Page 1

LTC4110

Battery Backup

System Manager

FEATURES

n

Complete Backup Battery Manager for Li-Ion/

Polymer, Lead Acid, NiMH/NiCd Batteries and

Super Capacitors

n

Charge and Discharge Battery with Voltages Above

and Below the Input Supply Voltage

n

“No Heat” Battery Calibration Discharge Using

System Load

n

Automatic Battery Backup with Input Supply

Removal Using PowerPath™ Control

n

Standalone for Li-Ion/Polymer, SLA, and Supercaps

n

Optional SMBus/I2C Support Allows Battery

Capacity Calibration Operation with Host

n

Over- and Under-Battery Voltage Protection

n

Adjustable Battery Float Voltage

n

Precision Charge Voltage ±0.5%

n

Programmable Charge/Calibration Current Up to

3A with ±3% Accuracy

n

Optional Temperature Qualifi ed Charging

n

Wide Backup Battery Supply Range: 2.7V to 19V

n

Wide Input Supply Range: 4.5V to 19V

n

38-Lead (5mm × 7mm) QFN Package

APPLICATIONS

n

Backup Battery Systems

n

Server Memory Backup

n

Medical Equipment

n

High Reliability Systems

DESCRIPTION

The LTC®4110 is a complete single chip, high effi ciency,

fl yback battery charge and discharge manager with automatic switchover between the input supply and the backup

battery or super capacitor. The IC provides four modes of

operation: battery backup, battery charge, battery calibration and shutdown. Battery backup and battery charge are

automatic standalone modes, while the optional calibration

mode requires a CPU host to communicate over an SMBus.

During calibration the fl yback charger is used in reverse

to discharge the battery with a programmable constant

current into the system load eliminating heat generation.

Three status outputs can be individually reconfi gured over

the SMBus to become GPIOs. User programmable overdischarge protection is provided. The SHDN pin isolates

the battery to support shipping the product with a charged

battery installed.

Multiple LTC4110s can be combined to form a redundant

battery backup system or increase the number of battery

packs to achieve longer backup run times.

The LTC4110 is available in a low profi le (0.75mm), 38-pin

5mm × 7mm QFN package. The QFN features an exposed

metal die mount pad for optimum thermal performance.

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation. PowerPath

is a trademark of Linear Technology Corporation. All other trademarks are the property of their

respective owners.

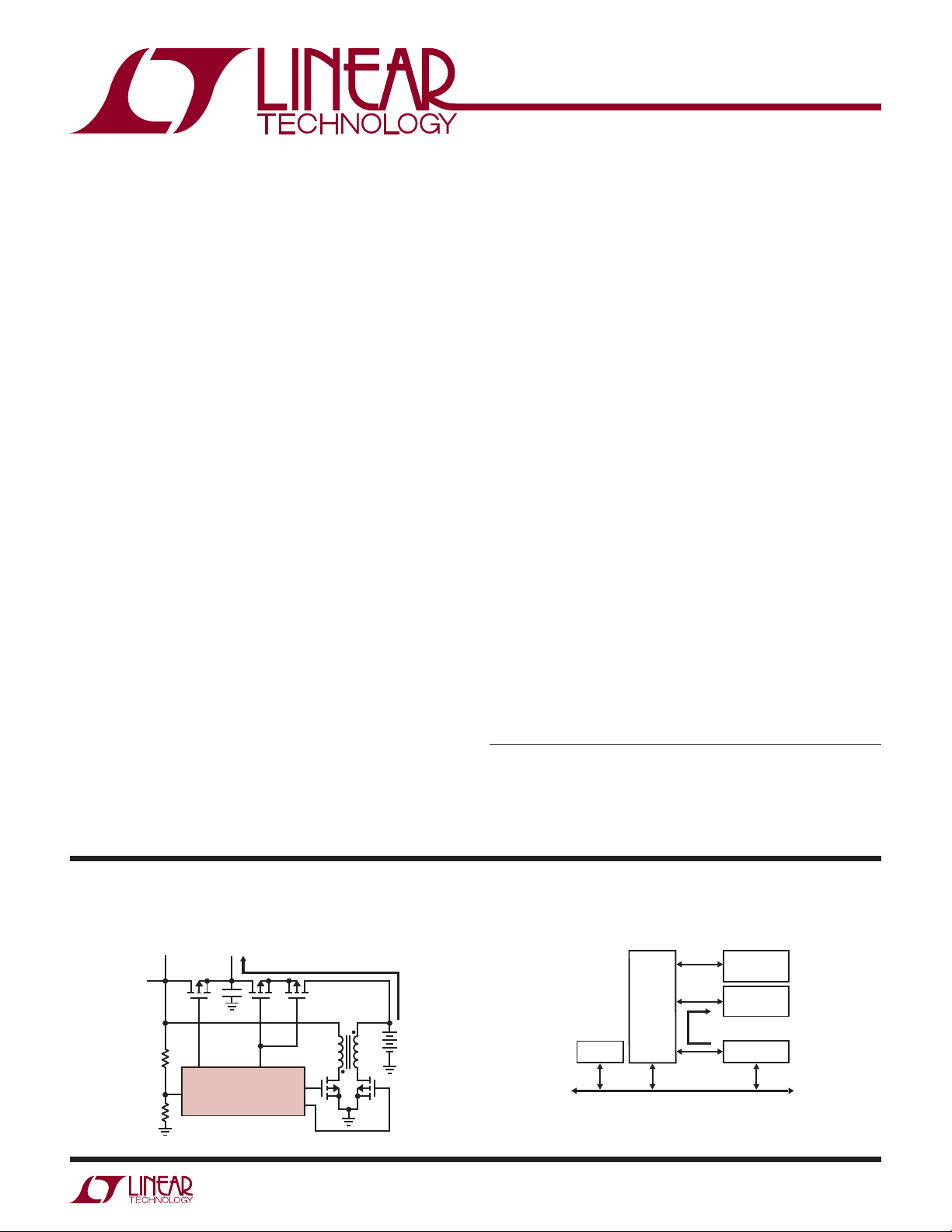

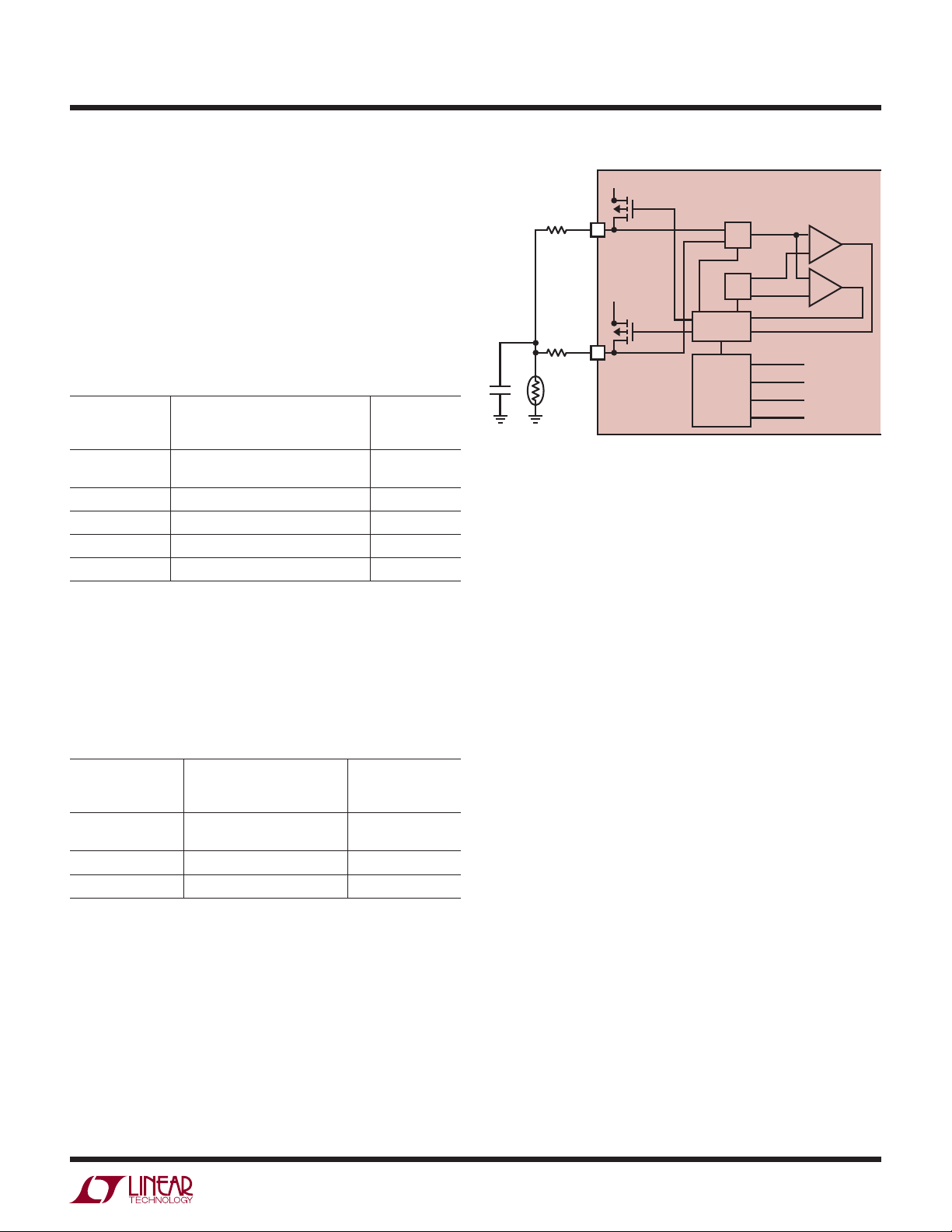

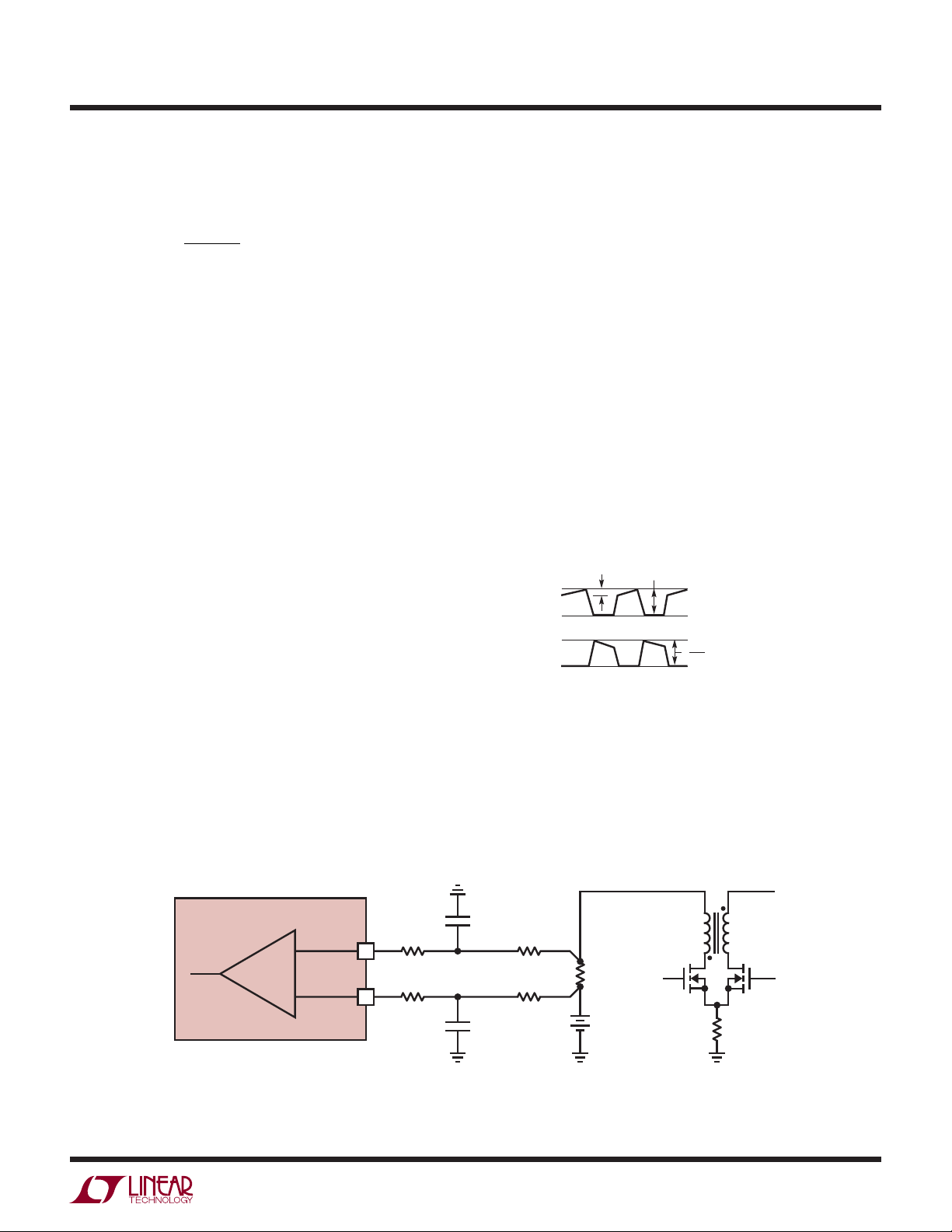

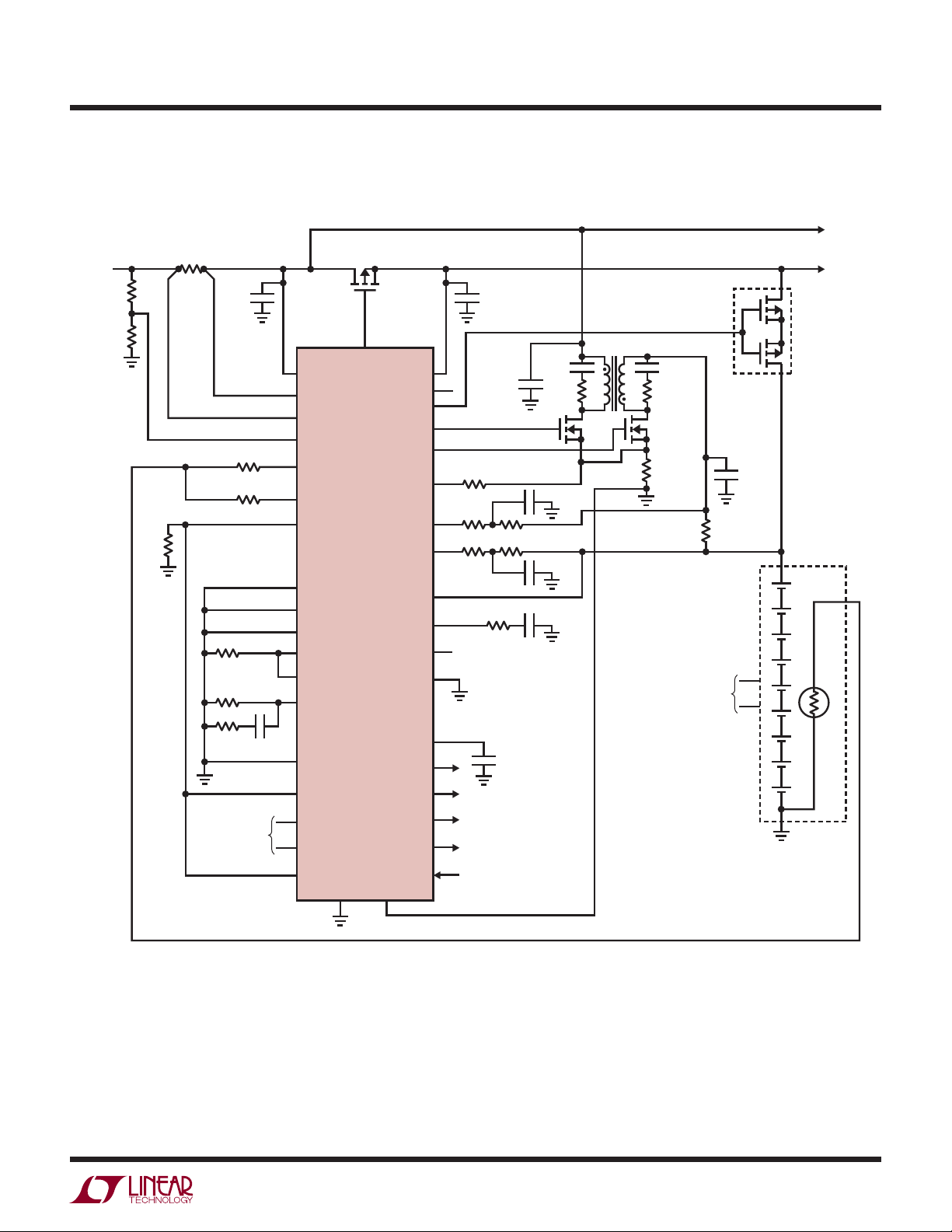

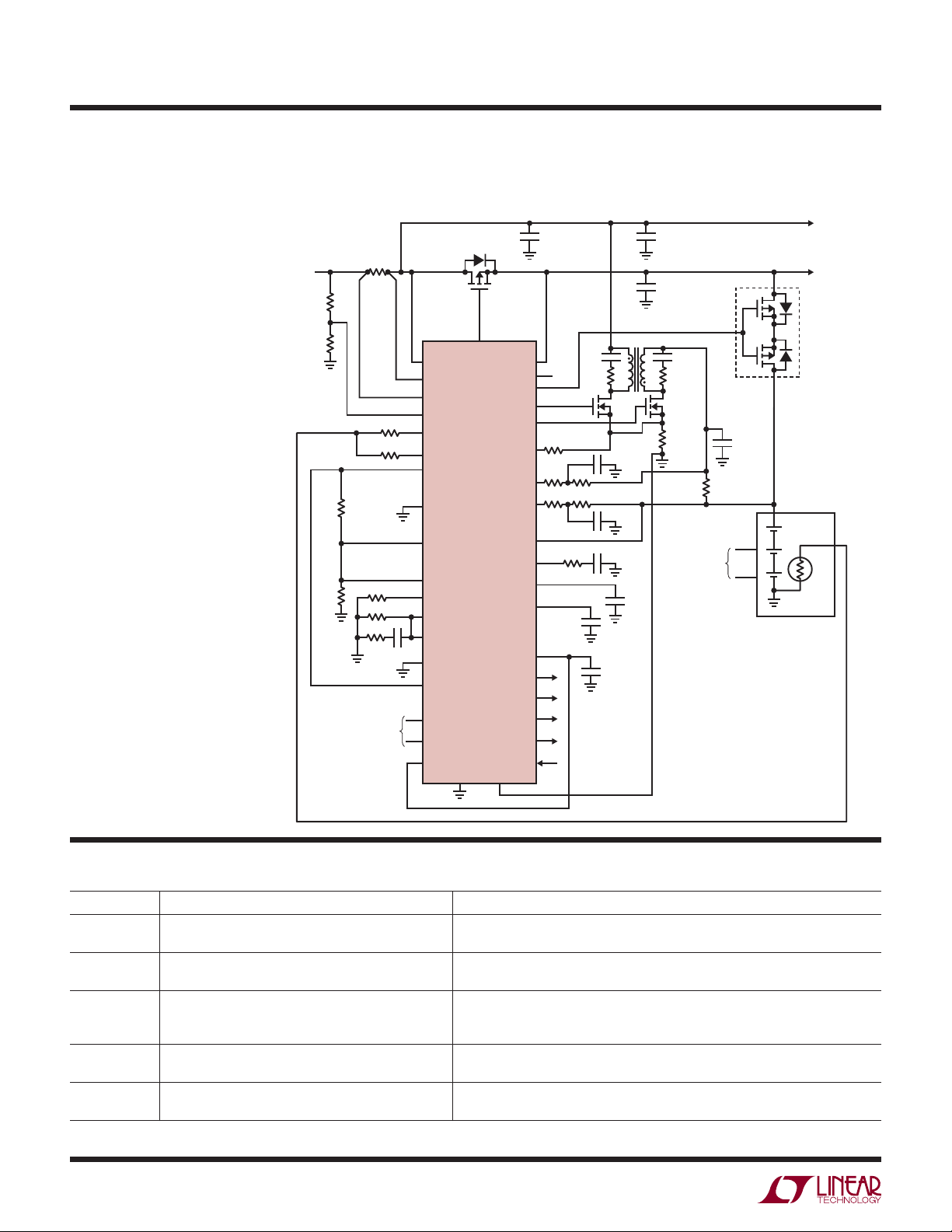

TYPICAL APPLICATION

Battery Backup System Manager Server Backup System (In Backup Mode)

SYSTEM LOAD

DCIN

0V

UVLO

SET POINT

BACKUP LOAD (DCOUT)

INID BATID

LTC4110

DCDIV

CURRENT FLOW

ON ONOFF

CHGFET

DCHFET

4110 F01

BATTERY

HOST CPU

LTC4110

BATTERY

BACKUP

SYSTEM

MANAGER

CURRENT FLOW

2

I

C BUS

SYSTEM LOAD

(DC/DC, ETC.)

BACKUP LOAD

(MEMORY, ETC.)

