L DESIGN FEATURES

Feature-Packed Charger Handles

All Battery Chemistries and Produces

3A/50W for Fast Charging from a

4mm × 4mm QFN

Introduction

The LTC 4009, L TC400 9 -1 and

LTC4009-2 are a family of high power

battery charger ICs that achieve a small

circuit size and high performance without compromising functionality. The

family operates with high efficiency

while packing the most desirable

charging and protection features into

a space-efficient 20-lead 4mm × 4mm

QFN package. When combined with

just a few external components and

termination control, the LTC4009

family facilitates construction of

chargers capable of delivering up to

3A to batteries with output power

levels approaching 50W. These ICs are

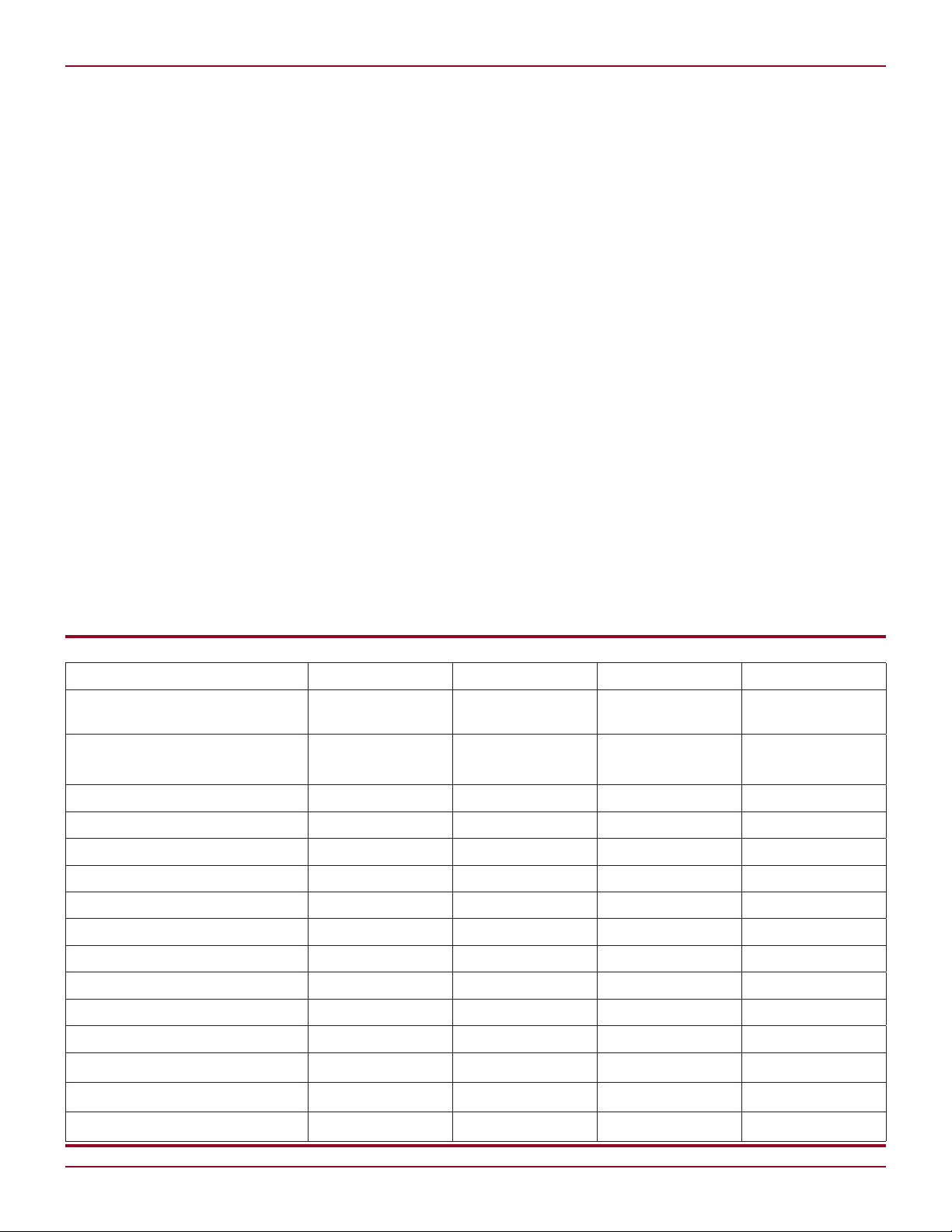

Feature LTC4009 LTC4009-1 LTC4009-2 LTC4008

Output Voltage Selection

especially well-suited to implementing

microprocessor-controlled chargers

for all chemistry types, including

smart batteries.

