FEATURES

■

Complete Fast Charger Controller for Single,

2-, 3- or 4-Series Cell NiMH/NiCd Batteries

■

No Firmware or Microcontroller Required

■

Termination by –∆V, Maximum Voltage or

Maximum Time

■

No Sense Resistor or Blocking Diode Required

■

Automatic Recharge Keeps Batteries Charged

■

Programmable Fast Charge Current: 0.4A to 2A

■

Accurate Charge Current: ±5% at 2A

■

Fast Charge Current Programmable Beyond 2A with

External Sense Resistor

■

Automatic Detection of Battery

■

Precharge for Heavily Discharged Batteries

■

Optional Temperature Qualified Charging

■

Charge and AC Present Status Outputs Can Drive LED

■

Automatic Sleep Mode with Input Supply Removal

■

Negligible Battery Drain in Sleep Mode: <1µA

■

Manual Shutdown

■

Input Supply Range: 4.5V to 10V

■

Available in 16-Lead DFN and TSSOP Packages

U

APPLICATIO S

■

Portable Computers, Cellular Phones and PDAs

■

Medical Equipment

■

Charging Docks and Cradles

■

Portable Consumer Electronics

LTC4060

Standalone Linear NiMH/NiCd

Fast Battery Charger

U

DESCRIPTIO

The LTC®4060 is a complete fast charging system for NiMH

or NiCd batteries. Just a few external components are

needed to design a standalone linear charging system.

An external PNP transistor provides charge current that is

user programmable with a resistor. A small external capacitor sets the maximum charge time. No external current

sense resistor is needed, and no blocking diode is required.

The IC automatically senses the DC input supply and battery insertion or removal. Heavily discharged batteries are

initially charged at a C/5 rate before a fast charge is applied.

Fast charge is terminated using the – ∆V detection method.

Backup termination consists of a programmable timer and

battery overvoltage detector. An optional external NTC thermistor can be used for temperature-based qualification of

charging. An optional programmable recharge feature automatically recharges batteries after discharge.

Manual shutdown is accomplished with the SHDN pin, while

removing input power automatically puts the LTC4060 into

sleep mode. During shutdown or sleep mode, battery drain

is <1µA.

The LTC4060 is available in both low profile (0.75mm) 16pin 5mm × 3mm DFN and 16-lead TSSOP packages. Both

feature exposed metal die mount pads for optimum thermal performance.

, LTC and LT are registered trademarks of Linear Technology Corporation.

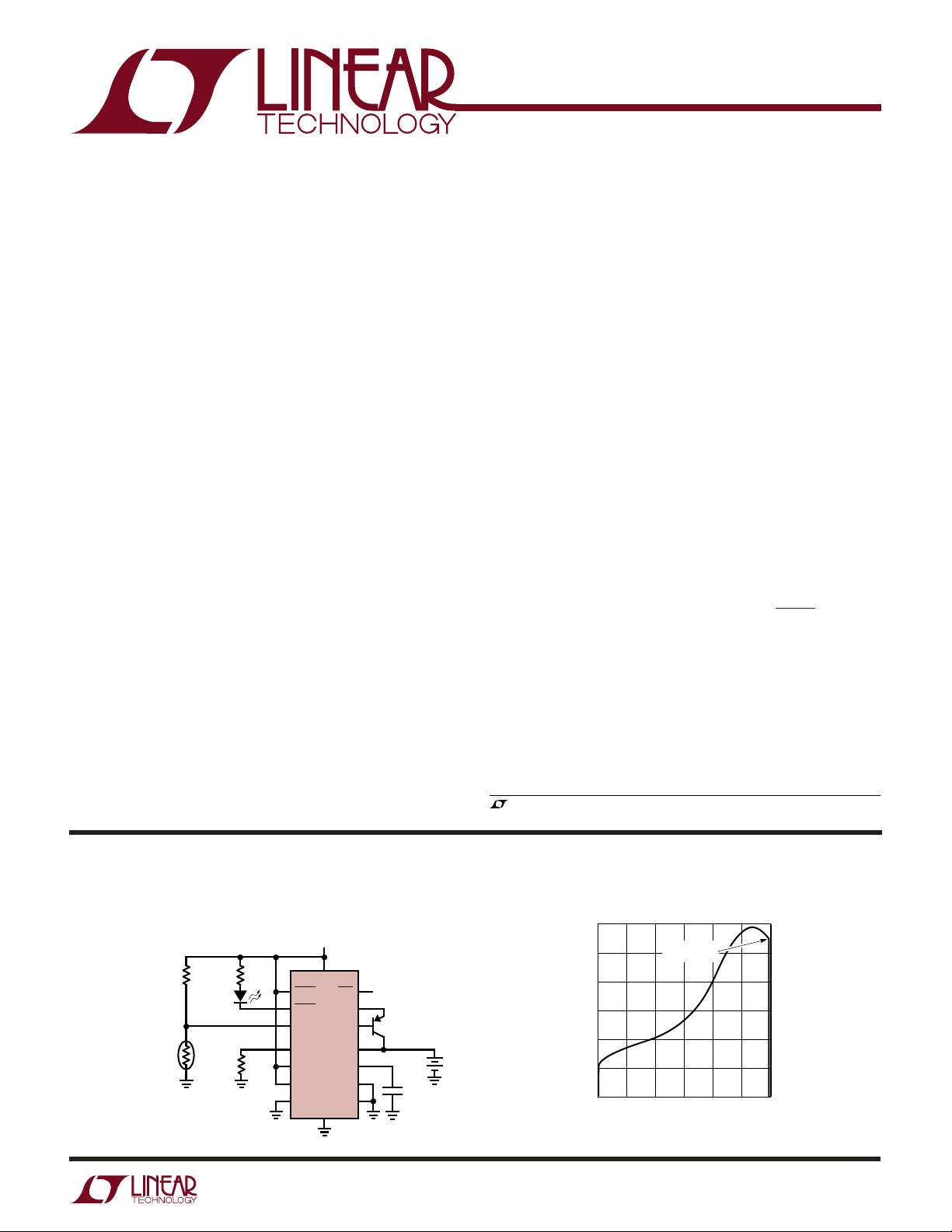

TYPICAL APPLICATIO

2-Cell, 2A Standalone NiMH Fast Charger with

Optional Thermistor and Charge Indicator

330Ω

“CHARGE”

NTC

698Ω

SHDN

CHRG

NTC

PROG

ARCT

SEL0

SEL1

U

V

IN =

V

CC

SENSE

LTC4060

PAUSE

GND

5V

ACP

DRIVE

BAT

TIMER

CHEM

1.5nF

4060 TA01

+

NiMH

BATTERY

2-Cell NiMH Charging Profile

3.40

–∆V

TERMINATION

3.30

3.20

BATTERY VOLTAGE (V)

3.10

0

10 20 30 40

CHARGE TIME (MINUTES)

50

60

4060 TA01b

4060f

1

LTC4060

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VCC to GND ............................................... –0.3V to 11V

