FEATURES

■

N-Channel Synchronous MOSFET Driver

■

Programmable Timeout

■

Reverse Inductor Current Sense

■

Gate Drive Transformer Synchronization

Sequence Monitor

■

Wide VCC Supply Range: 4.5V to 11V

■

15ns Rise/Fall Times at VCC = 5V, CL = 4700pF

■

Undervoltage Lockout

■

Small 16-Lead SSOP Package

U

APPLICATIO S

■

48V Input Isolated DC/DC Converters

■

Isolated Telecom Power Supplies

■

Distributed Power Step-Down Converters

■

Industrial Control System Power Supplies

■

Automotive and Heavy Equipment

LTC3901

Secondary Side

Synchronous Driver for Push-Pull

and Full-Bridge Converters

U

DESCRIPTIO

The LTC®3901 is a secondary side synchronous rectifier

driver designed to be used in isolated push-pull and fullbridge converter power supplies. The chip drives two

external N-channel MOSFETs and accepts a transformergenerated bipolar input to maintain sychronization with

the primary side controller.

The LTC3901 provides a full range of protection features

for the external MOSFETs. A programmable timeout function is included that disables both drivers when the synchronization signal is missing or incorrect. Additionally,

the chip senses the output inductor current through the

drain-source resistance of the two MOSFETs, turning off

the MOSFETs if the inductor current reverses. The LTC3901

also shuts off the drivers if the supply is low or if the

synchronization sequence is incorrect.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