High Performance

The LTC4009 family builds upon the

proven quasi-constant frequency,

constant off-time PWM control architecture found in other Linear

Technology battery chargers such as

the LTC4006, LTC4007, LTC4008,

and LTC4011. This buck topology

provides continuous switching with

synchronous rectification, even with

no load current.

Table 1. LTC4009 family features

External Resistor

Divider

Pin Programmable

at 4.1V/cell

by James A. McKenzie

Normally the charger operates over

a wide duty cycle range in a manner

similar to a fixed-frequency PWM controller running at 550kHz. However,

if the input or output voltage drives

the duty cycle to extremes, below 20%

or above 80%, the LTC4009 smoothly

adjusts the operating frequency

downward to avoid pulse-skipping

that might otherwise begin to occur

at 550kHz. Under very low dropout

conditions requiring high duty cycle

operation, the internal watchdog

timer on the LTC4009 prevents the

charger from switching below 25kHz.

This allows the charger to achieve a

Pin Programmable

at 4.2V/cell

External Resistor

Divider

Output Voltage Accuracy

(Room Temperature)

Maximum Charge Current 3A 3A 3A 4A

Charge Current Accuracy ±5% ±5% ±5% ±5%

Input Current Limit Accuracy ±4% ±4% ±4% ±7%

Input Current Limit/Indicator

External PWM Switching MOSFETs All NFET All NFET All NFET PFET/NFET

Nominal PWM Frequency 550kHz 550kHz 550kHz 300kHz

Shutdown Pin

C/10 Indicator

Charge Current Monitor

Termination Method External External External External

Fault Indicator

Thermistor Interface

INFET Control

18

±0.5% + Divider Error ±0.6% ±0.6% ±0.8% + Divider Error

L L L L

L L L

L L L L

L L L L

Linear Technology Magazine • September 2008

Merged with ACP

L

L

L

DESIGN FEATURES L

CLP

FROM

ADAPTER

15V AT 2A

BULK

CHARGE

0.1µF

5.1k

D2

D1

D3

Q1

294k

10pF

25mΩ

3.01k

0.1µF

2µF

Q2

Q3

D4

L1

6.8µH

33mΩ

3-CELL

Li-Ion

BATTERY

STACK

DCIN

CHRG

0.1µF

22.1k

2.43k

3k

RED

6.04k

26.7k

53.6k

LTC4009

DCDIV

ACP

ICL

SHDN

ITH

PROG

CLN

BOOST

TGATE

SW

INTV

DD

BGATE

TO/FROM

MCU

GND

CSP

CSN

BAT

FBDIV

V

FB

20µF

POWER TO SYSTEM

0.1µF

4.7nF

20µF

3.01k

31.2k

D2, D4, D5: MBR230LSFT1

D3:CMDSH-3

Q1: 2N7002

Q2, Q3: Si7212DN

L1: IHLP-2525CZ-11

+

D5

maximum duty cycle of 98% or higher

without producing frequencies that

could extend down into the audible

range.

With a synchronous rectifier, not

only are high current applications

supported at efficiency levels greater

than 90%, but switching activity is

continuous and independent of the

load current. Maintaining full continuous conduction mode in the inductor

at final output voltage, under no-load

conditions, avoids pulse-skipping

which can generate audible noise and

provide poor load regulation.

The input current limit accuracy

is typically ±3% and a maximum of

±4% over the full operating temperature range. Output voltage accuracy

is typically ±0.5% and a maximum of

±0.8% over temperature.

Small PCB Footprint

Besides its small surface mount package size, the LTC4009 family offers

other features that drive down the

total solution size.

