L DESIGN FEATURES

V

OUT

(AC)

50mV/DIV

V

SW

20V/DIV

I

L

10A/DIV

I

LOAD

10A/DIV

5µs/DIV

LOAD STEP 0A TO 10A

VIN = 12V

V

OUT

= 1.2V

MODE = 0V

SW FREQ = 400kHz

V

OUT

(AC)

50mV/DIV

V

SW

20V/DIV

I

L

10A/DIV

I

LOAD

10A/DIV

5µs/DIV

LOAD STEP 10A TO 0A

VIN = 12V

V

OUT

= 1.2V

MODE = 0V

SW FREQ = 400kHz

Compact No R

SENSE

Controllers

Feature Fast Transient Response

and Regulate to Low V

from Wide Ranging V

Introduction

The trend in digital electronics is to

lower voltages and increasing load currents. This puts pressure on DC/DC

converters to produce low voltages

from increasingly voltage-variable

supplies, such as stacked batteries

and unregulated intermediate power

buses, so power converters must be

optimized for low output voltages, low

duty factors, and wide control bandwidths. To meet these requirements,

the DC/DC controller IC must offer

high voltage accuracy, good line and

load regulation, and fast transient

response. The constant on-time valley current mode architecture used in

the LTC3878 and LTC3879 is ideally

suited to low duty factor operation,

offering a compact solution with excellent system performance.

The LTC3878 and LTC3879 are

a new generation of No R

controllers that meet the demanding

requirements of low voltage supplies

for digital electronics. The LTC3878 is

a pin compatible replacement for the

LTC1778 in designs where EXTVCC

is not required. The LTC3879 adds

separate RUN and TRACK/SS pins for

applications requiring voltage tracking. Both devices offer continuously

programmable current limit, using

the bottom MOSFET VDS voltage to

sense current.

