查询LTC3806供应商

FEATURES

■

High Efficiency at Full Load

■

Better Cross Regulation Than Nonsynchronous

Converters (Multiple Outputs)

■

Soft-Start Minimizes Inrush Current

■

Current Mode Control Provides Excellent

Transient Response

■

High Maximum Duty Cycle: 89% Typical

■

±2% Programmable Undervoltage Lockout Threshold

■

±1% Internal Voltage Reference

■

Micropower Start-Up

■

Constant Frequency Operation (Never Audible)

■

3mm × 4mm 12-Pin DFN Package

LTC3806

Synchronous

Flyback DC/DC Controller

U

DESCRIPTIO

The LTC®3806 is a current mode synchronous flyback

controller that drives N-channel power MOSFETs and

requires very few external components. It is intended for

medium power applications where multiple outputs are

required. Synchronous rectification provides higher efficiency and improved output cross regulation than

nonsynchronous converters.

The IC contains all the necessary control circuitry including a 250kHz oscillator, precision undervoltage lockout

circuit with hysteresis, gate drivers for primary and synchronous switches, current mode control circuitry and

soft-start circuitry.

U

APPLICATIO S

■

48V Telecom Supplies

■

12V/42V Automotive

■

24V Industrial

■

VoIP Phone

■

Power Over Ethernet

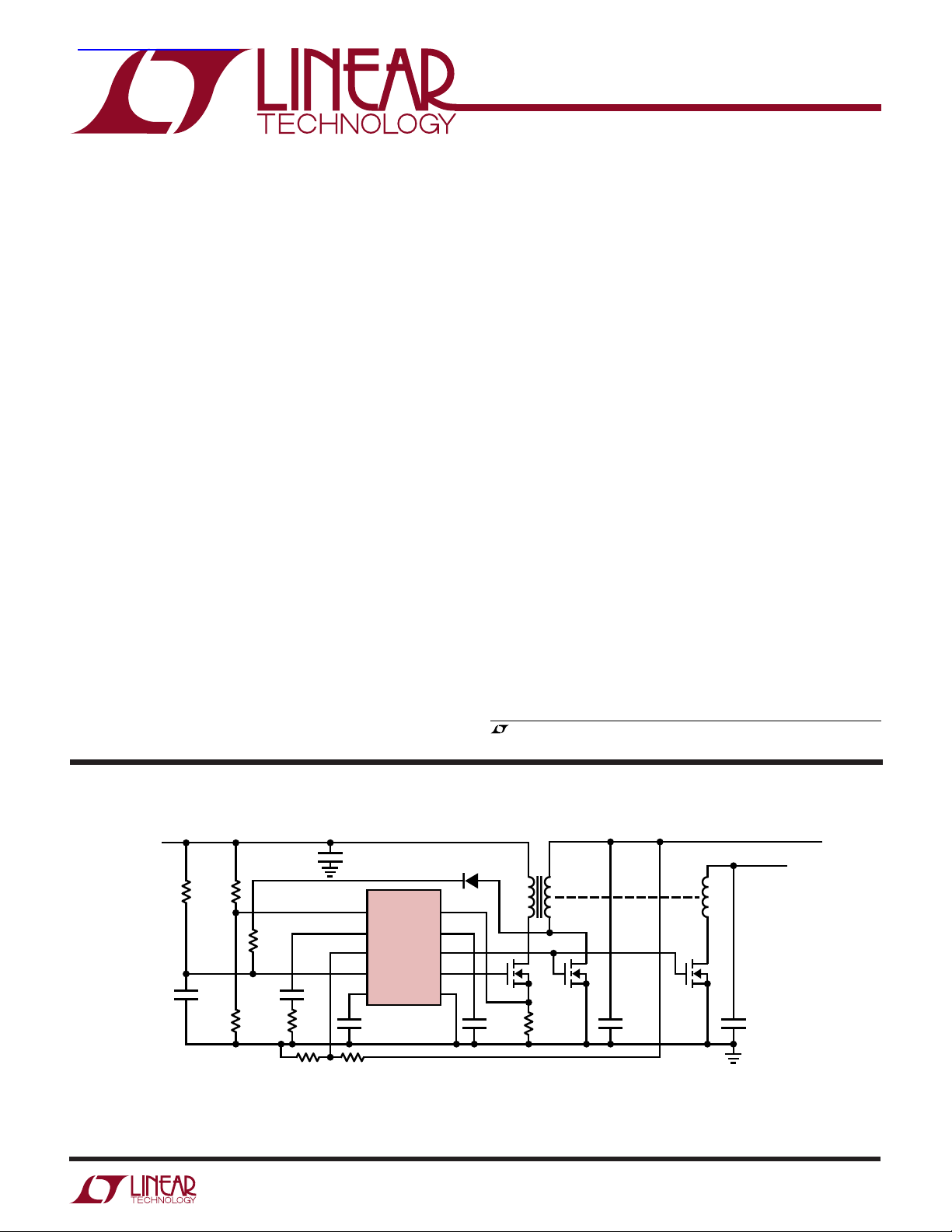

TYPICAL APPLICATIO

V

IN

36V TO 72V

604k

C1

100µF

R2

R8

100Ω

R3

26.7k

51k

R1

R4

3.4k

C2

1nF

U

C7

4.7µF

RUN

I

TH

FB

V

IN

INTV

C3

4.7µF

LTC3806

SENSE

CC

GND

Programmable soft-start reduces inrush currents. This

makes it easier to design compliant Power Over Ethernet

supplies.

Low start-up current reduces power dissipation in the

start-up resistor and reduces the size of the external startup capacitor.

