Bootstrap Biasing of High Input Voltage Step-Down Controller

Increases Converter Efficiency

Design Note 493

Goran Perica and Victor Khasiev

Introduction

High voltage buc k DC/DC controller s such as the LTC3890

(dual output) and LTC3891 (single output) are popular in

automotive applications due to their extremely wide 4V to

60V input voltage range, eliminating the need for a snubber and voltage suppression circuitry. These controllers

are also well suited for 48V telecom applications where

no galvanic isolation is required.

In a typical application for these controllers, the IC’s

supply voltage (INTV

) is provided by the on-chip LDO.

CC

This LDO produces 5V from input voltages up to 60V to

bias control circuitry and provide power FET gate drive.

Although simple, this built-in biasing scheme can be inefficient. Power losses can be significant in applications

where the input voltage is consistently high, such as in

48V telecom applications. Reducing the power losses

in the bias conversion can increase efficiency and also

reduce the controller case operating temperature.

Employing EXTVCC to Improve Efficiency

One of the at tractive feat ures of the LTC3890 and LTC3891

controllers is the external power input (EXTV

). This is

CC

a second on-chip LDO, which can be used to bias the

chip. When the input voltage is consistently high, it is

more efficient to produce the biasing voltage by stepping down the converter’s output voltage, which is fed

into EXTV

, rather than generating 5V INTVCC from the

CC

high input voltage.

