advertisement

Fast, High Effi ciency, Standalone NiMH/NiCd Battery Charging

Design Note 380

Fran Hoffart

Introduction

Although recent popular attention is focused on Lithium

Ion batteries, one must not forget that other battery

chemistries, such as Nickel Cadmium (NiCd) and Nickel

Metal Hydride (NiMH) have advantages in rechargeable

power systems. Nickel- based batteri es are robust, capable

of high discharge rates, have good cycle life, do not

require special protection cir cuitry and are less ex pensive

than Li-Ion. Among the two, NiMH batteries are rapidly

replacing NiCd because of their higher capacity (40% to

50% more) and the environmental concerns of the toxic

cadmium contained in NiCd batteries.

®

The LTC

4010 and LTC4011 are NiCd/NiMH battery

chargers that simplify Nickel-based battery charger

design and include power control and charge termination

for fast charging up to 16 series-connected cells using a

synchronous buck topology. The LTC4011 provides a full

feature se t in a 20-lead TSSOP while t he LTC4010 comes in

a 16-lead TSSOP. The LTC4010 removes the PowerPath

TM

control output, top-off charge indicator, DC power sense

input and provides limited thermistor options.

49.9k

(1.5 HRS)

0.1mF

Q3A

18

V

CC

20

INFET

2

FAULT

3

CHRG

13

TOC

19

READY

1

DCIN

10

TIMER

4

CHEM

5

GND

14

INTV

DD

LTC4011

21 (BACKSIDE)

TGATE

BGATE

SENSE

V

9V to 30V

V

IN

CHEM PIN

NiMH NiCd

Q1: FDC658P

Q2: Si3434DV

Q3: FDR8508P

LEDS

3k 3k 3k 3k

2Ok

3.3V

Figure 1. Full Featured Standalone 2A, 4-Cell NiMH Fast Charger with PowerPath Control

NiCd/NiMH Battery Charging Basics

Batteries come in many sizes and capacity ratings.

When specifying charge current, it is commonly related

to a battery’s capacity, or simply “C”. The letter “C” is a

term used to indicate the manufacturers’ stated battery

discharge capacity which is measured in milliamp-hours

(mAh). This capacity rating becomes important when

fast charging because it determines the required charge

current for proper charge termination.

There are several commonly used methods for charging

Nickel batteries. They are all related to the length of the

charge cycle which determines the recommended charge

current. A slow charge (or low rate charge) consists of a

relatively low charge current, typically 0.1C, applied for

approximately 14 hours set by a timer. A quick charge

applies a constant current of approximately 0.3C to the

battery while a fast charge applies a constant current of

1C or higher. Both quick and fast charge cycles require

that the charge current terminate when the battery

becomes fully charged.

, LTC and LT are registered trademarks and PowerPath is a trademark of Linear

Technology Corporation. All other trademarks are the property of their respective

PGND

BAT

V

CELL

V

CDIV

V

TEMP

owners.

RT

100k

17

15

16

11

12

30.1k

(4 CELLS)

8

10k

9

6

9.76k

7

10k

0.1mF

0.1mF

10mF

Q1

Q2

1A

28k

10mH

I

VIN

18V

I

BATT

R

SENSE

0.05

(2A)

10mF

NTC MURATA NCP18XH

Q3B

+

0603 SIZE

TO

SYSTEM

LOAD

I

DISCHARGE

2000mAh

NiMH

(4 CELLS)

NTC

10k

DN380 F01

01/06/380

During a fast charge cycle, a constant current is applied

to the battery while allowing the battery voltage to rise

to the level required (within limits) to force this current.

As the battery accepts charge, the battery voltage and

temperature slowly rise. As the battery approaches full

charge, the voltage rises faster, reaches a peak, then

begins to drop (–ΔV); at the same time, the battery

temperature begins to quickly rise (ΔT/Δt). Most fast or

quick charge termination methods use one or both of

these conditions to end the charge cycle.

Complete 4-Cell NiMH Battery Charger

Figure 1 shows a fast, 2A charger featuring the

high effi ciency LTC4011 550kHz synchronous buck

converter. The LTC4011 simplifi es charger design by

integrating all of the features needed to charge Ni-based

batteries, including constant current control circuitry,

charge termination, automatic trickle and top off

charge, automatic recharge, programmable timer,

PowerPath control and multiple status outputs. Such a

high level of integration lowers the component count,

enabling a complete charger to occupy less than 4cm

2

of board area.

Initial battery qualifi cation verifi es that suffi cient input

voltage is pres ent for charging and that the bat tery voltage

and battery temperature are within an acceptable range

before charging at full current. For deeply discharged

batteries, a low current trickle charge is applied to raise

the bat tery voltage to an appropr iate level before applying

full charge current. When qualifi cation is complete, the

full programmed constant-current begins.