Input Voltage

SHDN, NTC, SEL0, SEL1, PROG, ARCT,

BAT, CHEM, TIMER, PAUSE ...... –0.3V to VCC + 0.3V

Output Voltage

CHRG, ACP, DRIVE ................... –0.3V to VCC + 0.3V

Output Current (SENSE) ...................................... –2.2A

Short-Circuit Duration (DRIVE) ...................... Indefinite

U

W

U

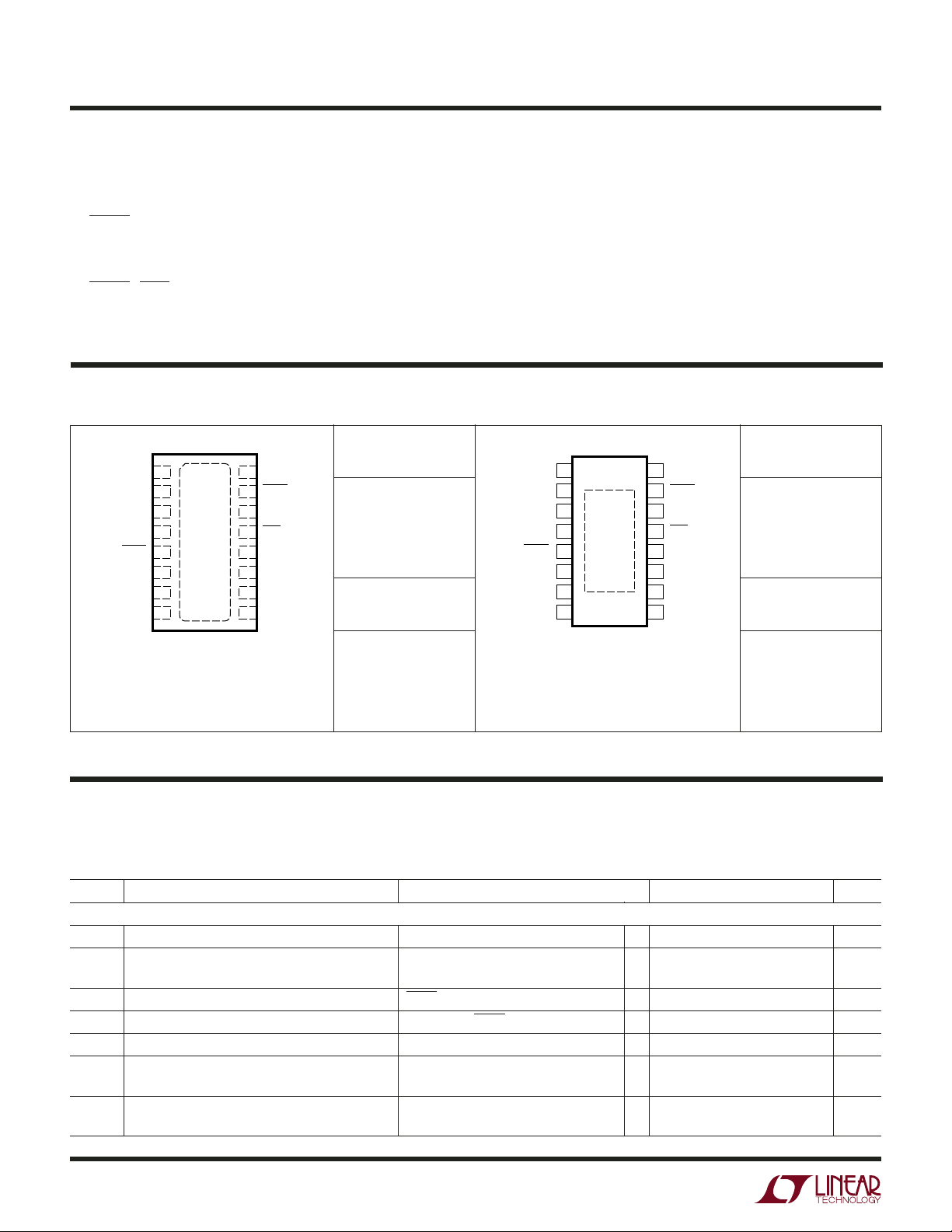

PACKAGE/ORDER INFORMATION

TOP VIEW

DRIVE

1

BAT

2

SENSE

3

TIMER

4

SHDN

5

PAUSE

6

PROG

7

ARCT

8

DHC16 PACKAGE

16-LEAD (5mm × 3mm) PLASTIC DFN

T

= 125°C, θJA = 37°C/W

JMAX

EXPOSED PAD (PIN 17) IS GND

MUST BE SOLDERED TO PCB TO OBTAIN

= 37°C/W OTHERWISE θJA = 140°C

θ

JA

16

GND

15

CHRG

14

V

CC

ACP

13

17

CHEM

12

NTC

11

SEL1

10

SEL0

9

ORDER PART

NUMBER

LTC4060EDHC

DHC PART

MARKING

4060

Operating Ambient Temperature Range

(Note 2) ............................................. – 40°C to 85°C

Operating Junction Temperature (Note 3) ........... 125°C

Storage Temperature Range

TSSOP Package ............................... – 65°C to 150°C

DFN Package .................................... –65°C to 125°C

Lead Temperature (Soldering, 10 sec)

TSSOP Package ................................................ 300°C

TOP VIEW

1

DRIVE

2

BAT

3

SENSE

4

TIMER

SHDN

PAUSE

PROG

ARCT

16-LEAD PLASTIC TSSOP

T

JMAX

EXPOSED PAD (PIN 17) IS GND

MUST BE SOLDERED TO PCB TO OBTAIN

θJA = 37°C/W OTHERWISE θJA = 135°C

17

5

6

7

8

FE PACKAGE

= 125°C, θJA = 37°C/W

GND

16

CHRG

15

V

14

CC

ACP

13

CHEM

12

NTC

11

SEL1

10

SEL0

9

ORDER PART

NUMBER

LTC4060EFE

FE PART

MARKING

4060EFE

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, V

The ● indicates specifications which apply over the full operating

= 2.8V, GND = 0V unless otherwise specified. All

BAT

currents into the device pins are positive and all currents out of the device pins are negative. All voltages are referenced to GND

unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VCC Supply

V

I

I

I

I

V

V

CC

SD

BSD

BSL

CC

UVI1

UVD1

Operating Voltage Range (Note 4) ● 4.50 10 V

VCC Supply Current (Note 9) I

= 2mA (R

PROG

PAUSE = V

CC

= 698Ω), 2.9 4.3 mA

PROG

VCC Supply Shutdown Current SHDN = 0V 250 325 µA

Battery Pin Leakage Current in Shutdown (Note 5) V

Battery Pin Leakage Current in Sleep (Note 6) VCC = 0V, V

= 2.8V, SHDN = 0V –1 0 1 µA

BAT

= 5.6V –1 0 1 µA

BAT

Undervoltage Lockout Exit Threshold SEL0 = 0, SEL1 = 0 and SEL0 = VCC, ● 4.25 4.36 4.47 V

SEL1 = 0, V

Increasing

CC

Undervoltage Lockout Entry Threshold SEL0 = 0, SEL1 = 0 and SEL0 = VCC, ● 4.15 4.26 4.37 V

SEL1 = 0, V

Decreasing

CC

4060f

2

LTC4060

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● indicates specifications which apply over the full operating

= 25°C. VCC = 5V, V

A

= 2.8V, GND = 0V unless otherwise specified. All

BAT

currents into the device pins are positive and all currents out of the device pins are negative. All voltages are referenced to GND

unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

UVI2

V

UVD2

V

UVI3

V

UVD3

V

UVH

Charging Performance

I

FCH

I

FCL

I

PCH

I

PCL

I

BRD

V

BR

V

BRH

V

BOV

V

BOVH

V

FCQ

V

FCQH

V

IDT

V

IDTH

V

MDV

V

PROG

V

ART

V

ARDT

V

ARH

V

ARDEF

V

ARDIS

I

ARL

V

CLD

V

CLDH

V

HTI

Undervoltage Lockout Exit Threshold SEL0 = 0, SEL1 = VCC, VCC Increasing ● 6.67 6.81 6.95 V

Undervoltage Lockout Entry Threshold SEL0 = 0, SEL1 = VCC, VCC Decreasing ● 6.57 6.71 6.85 V

Undervoltage Lockout Exit Threshold SEL0 = VCC, SEL1 = VCC, VCC Increasing ● 8.28 8.47 8.65 V

Undervoltage Lockout Entry Threshold SEL0 = VCC, SEL1 = VCC, VCC Decreasing ● 8.18 8.37 8.55 V

Undervoltage Lockout Hysteresis For All SEL0, SEL1 Options 100 mV

High Fast Charge Current (Notes 7, 10) R

Low Fast Charge Current (Note 7) R

High Precharge Current (Note 7) R

Low Precharge Current (Note 7) R

Battery Removal Detection Bias Current 4.5V < VCC < 10V, V

Battery Removal Threshold Voltage (Note 8) V

Battery Removal Threshold Hysteresis Voltage V

= 698Ω, 5V < VCC < 10V ● 1.9 2 2.1 A

PROG

= 3480Ω, 4.5V < VCC < 10V ● 0.35 0.4 0.45 A

PROG

= 698Ω, 4.5V < VCC < 10V 320 400 480 mA

PROG

= 3480Ω, 4.5V < VCC < 10V 40 80 120 mA

PROG

= VCC – 0.4V ● –450 –300 –160 µA

BAT

Increasing, 4.5V < VCC < 10V ● 1.95 2.05 2.15 V

CELL

Decreasing 50 mV

CELL

(Note 8)

Battery Overvoltage Threshold (Note 8) V

Battery Overvoltage Threshold Hysteresis (Note 8) V

Fast Charge Qualification Threshold Voltage V

Increasing, 4.5V < VCC < 10V ● 1.85 1.95 2.05 V

CELL

Decreasing 50 mV

CELL

Increasing, 4.5V < VCC < 10V 840 900 960 mV

CELL

(Note 8)

Fast Charge Qualification Threshold Hysteresis V

Decreasing 50 mV

CELL

Voltage (Note 8)

Initial Delay Hold-Off Threshold Voltage (Note 8) V

Initial Delay Hold-Off Threshold Hysteresis Voltage V

Increasing, 4.5V < VCC < 10V 1.24 1.3 1.36 V

CELL

Decreasing 50 mV

CELL

(Note 8)

–∆V Termination (Note 8) CHEM = VCC (NiCd) ● 11 16 21 mV

CHEM = 0V (NiMH)

Program Pin Voltage 4.5V < VCC < 10V, R

= 635Ω ● 1.45 1.5 1.54 V

PROG

● 5814mV

and 3480Ω

Automatic Recharge Programmed Threshold V

Voltage Accuracy (Note 8) 4.5V < V

Automatic Recharge Default Threshold Voltage V

Accuracy (Note 8) 4.5V < V

Automatic Recharge Threshold Voltage Hysteresis V

Decreasing, V

CELL

CELL

CELL

< 10V

CC

Decreasing, V

< 10V

CC

Increasing 50 mV

= 1.1V, ● 1.065 1.1 1.135 V

ARCT

= VCC, ● 1.235 1.3 1.365 V

ARCT

(Note 8)

