L DESIGN FEATURES

MODE/PLLIN

FREQ/PLLFLTR

RUN

TK/SS

I

TH

V

FB

SENSE

–

SENSE

+

V

IN

TG

BOOST

SW

INTV

CC

BG

GND

I

LIM

LTC3851

0.1µF

0.047µF

0.1µF

330pF

2200pF

R

FREQ

82.5k

15k

V

OUT

3.3V

15A

47pF

+

4.7µF

+

C

OUT

330µF

s2

C

IN

22µF

HAT2170H

HAT2170H

C

OUT

: SANYO 6TPE330MIL

CIN: SANYO 63HVH22M

L1: VISHAY IHLP5050-EZERR68M01

CMDSH05-4

154k

1%

48.7k

1%

V

IN

4.5V TO 32V

L1

0.68µH

3.01k

0.1µF

30.1k

R

FREQ

(k)

10

100

OSCILLATOR FREQUENCY (kHz)

500

250

750

1000

36 60 160 1000

Synchronous Buck Controller in

3mm × 3mm QFN Fits Automotive

and Industrial Applications with

4V–38V Input Capability

Introduction

The LTC3851 is a versatile synchronous step-down switching regulator

controller that is available in a space

saving 16-lead 3mm × 3mm QFN or

convenient narrow SSOP packages. Its

wide input range of 4V to 38V makes it

well-suited for regulating power from a

variety of sources, including automotive batteries, 24V industrial supplies

and unregulated wall transformers.

The strong onboard drivers allow the

use of high power external MOSFETs

to produce output currents up to 20A

with output voltages ranging from

0.8V to 5.5V.

The constant frequency peak cur-

rent mode control architecture provides

excellent line and load regulation along

with load current sharing capability

and dependable cycle-by-cycle current

limiting. OPTI-LOOP® compensation

simplifies loop stability design and

provides well-behaved regulation over

a broad range of operating conditions.

The LTC3851 has ±1% output voltage

tolerance over temperature. The part’s

low minimum on-time (90ns, typical)

allows for low duty cycle operation

even with switching frequencies as

high as 750kHz.

Two Current Sensing Options

The LTC3851 features a high input

impedance current sense comparator.