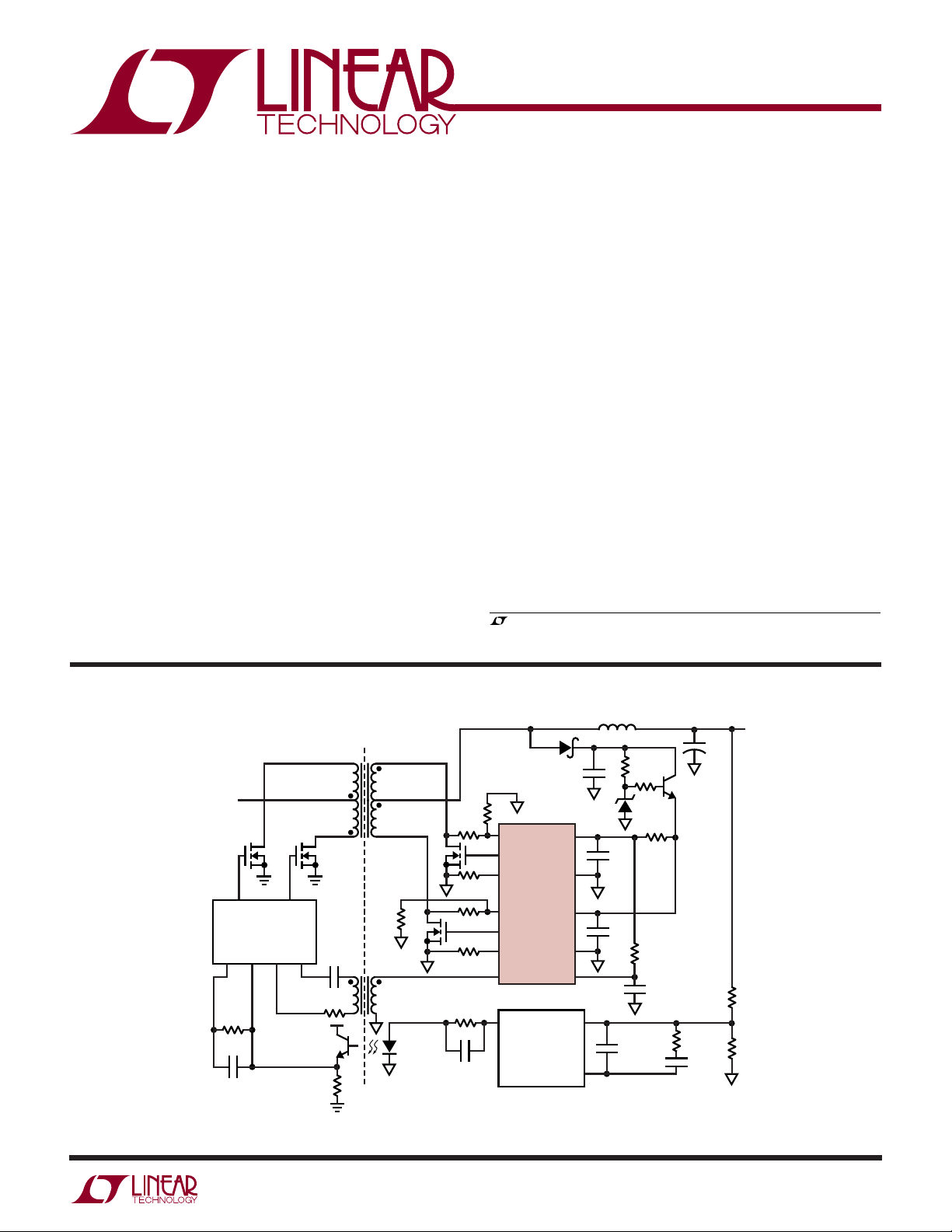

TYPICAL APPLICATIO

V

IN

36V TO 72V

MA MB ME

DRVA DRVB

LTC3723

PUSH-PULL

CONTROLLER

COMP V

FB

U

ISOLATION

BARRIER

T1

+

CSE

ME

CSE

CSF

MF

SDRBSDRA

T2

MF

CSF

SYNC

OUT

LT4430 OR LT1431

V

–

GND

LTC3901

+

PV

–

PGND

TIMER

OPTOCOUPLER

DRIVER

COMP

CC

CC

L1

+

FB

C

3901 F01

OUT

V

12V

OUT

Figure 1. Simplified Isolated Push-Pull Converter

3901f

1

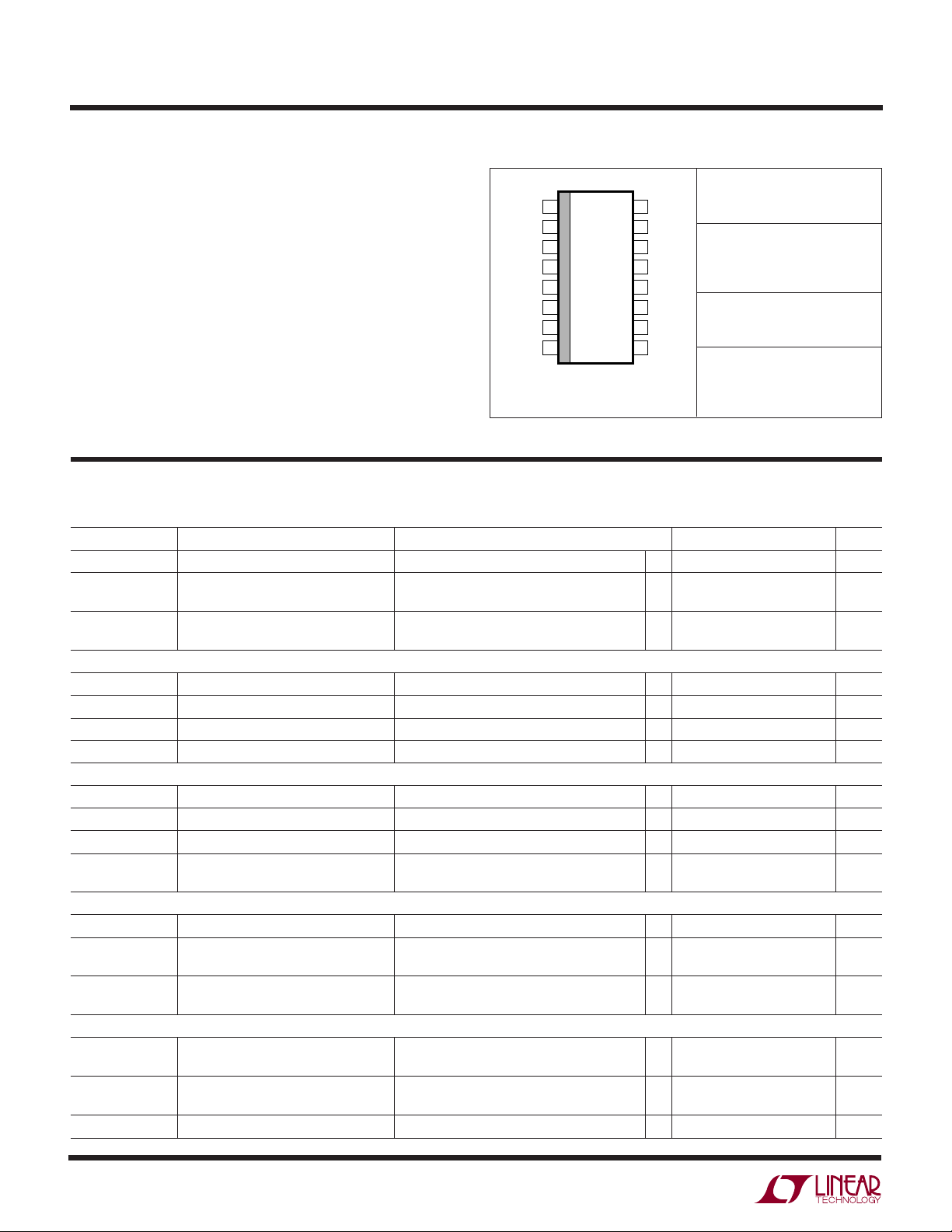

LTC3901

TOP VIEW

GN PACKAGE

16-LEAD NARROW PLASTIC SSOP

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

PV

CC

ME

ME

PGND

CSE

–

CSE

+

TIMER

GND

V

CC

MF

MF

PGND

CSF

–

CSF

+

GND

SYNC

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage

, PV

V

CC

Input Voltage

–

CSE

, CSF–, TIMER ................. –0.3V to (VCC + 0.3V)

SYNC ...................................................... –12V to 12V

Input Current

CSE+, CSF

Operating Temperature Range (Note 2) ...–40°C to 85°C

Storage Temperature Range ..................–65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ELECTRICAL CHARACTERISTICS

temperature range. V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

V

UVLO

I

VCC

Timer

V

TMR

I

TMR

t

TMRDIS

V

TMRMAX

Current Sense (Note 5)

ICS+CS

ICS–CS

V

CSMAX

V

CS

SYNC Input

I

SYNC

V

SYNCP

V

SYNCN

Driver Output

R

ONH

R

ONL

I

PK

2

WW

W

............................................................................

CC

+

.....................................................................

= 5V, TA = 25°C unless otherwise specified. (Note 3)

CC

Supply Voltage Range ● 4.5 5 11 V

VCC Undervoltage Lockout Threshold Rising Edge ● 4.1 4.5 V

V

Undervoltage Lockout Hysteresis Rising Edge to Falling Edge 0.5 V

CC

VCC Supply Current V

Timer Threshold Voltage ● –10% VCC/5 10% V

Timer Input Current V

Timer Discharge Time C

Timer Pin Clamp Voltage C

+

Input Current VCS+ = 0V ● ±1 µA

–

Input Current VCS– = 0V ● ±1 µA

CS+ Pin Clamp Voltage IIN = 5mA, Driver Off 11 V

Current Sense Threshold Voltage VCS– = 0V 7.5 10.5 13.5 mV

SYNC Input Current V

SYNC Input Positive Threshold ● 1.0 1.4 1.8 V

SYNC Positive Input Hysteresis (Note 7) 0.2 V

SYNC Input Negative Threshold ● –1.8 –1.4 –1.0 V

SYNC Negative Input Hysteresis (Note 7) 0.2 V

Driver Pull-Up Resistance I

Driver Pull-Down Resistance I

Driver Peak Output Current (Note 7) 2 A

U

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

12V

15mA

T

= 125°C, θJA = 130°C/W

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

The ●

denotes specifications which apply over the full operating

= 0V ● 0.5 1 mA

SYNC

f

= 100kHz, CME = CMF = 4700pF (Note 4) ● 715 mA

SYNC

= 0V ● –6 –10 µA

TMR

= 1000pF, R

TMR

= 1000pF, R

TMR

(Note 6)

= ±10V ● ±1 ±10 µA

SYNC

= –100mA 0.9 1.2 Ω

OUT

= 100mA 0.8 1.2 Ω

OUT

= 4.7k ● 40 120 ns

TMR

= 4.7k 2.5 V

TMR

● 318mV

● 1.6

● 1.6

NUMBER

LTC3901EGN

GN PART

MARKING

3901

3901f

LTC3901

ELECTRICAL CHARACTERISTICS

temperature range.

V

= 5V, TA = 25°C unless otherwise specified. (Note 3)

CC

The ●

denotes specifications which apply over the full operating

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Switching Characteristics (Note 8)

t

d

tr, t

f

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3901E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design; characterization and correlation

with statistical process controls.

Note 3: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Note 4: Supply current in normal operation is dominated by the current

needed to charge and discharge the external MOSFET gates. This current

SYNC Input to Driver Output Delay CME = CMF = 4700pF, V

Driver Rise/Fall Time CME = CMF = 4700pF, V

will vary with supply voltage, switching frequency and the external

MOSFETs used.

Note 5: Both CSE

the same performance specifications.

Note 6: The current sense comparator threshold has a 0.33%/°C

temperature coefficient (TC) to match the TC of the external MOSFET

R

DSON

Note 7: Guaranteed by design, not subject to test.

Note 8: Rise and fall times are measured using 10% and 90% levels. Delay

times are measured from ±1.4V at SYNC input to 20%/80% levels at the

driver output.

= ±5V ● 60 120 ns

SYNC

= ±5V 15 ns

SYNC

+

, CSE– and CSF+, CSF– current sense comparators have

.

