.3V

3.3VIN are connected to 5VIN and 3.3V

5V

.

OUT

is connected to

OUT

SENSE

and

For applications where the BD_SEL# connector pin is

typically connected to ground on the backplane, the circuit

in Figure 11 allows the LTC4244 to be reset simply by

pressing a pushbutton switch on the CPCI plug in board.

This arrangement eliminates the requirement to extract

and reinsert the CPCI board in order to reset the LTC4244’s

circuit breaker.

V(I/O)

PCB EDGE

BACKPLANE

CONNECTOR

BD_SEL#

GROUND

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 11. BD_SEL# Pushbutton Toggle Switch

BACKPLANE

CONNECTOR

PUSHBUTTON

SWITICH

100Ω

0.25W

1.2k

1k

5

8

OFF/ON

LTC4244*

GND

4244 F11

5V

LONG 5V

GROUND

BACKPLANE

CONNECTOR

Z4: SMAJ5.0A

*ADDITIONAL PINS OMITTED FOR CLARITY

PCB EDGE

BACKPLANE

CONNECTOR

5V

IN

Z4

3.3V

8

GND

Figure 10. No 3.3V Supply Application Circuit

R2

0.007Ω

1317 16 18 31514

3.3V

IN

SENSE

5V

5V

IN

LTC4244*

SENSE

Q2

IRF7457

GATE

R4

10Ω

3.3V

OUT

5V

OUT

C1

R5

0.33µF

1k

5V

OUT

4244 F10

42441f

19

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

Power MOSFET Selection Criteria

The LTC4244 uses external MOSFETs to limit the 5V and

3.3V supply currents. The following criteria should be

used when selecting these MOSFET’s:

1. The on resistance should be low enough to prevent an

excessive voltage drop across the sense resistor and

the series MOSFET at rated load current given the

amount of gate to source voltage provided by the

LTC4244.

2. The drain-to-source breakdown voltage should be high

enough for the device to survive overvoltage transients

that may occur during fault conditions (the 5V and 3.3V

transient voltage limiters shown in Figure 1 will limit the

maximum drain-source voltage seen by these MOSFET’s

during fault conditions).

3. The MOSFET package must be able to handle the

maximum, steady state power dissipation for the ON

state without exceeding the device’s rated maximum

junction temperature. The MOSFET’s steady-state, dissipated power can be expressed as:

PON = I

MAX

2

• R

DS(ON)

(8)

The increase in steady-state junction-to-ambient temperature is given by:

TJ – TA = PON • R

θJA

(9)

4. The MOSFET package must be able to dissipate the heat

resulting from the power pulse during the transition

from off to on. A worst-case approximation for the

magnitude of the power pulse is:

P

OFF-ON

where nV

VI I

n

<

= 5V

OUT

•

()

OUT INRUSH LOAD

or 3.3V

OUT

+

2

, I

OUT

INRUSH

(10)

is the transient current initially charging the load capacitance and

I

is the steady-state load current. The duration, tON,

LOAD

of the power pulse can be expressed as:

CV

t

=

ON

•

LOAD OUT

I

INRUSH

(11)

5. The MOSFET package must be able to sustain the

maximum pulse power that occurs in the event the

LTC4244 attempts to power-up either the 5V or 3.3V

back-end supply into a short circuit (see Design Example for a sample calculation).

Table 8 lists some power MOSFET’s that can be used with

the LTC4244.

Input Overvoltage Transient Protection

Hot plugging a board into a backplane generates inrush

currents from the backplane power supplies due to the

charging of the plug-in board capacitance. To reduce this

transient current to a safe level, the CPCI Hot Swap

specification restricts the amount of unswitched capacitance used on the input side of the plug-in board. Each

medium or long power pin connected to the CPCI female

connector on the plug-in board is required to have a 10nF

ceramic bypass capacitor to ground. Bulk capacitors are

only allowed on the switched output side of the LTC4244

(5V

OUT

, 3.3V

OUT

, 12V

OUT

, V

). Some bulk capaci-

EEOUT

tance is allowed on the 5VIN and 3.3VIN Early Power

planes, but only because a current limiting resistor is

assumed to decouple the connector pin from the bulk

capacitance. Circuits normally placed on the unswitched

side Early Power plane (PCI Bridge, for example) need to

to be decoupled by a current limiting resistor.

Disallowing bulk capacitors on the input power pins mitigates the inrush current during Hot Swap. However, it also

tends to create a resonant circuit formed by the inductance

of the backplane power supply trace in series with the

inductance of the connector pin and the parasitic capacitance of the plug-in board (mainly due to the large power

FET). Upon board insertion, the ringing of this circuit can

exhibit a peak overshoot of 2.5 times the steady-state

voltage (>30V for 12VIN).

