Final Electrical Specifications

查询LTC4054供应商

LTC4054-4.2/LTC4054X-4.2

Standalone Linear

Li-Ion Battery Charger with

Thermal Regulation in ThinSOT

FEATURES

■

Programmable Charge Current Up to 800mA

■

No External MOSFET, Sense Resistor or Blocking

Diode Required

■

Complete Linear Charger in ThinSOTTM Package for

Single Cell Lithium-Ion Batteries

■

Constant-Current/Constant-Voltage Operation with

Thermal Regulation to Maximize Charge Rate

Without Risk of Overheating

■

Charges Single Cell Li-Ion Batteries Directly

from USB Port

■

Preset 4.2V Charge Voltage with ±1% Accuracy

■

Charge Current Monitor Output for Gas

Gauging

■

Automatic Recharge

■

Charge Status Output Pin

■

C/10 Charge Termination

■

25µA Supply Current in Shutdown

■

2.9V Trickle Charge Threshold (LTC4054)

■

Available Without Trickle Charge (LTC4054X)

■

Soft-Start Limits Inrush Current

U

APPLICATIO S

■

Cellular Telephones, PDAs

■

Portable MP3 Players

■

Charging Docks and Cradles

■

Bluetooth Applications

U

February 2003

DESCRIPTIO

The LTC®4054 is a complete constant-current/constantvoltage linear charger for single cell lithium-ion batteries.

Its ThinSOT package and low external component count

make the LTC4054 especially well-suited for portable

applications. Furthermore, the LTC4054 is specifically

designed to work within USB power specifications.

No external sense resistor is needed and no blocking diode

is required due to the internal MOSFET architecture. Thermal feedback regulates the charge current to limit the die

temperature during high power operation or high ambient

temperature. The charge voltage is fixed at 4.2V and the

charge current can be programmed externally with a

single resistor. The LTC4054 automatically terminates the

charge cycle when the charge current drops to 1/10th the

programmed value after the final float voltage is reached.

When the input supply (wall adapter or USB supply) is

removed, the LTC4054 automatically enters a low current

state, dropping the battery drain current to less than 2µA.

The LTC4054 can be put into shutdown mode, reducing

the supply current to 25µA.

Other features include charge current monitor, undervoltage

lockout, automatic recharge and a status pin to indicate

charge termination and the presence of input voltage.