Valley Current Mode

Control Simplifies Loop

Compensation…

There are two common implementations of current mode control. Peak

current mode control regulates the

high side MOSFET on-time, while

valley current mode regulates the

bottom side MOSFET off-time. The

current mode loop bandwidth is in-

18

SENSE

™

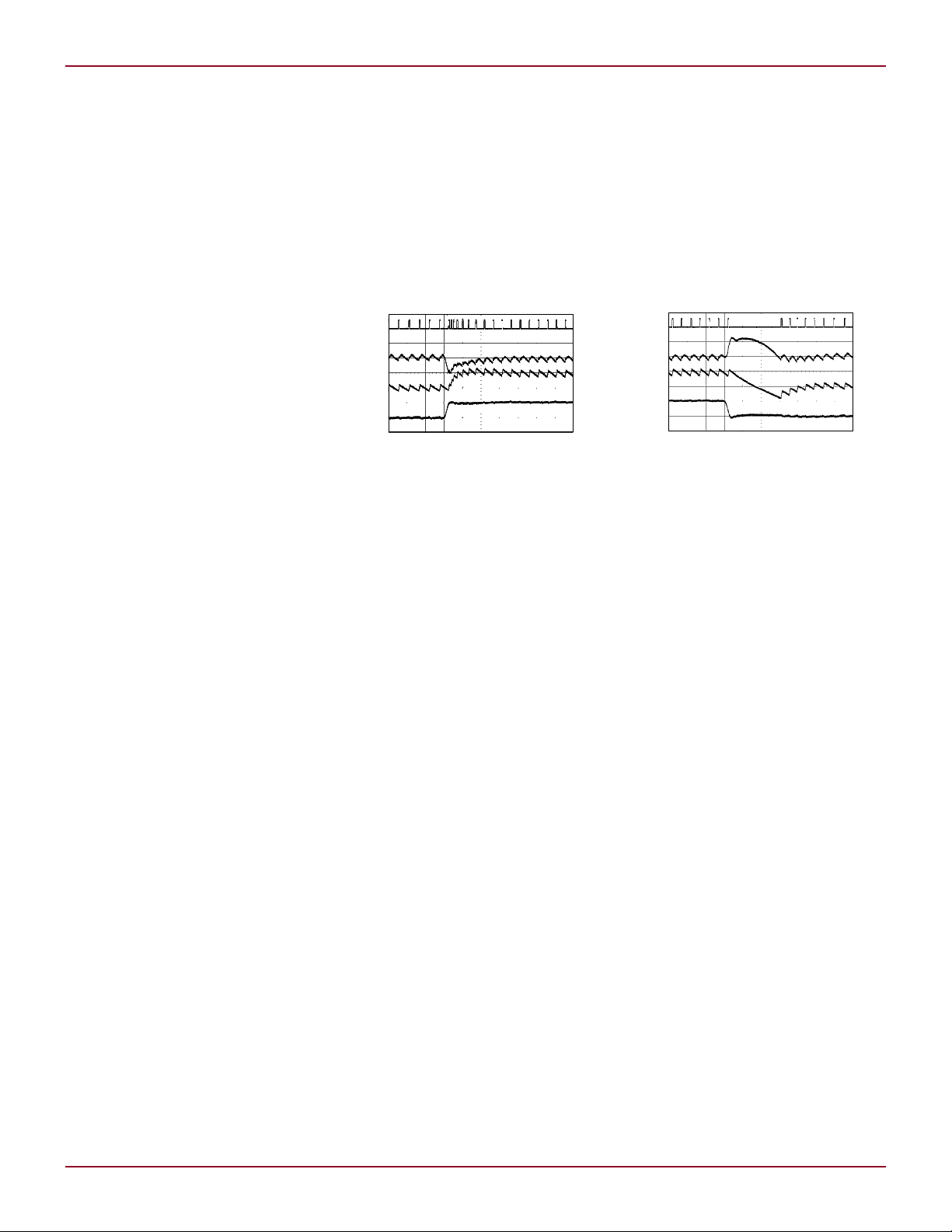

Figure 1. Transient response,

positive load step

versely proportional to the on-time for

a peak current controller and inversely

proportional to the off-time for a valley

mode controller. A peak current mode

controller with an on-time of 50ns

must have a closed current loop bandwidth exceeding 20MHz. For a valley

current mode controller, the current

loop bandwidth is determined by the

typical off-time of 220ns, resulting in a

closed current loop bandwidth requirement of only 4.5MHz. Consequently,

valley current mode control has less

stringent bandwidth requirements for

the same system performance when

compared to a peak current mode

control in a similar application. This

allows the LTC3878 and LTC3879 to

offer high performance, low duty factor

operation at reasonable current loop

bandwidths.

The constant on-time valley current

mode control of the LTC3878 and

LTC3879 simplifies compensation

design by eliminating the need for

slope compensation. A fixed frequency

valley mode controller requires slope

compensation when operating at less

than 50% duty factor to prevent subcycle oscillation. Subcycle oscillation

occurs because the PWM pulse width

IN

OUT

by Terry J. Groom

Figure 2. Transient response,

load release

is not uniquely determined by inductor

current alone. This oscillation cannot

exist in constant-on-time control because the PWM pulse width is uniquely

determined by the internal open loop

pulse generator. True current mode

control and constant on-time combine

to give the LTC3878 and LTC3879

performance advantages over other

constant on-time regulators or fixed

frequency valley current mode control

architectures.

…and Improves Transient

Response Time

In a buck controller, transient response

is largely determined by how quickly

the inductor current responds to loop

disturbances. The most demanding

loop disturbances are load steps and

load releases.

The inherent speed advantage of

a constant on-time architecture lies

in the fact that the regulator is pulse

frequency modulated (PFM) insead

of pulse width modulated (PWM).

Although the switching frequency is

fixed in steady state operation, it can

increase or decrease as required in

response to an output load step or

load release.