There are two methods for abating the effects of these high

voltage transients: using voltage limiters to clip the transient to a safe level and snubber networks. Snubber

networks are series RC networks whose time constants

20

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

are experimentally determined based on the board’s parasitic resonance circuits. As a starting point, the capacitors

in these networks are chosen to be 10× to 100× the power

MOSFET’s C

under bias. The series resistor is a value

OSS

determined experimentally that ranges from 1Ω to 50Ω,

depending on the parasitic resonance circuit. Note that in

all LTC4244 circuit schematics,

both

transient voltage

limiters and snubber networks have been added to the

12VIN and V

supply rails and should always be used.

EEIN

Snubber networks are not necessary on the 3.3VIN or the

5V

IN

5V

3V

IN

3.3V

Z3 Z4

3.3V

0.005Ω

17

IN

R1

3.3V

SENSE

Q1

IRF7457

15

GATE

R3

10Ω

3.3V

LTC4244*

18

OUT

GND

5VIN supply lines since their absolute maximum voltage

ratings are 13.5V. Transient voltage limiters, however, are

recommended as these devices provide large-scale transient protection for the LTC4244 in the event of abrupt

changes in supply current. All protection networks should

be mounted very close to the LTC4244’s supply pins using

short lead lengths to minimize trace resistance and inductance. This is shown schematically in Figures 12 and 13

and a recommended layout of the transient protection

devices around the LTC4244 is shown in Figure 14.

R2

0.007Ω

13

5V

IN

5V

1416

SENSE

Q2

IRF7457

R4

10Ω

5V

OUT

5V

3V

OUT

3.3V

C1

R5

0.047µF

1k

3

5V

OUT

Z3, Z4: SMAJ5.0A

*ADDITIONAL DETAILS OMITTED FOR CLARITY

Figure 12. Place Transient Protection Devices Close to LTC4244’s 5VIN and 3.3VIN Pins

12VIN–12V

R13

Z1 Z2

10Ω

C4

0.1µF

Z1, Z2: SMAJ12CA

*ADDITIONAL DETAILS OMITTED FOR CLARITY

12V

LTC4244*

1

IN

GND

IN

2

V

EEIN

8

R14

10Ω

C5

0.1µF

4244 F16

Figure 13. Place Transient Protection Devices

Close to LTC4244’s 12VIN and V

EEIN

Pins

8

VIAS TO

GND PLANE

Z3

Z1

C5

R14

C4

R13

Z1

12V

*ADDITIONAL DETAILS OMITTED FOR CLARITY

DRAWING IS NOT TO SCALE!

IN

4244 F12

3.3V

IN

20

19

18

17

16

LTC4244*

1

2

3

4

5

V

EEIN

5V

15

14

6

7

GND

Figure 14. Recommended Layout for Transient Protection

Components

IN

13

12

11

Z4

8

9

10

4244 F14

42441f

21

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

PCB Layout Considerations

For proper operation of the LTC4244’s circuit breaker,

4-wire Kelvin sense connections between the sense resistor and the LTC4244’s 5VIN and 5V

and 3.3V

pins are strongly recommended. The PCB

SENSE

pins and 3.3V

SENSE

IN

layout should be balanced and symmetrical to minimize

wiring errors. In addition, the PCB layout for the sense

resistors and the power MOSFETs should include good

thermal management techniques for optimal device power

dissipation. A recommended PCB layout for the sense

resistor, the power MOSFET and the GATE drive components around the LTC4244 is illustrated in Figure 15. In Hot

CURRENT FLOW

3.3V

3.3V

TO LOAD

IN

SENSE

RESISTOR

Swap applications where load currents can be 10A, narrow PCB tracks exhibit more resistance than wider tracks

and operate at more elevated temperatures. Since the

sheet resistance of 1 ounce copper foil is approximately

0.45mΩ/o, track resistance and voltage drops add up

quickly in high current applications. Thus, to keep PCB

track resistance, voltage drop and temperature to a minimum, the suggested trace width in these applications for

1 ounce copper foil is 0.03” for each ampere of DC current.

In the majority of applications, it will be necessary to use

plated-through vias to make circuit connections from

component layers to power and ground layers internal to

CURRENT FLOW

SO-8

D

D

D

D

TO LOAD

G

S

S

S

WW

3.3V

3.3V

OUT

TRACK WIDTH W:

0.03" PER AMPERE

ON 1 OZ Cu FOIL

20

19

18

17

16

LTC4244*

1

2

3

4

5

C

TIMER

W

*ADDITIONAL DETAILS OMITTED FOR CLARITY

DRAWING IS NOT TO SCALE!