BATTERY

4110 TA01b

4110fa

1

Page 2

LTC4110

(Note 1)

DCIN, BAT, DCOUT, DCDIV, SHDN

to GND ....................................................... –0.3V to 20V

Input Voltage (CLP, CLN) ...............–0.3V to DCIN + 0.3V

Input Voltage (CSP, CSN) ................–0.3V to BAT + 0.3V

Input Voltage

(GPIO1, GPIO2, GPIO3, SELC, SELA, TYPE, V

THA, THB, I

Input Voltage (V

, ACPDLY, SDA, SCL) .... – 0.3V to 7V

SENSE

, V

CAL

) ....................... – 0.3V to 1.35V

DIS

Output Voltage

(ACPb, GPIO1, GPIO2, GPIO3) ................–0.3V to 7V

CLP-CLN, CSP-CSN ..................................................±1V

Operating Temperature Range (Note 2)....–40°C to 85°C

Junction Temperature (Note 3) ............................. 105°C

Storage Temperature Range

QFN Package ......................................–65°C to 125°C

CHG

,

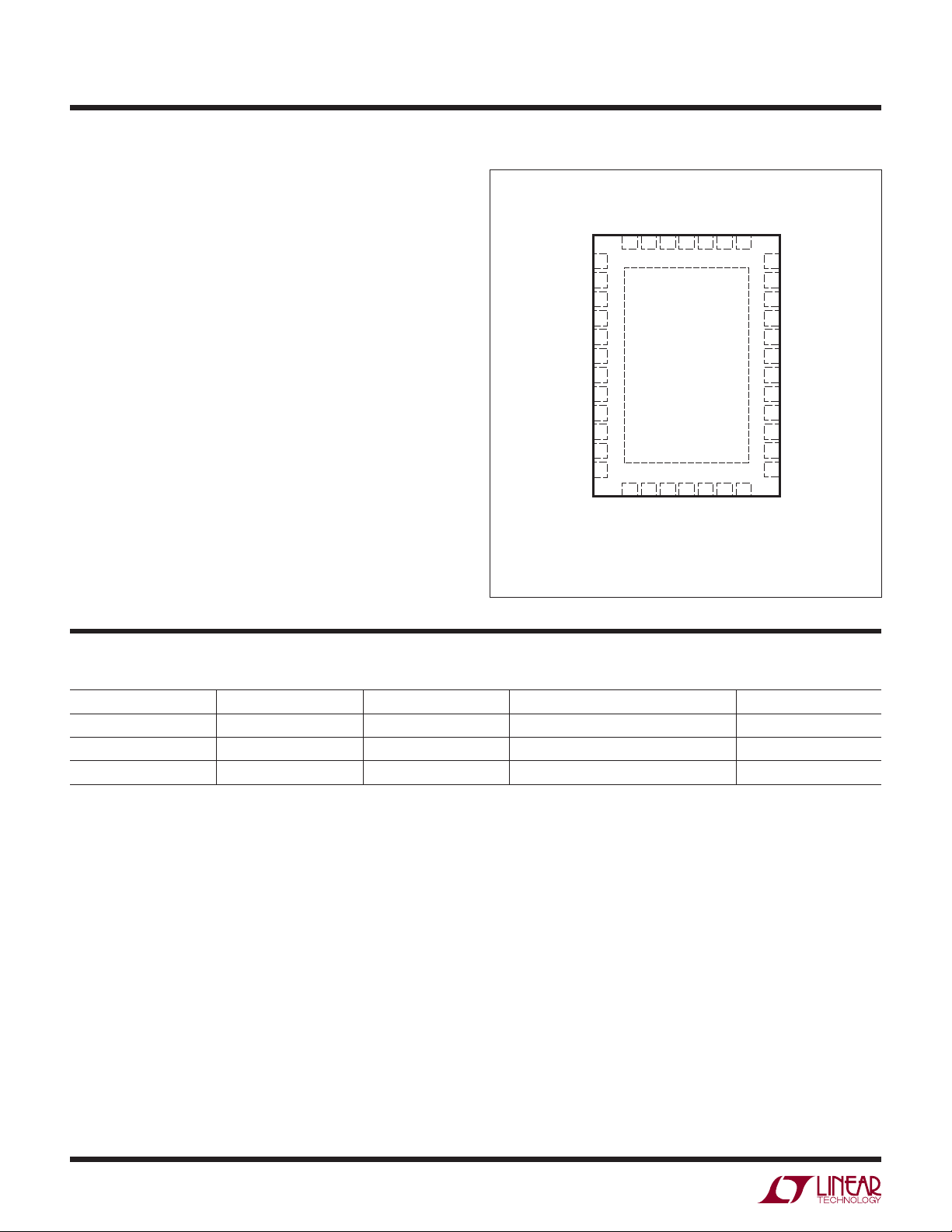

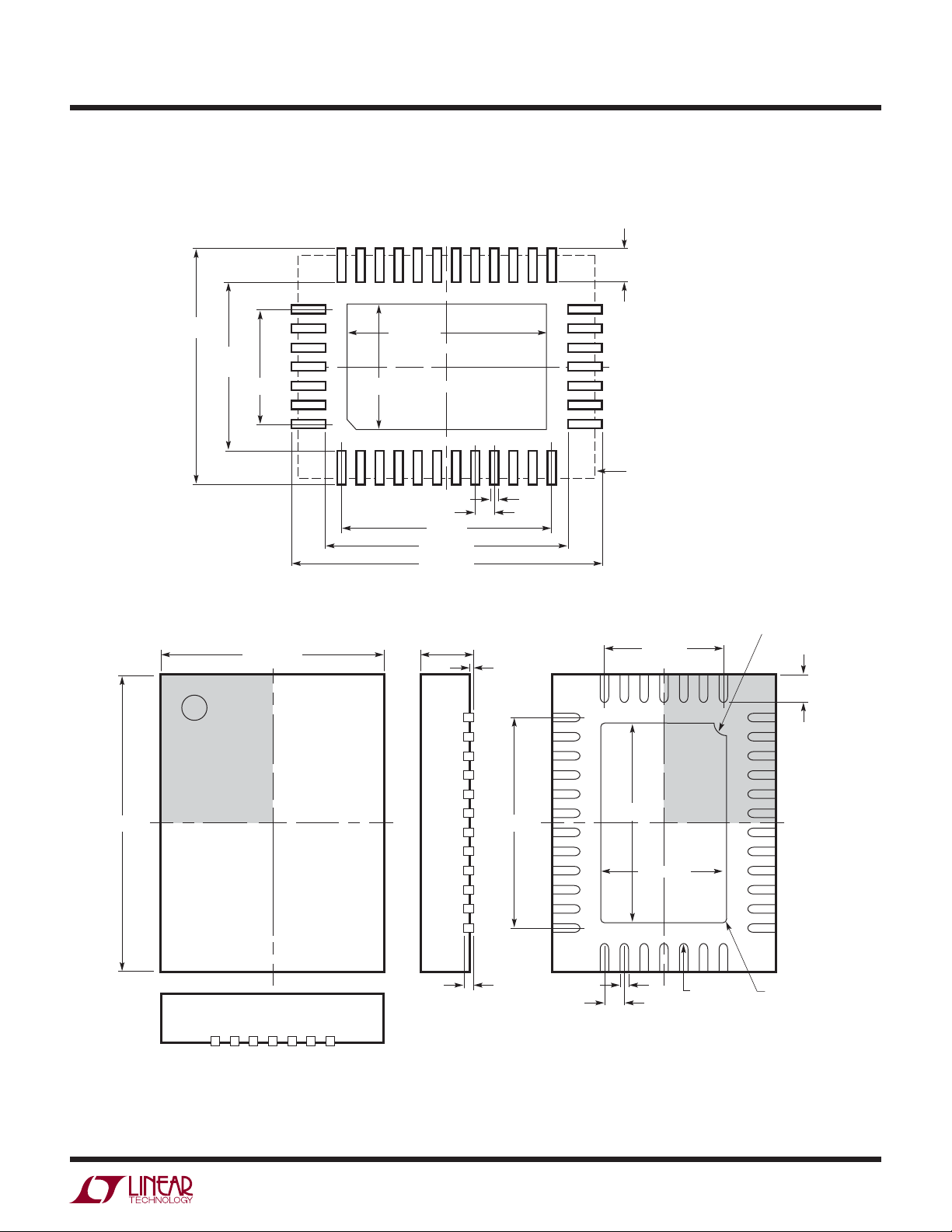

PIN CONFIGURATIONABSOLUTE MAXIMUM RATINGS

TOP VIEW

INID

DCOUTNCBATID

38 37 36 35 34 33 32

1DCIN

CLN

2

CLP

3

ACPDLY

4

DCDIV

5

SHDN

6

SDA

7

SCL

8

GPI01

9

GPI02

10

GPI03

11

SELA

12

13 14 15 16

DIS

V

ACPb

38-LEAD (5mm s 7mm) PLASTIC QFN

EXPOSED PAD (PIN 39) IS GND, MUST BE SOLDERED TO PCB

UHF PACKAGE

T

= 100°C, θJA = 34°C/W

JMAX

V

CAL

39

CHG

V

VDDCHGFET

17 18 19

REF

V

TIMER

DCHFET

31

30

29

28

27

26

25

24

23

22

21

20

TYPE

BAT

SELC

I

SENSE

SGND

CSN

CSP

I

TH

I

CHG

I

CAL

I

PCC

THB

THA

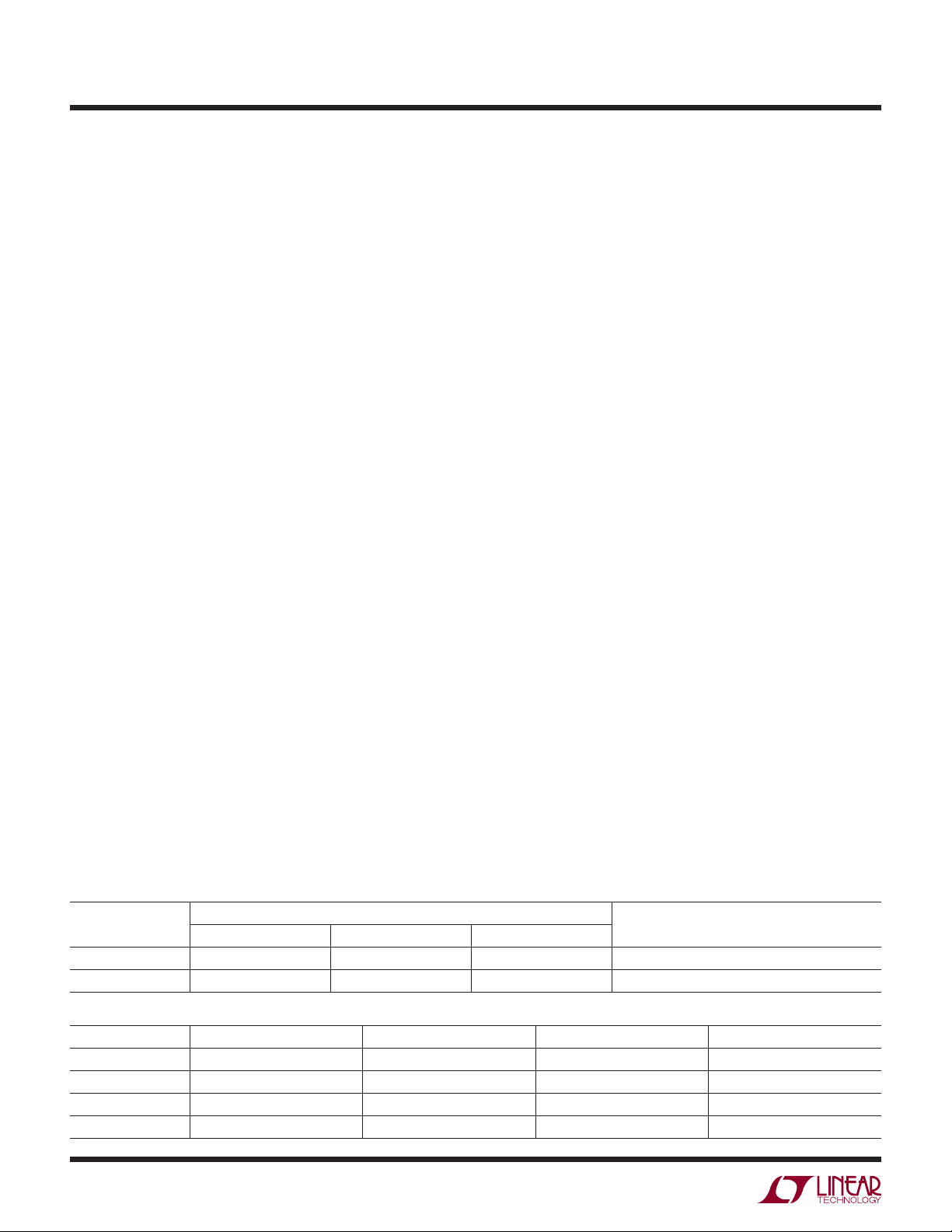

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC4110EUHF#PBF LTC4110EUHF#TRPBF 4110

38-Lead (5mm × 7mm) Plastic QFN

LEAD BASED FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC4110EUHF LTC4110EUHF#TR 4110

38-Lead (5mm × 7mm) Plastic QFN

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

–40°C to 85°C

–40°C to 85°C

2

4110fa

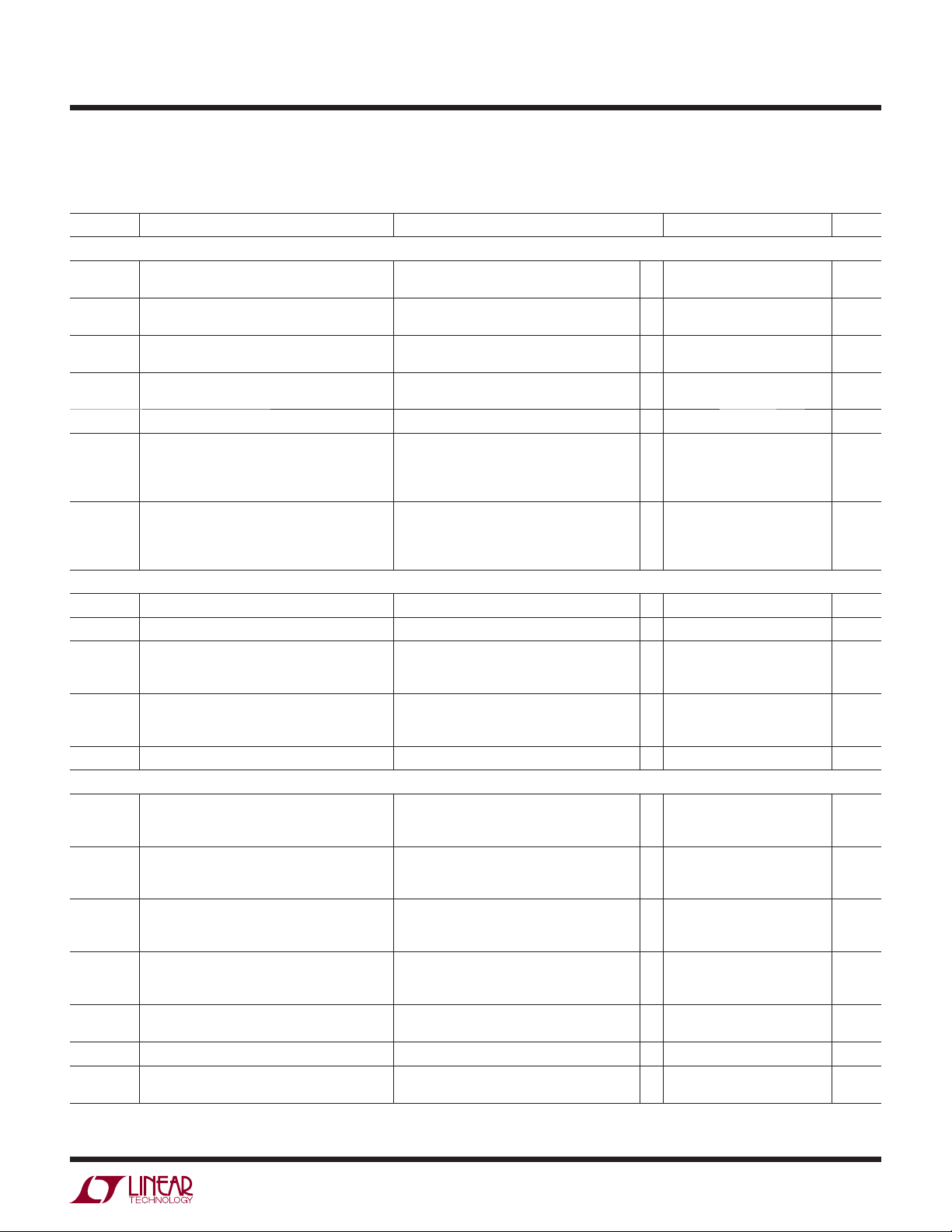

Page 3

LTC4110

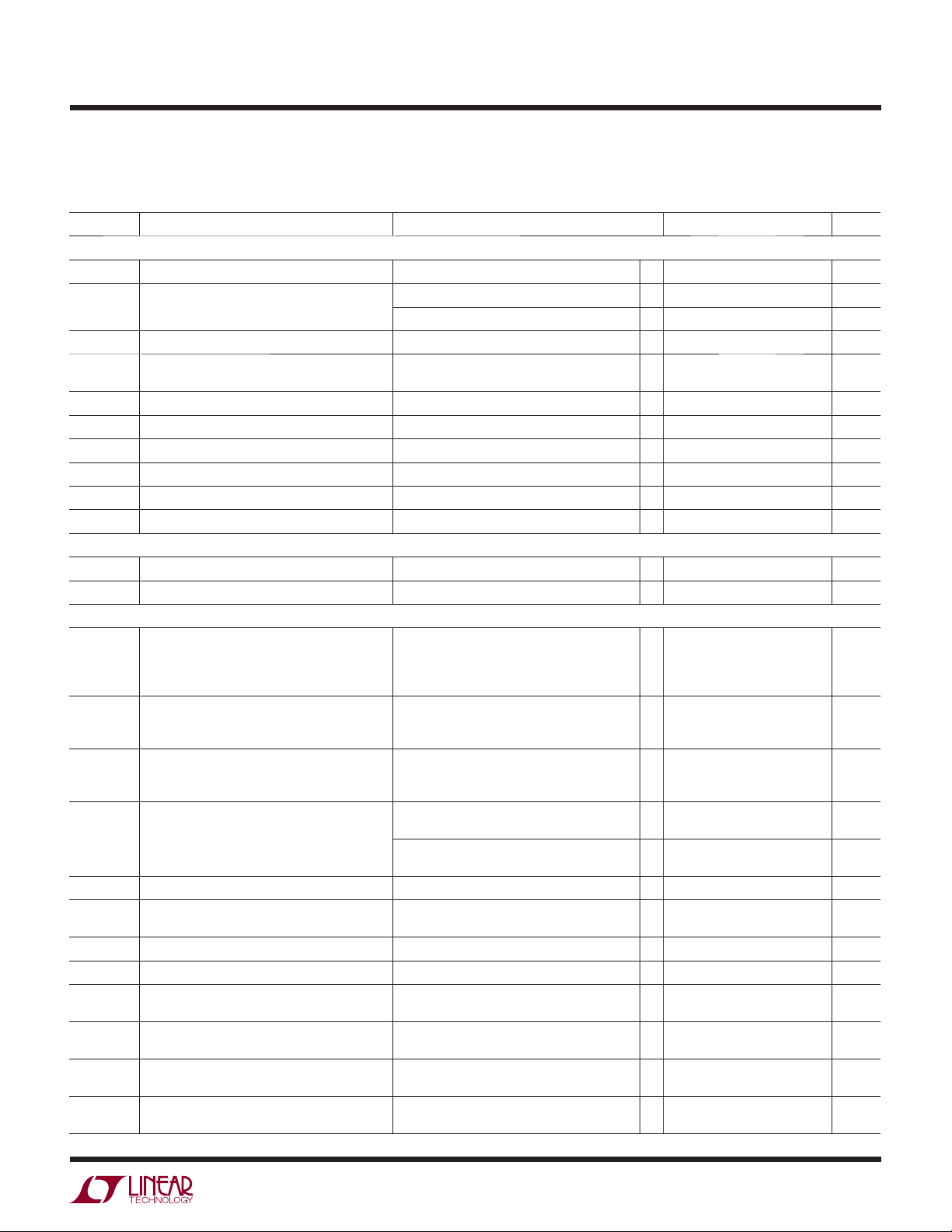

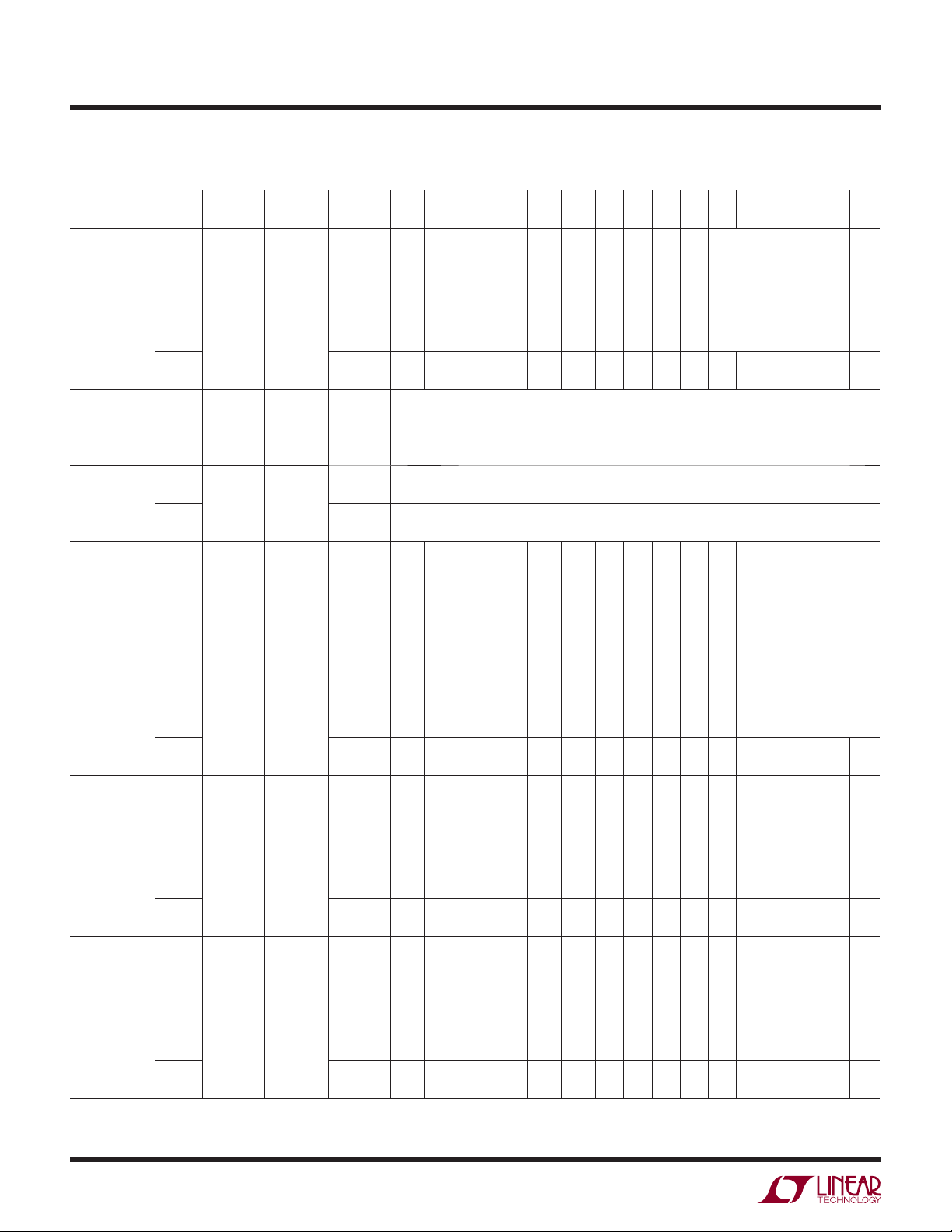

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

GND = SGND = CLP = CLN = SHDN = 0V and R

VREF

= 25°C. Unless otherwise specifi ed, V

A

= 49.9k. All currents into device pins are positive and all currents out of device pins

are negative. All voltages are referenced to GND, unless otherwise specifi ed.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Input

