Page 1

High Effi ciency USB Power Management System Safely Charges

Li-Ion/Polymer Batteries from Automotive Supplies

– Design Note 464

George H. Barbehenn

Introduction

Automotive power systems are unforgiving electronic

environments. Transients to 90V can occur when the

nominal voltage r ange is 10V to 15V (ISO7637), along wi th

b at t er y r ev er sa l i n s om e c as es. It ’s fai rl y s t ra i gh t for w ar d

to build automotive electronics around this system, but

increasingly end users want to operate portable electronics, such as GPS systems or music/video players,

and to charge their Li-Ion batteries from the automotive

battery. To do so requires a compact, robust, effi cient

and easy-to-design charging system.

Complete USB/Battery Charging Solution for Use in

Large Transient Environments

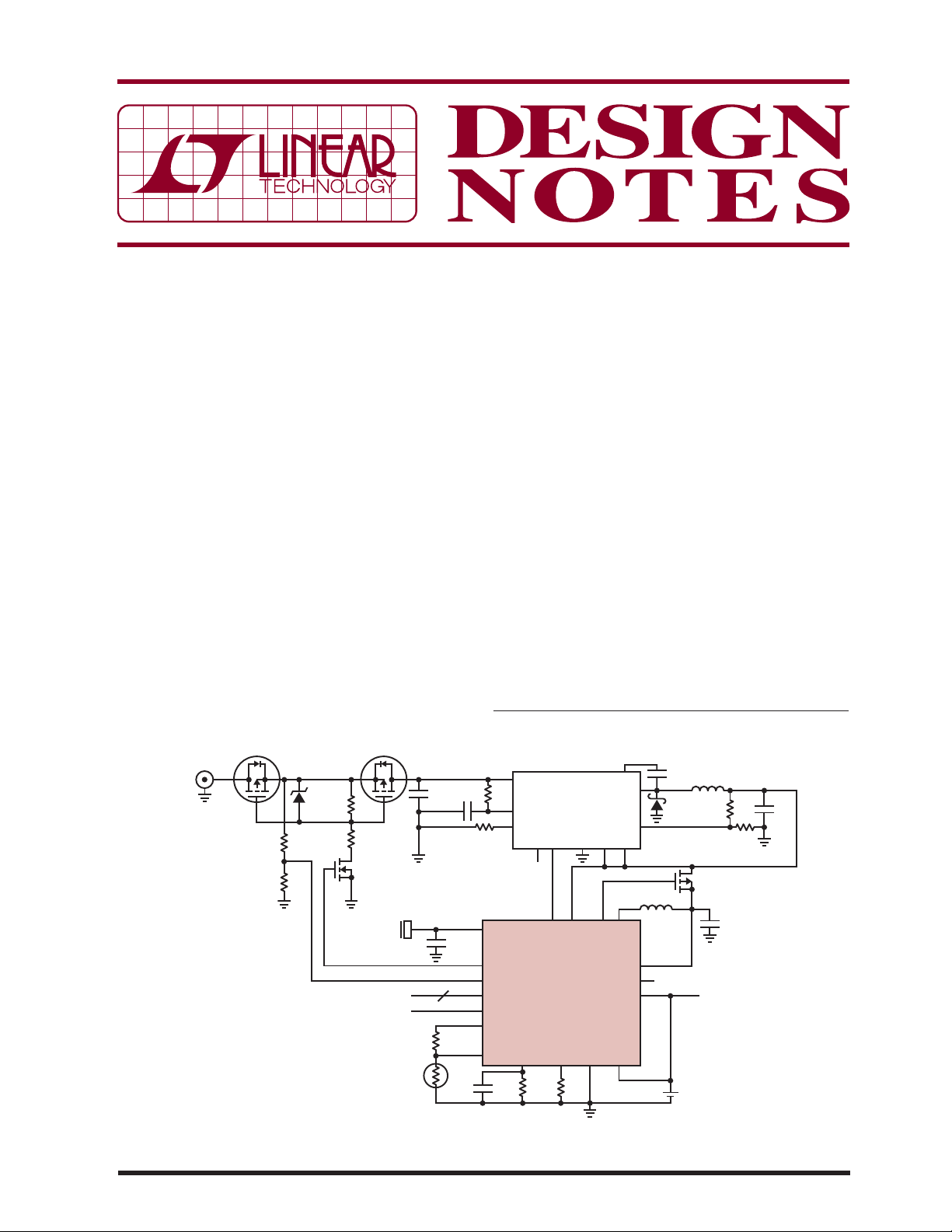

Figure 1 shows such a design. This complete PowerPat h™

manager and bat tery charger system se amlessly charges

the Li-Ion battery from a wide ranging high voltage or

USB source.

AUTOMOTIVE,

FIREWIRE,

ETC.

HVIN

M1

ZXMP10A18G

R3

33k

R4

10k

D1

MMBZ5240BLT1G

10V

OVGATE

M2

ZXMP10A18G

R5

10k

R1

1k

M3

ZXMN10A08E6

USB

TO μC

TO μC

V

IN

C6

C1

68nF

4.7μF

C2

10μF

0805

15-17

R7

100k

R8

T

100k

In this circuit, the LTC

Ion battery charger controls an LT3480 HV step-down

regulator. The LTC4098’s Bat-Track™ feature provides

a high effi ciency, low power dissipation battery charger

from low and high voltages alike. The Bat-Track feature

controls an internal input current-limited switching regulator to regulate V

OUT

maximizes battery charger effi ciency, and thus minimizes

power dissipation by operating the battery charger with

minimal headroom. Furthermore, the Bat-Track feature