Automatic Recharge Pin Default Enable Threshold V

CC

V

CC

Voltage – 0.8 – 0.2

Automatic Recharge Pin Disable Threshold 250 650 mV

Voltage

Automatic Recharge Pin Pull-Down Current V

NTC Pin Cold Threshold Voltage V

NTC Pin Cold Threshold Hysteresis Voltage V

NTC Pin Hot Charge Initiation Threshold Voltage V

= 1.3V ● 0.15 1.5 µA

ARCT

Decreasing, 4.5V < VCC < 10V ● 0.83 • 0.86 • 0.89 • V

NTC

Increasing 150 mV

NTC

Decreasing, 4.5V < VCC < 10V ● 0.47 • 0.5 • 0.53 • V

NTC

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

4060f

V

3

LTC4060

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● indicates specifications which apply over the full operating

= 25°C. VCC = 5V, V

A

= 2.8V, GND = 0V unless otherwise specified. All

BAT

currents into the device pins are positive and all currents out of the device pins are negative. All voltages are referenced to GND

unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

HTIH

V

HTC

V

HTCH

V

NDIS

I

NL

t

ACC

Output Drivers

I

DRV

R

DRV

V

OL

I

OH

Control Inputs

V

IT

V

ITH

I

IPD

I

IPU

NTC Pin Hot Charge Initiation Hysteresis Voltage V

NTC Pin Hot Charge Cutoff Threshold Voltage V

NTC Pin Hot Charge Cutoff Hysteresis Voltage V

Increasing 100 mV

NTC

Decreasing, 4.5V ≤ VCC ≤ 10V ● 0.37 • 0.4 • 0.43 • V

NTC

Increasing 100 mV

NTC

V

CC

V

CC

V

CC

NTC Pin Disable Threshold Voltage 25 250 mV

NTC Pin Pull-Down Current V

Timer Accuracy R

Drive Pin Sink Current V

Drive Pin Resistance to V

CC

ACP, CHRG Output Pins Low Voltage I

ACP, CHRG Output Pins High Leakage Current Outputs Inactive, V

= 2.5V ● 0.15 1.5 µA

NTC

= 698Ω, C

PROG

= 3480Ω, C

R

PROG

= 4V ● 40 70 120 mA

DRIVE

V

= 4V, Not Charging 4700 Ω

DRIVE

= I

ACP

= 10mA 0.8 V

CHRG

= 1.2nF and –15 0 15 %

TIMER

= 470pF

TIMER

= V

CHRG

ACP

= V

CC

–2 2 µA

SHDN, SEL0, SEL1, CHEM, PAUSE Pins Digital VCC = 10V 350 650 mV

Input Threshold Voltage

SHDN, SEL0, SEL1, CHEM, PAUSE Pins Digital 50 mV

Input Hysteresis Voltage

SHDN, SEL0, SEL1, CHEM Pins Digital Input VCC = 10V, VIN = V

CC

0.4 2 µA

Pull-Down Current

PAUSE Pin Digital Input Pull-Up Current VIN = GND –2 –0.4 µA

Note 1: Absolute Maximum Ratings only indicate limits for survivability.

Operating the device beyond these limits may result in permanent damage.

Continuous or extended application of these maximum levels may

adversely affect device reliability.

Note 2: The LTC4060 is guaranteed to meet performance specifications

from 0°C to 70°C ambient temperature range and 0°C to 85°C junction

temperature range. Specifications over the –40°C to 85°C operating

ambient temperature range are assured by design, characterization and

correlation with statistical process controls.

Note 3: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Overtemperature protection is activated at a temperature of approximately 145°C,

which is above the specified maximum operating junction temperature.

Continuous operation above the specified maximum operation temperature

may result in device degradation or failure. Operating junction temperature

(in °C) is calculated from the ambient temperature TA and the average

T

J

power dissipation P

TJ = TA + θ

Note 4: Short duration drops below the minimum V

(in watts) by the formula:

D

• P

JA

D

specification of

CC

several microseconds or less are ignored by the undervoltage detection

circuit.

Note 5: Assumes that the external PNP pass transistor has negligible B-C

reverse leakage current when the collector is biased at 2.8V (V

charged cells in series) and the base is biased at V

CC

.

BAT

for two

Note 6: Assumes that the external PNP pass transistor has negligible B-E

reverse leakage current when the emitter is biased at 0V (V

base is biased at 5.6V (V

for four charged cells in series).

BAT

) and the

CC

Note 7: The charge current specified is the regulated current through the

internal current sense resistor that flows into the external PNP pass

transistor’s emitter. Actual battery charging current is slightly less and

depends upon PNP alpha.

Note 8: Given as a per cell voltage (V

/Number of Cells).

BAT

Note 9: Supply current includes the current programming resistor current

of 2mA. The charger is paused and not charging the battery.

Note 10: The minimum V

supply is set at 5V during this test to

CC

compensate for voltage drops due to test socket contact resistance and 2A

of current. This ensures that the supply voltage delivered to the device

under test does not fall below the UVLO entry threshold. Specification at

the minimum V

of 4.5V is assured by design and characterization.

CC

4060f

4

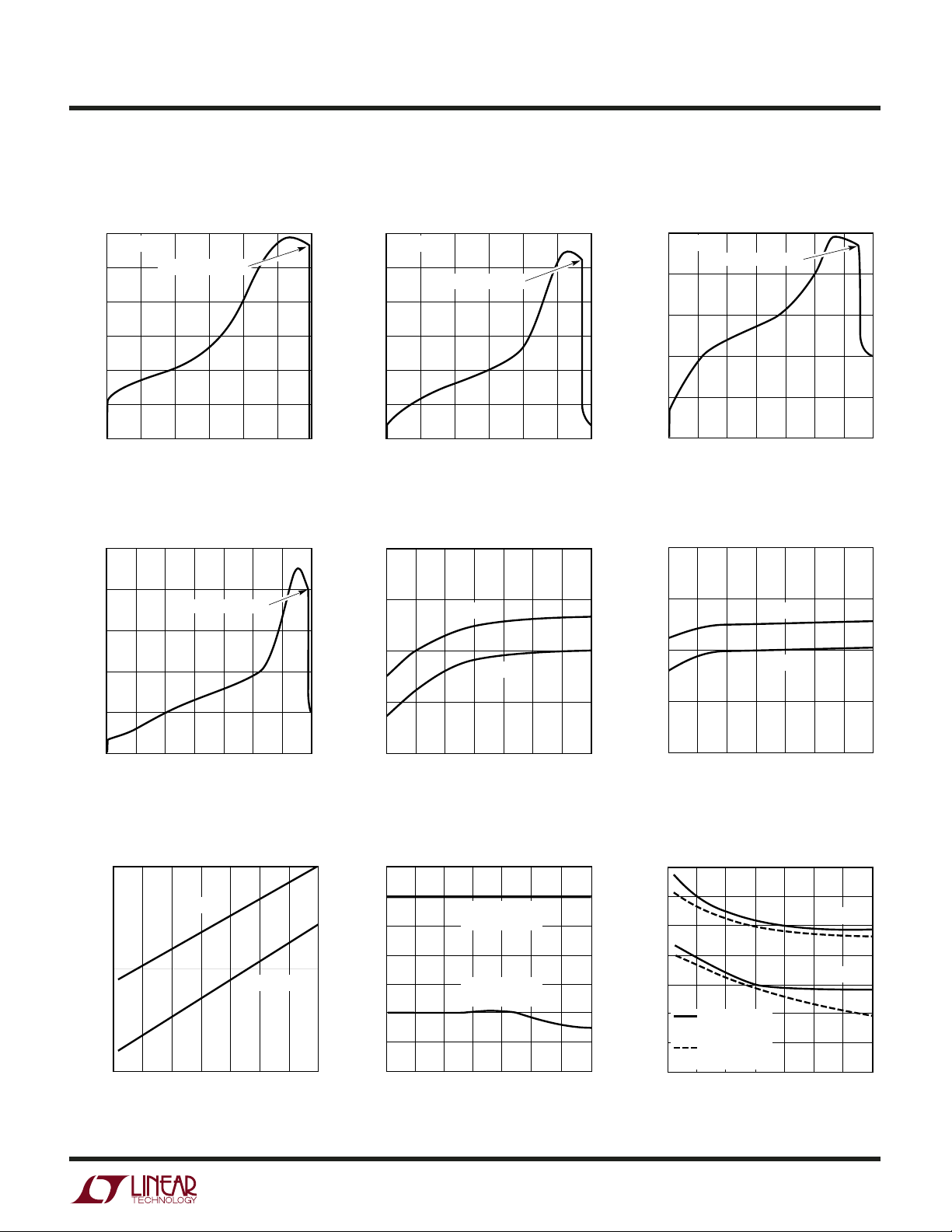

UW

TEMPERATURE (°C)