UW

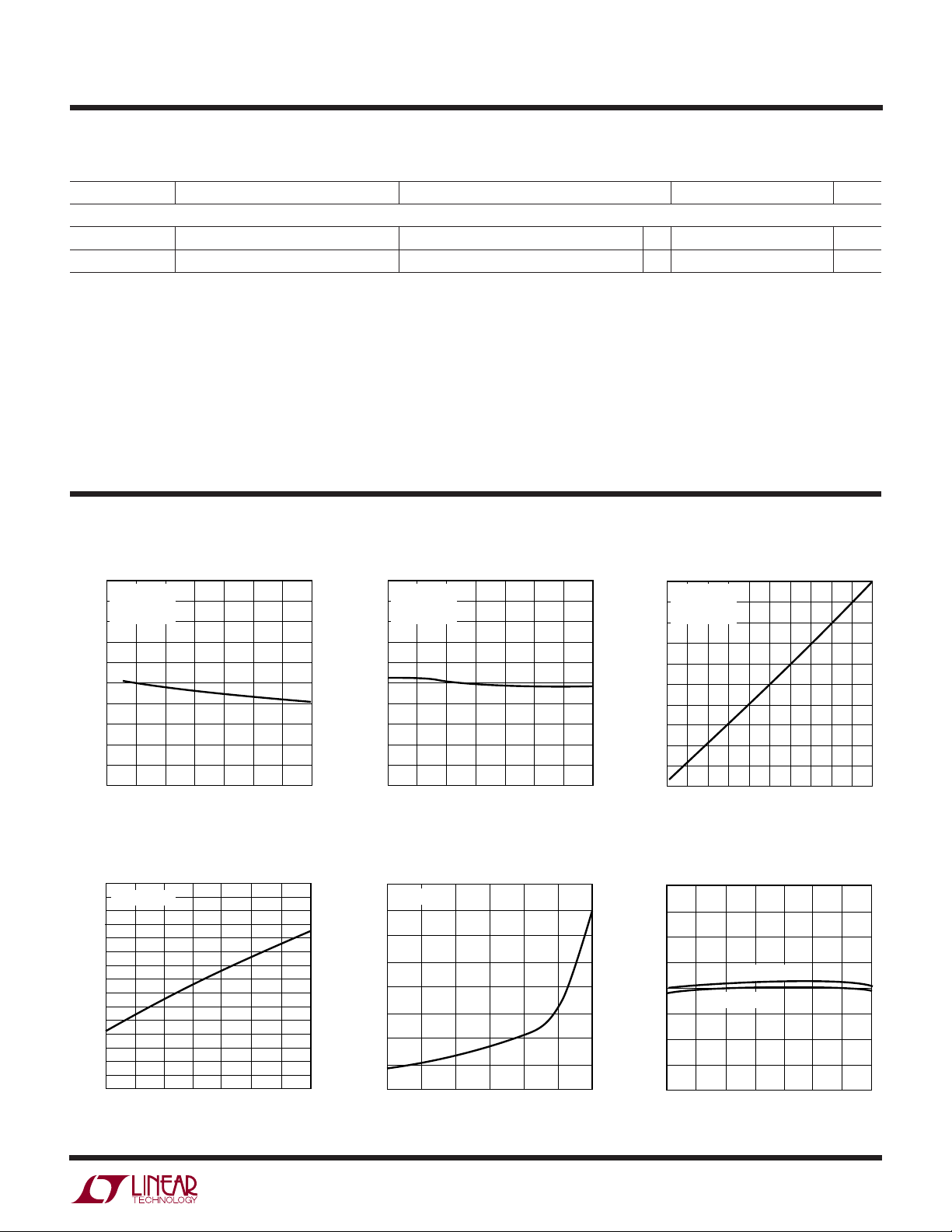

TYPICAL PERFOR A CE CHARACTERISTICS

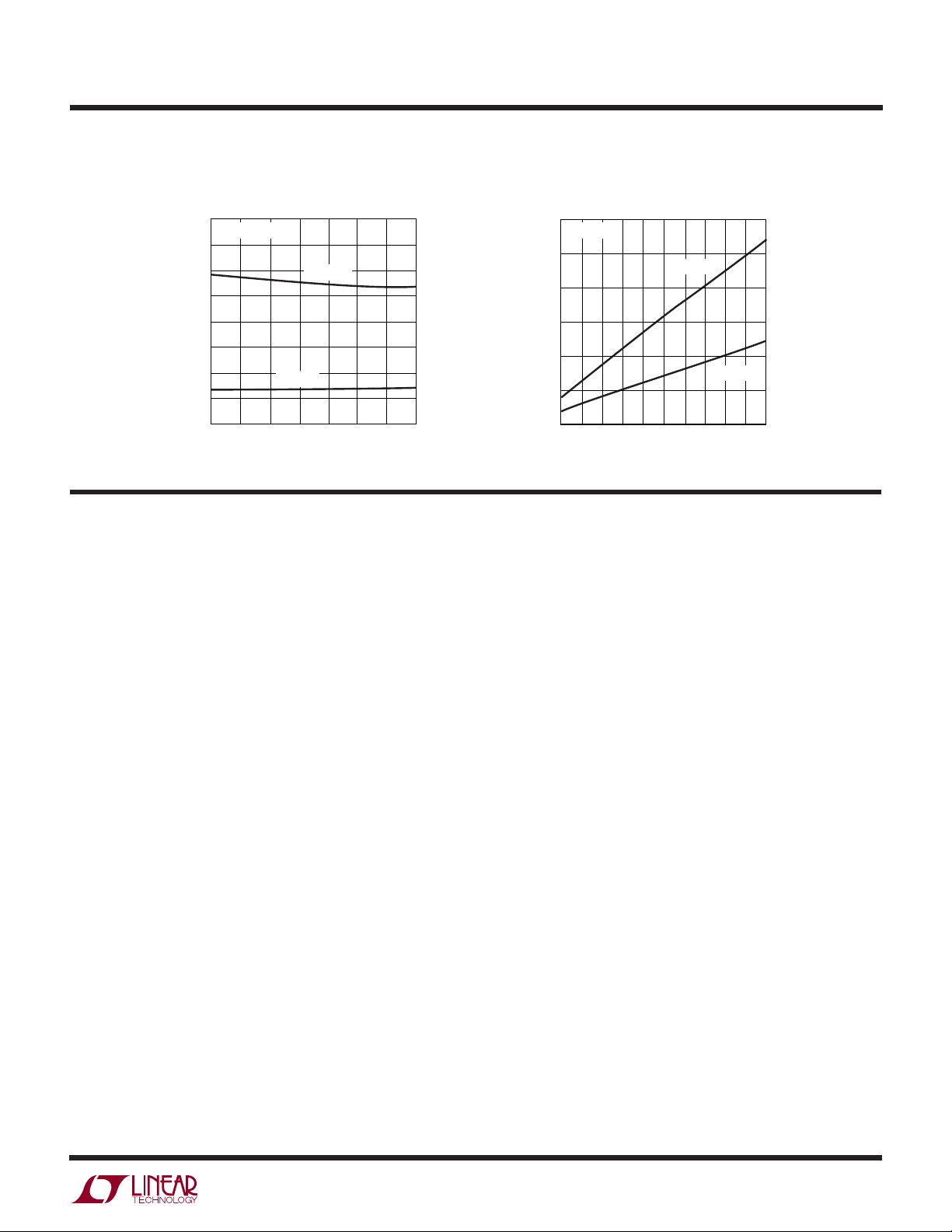

Timeout vs V

5.25

TA = 25°C

5.20

R

TMR

C

TMR

5.15

5.10

5.05

5.00

4.95

TIMEOUT (µs)

4.90

4.85

4.80

4.75

4

5

= 51k

= 470pF

CC

8

7

6

VCC (V)

Current Sense Threshold vs

Temperature

18

VCC = 5V, 11V

17

16

15

14

13

12

11

10

9

8

7

6

5

CURRENT SENSE THRESHOLD (mV)

4

3

–50 100

050–25 25 75 125

TEMPERATURE (°C)

Timeout vs Temperature

5.25

VCC = 5V

5.20

5.15

5.10

5.05

5.00

4.95

TIMEOUT (µs)

4.90

4.85

4.80

10

11

3901 G01

9

4.75

= 51k

R

TMR

= 470pF

C

TMR

–50 0

–25

V

CS(MAX)

50

25

TEMPERATURE (°C)

75

100

Clamp Voltage vs CS

125

3901 G02

+

Input Current

18

TA = 25°C

17

16

15

14

CLAMP VOLTAGE (V)

13

12

CS(MAX)

V

11

3901 G04

10

05

10 2015

+

CS

INPUT CURRENT (mA)

25

30

3901 G05

Timeout vs R

10

TA = 25°C

9

= 5V

V

CC

= 470pF

C

TMR

8

7

6

5

4

TIMEOUT (µs)

3

2

1

0

0 10203040506070 8090100

TMR

R

TMR

(kΩ)

SYNC Positive Threshold vs

Temperature

1.8

1.7

1.6

1.5

1.4

1.3

1.2

SYNC POSITIVE THRESHOLD (V)

1.1

1.0

–25 25 75 125

–50

VCC = 11V

VCC = 5V

050

TEMPERATURE (°C)