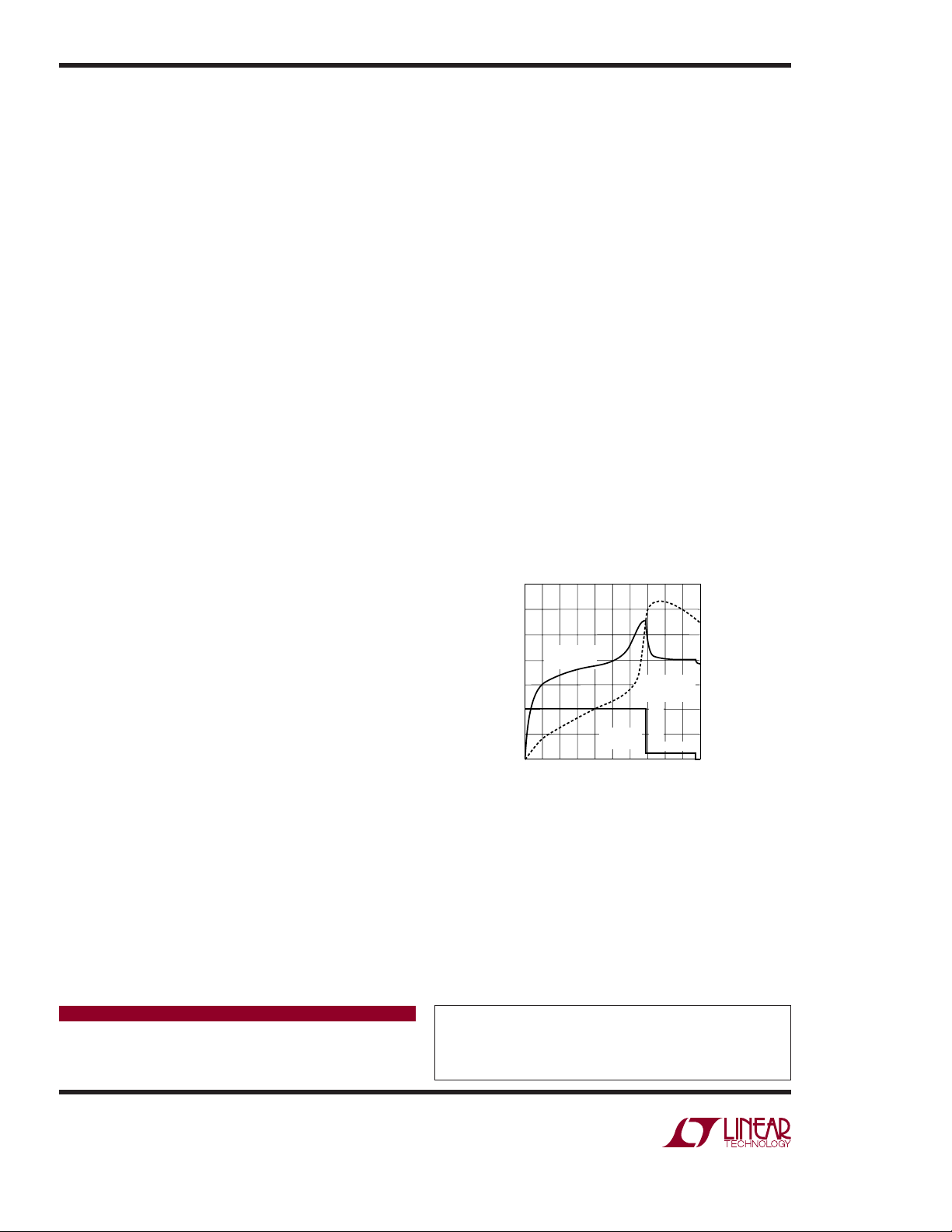

Standalone Charge Termination

The charge termination methods used by the LTC4010

and LTC4011 utilize battery voltage and battery

temperature changes to reliably indicate when full

charge is reached as a function of the charge current

selected. The charge current must be suffi ciently high

(between 0.5C and 2C) for the battery to exhibit the

voltage and temperature profi le required for proper

charge termination. Figure 2 shows a typical fast-charge

profi le displaying charge current, battery temperature

and per cell voltage. This profi le indicates that the charge

cycle terminated due to the rate of temperature rise

or ΔT/Δt.

The –ΔV charge termination algorithm begins shortly

after the full charge current starts fl owing. A fi xed delay

time prevents false termination due to battery voltage

fl uctuations from batteries that are deeply discharged

or haven’t been charged recently. For batteries that are

near full charge, the –ΔV termination sequence begins

immediately to prevent overcharging.

During the charge cycle, both the –ΔV and ΔT/Δt

termination methods are active. For NiMH batteries,

the –ΔV termination requires that the single cell battery

voltage drop 10mV from the peak voltage or the rateof-temperature rise (ΔT/Δt) be greater than 1°C/minute.

The measurements are taken every 30 seconds and the

results must be consistent for four measurements for

termination to take place. Typically the ΔT/Δt termination

method occurs earlier in the charge cycle. If this occurs,

the LTC4010/4011 adds a top-off charge at a reduced

charge current for 1/3 of the programmed time. Top-off

only occurs when charging NiMH batteries.

After the charge cycle has ended, the charger continues

monitoring the bat tery voltage. If the voltage drops below

a fi xed threshold level, due to an external load on the battery or self-discharge, a new charge cycle begins with the

charge termination algorithms immediately enabled.

1.60

1.55

1.50

)

V( E

SINGLE CELL

G

ATL

O

V LLE

C

1.45

1.40

1.35

1.30

1.25

VOLTAGE

BATTERY

TEMPERATURE

2A

CURRENT

CHARGE

0

40

20

TIME (MIN)

1A

60 80

Figure 2. Typical NiMH Fast Charge Profi le

TOP-OFF

100

DN380 • F02

42

40

( ERUTAREPMET YRETTAB ° )C

38

36

34

32

30

28

Conclusion

The LTC4010 and LTC4011 provide complete standalone

solutions for reliable, robust and safe fast charging of

NiCd and NiMH batteries. Proper charging is critical to

not only obtain maximum battery capacity but to also

avoid high temperatur es, overcharge and other conditions

which adversely affect battery life.

Data Sheet Download

http://www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

For applications help,

call (408) 432-1900, Ext. 2364

dn380 LT/TP 0106 409K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2006

Loading...

Loading...