The LTC3806 is available in a 12-pin, exposed pad DFN

package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

V

OUT1

3.3V

V

3A

C6

470µF

OUT2

2.5V

3A

D1

SS

G2

G1

T1

•

••

M1 M2 M3

C4

0.47µF

R5

0.056Ω

C5

470µF

R7

12.4k

R6

21k

Figure 1. Multiple Output Flyback Converter for Telecom

3806 F01

3806f

1

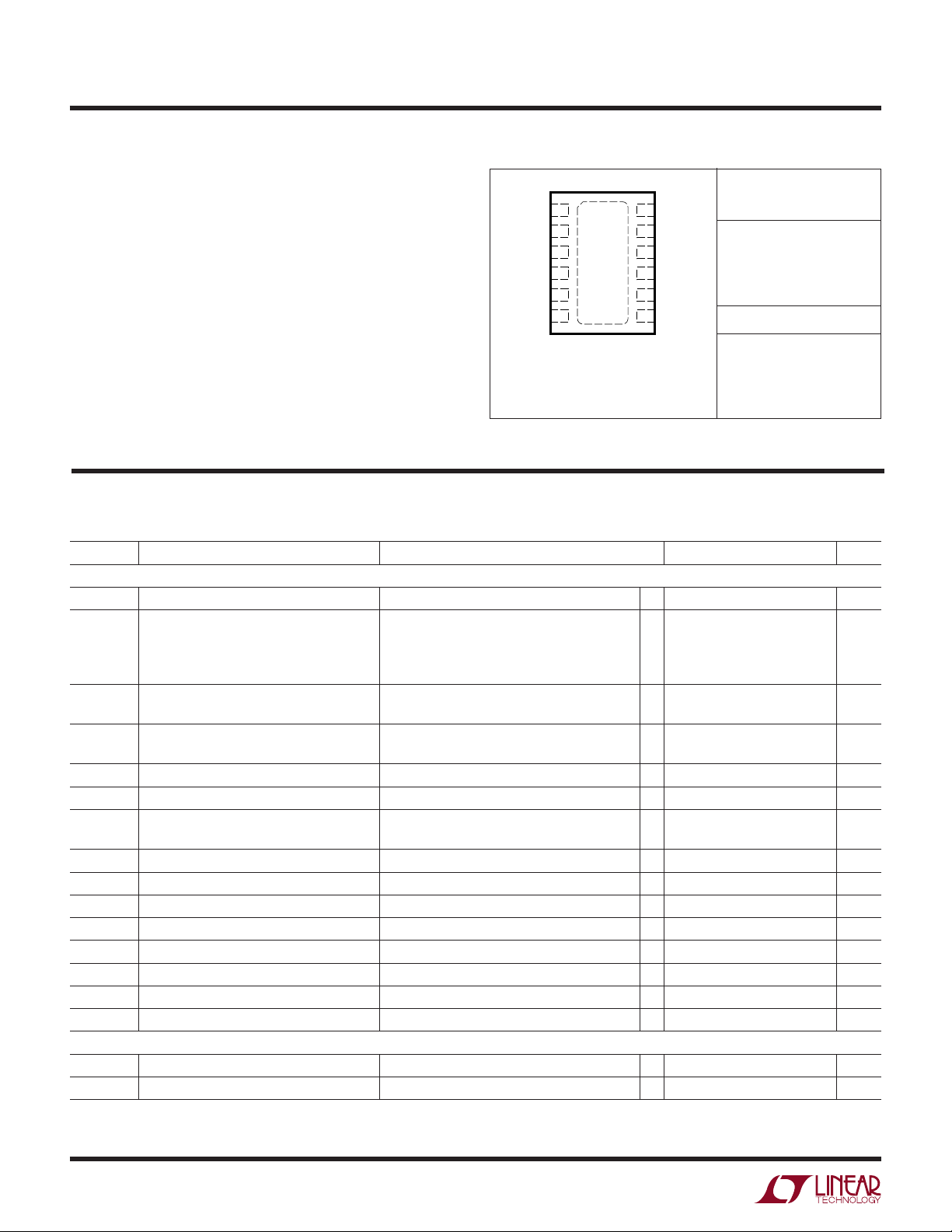

LTC3806

12

11

10

9

8

7

1

2

3

4

5

6

SENSE

NC

SS

G1

G2

GND

RUN

I

TH

FB

NC

V

IN

INTV

CC

TOP VIEW

13

DE12 PACKAGE

12-LEAD (4mm × 3mm) PLASTIC DFN

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VIN Voltage ............................................................. 25V

INTVCC Voltage ......................................................... 8V

INTVCC Output Current ........................................ 50mA

G1, G2 Voltages....................... –0.3V to V

ITH, FB, SS Voltages .................................–0.3V to 2.7V

RUN Voltage ............................................... –0.3V to 7V

SENSE Pin Voltage ..................................... –0.3V to 8V

Operating Ambient Temperature Range

(Note 2) .................................................. – 40°C to 85°C

Junction Temperature (Note 3)............................ 125°C

Storage Temperature Range ................. –65°C to 125°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are TA = 25°C. VIN = 10V, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loop

V

IN(MIN)

I

Q

+

V

RUN

–

V

RUN

V

RUN(HYST)

I

RUN

V

FB

I

FB

∆VFB/∆VINLine Regulation 10V ≤ VIN ≤ 20V 0.01 %/V

∆VFB/∆V

g

m

V

SENSE(MAX)

I

SENSE(ON)

I

SENSE(OFF)

I

SS

Oscillator

f

OSC

DC(MAX) Maximum Duty Cycle 84 89 94 %

2

Minimum Input Voltage (Note 4) 10 V

Input Voltage Supply Current (Note 5)

Quiescent 1000 µA

Shutdown Mode V

Start-Up Mode V

Rising RUN Input Threshold Voltage VIN = 20V 1.205 1.230 1.255 V

Falling RUN Input Threshold Voltage VIN = 20V 1.116 1.139 1.162 V

RUN Pin Input Threshold Hysteresis VIN = 20V 45 91 137 mV

RUN Input Current 160 nA

Feedback Voltage V

Feedback Pin Input Current V

Load Regulation VTH = 0.55V to 0.95V (Note 6) ● –1 –0.1 %

ITH

Error Amplifier Transconductance ITH Pin Load = ±5µA (Note 6) 650 µMho

Maximum Current Sense Input Threshold 110 150 190 mV

SENSE Pin Current (G1 High) V

SENSE Pin Current (G1 Low) V

SS Pin Source Current VSS = 1.5V 3 5 8 µA

Oscillator Frequency 210 250 290 kHz

WW

W

U

INTVCC

+ 0.3V

The ● denotes specifications which apply over the full operating

= 0V 50 90 µA

RUN

> 1.255V, VIN < 7V 80 140 µA

RUN

= 0.75V (Note 6) 1.218 1.230 1.242 V

ITH

= 0.75V (Note 6) 18 100 nA

ITH

= 0V 35 50 µA

SENSE

= 1V 0.1 5 µA

SENSE

U

W

U

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

LTC3806EDE

DE PART MARKING

3806

T

= 125°C, θJA = 34°C/W

JMAX

EXPOSED PAD (PIN 13) IS GND

MUST BE SOLDERED TO PCB

Consult LTC Marketing for parts specified with wider operating temperature ranges.

= 1.5V, unless otherwise specified.

RUN

● 1.181 1.279 V

● 1.093 1.185 V

● 1.212 1.248 V

3806f

LTC3806

TEMPERATURE (°C)

–40

0

FB PIN CURRENT (nA)

5

10

15

20

25

30

–15 10 35 60

3806 G03

85

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are TA = 25°C. VIN = 10V, V

The ● denotes specifications which apply over the full operating

= 1.5V, unless otherwise specified.

RUN

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Regulator

V

INTVCC

∆INTV

∆V

IN

V

LDO(LOAD)

+

V

UVL

–

V

UVL

INTVCC Regulator Output Voltage VIN = 10V 6 6.9 7.8 V

INTVCC Regulator Line Regulation 10V ≤ VIN ≤ 20V 100 mV

CC

INTVCC Load Regulation 0 ≤ I

≤ 20mA –6 –3 %

INTVCC

Rising VIN Threshold Voltage 14 15 16 V

Falling VIN Threshold Voltage 7.5 8 8.5 V

Gate Drivers

t

r1

t

f1

t

r2

t

f2

t

DEAD

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: The LTC3806E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: T

dissipation P

TJ = TA + (PD • 34°C/W)

Gate Driver 1 Output Rise Time CL1 = 3300pF 25 100 ns

Gate Driver 1 Output Fall Time CL1 = 3300pF 18 100 ns

Gate Driver 2 Output Rise Time CL2 = 4700pF 25 100 ns

Gate Driver 2 Output Fall Time CL2 = 4700pF 18 100 ns

Gate Driver Dead Time CL1 = 3300pF, CL2 = 4700pF 100 ns

Note 4: The minimum operating voltage is allowed once operation begins.

To begin operation, V

threshold with V

must be above the rising undervoltage lockout

IN

above the rising RUN input threshold.

RUN

Note 5: The dynamic input supply current is higher due to power MOSFET

• f

gate charging (Q

). See Applications Information.

G

OSC

Note 6: The LTC3806 is tested in a feedback loop which servos VFB to the

is calculated from the ambient temperature TA and power

J

according to the following formula:

D

reference voltage with the I

(the no load to full load operating voltage range for the I

pin forced to a voltage between 0V and 1.4V

TH

pin is 0.3V to

TH

1.23V).