Linear Technology Magazine • June 2009

DESIGN FEATURES L

f Hz

MAX

ON OFF MIN

t t

=

(

)

+

1

( )

( )

f g EA R

I

C

V

V

CGO m C

LIMIT

OUT

REF

OUT

= • •( )

.1 6

1

I

L

5A/DIV

V

OUT

0.5V/DIV

TRACK/SS

0.5V/DIV

20ms/DIV

VIN = 12V

V

OUT

= 1.2V

SW FREQ = 400kHz

+

TRACK/SS

LTC3879

BOOST

16

C

B

0.22µF

M1

RJK0305DPB

C

VCC

4.7µF

C

C1

220pF

C

C2

33pF

D

B

CMDSH-3

L1

0.56µH

C

OUT1

330µF

2.5V

s2

C

OUT2

47µF

6.3V

s2

+

C

IN1

10µF

50V

s3

C

IN2

100µF

50V

V

OUT

1.2V

15A

V

IN

4.5V TO 28V

1

PGOOD

R

PG

100k

R2

80.6k

R

C

27k

R

FB1

10.0k

R1

10.0k

TG

152

V

RNG

SW

143

MODE PGND

134

I

TH

BG

125

SGND INV

CC

116

I

ON

V

IN

107

V

FB

RUN

98

R

ON

432k

R

FB2

10.0k

M2

RJK0330DPB

C

IN1

: UMK325BJ106MM s3

C

OUT1

: SANYO 2R5TPE330M9 s2

C

OUT2

: MURATA GRM31CR60J476M s2

L1: VISHAY IHLP4040DZ-11 0.56µH

C

SS

0.1µF

LOAD CURRENT (A)

30

EFFICIENCY (%)

90

100

20

10

80

50

70

60

40

0.01 1 10 100

0

0.1

CONTINUOUS

MODE

DISCONTINUOUS

MODE

VIN = 12V

V

OUT

= 1.2V

SW FREQ = 400kHz

The maximum frequency in response to a load step is determined

by the on-time plus the off-time:

In low duty factor applications the

maximum frequency is typically much

greater than the nominal operating frequency, producing excellent transient

characteristics.

Figure 1 shows the load step response of a 12V-to-1.2V converter

operating at 400kHz. In this case the

on-time is equal to 250ns and the

minimum off-time is 220ns. The maximum frequency available to respond

to a load step is 2.12MHz, which is

over five times the nominal switching

frequency. Note the increase in switching frequency of the VSW waveform

in response to the 10A load step. The

increase in switching frequency causes

the inductor current to ramp faster in

constant on-time PFM controllers than

is possible in a true fixed frequency

PWM.

In response to a load release

(Figure 2), the minimum frequency

is effectively zero, since the bottom

gate is held high as long as needed

to ramp the inductor current down

to the internal regulation set point.

In this example, the inductor current ramps from 11A to –8A in 13µs

as the output recovers from the load

step. For both load transient cases,

variable frequency has an inherent

speed advantage over fixed frequency

in transient recovery.

Start-Up Options

The LTC3878 offers the simplicity of

current limited start-up through the

combined RUN/SS pin. When RUN/SS

is greater than 0.7V all internal bias is

activated. Once RUN/SS exceeds 1.5V,

switching begins. The current limit is

gradually increased as the RUN/SS

pin voltage ramps until reaching full

Figure 3. Start-up into a prebiased output

Transient settling requires both

the large signal ramping of inductor current and the stable settling of

the output to the desired regulation

point. Excessive output overshoot or

ringing indicates marginal system

stability likely caused by inadequate

compensation. A rough compensation

check can be made by calculating the

gain crossover frequency, given by the

following equation (where V

for the LTC3878 and V

REF

= 0.8V

REF

= 0.6V for

the LTC3879):

As a rule of thumb, the gain crossover frequency should be less than

20% of the switching frequency. With

any analog system, transient response

is determined by closed loop bandwidth. In order to optimize for transient

performance, it is desirable to have a

small inductor and a wide closed loop

bandwidth. A small inductor is desired

for quick output current response,

while the closed loop bandwidth and

phase margin determines how quickly

the output settles after a load step.

output at approximately 3V.

separate RUN and TRACK/SS pins. All

internal bias is activated when RUN

exceeds 0.7V. Switching begins when

RUN exceeds 1.5V. The TRACK/SS

pin can also be used for input voltage tracking, where the LTC3879’s

output tracks the voltage on the

TRACK/SS pin until it exceeds 0.6V.