3901 G03

100

3901 G06

3901f

3

LTC3901

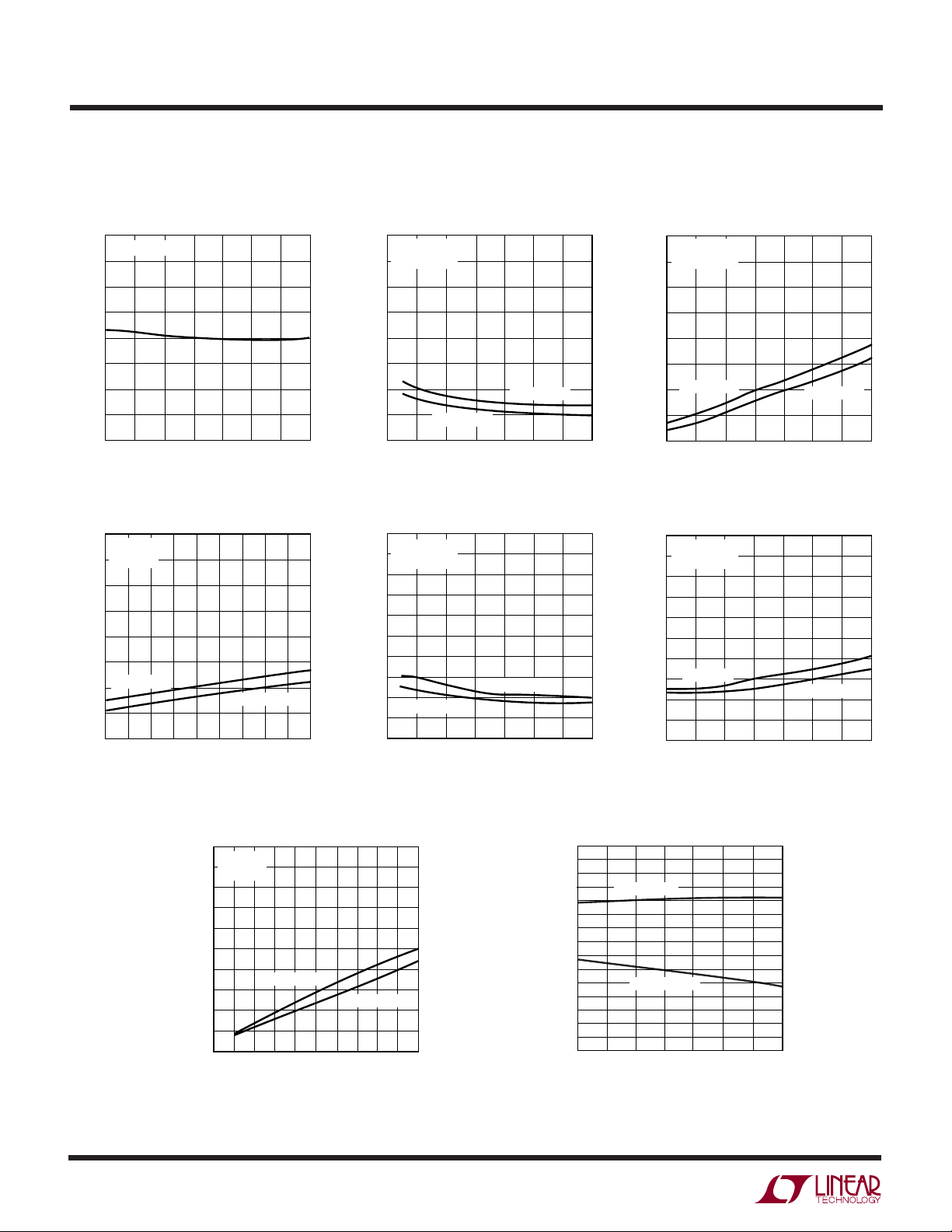

UW

TYPICAL PERFOR A CE CHARACTERISTICS

SYNC Negative Threshold vs

Temperature Propagation Delay vs V

–1.0

VCC = 5V, 11V

–1.1

–1.2

–1.3

–1.4

–1.5

–1.6

SYNC NEGATIVE THRESHOLD (V)

–1.7

–1.8

–50

Propagation Delay vs C

120

TA = 25°C

V

110

100

90

80

70

SYNC TO ME

60

PROPAGATION DELAY (µs)

50

40

123 10

050

–25 25 75 125

TEMPERATURE (°C)

LOAD

= 5V

CC

SYNC TO MF

4567 98

C

(nF)

LOAD

100

3901 G07

3901 G10

120

TA = 25°C

= 4.7nF

C

110

LOAD

100

90

80

70

60

PROPAGATION DELAY (µs)

50

40

4

SYNC TO MF

57911

68

Rise/Fall Time vs V

50

TA = 25°C

45

40

35

30

25

20

15

RISE/FALL TIME (ns)

10

= 4.7nF

C

LOAD

FALL TIME

5

0

410

6857911

Rise/Fall Time vs Load

Capacitance

50

TA = 25°C

45

= 5V

V

CC

40

35

30

25

20

15

RISE/FALL TIME (ns)

10

5

0

RISE TIME

FALL TIME

1023 104567 98

C

(nF)

LOAD

V

V

(V)

CC

(V)

CC

CC

SYNC TO ME

10

3901 G08

CC

RISE TIME

3901 G11

Undervoltage Lockout Threshold

Voltage vs Temperature

4.5

4.4

4.3

4.2

4.1

4.0

3.9

3.8

3.7

3.6

VOLTAGE (V)

3.5

3.4

3.3

3.2

UNDERVOLTAGE LOCKOUT THRESHOLD

3.1

3.0

–50 100

RISING EDGE

FALLING EDGE

Propagation Delay vs

Temperature

120

VCC = 5V

= 4.7nF

C

110

LOAD

100

90

80

70

SYNC TO ME

60

PROPAGATION DELAY (µs)

50

40

–50 100

050–25 25 75 125

TEMPERATURE (°C)

Rise/Fall Time vs Temperature

50

VCC = 5V

45

40

35

30

25

20

15

RISE/FALL TIME (ns)

10

5

0

050–25 25 75 125

TEMPERATURE (°C)

= 4.7nF

C

LOAD

RISE TIME

–50 100

050–25 25 75 125

TEMPERATURE (°C)

3901 G143901 G13

SYNC TO MF

3901 G09

FALL TIME

3901 G12

4

3901f

UW

TYPICAL PERFOR A CE CHARACTERISTICS

V

Supply Current vs

CC

Temperature

20

C

= 4.7nF

LOAD

18

16

14

12

10

SUPPLY CURRENT (mA)

8

CC

V

6

4

–50 100

VCC = 11V

VCC = 5V

050–25 25 75 125

TEMPERATURE (°C)

3901 G15

30

25

20

15

10

SUPPLY CURRENT (mA)

V

Supply Current

CC

vs Load Capacitance

TA = 25°C

5

0

1023 104567 98

C

LOAD

LTC3901

VCC = 11V

VCC = 5V

(nF)

3901 G16

U

UU

PI FU CTIO S

P

VCC (Pin 1): Driver Supply Input. This pin powers the

ME and MF drivers. Bypass this pin to PGND using a 4.7µF

low ESR capacitor in close proximity to the LTC3901. This

pin should be connected to the same supply voltage as the

VCC pin.

ME (Pin 2, 3): Driver Output for ME. This pin drives the

gate of the external N-channel MOSFET, ME.

PGND (Pin 4,13): Power Ground. Both drivers return to

this pin. Connect PGND to a high current ground node in

close proximity to the sources of ME and MF.

CSE+, CSE– (Pin 6, 5): ME Current Sense Differential

Input. Connect CSE+ through a series resistor to the drain

of ME and CSE– through a series resistor to the source of

ME. The LTC3901 monitors the CSE inputs 250ns after ME

goes high. If the inductor current reverses and flows into

ME causing CSE+ to rise above CSE– by more than 10.5mV,

the LTC3901 pulls ME low. See the Current Sense section

for more details on choosing the resistance values for

R

to R

CSE1

TIMER (Pin 7): Timer Input. Connect this pin to an external

R-C network to program the timeout period. The LTC3901

resets the timer at every positive and negative transition of

the SYNC input. If the SYNC signal is missing or incorrect,

the LTC3901 pulls both ME and MF low once the TIMER

pin goes above the timeout threshold. See the Timer section for more details on programming the timeout period.

CSE3

.

GND (Pin 8,10): Signal Ground. All internal low power

circuitry returns to this pin. To minimize differential ground

currents, connect GND to PGND right at the LTC3901.

SYNC (Pin 9): Driver Synchronization Input. 0V at this pin

forces both ME and MF high after an initial negative pulse.

A subsequent positive pulse at SYNC input forces ME to

pull low, whereas a negative pulse forces MF to pull low.

The SYNC signal should alternate between positive and

negative pulses. If the SYNC signal is incorrect, the LTC3901

pulls both MF and ME low.

CSF+, CSF– (Pin 11, 12): MF Current Sense Differential

Input. Connect CSF+ through a series resistor to the drain

of MF and CSF– through a series resistor to the source of

MF. The LTC3901 monitors the CSF inputs 250ns after MF

goes high. If the inductor current reverses and flows into

MF causing CSF+ to rise above CSF– by more than 10.5mV,

the LTC3901 pulls MF low. See the Current Sense section

for more details on choosing the resistance values for

R

CSF1

to R

CSF3

.