–50

0.5

1.0

1.7

25 75

4060 G09

0

–0.5

–25 0

50 100 125

–1.0

–1.5

1.5

ERROR (%)

VCC = 10V

VCC = 4.5V

R

PROG

= 3480Ω

C

TIMER

= 470pF

R

PROG

= 698Ω

C

TIMER

= 1.2nF

TYPICAL PERFOR A CE CHARACTERISTICS

LTC4060

NiMH Battery Charging

Characteristics at 1C Rate

1.70

TA = 25°C

–∆V TERMINATION

1.65

1.60

CELL VOLTAGE (V)

1.55

0

10 20 30 40

CHARGE TIME (MINUTES)

NiCd Battery Charging

Characteristics at C/2 Rate

1.65

1.60

–∆V TERMINATION

1.55

1.50

CELL VOTLAGE (V)

1.45

NiCd Battery Charging

Characteristics at 1C Rate

1.7

TA = 25°C

–∆V TERMINATION

1.6

1.5

CELL VOLTAGE (V)

1.4

0

50

60

4060 G01

10 20 30 40

CHARGE TIME (MINUTES)

I

vs Temperature and

FCH

50

60

4060 G02

Supply Voltage

2.010

2.005

(A)

2.000

FCH

I

1.995

VCC = 10V

VCC = 4.5V

NiMH Battery Charging

Characteristics at C/2 Rate

1.60

TA = 25°C

1.55

1.50

1.45

CELL VOTLAGE (V)

1.40

1.35

020

I

–∆V TERMINATION

60

40

CHARGE TIME (MINUTES)

vs Temperature and

FCL

Supply Voltage

402

401

(mA)

400

FCL

I

399

80

VCC = 10V

VCC = 4.5V

100

120

140

4060 G03

1.40

–260

(µA)

–300

BRD

I

–340

020

–50

60

40

CHARGE TIME (MINUTES)

I

vs Temperature and

BRD

Supply Voltage

VCC = 10V

–25 0 25 50

TEMPERATURE (°C)

80

100

120

4060 G04

VCC = 4.5V

75 100 125

4060 G07

140

1.990

–50

–25 0 25 50

V

MDV

Supply Voltage

18

16

14

12

(mV)

MDV

10

V

8

6

4

–50

–25 0

TEMPERATURE (°C)

75 100 125

vs Temperature and

NiCd

4.5V ≤ V

4.5V ≤ V

TEMPERATURE (°C)

≤ 10V

CC

NiMH

≤ 10V

CC

50 100 125

25 75

4060 G05

4060 G08

398

–50

–25 0 25 50

t

vs Temperature and

ACC

Supply Voltage

TEMPERATURE (°C)

75 100 125

4060 G06

4060f

5

LTC4060

U

UU

PI FU CTIO S

DRIVE (Pin 1): Base Drive Output for the External PNP

Pass Transistor. Provides a controlled sink current that

drives the base of the PNP. This pin has current limit

protection for the LTC4060.

BAT (Pin 2): Battery Voltage Sense Input Pin. The LTC4060

uses the voltage on this pin to monitor battery voltage and

control the battery current during charging. An internal

resistor divider is connected to this pin which is disconnected when in shutdown or when no power is applied to

VCC.

SENSE (Pin 3): Charge Current Sense Node Input. Current

from V

tor and reappears at the SENSE pin to supply current to the

external PNP emitter. The PNP collector provides charge

current directly to the battery.

TIMER (Pin 4): Charge Timer Input. A capacitor connected

between TIMER and GND along with a resistor connected

from PROG to GND programs the charge cycle timing

limits.

SHDN (Pin 5): Active Low Shutdown Control Logic Input.

When pulled low, charging stops and the LTC4060 supply

current is minimized.

PAUSE (Pin 6): Pause Enable Logic Input. The charger can

be paused, turning off the charge current, disabling termination and stopping the timer when this pin is high. A low

level will resume the charging process.

PROG (Pin 7): Charge Current Programming Input. Provides a virtual reference of 1.5V for an external resistor

(R

PROG

battery charge current. The fast charge current will be 930

times the current through this resistor. This voltage is also

usable as system voltage reference.

passes through the internal current sense resis-

CC

) tied between this pin and GND that programs the

SEL0, SEL1 (Pins 9, 10): Number of Cells Selection Logic

Input. For single cell, connect both pins to GND. For two

cells, connect SEL1 to GND and SEL0 to V

cells, SEL1 connects to V

cells, connect both pins to V

NTC (Pin 11): Battery Temperature Input. An external NTC

thermistor network may be connected to NTC to provide

temperature-based charge qualification. Connecting NTC

to GND inhibits this function.

CHEM (Pin 12): Battery Chemistry Selection Logic Input.

When connected to a high level NiCd fast charge –∆V

termination parameters are used. A low level selects NiMH

parameters.

ACP (Pin 13): Open-Drain Power Supply Status Output.

When V

old, the ACP pin will pull to ground. Otherwise the pin is

high impedance. This output is capable of driving an LED.

VCC (Pin 14): Power Input. This pin can be bypassed to

ground with a capacitance of 1µF.

CHRG (Pin 15): Open-Drain Charge Indicator Status Output. The LTC4060 indicates it is providing charge to the

battery by driving this pin to GND. If charging is paused or

suspended due to abnormal battery temperature, the pin

remains pulled to GND. Otherwise the pin is high impedance. This output can drive an LED.

GND (Pin 16): Ground. This pin provides a ground for the

internal voltage reference and other circuits. All voltage

thresholds are referenced to this pin.

Exposed Pad (Pin 17): Thermal Connection. Internally

connected to GND. Solder to PCB ground for optimum

thermal performance.

is greater than the undervoltage lockout thresh-

CC

and SEL0 to GND. For four

CC

.

CC

For three

CC.

ARCT (Pin 8): Autorecharge Threshold Programming

Input. When the average cell voltage falls below this

threshold, charging is reinitiated. The voltage on this pin

is conveniently derived by using two series PROG pin

resistors and connecting to their common. Connecting

ARCT to VCC invokes a default threshold of 1.3V. Connecting ARCT to GND inhibits autorecharge.

6

4060f

BLOCK DIAGRA

VOLTAGE

REFERENCE

1.5V

PROG

R

PROG

7

NTC

11

CHRG

15

ACP

13

SHDN

5

PAUSE

6

W

I

OSC

+

–

THERMISTOR

I

I/5

A1

INTERFACE

CURRENT

DIVIDER

I I/5

R1

31.5Ω

–

V

CC

COLD

HOT

CUTOFF

CHARGER STATE

CONTROL LOGIC

I

OSC

14

A2

V

CC

+

R2

0.03Ω

SUPPLY GOOD

OUTPUT DRIVER

CURRENT LIMIT

OVERTEMPERATURE

DETECT

AND

IC

UVLO

A/D

CONVERTER

BATTERY

DETECTOR

SEL0

SEL1

SENSE

DRIVE

I

BRD

BAT

LTC4060

3

1

2

+

GND

16, 17

12

CHEM

10

SEL1

SEL0

9

OSCILLATOR

TIMER

4

C

TIMER

AUTORECHARGE

DETECTOR

ARCT

8

4060 BD

4060f

7

LTC4060

OPERATIO

U

The LTC4060 is a complete linear fast charging system for

NiMH or NiCd batteries. Operation can be understood by

referring to the Block Diagram, State Diagram (Figure 1)

and application circuit (Figure 2). While in the unpowered

sleep mode, the battery is disconnected from any internal

loading. The sleep mode is exited and the shutdown mode

is entered when VCC rises above the UVLO (Undervoltage

Lock Out) exit threshold. The UVLO thresholds are dependent upon the number of series cells programmed by the

SEL0 and SEL1 pins. When shutdown occurs the ACP pin

goes from a high to low impedance state. The shutdown

mode is exited and the charge qualification mode entered

SUPPLY

GOOD

LOW OR NO

SUPPLY

SLEEP

(ACP = 0)

when all of the following conditions are met: 1) there is no

manual shutdown command from SHDN, 2) the battery

overvoltage detector does not detect a battery overvoltage, 3) the battery removal detector detects a battery in

place, 4) pause is inactive and 5) the IC’s junction temperature is normal. Once in the charge qualification mode the

thermistor interface monitors an optional thermistor network to determine if the battery temperature is within

charging limits. If the temperature is found within limits

charging can begin. While charging, the CHRG pin pulls to

GND which can drive an LED.