DCIN Operating Voltage Range Charge or Calibration Modes

DCOUT Operating Voltage Range Charge or Calibration Modes

Backup Mode

V

BAT

I

SPLY

I

BIDL

I

BBU

I

BSD

V

UVI

V

UVD

V

UVH

Regulator

V

DD

V

DD

V

DD(MIN)

Charging Performance

V

FTO L

V

FATOL

I

BTOL

I

PTO L

I

SKVA

I

SRCA

I

SKCA

I

VCHG

V

BC

V

BCH

V

AR

V

ARH

Operating Voltage Range Backup Mode

Supply Current (I

DCIN

+ I

) in Idle Mode

DCOUT

(Note 4)

Battery Current in Idle Mode (Notes 4 and 5) 30 45 µA

Battery Current in Backup Mode (Note 5) V

Battery Current in Shutdown (Note 5) V

Undervoltage Lockout Exit Threshold V

Undervoltage Lockout Entry Threshold V

= 0 2 3 mA

DCIN

= V

, V

SHDN

Increasing

DCIN

Decreasing

DCIN

BAT

= 0 20 45 µA

DCIN

Undervoltage Lockout Hysteresis 400 mV

Output Voltage No Load

Output Voltage IDD = –10mA

Charge Float Voltage Accuracy 4.20V for Li-Ion. 2.35V for Lead Acid (Note 8)

V

= GND

CHG

–5°C < T

–40°C < T

< 85°C (Note10)

A

< 85°C

A

Charge Float Voltage Adjust Accuracy 0.3V and –0.3V for Li-Ion Batteries,

0.15V and –0.15V for Lead Acid Batteries

(Note 8)

Bulk Charge Current Accuracy (Note 7) V

Preconditioning and Wake-Up Current

Accuracy (Note 7)

– V

CSP

V

BAT

–40°C < T

V

BAT

=100mV

CSN

≥ 3.1V

< 85°C

A

≥ 3.3V (Note 8), V

CSP

– V

= 10mV;

CSN

Li-Ion and NiMH/NiCd Batteries Only

V

≤ 3.3 (Note 8), V

BAT

CSP

– V

= 10mV;

CSN

Li-Ion and NiMH/NiCd Batteries Only

Voltage Error Amplifi er Sink Current at ITH Pin V

Current Error Amplifi er Source Current at ITH

= 2V 96 µA

ITH

V

= 2V –24 µA

ITH

Pin

Current Error Amplifi er Sink Current at ITH Pin V

V

Pin Bias Current V

CHG

Bulk Charge Threshold Voltage;

V

Increasing (Note 8)

BAT

Bulk Charge Threshold Voltage Hysteresis;

V

Decreasing (Note 8)

BAT

Auto Recharge Threshold Voltage;

V

Decreasing

BAT

Auto Recharge Threshold Hysteresis Voltage;

V

Increasing

BAT

= 2V 24 µA

ITH

= 1.25V –100 100 nA

CHG

CHG

= GND

Li-Ion, V

NiMH/NiCd

CHG

= GND

Li-Ion, V

NiMH/NiCd

Standard Li-Ion Only;

Specifi ed as Percentage of Float Voltage 93 95 97 %

Standard Li-Ion Only; Specifi ed as

Percentage of Float Voltage

DCIN

= V

l

l

l

l

DCOUT

= V

DCDIV

= 12V, V

4.5 19 V

4.5 19 V

2.7 19 V

2.7 19 V

23 mA

l

3.7 4 4.45 V

l

3.4 3.7 4.1 V

l

4.5 4.75 5 V

l

4.25 V

–0.5

–0.8

l

–1

l

–2 2 %

–3

l

–5

0.5

0.8

1

3

5

–30 30 %

–40 40 %

2.80

0.84

3.00

0.90

3.20

0.96

85

40

2%

= 8.4V,

BAT

%

%

%

%

%

mV

mV

4110fa

V

V

3

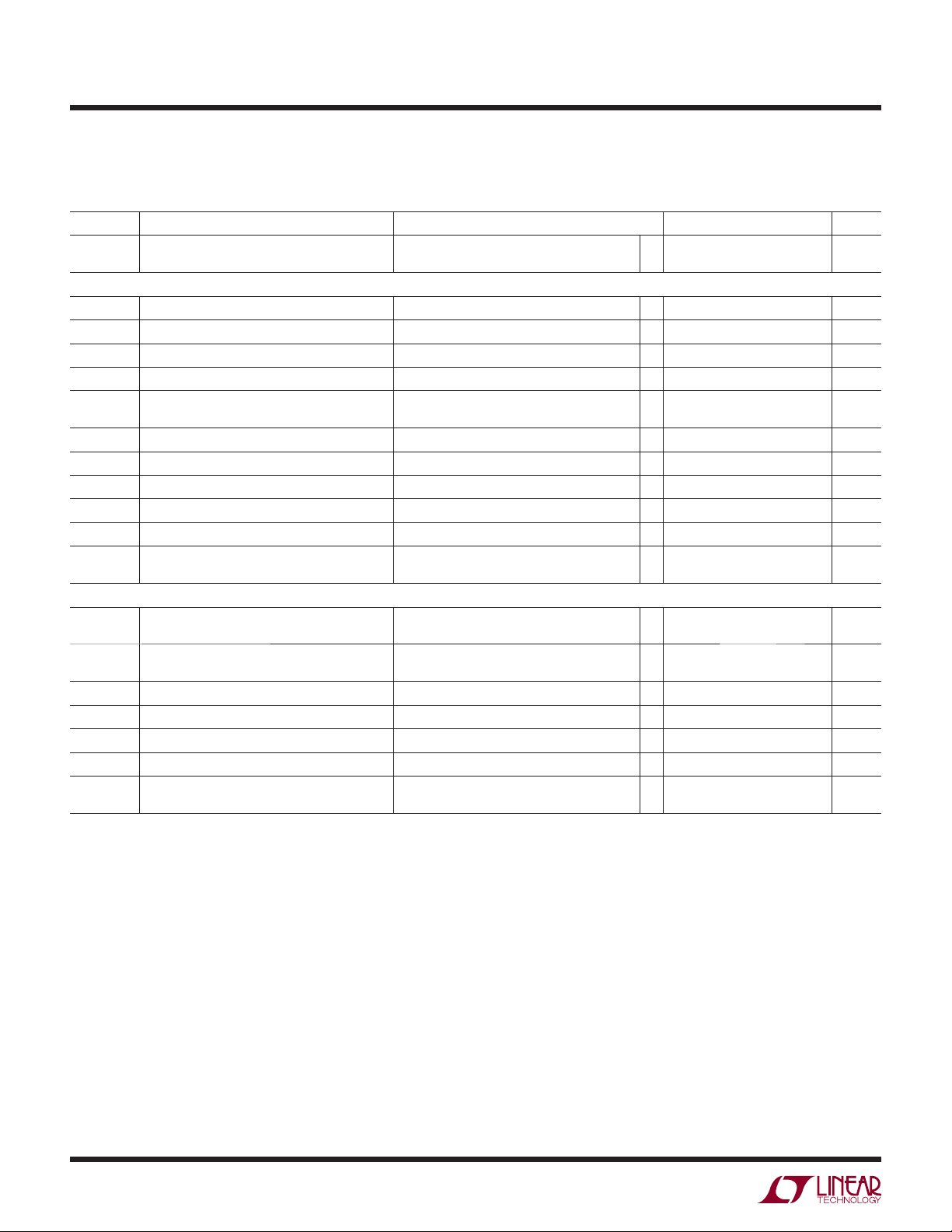

Page 4

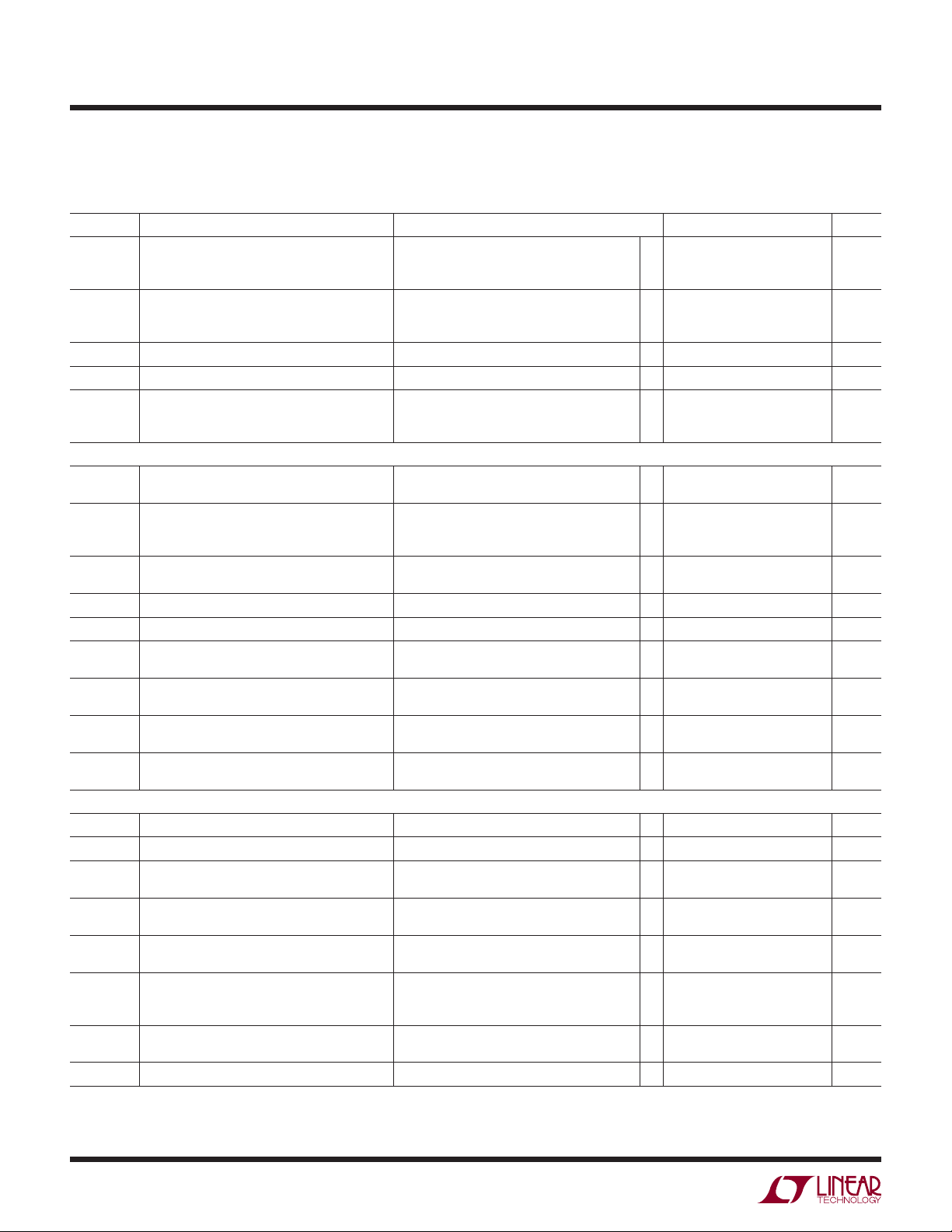

LTC4110

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

GND = SGND = CLP = CLN = SHDN = 0V and R

VREF

= 25°C. Unless otherwise specifi ed, V

A

= 49.9k. All currents into device pins are positive and all currents out of device pins

are negative. All voltages are referenced to GND, unless otherwise specifi ed.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

BOV

V

BOVH

V

REF

F

TMR

t

TIMEOUT

Calibration Performance

V

CTOL

V

CTOLH

V

CATOL

I

FTO L

I

VCAL

I

BDT

I

BDH

V

OVP

V

OVPH

AC Present and Discharge Cut-Off Comparators

V

AC

V

ACH

I

AC

t

AC

V

DTOL

V

DTOLH

V

DATOL

I

VDIS

Battery Overvoltage Threshold;

V

Increasing

BAT

All Li-Ion, Lead Acid as Percentage of

Float Voltage

NiMH/NiCd (Note 8)

Battery Overvoltage Threshold Hysteresis;

V

Increasing.

BAT

All Li-Ion, Lead Acid as Percentage of

Float Voltage

NiMH/NiCd (Note 8)

Reference Pin Voltage Range

Programmed Timer Accuracy C

TIMER

= 47nF

Time Between Receiving Valid

ChargingCurrent() and ChargingVoltage()

Commands. Wake-Up Timer.

Calibration Cut-Off Default Voltage Accuracy;

V

Decreasing

BAT

Calibration Cut-Off Default Voltage Hysteresis;

V

Increasing. (Note 8)

BAT

2.75V for Li-Ion, 1.93V for Lead Acid,

V

= GND (Note 8), 0.95V for NiMH/NiCd l

CAL

Li-Ion

Lead Acid

NiMH/NiCd

Calibration Cut-Off Voltage Adjust Accuracy ±400mV for Li-Ion, ±300mV for Lead Acid,

±200mV for NiMH/NiCd (Note 8)

Calibration Current Accuracy (Note 7) V

V

Pin Leakage Current V

CAL

Back-Drive Current Limit Threshold V

Back-Drive Current Limit Threshold Hysteresis V

Calibration Mode Input Overvoltage

– V

CSP

CAL

CLP

V

CLN

CLP

V

CLN

V

DCDIV

= –100mV

CSN

= 1.25V –100 100 nA

– V

Decreasing

CLN

= V

DCIN

– V

Increasing

CLN

= V

DCIN

Rising

Comparator DCDIV Pin Threshold

Calibration Mode Input Overvoltage

V

Falling 100 mV

DCDIV

Comparator DCDIV Pin Hysteresis

AC Present Comparator DCDIV Pin Threshold V

AC Present Comparator DCDIV Pin Hysteresis V

AC Present Comparator DCDIV Pin Input Bias

Falling

DCDIV

Rising 50 mV

DCDIV

V

= 1.25V 100 nA

DCDIV

Current

ACPb Pin Externally Programmed Falling Delay C

Discharge Cut-Off Default Voltage Accuracy;

V

Decreasing

BAT

Discharge Cut-Off Default Voltage Hysteresis;

V

Increasing (Note 8)

BAT

= 100nF, R

ACPDLY

V

Stepped From 1.17V to 1.30V 8 10 12 ms

DCDIV

VREF

= 49.9k,

2.75V for Li-Ion, 1.93V for Lead Acid,

V

= GND, 0.95V for NiMH/NiCd

DIS

Li-Ion

Lead acid

NiMH/NiCd

Discharge Cut-Off Voltage Adjust Accuracy ±400mV for Li-Ion, ±300mV for Lead Acid,

±200mV for NiMH/NiCd

V

Pin Bias Current V

DIS

= 1.25V –100 100 nA

DIS

DCIN

= V

l

l

l

l

l

l

DCOUT

105

1.80

= V

DCDIV

107.5

1.85

2

40

= 12V, V

110

1.90

= 8.4V,

BAT

%

%

mV

1.208 1.220 1.232 V

–15 0 15 %

140 175 210 sec

–1.1

–1.3

85

50

40

1.1

1.3

%

%

mV

mV

mV

–1.5 1.5 %

–5 5 %

71013 mV

1mV

l

1.4 1.5 1.6 V

l

1.196 1.22 1.244 V

l

–1.5 1.5 %

85

50

40

l

22%

mV

mV

mV

V

4

4110fa

Page 5

LTC4110

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

GND = SGND = CLP = CLN = SHDN = 0V and R

VREF

= 25°C. Unless otherwise specifi ed, V

A

= 49.9k. All currents into device pins are positive and all currents out of device pins

are negative. All voltages are referenced to GND, unless otherwise specifi ed.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Input and Battery Ideal Diodes and Switches

V

V

V

V

V

FR

REV

GON

GOFF

FO

Forward Regulation Voltage (V

V

BAT-VDCOUT

)

DCIN-VDCOUT

Reverse Voltage Turn-Off Voltage

(V

DCIN-VDCOUT

“ON” Gate Clamping Voltage (V

V

BAT-VBATID

“OFF” Gate Voltage (V

, V

)

BAT-VDCOUT

DCIN-VINID

)

DCIN-VINID

, V

BATID Fast-On Voltage Comparator Threshold I

INID Pin Delay Times

t

IIDON

t

IIDOFF

Turn “ON”

Turn “OFF”

BATID Pin Delay Times

t

BIDON

t

BIDOFF

Turn “ON”

Turn “OFF”

PWM Flyback Converter

V

V

V

OHF

OLF

OLFX

CHGFET, DCHFET High I

CHGFET, DCHFET Low I

CHGFET, DCHFET in Shutdown and Backup

Modes

CHGFET, DCHFET Transition Times

t

R

t

F

F

PWM

Rise Time

Fall Time

PWM Oscillator Switching Frequency

SafetySignal Decoder and Thermistor Interface

SS

OR

SafetySignal Decoder

SafetySignal Trip

(RES_COLD/RES_OR)

SS

CLD

SafetySignal Decoder

SafetySignal Trip

(RES_IDEAL/RES_COLD)

SS

IDL

SafetySignal Decoder

SafetySignal Trip

(RES_HOT/RES_IDEAL)

SS

HOT

SafetySignal Decoder

SafetySignal Trip

(RES_UR/RES_HOT)

V

HOT

V

HOTH

V

REM

THB Pin Hot Threshold Voltage V

THB Pin Hot Threshold Hysteresis Voltage V

THB Pin Battery Removal Threshold Voltage V

,

,

BAT-VBATID

2.7V ≤ V

2.7V ≤ V

I

INID

)I

INID

V

BATID

C

SHDN

INID

≤ 19V

DCIN

≤ 19V

DCIN

, I

= 1μA 7 8.3 9.7 V

BATID

, I

= –10μA

BATID

= 0V and V

(Shutdown)

DCIN

> 500µA 45 100 mV

= 10nF

DCIN is Switched Between 12.2V and 11.8V

From DCOUT – V

From DCOUT – V

C

= 2.5nF

BATID

to DCOUT –6V

GOFF

to DCOUT –1.5V

GON

BAT is Switched Between 12.2V and 11.8V

From DCOUT – V

From DCOUT – V

, I

CHGFET

DCHFET

, I

CHGFET

DCHFET

V

= V

DCIN

Mode), V

I

CHGFET

C

C

R

DCDIV

DCIN

, I

DCHFET

= 1.6nF, 10% to 90%

LOAD

= 1.6nF, 10% to 90%

LOAD

= 1130Ω ±1%, CTH = 1nF (Note 6) R

THA

to DCOUT –6V

GOFF

to DCOUT –1.5V

GON

= –1mA 4.5 4.75 5.25 V

= 1mA 50 mV

= V

= V

= 0V (Shutdown

DCOUT

= 0V (Backup Mode)

DCDIV

= 1µA

= 54.9k ±1%.