MF (Pin 14, 15): Driver Output for MF. This pin drives the

gate of the external N-channel MOSFET, MF.

VCC (Pin 16): Power Supply Input. All internal circuits

except the drivers are powered from this pin. Bypass this

pin to GND using a 1µF capacitor in close proximity to the

LTC3901.

3901f

5

LTC3901

BLOCK DIAGRA

9

SYNC

+

CSE

6

–

CSE

5

+

CSF

11

–

CSF

12

TIMER

7

W

10.5mV

+

–

10.5mV

+

–

+1.4V

–1.4V

Z

11V

CSF

Z

11V

S

S

ISE

CSE

ISF

TMR

+

–

SYNC

–

SYNC

AND

DRIVER

LOGIC

TIMER

RESET

R1

180k

DISABLE

DRIVER

UVLO

V

16

CC

PV

1

CC

3

ME

4

PGND

14

MF

13

PGND

+

SYNC

R2

45k

M

U

TMR

Z

TMR

0.5 • V

CC

WUU

APPLICATIO S I FOR ATIO

Overview

Push-pull and full bridge converters use power transformers to provide input-to-output isolation and voltage stepup/down. Diodes are used as a simple solution for secondary side rectification. Unfortunately, as output currents

increase, the loss associated with diode forward voltage

drop results in low overall efficiency. The LTC3901 overcomes this problem by providing control and drive for two

external N-channel synchronous MOSFETs. Synchronization to the primary side controller is maintained through a

small signal transformer.

Figure 1 shows a simplified push-pull converter application. T1 is the power transformer; MA and MB are the

primary side power transistors driven by the LTC3723

controller’s DRVA and DRVB outputs. The gate drive

transformer T2 is driven by the LTC3723’s SDRA and

SDRB outputs and provides the synchronization signal to

the LTC3901 on the secondary side. When both SDRA and

SDRB are high, there is no voltage across the transformer’s

primary and the LTC3901 SYNC input is approximately 0V.

According to the polarity of the transformer: if SDRA goes

low while SDRB is high, SYNC is positive; if SDRB goes

low while SDRA is high, SYNC is negative. ME and MF are

108

3901 BD

GND GND

the secondary side synchronous switches driven by the

LTC3901’s ME and MF output. Inductor L1 and capacitor

C

form the output filter, providing DC output voltage to

OUT

the load. The feedback path from V

through the opto-

OUT

coupler driver and optocoupler back to the primary side

controller is also shown in Figure 1.

Each full cycle of the push-pull converter consists of four

distinct periods. Figure 2 shows the push-pull converter

waveforms.

DRVA

DRVB

SDRA

SDRB

SYNC

ME

MF

Figure 2. Push-Pull Converter Switching Waveforms

0V

3901 F02

3901f

6

WUUU

APPLICATIO S I FOR ATIO

LTC3901

In the first period, SDRA goes low (followed by DRVA

going high) and T2 generates a positive voltage at the

LTC3901’s SYNC input. The LTC3901’s ME output then

pulls low. Current flows to the load through MOSFET MF,

T1’s secondary and L1.

In the second period, SDRA goes high and T2 provides

approximately 0V at the LTC3901 SYNC input. This causes

the LTC3901’s ME output to go high and both MOSFET ME

and MF to conduct. This is the free-wheeling period with

T1 secondary winding shorted.

In the third period, SDRB goes low (followed by DRVB

going high) and T2 generates a negative voltage at the

LTC3901’s SYNC input. The LTC3901’s MF output then

pulls low. Current flows to the load through MOSFET ME,

T1’s secondary and L1.

The last period is also a free-wheeling period like the

second period. Both SDRA and SDRB are high and the

LTC3901 forces both MOSFETs ME and MF to conduct.

External MOSFET Protection

A programmable timer and two differential input current

sense comparators are included in the LTC3901 for protection of the external MOSFETs during power down and

Burst Mode® operation. The chip also shuts off the

MOSFETs if V

< 4.1V or if the synchronization sequence

CC

is incorrect.

When the primary controller is powering down, the

LTC3901 continues to operate by drawing power from the

V

bypass cap, C

CC

. The primary controller synchro-

VCC

nous output stops switching and the LTC3901 SYNC input

goes to 0V. Both ME and MF remain on and the decreasing

inductor current continues to flow into the load. Once the

inductor current decreases to zero, it reverses direction,

discharging the output capacitor C

both MOSFETs. At the same time, the C

to GND through

OUT

voltage contin-

VCC

ues to drop. When the voltage drops below 4.1V, the

LTC3901 shuts down and pulls both ME and MF low. This

causes the inductor current to stop suddenly and the drain

voltage of both MOSFETs to fly high, due to the buildup of

inductor energy. In the absence of a protection timer, if the

inductor energy is high due to a long period of current

reversal, the drain voltage can go above the MOSFET’s

voltage rating and cause damage to the MOSFET.

MOSFETs are also kept on for long periods when the

primary controller enters Burst Mode operation. Both ME

and MF stop switching until the primary controller exits

Burst Mode operation. This would also cause the inductor

current to reverse and the drains to fly high.

In both of these situations, the timer and/or current sense

comparator shuts off the drivers before or immediately

after the inductor current reverses direction. This prevents

the buildup of inductor energy.

Timer

The timer circuit (Figure 3) operates by using an external

R-C charging network to program the timeout period. On

every transition at the SYNC input, the chip generates a

200ns pulse to reset the timer capacitor. If the SYNC signal

is missing or incorrect (allowing the timer capacitor voltage to go high) it shuts off both drivers once the voltage

reaches the timeout threshold. Figure 4 shows the timer

waveforms.

V

CC

TIMER

RESET

16

V

CC

TIMER

Z

TMR

0.5 • V

CC

M

TMR

7

3901 F03

R

TMR

32k

C

TMR

470pF

TIMEOUT

THRESHOLD

3901 F02

0V

SYNC

ME

MF

TIMER RESET

(INTERNAL)

TIMER

LTC3901

TMR

TIMEOUT

R1

180k

R2

45k

Figure 3. Timer Circuit

Burst Mode is a registered trademark of Linear Technology Corporation.

Figure 4. Timer Waveforms

3901f

7

LTC3901

SYNC

ME

MF

3901 F05

0V

EXPECTED POSITIVE SYNC PULSE,

MF PULLS HIGH

SECOND NEGATIVE SYNC PULSE,

BOTH ME AND MF PULL LOW

U

WUU

APPLICATIO S I FOR ATIO

The timeout period is determined predominantly by the

external R

TMR

and C

VCC voltage. This independence is achieved by making the

timeout threshold a ratio of V

internally by R1 and R2 (see Figure 3). The Timeout period

should be programmed to around 1 period of the primary

switching frequency using the following formula:

TIMEOUT = 0.2 • R

To reduce error in the timeout setting due to the discharge

time, select C

a C

TMR

R

. C

TMR

TMR

around 470pF and then calculate the required

should be placed as close as possible to the

TMR

LTC3901 with minimum PCB trace between C

TIMER pin and GND. This is to reduce any ringing caused

by the PCB trace inductance when C

ringing may introduce error to the timeout setting.

The timer input also includes a current sinking clamp

circuit (Z

in Figure 3) that clamps this pin to about

TMR

0.5 • VCC if there is missing SYNC/timer reset pulse. This

clamp circuit prevents the timer capacitor from getting

fully charged up to the rail, which would result in a longer

discharge time. The current sinking capability of the circuit

is around 1mA.

The timeout function can be disabled by connecting the

timer pin to GND.

values and is independent of the

TMR

. The ratio is 0.2x, set

CC

TMR

• C

+ 0.27E-06

TMR

between 100pF and 1000pF. Start with

, the

TMR

discharges. This

TMR

polarity. In some situations, for example during power-up

or power-down, the SYNC pulse magnitude may be low

(slightly higher or lower than the threshold of the comparators). This can cause only one of the SYNC comparators to

trip. This also appears as a double pulse to the sequential

logic and both drivers will be shut off.