Once TRACK/SS exceeds 0.6V the

output regulates to the internal 0.6V

reference. An internal 1µA pull-up current is available to create a soft-start

voltage ramp when a small capacitor

is connected to TRACK/SS. Together,

RUN and TRACK/SS enable a number

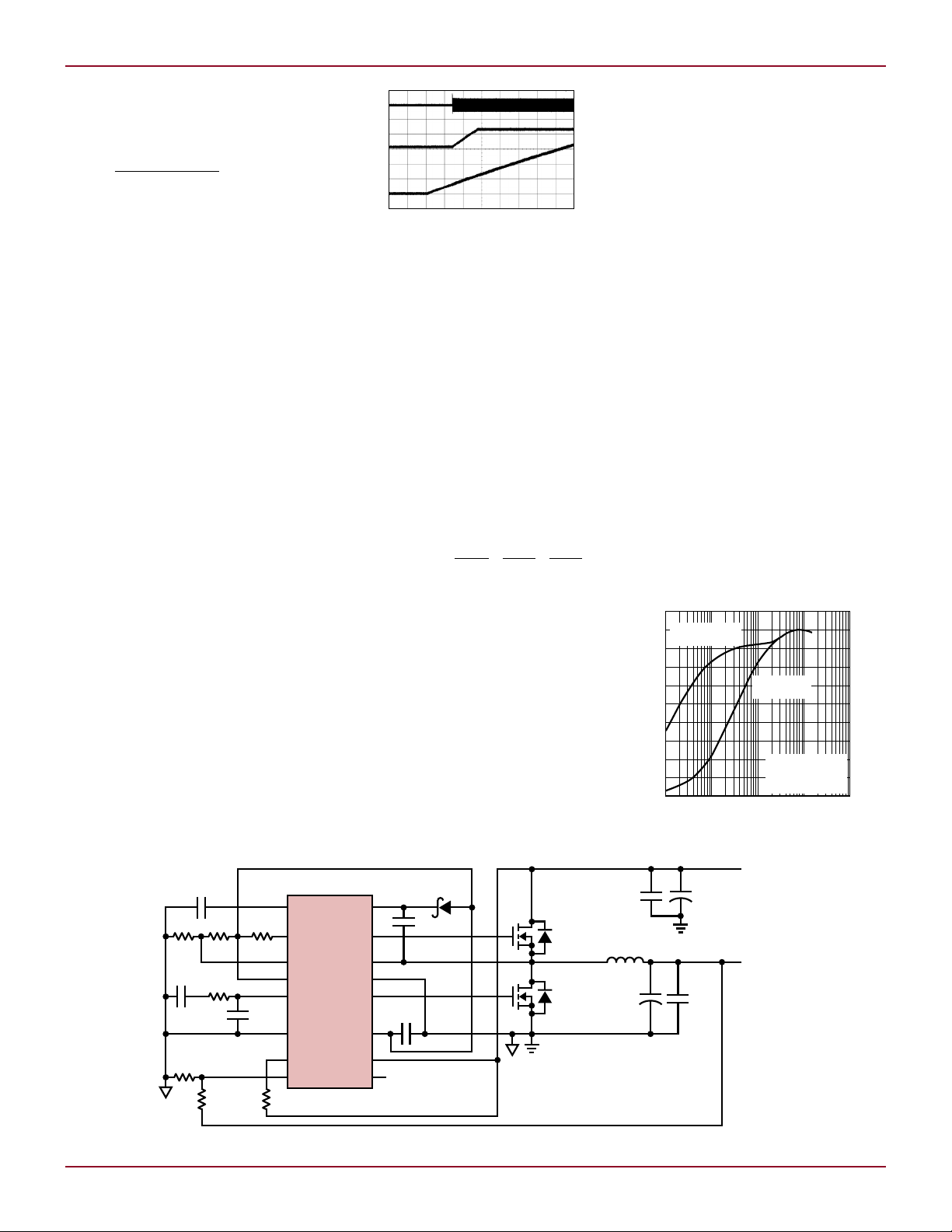

Figure 4. Efficiency for application in Figure 5

The LTC3879 adds the flexibility of

Linear Technology Magazine • June 2009

Figure 5. Wide input range to 1.2V at 15A, operating at 400kHz

19

L DESIGN FEATURES

+

TRACK/SS

V

MASTER

LTC3879

BOOST

16

C

B

0.22µF

M1

RJK0305DPB

C

VCC

4.7µF

C

C1

330pF

C

C2

47pF

D

B

CMDSH-3

L1

0.44µH

C

OUT1

330µF

2.5V

s3

C

OUT2

100µF

6.3V

s2

+

C

IN1

10µF

16V

s2

C

IN2

180µF

16V

V

OUT

1.2V

20A

V

IN

4.5V TO 14V

1

PGOOD

R

PG

100k

R2

57.6k

R

TR2

10.0k

R

C

15k

R

FB1

10.0k

R1

10.0k

R

TR1

10.0k

TG

152

V

RNG

SW

143

MODE PGND

134

I

TH

BG

125

SGND INV

CC

116

I

ON

V

IN

107

V

FB

RUN

98

R

ON

576k

R

FB2

10.0k

C

PL

470pF

C

F

0.1µF

R

F

1Ω

M2

RJK0330DPB

C

IN1

: TDK C3225X5R1C106MT s2

C

OUT1

: SANYO 2R5TPE330M9 s3

C

OUT2

: MURATA GRM31CR60J107ME39 s2

L1: PULSE PA0513.441NLT

5ms/DIV

VIN = 12V

V

OUT

= 1.2V

SW FREQ = 400kHz

V

MASTER

0.5V/DIV

V

OUT

0.5V/DIV

Figure 6. Coincident tracking example produces 1.2V at 20A, operating at 300kHz

of start-up supply sequencing and

tracking options.

Both the LTC3878 and LTC3879

have the ability to start up onto prebiased outputs. Because current limit

is ramped in the LTC3878, prebiased

output voltages are not an issue. The

LTC3879 output tracks the input on

the TRACK/SS pin. To accommodate

prebiased outputs, the LTC3879 will

not switch until the TRACK/SS pin

exceeds the VFB voltage. Once TRACK/

SS exceeds VFB the output follows the

TRACK/SS pin in continuous conduction mode until the output regulates

to the internal reference.

In Figure 3 the LTC3879 output

is prebiased to 0.5V. The TRACK/SS

pin ramps from zero and crosses the

prebiased output feedback point at

approximately 28ms, when switching