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

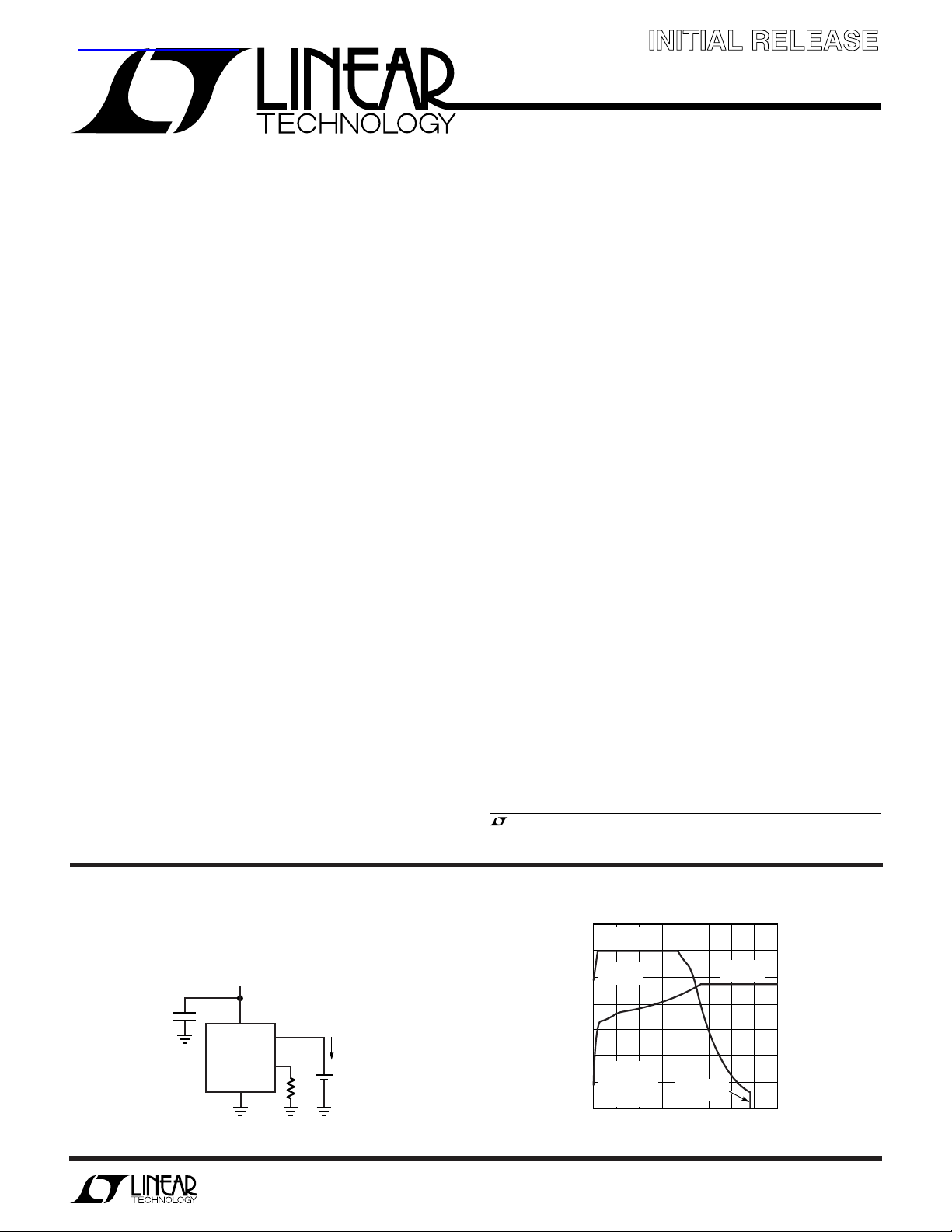

TYPICAL APPLICATIO

600mA Single Cell Li-Ion Charger

4.5V TO 5.25V

1µF

LTC4054-4.2

U

Complete Charge Cycle (750mAh Battery)

700

600

V

IN

4

V

GND

3

CC

BAT

5

PROG

2

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1.65k

600mA

4.2V

Li-Ion

BATTERY

405442 TA01a

CONSTANT

500

POWER

400

300

200

CHARGE CURRENT (mA)

VCC = 5V

θ

JA

100

R

PROG

= 25°C

T

A

0

0.25 0.75 1.25 1.75

0

CONSTANT

CURRENT

CONSTANT

VOLTAGE

= 130°C/W

= 1.65k

0.5 1.0 2.0

CHARGE

TERMINATED

TIME (HOURS)

1.5

4.75

4.50

BATTERY VOLTAGE (V)

4.25

4.00

3.75

3.50

3.25

3.00

405442 TAO1b

405442i

1

LTC4054-4.2/LTC4054X-4.2

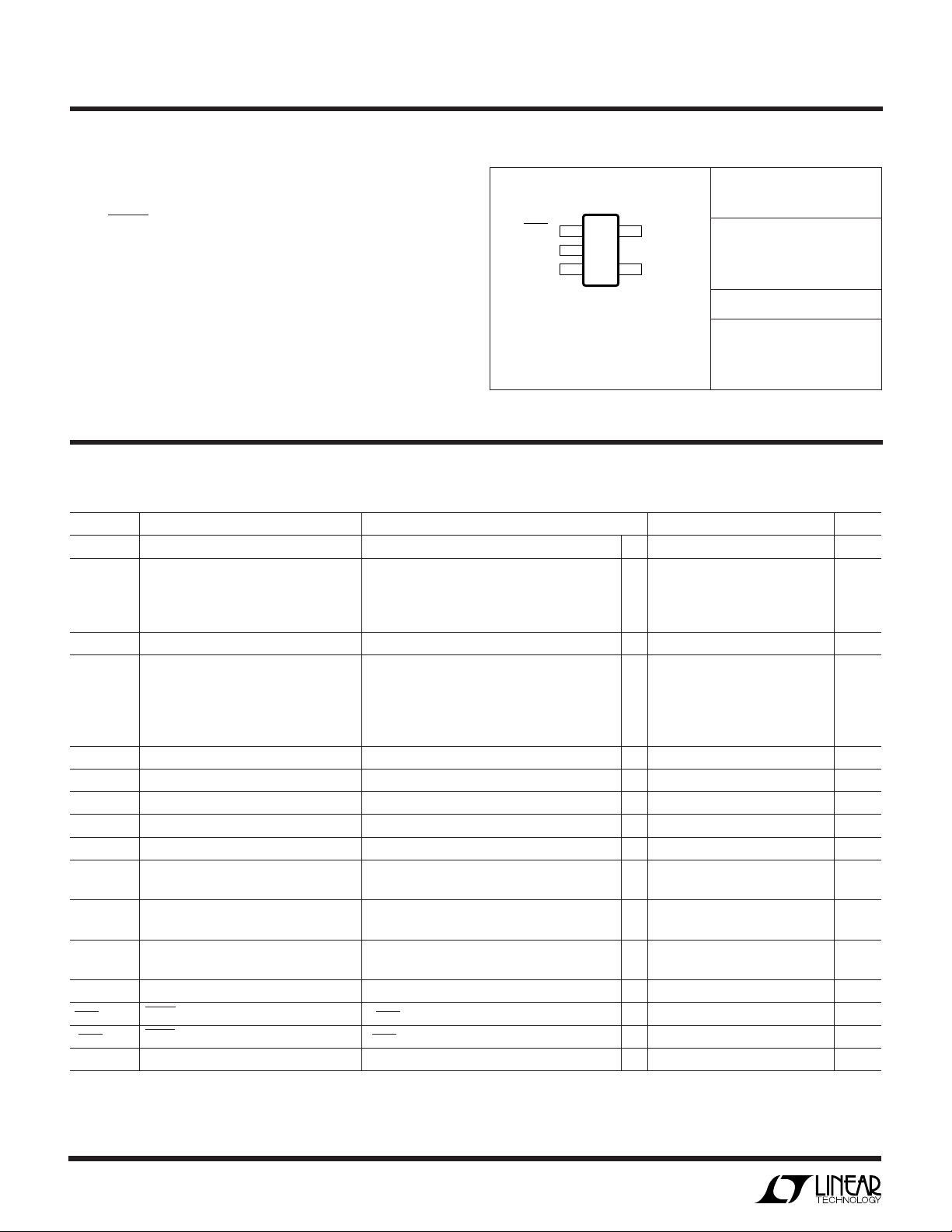

PACKAGE/ORDER I FOR ATIO

UU

W

CHRG 1

GND 2

TOP VIEW

S5 PACKAGE

5-LEAD PLASTIC TSOT-23

BAT 3

5 PROG

4 V

CC

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Input Supply Voltage (VCC) ......................... –0.3 to 10V