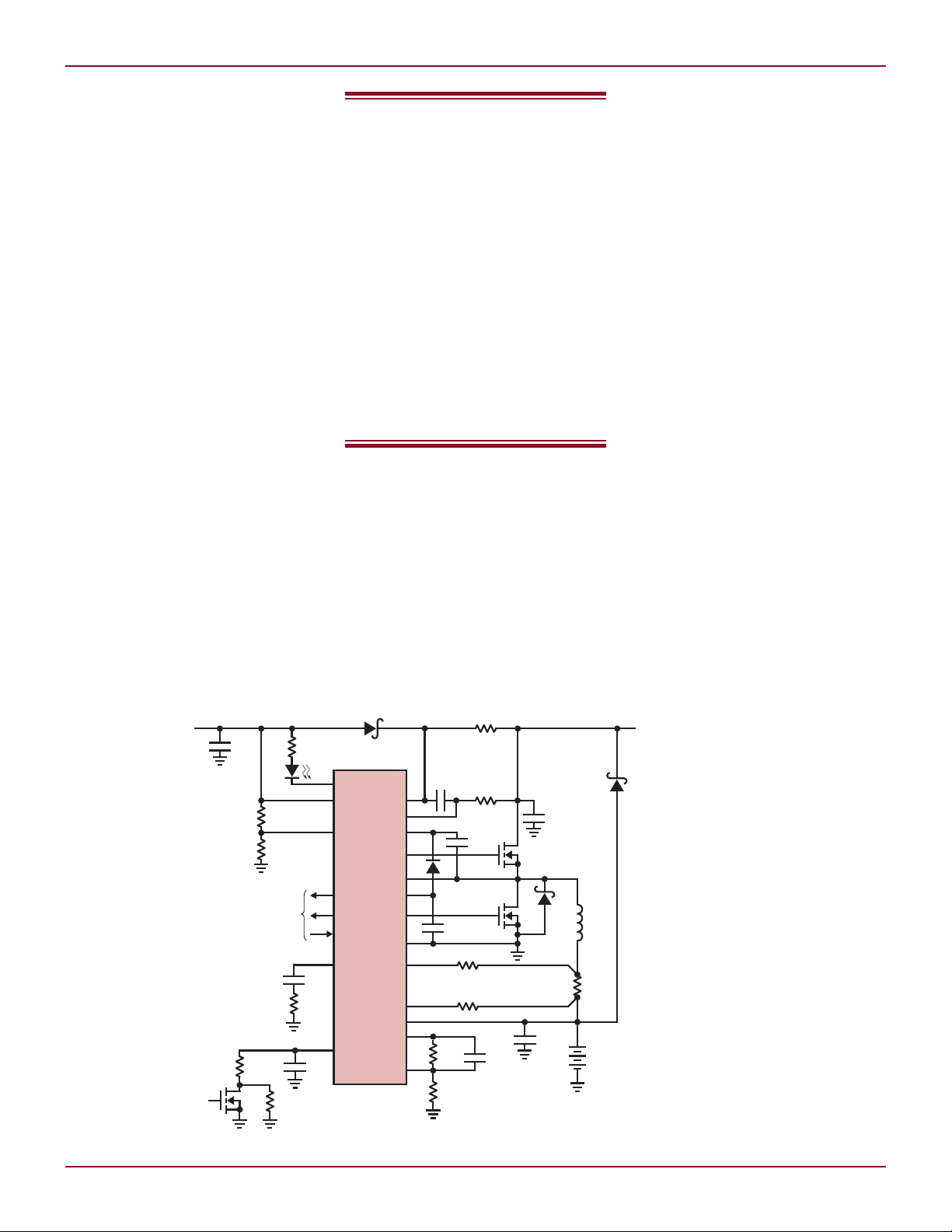

For instance, as shown in Figure 1,

the family supports direct drive of both

an N-channel MOSFET power switch

and N-channel MOSFET synchronous

When combined with just

a few external components

and termination control, the

LTC4009 family facilitates

construction of chargers

capable of delivering

up to 3A to batteries

with output power levels

approaching 50W. These

ICs are especially well

suited to implementing

microprocessor-controlled

chargers for all chemistry

types, including smart

batteries.

rectifier. N-channel MOSFETs are

desirable in high current applications because of their lower R

and the LTC4009 family uses a novel

adaptive gate drive that is insensitive

to MOSFET inertial delays to avoid

overlap conduction losses. Many

suppliers now source dual N-channel

MOSFETs in a single space-efficient

package, often with individual drive

DS(ON)

,

capabilities tailored to synchronous

buck PWM switching topologies.

Increasing the switching frequency

to 550kHz and adjusting internal bias

circuits to allow higher charge current

ripple minimize both the inductor size

and output capacitance requirements.