begins. Once switching begins the output enjoys a smooth soft-start ramp.

The LTC3879 operates in continuous

conduction mode during start-up, regardless of the mode setting, allowing

regulation of the output voltage to the

TRACK/SS input pin voltage during

soft-start.

High Efficiency

The LTC3879 and LTC3879 offer

excellent efficiency through the combination of strong gate drivers and short

dead time. The top gate driver offers

a 2.5Ω pull up resistance and a 1.2Ω

pull down, while the bottom gate driver

offers a 2.5Ω pull up and a 0.7Ω pull

20

down. Dead time has been measured

as low as 12ns, minimizing switching

loss. Efficiency has been measured at

91.8% in a 1.2V/20A application.

The LTC3878 and LTC3879 offer

both discontinuous conduction mode

(DCM) and continuous conduction

mode (CCM) operation. Figure 4 shows

peak efficiency over 90% for 12V and

15A in CCM. In CCM, either the top

MOSFET or the bottom MOSFET is

active and the output inductor is

continuously conducting. In DCM,

the top and bottom MOSFET can be

off simultaneously in order to improve

low current efficiency. In Figure 4, at

100mA, the efficiency is greater than

70% in DCM, compared to only 20%

in CCM. Improvements in efficiency in

DCM are seen when the load is less

than the DC average of the steady state

ripple current, causing the regulator to

enter discontinuous conduction.

Application Example:

4.5V-to-28V In to 1.2V Out

with 90% Peak Efficiency

Figure 5 shows an application that

converts a wide 4.5V-to-28V input

voltage to a 1.2V ±5% output at 15A.

The nominal ripple current is chosen to

be 35% resulting in a 0.55µH inductor

and ripple current of 5.1A. Because the

top MOSFET is on for a short time, an

RJF0305DPB (R

nal), C

MILLER

= 150pF, V

sufficient. The stronger RJK0330DPB

is chosen for the bottom MOSFET, with

= 10mΩ (nomi-

DS(ON)

MILLER

= 3V) is

a typical R

of 3.8mΩ. This results

DS(ON)

in 90% peak efficiency. Note that the

efficiency, transient and start-up

waveforms in Figures 1–4 were taken

from this design example.