Current Sense

The differential input current sense comparators, ISE and

ISF (Figure 6), are used for sensing the voltage across the

drain-to-source terminal of the MOSFET through the CSX

+

and CSX– pins. There are two sets of comparator inputs,

one for each MOSFET (ME and MF). If the inductor current

reverses into the MOSFET causing CSX+ to rise above

CSX– by more than 10.5mV, the LTC3901 turns off the

respective MOSFET. This comparator is used to prevent

inductor reverse current buildup during power-down or

Burst Mode operation, which may cause damage to the

MOSFETs. The 10.5mV input threshold has a positive

temperature coefficient, which closely matches the TC of

the external MOSFET R

. The current sense com-

DS(ON)

parator is only active 250ns after the respective driver

Synchronization Sequence

A typical push-pull converter cycle always turns off ME

and MF alternately. The SYNC input should alternate

between a positive and negative pulse. The LTC3901

includes a sequential logic to monitor the SYNC input

pulses. If after one positive pulse the SYNC comparator

receives another positive pulse, the LTC3901 sequential

logic shuts off both drivers until a negative pulse appears.

The same applies to double negative pulses; the driver will

turn on only after receiving a positive pulse. This is to

protect the external components in situations where only

one polarity of the SYNC pulse is present and the corresponding driver remains on. Figure 5 shows the SYNC

double pulse operation.

The LTC3901 has two separate SYNC comparators (S+ and

S– in the Block Diagram) to detect the positive and negative pulses. The threshold voltages of both comparators

are designed to be of the same magnitude but opposite in

8

Figure 5. SYNC Double Pulse Operation

T1

ME

R

CSF1

MF

R

CSF3

Figure 6. Current Sense Circuit

R

R

CSE1

CSE3

R

R

CSE2

CSF2

+

CSE

6

10.5mV

–

CSE

CSF

CSF

+

–

+

–

LTC3901

10.5mV

+

–

5

11

12

Z

11V

Z

11V

ISE

CSE

ISF

CSF

3901 F06

3901f

LTC3901

U

WUU

APPLICATIO S I FOR ATIO

output goes high; this is to avoid any ringing immediately

after the MOSFETs are switched on.

Under no/light load conditions, if the inductor average

current is less than half of its peak-to-peak ripple current,

the inductor current will reverse into MOSFETs during a

portion of the free-wheeling period, forcing CSX

above CSX

–

. The current sense comparator input threshold is set at 10.5mV to prevent tripping under this normal

no load condition. If at no load, the product of the inductor

negative peak current and MOSFET R

DS(ON)

10.5mV; this may trip the comparator and force the

LTC3901 to operate in discontinuous mode. Figure 7

shows the LTC3901 operating in discontinuous mode; the

driver’s output goes low before the next SYNC transition

edge when the inductor current goes negative. In pushpull topology, both MOSFETs conduct the same amount of

current during the free-wheeling period; this will trip both

comparators at the same time. Discontinuous mode is

sometimes undesirable because if the load current sud-

SDRA

SDRB

SYNC

ME

MF

L1

CURRENT

CURRENT SENSE

COMPARATOR TRIP

Figure 7a. Discontinuous Mode Operation at No Load

SYNC

+

to rise

is higher than

0V

0V

0V

denly increases when the MOSFETs are off, it creates a

large output voltage drop. To overcome this, add a resistor

divider, R

CSX1

and R

at the CSX+ pin to increase the

CSX2

10.5mV threshold so that the LTC3901 operates in continuous mode at no load.

The LTC3901 CSX+ pin has an internal current sinking

clamp circuit (Z

) that clamps the pin to around 11V.

CSX

The clamp circuit, together with the external series resistor R

1, protects the CSX

CSX

+

pins from the high MOSFET

drain voltage in the power delivery cycle. During the power

delivery cycle, one of the MOSFETs (ME or MF) is off. The

drain voltage of the MOSFET that is off is determined by the

primary input voltage and the transformer turn ratio. This

voltage can be high and may damage the internal circuit if

CSX+ is connected directly to the drain of its MOSFET. The

current sinking capability of the clamp circuit is 5mA

minimum.

The value of the resistorsR

CSX1

, R

CSX2

and R

CSX3

should

be calculated using the following formulas to meet both

the clamp and threshold voltage requirements:

k = {48 • I

R

= {200 • V

CSX2

R

= k • R

CSX1

R

= {R

CSX3

If k = 0 or less than zero, R

= R

CSX3

RIPPLE

CSX2

CSX1

= {V

• R

DS(ON)

IN(MAX)

• R

CSX2

IN(MAX)

} –1

• NS/NP –2200 • (1 + k)} /k

} / {R

CSX2

CSX1

+ R

CSX2

}

is not needed and R

• (NS/NP) – 11V} / 5mA

CSX1

where:

I

R

V

= Inductor peak-to-peak ripple current

RIPPLE

= On-resistance of MOSFET at I

DS(ON)

IN(MAX)

= Primary side main supply maximum input

RIPPLE

/2

voltage

NS/NP = Power transformer T1, turn ratio

ME

MF

CURRENT

L1

ADJUSTED CURRENT SENSE THRESHOLD

Figure 7b. Continuous Mode Operation

with Adjusted Current Sense Threshold

0V

3901 F06

If the LTC3901 still operates in discontinuous mode with

the calculated resistance value, increase the value of

R

to raise the threshold. The resistors R

CSX1

R

and the CSX+ pins input capacitance plus the PCB

CSX2

CSX1

and

trace capacitance forms an R-C delay; this slows down the

response time of the comparators. The resistors and CSX

+

input leakage currents also create an input offset error.

To minimize this delay and error, do not use resistance

value higher than required and make the PCB trace from

3901f

9

LTC3901

3901 F09

D3

MBR0540

T1

SECONDARY

WINDING

0.1µF

R

Z

2k

R

B

OPTIONAL

Q

REG

FZT690B

C

PVCC

4.7µF

C

VCC

1µF

PV

CC

V

CC

6V

D

Z

R

VCC

100Ω

U

WUU

APPLICATIO S I FOR ATIO

the resistors to the LTC3901 CSX+/CSX– pins as short as

possible . Add a series resistor, R

parallel sum of R

connect the other end of R

CSX1

and R

CSX3

CSX2

directly to the source of the

MOSFET.

SYNC Input

Figure 8 shows the external circuit for the LTC3901 SYNC

input. The gate drive transformer (T2) should be selected

based on the primary switching frequency and SDRA/

SDRB output voltage.

The values of the C

and R

SG

SYNC

to obtain a optimum SYNC pulse shape and amplitude. The

amplitude of the SYNC pulse should be much higher than

the LTC3901 SYNC threshold of ±1.4V. Amplitudes greater

than ±5V will help to speed up the SYNC comparator and

reduce the propagation delay from SYNC to the drivers.

When SDRA and SDRB lines go low, the resulting undershoot or overshoot must not exceed the minimum SYNC

threshold of ±1V.

C

SG

0.1µF

SDRB

PRIMARY

CONTROLLER

SDRA

R

SG

220Ω

Figure 8. SYNC Input Circuit

VCC/PVCC Regulator

The VCC/PVCC supply for the LTC3901 can be generated by

peak rectifying the transformer secondary winding as

shown in Figure 9. The Zener diode DZ sets the output

voltage (VZ – 0.7V). Resistor RB (on the order of a few

hundred ohms), in series with the base of Q

required to surpress high frequency oscillations depending on Q

’s selection. A power MOSFET can also be used

REG

by increasing the zener diode value to offset the drop of the

gate-to-source voltage. The VCC input is separated from

the PVCC input through a 100Ω resistor. This lowers the

driver switching feedthrough. Connect a 1µF bypass ca-

pacitor for the VCC supply. PVCC supply current varies

linearly with the supply voltage, driver load and clock

frequency. A 4.7µF bypass capacitor for the PVCC supply

is sufficient for most applications. Alternatively, the

LTC3901 can be powered directly by V

10

, with value equal to

CSX3

to the CSX– pin and

should then be adjusted

T2

LTC3901

SYNC

R

SYNC

4.7k

3901 F08

REG

if the voltage is

OUT

, may be

Figure 9. VCC/PVCC Regulator

higher than 4.5V. This reduces the number of external

components needed.