GATE

15

14

6

7

R3

R5

13

12

11

8

9

10

CURRENT FLOW

TO SOURCE

C1

VIA/PATH

TO GND

VIA TO

GND PLANE

GNDGND

4244 F15

Figure 15. Recommended Layout for Power MOSFET, Sense Resistor and GATE Components for the 3.3V Rail

22

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

the PC board. For 1 ounce copper foil plating, a general rule

is 1 ampere of DC current per via making sure the via is

properly dimensioned so that solder completely fills the

void. For other plating thicknesses, check with your PCB

fabrication facility.

Design Example

As a design example, consider a CPCI Hot Swap application with the following power supply requirements:

Table 4. Design Example Power Supply Requirements

VOLTAGE MAXIMUM DC LOAD

SUPPLY SUPPLY CURRENT CAPACITANCE

12V 450mA 100µF

5V 5A 2200µF

3.3V 7A 2200µF

–12V 100mA 100µF

The first step is to select the appropriate values of R

SENSE

for the 5V and 3.3V supplies. Calculating the value of

R

is based on I

SENSE

LOAD(MAX)

and the lower limit for the

circuit breaker threshold voltage (47mV for both the 5V

and 3.3V circuit breakers). If a 1% tolerance is assumed

for the sense resistors, then 5mΩ and 7mΩ resistor

values yield the following minimum and maximum I

TRIP

values:

perature curve, the device’s on-resistance can be expected

to increase by about 20% over its room temperature value.

Recalculation of the steady-state values of RON and junction temperature yields approximately 12.6mΩ and 81°C,

respectively. The I • R drop across the 3.3V sense resistor

and series MOSFET at maximum load current under these

conditions will be less than 124mV.

The next step is to select appropriate values for C1 and

C

. Assuming that the total current for the 5V supply

TIMER

is constrained to less than 6A during power-up (6 × 5V

medium length connector pins at 1A per pin), then the

inrush current shouldn’t exceed:

I

INRUSH

< 6A – I

LOAD(5VOUT)

= 6A – 5A = 1A (12)

This yields:

IF

GATE MAX

>

C

1

⇒>

1

C

()

I

INRUSH MAX

µµ

100 2200

AF

•

()

•

1

A

2200

µ

=

220

nF

(13)

Hence a C1 value of 330nF ±10% should suffice. The value

of C

for this design example will be constrained by

TIMER

the duration of the 12V supply inrush current, which

according to Equation 2 is:

Table 5. I

R

SENSE

vs R

TRIP

(1% RTOL) I

5mΩ 9.3A 11.5A

7mΩ 6.6A 8.2A

SENSE

TRIP(MIN)

I

TRIP(MAX)

So sense resistor values of 7mΩ and 5mΩ should suffice

for the 5V and 3.3V supplies, respectively.

The second step is to select MOSFETs for the 5V and 3.3V

supplies. The IRF7457’s on resistance is less than 10.5mΩ

for V

> 4.5V and a junction temperature of 25°C. Since

GS

the maximum load current requirement for the 3.3V supply is 7A, the steady-state power the device may be

required to dissipate is 514mW. The IRF7457 has a

junction-to-ambient thermal resistance of 50°C/Watt. If a

maximum ambient temperature of 50°C is assumed, this

yields a junction temperature of 75.7°C. According to the

IRF7457’s Normalized On-Resistance vs Junction Tem-

CV

••

212

t

()

ON VOUT

12

t

⇒<

()

ON VOUT

12

<

II

LIMIT MIN LOAD MAX

2 100 12

550 450

LOAD

–

() ( )

••

FV

µ

mA mA

–

=

24

(14)

ms

In order to guarantee that the LTC4244’s TIMER fault

inhibit period is greater than 24ms, the value of C

TIMER

should be:

ms I

24

•

TIMER MAX

C

C

⇒>

TIMER

TIMER

>

VV

12

–

ms A

24 26

VV

12 1 9

–.

•

()

TIMER MAX

()

µ

=

61 8

.

(15)

nF

So a value of 82nF (±10%) should suffice.

42441f

23

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

The next step is to verify that the thermal ratings of the

external 5V and 3.3V MOSFETs aren’t being exceeded

during power-up cycles into the designed loads or into a

short circuit.