Tracking

Figure 6 shows a LTC3879 in a

1.2V/20A output, 300kHz application

design with coincident rail tracking. In

coincident tracking, two supplies ramp

up in unison until the lower voltage

supply reaches regulation, at which

point the higher voltage supply continues to ramp to its regulated value.

Coincident tracking is implemented by

making the resistor divider from the

master voltage to the TRACK/SS pin

equal to the feedback divider from V

to VFB. In Figure 6, the output is 1.2V,

so the divider is equal to 0.6V/1.2V,

or 0.5. This design tracks any master

supply that is equal to or greater than

1.2V. The TRACK/SS pin should be

greater than 0.65V in regulation to

ensure that the LTC3879 has sufficient

Figure 7. Coincident tracking waveforms

for application in Figure 6

Linear Technology Magazine • June 2009

OUT

DESIGN FEATURES L

t

t

t

V

IN

18V TO 72V

GND

5V, 2A

+V

OUT

–V

OUT

PA1277NL

T1

162k

1k

6.81k

10pF

2200pF

1µF

330pF

22.1k

M1

Si4848DY

LT4430ES6

0.47µF

PS2801-1

UPS840

C

OUT

100µF

×2

BAT54C

BAS516

C

IN

1µF

×2

4.7nF

10k

51.1Ω

BAV21W

BAS516

6.81k

0.04Ω

105k

4.7µF

0.1µF

INTVCC

GATE

SENSE

SYNC

GND

V

IN

LT3758

V

IN

SS

VC

SHDN/UVLO

FBX

RT

8.66k 36.5k

100pF

OPTO

COMP

FB

V

IN

GND

OC

margin to switch from tracking the

TRACK/SS input voltage to regulating

to the internal reference.

Figure 7 shows typical tracking

waveforms of the application in Figure 6. V

voltage, V

and the reference supply

OUT

MASTER

, are equal and track

together during start-up until they

reach 1.2V, at which point V

lates to 1.2V while V

MASTER

regu-

OUT

continues

ramping to 1.8V.

Conclusion

The LTC3878 and the LTC3879 support a VIN range from 4V to 38V (40V

abs max). The regulated output voltage

is programmable from 90% VIN down to

LT3757/58, continued from page 4

An 18V–72V Input,

5V/2A Output Isolated

Flyback Converter

The basic design shown in Figure 7

can be modified to provide DC isolation between the input and output

with the addition of a reference, such

as the LT4430, on the secondary side

of the transformer and an optocoupler

0.8V (for the LTC 3878) and 0.6V (for

the LTC3879). The output regulation

accuracy is ±1% over the full –40°C to

85°C temperature range. The operating

frequency is resistor programmable

and is compensated for variations in

VIN. Current limit is continuously programmable and is measured without

a sense resistor by using the voltage

drop across the external synchronous

bottom MOSFET.

The valley current mode architecture is ideal for low duty factor

operation and allows very low output

voltages at reasonable current loop

bandwidths. Compensation is easy

to design and offers robust and stable

to provide feedback from the isolated

secondary to the LT3758. Figure 8

shows an 18V–72V input, 5V/2A output isolated flyback converter.

Conclusion

The LT3757 and LT3758 are versatile

control ICs optimized for a wide variety

of single-ended DC/DC converter to-

operation even with low ESR ceramic

output capacitors. The LTC3878 offers current limited start-up, while

the LTC3879 has separate run and

output voltage tracking pins. The

LTC3878 is available in the GN16

package, and the LTC3879 is available in thermally enhanced MSE16

and QFN (3mm × 3mm) packages.

Excellent performance and compact

size make the LTC3878 and LTC3879

well suited to small, tightly constrained

applications such as distributed power

supplies, embedded computing and

point of load applications.

L

pologies. Both offer a particularly wide

input voltage range. These ICs produce

space saving, cost efficient and high

performance solutions in any of these

topologies. The range of applications

extends from single-cell, lithiumion powered systems to automotive,

industrial and telecommunications

power supplies. L

Linear Technology Magazine • June 2009

Figure 8. 18V–72V input, 5V/2A isolated flyback converter

21

Loading...

Loading...