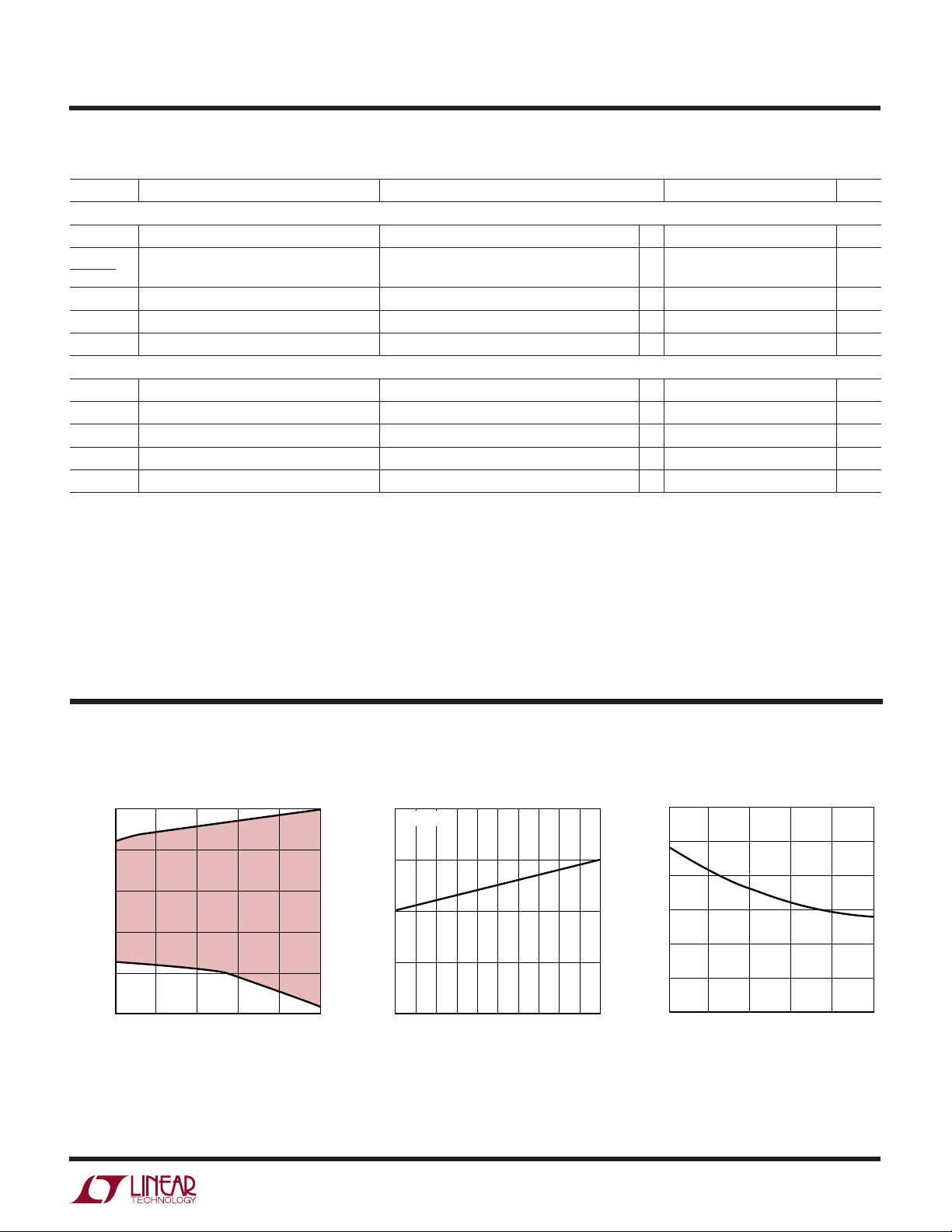

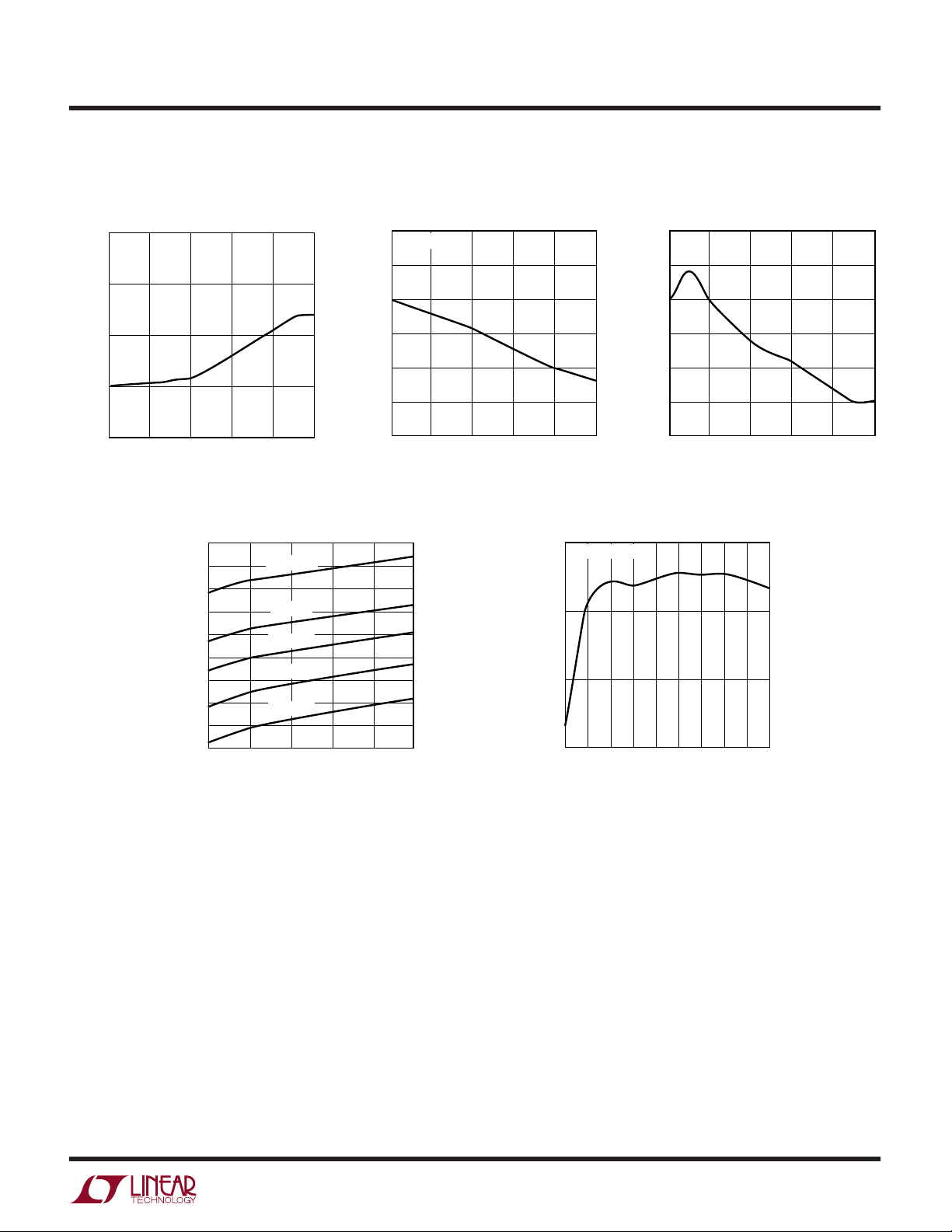

TYPICAL PERFOR A CE CHARACTERISTICS

1.2400

1.2350

1.2300

1.2250

FB VOLTAGE (V)

1.2200

1.2150

UW

FB Voltage vs Temperature FB Voltage Line Regulation FB Pin Current vs Temperature

1.2310

TA = 25°C

1.2305

1.2300

FB VOLTAGE (V)

1.2295

–40

–15

10

TEMPERATURE (°C)

35

60

3806 G01

1.2290

85

11

12

10

15

16

17

18

19

13

14

VIN (V)

20

3806 G02

3806f

3

LTC3806

TEMPERATURE (°C)

–40

1.10

RUN THRESHOLDS (V)

