Switching USB Power Manager with PowerPath Control Offers

Fastest Charge Time with Lowest Heat – Design Note 415

Dave Simmons

Introduction

Lithium-Ion and Lithium Polymer batteries are common

in portable consumer products because of their relatively

high energy density—they provide more capacity than

other available chemistries within given size and weight

constraints. USB battery charging is also becoming

commonplace, as many portable devices require frequent

interfacing with a PC for data transfer.

A s p o r t a b l e pr o d u c t s b e c o me m o r e c o m p le x , t h e n e e d f o r

higher capacit y batteries increases, with a corresponding

need for more adv anced batter y chargers. Lar ger batteries

require either higher charging current or additional time

to charge to their full capacity. Most consumers look for

shorter charge times, so increasing the charge current

seems obviously pre ferable, but increasing charge curren t

presents two major problems. First, with a linear charger,

increased current creates additional power dissipation

(i.e., heat). Second, the charger must limit the current

drawn from the 5V USB bus to either 100mA (500mW)

or 500mA (2.5W) depending on the mode that the host

controller has negotiated.

TO USB

OR WALL

ADAPTER

V

BUS

11

/N

I

SWITCH

PWM AND

GATE DRIVE

PowerPathTM Controllers Deliver More Power to the

System Load

There are two methods commonly used to extract power

from a USB port. The fi rst method uses a current limited

battery charger directly between the USB port and the

battery. This is referred to as a Battery Fed System

because the system load is powered directly from the

• V

battery. Available power is given by I

is the only volt age available to the system load. When

V

BAT

USB

because

BAT

the battery is low, nearly half of the available power can

be lost within the linear battery charger element. In low

battery voltage protection mode, as little as 5% of the

available power may be usable.

The second method develops an intermediate voltage

between the USB port and the battery. This intermediate voltage bus topology is referred to as a PowerPath

System. In PowerPath ICs, a current limited switch is

placed between the USB port and the intermediate volt-

, LT, LTC, LTM are registered trademarks of Linear Technology Corporation.

PowerPath is a trademark of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

SW

12

V

OUT

10

SYSTEM LOAD

3.5V TO (BAT + 0.3V)