reduces charge time by allowing a charge current greater

than the USB input current limit—the switching regulator

behaves like a transformer exchanging output voltage for

output current.

The LTC4098 can extend the Bat-Track concept to an

auxiliary regulator via the WALL and V

suffi cient voltage is present on WALL, Bat-Track takes

L, LT, LTC and LTM are registered trademarks and PowerPath and Bat-Track are

trademarks of Linear Technology Corporation. All other trademarks are the property of

their respective owners.

4

V

IN

R2

13

R6

40.2k

2

1

8

4

5

150k

5

RUN/SS

10

R

V

BUS

OVGATE

OVSENS

D0–D2

CHRG

NTCBIAS

NTC

CLPROG PROG

C3

0.1μF

0603

LT3480

T

PG GNDV

C

7

9

11 1 6

20 18 19 14

VCWALL ACPR

LTC4098

3 7 9, 21 6

R9

2.94k

GNDSWBATSENS

R10

1k

®

4098 USB power manager/Li-

to approximately V

BD

2

BOOST

SYNC

V

IDGATE

OUT

BAT

C7

0.47μF

3

SW

8

FB

L1

3.3μH

12

10

11

+

Li-Ion

DN464 F01

L2

10μH

M4

SYSTEM

LOAD

C5

10μF

0805

R11

499k

R12

100k

BAT

C

HVBUCK

+ 0.3V which

pins. When

C4

22μF

Figure 1. LTC4098 USB Power Manager/Li-Ion Battery Charger Works with an LT®3480 HV Buck Regulator to Accept Power

from an Automotive Environment or Firewire System. Overvoltage Protection Protects Both ICs and Downstream Circuits

05/09/464

Page 2

control of the auxiliary regulator’s output via the VC pin,

maintaining the regulator’s output at V

BAT

+ 0.3V.

The LTC4098 also includes an over voltage protec tion function—important in volatile supply voltage environments.

Overvoltage protection shuts off a protection N-channel

MOSFET (M2) when the volt age at the OVSENSE pin exceeds

approximately 6V. The upper limit of voltage protection is

limited only by the breakdown voltage of the MOSFET, and

by the current fl owing into the OVSENS pin.