1.12

1.14

1.16

1.18

1.20

1.22

TRIP

–15 10 35 60

3806 G10

85

RELEASE

UW

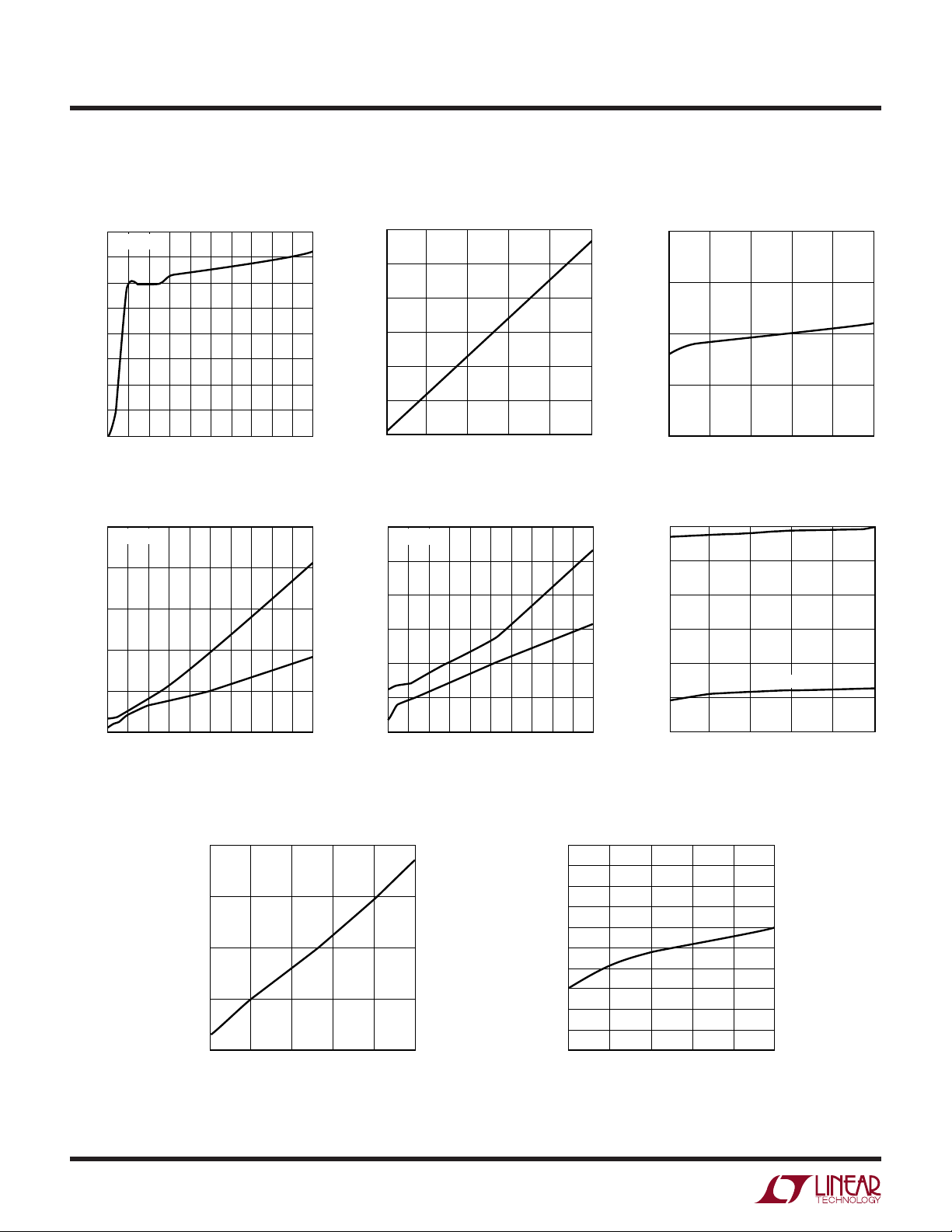

TYPICAL PERFOR A CE CHARACTERISTICS

Shutdown Mode IQ vs V

80

TA = 25°C

70

60

(µA)

Q

50

40

30

20

SHUTDOWN MODE, I

10

0

4 8 12 20142 6 10 18

0

VIN (V)

G1 Rise and Fall Time vs C

250

TA = 25°C

200

150

TIME (ns)

100

Shutdown Mode I

IN

16

3806 G04

L

vs Temperature Soft-Start Current vs Temperature

80

75

(µA)

Q

70

65

60

SHUTDOWN MODE, I

55

50

–40

–15 10 35 60

G2 Rise and Fall Time vs C

120

TA = 25°C

100

80

60

TIME (ns)

40

Q

TEMPERATURE (°C)

7.0

6.5

6.0

5.5

SOFT-START CURRENT (µA)

85

3806 G05

L

5.0

–40

–15 10 35 60

TEMPERATURE (°C)

RUN Thresholds vs Temperature

85

3806 G06

50

0

20

4000

0

8000

CL (pF)

12000

16000

20000

3806 G07

0

4000

0

8000

12000

16000

20000

C

(pF)

L

3806 G08

Maximum Sense Threshold

Frequency vs Temperature

260

255

250

FREQUENCY (kHz)

245

240

–40

–15

10

TEMPERATURE (°C)

35

60

85

3806 G11

vs Temperature

155

154

153

152

151

150

149

148

147

MAX SENSE THRESHOLD (mV)

146

145

–40

–15

10

TEMPERATURE (°C)

35

60

85

3806 G12

3806f

4

UW

VIN (V)

10

6.990

INTV

CC

VOLTAGE (V)

6.995

7.000

7.005

7.010

7.015

7.020

12 14 16 18

3806 G15

20

TYPICAL PERFOR A CE CHARACTERISTICS

SENSE Pin Current

vs Temperature INTVCC Load Regulation INTVCC Line Regulation

32.0

31.5

7.020

7.015

7.010

TA = 25°C

LTC3806

SENSE PIN CURRENT (µA)

31.0

30.5

30.0

–40

–15

10

TEMPERATURE (°C)

2.8

2.7

2.6

2.5

2.4

2.3

2.2

DROPOUT VOLTAGE (V)

2.1

2.0

1.9

35

60

85

3806 G13

INTVCC Dropout Voltage

vs Current, Temperature

TA = –40°C

TA = 0°C

TA = 25°C

TA = 55°C

TA = 85°C

0

10 30

20

INTVCC LOAD (mA)

7.005

VOLTAGE (V)

CC

7.000

INTV

6.995

6.990

0

40

3806 G16

10 20 30 40

INTVCC LOAD (mA)

50

50

3806 G14

Efficiency vs Output Power

90

FIGURE 8 CIRCUIT

85

EFFICIENCY (%)

80

75

30 50 70 90

% OF MAXIMUM OUTPUT POWER

1002010 40 60 80

3806 G17

3806f

5

LTC3806

U

UU

PI FU CTIO S

RUN (Pin 1): The RUN pin provides the user with an

accurate means for sensing the input voltage and programming the start-up threshold for the converter. The

falling RUN pin threshold is nominally 1.14V and the

comparator has 91mV of hysteresis for noise immunity.

When the RUN pin is below this input threshold, the gate

drive outputs G1 and G2 are held low. The absolute

maximum rating for the voltage on this pin is 7V.

ITH (Pin 2): Error Amplifier Compensation Pin. The current

comparator input threshold increases with this control

voltage. Nominal voltage range for this pin is 0V to 1.4V.

FB (Pin 3): Receives the feedback voltage from the external resistor divider across the main output. Nominal

voltage for this pin in regulation is 1.230V.

NC (Pins 4, 11): Do Not Connect.

VIN (Pin 5): Main Supply Pin. Must be closely decoupled

to ground.

INTV

gate drivers and control circuits are powered from this

voltage. Decouple this pin locally to the IC ground with a

minimum 4.7µF low ESR ceramic capacitor.

GND (Pins 7, 13): Ground Pins. Exposed pad must be tied

to electrical ground.

G2 (Pin 8): Secondary-Side Gate Driver Output. This pin

drives the gates of all of the synchronous rectifiers.

G1 (Pin 9): Primary-Side Gate Driver Output.

SS (Pin 10): Soft-Start. A capacitor between this pin and

ground sets the rate at which the current comparator input

threshold may increase when the IC is initially enabled.

Increasing the size of the capacitor slows down the ramp

rate and reduces the inrush current.

SENSE (Pin 12): Current Sense Input for the Control Loop.

Connect this pin to the current sense resistor in the source

of the primary side power MOSFET. Internal leading edge

blanking is provided.

(Pin 6): The Internal 6.9V Regulator Output. The

CC

6

3806f

BLOCK DIAGRA

LTC3806

W

SENSE

12

I

TH

2

FB

3

GND

7

NC: PINS 4 AND 11

SLOPE

COMPENSATION

V-TO-I

R

I

EA

–

g

m

LOOP

LOOP

+

1.230V

V

+

–

REF

OSC

C1

CURRENT

COMPARATOR

PWM

LATCH

S

Q

R

SOFT-START

BIAS AND

START-UP CONTROL

LOGIC

RUN

COMPARATOR

INTV

CC

INTV

CC

+

C2

G1

9

G2

8

SS

10

RUN

1

–

V

IN

5

–

UV2

+

REGULATOR

+

–

+

UV1

6.9V

INTV

CC

6

–

3806 BD

3806f

7

LTC3806

OPERATIO

U

Main Control Loop

The LTC3806 is a constant frequency, current mode

flyback converter controller. A secondary-side gate driver

capable of driving several MOSFET synchronous rectifiers

is provided. To insure best cross regulation, DC/DC converters using this controller operate in forced continuous

conduction (current is always flowing in either the primary

or secondary winding(s) of the transformer.)

For circuit operation, please refer to the Block Diagram of

the IC and Figure 1. In normal operation, the primary-side

power MOSFET is turned on when the oscillator sets the

PWM latch and is turned off when the current comparator

C1 resets the latch. V

to an internal 1.230V reference by error amplifier EA,

which outputs an error signal at the ITH pin. The voltage of

the ITH pin sets the current comparator C1 input threshold.

When the load current on either output increases, a fall in

the FB voltage relative to the reference voltage causes the

ITH pin to rise increasing the primary-side peak current

thereby maintaining regulation. Regulation of V

indirect, occurring via transformer action.

The RUN pin and undervoltage comparators control

whether the IC is enabled or is in a low current state. With

is divided down and compared

OUT1

OUT2

is

the RUN pin below 1.139V, the chip is off and the input

supply current is typically only 50µA. If the RUN pin is

above 1.230V, most internal circuitry remains off until V

exceeds the undervoltage comparator UV2 threshold. This

reduces start-up current to approximately 80µA allowing

smaller values for C1 and larger values for R1 to be used.

The undervoltage comparator UV1 keeps G1 and G2 low

until INTVCC voltage is >4.7V to insure that gate drivers

will switch the external power MOSFETs properly.