MANUAL

SHUTDOWN

(SHDN = 0)

BATTERY REMOVED,

SHUTDOWN

BATTERY OVERVOLTAGE,

CHARGE PERIOD TIMED

OUT OR IC TOO HOT

< AUTORECHARGE

V

CELL

THRESHOLD

AUTOMATIC

RECHARGE

–∆V TERMINATION

ADEQUATE SUPPLY

AND CHARGER ENABLED

CHARGE

QUALIFICATION

BATTERY PRESENT AND

TEMPERATURE GOOD

(OPTIONAL)

PRECHARGE

/5)

(I

MAX

ADEQUATE V

TEMPERATURE GOOD

(OPTIONAL)

FAST CHARGE

)

(I

MAX

4060 F01

CELL

AND

8

Figure 1. LTC4060 Basic State Diagram

4060f

OPERATIO

LTC4060

U

The charge current is set with an external current programming resistor connected between the PROG pin and

GND. In the Block Diagram, amplifier A1 will cause a virtual

1.5V to appear on the PROG pin and thus, all of the programming resistor’s current will flow through the N-channel

FET to the current divider. The current divider is controlled

by the charger state control logic to produce a voltage

across R1, appropriate either for precharge (I/5) or for fast

charge (I), depending on the cell voltage. The current divider also produces a constant current I

with an external capacitor tied to the TIMER pin, sets the

Oscillator’s clock frequency. During charging, the external

PNP transistor’s collector will provide the battery charge

current. The PNP’s emitter current flows into the SENSE

pin and through the internal current sense resistor R2

(0.03Ω). This current is slightly more than the collector

current since it includes the base current. Amplifier A2 and

the output driver will drive the base of the external PNP

through the DRIVE pin to force the same reference voltage

that appears across R1 to appear across the R2. The precision ratio between R1 and R2, along with the current

programming resistor, accurately determines the charge

current.

When charging begins, the charger state control logic will

enable precharge of the battery. When the cell voltage

exceeds the fast charge qualification threshold, fast charge

begins. If the cell voltage exceeds the initial delay hold off

threshold voltage just prior to precharge, then the A/D

converter immediately monitors for a –∆V event to

terminate charging while in fast charge. Otherwise, the

fast charge voltage stabilization hold off period must

expire before the A/D converter monitors for a –∆V event

from which to terminate charging. The –∆V magnitude for

termination is selected for either NiMH or NiCd by the

CHEM pin. Should the battery temperature become too hot

or too cold, charging will be suspended by the charger

state control logic until the temperature enters normal

limits. A termination timer puts the charger into shutdown

mode if the programmed time has expired. After charging

has ended, the optional autorecharge detector function

monitors for the battery voltage to drop to either a default

or externally programmed cell voltage before automatically restarting a charge cycle.

, that along

OSC

The SHDN pin can be used to return the charger to a

shutdown and reset state. The PAUSE pin can be used to

pause the charge current and internal clocks for any

interval desired.

Fault conditions, such as overheating of the IC due to

excessive PNP base current drive, are monitored and

limited by the IC overtemperature detection and output

driver and current limit blocks.

When either VCC is removed or manual shutdown is

entered, the charger will draw only tiny leakage currents

from the battery, thus maximizing standby time. With V

removed, the external PNP’s base is connected to the

battery by the charger. In manual shutdown, the base is

connected to VCC by the charger.

Undervoltage Lockout

An internal undervoltage lockout circuit (UVLO) monitors

the input voltage and keeps the charger in the inactive

sleep mode until VCC rises above the undervoltage exit

threshold. The ACP pin is high impedance while in the

sleep mode and becomes low impedance to ground when

in the active mode. The threshold is dependent upon the

number of series cells selected by the SEL0 and SEL1 pins

(see V

table). The UVLO circuit has a built-in hysteresis of 100mV.

The thresholds are chosen to provide a minimum voltage

drop of approximately 600mV between minimum V

BAT at a battery cell voltage of 1.8V. This helps to protect

against excessive saturation in the external power PNP

when the supply voltage is near its minimum. While

inactive the LTC4060 reduces battery current to just a

negligible leakage current (I

Manual Shutdown Control

The LTC4060 can be forced into a low quiescent current

shutdown while VCC is present by applying a low level to

the SHDN pin. In manual shutdown, charging is inhibited,

the internal timer is reset and oscillator disabled, CHRG

status output is high impedance and ACP continues to

provide the correct status. The LTC4060 will draw low current from the supply (ISD), and only a negligible leakage

current is applied to the battery (I

UVI1-3

and V

in the Electrical Characteristics

UVD1-3

).

BSL

). If a high level is

BSD

CC

CC

and

4060f

9

LTC4060

OPERATIO

U

applied to the SHDN pin, shutdown ends and charge qualification is entered.

Charge Qualification

After exiting the sleep or shutdown modes the LTC4060

will check for the presence of a battery and for proper

battery temperature (if a thermistor is used) before initiating charging.

When V

a battery is assumed to be present. Should V

above 1.95V (V

CELL

(V

/Number of Cells) is below 2.05V (VBR),

BAT

) for a time greater than the battery

BOV

CELL

rise

overvoltage event delay shown in the far right column of

Table 1, then a battery overvoltage condition is detected

and charging stops. Once stopped in this way, qualification can be reinitiated after V

(V

BOV

– V

) only by removing and replacing the battery

BOVH

has fallen below 1.9V

CELL

(or replacing the battery if the overvoltage condition is a

result of battery removal), toggling the SHDN pin low to

high or removing and reapplying power to the charger.

If the NTC pin voltage is above the temperature disable

threshold (V

), the LTC4060 verifies that the ther-

NDIS

mistor temperature is between 5°C and 45°C. Charging

will not initiate until these temperature limits are met.

The LTC4060 continues to qualify important voltage and

temperature parameters during all charging states. If V

CC

drops below the undervoltage lockout threshold, sleep

mode is entered.

If the internal die temperature becomes excessive, charging stops and the part enters the shutdown state. Once in

the shutdown state charge qualification can be reinitiated

only when the die temperature drops to normal and then

by removing and replacing the battery or toggling the

SHDN pin low to high or removing and reapplying power

to the charger.

Precharge

The state that is entered when qualified charging begins is

precharge. The CHRG status output is set low and remains

low during both precharge and fast charge. If the voltage

on V

is below the 900mV (V

CELL

) fast charge qualifica-

FCQ

tion voltage, the LTC4060 charges using one-fifth the

maximum programmed charge current. The cell voltage is

continuously checked to determine when the battery is

ready to accept a fast charge. Until this voltage reaches

V

, the LTC4060 remains in precharge.

FCQ

If an external thermistor indicates that the sensed temperature is beyond a range of 5°C to 45°C charging is

suspended, the charge timer is paused and the CHRG

status output remains low. Normal charging resumes

from the previous state when the sensed temperature

rises above 5°C or falls below 45°C.

Fast Charge

When the average cell voltage exceeds V

, the LTC4060

FCQ

transitions from the precharge to the fast charge state and

Table 1. LTC4060 Time Limit Programming Examples

TYPICAL BATTERY CHARGE BATTERY AUTOMATIC

FAST VOLTAGE TIME VOLTAGE RECHARGE UVLO EXIT, BATTERY

FAST CHARGE STABILIZATION LIMIT SAMPLING ENTRY INSERTION/REMOVAL/OVERVOLTAGE,

CHARGE RATE HOLD OFF (t

CURRENT R

2A 698Ω 1nF 1.5 4.6 to 5.7 1.1 15 15 to 31 175 to 260

2A 698Ω 1.5nF 1 6.9 to 8.4 1.6 23 23 to 46 260 to 390

2A 698Ω 1.8nF 0.75 8.4 to 10.3 2 28 28 to 56 320 to 480

2A 698Ω 2.7nF 0.5 12.6 to 15.4 3 42 42 to 84 480 to 720

400mA 3480Ω 180pF 1.5 4.2 to 5.2 1 14 14 to 28 160 to 240

400mA 3480Ω 270pF 1 6.3 to 7.7 1.5 21 21 to 42 240 to 360

400mA 3480Ω 390pF 0.75 8.9 to 11 2.1 30 30 to 60 340 to 510

400mA 3480Ω 560pF 0.5 12.6 to 15.4 3 42 42 to 84 480 to 720

PROGCTIMER

(C) (MINUTES) (HOURS) (SECONDS) (SECONDS) THERMISTOR EVENT DELAYS (ms)

) INTERVAL DELAY FAST CHARGE ENTRY AND

MAX

10

4060f

OPERATIO

LTC4060

U

charging begins at the maximum current set by the

exter

nal programming resistor connected between the

PROG pin and GND.

If an external thermistor indicates sensed temperature is

beyond a range of 5°C to 55°C charging is suspended, the

charge timer is paused and the CHRG status output

remains low. Normal charging resumes from the previous

state when the sensed temperature rises above 5°C or falls

below 45°C. Voltage-based termination (–∆V) is then

reset and immediately enabled. If voltage-based termination was imminent when the temperature limits were

exceeded, charge termination will occur.

Charge Termination

Once fast charge begins and after an initial battery voltage

stabilization hold-off period shown in Table 1, voltagebased termination (–∆V) is enabled. This period is used to

prevent falsely terminating on a –∆V event that can occur

almost immediately after initiating charging on some

heavily discharged or stored batteries. However, if V

was measured to be above 1.3V (V

to the precharge cycle, then a mostly charged battery is

assumed and voltage-based termination (–∆V) is enabled

without delay.