Overvoltage Protection Covers the Entire Battery

Charger/Power Manager System

The overvoltage protection function of the LTC4098 can

protect a ny part of the circui t. In Figure 1, the pro tection has

been extended to the LT3480 V

input. The overvoltage

IN

shutdown threshold has been set to 24V. This threshold

provides ample margin against destructive overvoltage

events without interfering with normal operation.

In Figure 1, M1 is a P-channel MOSFET that provides

reverse volt age protection, wherea s M2 is the overvoltage

protection MOSFET, and M3 level-shifts the OVGATE

output of the LTC4098.

If the HVIN voltage is less than zero, the gate and source

v ol t a ge s of bo t h M 1 a n d M 2 ar e h e ld at g ro un d th r ou g h R 3,

R4, and R5, ensuring that they are of f. If the HVIN volt age is

betwe en 8V and approximately 24V, the gat e of M3 is driven

high via the LTC4098’s OVGATE pin. This turns on M1 and

M2 by pulling their gates 7V to 10V below their sources via

M3, D1, R1 and R5. With M1 and M2 on current fl ows from

HVIN to V

and the system operates normally.

IN

If the HVIN input exce eds approximately 24V, the LTC4098

drives the gate of M3 to ground, which allows R5 to

reduce the V

and disconnecting HVIN from V

M1, M2 and M3 have a BV

of M1 and M2 to zero, shutting them off

GS

.

IN

of 100V, so that this circuit

DSS

can tolerate voltages of approximately –30V to 100V. It

will operate normally from 8V to approximately 24V. This

combination is ideal for the harsh automotive environment,

providing a robust, low co st and effect ive solution for Li-Ion

battery charging from an automotive power system.

Finally, setting the OVSENS resistor divider requires some

care. For an OVSENS voltage between approximately 2V

and 6V, V

OVGATE

= 1.9 • V

. OVSENS is clamped at

OVSENS

6V and the current into (or out of) OVSENS should not

exceed 10mA. The chos en resistor divider at tenuates HVIN

by a factor of 4, so M3 has suffi cient gate voltage to turn

on when HVIN exceeds approximately 8V. When HVIN

= 100V, the current into OVSENS is just 2.25mA—well

below the 10mA limit.