Prior to normal operation, soft-start pin SS is low clamping the output of the V-to-I converter to a low value causing

current comparator C1 to trip at a low threshold. Once

operation begins, the SS pin ramps up causing the clamp

voltage to rise as well. This allows progressively higher

trip points on comparator C1 and progressively higher

peak currents to be supplied to the primary of the transformer. Soft-start is completed when the voltage on the SS

pin exceeds the voltage on the ITH pin.

The nominal operating frequency of the LTC3806 is 250kHz.

Since forced continuous operation is used, the noise

spectrum over all operating conditions is well controlled

with virtually all noise occurring at the operating frequency

and its harmonics.

IN

8

3806f

WUUU

APPLICATIO S I FOR ATIO

LTC3806

INTVCC Regulator Bypassing and Operation

An internal voltage regulator produces the 6.9V supply

that powers the gate drivers and logic circuitry within the

LTC3806. The INTVCC regulator can supply up to 50mA

and must be bypassed to ground immediately adjacent to

the IC pins with a minimum of 4.7µF ceramic capacitor.

Good bypassing is necessary to supply the high transient

currents required by the MOSFET gate drivers.

In an actual application, most of the IC supply current is

used to drive the gate capacitances of the power MOSFETs.

As a result, high input voltage applications with large

power MOSFETs can cause the LTC3806 to exceed its

maximum junction temperature rating. The junction temperature can be estimated using the following equations:

I

P

TJ = TA + PIC • R

Q(TOT)

= V

IC

= IQ + f • Q

• (IQ + f • QG)

IN

TH(JA)

G

where

IQ is the static supply current

QG is the total gate charge of all external power MOSFETs

If VIN is set to 10V, the power dissipation is:

P

= 10 • 27mA = 270mW

IC

and the junction temperature (assuming 70 degree ambient temperature) is:

TJ = 70°C + 270mW • 120°C/W = 102.4°C

To prevent the maximum junction temperature from being

exceeded, the input supply current must be checked when

operating at high VIN. If junction temperature is too high,

using a separate transformer winding to lower VIN may be

tried. Prior to adding an additional transformer winding

(which raises transformer cost), be sure to check with

power MOSFET manufacturers for their newest low QG,

low R

devices. Power MOSFET manufacturing tech-

DS(ON)

nologies are continually improving, with newer and better

performance devices being introduced almost yearly.

Output Voltage Programming

This IC will generally be used in DC/DC converters with

multiple outputs. The output voltage of the master output

(V

) is set by a resistor divider according to the

OUT1

following formula:

P

is the power dissipated in the IC

IC

f is the switching frequency, nominally 250kHz

R

is the package thermal resistance, junction to

TH(JA)

ambient, nominally 34°C/W for the 12-pin DFN package

As an example, consider a 2-output power supply that

uses an Si7450DP primary-side power MOSFET, that has

a maximum total gate charge of 42nC and two Si4840DY

power MOSFETs (one for each output), each of which has

28nC maximum total gate charge.

The total gate charge is:

QG = 42nC + 2 • 28nC = 98nC

The total supply current is:

I

= 2000µA + 98nC • 250kHz = 27mA

Q(TOT)

This demonstrates how significant the gate charge current

can be when compared to static quiescent current in the

IC.

R

6

VV

OUT1

1 230 1

=+

.•

R

7

The external resistor divider is connected as shown in

Figure 1. The resistors R6 and R7 are typically chosen so

that the error caused by the current flowing into the FB pin

during normal operation is less than 1% (this translates to

a maximum value of R7 of about 120k).

The nominal slave output (V

) voltage is set according

OUT2

to the following formula:

V

OUT2

= V

OUT1

• N21

where N21 is the turns ratio of the transformer windings

between V

OUT2

and V

OUT1

.

If additional slave outputs are added their voltage is

determined by the equation:

V

OUTN

= V

OUT1

• N

N1

where NN1 is the turns ratio of the transformer windings

between V

OUTN

and V

OUT1

.

3806f

9

LTC3806

RA

RKV

V

RB

R

KVV

OUT

REF

OUT

REF

6

7

1

6

7

1

1

1

2

=

=

–

–

–

WUUU

APPLICATIO S I FOR ATIO

Cross regulation and tracking between the master and slave

outputs are impacted by transformer and secondary-side

power MOSFET selection. Select a power MOSFET with

low on resistance. In addition, a transformer with low

winding resistances and highest coupling coefficient will

have better cross regulation and tracking.

Composite Feedback

In applications where accuracy is important on more than

one output, composite feedback may be used. This sacrifices some of the accuracy of one output for improved

accuracy on the other output(s). Figure 2 shows how

composite feedback can be applied to two outputs.

OUT1 OUT2

R6B

R6A

FB

R7

3806 F02

Figure 2. Composite Feedback

Select a value for R7 less than or equal to 120k. Now

choose the fraction K of the total feedback taken from

V

. The higher the fraction used, the tighter V

OUT1

controlled, but the poorer V

is controlled (since it

OUT2

OUT1

is

contributes less to the total feedback). The values for R6A

and R6B can now be calculated:

This technique can easily be extended to more outputs if

needed.

Programming Turn-On and Turn-Off Thresholds

with the RUN Pin

The LTC3806 leaves a comparator detection circuit and

the voltage reference active even when the device is shut

down (Figure 3). This allows users to accurately program

an input voltage at which the converter will turn on and off.

V

IN

RUN

GND

6V

1.230V

REFERENCE

+

–

RUN

COMPARATOR

BIAS AND

START-UP

CONTROL

3806 F03a

INPUT

SUPPLY

+

OPTIONAL

FILTER

CAPACITOR

–

R2

R1

Figure 3a. Programming the Turn-On and Turn-Off Thresholds Using the RUN Pin

V

IN

RUN

GND

6V

1.230V

+

–

RUN

COMPARATOR

3806 F03c

EXTERNAL

LOGIC CONTROL

RUN

6V

1.230V

COMPARATOR

+

–

3806 F03b

RUN

INPUT

SUPPLY

+

R2

1M

–

Figure 3b. On/Off Control Using External Logic Figure 3c. External Pull-Up Resistor On

RUN Pin for “Always On” Operation

3806f

10

WUUU

APPLICATIO S I FOR ATIO

LTC3806

The rising threshold voltage on the RUN pin is equal to the

internal reference voltage of 1.230V. The comparator has

91mV of hysteresis to increase noise immunity.

The turn-on and turn-off input voltage thresholds are

programmed using a resistor divider according to the

following formulas:

R

2

VV

IN OFF

()

VV

IN ON

()

.•

=+

1 139 1

.•

=+

1 230 1

R

1

R

2

R

1

The resistor R1 is typically chosen to be less than 1M. For

applications where the RUN pin is only to be used as a

logic input, the user should be aware of the 7V Absolute

Maximum Rating for this pin! The RUN pin can be

connected to the input voltage through an external 1M

resistor, as shown in Figure 3c, for “always on” operation.

Application Circuits

A basic LTC3806 application circuit is shown in Figure 1.

External component selection is driven by the characteristics of the load and the input supply.

For a 50% duty factor, this reduces to:

V

1

N

IDEAL

If N

IDEAL

a ratio of small integers that comes close to N

OUT

=

V

IN

is integer, use this for your turns ratio. If not, find

. If these

IDEAL

conditions are met, bifilar winding techniques can be used

that will improve coupling coefficient. Cross regulation

will be better and primary-side snubbing may be reduced

or eliminated.

The selected turns ratio doesn’t have to be perfectly equal

to N

because a flyback converter’s output voltage is

IDEAL

not set through transformer action. Instead, the transformer stores energy when the primary-side switch turns

on and transfers this energy to the output(s) by flyback

action when the primary-side switch turns off.

Cross regulation may be improved by using a target duty

factor which is less than 50%. This improves cross

regulation because the secondary-side MOSFETs (synchronous rectifiers) will be on a larger percentage of the

time (thereby increasing the average coupling between the

outputs). Duty factor is reduced by proportionately increasing all turns ratios.

Duty Cycle Considerations

Current and voltage stress on the power switch and

synchronous rectifiers, input and output capacitor RMS

currents and transformer utilization (size vs power) are

impacted by duty factor. Unfortunately duty factor cannot

be adjusted to simultaneously optimize all of these requirements. In general, avoid extreme duty factors since

this severely impacts the current stress on most of the

components. A reasonable target for duty factor is 50% at

nominal input voltage. Using this rule of thumb, calculate

the ideal transformer turns ratio:

N

IDEAL

V

OUT

=

1

V

IN

D

1•–

D

Reduced duty factor has the following effect on MOSFET

stresses:

MOSFET MOSFET

LOCATION CURRENT STRESS VOLTAGE STRESS

Primary Increased Reduced

Secondary Reduced Increased

The duty factor with the selected turns ratio will equal:

V

OUT

D

=

VNV

OUT IN

While the output(s)/input turns ratio are not critical,

1

•

+

()

1

the

turns ratio between outputs are critical and affect the

accuracy of the slave output voltages.