PROG............................................. –0.3V to VCC + 0.3V

BAT, CHRG ................................................. –0.3V to 7V

BAT Short-Circuit Duration .......................... Continuous

BAT Pin Current ................................................. 800mA

PROG Pin Current................................................ 800µA

Maximum Junction Temperature .......................... 125°C

Operating Temperature Range (Note 2) .. – 40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

Lead Temperature (Soldering, 10 sec)..................300°C

ORDER PART

NUMBER

LTC4054ES5-4.2

LTC4054XES5-4.2

S5 PART MARKING

T

= 150°C, (θJA = 100°C/ W TO

JMAX

150°C/W DEPENDING ON PC BOARD LAYOUT)

Consult LTC Marketing for parts specified with wider operating temperature ranges.

(N0TE 4)

LTH7

LTADY

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

V

FLOAT

I

BAT

I

TRIKL

V

TRIKL

V

TRHYS

V

UV

V

UVHYS

V

MSD

V

ASD

I

TERM

V

PROG

I

CHRG

V

CHRG

∆V

RECHRG

Input Supply Voltage ● 4.25 6.5 V

Input Supply Current Charge Mode (Note 3), R

Standby Mode (Charge Terminated)

Shutdown Mode (R

< V

V

CC

BAT

Regulated Output (Float) Voltage 0°C ≤ TA ≤ 85°C, I

BAT Pin Current R

Trickle Charge Current V

Trickle Charge Threshold R

Trickle Charge Hysteresis R

VCC Undervoltage Lockout Threshold From VCC Low to High ● 3.7 3.8 3.92 V

VCC Undervoltage Lockout Hysteresis ● 150 250 300 mV

Manual Shutdown Threshold PROG Pin Rising ● 1.15 1.21 1.30 V

VCC – V

C/10 Termination Current Threshold R

PROG Pin Voltage R

CHRG Pin Weak Pull-Down Current V

CHRG Pin Output Low Voltage I

Recharge Battery Threshold V

Lockout Threshold VCC from Low to High 70 100 140 mV

BAT

= 10k, Current Mode ● 93 100 107 mA

PROG

R

= 2k, Current Mode ● 465 500 535 mA

PROG

Standby Mode, V

Shutdown Mode (R

Sleep Mode, V

< 2.9V, R

BAT

= 2k, V

PROG

= 2k (Note 6) 60 80 110 mV

PROG

PROG Pin Falling

V

from High to Low 5 30 50 mV

CC

= 10k (Note 5) ● 0.085 0.10 0.115 mA/mA

PROG

= 2k ● 0.085 0.10 0.115 mA/mA

R

PROG

= 10k, Current Mode ● 0.93 1.0 1.07 V

PROG

= 5V 8 20 35 µA

CHRG

= 5mA 0.35 0.6 V

CHRG

- V

FLOAT

RECHRG

PROG

, or VCC < VUV)

BAT

= 4.2V ● 0 –2.5 –6 µA

BAT

PROG

= 0V ±1 ±2 µA

CC

= 2k (Note 6) ● 20 45 70 mA

PROG

Rising (Note 6) 2.8 2.9 3.0 V

BAT

= 2k ● 1200 2000 µA

PROG

Not Connected, ● 25 50 µA

= 40mA 4.158 4.2 4.242 V

Not Connected) ±1 ±2 µA

● 200 500 µA

● 0.9 1.0 1.1 V

100 150 200 mV

2

405442i

LTC4054-4.2/LTC4054X-4.2

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

T

LIM

R

ON

t

SS

t

RECHARGE

t

TERM

I

PROG

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: The LTC4054E-4.2 and the LTC4054XE-4.2 are guaranteed to meet

performance specifications from 0°C to 70°C. Specifications over the

–40°C to 85°C operating temperature range are assured by design,

characterization and correlation with statistical process controls.

Junction Temperature in Constant 120 °C

Temperature Mode

Power FET “ON” Resistance Current Mode 600 mΩ

(Between V

Soft-Start Time I

Recharge Comparator Filter Time V

Termination Comparator Filter Time I

PROG Pin Pull-Up Current 3 µA

U

and BAT)

CC

UU

BAT

BAT

BAT

The ● denotes specifications which apply over the full operating

= 0 to I

High to Low 0.75 2 ms

Falling 400 1000 µs

=1000V/R

BAT

PROG

Note 3: Supply current includes PROG pin current but does not include

any current delivered to the battery through the BAT pin.

Note 4: See Thermal Considerations.