This is particularly important because

these components tend to dominate

the overall solution size due to continual improvements in IC and passive

SMD packaging technology.

The physical layout of a typical

3A application is shown in Figure 3,

requiring only 240mm2 of board

space.

A Rich Tradition

The LTC4009 family builds upon the

general purpose features offered by

the LTC4008 and the output voltage

programming convenience afforded

by the LTC4006. Each member of the

LTC4009 family contains the same

charge current and input current limit

programming features, along with a

full complement of charge monitoring, safety and fault management

functions. The LTC4009 has a fully

adjustable output voltage, which is set

with a simple resistor divider. Charge

Linear Technology Magazine • September 2008

Figure 1. A 12.6V, 3A lithium-ion charger

19

CLP

18V AT 3A FROM

ADAPTER

CHARGE

CURRENT

MONITOR

0.1µF

5.1k

33mΩ

3.01k

0.1µF

L1

6.8µH

50mΩ

DCIN

0.1µF

2µF

0.1µF

22.1k

1.74k

6.04k

26.7k

LTC4009-1

DCDIV

CHRG

ACP

ICL

SHDN

ITH

PROG

CLN

BOOST

TGATE

SW

INTV

DD

INTV

DD

BGATE

TO/FROM

MCU

GND

CSP

CSN

BAT

FVS1

FVS0

20µF

POWER TO

SYSTEM

4.7nF

20µF

4-CELL

Li-Ion

BATTERY

STACK

3.01k

+

D3

D4

D1

D2

Q2

Q3

D1, D3, D4: MBR230LSFT1

D2: CMDSH-3

Q1, Q2: Si7212DN

L1: IHLP-2525CZ-11

L DESIGN FEATURES

current accuracy is maintained at

output voltages below 6V, making the

LTC4009 ideal for charging nickelbased chemistries or supercaps.

The LTC4009-1 and LTC4009-2

are easy to use in lithium-based

battery products containing one to

four series cells. Each has a range

of output voltages that can be selected simply by strapping two pins

to either ground or the output of the

onboard 5V regulator, as shown for the

LTC4009-1 in Figure 2. No other external components are required to set

this precision voltage. The LTC4009-1

provides 4.1V/cell settings in support

of evolving consumer product safety

standards or coke-anode cells, while

the LTC4009-2 utilizes 4.2V/cell for

conventional full-capacity charging

of graphite-anode lithium-ion packs.

The ICs contain a dedicated PMOS

switch that during shutdown removes

the additional current drained from

the battery by the resistive feedback

divider, whether external or internal.

Table 1 compares the features of the

LTC4009 family to the LTC4008.

Battery Charge Management

The LTC4009 family contains all of the

features required for complete external

charge control and state monitoring

with a logic-level shutdown control

input and three open-drain status

outputs. All charging is unconditionally suspended and battery drain

is reduced to its lowest levels if the

SHDN input is asserted by driving the

pin to ground. DC input supply voltage is sensed by feeding an external

resistor voltage divider to the DCDIV

sense input. The AC present status

output indicates whether or not this

input voltage is within a valid range

for charging under all modes of operation, whether charging is in progress

or suspended. There is a charge status

output that indicates when the battery

is being charged. The drive level of

this pin changes from low impedance

(about 2k) to a 25µA pull-down current

source to indicate that the charge current has dropped to one-tenth of the

programmed full-scale bulk value.

These control inputs and status

outputs of the LTC4009, along with

20

Figure 2. A 16.4V, 2A lithium-ion charger

the analog current monitor output,

can be used by the host system to

perform necessary preconditioning,

charge termination and safety timing

functions.

Charge Fault Management:

Safety First

The LTC4009 family has a built-in fault

management system that suspends

charging immediately for various internal and external fault conditions.

First, battery overvoltage protection is

provided with a comparator that looks

for sudden loss of battery load during

charge. This comparator instantly sus-

Figure 3. A typical LTC4009 application layout

pends PWM activity when the battery

voltage rises above the programmed

output voltage by 6%. This protects the

charger, the battery, and downstream

components in charger-fed topologies

under the condition where the battery

is suddenly removed or if internal

battery pack electronics momentarily

disconnect the load in order to perform

functions such as calibration or pulse

charging.

Next, the DC sensing input has both

under and overvoltage threshold limits

to ensure the system is protected from

starting or running during unsafe

conditions, such as transient input

overvoltage or an overloaded DC input

adapter.