The LTC3901 has an UVLO detector that pulls the drivers’

output low if V

V

= 1V to 4.1V. The UVLO detector has 0.5V of hyster-

CC

< 4.1V. The output remains off from

CC

esis to prevent chattering.

In a typical push-pull converter, the secondary side cir-

cuits have no power until the primary side controller starts

operating. Since power for the LTC3901 is derived from

the power transformer T1, the LTC3901 will initially remain off. During this period (V

< 4.1V), the synchronous

CC

MOSFETs ME and MF will remain off and the MOSFETs’

body diodes will conduct. The MOSFETs may experience

very high power dissipation due to a high voltage drop in

the body diodes. To prevent MOSFET damage, a V

CC

voltage greater than 4.1V should be provided quickly. The

V

supply circuit in Figure 9 will provide power for the

CC

LTC3901 within the first few switching pulses of the

primary controller, preventing overheating of the MOSFETs.

Full-Bridge Converter Application

The LTC3901 can be used in full-bridge converter applications. Figure 10 shows a simplified full-bridge converter

circuit. The LTC3901 circuit and operation is the same as

in the push-pull application (refer to Figure 1). On the primary side there are four power MOSFETs, MA to MD, driven

by the respective outputs of the primary controller. Transformer T3 and T4 step up the gate drives for MA and MC.

Each full cycle of the full-bridge converter includes four

distinct periods which are similar to those found in the

push-pull application. Figure 11 shows the full-bridge

converter switching waveforms. The shaded areas correspond to power delivery periods.

3901f

WUUU

the

APPLICATIO S I FOR ATIO

V

IN

MA

T3

MB

ISOLATION

BARRIER

MC

T4

MD

LTC3901

L1

+

T1

L2

C

OUT

V

OUT

AB CD

LTC3722-1

FULL-BRIDGE CONTROLLER

COMP V

MA

MB

MC

MD

E

FB

FE

6

+

CSE

3

ME

MF

T2

ME

5

CSE

11

CSF

14

MF

12

CSF

9

SYNC

OUT

OPTOCOUPLER

–

LTC3901

+

–

DRIVER

V

CC

GND

PV

CC

PGND

TIMER

FB

COMP

16

8,10

1

4,13

7

Figure 10. Simplified Isolated Full-Bridge Converter

In the first period, MB turns off, E goes low (followed by

MA turning on), and the LTC3901 forces ME to turn off.

The primary side delivers power to the load through

MOSFET MF, T1 and L1.

In the second period, MA remains on, MD turns off, and

MC turns on. E goes high and the LTC3901 forces both ME

and MF to conduct. This is the free-wheeling period with

the T1 secondary output shorted.

3901 F10

F

SYNC

ME

MF

0V

3901 F11

Figure 11. Full-Bridge Converter Switching Waveforms

In the third period, MA turns off, F goes low (followed by

MB turning on), and the LTC3901 forces MF to turn off.

The primary side delivers power to the load through

MOSFET ME, T1 and L2.

Like the second period, the last period is a free-wheeling

period. MB remains on, MC turns off, MD turns on, F goes

high, and the LTC3901 forces both ME and MF to conduct.

The timeout and current sense operations are the same as

in the push-pull application.

3901f

11

LTC3901

U

WUU

APPLICATIO S I FOR ATIO

MOSFET Selection

The required MOSFET R

based on allowable power dissipation and maximum required output current.

The MOSFETs body diodes conduct during the power-up

phase, when the LTC3901 V

ME and MF signals stay low and the inductor current flows

through the body diodes. The body diodes must be able to

handle the load current during start-up until V

4.1V.

The LTC3901 drivers dissipate power while the MOSFETs

are switching. The power dissipation increases with switching frequency, PVCC, and size of the MOSFETs. To calculate the driver dissipation, the total gate charge QG is used.

This parameter is found on the MOSFET manufacturers’

data sheets.

The power dissipated in each LTC3901 MOSFET driver is:

P

where fSW is the switching frequency of the converter.

= QG • PVCC • f

DRIVER

should be determined

DS(ON)

supply is ramping up. The

CC

CC

SW

reaches

PC Board Layout Checklist

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC3901:

1. Connect the 1µF C

possible to the V

C

bypass capacitor as close as possible to the PV

PVCC

and PGND pins.

2. Connect the two MOSFET drain terminals directly to the

transformer. The two MOSFET sources should be as close

together as possible.

3. Keep the timer, SYNC and VCC regulator circuit away

from the high current path of ME, MF and T1.

4. Place the timer capacitor, C

the LTC3901.

5. Keep the PCB trace from the resistors R

R

to the LTC3901 CSX+/CSX– pins as short as pos-

CSX3

sible. Connect the other ends of the resistors directly to the

drain and source of the MOSFET.

CC

bypass capacitor as close as

VCC

and GND pins. Connect the 4.7µF

CC

as close as possible to

TMR

CSX1

, R

CSX2

and

6. Make the connection between GND and PGND right at

the LTC3901 pins.