3806f

11

LTC3806

WUUU

APPLICATIO S I FOR ATIO

Some common secondary turns ratios:

V

OUT

2.5 3

3.3 4

3.3 2

5.0 3

1.8 6

3.3 11

1.8 5

2.5 7

2.5 3

3.3 4

5.0 6

TURNS

For example, assume we need a regulator that operates

with a nominal 48V input to produce one 3.3V output and

one 5V output. The ideal turns ratio for the 3.3V (master)

output is:

N

IDEAL1

33

48

0 06875==..

We select a turns ratio of 1/15 or N1 = 0.066…

For the 5V output, the ideal turns ratio is:

NN

IDEAL2

5

1

33

.

0 1010==•

. ...

If we choose:

1

N2 =

10

and we assume OUT1 is exact, the voltage on slave

output␣ 2 is:

V

OUT

D

=

VNV

OUT IN

1

+

()

1

=

•

33

.

V

33

.

+

V

48

15

=

0 508

V

.

Input Power

The maximum input power is:

N

P

∑

OUTK

=1

P

IN

where P

K

=

Eff

is the maximum power supplied by output K

OUTK

and Eff represents the efficiency of the converter.

Continuing the previous example, assume OUT1 delivers

3.3V at 2A and OUT2 delivers 4.95V at 0.5A. For a

conversion efficiency at maximum output power of 80%:

VA V A

33 2 495 05

P

.• . •.

=

IN

+

080

.

=

11 34

W

.

Transformer Selection

The transformer primary inductance, LP, is selected based

on the percentage peak-to-peak ripple current (X) in the

transformer relative to its maximum value. In general, X

should range from 20% to 40% ripple current (i.e., X = 0.2

to 0.4). Higher values of ripple will increase conduction

losses, while lower values will require larger cores.

Ripple current and percentage ripple will be largest at

minimum duty factor D, in other words at the highest input

voltage. LP can be calculated from:

1

L

VV

OUT2

33

10

33 15 495===.• .•. .

1

15

This does not include any other errors, so make sure that

the error in V

is only a fraction of what your specifica-

OUT2

=

P

where f is nominally 250kHz.

Continuing the example, allow 40% maximum ripple at a

maximum input voltage of 72V:

tion allows. When dealing with large numbers of outputs

trial and error is usually required to get reasonable turns

D

MIN

ratios on all outputs while keeping the errors (due to

imperfect turns ratios) low.

For the selected turns ratios, the duty factor for this design

L

==µ

P

with 48V input would be:

12

VD

IN MAX MIN

=

22

MAX IN

33

.

V

+

.

V

•

72

V

()

fX P

••

33

=

0 407

.

15

22

V

72 0 407

•.

250000 0 4 11 34

Hz W

•.• .

757

H

3806f

WUUU

APPLICATIO S I FOR ATIO

LTC3806

For a minimum input voltage of 36V, the largest duty factor

is:

V

33

33

.

.

V

+

36

=

0 579

.

V

D

MAX

=

15

and the minimum percentage ripple is:

22

VD

•

X

MIN

IN MAX

=

fL P

••

PIN

22

V

36 0 579

=

kHz H W

250 757 11 34

•.

µ

••.

=

20 2

.%

Transformer Core Selection

Once LP is known, the type of transformer must be selected.

High efficiency converters generally cannot afford the core

loss found in low cost powdered iron cores, forcing the use

of more expensive ferrite cores. Actual core loss is independent of core size for a fixed inductance, but is very

dependent on the inductance selected. As inductance increases, core losses go down. Unfortunately, increased

inductance requires more turns of wire and therefore copper losses will increase. Generally, there is a tradeoff between core losses and copper losses that needs to be

balanced. In addition, increased winding resistance will

degrade cross regulation.

Ferrite designs have very low core losses and are preferred

at high switching frequencies, so design goals can concentrate on copper losses and preventing saturation.

Ferrite core material saturates “hard,” meaning that the

inductance collapses rapidly when the peak design current

is exceeded. This results in an abrupt increase in inductor

ripple current and consequently, output voltage ripple. Do

not allow the core to saturate! The maximum peak

primary current occurs at minimum VIN:

P

I

=+

PK

VD

IN

•

()

IN MIN MAX

•1

X

MIN

2

Current Sense Resistor Selection

The control circuit limits the maximum voltage drop

across the sense resistor to about 120mV (at low duty

cycle), and only about 70mV at a duty cycle of 92% due to

slope compensation. Use Figure 4 and D

to determine

MAX

the maximum allowable drop in the sense resistor. Using

this value calculate:

V

R

SENSE

Figure 4. Maximum SENSE Threshold Voltage vs Duty Cycle

DROP

≤

I

PK

200

TA = 25°C

150

100

50

MAXIMUM CURRENT SENSE VOLTAGE (mV)

0

0.2

0

0.5

0.4

DUTY CYCLE

0.8

1.0

3806 F04

Capacitor Selection

In a flyback converter, the input and output current flows

in pulses placing severe demands on the input and output

filter capacitors. The input and output filter capacitors

should be selected based on RMS current ratings and

ripple voltage.

Select an input capacitor with a ripple current rating

greater than:

I

RMS

=

P

IN

V

()

IN MIN

–1

D

D

MAX

MAX

Continuing the example:

W

11 34

I

RMS RMS

.–.

==

36

V

1 0 579

0 579

.

0 269

.

A

Low effective series resistance and inductance is also

important in the input capacitor since it affects the electromagnetic interference suppression. In some instances

high ESR can also produce stability problems because

flyback converters exhibit a negative input resistance

3806f

13

LTC3806

WUUU

APPLICATIO S I FOR ATIO

characteristic. Refer to Application Note 19 for more

information.

The output capacitor is sized to handle the ripple current

and to insure acceptable output voltage ripple. The output

capacitor should have a ripple current rating greater than:

D

II

=

RMS OUT

1–

MAX

D

MAX

This should be calculated for each output. For our example, the OUT1 capacitor needs an RMS current rating

greater than:

0 579

IA A

==2

RMS RMS

.

1 0 579

–.

235

.

The OUT2 capacitor RMS current rating is calculated in a

similar manner. The capacitor rating should be greater

than 586mA

. One final note, most capacitor manufac-

RMS

turers base their ripple current ratings on only 2000 hours

life. This makes it advisable to further derate the capacitor

or to choose a capacitor rated at a higher temperature than

required.

Contributions of ESR (equivalent series resistance), ESL

(equivalent series inductance) and the bulk capacitance

must be considered when choosing the correct component for a given output ripple voltage. The effects of these

three parameters (ESR, ESL and bulk C) on the output

voltage ripple waveform are illustrated in Figure 5 for a

typical flyback converter.

The capacitance calculation begins with the maximum

acceptable ripple voltage (expressed as a percentage of

the output voltage), and how this ripple should be divided

between the ESR step and the charging/discharging ∆V.

For the purpose of simplicity we will choose 2% for the

maximum output ripple, to be divided equally between the

ESR step and the charging/discharging ∆V. This percentage ripple will change, depending on the requirements of

the application, and the equations provided below can

easily be modified.

For a 1% contribution to the total ripple voltage, the ESR

of the output capacitor can be determined using the

following equation:

ESR

COUT

≤

VD

()

OUT MAX

I

OUT

001 1.• •–

For the bulk C component, which also contributes 1% to

the total ripple:

I

C

OUT

≥

OUT

VF

001.• •

OUT

For many designs it is possible to choose a single capacitor type that satisfies both the ESR and bulk C requirements for the design. In certain demanding applications,

however, the ripple voltage can be improved significantly

by connecting two or more types of capacitors in parallel.

For example, using a low ESR ceramic capacitor can

minimize the ESR step, while an electrolytic capacitor can

be used to supply the required bulk C.

14

PRIMARY

CURRENT

SECONDARY

CURRENT

OUTPUT VOLTAGE

RIPPLE WAVEFORM

Figure 5. Typical Flyback Converter Waveforms (Single Output)

I

PRI

I

PRI

N

∆V

COUT

∆V

ESR

RINGING

DUE TO ESL

3806 F05

3806f

WUUU

I

I

D

RMSSEC

OUT

MAX

=

−1

APPLICATIO S I FOR ATIO

LTC3806

Continuing our previous example the filter capacitor for

output 1 needs:

001 33 1 0579

ESR

COUT

C

≥=µ

OUT

.•. •–.