This allows the use of the inductor’s

DC resistance (DCR) as the current

sense element in conjunction with an

RC filter. DCR current sensing allows

the designer to eliminate the need for a

discrete sense resistor, thereby maximizing efficiency and lowering solution

cost. Alternately, higher current sense

accuracy may be achieved by connecting the SENSE+ and SENSE– pins to a

precision sense resistor in series with

the inductor. The LTC3851 offers the

choice of three pin-selectable maximum current sense thresholds (30mV,

by Mark Mercer

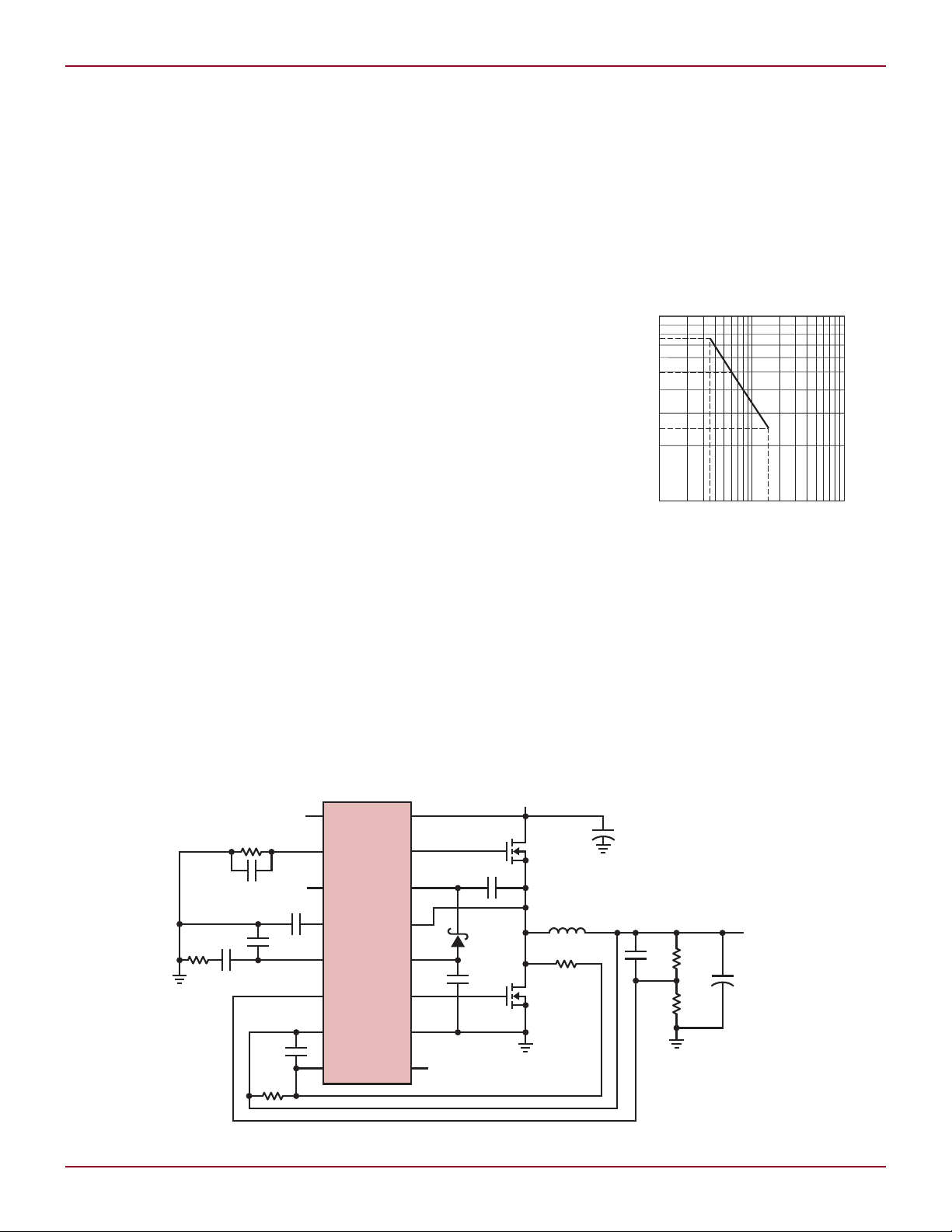

Figure 1. Relationship between oscillator

frequency and resistor connected between

FREQ/PLLFLTR and GND

50mV and 75mV) to accommodate a

wide range of DCR values and output

current levels.