Smart Batteries and Li-Ion Only

R

= 1130Ω ±1%, CTH = 1nF (Note 6) R

THA

= 54.9k ±1%

Smart Batteries and Li-Ion Only

R

= 1130Ω ±1%, CTH = 1nF (Note 6) R

THA

= 54.9k ±1%

Smart Batteries and Li-Ion Only

R

= 1130Ω ±1%, CTH = 1nF (Note 6) R

THA

= 54.9k ±1%

Smart Batteries and Li-Ion Only

Decreasing; Lead Acid Only

THB

Increasing; Lead Acid Only 50 mV

THB

Increasing; Lead Acid Only

THB

THB

THB

THB

THB

DCIN

= V

l

l

DCOUT

= V

DCDIV

= 12V, V

10 20 32 mV

–30 –18 –8 mV

0.25 V

450

8

15

8

700

20

60

20

100 mV

35

15

l

255 300 340 kHz

l

95 100 105 k

l

28.5 30 31.5 k

l

2.85 3 3.15 k

l

425 500 575 Ω

l

0.28 •

V

l

0.90 •

V

THA

THA

0.30 •

V

THA

0.94 •

V

THA

65

65

0.36 •

V

THA

0.96 •

V

THA

= 8.4V,

BAT

µs

µs

µs

µs

ns

ns

V

V

4110fa

5

Page 6

LTC4110

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

GND = SGND = CLP = CLN = SHDN = 0V and R

VREF

= 25°C. Unless otherwise specifi ed, V

A

= 49.9k. All currents into device pins are positive and all currents out of device pins

are negative. All voltages are referenced to GND, unless otherwise specifi ed.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

REMH

Logic and Status Output Levels

V

ILS

V

IHS

V

OLS

V

OLG

I

OHG

V

ILG

V

IHG

V

ILSD

V

IHSD

I

ISD

T

LR

SMBus Timing (Note 9)

t

HIGH

t

LOW

t

TO

t

F

t

SU-STA

t

HD-STA

t

HD-DAT

THB Pin Battery Removal Threshold

V

Decreasing; Lead Acid Only 25 mV

THB

Hysteresis Voltage

SCL/SDA Input Pins Low Voltage

SCL/SDA Input Pins High Voltage

SDA Output Pin Low Voltage I

ACPb, GPIO1,2,3 Output Pins Low Voltage I

PULL-UP

, I

ACPb

= 350µA

, I

GPIO1

GPIO2

, I

= 10mA 1 V

GPIO3

ACPb, GPIO1,2,3 Output Pins Open

Leakage Current Outputs Open, V

ACPb

, V

GPIO1,2,3

= 5V –2 2 µA

GPIO Input Low Voltage

GPIO Input High Voltage

SHDN Input Pin Low Voltage 0.5 V

SHDN Input Pin High Voltage 2.4 V

SHDN Input Pin Pull-Up Current V

Logic Reset Duration After Power-Up

From Zero

SCL Serial Clock High Period I

SCL Serial Clock Low Period I

= 2.4V –3.5 –2 –1 µA

SHDN

V

Transition From 0V to 5V in <1ms;

DCIN

V

= 0

BAT

PULL-UP

R

= 9.31k

PU

PULL-UP

R

= 9.31k

PU

= 350µA, C

= 350µA, C

LOAD

LOAD

= 250pF,

= 250pF,

Timeout Period

SDA/SCL Fall Time C

= 250pF, RPU = 9.31k

LOAD

Start Condition Set-Up Time

Start Condition Hold Time

SDA to SCL Falling-Edge Hold Time,

Slave Clocking in Data

DCIN

= V

l

l

l

l

l

DCOUT

= V

DCDIV

= 12V, V

= 8.4V,

BAT

0.8 V

2.1 V

0.4 V

1V

1.5 V

1s

l

4µs

l

4.7 µs

l

25 ms

l

l

4.7 µs

l

4µs

l

300 ns

300 ns

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime. Specifi c functionality or parametric performance

of the device beyond the limits expressly given in the Electrical

Characteristics table is not implied by these maximum ratings.

Note 2: The LTC4110E is guaranteed to meet performance specifi cations

from 0°C to 85°C. Specifi cations over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: This IC includes overtemperature protection that is intended

to protect the device during momentary overload conditions.

Overtemperature protection will become active at a junction temperature

greater than the maximum operating junction temperature. Continuous

operation above the specifi ed maximum operation temperature may result

in device degradation or failure. Operating junction temperature T

°C) is calculated from the ambient temperature T

dissipation P

(in watts) by the formula TJ = TA + θ

D

and the average power

A

• PD.

JA

J

(in

6

Note 4: The LTC4110 is idle with no application load. It is not charging

or calibrating the battery and is not in backup or shutdown mode. The

internal clock is running and the SMBus is functional.

Note 5: Combined current of CSP, CSN and BAT pins set to V

with no

BAT

application load.

Note 6: C

is defi ned as the sum of capacitance on THA, THB

TH

SafetySignal.

Note 7: Does not include tolerance of current sense or current

programming resistors.

Note 8: Given as a per cell voltage referred to the BAT pin (V

/number of

BAT

series cells).

Note 9: Refer to System Management Bus Specifi cation, Revision 1.1,

section 2.1 for Timing Diagrams and section 8.1, for t

LOW

and t

TIMEOUT

requirements.

Note 10: Specifi cations over the –5°C to 85°C operating ambient

temperature range are assured by design, characterization and correlation

with statistical process controls.

4110fa

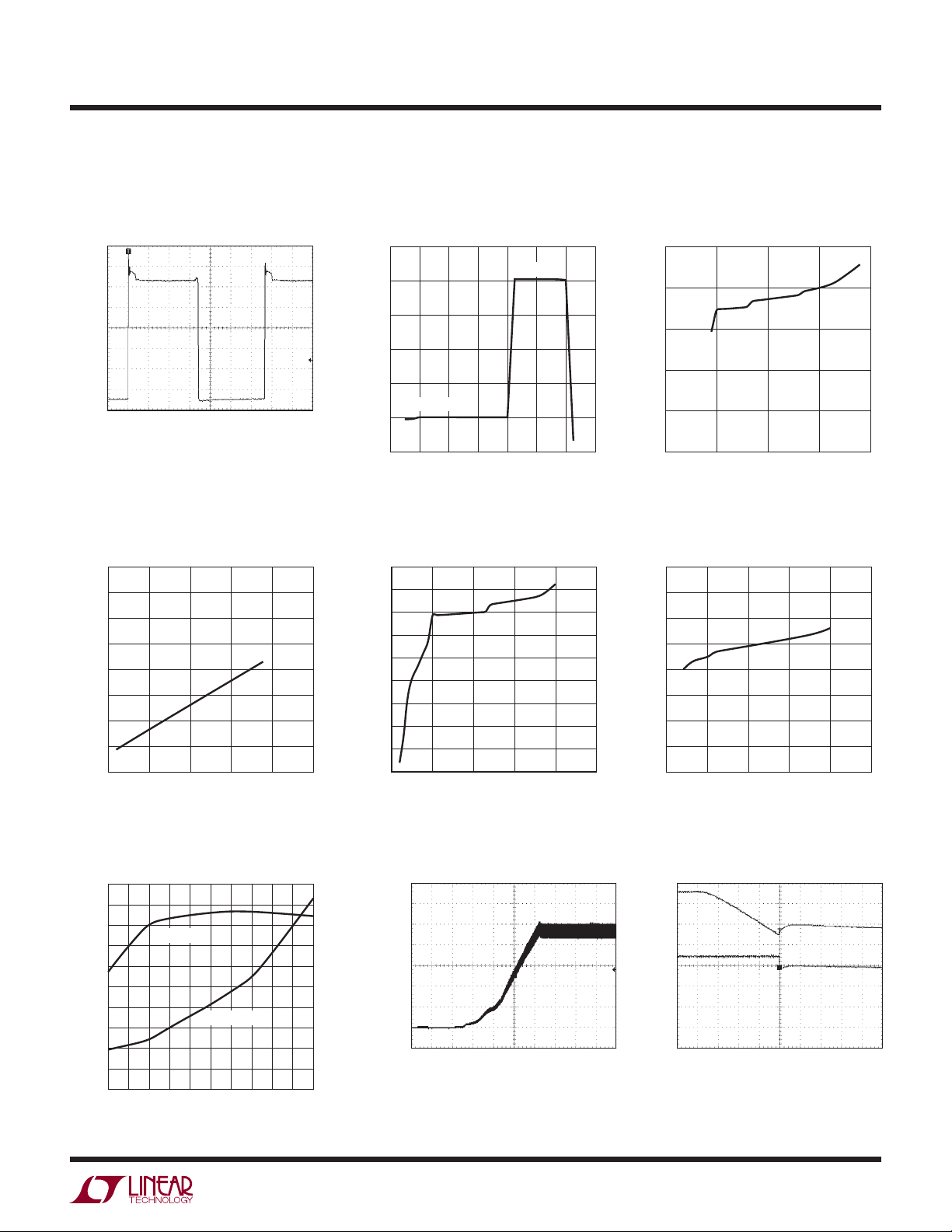

Page 7

TYPICAL PERFORMANCE CHARACTERISTICS

Output Charging Characteristics

Typical CHGFET and DCHFET

Waveforms

Showing Constant Current and

Constant Voltage Operation

1200

1000

CC

LTC4110

Supply Current vs DCIN Voltage in

Idle Mode

2.5

2.0

5V/DIV

0V

= 12V

V

IN

= 12V (NiMH)

V

BAT

500ns/DIV

Battery Leakage in Idle

Mode – IBIDL

140

120

100

80

(µA)

60

BAT

I

40

20

0

–20

0 5 10 15 2520

V

BAT

(V)

4110 G01

4110 G04

800

(mA)

600

BAT

I

400

PRE-CHARGE

200

0

042 6 8 101214

Battery Current in Backup

Mode – IBBU

1.8

1.6

1.4

1.2

1.0

(mA)

0.8

BAT

I

0.6

0.4

0.2

0

0 5 10 15 2520

Charging Effi ciency/Power Loss,

12VIN and 12.6V

(Xfmr = BH

OUT

510-1019) Soft-Start Waveform

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.05 0.20.1 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.00

EFFICIENCY

I

POWER LOSS

(A)

LOAD

4110 G07

2.5

2.0

POWER LOSS (W)

1.5

1.0

0.5

0

0.2A/DIV

0A

V

V

BAT

BAT

(V)

(V)

2ms/DIV

CV

4110 G02

4110 G05

4110 G08

1.5

(mA)

DCIN

I

1.0

0.5

0

0 5 10 15 20

DCIN (V)

Battery Leakage in Shutdown

Mode vs Battery Voltage

40

35

30

25

(µA)

20

BAT

I

15

10

5

0

0

15

V

(V)

BAT

Backup Mode On and Off

Waveform

V

BACKUP

2V/DIV

V

BATTERY

3V/DIV

0V

NiMH BATTERY (12V)

= 3A

I

LOAD

= 15V FALLING

V

IN

10ms/DIV

4110 G03

2520105

4110 G06

4110 G09

4110fa

7

Page 8

LTC4110

PIN FUNCTIONS

DCIN (Pin 1): External DC Power Sense Input. Provides a

control input and supply for the main supply ideal diode

function.

CLN (Pin 2): Current Limit Sense Negative Input. See

CLP pin.

CLP (Pin 3): Current Limit Sense Positive Input. This pin

and the CLN pin form a differential input that senses voltage on an external resistor for reverse current entering the

power source while in low loss calibration mode. Should

the current approach reversal, this function will terminate

calibration. An RC fi lter may be required to fi lter out system

load noise. Connect both CLP and CLN pins to GND to

disable this function. A differential voltage of >1V between

the CLP and CLN pins may damage the device.

ACPDLY (Pin 4): ACPb Delay Control Pin. A capacitor

connected from ACPDLY to GND and a resistor from

to GND programs delay in the ACPb pin high-to-low

V

REF

transition. Open if minimum delay is desired.

DCDIV (Pin 5): AC Present Detection Input. Backup

operation is invoked when the system power voltage,

divided by an external resistor divider, falls below the

threshold of this pin.

SHDN (Pin 6): Active High Shutdown/Reset Control Logic

Input. Forces micropower shutdown mode if high when

DCIN supply is removed. Forces all registers to reset if high

when DCIN supply is present. Normally tied to ground.

Internal pin pull-up current.

SDA (Pin 7): SMBus Bidirectional Data Signal. Connect

when not in use.

to V

DD

SCL (Pin 8): SMBus Clock Signal Input From SMBus Host.

Connect to V

GPIO1 (Pin 9): General Purpose I/O or Charge Status Pin. A

logic-level I/O bit port that is confi gurable as a host-driven

input/output port or as a battery charge status output (CHGb)

with an open-drain N-MOSFET that is asserted low when any

when not in use.

DD

smart battery or Li-Ion battery is in any phase of charging

or when lead acid battery charge current is >C/x where:

C

x

= •5

I

(See C/x Charge Termination section for more details).

If the No SMBus option is selected with the SELA pin,

the GPIO1 pin defaults as battery charge status. Refer

to Table 5a.

GPIO2 (Pin 10): General Purpose I/O Pin. A logic-level I/O bit

port that is confi gurable as a host-driven input/output port

or as a battery undervoltage status output (BKUP_FLTb)

with an open-drain N-MOSFET that is asserted low only

while in backup mode if the battery’s average cell voltage

drops below voltage programmed by the V

No SMBus option is selected with the SELA pin, then the

GPIO2 pin defaults as battery undervoltage status. Refer

to Table 5c.

GPIO3 (Pin 11): General Purpose I/O Pin. A logic-level I/O

bit port that is confi gurable as a host-driven input/output

port or as a calibration complete status output (CAL_COMPLETEb) with an open-drain N-MOSFET that is asserted

low when calibration has been completed. If the SELA pin

is programmed for no SMBus use then the status output

is charge fault (CHGFLTb) instead of calibration complete.

Refer to Table 5e.

SELA (Pin 12): SMBus Address Selection Input. Selects

the LTC4110 SMBus address to facilitate redundant backup

systems when standard batteries are used. Connect to

GND for 12h, V

a smart battery is selected by the TYPE pin, the SELA pin

must be connected to GND to select address 12h. If the

SMBus is not used or to force all GPIOs to status mode

upon power-up, connect pin to a typically 0.5 • V

age from V

if used, will be 12h.

CHG

DIS

for 28h and the V

DD

pin resistor divider. The SMBus address,

REF

pin for 20h. When

REF

pin. If the

volt-

REF

8

4110fa

Page 9

PIN FUNCTIONS

LTC4110

ACPb (Pin 13): AC Present Status Digital Output. OpenDrain N-MOSFET output is asserted low when the main

supply is present as detected by the DCDIV pin and internal

DCIN UVLO.

(Pin 14): Battery Discharge Voltage Limit During

V

DIS

Backup Program Input. Battery threshold voltage at which

backup mode will terminate by turning off the isolation

P-MOSFET with the BATID pin. Adjustable from external

resistor string biased from V

pin. For default threshold

REF

connect to GND pin.

(Pin 15): Battery Voltage Limit During Calibra-

V

CAL

tion Program Input. Battery threshold voltage at which

calibration will terminate. Adjustable from external resistor

string biased from V

pin. For default threshold connect

REF

to GND pin.

(Pin 16): Battery Float Voltage Program Input. Trims

V

CHG

the fl oat voltage during charging. Programmed from

external resistor string biased from V

pin. Connect to

REF

GND for default fl oat voltage.

(Pin 17): Voltage Reference Output and Timing Pro-

V

REF

gramming Input. Provides a typical virtual reference of 1.220V

(V

) for an external resistor divider tied between this pin and

REF

GND that programs the V

Total resistance from V

, V

CAL

and V

CHG

to GND, along with the capacitor

REF

pin functions.

DIS

on the timer pin, programs the charge time. Voltage reference output remains active in all modes except shutdown.

Load current must be between 10µA and 25µA.

TIMER (Pin 18): Charge Timing Input. A capacitor connected between TIMER and GND along with the resistance

connected from V

to GND programs the charge time

REF

intervals.

TYPE (Pin 19): Refer to Table 8.

THA (Pin 20): SafetySignal Force/Sense Pin to Smart

Battery and Force Pin to Lead Acid Battery Thermistor.

See description of operation for more detail. The maximum allowed combined capacitance on THA, THB and

SafetySignal is 1nF. For lead acid battery applications the

maximum capacitance on the THA pin is 50pF.

THB (Pin 21): SafetySignal Force/Sense Pin to Smart

Battery and Sense Pin to Lead Acid Battery Thermistor.

See description of operation for more detail. The maximum allowed combined capacitance on THA, THB and

SafetySignal is 1nF.

I

(Pin 22): Battery Preconditioning Charge Current

PCC

Program Input. Programs the battery current during

preconditioning or wakeup charging. Programmed from

external resistor to GND.

(Pin 23): Battery Discharge Current During Calibration

I

CAL

Program Input. Programs the constant discharge current at

the battery during calibration. Programmed from external

resistor to GND.

(Pin 24): Battery Current During Charge Program Input.

I

CHG

Programs the battery current while constant-current bulk

charging. Programmed from external resistor to GND.

(Pin 25): Control Signal of the Current Mode PWM. AC

I

TH

compensates control loop. Higher I

voltage corresponds

TH

to higher charging current.

CSP (Pin 26): Current Sense Positive Input. This pin and

the CSN pin measure voltage across the external current

sense resistor to control battery current during charging

and calibration.

CSN (Pin 27): Current Sense Negative Input. This pin and

the CSP pin measure voltage across the external current

sense resistor to control battery current during charging

and calibration.

SGND (Pin 28): Signal Ground Reference Input. This pin

should be Kelvin connected to the fl yback current sense

resistor and to the battery return.

(Pin 29): Current Sense Input. Senses current in

I

SENSE

the fl yback transformer by monitoring voltage across the

external current sense resistor. This pin should be Kelvinconnected to the resistor.

SELC (Pin 30): Refer to Table 8.

4110fa

9

Page 10

LTC4110

PIN FUNCTIONS

BAT (Pin 31): Battery Voltage Sense Input. This pin is used

to monitor the battery and control charging voltage through

an internal resistor divider connected to this pin that is

disconnected in shutdown mode. Also provides a control

input for battery ideal diode functions. Pin should be Kelvinconnected to battery to avoid voltage drop errors.

DCHFET (Pin 32): Drives the Gate of an External N-MOSFET.

Used to drive energy into the battery side of the high effi ciency switch mode converter during low loss calibration

discharge of the battery. Provides synchronous rectifi cation

during battery charging.

CHGFET (Pin 33): Drives the Gate of an External NMOSFET. Used to drive energy into the supply side of

the high effi ciency switch mode converter during battery

charging. Provides synchronous rectifi cation during low

loss calibration mode.

(Pin 34): Bypass Capacitor Connection for Internal

V

DD

VDD Regulator. Bypass at pin with 100nF low ESR capacitor to GND.

BATID (Pin 35): Drives the Gate of the Battery P-MOSFET

Ideal Diode. Controls low loss ideal diode between the

battery and backup load when in backup mode. When not

in backup mode, the P-MOSFET is turned off to prevent

battery power from back driving into main power.

NC (Pin 36): No Connect.

DCOUT (Pin 37): System Power Output Voltage Monitor

Input. Provides a control input for supply input ideal diode

and battery ideal diode functions. Also supplies power to the

IC. Bypass at pin with 100nF low ESR capacitor to GND.

INID (Pin 38): Drives the Gate of the Supply Input P-MOSFET

Ideal Diode. Controls low loss ideal diode between the supply input and backup load when not in backup mode.

Exposed Pad (Pin 39): Ground. The Exposed Pad must

be soldered to the PCB.