Note 5: I

with indicated PROG resistor.

Note 6: This parameter is not applicable to the LTC4054X.

is expressed as a fraction of measured full charge current

TERM

100 µs

PI FU CTIO S

CHRG (Pin 1): Open-Drain Charge Status Output. When

the battery is charging, the CHRG pin is pulled low by an

internal N-channel MOSFET. When the charge cycle is

completed, a weak pull-down of approximately 20µA is

connected to the CHRG pin, indicating an “AC present”

condition. When the LTC4054 detects an undervoltage

lockout condition, CHRG is forced to a high impedance

state.

GND (Pin 2): Ground.

BAT (Pin 3): Charge Current Output. Provides charge

current to the battery and regulates the final float voltage

to 4.2V. An internal precision resistor divider from this pin

sets the float voltage and is disconnected in shutdown

mode.

VCC (Pin 4): Positive Input Supply Voltage. Provides

power to the charger. VCC can range from 4.25V to 6.5V

and should be bypassed with at least a 1µF capacitor.

When VCC drops to within 30mV of the BAT pin voltage, the

LTC4054 enters shutdown mode, dropping I

BAT

to less

than 2µA.

PROG (Pin 5): Charge Current Program, Charge Current

Monitor and Shutdown Pin. The charge current is programmed by connecting a 1% resistor, R

, to ground.

PROG

When charging in constant-current mode, this pin servos

to 1V. In all modes, the voltage on this pin can be used to

measure the charge current using the following formula:

I

BAT

= (V

PROG/RPROG

) • 1000

The PROG pin can also be used to shut down the charger.

Disconnecting the program resistor from ground allows

a 3µA current to pull the PROG pin high. When it reaches

the 1.21V shutdown threshold voltage, the charger enters

shutdown mode, charging stops and the input supply

current drops to 25µA. This pin is also clamped to

approximately 2.4V. Driving this pin to voltages beyond

the clamp voltage will draw currents as high as 1.5mA.

Reconnecting R

to ground will return the charger to

PROG

normal operation.