05/07/415

2

CLPROG

–

+

1.188V 3.6V

AVERAGE INPUT

CURRENT LIMIT

CONTROLLER

AVERAGE OUTPUT

VOLTAGE LIMIT

CONTROLLER

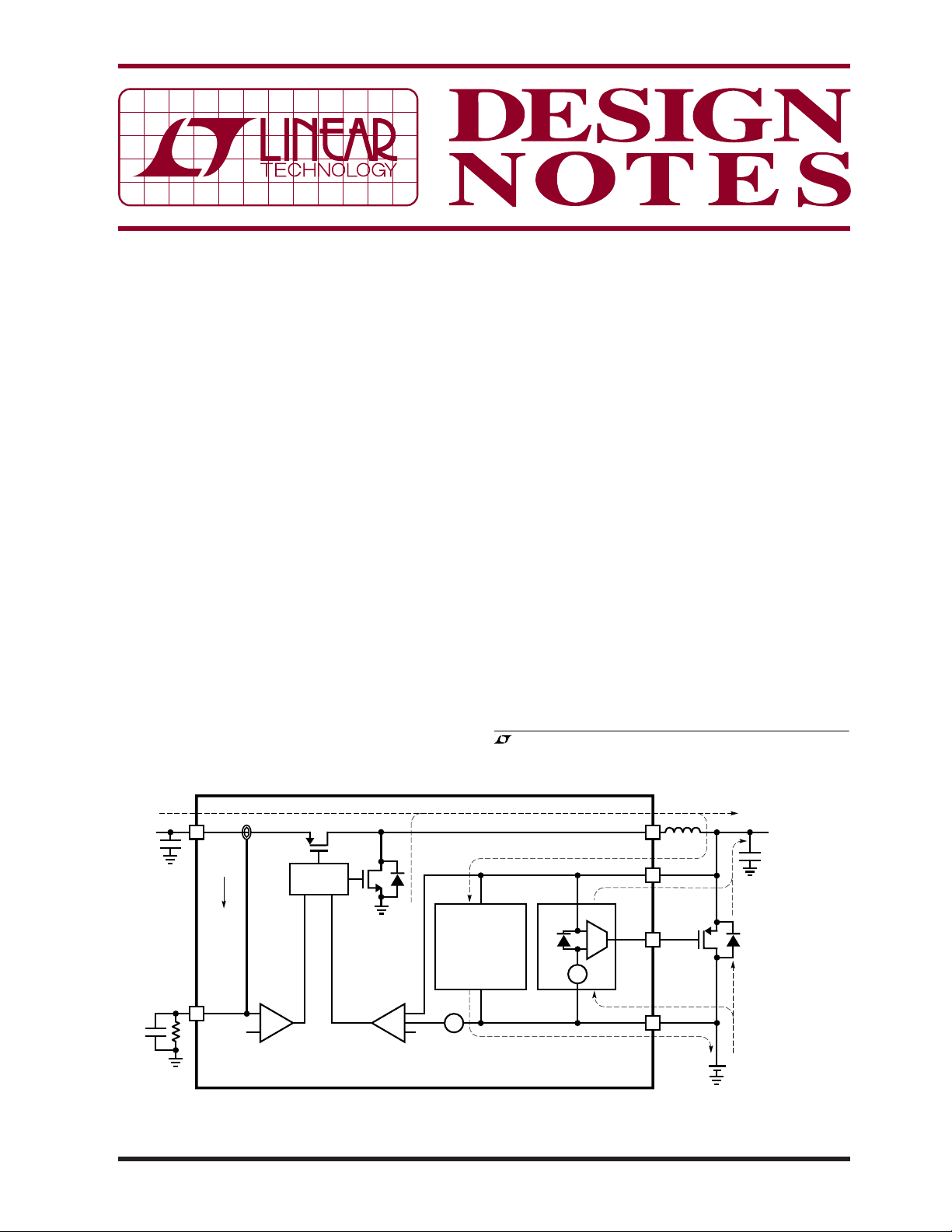

Figure 1. LTC4088 PowerPath Topology

–

+

+

CONSTANT CURRENT

CONSTANT VOLTAGE

BATTERY CHARGER

0.3V

+

–

IDEAL

DIODE

0V

15mV

OPTIONAL

+

EXTERNAL

IDEAL DIODE

PMOS

SINGLE CELL

Li-Ion

+

GATE

BAT

8

9

DN415 F01

–

–

+

age. The intermediate voltage, V

, then powers both

OUT

a linear battery charger as well as the entire portable

product. By using the intermediate voltage bus topology,

the battery is decoupled from the system load and charging can be carried out opportunistically. During charging

with a PowerPath system, the full 2.5W from the USB

port is made available to the system load as long as the

input current limit has not been exceeded. In this case

is just under the input voltage (5V for example).

V

OUT

However, since the battery voltage is much lower than

the 5V input, signifi cant power is still lost to the linear

battery charger element.

LTC4088 Makes Charging More Effi cient

The LTC®4088 replaces the current limited switch in traditional PowerPath systems with a 2.25MHz buck mode

synchronous switching regulator, as shown in Figure 1.

The intermediate voltage, V

, is regulated to just above

OUT

the battery voltage. Because power is conserved in a

switching regulator, the available output current is higher

than the input current.