10

4110fa

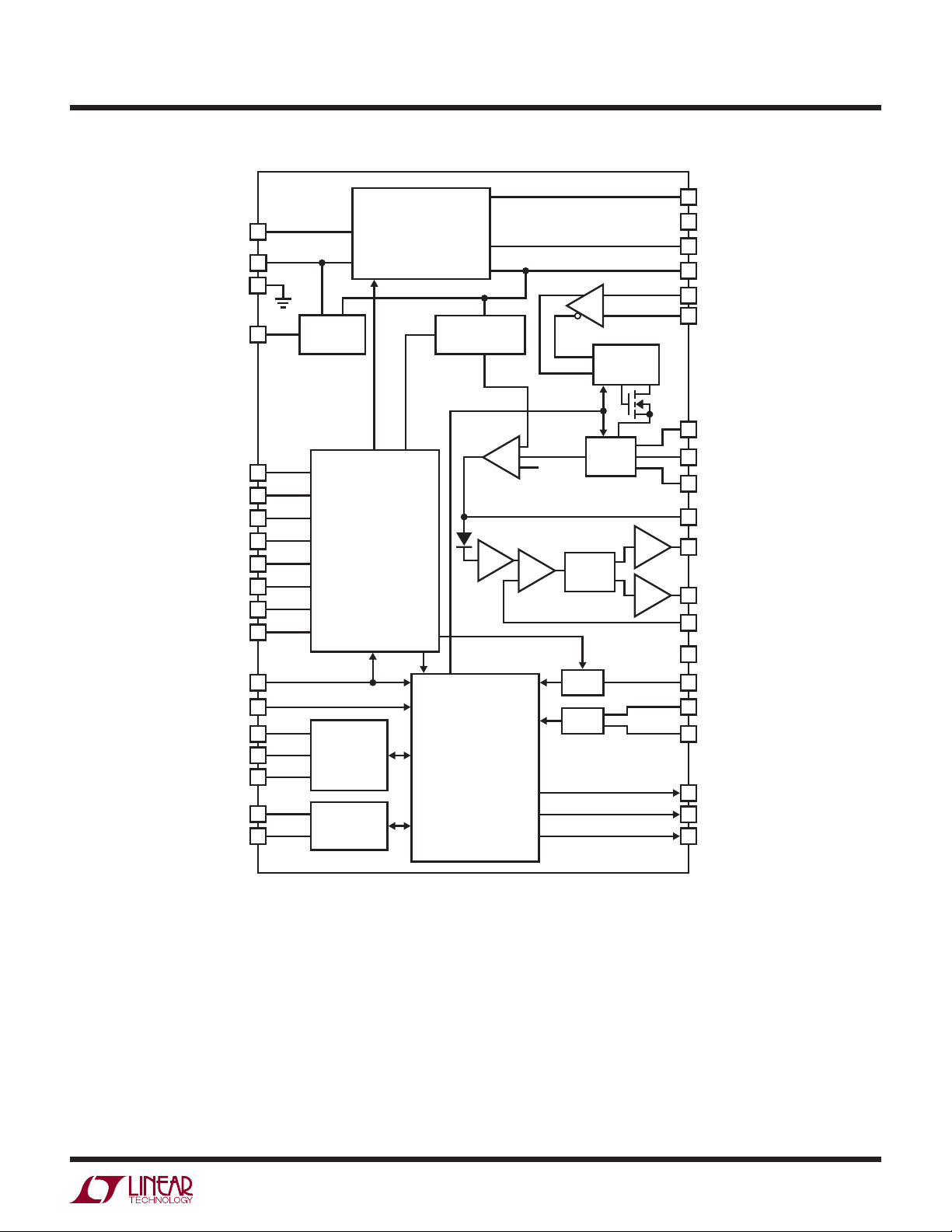

Page 11

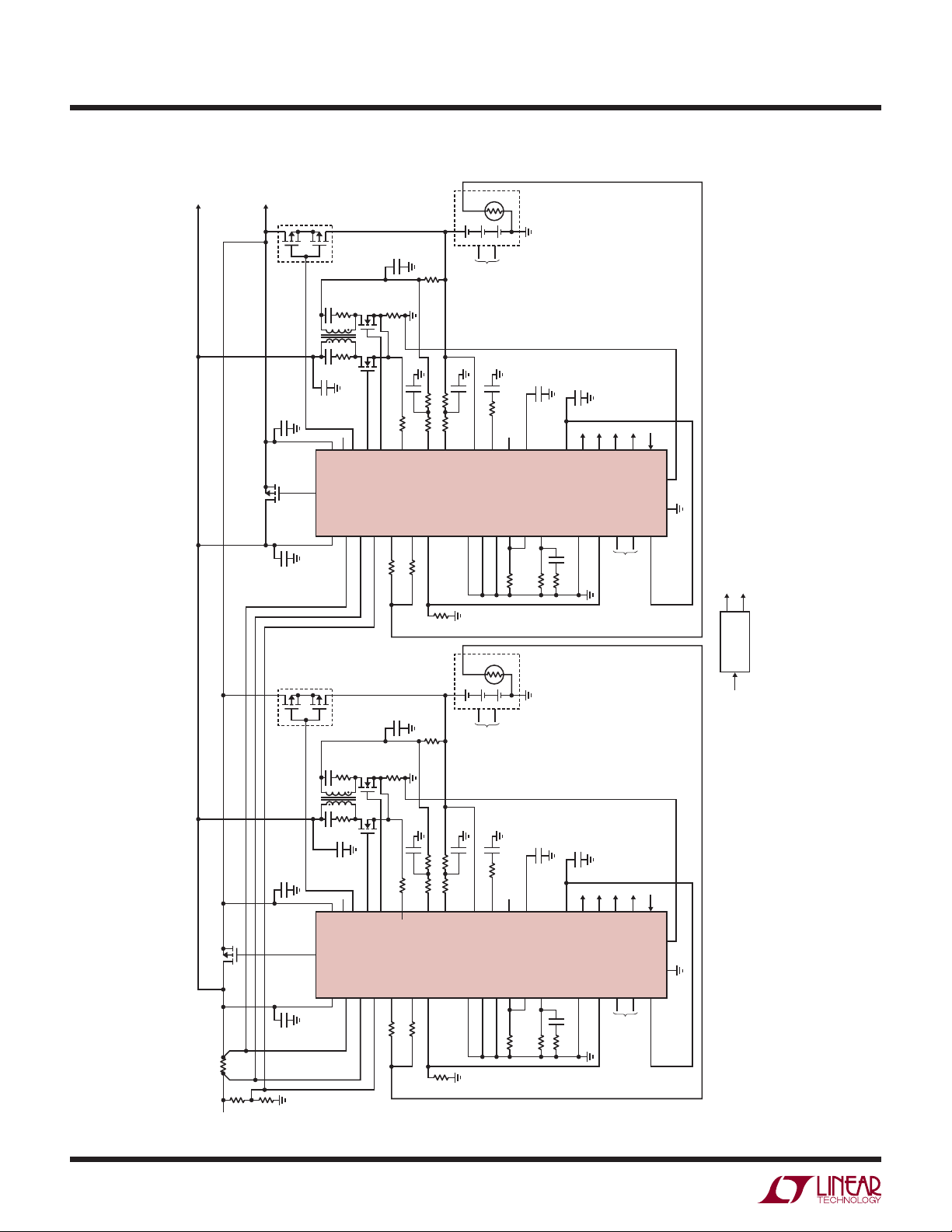

BLOCK DIAGRAM

38INID

1DCIN

39GND

34V

DD

3CLP

2CLN

5DCDIV

17V

REF

16V

CHG

15V

CAL

14V

DIS

30SELC

SUPPLY INPUT BATTERY

PowerPath CONTROLLER

V

DD

REGULATOR

VOLTAGE REFERENCE

ANALOG COMPARATORS

AND SWITCHES

OF CELLS

NUMBER

PRECISION

VOLTAGE DIVIDER

–

EA

+

–

÷10

+

PROGRAMMING CURRENT

CURRENT

SELECTION

1.220

CA

CURRENT

SWITCH

PWM

LOGIC

–

+

CHG/DCH

SWITCH

37 DCOUT

36 NC

35 BATID

31 BAT

27 CSN

26 CSP

22 I

PCC

24 I

CHG

23 I

CAL

25 I

TH

33 CHGFET

32 DCHFET

29 I

SENSE

28 SGND

LTC4110

19TYPE

6SHDN

7SDA

8SCL

12SELA

20THA

21THB

SMBus

INTERFACE

AND CONTROL

THERMISTOR

INTERFACE

TIMER/

CONTROLLER

OSC

UVLO

18 TIMER

4 ACPDLY

13 ACPb

9 GPIO1

10 GPIO2

11 GPIO3

4110 BD

4110fa

11

Page 12

LTC4110

OPERATION

OVERVIEW

In the typical application, the LTC4110 is placed in series

with main power supply that powers all or part of the

system, which must include the device(s) or system that

needs battery backup.

The LTC4110 has four modes of operation:

• Battery Backup Mode

• Battery Charge Mode

• Battery Calibration Mode

• Shutdown Mode

The LTC4110 provides complete PowerPath control for

the battery backed up load switching automatically from

the main power supply to the battery when battery backup

mode is required. Low loss ideal diode FET switches are

used to connect the main supply or the battery to the

backup load which permit multiple LTC4110’s to work

together in a scalable fashion to permit longer backup

times, redundancy and/or higher load currents. In battery

charge mode, power is drawn from the main supply by a

high effi ciency synchronous fl yback charger. The LTC4110

maintains the state of charge (SOC) of the battery at all

times so the battery is ready at all times. Use of a fl yback

converter permits charging of batteries who’s termination

voltage can be greater than the main supply voltage, while

at the same time providing high DC isolation to minimize

parasitic drain on the battery. Testing, maintenance support

and capacity verifi cation of the battery is supported through

the LTC4110’s calibration mode. In calibration mode, the

same synchronous fl yback used to charge the battery is

also used in reverse to allow safe controlled discharge of

the battery back into the main supply eliminating wasted

heat and energy. The product will not need to provide any

additional thermal management to support this mode.

Shutdown mode disconnects the battery from the load to

preserve capacity and permits shipping the product with

an energized battery installed at the factory, eliminating

battery installation at the site. The LTC4110 supports

optional control and monitoring of all activities by a host

including faults over the industry standard SMBus, which

2

is a variation of the I

C bus. However no host is required

as the LTC4110 is fully functional in a standalone mode.

Combining all these functions into a single IC reduces

circuit area compared to presently available solutions.

The LTC4110 is designed to work with both standard

battery and smart battery confi gurations. Smart batteries

are standard batteries with industry standard gas gauge

electronics built in offering accurate SOC information for

the host. Furthermore, being intimate with all aspects of

the battery, it also has the ability to control the charge

process. Smart batteries use the SMBus as the communication bus for data exchange and charge control.

For more information about smart batteries, see www.

sbs-forum.org for specifi cations or contact Linear Technology Applications.

It is important to know that the LTC4110 uses the TYPE

pin to learn what type of battery it will be working with.

The TYPE pin setting globally affects all of the operating

modes, options including GPIO and control ranges. Table 1

and Table 2 give you a complete breakdown of all the

battery types supported relative to the TYPE pin settings

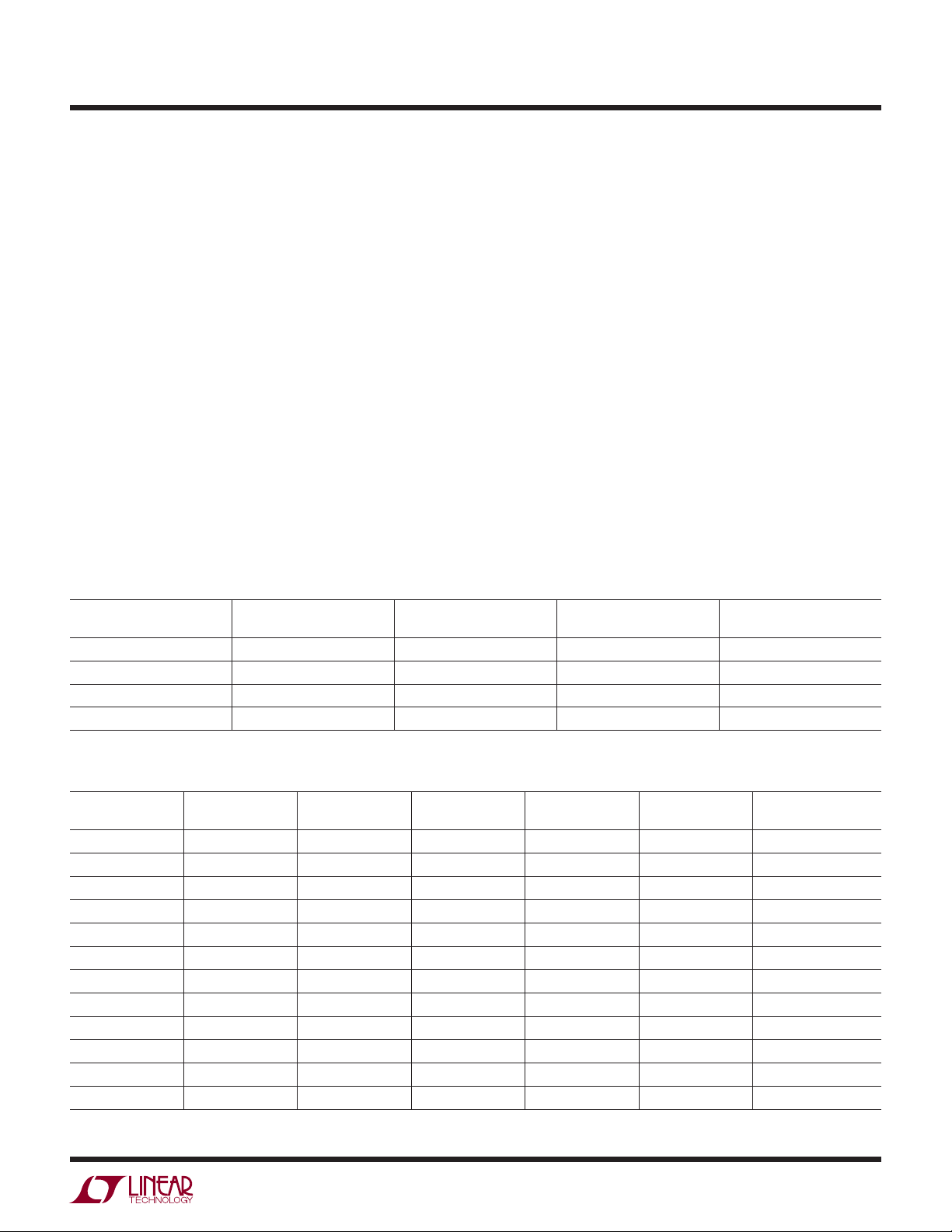

Table 1. LTC4110 Battery Pack Charge Mode Capabilities

BATTERY TYPE CHEMISTRY MAXIMUM CHARGE TIME (SLA EXCLUDED)

Li-Ion/Polymer Nickel SLA/Lead Acid

Standard Battery Yes No Yes Adj. Up to 12 Hours

Smart Battery Yes Yes Yes Unlimited

Table 2. LTC4110 Battery Pack Charge Voltage Capabilities

CHEMISTRY V

Lead Acid 2.35V ±0.15V 2, 3, 5 and 6 4, 6, 10 and 12

Li-Ion/Polymer 4.2V ±0.3V 1, 2, 3 and 4 3.6, 7.2, 10.8 and 14.4

NiMH/NiCd N/A N/A 4, 6, 9 and 10 4.8, 7.2, 10.8 and 12

Super Caps 2.5V, 2.7V or 3V Yes 2 to 7 5 to 18

FULL CHARGE V

CELL

ADJ. RANGE SERIES CELL COUNT NOMINAL STACK VOLTAGE (V)

CELL

4110fa

12

Page 13

OPERATION

LTC4110

and ranges. It should be noted that even if the LTC4110

TYPE pin is not set to a smart battery mode, any SMBus

commands sent by a host or a smart battery are still

acted upon. For SuperCap support, see the Applications

Information section.

BATTERY BACKUP MODE

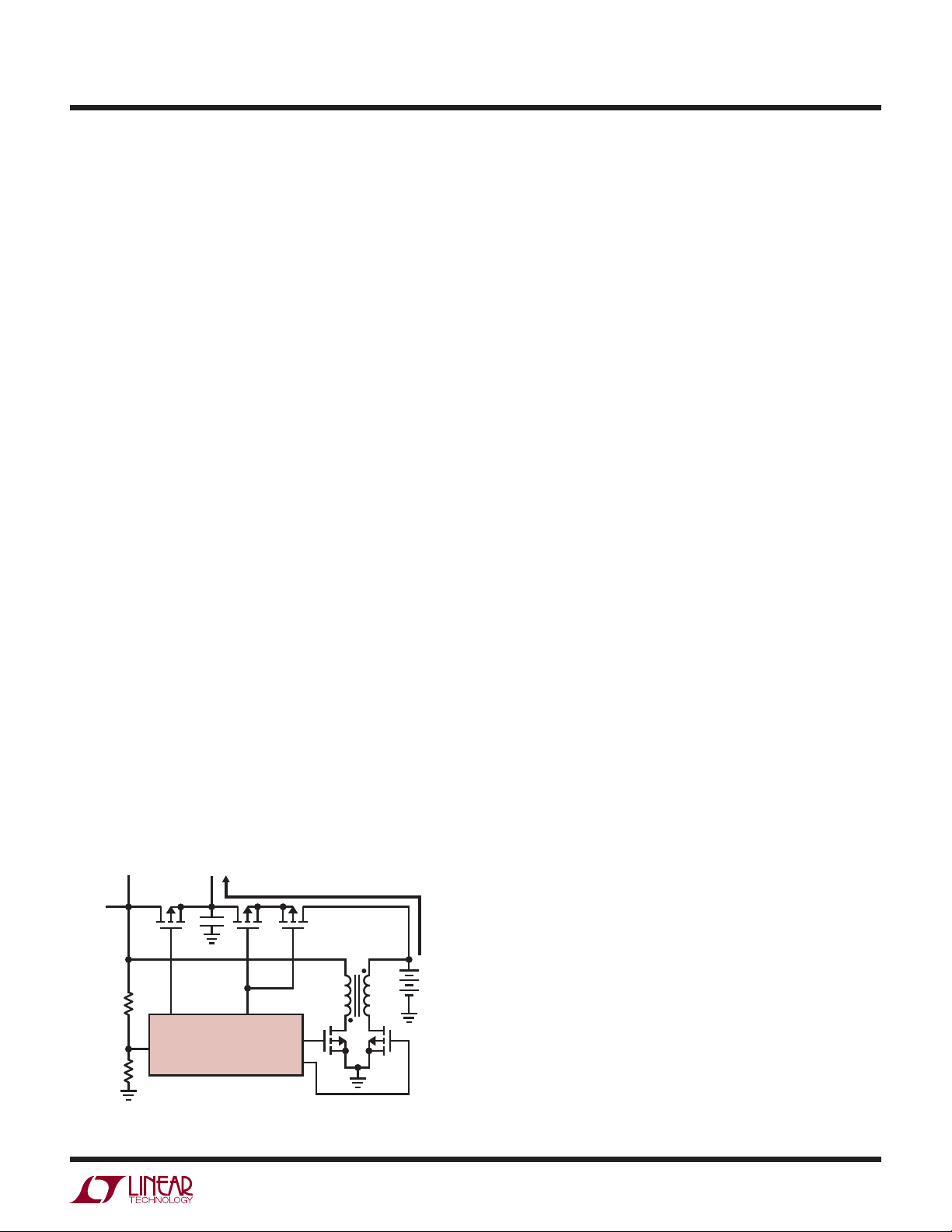

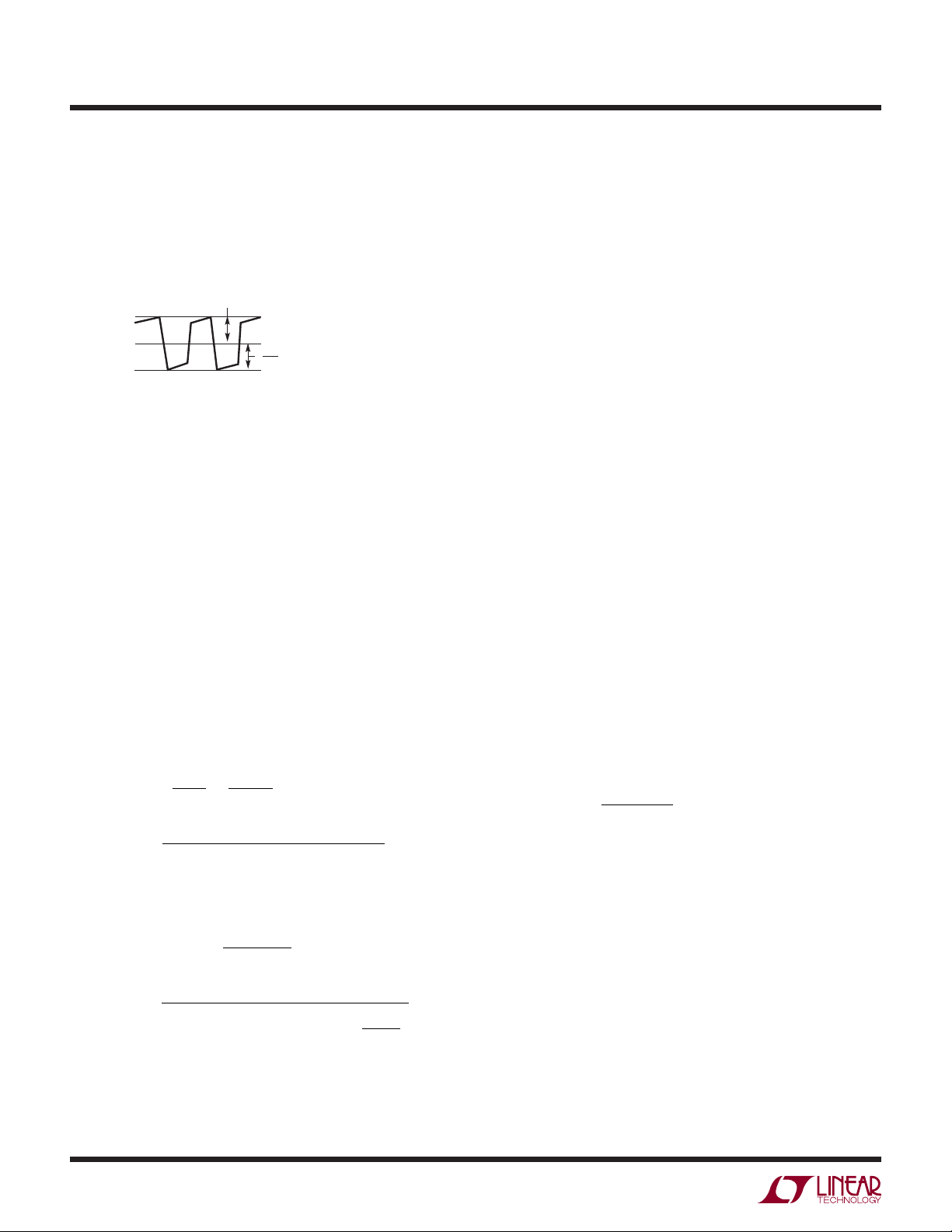

Figure 1 shows the LTC4110 in backup mode and the

corresponding PowerPath enabled. The LTC4110 use the

DCDIV pin to typically monitor the DCIN voltage through

an external resistor divider. The DCDIV pin sets the backup

mode threshold voltage and senses the need to enter

backup mode. DCDIV can alternately be driven with other

signals such as logic. When the DCDIV pin voltage drops

below the AC present threshold voltage (see V

) backup

AC

mode is entered. Backup mode is also entered whenever

the internal undervoltage lockout, UVLO, senses that DCIN

) or DCOUT has fallen to excessively low voltages.