405442i

3

LTC4054-4.2/LTC4054X-4.2

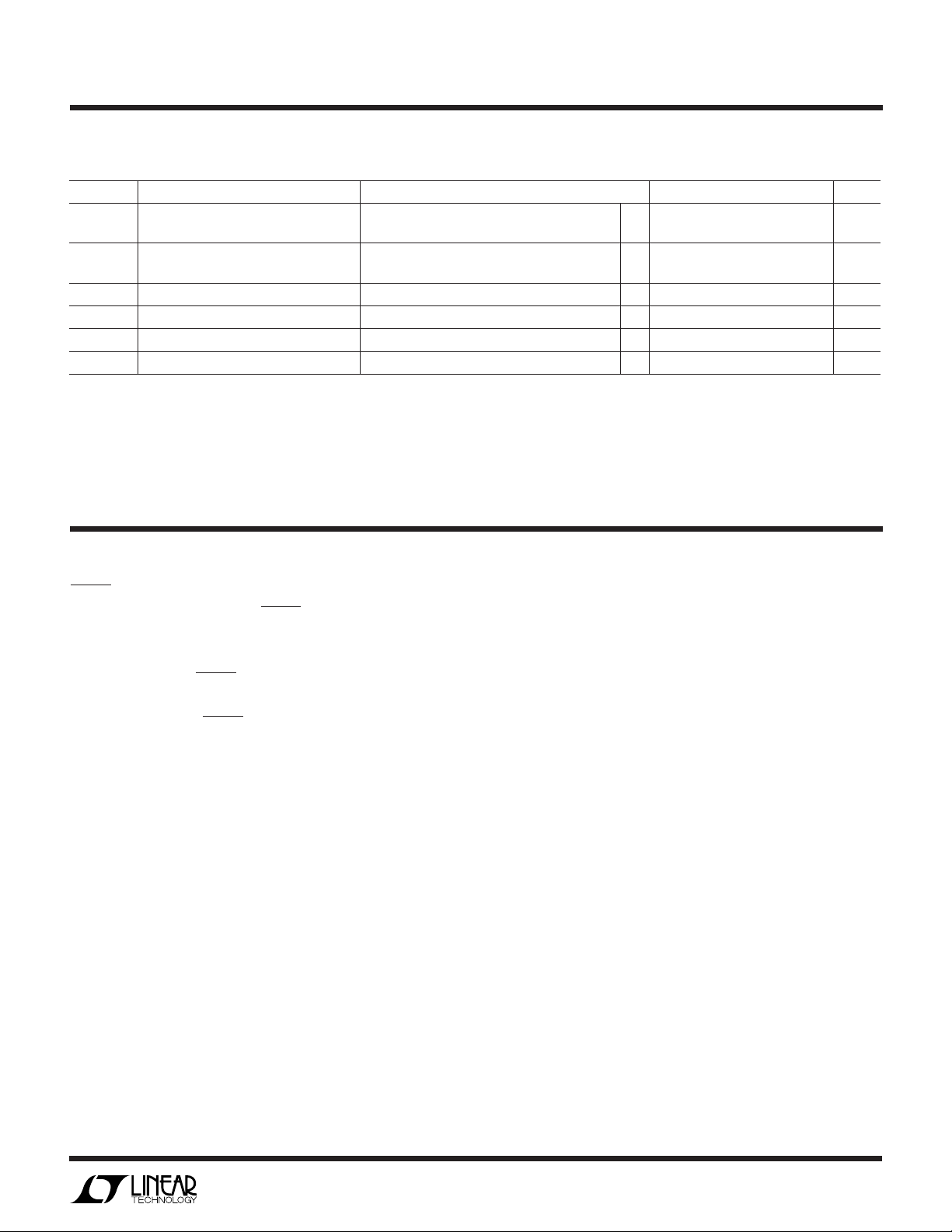

W

BLOCK DIAGRA

120°C

T

A

T

DIE

CA

+

–

4

V

CC

1× 1000×

–

+

MA

5µA

+

VA

–

REF

1.21V

–

BAT

3

R1

R2

SHDN

CHRG

1

STANDBY

TRICKLE CHARGE

DISABLED ON

LTC4054X

C3

–

2.9V TO BAT

C1

+

+

C2

R3

1V

R4

0.1V

R5

–

V

CC

3µA

+

PROG

5

R

PROG

GND

405442 BD

2

4

405442i

OPERATIO

LTC4054-4.2/LTC4054X-4.2

U

The LTC4054 is a single cell lithium-ion battery charger

using a constant-current/constant-voltage algorithm. It

can deliver up to 800mA of charge current (using a good

thermal PCB layout) with a final float voltage accuracy of

±1%. The LTC4054 includes an internal P-channel power

MOSFET and thermal regulation circuitry. No blocking

diode or external current sense resistor is required; thus,

the basic charger circuit requires only three external components. Furthermore, the LTC4054 is capable of operating from a USB power source.

Normal Charge Cycle

A charge cycle begins when the voltage at the VCC pin rises

above the UVLO threshold level and a 1% program resistor

is connected from the PROG pin to ground. If the BAT pin

is less than 2.9V, the charger enters trickle charge mode.

In this mode, the LTC4054 supplies approximately 1/10

the programmed charge current to bring the battery voltage up to a safe level for full current charging. (Note: The

LTC4054X does not include this trickle charge feature).

When the BAT pin voltage rises above 2.9V, the charger

enters constant-current mode, where the programmed

charge current is supplied to the battery. When the BAT

pin approaches the final float voltage (4.2V), the LTC4054

enters constant-voltage mode and the charge current

begins to decrease. When the charge current drops to

1/10 of the programmed value, the charge cycle ends.

Programming Charge Current

The charge current is programmed using a single resistor

from the PROG pin to ground. The battery charge current

is 1000 times the current out of the PROG pin. The

program resistor and the charge current are calculated

using the following equations:

The charge current out of the BAT pin can be determined

at any time by monitoring the PROG pin voltage using the

following equation:

V

I

BAT

PROG

= •1000

R

PROG

Charge Termination

The charge cycle terminates when the charge current falls

to 1/10th the programmed current. An internal comparator senses when the PROG pin voltage falls below 100mV

1

and puts the LTC4054 into standby mode. In standby

mode, the LTC4054 ceases to provide charge current to

the battery and the input supply current drops to 200µA.

If the battery voltage drops below 4.05V, a recharge cycle

will begin. To manually restart the charge cycle, the input

voltage must be removed and reapplied, or the charger

must be shut down and restarted by momentarily floating

the PROG pin.

Charge Status Indicator (CHRG)

The charge status output has three different states: strong

pull-down (~10mA), weak pull-down (~20µA) and high

impedance. The strong pull-down state indicates that the

LTC4054 is in a charge cycle. Once the charge cycle has

terminated, the pin state is determined by undervoltage

lockout conditions. A weak pull-down indicates that V

CC

meets the UVLO conditions and the LTC4054 is ready to

charge. High impedance indicates that the LTC4054 is in

undervoltage lockout mode: either VCC is within 100mV of

the BAT pin voltage or insufficient voltage is applied to the

VCC pin. A microprocessor can be used to distinguish

between these three states—this method is discussed in

the Applications Information section.

R

PROG

V

1000 1000

==

I

CHRG

I

,

CHRG

R

PROG

V

Note 1: Any external sources that hold the PROG pin above 100mV will prevent the LTC4054

from terminating a charge cycle.

405442i

5

LTC4054-4.2/LTC4054X-4.2

TRICKLE CHARGE

MODE

1/10TH FULL CURRENT

BAT > 2.9V

BAT < 2.9V

BAT > 2.9V

CHRG: STRONG

PULL-DOWN

CHARGE MODE

FULL CURRENT

CHRG: STRONG

PULL-DOWN

SHUTDOWN MODE

CHRG: Hi-Z IN UVLO

WEAK PULL-DOWN

OTHERWISE

PROG

RECONNECTED

OR

UVLO CONDITION

STOPS

PROG FLOATED

OR

UVLO CONDITION

I

CC

DROPS TO <30µA

POWER ON

PROG < 100mV

STANDBY MODE

NO CHARGE CURRENT

CHRG: WEAK

PULL-DOWN

2.9V < BAT < 4.05V

405442 F01

U

OPERATIO

Thermal Limiting

An internal thermal feedback loop reduces the programmed

charge current if the die temperature attempts to rise

above a preset value of approximately 120°C. This feature

protects the LTC4054 from excessive temperature and

allows the user to push the limits of the power handling

capability of a given circuit board without risk of damaging

the LTC4054. The charge current can be set according to

typical (not worst-case) ambient temperature with the

assurance that the charger will automatically reduce the

current in worst-case conditions. ThinSOT power considerations are discussed further in the Applications Information section.