≤

0 01 3 3 250

.•. •

V

()

A

2

A

2

V kHz

242

m

=Ω

7

F

To get an electrolytic capcitor with an ESR this low would

require C

much larger than 242µF. Combining a low

OUT

ESR ceramic capacitor in parallel with an electrolytic

capacitor provides better filtering at lower cost.

For output 2, the output capacitor needs an ESR less than

42mΩ and a bulk C greater than 40.4µF. This can be

achieved with a single high performance capacitor such as

a Sanyo OS-CON or equivalent.

Once the output capacitor ESR and bulk capacitance have

been determined, the overall ripple voltage waveform

should be verified on a dedicated PC board. Parasitic

inductance from poor layout can have a significant impact

on ripple. Refer to the layout section for details.

L

BV I

DSS PK

where L

≥++

is the primary-side leakage inductance and C

LKG

LKG

C

V

IN MAX

P

()

is the primary-side capacitance (mostly from the C

V

OUT MAX

()

N

OSS

P

of

the primary-side power MOSFET). A snubber may be

added to reduce the leakage inductance related spike. For

more information on snubber design, refer to Application

Note 19.

For each secondary-side power MOSFET, the BV

DSS

should

be greater than:

BV

≥ V

DSS

Next, select a logic-level MOSFET with acceptable R

OUT

+ V

IN(MAX)

• N

DS(ON)

at the nominal gate drive voltage (usually 6.9V—set by the

INTVCC regulator).

Calculate the required RMS currents next. For the primaryside power MOSFET:

P

I

RMSPRI

=

VD

IN MIN MAX

IN

•

()

Power MOSFET Selection

Important selection criteria for the power MOSFETs include the “on” resistance R

drain-to-source breakdown voltage (BV

mum drain current (I

D(MAX)

).

, input capacitance,

DS(ON)

DSS

) and maxi-

Narrow the choices for power MOSFETs by first looking at

the maximum drain currents. For the primary-side power

MOSFET:

P

I

=+

PK

VD

IN

•

()

IN MIN MAX

•1

X

MIN

2

For each secondary-side power MOSFET:

I

I

PK

OUT

=+

D

1

MAX

X

12–•

MIN

From the remaining MOSFET choices, narrow the field

based on BV

with a BV

DSS

. Select a primary-side power MOSFET

DSS

greater than:

For each secondary-side power MOSFET:

Calculate MOSFET power dissipation next. Because the

primary-side power MOSFET operates at high VDS, a term

for transition power loss must be included in order to get

an accurate fix on power dissipation. C

MILLER

is the most

critical parameter in determining the transition loss but is

not directly specified on MOSFET data sheets.

C

can be calculated from the gate charge curve in-

MILLER

cluded on most data sheets (Figure 6). The curve is generated by forcing a constant input current into the gate of

a common source, current source loaded stage and then

plotting the gate voltage versus time. The initial slope is the

result of the gate-to-source and the gate-to-drain capacitance. The flat portion of the curve is the result of the Miller

(gate-to-drain) capacitance as the drain voltage drops. The

upper sloping line is due to the gate-to-drain accumulation

capacitance and the gate-to-source capacitance. The Miller

3806f

15

LTC3806

WUUU

APPLICATIO S I FOR ATIO

VIN ≅ V

DS

V

charge (the increase in coulombs on the horizontal axis

from a to b while the curve is flat) is specified for a given

VDS, but can be adjusted for different VDS voltages by

multiplying by the ratio of the application VDS to the curve

specified VDS values. To estimate the C

the change in gate charge from points a and b on the

manufacturers data sheet and divide by the specified VDS.

With C

MOSFET power dissipation:

where RDR is the GATE1 driver resistance (maximum is

approximately 6Ω), V

age for the specified power MOSFET and f is the operating

frequency, typically 250kHz. The term (1 + δ) is generally

given for a MOSFET in the form of a normalized R

temperature curve, but δ = 0.005/°C can be used as an

approximation for low voltage MOSFETs.

The secondary-side power MOSFETs typically operate at

substantially lower VDS, so transition losses can be neglected. The dissipation may be calculated using:

For a known power dissipation in the power MOSFETs, the

junction temperatures can be obtained from the equation:

where TA is the ambient temperature and R

MOSFET thermal resistance from junction to ambient.

MILLER EFFECT

GS

a

C

= (QB – QA)/V

MILLER

Figure 6. Gate Charge Curve and Test Circuit

MILLER

PI R V

=+

DPRI RMSPRI DS ON IN MAX

P

IN MAX

()

••••

D

MIN

P

= I

DSEC

RMSSEC

TJ = TA + PD • R

b

Q

IN

DS

+

V

I

GATE

GS

–

3806 F06

MILLER

determined, calculate the primary-side power

2

•

RC

DR MILLER

is the typical gate threshold volt-

TH

2

• R

DS(ON)

TH(JA)

()

() ( )

+

1

δ

1

VV

INTVCC TH

–

(1 + δ)

TH(JA)

DEVICE

UNDER TEST

term, take

•

f

vs

DS(ON)

is the

Compare TJ against your initial estimate for TJ and if

necessary, recompute δ, power dissipations and TJ. Iterate as necessary.

Selecting the Compensation Network

Load step testing can be used to empirically determine

compensation. Application Note 25 provides information

on the technique. When the regulator has multiple outputs, compensation should be optimized for the master

output.

PC Board Layout Checklist

1. In order to minimize switching noise and improve output load regulation, the GND pin of the LTC3806 should

be connected directly to 1) the negative terminal of the

INTVCC decoupling capacitor, 2) the negative terminal

of the output decoupling capacitors, 3) the bottom terminal of the current sense resistor, 4) the negative terminal of the input capacitor and 5) at least one via to the

ground plane immediately adjacent to Pin 6 (GND).

2. Beware of ground loops in multiple layer PC boards. Try

to maintain one central ground node on the board and

use the input capacitor to avoid excess input ripple for

high output current power supplies. If the ground plane

is to be used for high DC currents, choose a path away

from the small-signal components.

3. Place the C

capacitor immediately adjacent to the

VCC

INTVCC and GND pins on the IC package. This capacitor

carries high di/dt MOSFET gate drive currents. A low

ESR X5R 4.7µF ceramic capacitor works well here.

4. The high di/dt loop from the bottom terminal of the

input capacitor through the sense resistor, primaryside power MOSFET, transformer primary and back

through the input capacitor should be kept as tight as

possible in order to reduce EMI. Also keep the loops

formed by the

outputs

as tight as possible.

5. Check the switching waveforms of the MOSFETs using

the actual PC board layout. Measure directly across the

power MOSFET terminals to verify that the BV

DSS

specification of the MOSFET is not exceeded due to

inductive ringing. If this ringing cannot be avoided and

16

3806f

WUUU

APPLICATIO S I FOR ATIO

LTC3806

exceeds the maximum rating of the device, either choose

a higher voltage device or specify an avalanche-rated

power MOSFET.

6. Place the small-signal components away from high

frequency switching nodes. (All of the small-signal

components on one side of the IC and all of the power

components on the other.) This allows the use of a

pseudo-Kelvin connection for the signal ground, where

high di/dt gate driver currents flow out of the IC ground

pin in one direction (to the bottom plate of the INTV

CC

decoupling capacitor) and small-signal currents flow in

the other direction.

7. Minimize the capacitance between the SENSE pin trace

and any high frequency switching nodes. The LTC3806

contains an internal leading edge blanking time of

approximately 180ns, which should be adequate for

most applications.

V

IN

25V TO 60V

R5

232kR447k

R1

22Ω

1N4148

C5

2.2µF

D1

R3

TBD

C7

220pF

Q4

Si4490DY

8. For optimum load regulation and true remote sensing,

the top of the output resistor divider should connect

independently to the top of the the output capacitor

(Kelvin connection), staying away from any high dV/dt

traces. Place the divider resistors near the LTC3806 in

order to keep the high impedance FB node short.

9. For applications with multiple switching power converters which connect to the same input supply, make sure

that the input filter capacitor for the LTC3806 is not

shared with other converters. AC input current from

another converter could cause substantial input voltage

ripple and this could interfere with the operation of the

LTC3806. A few inches of PC trace or wire (L ≅ 100nH)

between the CIN of the LTC3806 and the actual source

VIN should be sufficient to prevent current sharing

problems.