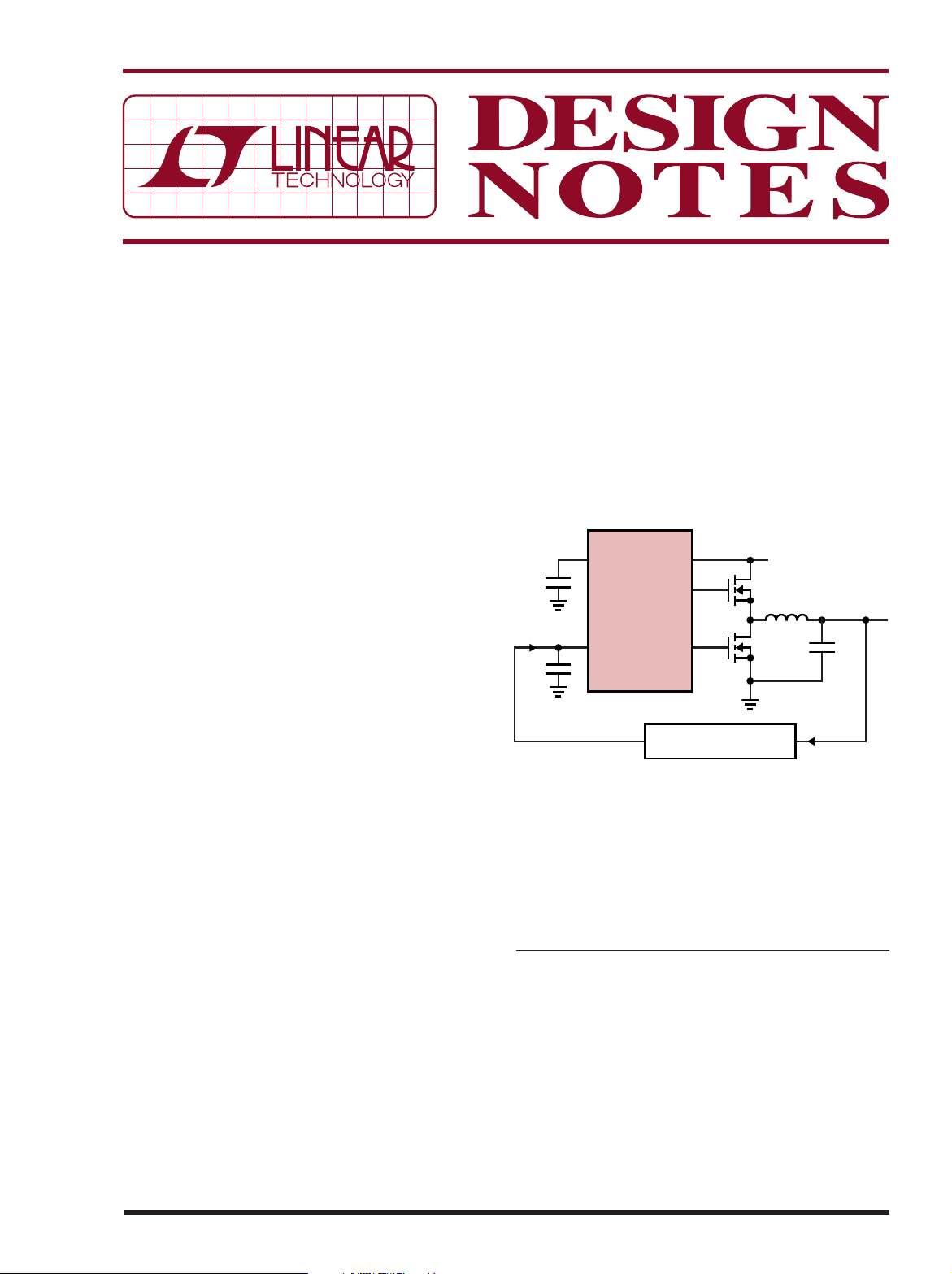

Figure 1 shows a block diagr am for this scheme. The output

can be directly connected to the EXT V

pin of the chip as

CC

long as the output voltage is above 4.7V. However, extra

circuitry (described in the following section) is required

for outputs below 4.7V.

INTV

CC

LTC3890

LTC3891

EXTV

CC

Figure 1. Block Diagram Showing External Bias

VIN (4.5V to 60V)

VOLTAGE DOUBLER OR BOOST

(FIGURE 2 OR FIGURE 3)

V

OUT

DN493 F01

(< 4.7V)

Voltage Doubler for Output Voltages Below 4.7V

When the controller’s output is below 4.7V, it must be

stepped up to allow the built-in LDO to work. A simple

voltage doubler solves this problem as long as the output

is higher than 2.5V. Below 2.5V output, a multivibratorbased circuit can be used.

L, LT, LTC, LTM, Linear Technology, and the Linear logo are registered trademarks of

Linear Technology Corporation. All other trademarks are the property of their respective

owners.

08/11/493

Figure 2 shows a simple, low cost solution for output

−

voltages between 2.5V and 4.7V. This is a voltage doubler scheme based on small P-channel and N-channel

MOSFETs, Q1 and Q2. The gates of these transistors are

controlled by the bottom gate driver, BG of the controller. When BG is high, Q2 is on, Q1 is off and capacitor

C1 charges from output voltage V

through D1. When

OUT

BG is low, Q2 is off, Q1 is on and capacitor C1 delivers

a voltage close to 2 • V

E3

EXTV

CC

Figure 2. Voltage Doubler Allows External Bias

from V

D2

MBR0520D1MBR0520

C2

2.2µF

in the Range of 2.5V to 4.7V

OUT

to EXTVCC.

OUT

C1

2.2µF

Q1

FDN340P

Q2

NDS331N

DN493 F02

E2

V

OUT

E1

BG

Figure 3 shows a solution for voltages below 2.5V. The

circuit consists of an astable multivibrator based on

transistors Q1 and Q2, and a boost based on N-channel

Q3 and inductor L1. Q1 and Q2 are biased from INTV

CC

and output voltage V

EXTV

. The multivibrator frequency is set at 50kHz to

CC

is stepped up to 5V, which feeds

OUT

minimize the EMI signature. The pulse width is defined

by the ratio of resistors R1 and R2, as per the following

expressions:

T •(1

0.7 • C1

T •D

0.7 • C2

EXTV

1

ƒ

CC

D)