Undervoltage Lockout (UVLO)

An internal undervoltage lockout circuit monitors the input

voltage and keeps the charger in shutdown mode until V

CC

rises above the undervoltage lockout threshold. The UVLO

circuit has a built-in hysteresis of 200mV. Furthermore, to

protect against reverse current in the power MOSFET, the

UVLO circuit keeps the charger in shutdown mode if V

CC

falls to within 30mV of the battery voltage. If the UVLO

comparator is tripped, the charger will not come out of

shutdown mode until VCC rises 100mV above the battery

voltage.

Automatic Recharge

Once the charge cycle is terminated, the LTC4054 continuously monitors the voltage on the BAT pin. A charge cycle

restarts when the battery voltage falls below 4.05V (which

corresponds to approximately 80% to 90% battery capacity). This ensures that the battery is kept at or near a fully

charged conditon and eliminates the need for periodic

charge cycle initiations. CHRG output enters a strong pulldown state during recharge cycles.

Manual Shutdown

At any point in the charge cycle, the LTC4054 can be put

into shutdown mode by removing R

thus floating the

PROG

PROG pin. This reduces the battery drain current to less

than 2µA and the supply current to less than 50µA. A new

charge cycle can be initiated by reconnecting the program

resistor.

6

Figure 1. State Diagram of a Typical Charge Cycle

405442i

WUUU

R

C

PROG

PROG

≤

π1210

5

••

APPLICATIO S I FOR ATIO

LTC4054-4.2/LTC4054X-4.2

Stability Considerations

The constant-voltage mode feedback loop is stable without an output capacitor provided a battery is connected to

the charger output. With no battery present, an output

capacitor is recommended to reduce ripple voltage. When

using high value, low ESR ceramic capacitors, it is recommended to add a 1Ω resistor in series with the capacitor.

No series resistor is needed if tantalum capacitors are

used.

In constant-current mode, the PROG pin is in the feedback

loop, not the battery. The constant-current mode stability

is affected by the impedance at the PROG pin. With no

additional capacitance on the PROG pin, the charger is

stable with program resistor values as high as 20k. However, additional capacitance on this node reduces the

maximum allowed program resistor. The pole frequency

at the PROG pin should be kept above 100kHz. Therefore,

R

10k

PROG

PROG

LTC4054

GND

if the PROG pin is loaded with a capacitance, C

PROG

, the

following equation can be used to calculate the maximum

resistance value for R

PROG

:

Average, rather than instantaneous, charge current may

be of interest to the user. For example, if a switching power

supply operating in low current mode is connected in

parallel with the battery, the average current being pulled

out of the BAT pin is typically of more interest than the

instantaneous current pulses. In such a case, a simple RC

filter can be used on the PROG pin to measure the average

battery current as shown in Figure 2. A 10k resistor has

been added between the PROG pin and the filter capacitor

to ensure stability.

CHARGE

CURRENT

MONITOR

CIRCUITRY

C

FILTER

405442 F02

Figure 2. Isolating Capacitive Load on PROG Pin and Filtering

405442i

7

LTC4054-4.2/LTC4054X-4.2

WUUU

APPLICATIO S I FOR ATIO

Power Dissipation

The conditions that cause the LTC4054 to reduce charge

current through thermal feedback can be approximated by

considering the power dissipated in the IC. Nearly all of

this power dissipation is generated by the internal

MOSFET—this is calculated to be approximately:

PD = (VCC – V

BAT

) • I

BAT

where PD is the power dissipated, VCC is the input supply

voltage, V

is the battery voltage and I

BAT

is the charge

BAT

current. The approximate ambient temperature at which

the thermal feedback begins to protect the IC is:

TA = 120°C – PDθ

TA = 120°C – (VCC – V

JA

BAT

) • I

BAT

• θ

JA

Example: An LTC4054 operating from a 5V USB supply is

programmed to supply 400mA full-scale current to a

discharged Li-Ion battery with a voltage of 3.75V. Assuming θJA is 150°C/W (see Board Layout Considerations),

the ambient temperature at which the LTC4054 will begin

to reduce the charge current is approximately:

TA = 120°C – (5V – 3.75V) • (400mA) • 150°C/W

TA = 120°C – 0.5W • 150°C/W = 120°C – 75°C

TA = 45°C

Moreover, when thermal feedback reduces the charge

current, the voltage at the PROG pin is also reduced

proportionally as discussed in the Operation section.

It is important to remember that LTC4054 applications do

not need to be designed for worst-case thermal conditions

since the IC will automatically reduce power dissipation

when the junction temperature reaches approximately

120°C.