These parts have several means of

detecting or avoiding reverse charge

current. For instance, reverse current

can occur in a synchronous system

if a slightly overcharged battery is

inserted, with the resulting reverse

current discharging the battery and/or

damaging other system components.

To prevent reverse currents, the parts

in this family first monitor the PROG

pin for reverse current. PROG outputs

a voltage analog of the average charge

current flowing in the system. Next, the

continued on page 33

Linear Technology Magazine • September 2008

part are shown in Table 1. Soft-start

LOAD STEP 1A-8A

VIN = 12V

V

OUT

= 1.2V

FCB = 0V

200mV

V

OUT

200mV/DIV

I

L

5A/DIV

LOAD CURRENT (A)

0.01

50

EFFICIENCY (%)

55

65

75

60

70

80

85

90

0.1 1 10

VIN = 12V

FREQ = 550kHz

CCMDCM

and latch off functions are controlled

by the RUN/SS pin, preventing inrush

current and current overshoot during

startup, and providing the option of

latch-off if an under voltage or short

circuit is presented. An open drain

power-good pin monitors the output

and pulls low if the output voltage is

±10% from the regulation point.

Conclusion

The LTC3608, LTC3609, LTC3610

and LTC3611 buck regulators offer the efficiency and power output

capability of separate (controller +

discrete) MOSFET solutions with

the ease-of-use and space-saving

advantages of traditional MOSFET on-the-die monolithics. These parts

also yield higher efficiencies than

Figure 3. Transient response for the typical

LTC3608 application represented in Figure 1

with a load step of 1A to 8A

traditional monolithic solutions.

They conserve power, save space, and

simplify power designs. They reduce

discrete components over controller-based solutions, making them a

DESIGN IDEAS L

Figure 2. Efficiencies for a typical

LTC3608 application in discontinuous

conduction mode (DCM) and continuous

conduction mode (CCM)

good fit in everything from low power

portable device applications such as

notebook and palmtop computers

to high-power industrial distributed

power systems.

L

LTC3610 LTC3611 LTC3608 LTC3609

PVIN Max 24V 32V 18V 32V

I

Max 12A 10A 8A 6A

LOAD

Package

R

DS(ON)

Top FET

R

DS(ON)

Bottom FET

LTC4009, continued from page 20

9mm × 9mm × 0.9mm

64-pin

12mΩ 15mΩ 14mΩ 19mΩ

6.5mΩ 9mΩ 8mΩ 12mΩ

LTC4009 family monitors the voltage

across the input blocking diode for

unexpected voltage reversal. Initial

startup, restarts from fault conditions,

and charge current reduction during

input current limit are also carefully

controlled to avoid producing reverse

current.

All members of the family provide

an input current limit flag to tell the

system when the adapter is running

at over 95% of its current capacity.

Finally, each IC features internal

over-temperature protection to prevent silicon damage during elevated

thermal operation.

Recovery from all fault conditions is

under full control of the analog feed-

Linear Technology Magazine • September 2008

Table 1. Integrated MOSFET buck regulators

9mm × 9mm × 0.9mm

64-pin

7mm × 8mm × 0.9mm

52-pin

back loops, which guarantees charging

remains suspended until the internal

feedback loops respond coherently and

report the need to supply current to

the load to maintain proper voltage or

current regulation.

Conclusion

The LTC4009 family integrates a full

set of charger building blocks in a small

PCB footprint. The result is a high

power battery charger IC with high

precision and a full set of monitoring

and fault handling features.

The LTC4009 provides adjustable

output voltage control with a simple,

external, user-programmed resistive

voltage divider. As such, it is suitable as

a general purpose charger that works

7mm × 8mm × 0.9mm

52-pin

with multiple battery chemistries and

supercaps. It offers direct control over

the entire charge process, facilitating

implementation of a wide range of

charge termination algorithms with

an external microprocessor.

The LTC4009-1 and LTC4009-2

feature pin-programmable output

voltage for common lithium-ion or

lithium-polymer battery pack configurations with one to four series cells.

For these chemistries, the number of

precision external application components is reduced without sacrificing

accuracy. Both 4.1V/cell (LTC4009-1)

and 4.2V/cell (LTC4009-2) options are

available, allowing the user to balance

capacity and safety per the demands

of the application.

L

3333

Loading...

Loading...