(V

UVD

In backup mode the battery P-MOSFET ideal diode is

enabled to backup the load from the battery. The supply

input P-MOSFET ideal diode isolates the main supply

input from the load and the fl yback switcher N-MOSFETs

are inhibited from turning on. Also, after the threshold is

passed, hysteresis (V

) is switched in. When the supply

ACH

is returning and the AC present threshold voltage plus the

hysteresis voltage is reached on the DCDIV pin, both of the

battery P-MOSFETs are rapidly switched off (t

dDOFF

) and

the supply input P-MOSFET ideal diode provides the load

current. When forward biased, the ideal diodes regulate

their forward voltage drop to 20mV typical (V

SYSTEM LOAD

DCIN

0V

UVLO

SET POINT

BACKUP LOAD (DCOUT)

CURRENT FLOW

ON ONOFF

INID BATID

DCDIV

LTC4110

Figure 1. Backup Mode Operation

CHGFET

DCHFET

) when the

FR

BATTERY

4110 F01

MOSFET is suffi ciently sized. If the voltage input falls and

results in a forward voltage below 20mV, then the ideal

diode will begin turning off at a slow rate. Should the ideal

diode see a –18mV typical (V

the ideal diode will turn off quickly (t

) or lower reverse voltage,

REV

).

dDOFF

While in backup, the battery’s average cell voltage is monitored to protect the battery from excessive discharge. If

the cell voltage drops below the value programmed by the

pin (Li-Ion default = 2.75V/cell, NiMH/NiCd default

V

DIS

= 0.95V/cell, lead acid default = 1.93V/cell), the battery

P-MOSFETs are rapidly turned off and the battery is disconnected from the load. If DCIN is above UVLO, the load

and the LTC4110 will be powered from the supply input. If

DCIN is below UVLO, the LTC4110 enters the micropower

shutdown mode (see the Shutdown Mode section for more

details). Also, the SMBus accessible BKUP_FLT fault bit

is set and maintained as long as suffi cient battery voltage

is present (V

≥ 2.7V). This fault bit can be read after

BAT

DCIN returns to a voltage level exceeding the internal

UVLO threshold (see V

) and DCOUT has regained suf-

UVI

fi cient voltage (see DCOUT) to provide internal power. If

the GPIO2 port is programmed as the BKUP_FLTb status

output after DCIN returns, it will be forced low to represent an inverted BKUP_FLT bit. When DCIN returns, as

sensed by the UVLO, the shutdown mode is automatically

cancelled and normal operation can resume, however, the

BKUP_FLT bit remains set until either the SHDN pin is set

high (all registers reset) or register bits POR_RESET or

BUFLT_RST are set. See the Shutdown Mode section for

details. During backup, the external thermistor network

is monitored for battery presence.

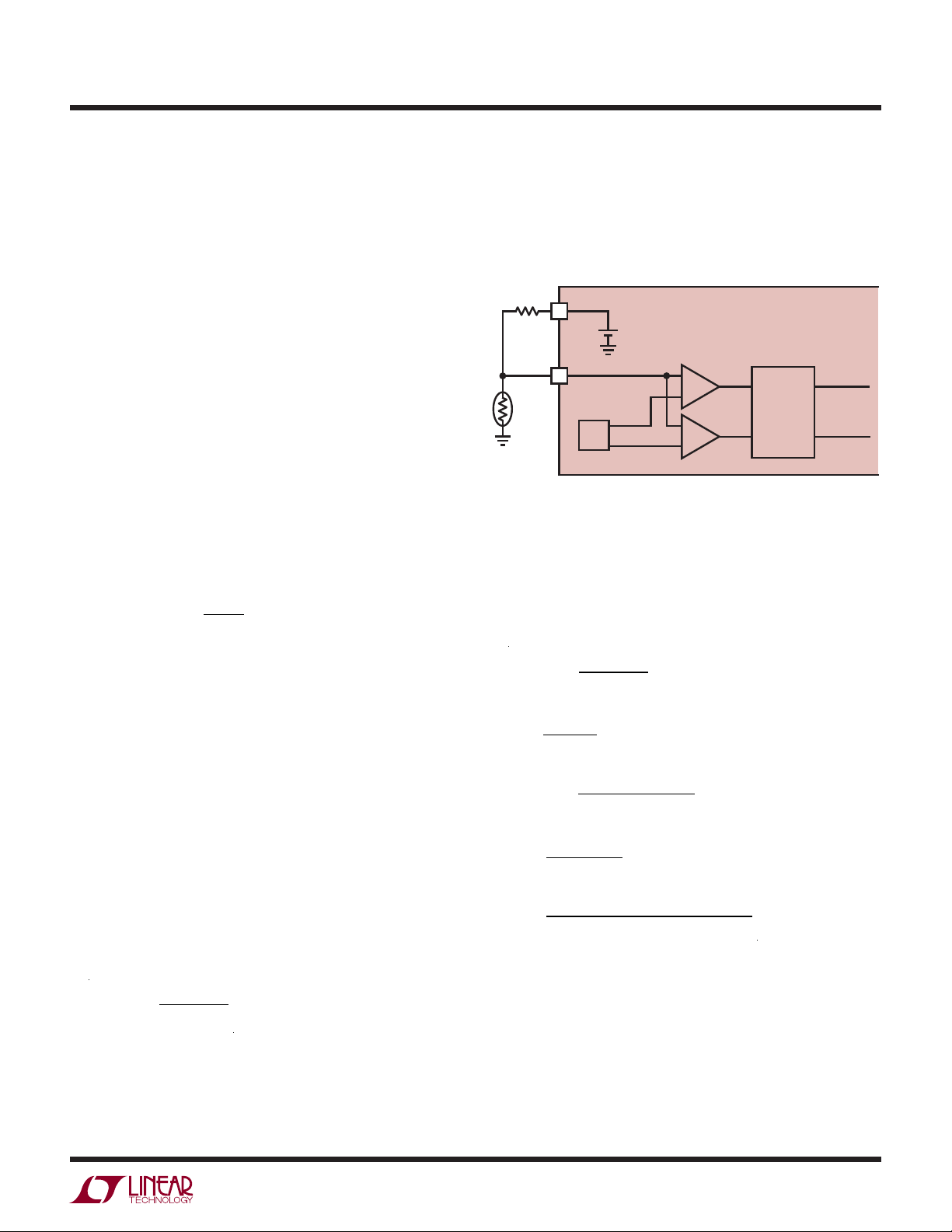

BATTERY CHARGE MODE

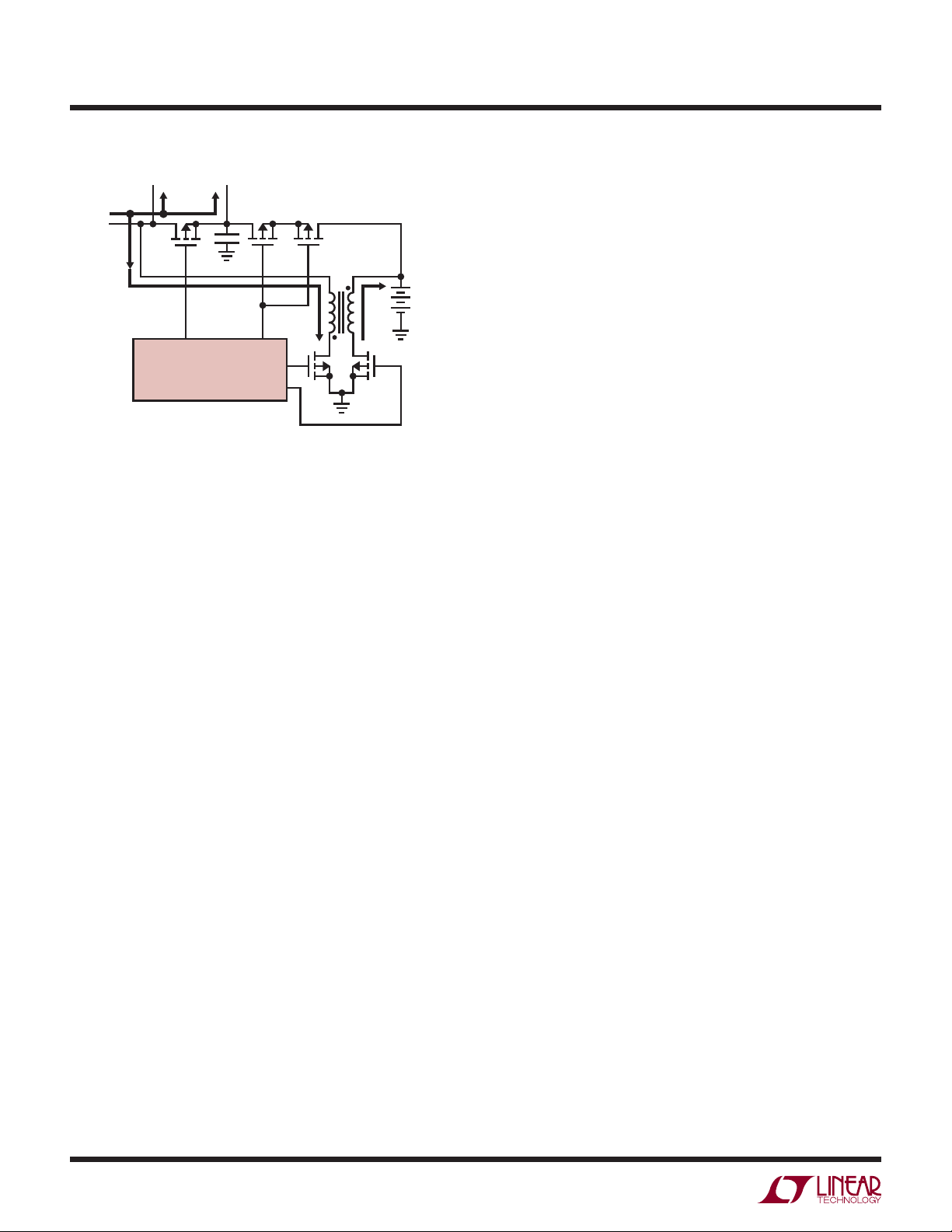

Figure 2 shows the charge path to charge a battery. Current is pulled from the supply input to charge the battery.

At the same time, the input supply provides power to

both the system load and the backup load. The battery

is isolated from the load at all times so it cannot affect

charger terminations algorithms.

If we ignore battery chemistry for a moment, as far as the

LTC4110 charger is concerned, there are only two basic

charge modes. When the TYPE pin selects a standard battery mode, charge termination is controlled by the LTC4110

4110fa

13

Page 14

LTC4110

OPERATION

BACKUP LOADSYSTEM LOAD

DCIN

OFF OFFON

CURRENT FLOW

INID BATID

LTC4110

Figure 2. Charge Mode Operation

CHGFET

DCHFET

BATTERY

4110 F02

for the battery chemistry selected. Specifi cally the TIMER

pin becomes active and used to detect faults conditions or

terminate the charge cycle itself as needed. Smart battery

SMBus charge control commands are still honored if any

are sent at any time. A smart battery can safely function

in a standard battery mode if identical in chemistry and

voltage confi guration as the standard battery. When the

TYPE pin selects a smart battery mode, this simply disables

the TIMER pin and its function in charge termination. The

smart battery is able to restart or terminate a charge cycle

at any time using charge commands over the SMBus. This

mode also enables smart battery wake-up and watchdog

functions based on t

TIMEOUT

per the smart battery standards. However it is not recommended to use a standard

battery with a LTC4110 confi gured for smart battery mode

operation. You can shorten battery life, damage or destroy

the battery. In the extreme case this can cause an explosion

since no charge termination mechanisms are active.

The following sections explain detailed operation for each

charge mode as selected by the TYPE pin.

STANDARD LI-ION/POLYMER BATTERY CHARGE MODE

The charger is programmed for standard Li-Ion batteries by

connecting the TYPE pin to GND. During Li-Ion charging,

the LTC4110 operates as a high effi ciency, synchronous,

PWM fl yback battery charger with constant-current and

constant fl oat voltage regions of operation. The constantcharge current is programmed by the combination of a

resistor (R

) from the I

CHG

pin to ground, a battery

CHG

current sense resistor (R

SNS(BAT)

) and CSP/CSN pin resistors. The constant voltage (fl oat voltage) is programmed

to one of four values (4.2V, 8.4V, 12.6V, 16.8V) depending

on the number of series cells using the SELC pin and can

be adjusted ±0.3V/cell with the V

pin. If adjusted, the

CHG

auto recharge threshold and overvoltage threshold will

track proportionally.

The charge cycle begins when the supply input is present

as sensed by the DCDIV pin and DCIN above UVLO, the

battery cell voltage is below the auto recharge threshold

(95% of the programmed fl oat voltage; see V

), thermis-

AR

tor temperature is within ideal limits, COLD, under range

(see SafetySignal Decoder section) or is optioned out and

the register bit CHARGE_INHIBIT is cleared (see Tables 6

and 7 for register details).

Soft-start ramps the charge current at a rate set by the

capacitor on the I

pin. When charging begins, the pro-

TH

grammable timer initiates timing and the CHGb (GPIO1

pin) status output is pulled LOW. An external capacitor

on the TIMER pin, along with the current set by the total

series resistance connected to the V

pin, sets the total

REF

charge time.

If the battery voltage is less than the 3.0V/cell bulk charge

threshold (V

), the charger will begin with a precondition-

BC

ing trickle charge current. The trickle current is programmed

by the resistor (R

) from the I

PCC

pin to ground. During

PCC

preconditioning trickle charging, if the battery voltage

stays below the bulk charge threshold (V

) 25% of the

BC

programmed bulk charge time, the battery may be defective

and the charge sequence will be terminated immediately.

To indicate this fault, the CHGb (GPIO1 pin) becomes high

impedance, the CHG_STATE_0 and CHG_STATE_1 register

bits will be set low and CHG_FLT register bit will be set

high. Charge is terminated and the timer reset until the

fault is cleared by the RESET_TO_ZERO or POR_RESET

SMBus write commands, SHDN pin toggle or the battery

removed and replaced. Removing the supply input will

not clear the fault if the battery is present.

If the battery voltage exceeds 107.5% (V

) of the

BOV

programmed fl oat voltage during any stage of charge,

the charger pauses until the voltage drops below the

hysteresis (V

). The timer is not stopped and no fault

BOVH

is indicated.

4110fa

14

Page 15

OPERATION

LTC4110

14

ANY

CHARGE

STAT E

8

PWM

STOPPED

(BATTERY OVP)

STOP

CHARGE

(OVERTEMPERATURE)

RESUME

CHARGE

STAT E

RESET

15

9

1

PRE-CONDITIONING

CHARGE

5 (PRE-CONDITIONING FAULT)

23

ANY

CHARGE

STAT E

11 (BATTERY NEEDS RECHARGE)

6 (BULK TIME FAULT)

BULK

CHARGE

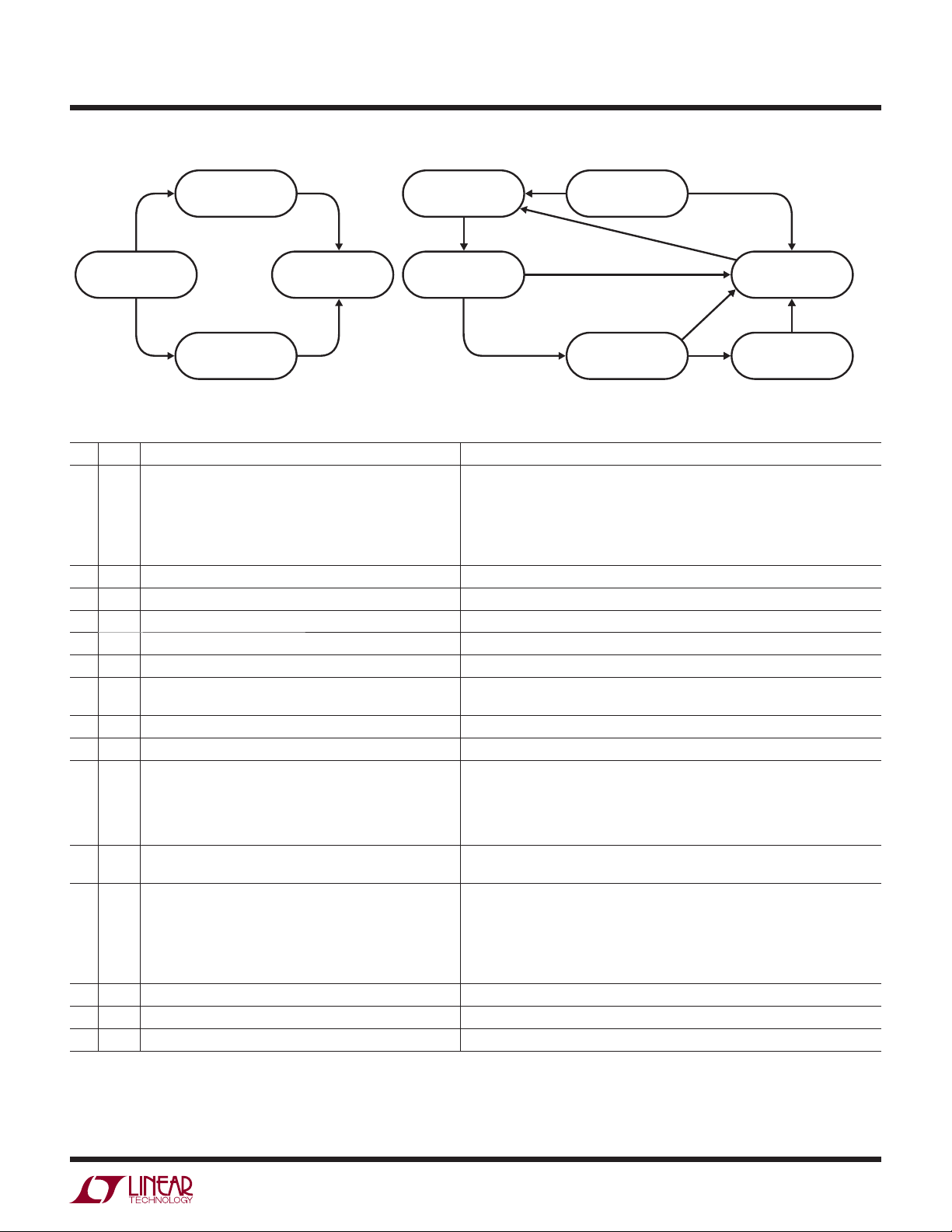

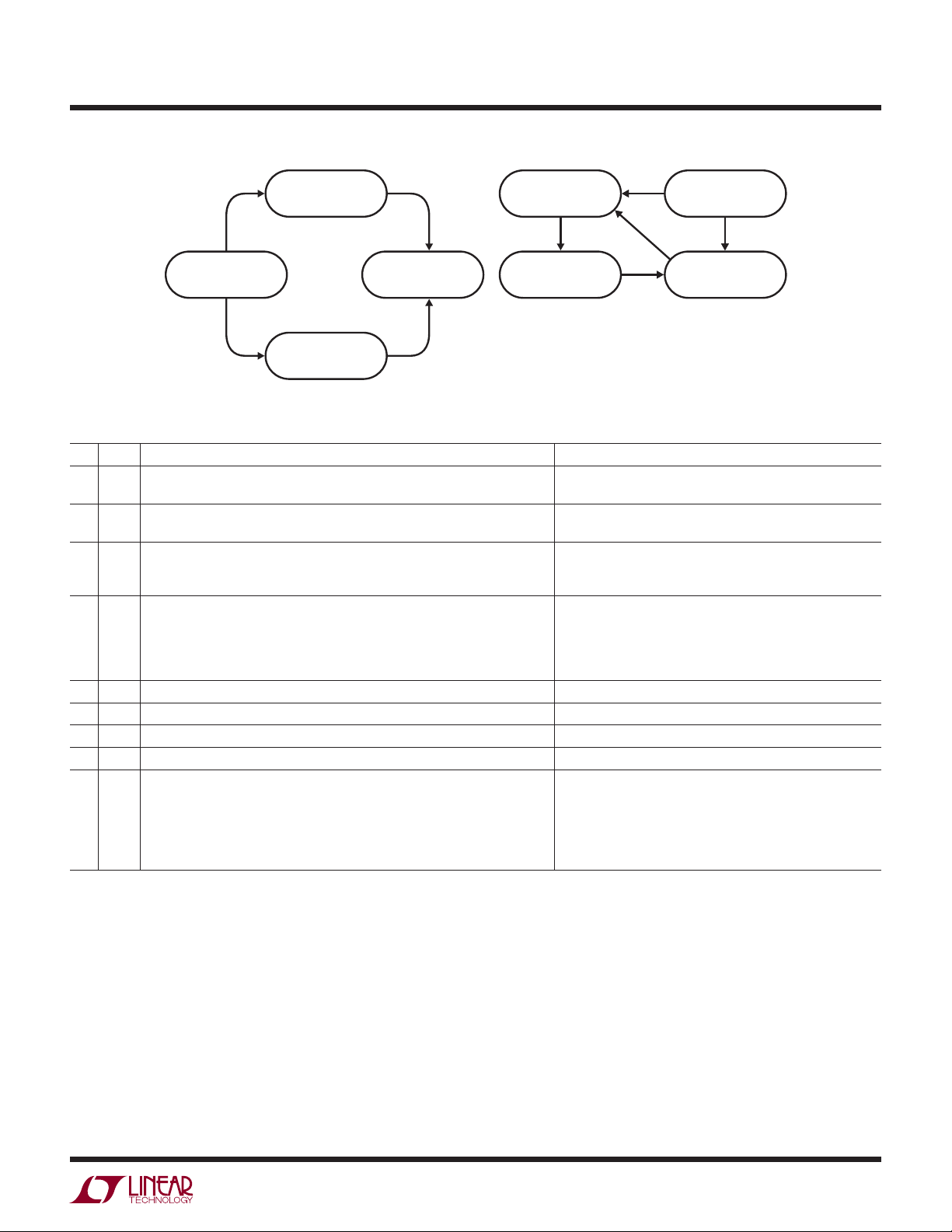

Figure 3. Standard Li-Ion Charge State Diagram (Does Not Include Calibration)

# Logic Event (T = True, F = False) [Notes] Notes and/or Actions (T = True, F = False)

I

1

RES_OR = F & DCDIV pin = T & SHDN pin = F &

CHARGE_INHIBITED = F & CHG_FLT = F & V

Or

RES_OR = F & DCDIV pin = T & SHDN pin = F &

BAT

< V

BC

CHARGE_INHIBITED = F & CHG_FLT=F &

ChargingVoltage() ≠ 0 & ChargingCurrent() ≠ 0

2V

BAT

> V

BC

3 C/5 = T Timer(Bulk) = Stopped & Timer/4(Top Off) = Started

4 Timer/4(Top Off = done [Battery is full] I

5 Timer/4(PreCond) = done before V

BAT

> V

BC

6 Timer(Bulk) = done before C/5 = T I

7

RESET_TO_ZERO = T [See ChargeMode()]

Or

CHARGE_INHIBIT=T [See ChargeMode()]

8 RES_HOT = T & RES_UR = F [See ChargeStatus()] I

9 RES_HOT = F [See ChargeStatus()] I

10

11

12

DCDIV pin = F

Or

RES_OR = T [Bat Removed, See ChargeStatus()]

Or

SHDN pin = T

Or

V

= T

UVD

Or

POR_RESET = T [See ChargeMode()]

V

= T [AutoRestart]

AR

Or

ChargingVoltage() & ChargingCurrent() ≠ 0

AlarmWarning() command is sent by Smart Battery over

SMBus with any of the following bits set to True:

OVER_CHARGED_ALARM

TERMINATE_CHARGE_ALARM

Or

Reserved ALARM

Or

OVER_TEMPERATURE_ALARM

Or

13 ChargingVoltage() or ChargingCurrent() = 0 sent I

14 V

15 V

Note: For all charge states, V

= T [Battery Overvoltage] PWM stopped. Timers remain running.