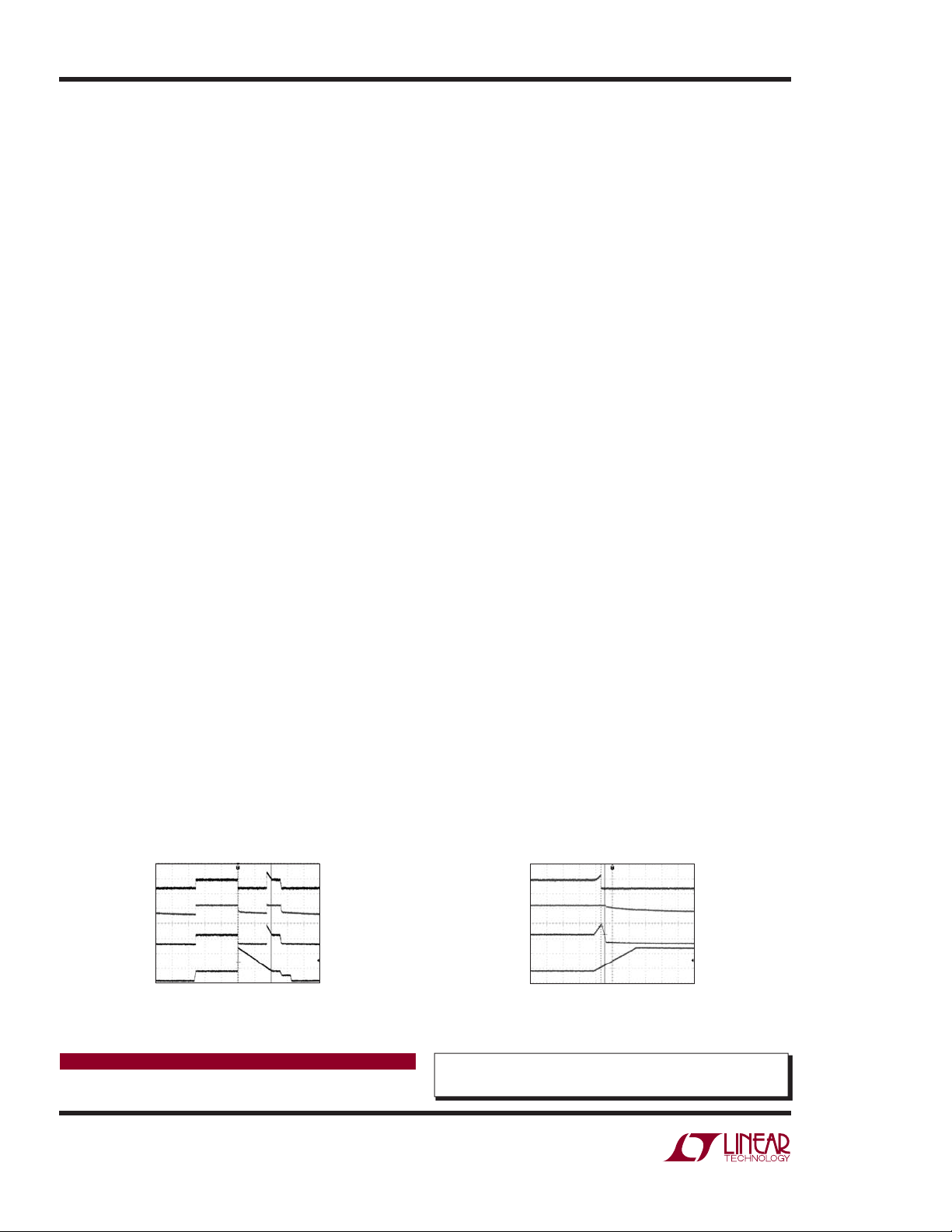

As shown in Figure 2, V

is only present when HVIN

IN

is in the 8V to 24V region. Figure 3 shows a close-up

centered on the load dump ramp. The ISO7637 test

ramp rises from 13.2V to 90V in 5ms. There is a 220μs

turn-off delay—OVGATE going low to the gates of M1

and M2—which results in an overshoot on V

maximum value of this overshoot is 3.5V (V

. The

IN

VIN(MAX)

≈

27.5V). The magni tude of this overshoot can be calcul ated

for different ramp rates, such that

V

OVERSHOOT

where ΔV = (90V – 13.6V), Δt = 5ms, and t

so, V

OVERSHOOT

= ΔV/Δt • t

= 3.36V.

DELAY

DELAY

= 220μs,

I f l e ss de la y, a nd th us le s s o ve rs ho o t, is de si re d, a n a c t i ve

turn-off circuit can reduce the delay from OVGATE to the

gates of M1 and M2 to a few microseconds.

Conclusion

The LT3480 high volt age step-down regul ator and LTC40 98

Li-Ion/Polymer battery charger, combined with a few

extern al components, produce a robust high per formance

Li-Ion charger suitable for port able electronics plugged into

an automotive power source and maintain compatibility

with USB power. The circuit provides all the functionality

that customer s expect, along with volt age protection from

battery reversal and load dump transients.

TRACE 1 = OVGATE

10V/DIV

TRACE 2 = HVBUCK

5V/DIV

TRACE 3 = V

IN

20V/DIV

TRACE 4 = HVIN

50V/DIV

200ms/DIV

DN464 F02

Figure 2. Overvoltage Protection Through

Input Transients per ISO7637 Standards

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

TRACE 1 = OVGATE

10V/DIV

TRACE 2 = HVBUCK

5V/DIV

TRACE 3 = V

IN

20V/DIV

TRACE 4 = HVIN

50V/DIV

2ms/DIV

DN464 F03

Figure 3. Closeup of Figure 2 Waveforms

Showing Overshoot on HVIN

For applications help,

call (978) 656-4700, Ext. 3752

dn464fa LT/TP 0509 REV A 155K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2009

Loading...

Loading...