An internal 1.5mV resolution A/D converter measures the

cell voltage after each battery voltage sampling interval

indicated in Table 1. The peak cell voltage is stored and

compared to the current cell voltage. When the cell voltage

has dropped by at least V

CHEM pin) from the peak for four consecutive battery

voltage sampling intervals, charging is terminated.

Back-up termination is provided by the charge time limiter,

whose time limit is indicated in Table 1, and by a battery

overvoltage detector. Once terminated by back-up termination, charge qualification can be reinitiated only by removing and replacing the battery or toggling the SHDN pin low

to high or removing and reapplying power to the charger.

Automatic Recharge

Once charging is complete, the optional programmable

automatic recharge state can be entered. This state, if

(magnitude selected by the

MDV

) immediately prior

IDT

CELL

enabled, will automatically restart the charger from the

charge qualification state without user intervention whenever the battery cell voltage drops below a set level. With

the advent of low memory effect NiMH and improved NiCd

cells an automatic recharge feature is practical and eliminates the need for very slow trickle charging.

The CHRG status output is high impedance in the automatic recharge state until charging begins. If the V

voltage drops below the voltage set on the ARCT pin for at

least the automatic recharge entry delay time as shown in

Table 1, the charge qualification state is entered and

charging will begin anew in fast charge. An easy way of

setting the voltage on the ARCT pin is by using two series

current programming resistors and connecting their common to the ARCT pin as shown in Figure 2. The PROG pin

will provide a constant 1.5V (V

voltage range of the ARCT pin is approximately 0.8V to

1.6V. A preprogrammed recharge threshold of 1.3V (V

is selected when the ARCT pin is connected to V

(V

pin is connected to ground (V

Pause

After charging is initiated, the PAUSE pin may be used to

pause operation at any time. Whenever the voltage on the

PAUSE pin is a logic high, the charge timer and all other

timers pause, charging is stopped and the fast charge termination algorithm is inhibited. The CHRG status output

remains at GND. If voltage-based termination was imminent before pause, charge termination will occur. Otherwise,

when pause ends, the charge timer and all other timers

resume timing, charging restarts and voltage-based termination (–∆V) is reset and immediately enabled. If the battery is removed while the PAUSE pin is a logic high, then

battery removal is detected and shutdown is entered. If the

battery is replaced while the PAUSE pin is a logic high, it

will not be detected until pause is turned off.

For pause periods or a series of periods where the battery

capacity could be significantly depleted, consider using

shutdown instead of pause to avoid having the safety timer

expire before the battery can be fully charged. Shutdown

resets the safety timer.

). Automatic recharge is disabled when the ARCT

ARDEF

). The programmable

PROG

).

ARDIS

CELL

ARDT

)

CC

4060f

11

LTC4060

OPERATIO

U

Battery Chemistry Selection

The desired battery chemistry is selected by programming

the CHEM pin to the proper voltage. When wired to GND,

a set of parameters specific to charging NiMH cells is

selected. When CHEM is connected to VCC, charging is

optimized for NiCd cells. The various charging parameters

are detailed in Table 2.

Cell Selection

The number of series cells is selected using the SEL0 and

SEL1 pins. For one cell, both pins connect to GND. For two

cells, SEL0 connects to VCC and SEL1 to GND. For three

cells, SEL0 connects to GND and SEL1 to VCC. For four

cells, both connect to VCC.

Table 2. LTC4060 Charging Parameters

STATE CHEM CHARGE TIME LIMIT T

Precharge Both t

Fast Charge NiCd t

NiMH t

MAX

MAX

MAX

MIN

5°C45°CI

5°C55°CI

5°C55°CI

T

MAX

Insertion and Removal of Batteries

The LTC4060 automatically senses the insertion or removal of a battery by monitoring the V

pin voltage.

CELL

Either the charge current, or if not charging then an

internal pull-up current (I

), will pull V

BRD

up when the

CELL

battery is removed. When this voltage rises above 2.05V

(VBR) for a time greater than the battery removal event

delay shown in Table 1, the LTC4060 considers the battery

to be absent. Inserting a battery, causing V

below both VBR and 1.95V (V

) for a period longer than

BOV

CELL

to fall

the battery insertion event delay shown in Table 1, results

in the LTC4060 recognizing a battery present and initiates

a completely new charge cycle beginning with charge

qualification. All battery currents are inhibited while in

shutdown.

I

CHRG

MAX

MAX

MAX

TYPICAL TERMINATION CONDITION

/5 V

≥ 0.9V

CELL

–16mV Per Cell After Initial t

–8mV Per Cell After Initial t

MAX

MAX

/12 Delay

/12 Delay

WUUU

APPLICATIO S I FOR ATIO

Programming Charge Current

The battery charge current is set with an external program

resistor connected from the PROG pin to GND. The formula for the battery fast charge current or I

II

=

MAX PROG

()

•

⎜

⎝

R

⎛

=

.

15

PROG

⎞

V

•930

930

⎟

⎠

or

R

PROG

where R

1395

=

I

MAX

is the total resistance from the PROG pin to

PROG

ground. For example, if 1A of fast charge current is

required:

R

PROG

1395

==

A

1

k

14. 1% Resistor

MAX

is:

Under precharge conditions, the current is reduced to

20% of the fast charge value (I

).The LTC4060 is

MAX

designed for a maximum current of 2A. This translates to

a maximum PROG pin current of 2.15mA and a minimum

program resistor of 698Ω. Reduced accuracy at low

current limits the useful fast charge current to a minimum

of approximately 200mA. Errors in the charge current can

be statistically approximated as follows:

One Sigma Error ≅ 7mA

For best stability over temperature and time, 1% metalfilm resistors are recommended. Capacitance on the PROG

pin should be limited to about 75pF to insure adequate AC

phase margin for its amplifier.

Different charge currents can be programmed by various

means such as by switching in different program resistors. A voltage DAC connected through a resistor to the

PROG pin or a current DAC connected in parallel with a

12

4060f

WUUU

APPLICATIO S I FOR ATIO

LTC4060

resistor to the PROG pin can also be used to program

current. Note that this will alter the timer periods unless

alternate TIMER pin capacitors are also programmed

through an analog switch.

The PROG pin provides a reference voltage of 1.5V (V

PROG

)

that may be tapped for system use. Current loading on

PROG is multiplied by 930 and appears as increased I

This may be compensated by adjustment of R

PROG

MAX.

. Total

PROG pin current must be limited to 2.3mA otherwise

absolute maximum ratings will be exceeded. When the

LTC4060 is in the shutdown mode, the PROG pin is forced

to ground potential to save power.

Programming the Timer

All LTC4060 internal timing is derived from the internal

oscillator that is programmed with an external capacitor at

the TIMER pin. The time periods shown in Table 1 scale

directly with the timer period. The programmable safety

timer is used to put a time limit on the entire charge cycle

for the case when charging has not otherwise terminated.

The time limit is programmed by an external capacitor at

the TIMER pin and is also dependent on the current set by

the programming resistor connected to the PROG pin. The

time limit is determined by the following equation:

t

(Hours) = 1.567 • 106 • R

MAX

CF

TIMER

()

=

.• • ()

t Hours

()

MAX

6

R

PROG

PROG

(Ω) • C

Ω1 567 10

TIMER

(F)

Some typical timing values are detailed in Table 1. The

timer begins at the start of a charge cycle. After the timeout occurs, the charge current stops and the CHRG output

assumes a high impedance state to indicate that the

charging has stopped.

Excessively short time-out periods may not allow enough

time for the battery to receive full charge or may result in

premature –∆V termination due to too short a battery

voltage stabilization hold-off period. Excessively long timeout periods may indicate too low a charge current which

may not allow voltage-based termination (–∆V) to work

properly. Time-out limits of less than 0.75 hour for faster

2C charge rates, or more than 3.5 hours for slower C/2

charge rates, are generally not recommended. Consult the

battery manufacturer for recommended periods.

An external timing source can also be used to drive the

TIMER pin for precise or programmed control. The high

level must be between 2.5V and V

and the low level must

CC

be between 0V and 0.25V. Also, the driving source must be

able to overdrive the internal current source and sink

which is 5% of the current through R

PROG

.

Battery Temperature Sensing

Temperature sensing is optional in LTC4060 applications.

To disable temperature qualification of all charging operations, the NTC pin must be wired to ground. A circuit for

temperature sensing using a thermistor with a negative

temperature coefficient (NTC) is shown in Figure 2. Internally derived VCC proportional voltages (V

CLD

, V

HTI

, V

HTC

)

are compared to the voltage on the NTC input pin to test the

temperature thresholds. The battery temperature is measured by placing the thermistor close to the battery pack.