BOV

= F PWM restarted.

BOV

is always active.

CHG

& Timer/4(PreCond) = Started & CHG = T & ALARM_INHIBITED = F

PPC

(RES_OR = F = Bat Inserted -> See ChargeStatus() )

(POR_RESET -> See ChargeMode()

I

= Off & I

PPC

= Off & CHG = F (Typical Full State)

CHG

I

= Off & CHG_FLT = T & CHG = F

PPC

= Off & CHG_FLT = T & CHG = F

CHG

or IPPC = Off & All Timers = Reset & CHG_FLT = F & CHG = F

I

CHG

or I

CHG

or I

CHG

or I

I

CHG

= On & Timer/4(PreCond) = Stopped & Timer(Bulk) = Started.

CHG

= Off & CHG_FLT = T, Timers paused.

PPC

= On & CHG_FLT = F, Timers resume.

PPC

= Off & All Timers = Reset & ALARM_INHIBITED = F & CHG_FLT =

PPC

F & CHG = F & CHARGE_INHIBITED = F

(The battery needs another charge cycle or Smart Battery has requested to

start another cycle.)

I

or I

CHG

= Off & All Timers = Reset & CHG = F & ALARM_INHIBITED = T

PPC

(ALARM_INHIBITED bit is found in ChargeStatus())

or I

CHG

= Off & CHG = F

PPC

7, 12, 1310

STOP

CHARGE

4 (BATTERY FULL)

TOP-OFF

CHARGE

4110 F03

4110fa

15

Page 16

LTC4110

OPERATION

When the battery voltage exceeds the bulk charge threshold

), the charger begins the bulk charge portion of the

(V

BC

charge cycle. As the battery accepts charge, the voltage

increases. Constant-current charge continues until the

battery approaches the constant voltage. At this time, the

charge current will begin to drop, signaling the beginning

of the constant-voltage portion of the charge cycle.

The charger will maintain the constant voltage across the battery until either C/x is reached or 100% of the programmed

bulk charge time has elapsed during bulk charge. When

the current drops to approximately 20% of the full-scale

charge current, an internal C/x comparator will initiate the

start of the top-off stage. The top-off stage charges for

25% of the total programmed bulk charge time. When the

time elapses, charge is terminated and CHGb (GPIO1 pin)

is forced to a high impedance state and CHG_STATE_0 and

CHG_STATE_1 register bits will be set low. Should the total

bulk charge time elapse before C/x is reached, charge is

terminated and a CHG_FLT fault is indicated until cleared

by the RESET_TO_ZERO or POR_RESET SMBus write

commands, SHDN pin toggle or the battery removed and

replaced. Fault conditions are not cleared when the supply

input is removed if the battery has suffi cient voltage.

An optional external thermistor network is sampled at

regular intervals to monitor battery temperature and to

detect battery presence. If the thermistor temperature is

hot (see the SafetySignal Decoder section), the charge

timer is paused, charge current is halted, CHG_FLTb (GPIO3

pin) is forced low and the CHG_FLT bit will be set high.

CHGb (GPIO1 pin) , CHG_STATE_0 and CHG_STATE_1

register bits will not be affected. When the thermistor

value returns to an acceptable value, charging resumes,

CHG_FLTb (GPIO3 pin) returns to high impedance and the

CHG_FLT bit will be reset low. An open thermistor indicates

absence of a battery. To defeat the temperature monitoring

function, replace the thermistor with a resistor to indicate

ideal battery temperature. When a thermistor is not used,

the resistor circuit must be routed through the battery

connector if battery presence detection is required.

After a charge cycle has ended without fault, the charge

cycle is automatically restarted if the average battery cell

voltage falls below the auto recharge threshold. At any

time charging can be forced to stop by pulling the SHDN

pin high or setting the CHARGE_INHIBIT bit high through

the SMBus.

SMART BATTERY CHARGE MODE

This section explains operation for smart batteries with a

SMBus interface. Smart Li-Ion is selected by connecting

the TYPE pin to the V

is selected by connecting the TYPE pin to the V

The LTC4110 only implements a subset of smart battery

charger commands; the actual charging algorithm is

determined by LTC4110 through external resistors even

if the battery is “smart.”

The LTC4110 operates as a high effi ciency, synchronous,

PWM fl yback battery charger with constant current and

constant fl oat voltage regions of operation. The constantcharge current is programmed by the combination of a

resistor (R

current sense resistor (R

resistors. For Li-Ion the constant voltage (fl oat voltage)

is programmed to one of four values (4.2V, 8.4V, 12.6V,

16.8V) depending on the number of series cells using the

SELC pin and can be adjusted ±0.3V/cell with the V

pin. For nickel batteries the constant-voltage function is

not used, however, a non-zero value is still required to be

written to the ChargingVoltage() register. The internal auto

recharge function is inhibited for smart batteries.

If the battery voltage exceeds 107.5% (V

programmed fl oat voltage during any stage of charge,

the charger pauses until the voltage drops below the

hysteresis (V

is indicated. This function is disabled when nickel based

smart batteries are used.

There are four states associated with smart battery charge

mode, namely:

• SMBus Wake-Up Charge State

• SMBus Preconditioning Charge State

• SMBus Bulk Charge State

• SMBus OFF State

These states are explained in the following four sections.

) from the I

CHG

BOVH

pin and smart Nickel (NiMH/NiCd)

DD

pin.

REF

pin to ground, a battery

CHG

SNS(BAT)

). The timer is not stopped and no fault

) and CSP/CSN pin

CHG

) of the

BOV

16

4110fa

Page 17

OPERATION

LTC4110

11

ANY

CHARGE

STAT E

8

PWM

STOPPED

(BATTERY OVP)

OFF

(OVERTEMPERATURE)

RESUME

CURRENT

STAT E

WAKE UP

CHARGE

12

9

2 4, 7, 13, 14

PRE-CONDITIONING

CHARGE

1

3

6 (BATTERY RECHARGE REQUEST)

RESET

BULK

CHARGE

5 (BAD BATTERY)

10

4

(BATTERY

FULL)

ANY

CHARGE

STAT E

OFF

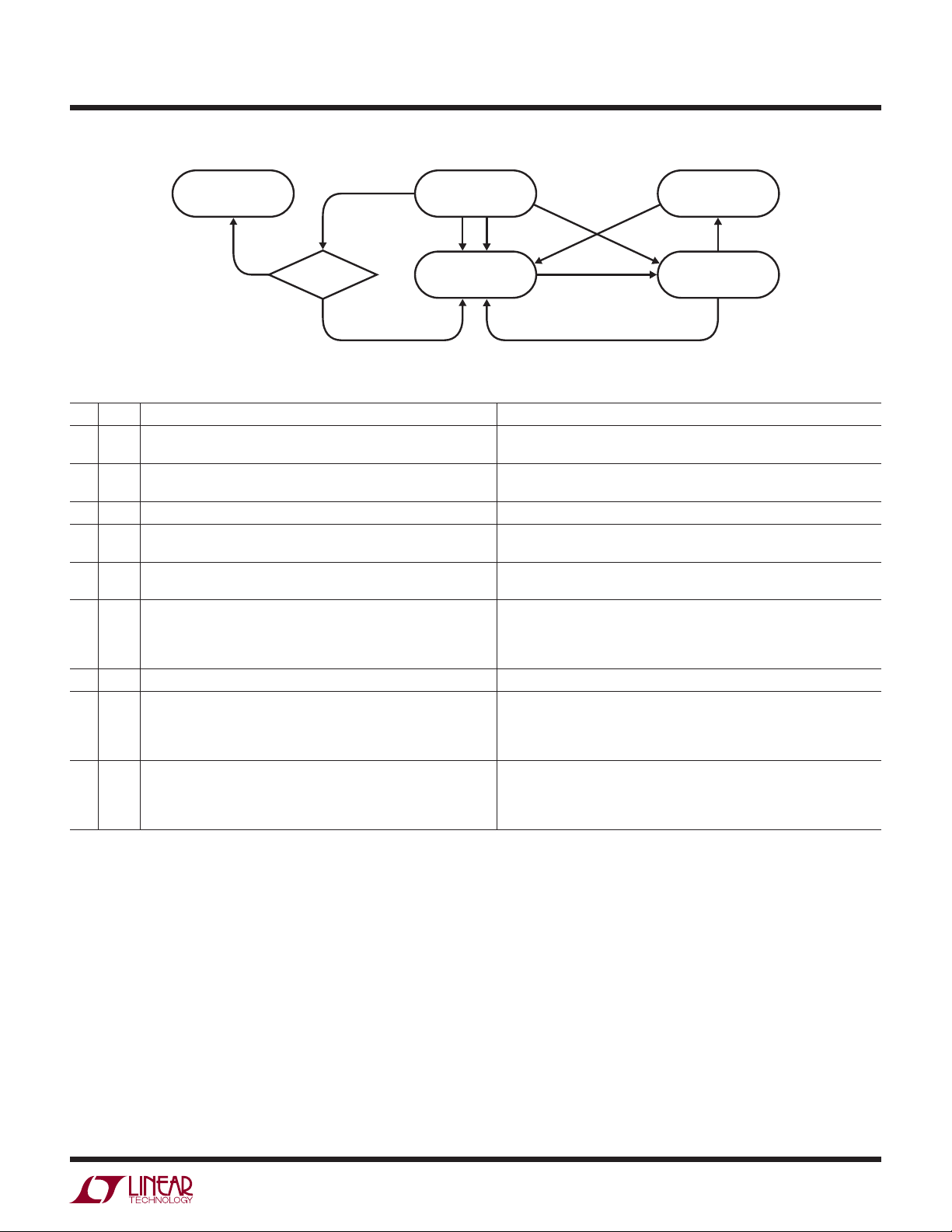

Figure 4. Smart Battery Charge State Diagram (Does Not Include Calibration)

# Logic Event (T = True, F = False) [Notes] Notes and/or Actions (T = True, F = False)

I

1

RES_OR = F & DCDIV pin = T & SHDN pin = F &

CHARGE_INHIBITED = F & CHG_FLT = F & RES_HOT = F

Or

RES_OR = F & DCDIV pin = T & SHDN pin = F &

CHARGE_INHIBITED = F & CHG_FLT = F & RES_HOT = T &

RES_UR = T

2 ChargingVoltage() & ChargingCurrent() ≠ 0 sent Timer/4(Pre-Charge) = Started & TTIMEOUT disabled & ALARM_

3V

BAT

> V

BC

4 ChargingVoltage() or ChargingCurrent() = 0 sent I

5 Timer/4(Pre-Charge) = Done before V

BAT

> V

BC

6 ChargingVoltage() & ChargingCurrent() ≠ 0 sent & RES_OR = F

& DCDIV pin = T & SHDN pin = F & CHARGE_INHIBITED = F &

CHG_FLT = F

7 TTIMEOUT = Done (Dead Battery or Loss of SMBus) I

8 RES_HOT = T & RES_UR = F [See ChargeStatus()] I

9 RES_HOT = F [See ChargeStatus()] I

10

11 V

12 V

13

14

DCDIV pin = F

Or

RES_OR = T [Bat Removed, See ChargeStatus()]

Or

SHDN pin = T

Or

V

= T

UVD

Or

POR_RESET = T [See ChargeMode()]

= T [Battery Overvoltage] PWM stopped. Timers remain running.

BOV

= F PWM restarted.

BOV

RESET_TO_ZERO = T [See ChargeMode()]

Or

CHARGE_INHIBIT = T [See ChargeMode()]

AlarmWarning() command is sent by Smart Battery over SMBus

with any of the following bits set to True:

OVER_CHARGED_ALARM

TERMINATE_CHARGE_ALARM

Or

Reserved ALARM

Or

OVER_TEMPERATURE_ALARM

Or

Note: V

is active in all charge states except for nickel batteries which operate in constant current mode.

CHG

= On (Constant Current only) & TTIMEOUT = Started & CHG = T

PPC

INHIBITED = F

I

PPC

= Off, I

= On, Timer/4(Pre-Charge) = Stopped & Timer(SMBus)

CHG

= Started

= Off & All Timers = Reset & CHG = F

CHG

I

= Off & All Timers = Reset & CHG = F

PPC

= On & Timer/4(Pre-Charge) = Started & CHG = T &

I

PPC

ALARM_INHIBITED = F

= Off & All Timers Reset & CHG = F

CHG

or I

CHG

CHG

I

CHG

= Off & CHG_FLT = T, Timer = Paused.

PPC

or I

= On & CHG_FLT = F, Timer = Resume.

PPC

or I

= Off & All Timers = Reset & CHG_FLT = F & CHG = F &

PPC

ALARM_INHIBITED = F & CHARGE_INHIBITED = F

or I

I

CHG

I

CHG

= Off & All Timers = Reset & CHG_FLT = F & CHG = F

PPC

or I

= Off. & All Timers = Reset & CHG = F &

PPC

ALARM_INHIBITED = T

(ALARM_INHIBITED bit is found in ChargeStatus())

4110 F04

4110fa

17

Page 18

LTC4110

OPERATION

SMBUS WAKE-UP CHARGE STATE

The battery will be charged with a fi xed “wake-up” current

regardless of previous ChargingCurrent() and ChargingVoltage() register values during wake-up charging. The current is identical to the preconditioning charge current which

is programmed with an external resistor through the I

pin. The wake-up timer has the same period as t

typically 175sec (see t

TIMEOUT

).

TIMEOUT

PCC

,

The following conditions must be met to allow wake-up

charge of the battery:

• The SafetySignal must be RES_COLD, RES_IDEAL, or

RES_UR.

• AC must be present. This is qualifi ed by DCDIV > V

+ V

and DCIN above UVLO.

ACH

AC

• Wake-up charge initiates if a battery does not write

non-zero values to ChargingCurrent() and CharginVoltage() registers when AC power is applied and a

battery is present or when AC is present and a battery

is subsequently connected.

• CHARGE_INHIBIT is set in the BBuControl() register.

Charge is stopped, however, the wake-up timer is not

paused. Clearing CHARGE_INHIBIT will enable the

LTC4110 to resume charging.

• There is insuffi cient DCIN voltage to charge the battery

as determined by the internal UVLO. This causes the

state machine to enter the reset state and stop all charge

activity. The LTC4110 will resume wake-up charging when

there is suffi cient DCIN voltage to charge the battery.

• The CAL_START bit in the BBuControl() register is set.

Charge is stopped and the LTC4110 enters the calibration state.

• Writing a zero value to either the ChargingVoltage() or

ChargingCurrent() register. The state machine will go

to the SMBus OFF state.

• RESET_TO_ZERO is set in the BBuControl() register.

Charge is stopped; the SMBus OFF State is entered.

SMBUS PRECONDITIONING CHARGE STATE

The following conditions will terminate the wake-up charge

state and end charge attempts, unless otherwise noted.

• The t

TIMEOUT

period is reached (see t

TIMEOUT

) when

the SafetySignal is RES_COLD or RES_UR. The state

machine will go to the SMBus OFF state. The CHG_FLT

bit is not set.

• The SafetySignal is registering RES_HOT. The state

machine will go to the SMBus OFF state.

• The SafetySignal is registering RES_OR. The state

machine will go to the reset state.

• The LTC4110 will leave the wake-up charge state and

go into the SMBus preconditioning charge state if the

ChargingCurrent() AND ChargingVoltage() registers

have been written to non-zero values.

• The AC power is no longer present (DCDIV < V

AC

or

DCIN below UVLO). The state machine will go to the

reset state.

• The ALARM_INHIBITED becomes set in the

ChargerStatus() register. The state machine will go to

the SMBus OFF state.

During the SMBus preconditioning charge state, the charger

will be operating in the preconditioning charge current

limit. The following conditions must be met in order to

allow SMBus preconditioning charge to start:

• The ChargingVoltage() AND ChargingCurrent() registers

must be written to non-zero values. The LTC4110 will

not directly report the status of these registers. The

battery needs only write one pair of ChargingVoltage()

and ChargingCurrent() registers to stay in this state. The

t

TIMEOUT

timer is not operational in SMBus precondition-

ing charge state.

• The SafetySignal must be RES_COLD, RES_IDEAL, or

RES_UR.

• AC must be present and suffi cient. This is qualifi ed by

DCDIV > V

AC

+ V

and DCIN > UVLO.

ACH

The following conditions will affect the SMBus preconditioning charge state as specifi ed below:

• The SafetySignal is registering RES_HOT. Charge is

stopped; the SMBus OFF state is entered.

18

4110fa

Page 19

OPERATION

LTC4110

• The SafetySignal is registering RES_OR. Charge is

stopped. The LTC4110 enters the reset state.

• The AC power is no longer present (DCDIV < V

DCIN < UVLO). The LTC4110 enters the reset state.

• ALARM_INHIBITED is set in the ChargerStatus()

register. Charge is stopped. The LTC4110 enters the

SMBus OFF state.

• CHARGE_INHIBIT is set in the BBuControl() register.

Charge is stopped, however, the T/4 timer is not paused.

Clearing CHARGE_INHIBIT will enable the LTC4110 to

resume charge.

• RESET_TO_ZERO is set in the BBuControl() register.

Charge is stopped. The LTC4110 enters the SMBus

OFF state.

• Writing a zero value to ChargeVoltage() or ChargeCurrent() register. Charge is stopped. The LTC4110 enters

the SMBus OFF state.

• If the batter y voltage exceeds the bulk charge threshold,

the LTC4110 will enter the SMBus bulk charge state.

• If the T/4 timeout occurs, charge is stopped and the

LTC4110 enters the SMBus OFF state.

• The CAL_START bit in the BBuControl() register is

set. Charge is stopped and the LTC4110 enters the

calibration mode.

SMBus BULK CHARGE STATE

AC

or

• The ChargeCurrent() AND ChargeVoltage() registers

have not been written for t

and the LTC4110 enters the SMBus OFF state.

• The SafetySignal is registering RES_OR. Charge is

stopped and the LTC4110 enters the reset state.

• The SafetySignal is registering RES_HOT. Charge

is stopped and the LTC4110 enters the SMBus OFF

state.

• The AC power is no longer present (DCDIV < V

DCIN < UVLO). Charge is stopped and the LTC4110

enters the reset state.

• ALARM_INHIBITED is set in the ChargerStatus() register.

Charge is stopped and the LTC4110 enters the SMBus

OFF state.

• CHARGE_INHIBIT is set in the BBuControl() register.

Charge is stopped. Clearing CHARGE_INHIBIT will enable the LTC4110 to resume charge. The t

does not pause when CHARGE_INHIBIT is set.

• RESET_TO_ZERO is set in the BBuControl() register.

The LTC4110 enters the SMBus OFF state.

• Writing a zero value to the ChargeVoltage() or to the

ChargeCurrent() register. Charge is stopped and the

LTC4110 enters the SMBus OFF state.

• The CAL_START bit in the BBuControl() register is set.

Charge is stopped and the LTC4110 enters the calibration mode.