The amount of heating in the 5V and 3.3V MOSFETs during

a normal power cycle depends on the LTC4244’s GATE pin

current (refer to Gate Current vs Temperature plot in the

Typical Performance Characteristics section). The magnitude of the off-on power pulse that results in maximum

heating of the MOSFETs is given by Equation 10 as:

P

OFF-ON

n

=

•

VI I

()

OUT INRUSH MIN LOAD VOUT

+

() ( )

n

2

(16)

where

C

I

INRUSH MIN

LOAD

C MAX

()

1

I

•=

GATE MIN() ()

(17)

The duration of the power-pulse is given by Equation 11

as:

The duration and magnitude of the power pulse that

results during a short-circuit condition on either the 5V or

3.3V outputs are a function of the TIMER capacitor and the

LTC4244’s foldback current limit. Figure 16 shows the

worst-case power dissipated in the 5V and 3.3V external

FETs vs V

5VOUT

and V

3.3VOUT

, respectively. In the case of

the 3.3V external MOSFET, the maximum dissipated power

is 24 Watts (V

3.3VOUT

the maximum dissipated power is 22 Watts (V

= 0.9V). For the 5V external MOSFET,

=

5VOUT

1.75V). The maximum duration of the short-circuit powerpulse is given by Equation 19 as:

12

VV

–

TIMER MIN

tC

t

⇒<

tms

⇒<

<

PULSE TIMER MAX

()()

PULSE

PULSE

60 3

()

82 8 2 12 1 3

nF nF V V

+

.

.• –.

•

I

TIMER MIN

16

A

µ

()

()

(19)

t

INRUSH

CV

<

•

LOAD OUT

I

n

INRUSH MIN

()

(18)

Solving these equations for the 5V and 3.3V supplies

yields:

Table 6

P

OFF-ON

5V MOSFET 12.8W 90ms

3.3V MOSFET 11.8W 60ms

t

INRUSH(MAX)

Under these conditions, the IRF7457 datasheet’s Thermal

Response vs Pulse Duration curve indicates that the

junction-to-ambient temperature will increase by 60°C for

the 5V MOSFET and 46°C for the 3.3V MOSFET.

25

20

15

10

DISSIPATED POWER (W)

5

0

0

Figure 16. Worst-Case 5V and 3.3V MOSFET

Dissipated Power vs Output Voltage

3.3V MOSFET

1

OUTPUT VOLTAGE (V)

5V R

3.3V R

2

SENSE

SENSE

5V MOSFET

3

= 0.007Ω

= 0.005Ω

4

5

4244 F16

24

42441f

WUUU

APPLICATIO S I FOR ATIO

LTC4244/LTC4244-1

The IRF7457’s Thermal Response vs Pulse Duration curve

indicates that the worst-case increase in junction-toambient temperature during a power-cycle for the 3.3V

MOSFET is less than 96°C while the worst-case increase

in junction-to-ambient temperature for the 5V MOSFET is

less than 88°C.

Power MOSFET and Sense Resistor Selection

Tables 7 and 8 list current sense resistors and power

MOSFET transistors, respectively, that can be used with

the LTC4244’s circuit breakers. Table 9 lists supplier web

site addresses for discrete components mentioned

throughout the LTC4244 data sheet.

Obtaining Information on Specific Parts

For more information or to request a copy of the

CompactPCI specification, contact the PCI Industrial Computer Manufacturers Group at:

PCI Industrial Computer Manufacturers Group

Wakefield, MA 01880 USA

Phone: 01 (718) 224-1239

Web Site: http://www.picmg.com

Transient Voltage Suppressors SMAJ12A and SMAJ5.0A

are supplied by:

Diodes, Incorporated

Westlake Village, CA 91362 USA

Phone: 01 (805) 446-4800

Web Site: http://www.vishay.com or

http://www.diodes.com

Transistors MMBT2222A and MMBT3906 are supplied

by:

ON Semiconductor

Phoenix, AZ 85008 USA

Phone: 01 (602) 244-6600

Web Site: http://www.onsemi.com

42441f

25

LTC4244/LTC4244-1

WUUU

APPLICATIO S I FOR ATIO

Table 7. Sense Resistor Selection Guide

CURRENT LIMIT VALUE PART NUMBER DESCRIPTION MANUFACTURER

1A LR120601R055F 0.055Ω, 0.5W, 1% Resistor IRC-TT

WSL1206R055 Vishay Dale

2A LR120601R028F 0.028Ω, 0.5W, 1% Resistor IRC-TT

WSL1206R028 Vishay Dale

5A LR120601R011F 0.011Ω, 0.5W, 1% Resistor IRC-TT

WSL2010R011 Vishay Dale

7.6A WSL2512R007 0.007Ω, 1W, 1% Resistor Vishay Dale

10A WSL2512R005 0.005Ω, 1W, 1% Resistor Vishay Dale

Table 8. N-Channel Power MOSFET Selection Guide