Thermal Considerations

Because of the small size of the ThinSOT package, it is very

important to use a good thermal PC board layout to

maximize the available charge current. The thermal path

for the heat generated by the IC is from the die to the

copper lead frame, through the package leads, (especially

the ground lead) to the PC board copper. The PC board

copper is the heat sink. The footprint copper pads should

be as wide as possible and expand out to larger copper

areas to spread and dissipate the heat to the surrounding

ambient. Feedthrough vias to inner or backside copper

layers are also useful in improving the overall thermal

performance of the charger. Other heat sources on the

board, not related to the charger, must also be considered

when designing a PC board layout because they will affect

overall temperature rise and the maximum charge current.

The LTC4054 can be used above 45°C ambient, but the

charge current will be reduced from 400mA. The approximate current at a given ambient temperature can be

approximated by:

120 –

CT

°

I

BAT

=

–•θ

VV

()

CC BAT JA

A

Using the previous example with an ambient temperature of 60°C, the charge current will be reduced to

approximately:

I

=

BAT

=

ImA

BAT

120 60

5 3 75 150

–. • / . /

VV CWCCA

()

320

–

CC

°°

=

°

60

187 5

°

°

The following table lists thermal resistance for several

different board sizes and copper areas. All measurements

were taken in still air on 3/32" FR-4 board with one ounce

copper.

Table 1. Measured Thermal Resistance

COPPER AREA BOARD THERMAL RESISTANCE

TOPSIDE* BACKSIDE AREA JUNCTION-TO-AMBIENT

2500mm22500mm22500mm

1000mm22500mm22500mm

225mm22500mm22500mm

100mm22500mm22500mm

2

50mm

*Device is mounted on topside

2500mm22500mm

2

2

2

2

2

125°C/W

125°C/W

130°C/W

135°C/W

150°C/W

405442i

8

WUUU

APPLICATIO S I FOR ATIO

LTC4054-4.2/LTC4054X-4.2

Increasing Thermal Regulation Current

Reducing the voltage drop across the internal MOSFET

can significantly decrease the power dissipation in the IC.

This has the effect of increasing the current delivered to

the battery during thermal regulation. One method is by

dissipating some of the power through an external component, such as a resistor or diode.

Example: An LTC4054 operating from a 5V wall adapter is

programmed to supply 800mA full-scale current to a

discharged Li-Ion battery with a voltage of 3.75V. Assuming θJA is 125°C/W, the approximate charge current at an

ambient temperature of 25°C is:

I

BAT

=

120 25

VVCW

5 3 75 125

(–. )• /

–

=

608

mA

°

CC

°°

By dropping voltage across a resistor in series with a 5V

wall adapter (shown in Figure 3), the on-chip power

dissipation can be decreased, thus increasing the thermally regulated charge current.

CC

I

BAT

=

VIR V

(– – )•θ

S BAT CC BAT JA

°°120 25–

Using RCC = 0.25Ω, VS = 5V, V

= 3.75V, TA = 25°C and

BAT

θJA = 125°C/W we can calculate the thermally regulated

charge current to be:

I

= 708.4mA

BAT

While this application delivers more energy to the battery

and reduces charge time in thermal mode, it may actually

lengthen charge time in voltage mode if VCC becomes low

enough to put the LTC4054 into dropout. Figure 4 shows

how this circuit can result in dropout as RCC becomes

large.

1000

VS = 5V

800

600

400

THERMAL

MODE

CHARGE CURRENT (mA)

200

0

0

0.25

CONSTANT

CURRENT

VS = 5.25V

0.5

0.75

VS = 5.5V

RCC (Ω)

1.0

V

= 3.75V

BAT

= 25°C

T

A

= 125°C/W

θ

JA

R

PROG

1.25

DROPOUT

= 1.25kΩ

1.5

405442 F04

1.75

V

S

R

CC

V

CC

BAT

LTC4054-4.2

1µF

PROG

GND

Figure 3. A Circuit to Maximize Thermal Mode Charge Current

Solving for I

I

=

BAT

VV VV

(– )– (– )

S BAT S BAT

using the quadratic formula2.

BAT

2

2

R

CC

Li-Ion

CELL

R

PROG

405442 F03

4 120

RCT

CC A

°

(–)

θ

JA

Figure 4. Charge Current vs R

CC

This technique works best when RCC values are minimized

to keep component size small and avoid dropout. Remember to choose a resistor with adequate power handling

capability.

VCC Bypass Capacitor

Many types of capacitors can be used for input bypassing,

however, caution must be exercised when using multilayer ceramic capacitors. Because of the self-resonant and

high Q characteristics of some types of ceramic capacitors, high voltage transients can be generated under some

start-up conditions, such as connecting the charger input

to a live power source. Adding a 1.5Ω resistor in series

with an X5R ceramic capacitor will minimize start-up

voltage transients. For more information, refer to Application Note 88.

Note 2: Large values of RCC will result in no solution for I

will not generate enough heat to require thermal regulation.

. This indicates that the LTC4054

BAT

405442i

9

LTC4054-4.2/LTC4054X-4.2

WUUU

APPLICATIO S I FOR ATIO

Charge Current Soft-Start

The LTC4054 includes a soft-start circuit to minimize the

inrush current at the start of a charge cycle. When a charge

cycle is initiated, the charge current ramps from zero to the

full-scale current over a period of approximately 100µs.

This has the effect of minimizing the transient current load

on the power supply during start-up.