TIMEOUT

. Charge is stopped

or

AC

TIMEOUT

timer

The charger will be operating in the bulk charge current

limit during the SMBus bulk charge state. The following

conditions must be met in order to allow SMBus bulk

charge to start:

• The ChargeVoltage() AND ChargeCurrent() registers

must be written to non-zero values. The LTC4110 will

not directly report the status of these registers.

• The SafetySignal must be RES_COLD, RES_IDEAL, or

RES_UR.

• AC must be present and suffi cient. This is qualifi ed by

DCDIV > V

The following conditions will affect the SMBus bulk charge

state as specifi ed below:

AC

+ V

and DCIN > UVLO.

ACH

SMBus OFF STATE

This state is different from the reset state in that all charge

is disallowed regardless of the value of the thermistor. The

following conditions will affect the SMBus OFF state as

specifi ed below:

• The ChargeCurrent() AND ChargeVoltage() registers have both been written to non-zero values, the

battery thermistor is registering RES_COLD, RES_

IDEAL or RES_UR and CHARGE_INHIBT is clear. The

LTC4110 enters the SMBus preconditioning charge

state.

4110fa

19

Page 20

LTC4110

OPERATION

• The CAL_START bit in the BBuControl() register is set.

The LTC4110 enters the calibration state.

• The battery thermistor is registering RES_OR. The

LTC4110 enters the reset state.

LEAD ACID BATTERY CHARGE MODE

The charger is programmed for lead acid batteries by connecting the TYPE pin to a voltage derived from the V

pin resistor divider of nominally 0.5 • V

. During charge,

REF

REF

the LTC4110 operates as a high effi ciency, synchronous,

PWM fl yback battery charger with constant current and

constant fl oat voltage regions of operation. The constantcharge current is programmed by the combination of a

resistor (R

current sense resistor (R

) from the I

CHG

pin to ground, a battery

CHG

) and CSP/CSN pin resistors.

SNS

The fl oat voltage is programmed to one of four values

(4.7V, 7.05V, 11.75V, 14.1V) depending on the number of

series cells (2, 3, 5 or 6) using the SELC pin and can be

adjusted ±0.15V/cell with the V

CHG

pin.

A new charge cycle begins with the charger in the bulk

charge current limited state. In this state, the charger is

a current source providing a constant charge rate and the

CHGb (GPIO1 pin) is forced low. No time limits are placed

upon lead acid battery charge. The charger monitors the

battery voltage and as it reaches the fl oat voltage the

charger begins its fl oat charge. While in fl oat, the charge

current diminishes as the battery accepts charge. Float

voltage temperature compensation and temperature fault

monitoring, if desired, are accomplished with an external

thermistor network.

Charge is active when the supply input is present as sensed

by the DCDIV pin and DCIN above UVLO, thermistor

temperature is ideal according to the thermistor monitor

circuit (see SafetySignal Decoder) and the charge register

bit CHARGE_INHIBIT is cleared. Soft-start ramps the charge

current at a rate set by the capacitor on the I

pin. When

TH

charge begins, the CHGb (GPIO1 pin) status output is

forced to GND. At any time charge can be forced to stop by

pulling the SHDN pin high or setting the CHARGE_INHIBIT

bit high through the SMBus.

If the battery voltage exceeds 107.5% (V

) of the pro-

BOV

grammed fl oat voltage during any stage of charge, the

charger pauses until the voltage drops below the hysteresis

(V

). No fault is indicated.

BOVH

An optional external NTC thermistor network can be used

to provide an adjustable negative TC for the fl oat voltage,

monitor battery temperature and to detect battery presence. If the thermistor value indicates a hot temperature,

voltage falling to V

on THB pin, charge current is halted,

HOT

CHG_FLTb (GPIO3 pin) is forced low and the CHG_FLT bit

will be set high. CHGb (GPIO1 pin) and CHG_STATE_0 and

CHG_STATE_1 register bits will not be affected. When the

thermistor value returns to ideal when the voltage exceeds

V

HOT

+V

on THB pin, charge resumes CHG_FLTb

HOTH

(GPIO3 pin) returns to high impedance and the CHG_FLT

bit will be reset low. An open thermistor indicates an

over-range which is considered absence of a battery.

Low temperature is not monitored. However, since battery removal detection looks at the thermistor for a high

resistance (V

on THB pin), extremely cold temperatures

REM

may result in an indication of battery absence. To defeat

the temperature monitoring register, replace the thermistor with a resistor to indicate normal battery temperature.

When a thermistor is not used the resistor circuit must be

routed through the battery connector if battery presence

detection is required.

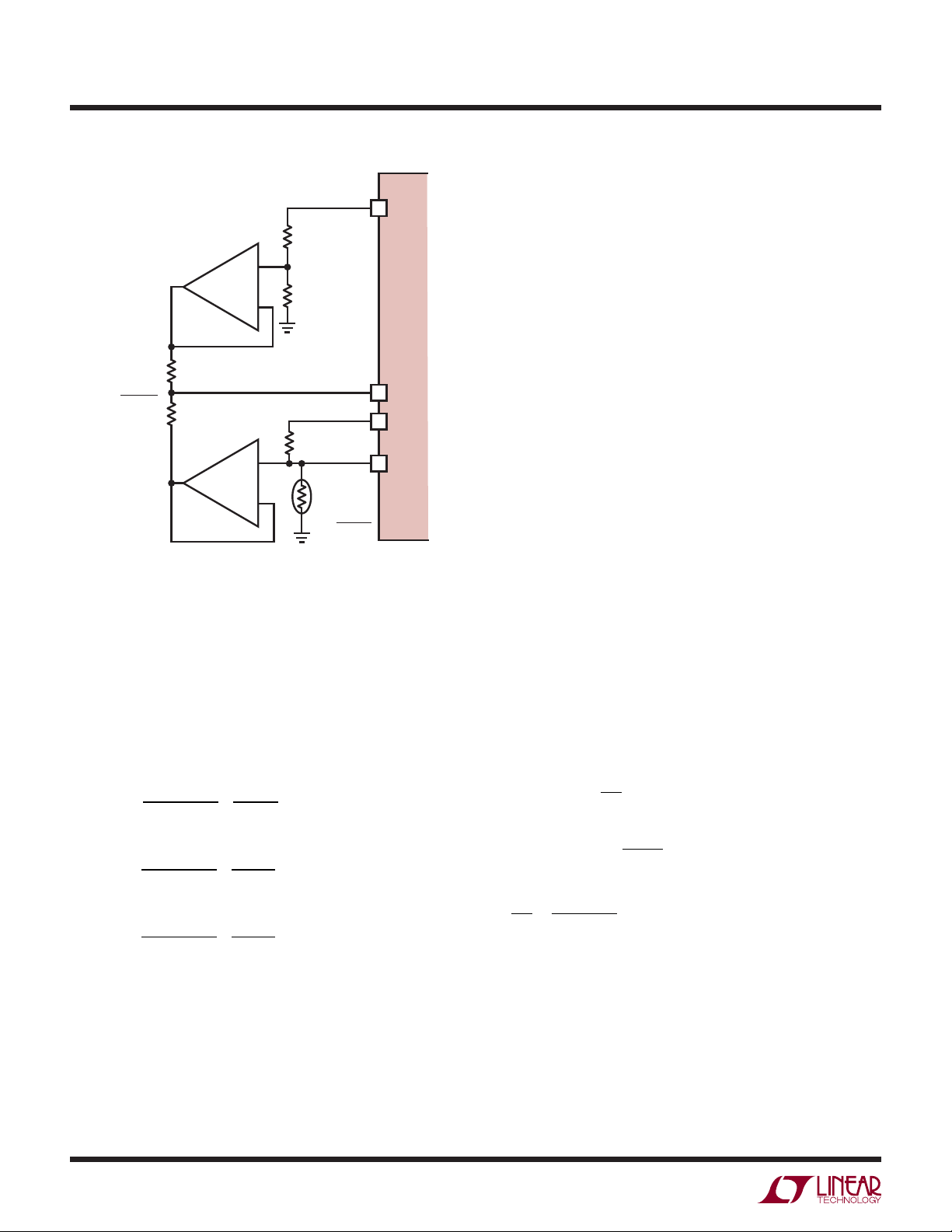

BATTERY CALIBRATION MODE

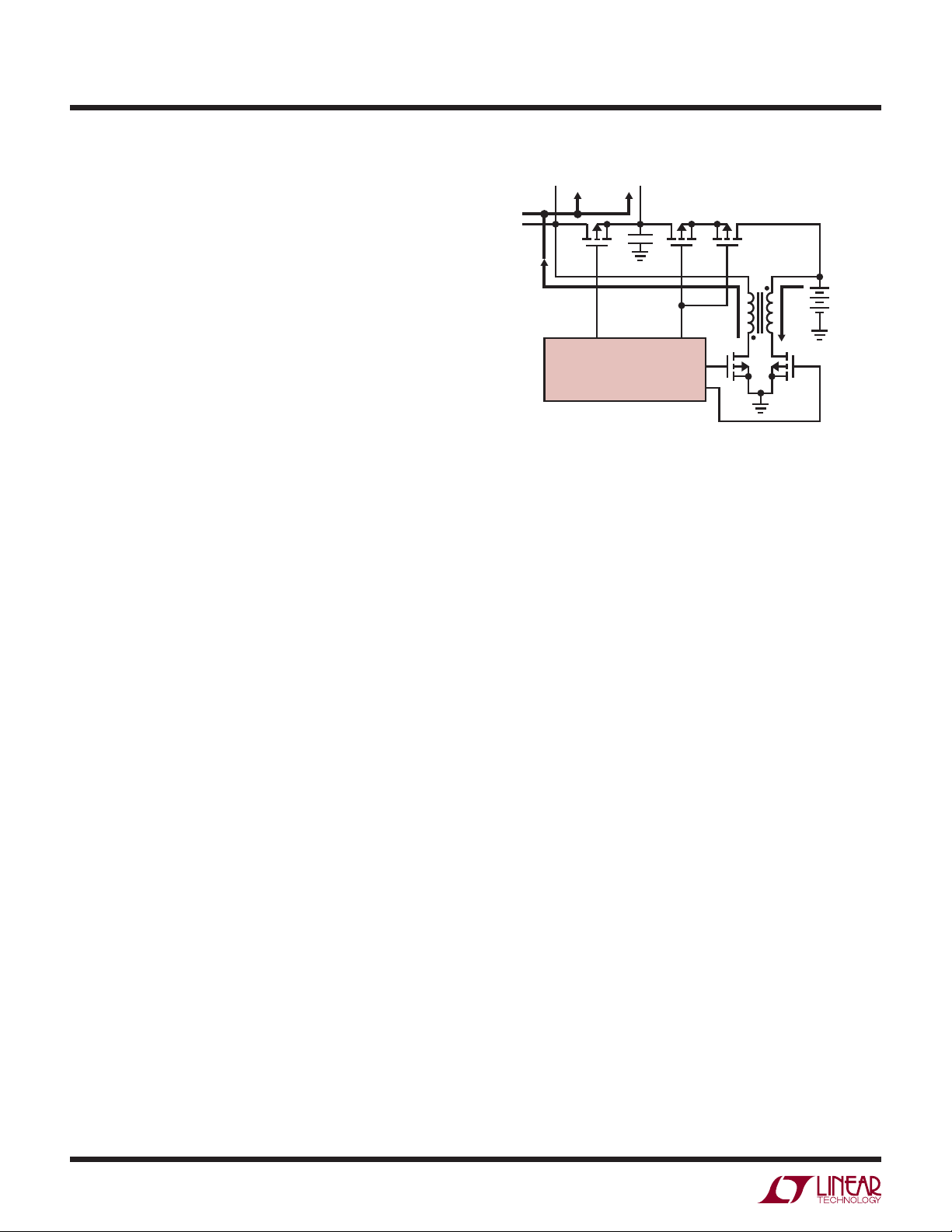

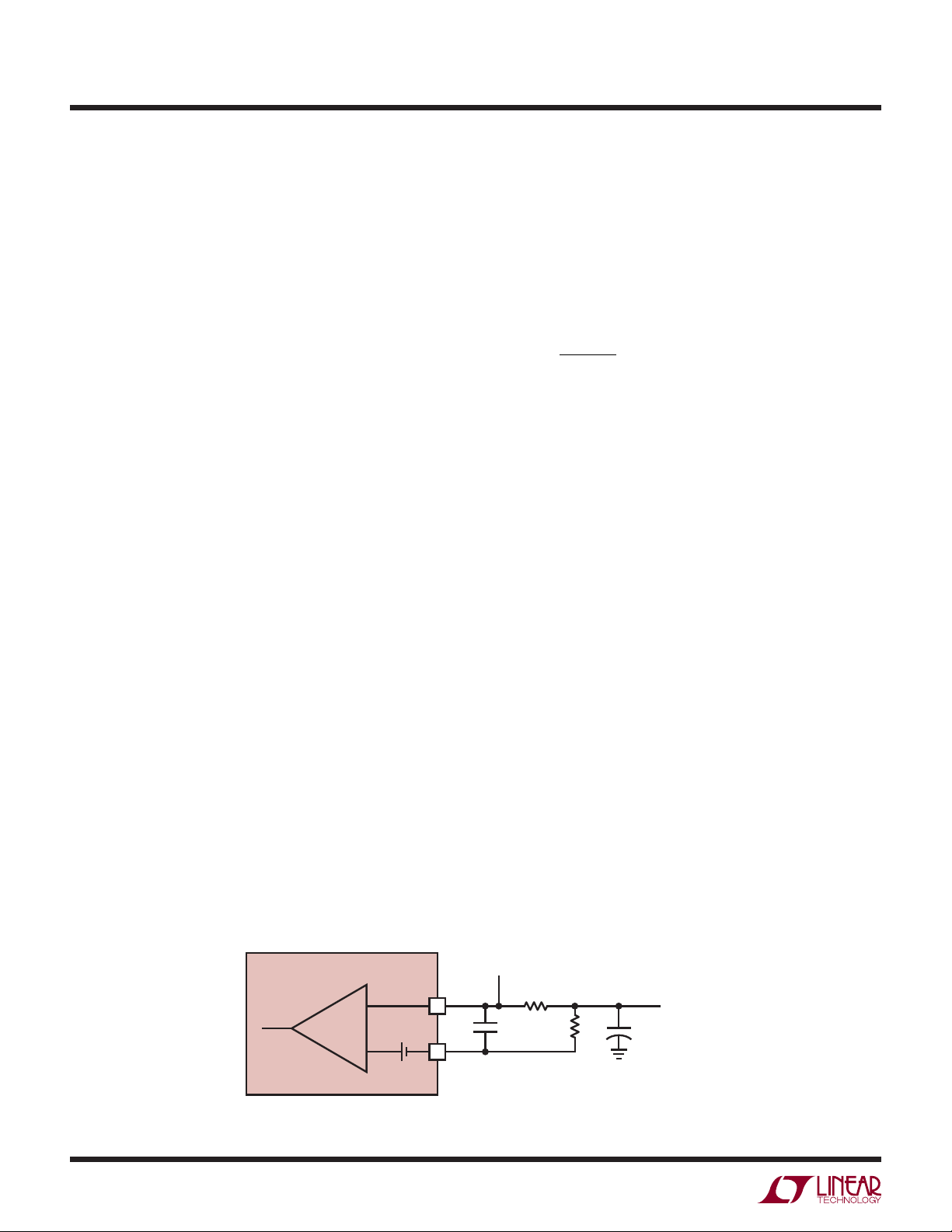

Figure 6 shows the LTC4110 in battery calibration mode and

the corresponding PowerPath enabled. During calibration,

the host CPU can calibrate a gas gauge or verify the battery’s

ability to support a load by use of a low heat producing

method. Calibration requires a host to communicate over

a SMBus. In the low heat method, a synchronous PWM

fl yback charger is used in reverse to discharge the battery

with a programmable constant-current into the system

load thereby saving space and eliminating heat generation

compared with resistive loads. Protection circuits prevent

accidental overdrive back into the power source if the

system load is insuffi cient. The constant-charge current

is programmed by the combination of a resistor (R

from the I

tor (R

SNS(BAT)

pin to ground, a battery current sense resis-

CAL

) and CSP/CSN pin resistors. Calibration is

CAL

)

initiated by setting the CAL_START bit in the BBuControl()

register. The CAL_ON bit in the BBuStatus() register will

20

4110fa

Page 21

OPERATION

LTC4110

7

ANY

CHARGE

STAT E

5

PWM

STOPPED

(BATTERY OVP)

STOP

(OVERTEMPERATURE)

RESUME

CHARGE

STAT E

RESET

8

6

19

CHARGE

4

2

3

ANY

CHARGE

STAT E

STOP

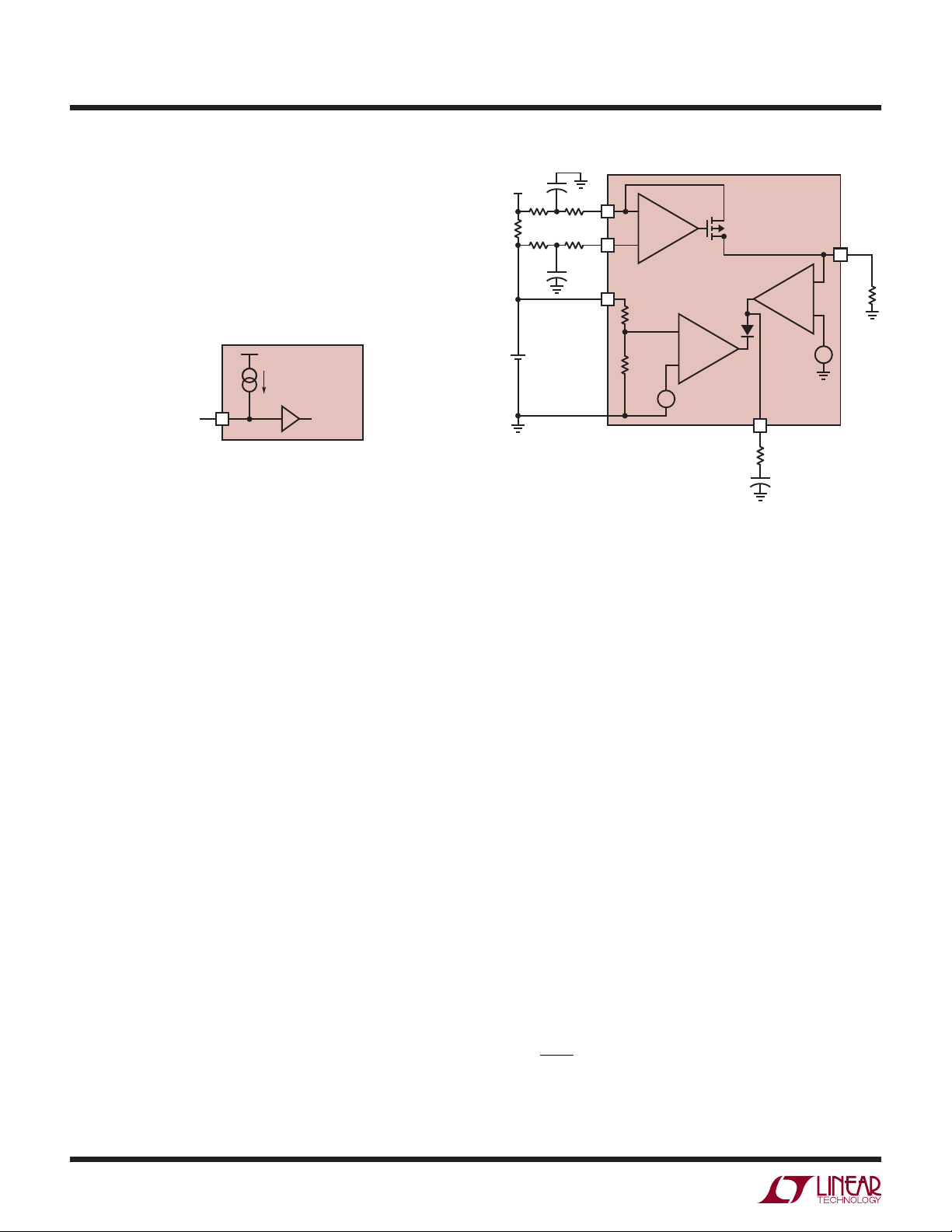

Figure 5. SLA Charge State Diagram (Does Not Include Calibration)

# Logic Event (T = True, F = False) [Notes] Notes and/or Actions (T = True, F = False)

1 RES_OR = F & DCDIV pin = T & SHDN pin = F & CHARGE_INHIBITED = F &

2

3

4

5 RES_HOT = T & RES_UR = F [See ChargeStatus()] I

6 RES_HOT = F [See ChargeStatus()] I

7V

8V

9

Note: For all charge states, V

CHG_FLT = F

VAR = T [AutoRestart]

Or

ChargingVoltage() & ChargingCurrent() ≠ 0 sent

ChargingVoltage() or ChargingCurrent() = 0 sent

Or

RESET_TO_ZERO = T [See ChargeMode()]

Or

CHARGE_INHIBIT = T [See ChargeMode()]

DCDIV pin = F

Or

RES_OR = T [Bat Removed, See ChargeStatus()]

Or

SHDN pin = T

Or

V

= T

UVD

Or

POR_RESET = T [See ChargeMode()]

= T PWM stopped. Timers remain running.

BOV

= F PWM restarted.

BOV

AlarmWarning() command is sent by Smart Battery over SMBus with any of

the following bits set to True:

OVER_CHARGED_ALARM

TERMINATE_CHARGE_ALARM