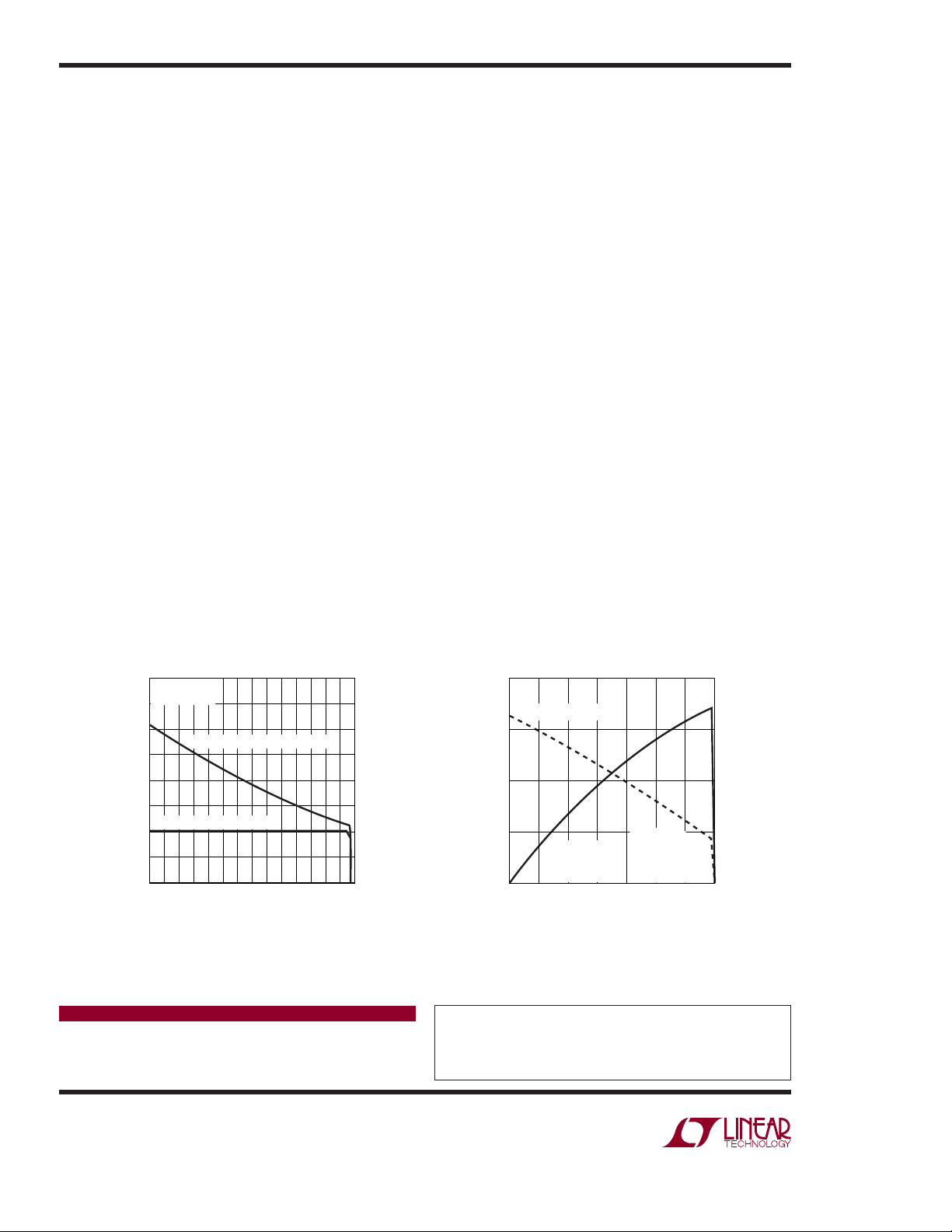

LTC4088 Reduces USB Charge Time

This additional current can be used to power the portable

product and charge the battery more quickly. Figure 2

shows the typical improvement in char ge current versus a

linear charger when powered from a 500mA USB port.

LTC4088 Eases Thermal Constraints

The second benefi t of the switching regulator is heat

reduction. Power lost by ineffi cient charging can cause

0.80

V

= 5V

BUS

= 500mA

I

BUS

0.75

0.70

0.65

0.60

CURRENT (A)

0.55

0.50

0.45

0.40

2.8

SWITCHING CHARGE CURRENT

LINEAR CHARGE CURRENT

3.0 3.2 3.6

3.4

V

BAT

3.8 4.0 4.2

DN415 F02

the external case of a portable product to become uncomfortably warm, and in extreme cases, it can cause

thermal limiting of the battery charger. Figure 3 shows

the typical effi ciency and power savings of the LTC4088

relative to a linear charger when connected to a 500mA

USB port.

The LTC4088 also includes a mode designed for use with

AC powered wall adapters, in which the maximum input

current is limited to 1A. Available current to the system

load and battery charger ranges somewhere between 1A

and 1.8A, depending on the battery voltage. Many higher

capacity batteries are capable of charging at these higher

rates, but with a volt or more difference between the wall

adapter and the battery, the accompanying dissipative

heating cannot be tolerated. Until now, these applications

simply had to settle for a lower than optimal charge rate,

and accompanying longer charge time.

Conclusion

The LTC4088 offers a dramatic advancement in battery

charging and power path management technology, with

its reduction in both heat generation and battery charge

time. Designed specifi cally for portable applications, its

high switching frequency and internal compensation

require only a small inductor and output capacitor. Only

the LTC4088’s unique topology of a buck mode switching

regulator working in tandem with a linear battery charger

can give this unparalleled performance.

92

POWER SAVED (W)

90

88

86

BATTERY CHARGE EFFICIENCY (%)

84

BATTERY

CHARGE

EFFICIENCY (%)

2.8

3.0 3.2 3.4 3.6

BAT (V)

V

= 5V

BUS

500mA MODE

= 2.94k

R

CLPROG

= 1k

R

PROG

3.8 4.0 4.2

DN415 F03

0.8

0.6

POWER SAVED (W)

0.4

0.2

0

Figure 2. Typical Charge Current for LTC4088 vs

Linear Charger When Powered from a 500mA USB Port

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

●

(408) 432-1900

FAX: (408) 434-0507 ● www.linear.com

Figure 3. Battery Charger Effi ciency and

Power Savings Relative to a Linear

Charger When Charging from a USB Port

For applications help,

call (408) 432-1900, Ext. 2364

dn415f LT/TP 0507 409K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...