T1

XFMR_EFD20

12

11

1

2

Q1

Si7806DN

D2

B260A

R2

10Ω

+

Q5

Si7806DN

Q2

C1

1nF

7

6

10

8

9

4

5

3

Si7806DN

C2

10µF

C6

100µF

C8

470µF

POSCAP

12V

400mA

5V

1.5A

3.3V

2A

R10

12.4k

C18

100µF

C19

220nF

C16

100pF

33k

R9

20V

LTC3806

1

RUN

2

I

TH

R17

12.4k

3

4

5

6

FB

NC

V

IN

INTV

C20

4.7µF

R16

76.8k

CC

C14

1nF

D4

SENSE

R13

42.3k

NC

GND

12

C15

11

220nF

10

SS

9

G1

8

G2

7

R14

0.056Ω

C25

100nF

R18

100k

D8

10V

3806 F07

C26

100µF

–5V

1.5A

Figure 7. Synchronous Flyback

3806f

17

LTC3806

WUUU

APPLICATIO S I FOR ATIO

Table 1. Recommended Component Manufacturers

VENDOR COMPONENTS TELEPHONE WEB ADDRESS

AVX Capacitors 207-282-5111 avxcorp.com

BH Electronics Transformers 952-894-9590 bhelectronics.com

Coiltronics Transformers 407-241-7876 coiltronics.com

Diodes, Inc. Diodes 805-446-4800 diodes.com

Fairchild MOSFETs 408-822-2126 fairchildsemi.com

General Semiconductor Diodes 516-847-3000 gerneralsemiconductor.com

International Rectifier MOSFETs, Diodes 310-322-3331 irf.com

IRC Sense Resistors 361-992-7900 irctt.com

Kemet Tantalum Capacitors 408-986-0424 kemet.com

Magnetics Inc. Toroid Cores 800-245-3984 mag-inc.com

Microsemi Diodes 617-926-0404 microsemi.com

Murata-Erie Capacitors 770-436-1300 murata.co.jp

Nichicon Capacitors 847-843-7500 nichicon.com

On Semiconductor Diodes 602-244-6600 onsemi.com

Panasonic Capacitors 714-373-7334 panasonic.com

Sanyo Capacitors 619-661-6835 sanyo.co.jp

Taiyo Yuden Capacitors 408-573-4150 t-yuden.com

TDK Capacitors, Transformers 562-596-1212 component.tdk.com

Thermalloy Heat Sinks 972-243-4321 aavidthermalloy.com

Tokin Capacitors 408-432-8020 tokin.com

United Chemicon Capacitors 847-696-2000 chemi-com.com

Vishay/Dale Resistors 605-665-9301 vishay.com

Vishay/Siliconix MOSFETs 800-554-5565 vishay.com

Vishay/Sprague Capacitors 207-324-4140 vishay.com

Zetex Small-Signal Discretes 631-543-7100 zetex.com

TYPICAL APPLICATIO

V

IN

36V TO 72V

R5

330k

R7

12.5k

D2

20V

18

R6

51k

R9

3.3k

C7

1nF

C5

100µF

U

Synchronous Forward Application

C1

1.5µF

R11

100Ω

D1

1N4148

C6

100pF

LTC3806

1

NC

2

RUN

3

I

TH

4

FB

5

V

IN

6

INTV

C3

4.7µF

R10

12.5k

CC

SENSE

GND

R8

20.5k

12

NC

11

10

SS

9

G2

8

G1

7

C8

470nF

C4

330pF

R1

220Ω

T1

PULSE PA0031

••

Q1

Si7450DP

R2

0.1Ω

Q2

Si7358DP

L1

4.7µH

Q3

Si7448DP

3806 TA01

V

3.3V

8A

C2

330µF

OUT

3806f

PACKAGE DESCRIPTIO

LTC3806

U

UE/DE Package

12-Lead Plastic DFN (4mm × 3mm)

(Reference LTC DWG # 05-08-1695)

0.65 ±0.05

3.50 ±0.05

1.70 ±0.05

(2 SIDES)2.20 ±0.05

PACKAGE OUTLINE

0.25 ± 0.05

3.30 ±0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

4.00 ±0.10

(2 SIDES)

PIN 1

TOP MARK

(NOTE 6)

0.200 REF

NOTE:

1. DRAWING PROPOSED TO BE A VARIATION OF VERSION

(WGED) IN JEDEC PACKAGE OUTLINE M0-229

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

0.50

BSC

3.00 ±0.10

(2 SIDES)

0.75 ±0.05

R = 0.20

TYP

1.70 ± 0.10

(2 SIDES)

0.00 – 0.05

R = 0.115

TYP

0.25 ± 0.05

3.30 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

0.50

BSC

127

16

0.38 ± 0.10

PIN 1

NOTCH

(UE12/DE12) DFN 0603

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3806f

19

LTC3806

TYPICAL APPLICATIO

V

IN

25V TO 60V

GND

C1

+

10µF

63V

ELEC

L1

3.3µH

C2

220nF

1206

225mW

20V

R2

R1

47k

232k

0805

0805

R3

12.4k

0603

D3

R4

33k

0603

C13

+

100µF

35V TANT

7343

1N4148W

SOD123

C9

100pF

0603

U

D1

C3

2.2µF

100V

1812

1nF

0603

C14

220nF

0603

V

OUT

3806 F08

12V

400mA

GND

V

OUT

5V

400mA

V

OUT

3.3V

3A

GND

V

OUT

2.5V

2A

D2

T1

XFMR EFD20

12

11

1

2

Si4490

LTC3806

1

RUN

2

I

TH

R6

12.4k

0603

3

4

5

6

FB

NC

V

INTV

C15

4.7µF

10V

0805

IN

C8

FB

CC

GND

SENSE

GND

13

12

11

NC

10

SS

9

G2

8

G1

7

R7

20.5k

0603

C12

220nF

0603

R5

0.033Ω

1206

1A 60V

B260A SMA

7

6

10

8

9

4

5

3

Q1

Si7806DN

Q2

Q3

Si7806DNQ4Si7806DN

+

C6

+

470µF

4V POSCAP

7343

C10

470µF

4V POSCAP

7343

C11

100µF

1210

C4

10µF

1812

C5

47µF

1812

C7

100µF

1210

Figure 8. Mulitple Output Flyback Converter for Telecom

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT®1619 Current Mode PWM Controller 300kHz Fixed Frequency, Boost, SEPIC Flyback Topology

LTC1624 Current Mode DC/DC Controller SO-8; 300kHz Operating Frequency; Buck, Boost, SEPIC Design;

Up to 36V

V

LTC1700 No R

TM

Synchronous Step-Up Controller Up to 95% Efficiency, Operation as Low as 0.9V Input

SENSE

LT1725 General Purpose Isolated Flyback Controller Drives External Power MOSFET, Senses Output Voltage Directly from

LTC1871 Wide Input Range Current Mode No R

Controller 50kHz to 1000kHz Frequency; Boost, Flyback and SEPIC Topology

SENSE

LTC1872 SOT-23 Boost Controller Delivers Up to 5A, 550kHz Fixed Frequency, Current Mode

LT1910 Protected High Side MOSFET Driver 8V to 48V Power Supply Range; Protected from –15V to 60V Supply

LT1930 1.2MHz SOT-23 Boost Converter Up to 34V Output, 2.6V ≤ VIN ≤ 16V, Miniature Design

LT1931 Inverting 1.2MHz, SOT-23 Converter Positive-to-Negative DC/DC Conversion, Miniature Design

LT1950 Single Switch Forward Controller 3V ≤ VIN ≤ 25V, 25W to 500W, Programmable Slope Compensation

LTC3401/LTC3402 1A/2A, 3MHz Synchronous Boost Converters Up to 97% Efficiency, Very Small Solution, 0.5V ≤ VIN ≤ 5V

LT3781/LTC1698 36V to 72V Input Isolated DC/DC Converter Chipset Synchronous Operation; Overvoltage/Undervoltage Protection;

LTC3803 SOT-23 Flyback Contoller Adjustable Slope Compensation, Internal Soft-Start, 200kHz

No R

is a trademark of Linear Technology Corporation.

SENSE

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

IN

Primary Side Switching—No Optoisolator Required, 16-Pin SSOP

Transients, Short-Circuit Protection, Automatic Restart Timer

10W to 100W Power Supply; 1/2-, 1/4-Brick Footprint

3806f

LT/TP 0104 1K • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPORATION 2004

Loading...

Loading...