As with all constant frequency,

peak current mode control switching

regulators, the LTC3851 utilizes slope

compensation to prevent sub-harmonic oscillations at high duty cycles. This

16

Figure 2. High efficiency 3.3V/15A power supply with DCR sensing

Linear Technology Magazine • September 2008

DESIGN FEATURES L

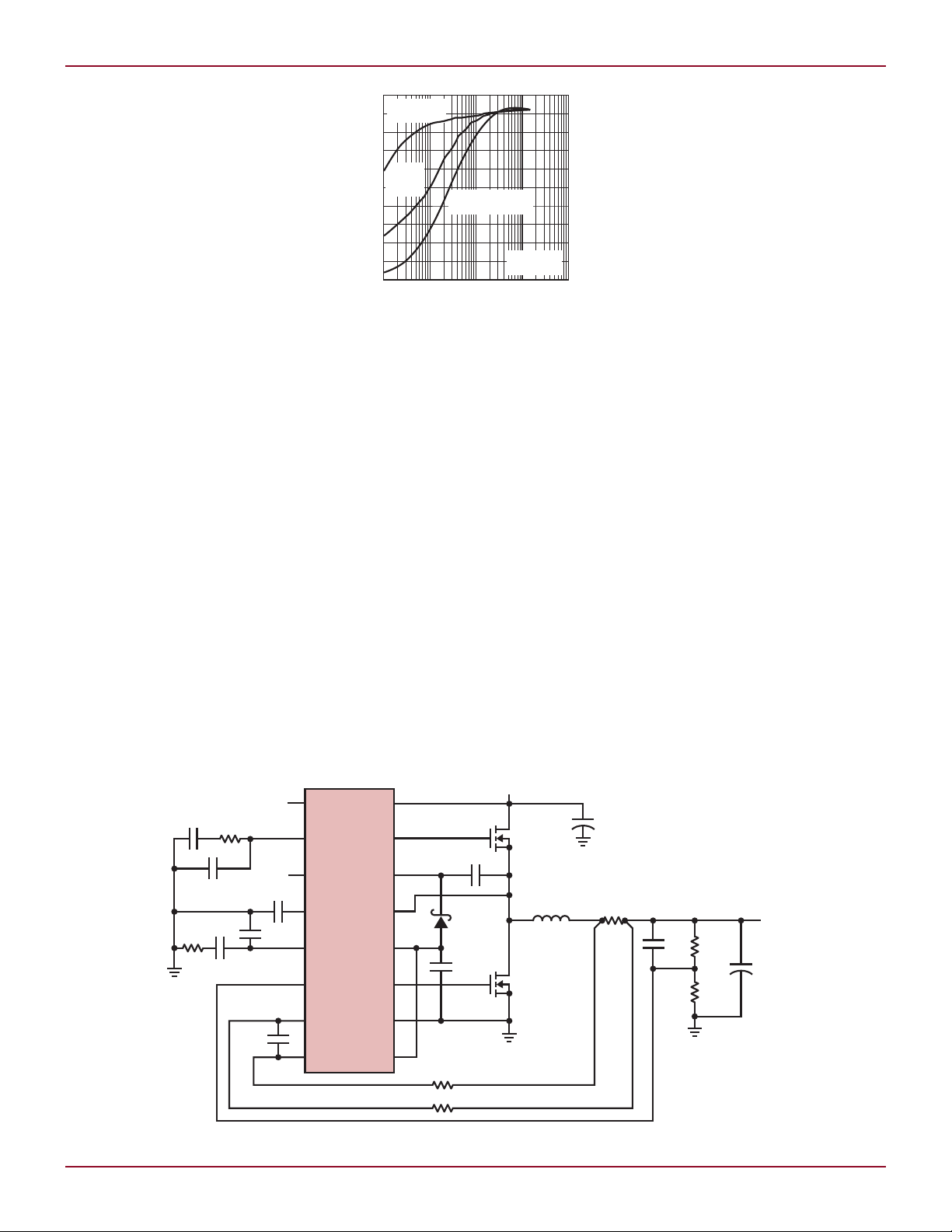

EFFICIENCY (%)

LOAD CURRENT (A)

1000.01

100

0

0.1 1 10

10

20

30

40

50

60

70

80

90

Burst Mode

OPERATION

CONTINUOUS

CONDUCTION MODE

PULSE-

SKIPPING

MODE

VIN = 12V

V

OUT

= 3.3V

MODE/PLLIN

FREQ/PLLFLTR

RUN

TK/SS

I

TH

V

FB

SENSE

–

SENSE

+

V

IN

TG

BOOST

SW

INTV

CC

BG

GND

I

LIM

LTC3851

0.1µF

0.1µF

100pF

1000pF

0.01µF

PLLIN

350kHz

1000pF

10k

10Ω

10Ω

7.5k

R

SENSE

0.002Ω

V

OUT

1.5V

15A

1000pF

+

4.7µF

+

C

OUT

330µF

s2

C

IN

180µF

33pF

RJK0305DPB

RJK0301DPB

C

OUT

: SANYO 2R5TPE330M9

L1: SUMIDA CEP125-OR6MC

CMDSH-3

42.2k

1%

48.7k

1%

V

IN

6V TO 14V

L1

0.68µH

is accomplished internally by adding

a compensating ramp to the inductor

current signal. Normally, this results

in a >40% reduction of maximum

inductor peak current at high duty

cycles. However, the LTC3851 uses

a novel scheme that allows the maximum peak inductor current to remain

stable throughout all duty cycles.