− V

CC

OUT

R1=

R2 =

EXTV

D =

T =

Conclusion

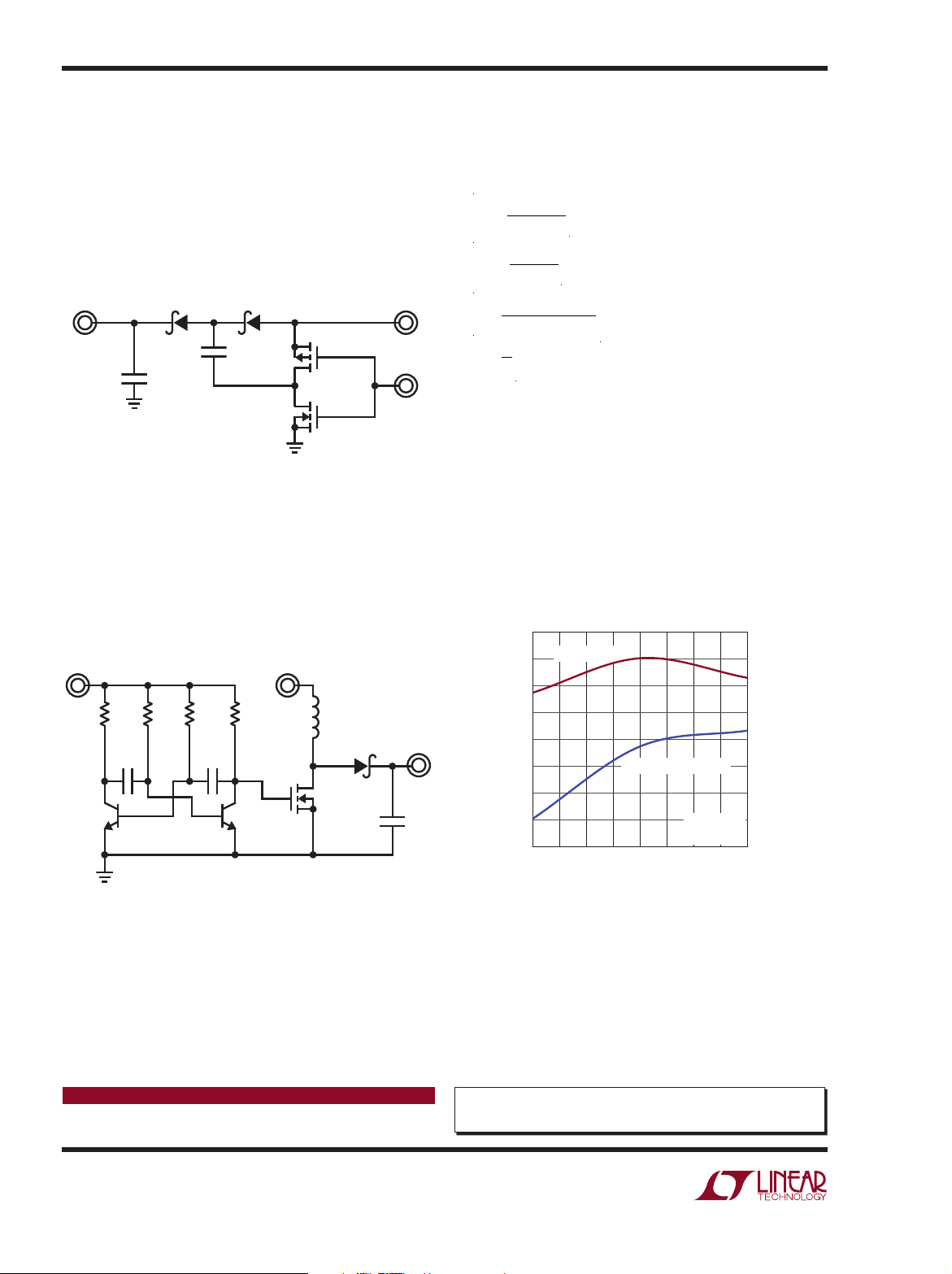

The efficiency of high input voltage DC/DC controllers

can be significantly improved by using the controller’s

output voltage to power the IC, instead of allowing the

internal LDO to produce the bias voltage. For input voltages above 30V, efficiency improvements of 2% to 3%

are realized when a voltage doubler circuit is used for a

3.3V at 5A output (see Figure 4). Similar efficiency improvements are shown for a 1.8V at 7A converter with a

multivibrator-based circuit.

INTV

E1

RC1

CC

R1

1k

93.1kR237.4k

C1

220pF

Q1

FMMT2222ATA

C2

220pF

E2

V

OUT

RC2

1k

Q2

FMMT2222ATA

L1

LPS5030-334ML

330µH

D1

MBR0520

Q3

TN0200K

Figure 3. Boost Controlled By Astable Multivibrator

Is Used for V

Data Sheet Download

www.linear.com

Lower Than 2.5V

OUT

DN493 F03

EXTV

C3

2.2µF

92

CHARGE PUMP

91

90

89

88

E3

CC

(%)

87

86

85

84

1

1.5 2 2.5 3 4.5 5

STANDARD SOLUTION

(A)

3.5 4

VIN = 50V

= 3.3V

V

OUT

DN493 F04

Figure 4. LTC3890/LTC3891

Efficiency Improvement

For applications help,

call (408) 432-1900, Ext. 2134

Linear Technology Corporation

dn493f LT/AP 0811 226K • PRINTED IN THE USA

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

LINEAR TECHNOLOGY CORPORATION 2011

Loading...

Loading...