12

3901f

L6 0.65µH

1µF

V

OUT

V

E

V

F

–V

OUT

–V

OUT

8.5V

100Ω

C4

3.3µF

50V

390pF

1µF

100Ω

2k

1/4W

Q1

D6

9.1V

C1, C2, C3

470µF

6.3V

×3

Si7892DP

×3

Si7892DP

×3

1

8

49

11

V

F

V

F

5

3901 TA01

V

OUT

–V

OUT

D1

470Ω

1W

D2

100k

1k

T1

9:9:7:1:1

T2

1(1.5mH):0.5

T1

9T(150µH):9T:7T:1T:1T

••

0.1µF

330pF

C7

2.2nF

250V

+

C5

68µF

20V

+

12

11

8

7

10

9

2

4

5

6

3

1

22Ω

360Ω

L4

1mH

D4

D5

–V

OUT

V

OUT

330Ω

47Ω

0.68µF

D7

1µF, 100V TDK C3225X7R2A105M

C1-C3: SANYO 6TPB470M

C4: TDK C3225X7R1H335M

C5: AVX TPSE686M020R0150

C6: TAIYO YUDEN TMK432BJ106KM

C7: MURATA DE2E3KH222MB3B

D1, D2: DIODES INC. ES1A

D4, D5: BAS21

D6: MMBD5239B

D7: BAT54

L4: COILCRAFT DO1608C-105

L5: VISHAY IHLP-2525CZ-01

L6: PULSE PA1294.650

Q1: FZT690B

Q2: FMMT3904

R1, R2: IRC LRC-LR2512-01-R060-G

T1: EFD25 TRANSPOWER TTI8696

T2: PULSE PA0785

Q2

Si7450DPSi7450DP

80Ω

1W

100pF

200V

80Ω

1W

100pF

200V

470Ω

R1

0.06Ω

1.5W

R2

0.06Ω

1.5W

L5

1µH

1µF

100V

×3

1µF

100V

V

IN

V

IN

–V

IN

3

42610

6

5

18

1

9

14

13

7

12

16

8

3

11

5

15

6

58

1

2

V

OUT

10V

8.5V

787Ω

100Ω

220pF

4.99k

1/4W

270Ω

2.49k

0.022µF

47nF

–V

OUT

GND-F

V

+

GND-S

COLL REF

LT1431CS8

SYNC PV

CC

CSF

+

LTC3901EGN

MOC207

0.1µF

LTC3723EGN-1

V

REF

DPRGSSFBGNDR

LEB

SPRGC

T

DRVB SDRB

SDRA

COMP

V

CC

UVLO

DRVA CS

820Ω

150k

30k

5V

33k

10k

0.47µF

68nF

220pF

1µF

100pF

100Ω

1/4W

10V

66.5k

V

IN

5V

383k

75k

12

4.99k

CSF

–

14

8

4

10 13

MF

15

MF

6

V

E

4.99k

1/4W

CSE

+

5

4.99k

40.2k

CSE

–

GND PGND GND PGND

7

TIMER

2

ME

316

1

ME V

CC

1µF

••

••

•

TYPICAL APPLICATIO S

165W 36V-72V Input to 3.3V at 50A Isolated Push-Pull Converter

LTC3901

U

3901f

13

LTC3901

5

46

A

B

11V12VV

IN

MMBT3904

15

LTC3723EGN-2

DRVB

SDRB

SDRA

COMP

V

CC

UVLO

12

62k

330pF

12V

MMBZ5242B

150pF

1

0.47µF

1µF

DRVA

DPRG V

REF

RAMP SPRG GND SSCS FBC

T

470pF

0.47µF

4.7k

0.22µF

2N7002

B

CS

+

T3

1(1.5mH):0.5

T1

5:4:4:2:2

1µF

8913

1k

22Ω

0.1µF

C1

2.2nF

250V

1µF

100V

1µF

100V

1µF

100V

1µF

100V

0.22µF

Si7370DP

×2

Si7852DP

×2

1

6

5

42

3

A

Si7370DP

×2

1500pF

100V

L2 0.22µH

L3

1mH

C3

68µF

V

F

•

•

11

3

2

8

19

5

4

16

10k

120Ω

30.1k

7

10

14

7.5Ω

D4 D5

7.5Ω

220pF

100Ω

10k

3k

4.7k

1/4W

100pF

215k

15k

1/4W

SYNC PV

CC

CSF

+

V

F

LTC3901EGN

CSF

–

8

11 12

1

41013 7

1µF

1µF

3901 TA02

–V

OUT

10V

MMBZ5240B

1k

V

OUT

MF MF

GND PGND GND PGND TIMER

V

CC

330pF

14 15

10k

3k

33.2k 100Ω

4.7k

1/4W

CSE

+

V

E

20Ω 1W

–V

OUT

V

OUT

V

OUT

–V

OUT

CSE

–

65

ME ME

23 16

MMBT3904

Si7852DP

×2

L1

0.56µH

72

4

CS

+

T2

70(980µH):1

8

7

1

3

12V

D2

D1

D3

3

5

1

6

•

••

•

•

•

•

9

11

V

E

+

LTC4440ES6

BOOSTIN

+

TG

TSGND

V

CC

11V

1µF

100V

V

IN

V

IN

–V

IN

48V

IN

1µF

100V

C2

180µF

16V

+

1µF

1µF, 100V TDK C4532X7R2A105M

C1: MURATA DE2E3KH222MB3B

C2: SANYO 16SP180M

C3: AVX TPSE686M020R0150

D1-D3: BAS21

D4, D5: MMBD914

L1: COILCRAFT DO1813P-561HC

L2: SUMIDA CDEP105-0R2NC-50

L3: COILCRAFT DO1608C-105

T1: PULSE PA0801.005

T2: PULSE P8207

T3: PULSE PA0785

U

TYPICAL APPLICATIO S

240W 42V-56V Input to Unregulated 12V Half-Bridge Converter

14

3901f

LTC3901

5

46

A

B

12V

V

IN

15

LTC3723EGN-1

DRVB

SDRB

SDRA

COMP

CS

V

CC

UVLO

9

150k

1

0.47µF

1µF

DRVA

DPRG V

REF

SPRGGND SSFB C

T

330pF

22nF

100k

D8

10V

68nF

270pF

T2

1(1.5mH):0.5

T1

4T:6T(65µHMIN):6T:2T:2T

243k

2.49k

9.53k

10k

750Ω

1k

100Ω

1/4W

813

3

Si7370DP

×2

L4

1mH

C3

68µF

20V

V

F

•

•

3

2

8

19

5

4

16

10k

33k

200Ω

1/4W

R1

0.03Ω

1.5W

66.5k

RLEB

12

7

14

220pF

22nF

100Ω

665Ω

1k

866Ω

6.19k

1/4W

1.5nF

464k

30k

1/4W

SYNC PV

CC

CSF

+

V

F

LTC3901EGN

CSF

–

8

11 12

1

41013 7

1µF

4.7µF

3901 TA03

–V

OUT

V

OUT

–V

OUT

D7

10V

V

OUT

MF MF

GND PGND GND PGND TIMER

V

CC

470pF

22nF

14 15

1k

866Ω

42.2k

100Ω

MMBT3904

1k

6.19k

1/4W

CSE

+

V

E

–V

OUT

V

OUT

V

F

V

OUT

12V/20A

–V

OUT

CSE

–

65

ME ME

23 16

Si7370DP

×2

Si7852DPSi7852DP

L5

0.56µH

112

4

12V

D5

D6

3

5

1

6

•

••

•

•

9

7

V

E

+

0.1µF

1

6

5

4

B

2

A

D3

LTC4440ES6

BOOSTIN

+

TG

TSGND

V

CC

12V

3

0.1µF

Si7852DP Si7852DP

1

6

5

42

B

D4

LTC4440ES6

BOOSTIN

+

TG

TSGND

V

CC

12V

1µF

100V

×3

V

IN

V

IN

–V

IN

42V TO 56V

1µF

100V

C1, C2

47µF

16V

×2

+

1µF

1µF

100V

1µF, 100V TDK C3225X7R2A105M

C1, C2: SANYO 16TQC47M

C3: AVX TPSE686M020R0150

C4: MURATA GHM3045X7R222K-GC

D2: DIODES INC. ES1B

D3-D6: BAS21

D7, D8: MMBZ5240B

L4: COILCRAFT DO1608C-105

L5: COILCRAFT DO1813P-561HC

L6: PULSE PA1294.132 OR

PANASONIC ETQP1H1R0BFA

R1, R2: IRC LRC2512-R03G

T1: PULSE PA0805.004

T2: PULSE PA0785

6

10

I

SNS

I

SNS

0.1µF

11

58

1

2

1

MOC207

C4

2.2nF

250V

0.1µF

3

6

5

8

GND-F

V

+

GND-S

COLL REF

LT1431CS8

A

1.5k

22Ω

4.7Ω

4.7Ω

R2

0.03Ω

1.5W

V

F

D2

470pF

100V

L6

1.25µH

1k

1/4W

10Ω

1W

6

93

EFFICIENCY (%)

94

95

96

97

81012

LOAD CURRENT (A)

EFFICIENCY

14

16 18 20

42V

IN

48V

IN

56V

IN

U

TYPICAL APPLICATIO S

3901f

15

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

240W 42V-56V Input to 12V at 20A Isolated 1/4 Brick (2.3" × 1.45")

LTC3901

PACKAGE DESCRIPTIO

U

GN Package

16-Lead Plastic SSOP (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1641)

.045 ±.005

.254 MIN

RECOMMENDED SOLDER PAD LAYOUT

.007 – .0098

(0.178 – 0.249)

.016 – .050

NOTE:

1. CONTROLLING DIMENSION: INCHES

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.150 – .165

.0250 BSC.0165 ± .0015

.015 ± .004

(0.38 ± 0.10)

0° – 8° TYP

× 45°

.229 – .244

(5.817 – 6.198)

.0532 – .0688

(1.35 – 1.75)

.008 – .012

(0.203 – 0.305)

TYP

16

15

12

.189 – .196*

(4.801 – 4.978)

14

12 11 10

13

5

4

3

678

.0250

(0.635)

BSC

.009

(0.229)

9

(0.102 – 0.249)

REF

.150 – .157**

(3.810 – 3.988)

.004 – .0098

GN16 (SSOP) 0204

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1693 High Speed Single/Dual N-Channel MOSFET Drivers CMOS Compatible Input, VCC Range: 4.5V to 13.2V

LTC1698 Isolated Secondary Synchronous Rectifier Controller Use with the LT1681, Optocoupler Driver, Pulse

Transformer Synchronization

LT1952 Synchronous DC/DC Forward Controller Programmable Volt-Second Clamp and Slope Compensation

LTC3722 Synchronous Dual Mode Phase Modulated Full-Bridge Controller 50W to 2kW Power Supply Design, Adaptive Direct Sense ZVS

LTC3723 Synchronous Push-Pull Controller Adjustable Push-Pull Dead Time, High Efficiency

LTC3900 Synchronous Rectifier Driver for Forward Converters Similar Function to the LTC3901 but for Forward Converter

LTC4441 6A MOSFET Driver Adjustable Gate Drive Voltage, Programmable Blanking

LT4430 Optocoupler Driver SOT-23, Prevents Overshoot

LT/TP 1104 1K • PRINTED IN USA

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

© LINEAR TECHNOLOGY CORPORATION 2003

3901f

Loading...

Loading...