Versatility

During heavy load operation, the

LTC3851 operates in constant frequency, continuous conduction mode.

At light loads, it can be configured

to operate in high efficiency Burst

Mode® operation, constant frequency

pulse-skipping mode or forced continuous conduction mode. Burst Mode

operation offers the highest efficiency

because energy is transferred from the

input to the output in pulse trains

of one to several cycles. During the

intervening period between pulse

trains, the top and bottom MOSFETs

are turned off and only the output

capacitor provides current to the load.

Forced continuous conduction mode

results in the lowest output voltage

ripple, but is the least efficient at light

loads. Pulse-skipping mode offers

a compromise—lower output ripple

than Burst Mode operation and more

efficiency than continuous conduction mode.

Figure 3. Efficiency vs load current with three

modes of operation for the circuit of Figure 2

The switching frequency of the

LTC3851 may be programmed from

250kHz to 750kHz by the resistor,

R

, connected to the FREQ/PLL-

FREQ

FLTR pin. This provides the flexibility

needed to optimize efficiency. Figure 1

shows a plot of the switching frequency

vs R

. Additionally, the switching

FREQ

frequency may be synchronized to

an external clock. While doing so,

the LTC3851 will operate in forced

continuous conduction mode.

The output voltage can be ramped

during start-up by means of an adjustable soft-start function, or it can

track an external ramp signal. Track

and soft-start control are combined in

a single pin, TK/SS. Whenever TK/SS

is less than 0.64V, the LTC3851 operates in pulse-skipping mode. This

feature allows for starting up into a

pre-biased load. When TK/SS is between 0.64V and 0.74V, the regulator

operates in forced continuous mode

to ensure a smooth transition from

start-up to steady state. Once TK/SS

exceeds 0.74V, the mode of operation is determined by the state of the

MODE/PLLIN pin.

The RUN pin enables or disables

the LTC3851. This pin has a precision

1.22V turn-on threshold which is useful for power supply sequencing. The

turn-off threshold is 1.10V. There is

an internal 2µA pull-up current source

on the RUN pin.

The LTC3851’s fault protection

features include foldback current

limiting, output overvoltage detection

and input undervoltage detection. If

an overload event causes the output

to fall to less than 40% of the target

regulation value, then the LTC3851

folds back the maximum current sense

threshold. This reduces the on-time in

order to minimize power dissipation in

the top MOSFET. If the output voltage

is more than 10% above the target

regulation value, the bottom MOSFET

turns on until the output falls back

into regulation. If the input voltage is

allowed to fall low enough such than

the output of the internal linear regulator falls below 3.2V, then switching

operation is disabled. This feature

continued on page 36

Linear Technology Magazine • September 2008

Figure 4. High efficiency 1.5V/15A power supply synchronized to 350kHz

17

L DESIGN IDEAS

BATTERY VOLTAGE (V)

2.7

EFFICIENCY (%)

80

90

3.9

70

60

3

3.3

3.5

4.2

100

R

CLPROG

= 3.01K

R

PROG

= 1K

I

VOUT

= 0mA

5x CHARGING EFFICIENCY

1x CHARGING EFFICIENCY

10µH

VOUT3

CAP3

IFB3

LT3587

8.06k

R

IFB3

EN/SS3

SW3

VIN

1µF

V

VIN

2.5V TO 5V

V

DAC-OUT

DAC

LTC2630

PWM

FREQ

2.5V

0V

MN1

Si1304BDL

IR05H40CSPTR

Figure 3. Battery charging efficiency vs

battery voltage with no external load

(P

should be pulled-up to the same voltage. In Figure 2 the LDO3V3 regulator

is used as the pull-up voltage for the

FAULT signal and the power supply

for the low power microcontroller

used to process pushbutton events

and sequence the power supplies.