CHRG Status Output Pin

With no battery present, the CHRG pin can provide an

indication that the input voltage is present and it is greater

than the undervoltage lockout threshold level. A weak

pull-down current of approximately 20µA indicates that

sufficient voltage is applied to VCC to begin charging.

When a discharged battery is connected to the charger, the

constant current portion of the charge cycle begins and

the CHRG pin pulls to ground. The CHRG pin can sink up

to 10mA to drive an LED that indicates that a charge cycle

is in progress.

When the battery is nearing full charge, the charger enters

the constant-voltage portion of the charge cycle and the

charge current begins to drop. When the charge current

drops below 1/10 of the programmed current, the charge

cycle ends and the strong pull-down is replaced by the

20µA pull-down, indicating that the charge cycle has

ended. If the input voltage is removed or drops below the

undervoltage lockout threshold, the CHRG pin becomes

high impedance. Figure 5 shows that by using two different value pull-up resistors, a microprocessor can detect all

three states from this pin.

To detect when the LTC4054 is in charge mode, force the

digital output pin (OUT) high and measure the voltage at

the CHRG pin. The N-channel MOSFET will pull the pin

voltage low even with the 2k pull-up resistor. Once the

charge cycle terminates, the N-channel MOSFET is turned

off and a 20µA current source is connected to the CHRG

pin. The IN pin will then be pulled high by the 2k pull-up

resistor. To determine if there is a weak pull-down current,

the OUT pin should be forced to a high impedance state.

The weak current source will pull the IN pin low through

the 800k resistor; if CHRG is high impedance, the IN pin

will be pulled high, indicating that the part is in a UVLO

state.

+

V

V

CC

LTC4054 µPROCESSOR

CHRG OUT

Figure 5. Using a Microprocessor to Determine CHRG State

800k

2k

V

DD

IN

405442 F05

10

405442i

PACKAGE DESCRIPTIO

LTC4054-4.2/LTC4054X-4.2

U

S5 Package

5-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1635)

0.62

MAX

3.85 MAX

0.20 BSC

DATUM ‘A’

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

2.62 REF

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

0.30 – 0.50 REF

0.95

REF

1.22 REF

1.4 MIN

0.09 – 0.20

(NOTE 3)

2.80 BSC

1.50 – 1.75

(NOTE 4)

1.00 MAX

PIN ONE

0.95 BSC

0.80 – 0.90

2.90 BSC

(NOTE 4)

1.90 BSC

0.30 – 0.45 TYP

5 PLCS (NOTE 3)

0.01 – 0.10

S5 TSOT-23 0302

405442i

11

LTC4054-4.2/LTC4054X-4.2

U

TYPICAL APPLICATIO

Full Featured Single Cell

Li-Ion Charger

VIN = 5V

4

V

330Ω

LTC4054-4.2

1

CHRG

CC

GND

2

BAT

PROG

3

5

500mA

2k

1µF

SHDN

405442 TA02

800mA Li-Ion Charger with

External Power Dissipation

VIN = 5V

0.25Ω

4

V

1µF

+

CC

LTC4054-4.2

GND

2

BAT

PROG

1.25k

800mA

3

5

+

405442 TA03

Basic Li-Ion Battery Charger with

Reverse Polarity Input Protection

5V WALL

ADAPTER

1µF

4

V

CC

LTC4054-4.2

GND

2

BAT

PROG

3

5

2k

500mA

+

405442 TA04

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1571 200kHz/500kHz Switching Battery Charger Up to 1.5A Charge Current; Preset and Adjustable Battery Voltages

LTC1729 Lithium-Ion Battery Charger Termination Controllers Time or Charge Current Termination, Preconditioning 8-Lead MSOP

LTC1730 Lithium-Ion Battery Pulse Charger No Blocking Diode Required, Current Limit for Maximum Safety

LTC1731 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

Charger Detection and Programmable Timer

LTC1732 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

Charger Detection and Programmable Timer, Input Power Good Indication

LTC1733 Monolithic Lithium-Ion Linear Battery Charger Standalone Charger with Programmable Timer, Up to 1.5A Charge Current

LTC1734 Lithium-Ion Linear Battery Charger in ThinSOT Simple ThinSOT Charger, No Blocking Diode, No Sense Resistor Needed

LTC1734L Lithium-Ion Linear Battery Charger in ThinSOT Accurate, Low Current Version of LTC1734

LTC1998 Lithium-Ion Low Battery Detector 1% Accurate 2.5µA Quiescent Current, SOT-23

LTC4050 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

Charger Detection and Programmable Timer, Input Power Good Indication,

Thermistor Interface

LTC4052 Monolithic Lithium-Ion Battery Pulse Charger No Blocking Diode or External Power FET Required

LTC4053 USB Compatible Monolithic Li-Ion Battery Charger Standalone Charger with Programmable Timer, Up to 1.25A Charge Current

LTC4410 USB Power Manager For Simultaneous Operation of USB Peripheral and Battery Charging from USB

Port, Keeps Current Drawn from USB Port Constant, Keeps Battery Fresh, Use

with the LTC4053, LTC1733, or LTC4054

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

405442i

LT/TP 0203 1.5K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2003

Loading...

Loading...