In Figure 2, a common 10k NTC thermistor such as a

Murata NTH4G series NTH4G39A103F can be used. R

HOT

should be a 1% resistor with a value equal to the value of

the chosen NTC thermistor at 45°C (V

NTC

= V

= 0.5 • V

HTI

CC

typ). Another temperature may be chosen to suit the

battery requirements. The LTC4060 will not initiate a

charge cycle or continue with a precharge if the value of the

thermistor falls below 4.42k which is a temperature rising

to approximately 45°C. However, once fast charging is in

progress, it will not be stopped until the thermistor drops

below 3k which is a temperature rising to approximately

55°C (V

NTC

= V

= 0.4 • VCC typ). Once reaching this

HTC

charge cutoff threshold, charging is suspended until the

value of the thermistor rises above approximately 4.8k

(falling temperature) or approximately 43°C (45°C – 2°C

hysteresis at V

= 5V) and then charging is resumed.

CC

Hysteresis avoids possible oscillation about the trip points.

Note that the comparator hysteresis voltages are constant

and when VCC increases the signal level from the thermistor increases thus making the temperature hysteresis

look smaller.

During suspension the charge current is turned off and the

safety timer is frozen. The LTC4060 is also designed to

suspend when the thermistor rises above 34k (falling

4060f

13

LTC4060

WUUU

APPLICATIO S I FOR ATIO

temperature) at approximately 0°C (5°C – 5°C hysteresis

at V

below 27k (rising temperature) which will be approximately 5°C (V

Many thermistors with an R

mately 7 will work. For lower power dissipation higher

values of thermistor resistance can be used. The Murata

NTH4G series offers resistances of up to 100k at 25°C.

It is important that the thermistor be placed in close

contact with the battery and away from the external PNP

pass transistor to avoid excessive temperature errors on

the sensed battery temperature. Furthermore, since VCC is

a high current path into the LTC4060, it is essential to

minimize voltage drops between the VCC supply pin and

the top of R

VCC pin.

Power Requirements

The DC power input to the VCC pin must always be within

proper limits while charging a battery. Voltages beyond

the absolute maximum ratings may damage the charger

and voltages falling below the UVLO entry thresholds, as

programmed by the SEL0 and SEL1 pins, will likely cause

the charger to enter the shutdown state (when the UVLO

exit threshold is exceeded charging will begin anew). While

the LTC4060 is designed to reject 60Hz or 120Hz supply

ripple, certain precautions are required. The instantaneous

ripple voltage must always be within the above mentioned

limits. Ripple voltage seen across the collector-base junction of the external PNP pass transistor will slightly modulate its beta and hence its base current. Since the emitter

current is precisely regulated by the LTC4060, any modulation of base current will appear at the collector. This

slightly modulated battery charge current into a battery

will usually produce an insignificant modulation voltage at

the battery. However, if excessive wire impedance to the

battery from the PNP exists, then it may be helpful to Kelvin

connect the BAT pin to a convenient point closest to the

battery to reduce ripple magnitude entering the LTC4060’s

battery monitoring circuits. The battery ground impedance should also be managed to limit ripple voltage at the

BAT pin. Excessive ripple into the BAT pin may cause the

charger to deviate from specified performance.

= 5V) and then resume when the thermistor falls

CC

= V

NTC

by Kelvin connecting R

HOT

= 0.86 • VCC typ).

CLD

to R

COLD

ratio of approxi-

HOT

directly to the

HOT

VCC Bypass Capacitor

A 1µF capacitor located close to the LTC4060 will usually

provide adequate input bypassing. However, caution must

be exercised when using multilayer ceramic capacitors.

Because of the self-resonance and high Q characteristics

of some types of ceramic capacitors, along with wiring

inductance, high voltage transients can be generated

under some conditions such as connecting or disconnecting a supply input to a hot power source. To reduce the Q

and prevent these transients from exceeding the absolute

maximum voltage rating, consider adding about 1Ω of

resistance in series with the ceramic input capacitor.

BAT Bypass Capacitor

This optional capacitor, connected between BAT and GND,

can be used to help filter excessive contact bounce during

the battery monitoring or charging process. The value will

depend upon the contact bounce open duration, but is typically 10µF. Another purpose of this capacitor is to bypass

transient battery load events that might otherwise disrupt

monitoring or charging. Should the battery connections not

be subject to excessive contact bounce or excessive battery voltage transients, then no BAT pin capacitor is required. The same caution mentioned above for the VCC bypass capacitor applies.

External PNP Transistor

The external PNP pass transistor must have adequate beta

and breakdown voltages, low saturation voltage and sufficient power dissipation capability that may include heat

sinking.

To provide 2A of charge current with the minimum available base current drive of 40mA (I

minimum PNP beta of 50.

The transistor’s collector to emitter breakdown voltage

must be high enough to withstand the difference between

the maximum supply voltage and minimum battery voltage. Almost any transistor will meet this requirement.

Additionally, when no power is supplied to the charger

(V

= 0V and V

IN

breakdown voltage must be high enough to prevent a

leakage path at the maximum battery voltage while not

= 0V), the transistor’s emitter to base

SENSE

min) requires a

DRV

14

4060f

WUUU

APPLICATIO S I FOR ATIO

LTC4060

charging (the DRIVE pin is internally switched to the BAT

pin). Most transistors will meet this requirement as well.

With low supply voltages, the PNP saturation voltage

(V

) becomes important. The V

CESAT

CESAT

must be less

than the minimum supply voltage minus the maximum

voltage drop across the internal current sense resistor and

bond wires (approximately 0.08Ω) and maximum battery

voltage presented to the charger accounting for wire I • R

drops.

V

CESAT

(V) < V

DD(MIN)

– (I

BAT(MAX)

• 0.08Ω + V

BAT(MAX)

)

For example, if it were desired to have a programmed

charge current of 2A with a minimum supply voltage of

4.75V and a maximum battery voltage of 3.6V (2 series

cells at 1.8V each), then the minimum operating V

V

(V) = 4.75 – (2 • 0.08 + 3.6) = 0.99V

CESAT

CESAT

is:

If the PNP transistor cannot achieve the saturation voltage

required, base current will dramatically increase. This is to

be avoided for a number of reasons: DRIVE pin current

may reach current limit resulting in the LTC4060 characteristics going out of specifications, excessive power

dissipation may force the IC into thermal shutdown, or the

battery could discharge because some of the current from

the DRIVE pin could be pulled from the battery through the

forward biased PNP collector base junction.

The actual battery fast charge current (I

) is slightly less

BAT

than the regulated charge current because the charger

senses the emitter current and the battery charge current

will be reduced by the base current. In terms of β (IC/IB)

I

can be calculated as follows:

BAT

⎛

⎞

IA I

() •=

BAT PROG

If β = 100 then I

930

is 1% low. The 1% loss can be easily

BAT

compensated for by increasing I

β

⎜

⎟

+

1

β

⎝

⎠

by 1%.

PROG

Another important factor to consider when choosing the

PNP pass transistor is its power handling capability. The

transistor’s data sheet will usually give the maximum rated

power dissipation at a given ambient temperature with a

power derating for elevated temperature operation. The

maximum power dissipation of the PNP when charging is:

P

D(MAX)

V

DD(MAX)

(W) = I

MAX(VDD(MAX)

is the maximum supply voltage and V

– V

BAT(MIN)

)

BAT(MIN)

is

the minimum battery voltage when discharged, but not

less than 0.9V/cell since less than 0.9V/cell invokes

precharge current levels.

Thermal Considerations

Internal overtemperature protection is provided to prevent

excessive LTC4060 die temperature during a fault condition. If the internal die temperature exceeds approximately

145°C, charging stops and the part enters the shutdown

state. The faults can be generated from insuffient heat

sinking, a shorted DRIVE pin or from excessive DRIVE pin

current to the base of an external PNP transistor if it’s in

deep saturation from a very low VCE. Once in the shutdown

state, charge qualification can be reinitiated only by removing and replacing the battery or toggling the SHDN pin

low to high or removing and reapplying power to the

charger. This protection is not designed to prevent overheating of the PNP pass transistor. Indirectly though, selfheating of the PNP thermally conducting to the LTC4060

can result in the IC’s junction temperature rising above

145°C, thus cutting off the PNP’s base current. This action

will limit the PNP’s junction temperature to some temperature well above 145°C. The user should insure that the

maximum rated junction temperature is not exceeded

under any normal operating condition. See Package/Order

Information for the θJA of the LTC4060 Exposed Pad

packages. The actual thermal resistance in the application

will vary depending on forced air cooling, use of the

Exposed Pad and other heat sinking means, especially the

amount of copper on the PCB to which the LTC4060 is

attached. The majority of the power dissipated within the

LTC4060 is in the current sense resitor and DRIVE pin

driver as given below:

PD = (I

TJ = TA + θJA • P

)2 • 0.08 + I

BAT

(VCC – VEB)

DRIVE

D

VEB is the emitter to base voltage of the external PNP.

4060f

15

LTC4060

TYPICAL APPLICATIO S

U

Full Featured 2A Charger Application

Figure 2 shows an application that utilizes the optional

temperature sensing and optional externally programmable automatic recharge features. It also has LEDs to

indicate charging status and the presence of sufficient

input supply voltage.