The FAULT pin also acts as an input

and hence, must be high before any

outputs are enabled.

Compact LED Driver

The LT3587 LED driver is designed

to drive up to six LEDs with average

LED currents between 20mA and 1µA.

When the LT3587’s V

a current regulated LED driver, the

V

FB3

protection function. By connecting a

resistor between V

device limits the maximum allowable

output voltage on V

is extremely important in LED applications because without it the client

device may be damaged if one of the

LEDs were to open; in such a case,

the output would continue to rise as

)

BAT/PBUS

is used as

OUT3

pin can be used as an overvoltage

and V

OUT

. This feature

OUT3

FB3

the

Figure 4. Six white LED driver with PWM and analog dimming

the current regulation loop increases

voltage in an attempt to regulate the

current.

The integrated LED driver in the

LT3587 is capable of accepting a direct

PWM dimming signal into its enable

input (EN/SS3) and/or accommodates

analog dimming via an external DAC.

See Figure 4 for a partial application

circuit showing the LED driver with

direct PWM and analog dimming.

LEDs can change color when the

current through them changes, but

PWM dimming maintains color consistency over the dimming range, as the

ON part of the PWM cycle is always the

same current. In PWM dimming, the

brightness of the LEDs is a function of

average current, adjusted by changing

the duty cycle of the PWM signal. In

analog dimming, the constant current

through the LEDs is adjusted, which

causes variations in color.

The LT3587 accepts PWM signals

with frequencies over 60Hz to assure

flicker-free operation. High PWM frequencies are achievable because of

the internal disconnect FET between

CAP3 and V

. This FET ensures

OUT3

that CAP3 maintains its steady-state

value while the PWM signal is low,

resulting in minimal startup delays.

For a 100Hz PWM dimming signal and

allowing for 10% deviation from linearity at the lowest duty cycle, the LT3587

allows for a dimming ratio of 30:1. If

the maximum amount of adjustment

range is desired, an external DAC,

such as the LTC2630, can be used to

feed an adjustment voltage onto the

IFB3 resistor, creating an LED current

range of 20,000:1.

Conclusion

Two highly integrated devices, the

LTC3586 and LT3587 can be combined

to create a complete USB compatible

power solution for portable cameras

and other feature-rich portable devices. The solution is robust, high

performance and compact, with efficient battery charging, instant-on

capability and LED protection.

L

LTC3851, continued from page 17

protects against insufficient turn-on

voltage for the top MOSFET.

3.3V/15A Regulator with

DCR Sensing

Figure 2 shows a 400kHz, 3.3V output

regulator using DCR current sensing.

The DC resistance of the inductor is

used as the current sense element,

eliminating the need for a discrete

sense resistor and thus maximizing

efficiency. Figure 3 shows a plot of the

36

36

efficiency vs load for all three modes

of operation with an input voltage of

12V.

1.5V/15A Regulator

Synchronized at 350kHz

Figure 4 illustrates a 1.5V output

regulator that is synchronized to

an external clock. The loop filter

components connected to the FREQ/

PLLFLTR pin are optimized to achieve

a jitter free oscillator frequency and

reduced lock time.

Conclusion

The LTC3851 combines high performance, ease of use and a comprehensive

feature set in a 3mm × 3mm 16-pin

package. DCR current sensing and

Burst Mode® operation keep efficiency

high. With a broad 4V to 38V input

range, strong MOSFET drivers, low

minimum on-time and tracking, the

LTC3851 is ideal for automotive electronics, server farms, datacom and

telecom power supply systems and

industrial equipment.

Linear Technology Magazine • September 2008

L

Loading...

Loading...