The PROG pin has a total resistance of 691Ω to ground

that programs the fast-charge current at the PNP’s emitter

to 2.02A (2A at the collector for beta of 100). The ARCT pin

voltage is programmed to 1.25V. When the battery cell

voltage falls below this automatic recharge will begin.

Optional capacitor C

filters excessive contact bounce.

BAT

This circuit can be modified to charge a 4A-Hr battery at a

C/2 rate simply by doubling the C

R

4.42k

“CHARGE”

TIMER

HOT

R

NTC

10k

capacitance.

R

LED

330Ω

5

SHDN

15

CHRG

11

NTC

7

PROG

R

PROG

115Ω

R

ARCT

576Ω

8

ARCT

9

SEL0

10

SEL1

V

5V

IN =

14

V

CC

SENSE

DRIVE

LTC4060

TIMER

PAUSE

GND

16

ACP

BAT

CHEM

Power Path Control

Proper power path control is an important consideration

when fast charging nickel cells. This control ensures the

system load remains powered at all times, but that normal

system operation and associated load transients do not

adversely affect the charging procedure. Figure 3 illustrates a 1A charger with power path control. When VIN is

applied the forward biased Schottky diode will power the

load while the P-channel FET will disconnect the battery

from the load. When VIN is removed, the FET will turn-on

to provide a low loss switch from the battery to the load,

and the diode will isolate V

presense of V

R

LED

330Ω

MJD210

4060 F02

“AC”

C

TIMER

1.5nF

13

3

1

2

4

12

6

IN

.

C

BAT

10µF

+

. The ACP output signals the

IN

2-CELL

NiMH

BATTERY

16

R

330Ω

“CHARGE”

R

PROG

1400Ω

Figure 2. Full Featured 2A Charger Application

V

5V

IN =

LED

V

SHDN

CHRG

NTC

PROG

ARCT

SEL0

SEL1

CC

ACP

SENSE

DRIVE

LTC4060

BAT

TIMER

CHEM

PAUSE

GND

16

5

15

11

7

8

9

10

R

AC

10k

13

3

1

2

4

12

6

FZT948

ACP

C

TIMER

820pF

+

2-CELL

NiMH

BATTERY

*DRAIN SOURCE DIODE OF MOSFET

Figure 3. 1A Charger Application with Power Path Control

B220A

FDG312P

*

C

10µF

4060 F03

TO LOAD

LOAD

4060f

TYPICAL APPLICATIO S

LTC4060

U

Trickle Charge

The trickle charge function is normally not required due to

the automatic recharge feature. However, the LTC4060

does provide a modest pull-up current (I

) as part of its

BRD

battery removal detection method. If additional current is

required for trickle charge or to support battery removal

detection with current loads greater than I

, then the

BRD

simple circuit of Figure 4 will facilitate that. The diode

insures no reverse discharge current when V

is removed

IN

and the resistor sets the trickle current.

Extending Charge Current

Extending the charge current beyond 2A can be accomplished by paralleling an external current sense resistor,

R

with the internal current sense resistor as shown in

ISET,

Figure 5. Bond wire, lead frame and PCB interconnect

V

IN

14

V

CC

LTC4060

SENSE

DRIVE

BAT

3

1

2

resistance and mismatches in the two sense resistor’s

value will cause charge current variability to increase in

proportion to the extension in current. Resistor R

ISET

should be connected directly to the LTC4060 to reduce

errors. The total current sense resistor, bond wire and lead

frame resistance is approximately 0.08Ω (T.C. ≅ 3500ppm/

°C). The formula for extended fast charge current is:

II

MAX EXT MAX

for R

ISET

=+

()

AA

•.

==

2153

= 0.16Ω and R

⎛

•

1

⎜

⎝

PROG

.

008

R

ISET

= 698Ω.

⎞

⎟

⎠

Adequate PNP beta is required to meet the DRIVE pin

capability and the increased PNP power dissipation will

require additional heat sinking.

1N4001

3.3k

+

2-CELL

NiMH

BATTERY

4060 F04

Figure 4. Adding Trickle Charge

V

IN

14

V

CC

0.08Ω

SENSE

DRIVE

LTC4060

Figure 5. Extended Charge Current Operation

BAT

R

ISET

0.16Ω

3

1

2

+

2-CELL

NiMH

BATTERY

4060 F05

4060f

17

LTC4060

TYPICAL APPLICATIO S

U

Reverse Input Voltage Protection

In some applications protection from reverse supply voltage is desired. If the supply voltage is high enough, a

series blocking diode can be used. In other cases, where

the voltage drop must be kept very low, a P-channel FET

as shown in Figure 6 can be used.

*

LTC4060

V

IN

*DRAIN BULK DIODE OF MOSFET

Figure 6. Low Loss Reverse Input Voltage Protection

14

V

CC

4060 F06

18

4060f

PACKAGE DESCRIPTIO

LTC4060

U

DHC Package

16-Lead Plastic DFN (5mm × 3mm)

(Reference LTC DWG # 05-08-1706)

0.65 ±0.05

3.50 ±0.05

1.65 ±0.05

(2 SIDES)2.20 ±0.05

4.40 ±0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

5.00 ±0.10

(2 SIDES)

PIN 1

TOP MARK

(SEE NOTE 6)

0.200 REF

NOTE:

1. DRAWING PROPOSED TO BE MADE VARIATION OF VERSION (WJED-1) IN JEDEC

PACKAGE OUTLINE MO-229

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

0.25 ± 0.05

0.50 BSC

PACKAGE

OUTLINE

3.00 ±0.10

(2 SIDES)

0.75 ±0.05

R = 0.20

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

TYP

R = 0.115

TYP

0.25 ± 0.05

0.50 BSC

4.40 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

169

18

0.40 ± 0.10

PIN 1

NOTCH

(DHC16) DFN 1103

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

4060f

19

LTC4060

PACKAGE DESCRIPTIO

U

FE Package

16-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1663)

Exposed Pad Variation BC

3.58

(.141)

4.90 – 5.10*

(.193 – .201)

3.58

(.141)

16 1514 13 12 11

10 9

6.60 ±0.10

4.50 ±0.10

RECOMMENDED SOLDER PAD LAYOUT

0.09 – 0.20

(.0035 – .0079)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

SEE NOTE 4

0.65 BSC

4.30 – 4.50*

(.169 – .177)

0.50 – 0.75

(.020 – .030)

MILLIMETERS

(INCHES)

2.94

(.116)

0.45 ±0.05

1.05 ±0.10

1345678

2

0.25

REF

0° – 8°

0.65

(.0256)

BSC

0.195 – 0.30

(.0077 – .0118)

TYP

4. RECOMMENDED MINIMUM PCB METAL SIZE

FOR EXPOSED PAD ATTACHMENT

*DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.150mm (.006") PER SIDE

2.94

(.116)

1.10

(.0433)

MAX

0.05 – 0.15

(.002 – .006)

FE16 (BC) TSSOP 0204

6.40

(.252)

BSC

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1732 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

LTC1733 Monolithic Lithium-Ion Linear Battery Charger Standalone Charger with Programmable Timer, Up to 1.5A Charge Current

LTC1734 Lithium-Ion Linear Battery Charger in ThinSOTTMSimple ThinSOT Charger, No Blocking Diode, No Sense Resistor Needed

LTC1734L Lithium-Ion Linear Battery Charger in ThinSOT Low Current Version of LTC1734; 50mA ≤ I

LTC1998 Lithium-Ion Low Battery Detector 1% Accurate 2.5µA Quiescent Current, SOT-23

LTC4006/LTC4007 4A Multicell Li-Ion Battery Chargers Standalone Charger, 6V ≤ VIN ≤ 28V, Up to 96% Efficiency,

LTC4008 4A Multichemistry Battery Charger Synchronous Operation for High Efficiency, AC Adapter Current Limit

LTC4052 Monolithic Lithium-Ion Battery Pulse Charger No Blocking Diode or External Power FET Required, ≤1.5A Charge Current

LTC4053 USB Compatible Monolithic Li-Ion Battery Charger Standalone Charger with Programmable Timer, Up to 1.25A Charge Current

LTC4054 Standalone Linear Li-Ion Battery Charger Thermal Regulation Prevents Overheating, C/10 Termination,

in ThinSOT C/10 Indicator, Up to 800mA Charge Current

LTC4055 USB Power Controller and Li-Ion Battery Charger Charges Directly from USB or Wall Adapter, New Topology Charges Faster and

LTC4058 Standalone Li-Ion Linear Charger in DFN Up to 950mA Charge Current, Kelvin Sense for High Accuracy,

LTC4058X C/10 Charge Termination

LTC4411 Low Loss PowerPathTM Controller in ThinSOT Automatic Switching Between DC Sources, Load Sharing,

LTC4412 Replaces ORing Diodes

ThinSOT and PowerPath are trademarks of Linear Technology Corporation.

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

Charger Detection and Programmable Timer, Input Power Good Indication

≤ 180mA

CHRG

±0.8% Charging Voltage Accuracy

More Efficiently

4060f

LT/TP 0904 1K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2004

Loading...

Loading...