L DESIGN FEATURES

LTC3805

I

TH

GND

SSFLT

RUN

GATE

OC

I

SENSE

SYNC

FS

FB

V

CC

118k

3.01k

68mΩ

2.2µF

× 2

1µF

1.33k

8.66k

221k

221k

V

IN

36V TO

72V

V

OUT

3.3V

AT 3A

221k

PDZ6.8B

6.8V

BAS516

20k

470pF

0.1µF

13.7k

42.2k

100µF

6.3V

× 3

FDC2512

UPS840

MMBTA42

Current Mode Flyback DC/DC

Controller Provides Tremendous

Design Flexibility

Introduction

By its nature, a flyback DC/DC converter is one of the most versatile power

converter topologies. Because it uses

a transformer, it can step up or step

down voltages and provide DC isolation

if needed. Applications include power

supplies for networking equipment,

Power-over-Ethernet (PoE), automotive, consumer and general system

house keeping. The LTC3805 has been

designed to enhance the flexibility of

the basic flyback converter, making

it possible to optimize a single design

for diverse applications. The converter

input and output voltage is limited only

by the rating of external components

such as the power MOSFET and the

transformer. The LTC3805 can be

programmed for frequency, slope

compensation, soft-start, input voltage RUN/STOP thresholds (including

programmable hysteresis), synchronization to an external frequency source,

and overcurrent protection to protect

the converter from faults.

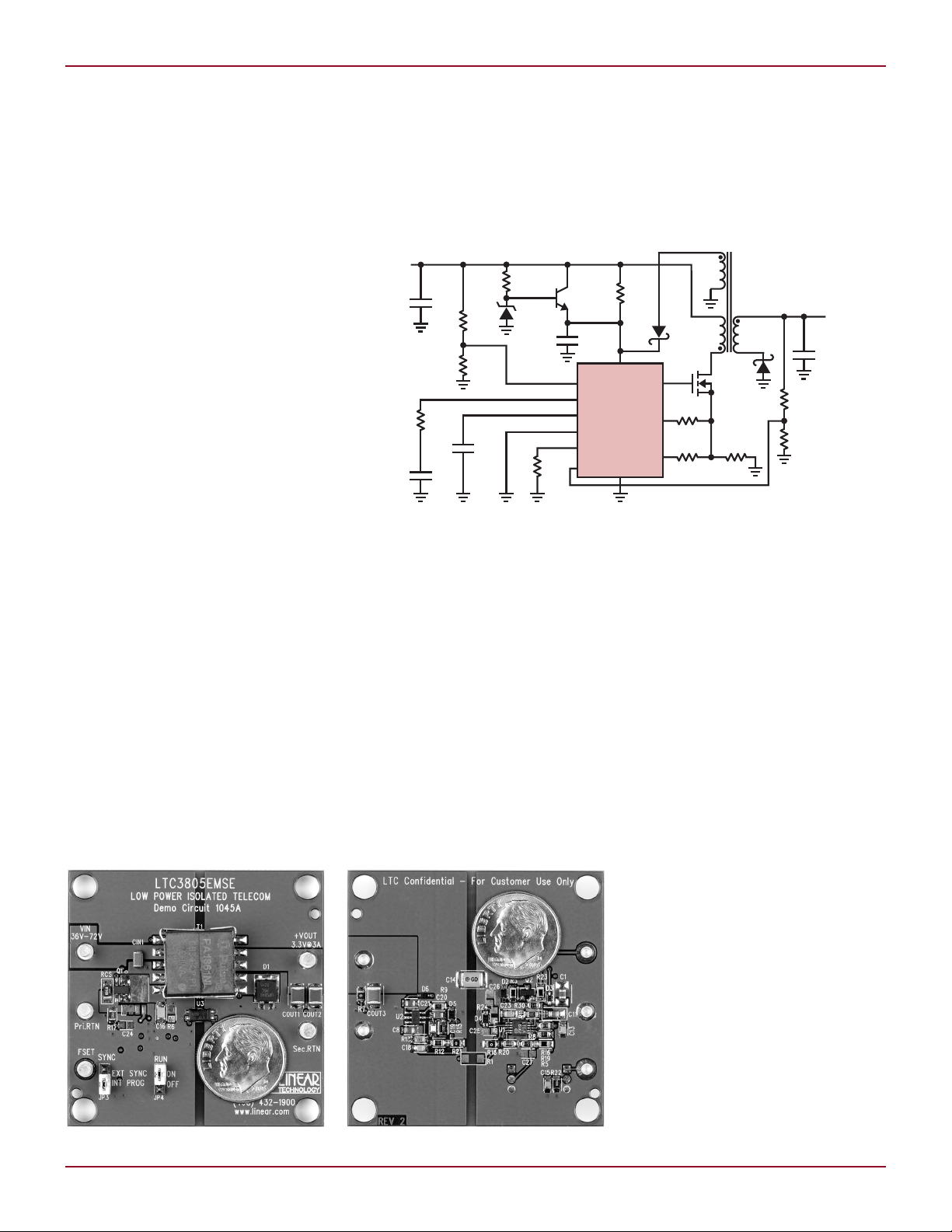

36V–72V to 3.3V at 3A

Non-Isolated Flyback

Figure 1 shows the LTC3805 in a

non-isolated flyback converter with

an input voltage range of 36V to 72V

and an output voltage of 3.3V at 3A.

The remainder of this section details

the design decisions made in creating

this converter and describes methods

for altering the design for various

applications. An isolated version of

the converter is described in the next

section.

VCC Power and Start-Up

In this design, start-up VCC power for

the LTC3805 is provided by an external

pre-regulator using an NPN transistor, a zener diode and two resistors.

Once the converter begins operation,

a winding on the transformer provides a bias supply which turns off

by Arthur Kelley

Figure 1. Non-isolated 36V to 72V to 3.3V 3A flyback converter

the NPN transistor to save power and

increase efficiency. Alternately, since

the LTC3805 has an ultralow shut

down current of 40µA, a simple trickle

charger could be used to eliminate the

NPN pre-regulator. The LTC3805 has

a VCC rising threshold of 8.5V and a

falling threshold of 4V so there is plenty

of hysteresis to implement a trickle

charger. In either case, note that VCC

is not connected to VIN so that almost

any input supply above 8.5V can be

accommodated by proper selection of

external components and that, once

started, the LTC3805 can run with

input supplies down to 4V.

-

Programming V

OUT

The FB pin monitors the output voltage by comparing it—via a resistive

divider—to the 0.8V internal reference

of the LTC3805. Since the FB pin is

not connected directly to the output,

8

Figure 2. Isolated 36V to 72V to 3.3V 3A flyback converter

the LTC3805 can accommodate any

output voltage down to 0.8V simply by

adjustment of the resistor values.

Selecting Frequency

The 200kHz operating frequency is

programmed by the 118k

Ω resistor

on the FS pin. By changing this resistor, the operating frequency can

Linear Technology Magazine • March 2007

DESIGN FEATURES L

I

OUT

(A)

0

0

EFFICIENCY (%)

20

30

40

50

60

70

1

2

80

90

100

10

3 4

36V

48V

60V

72V

V

IN

be set anywhere between 70kHz and

700kHz. High power designs tend to

use lower frequencies while low power

designs tend to use higher frequencies. The frequency programmability

of the LTC3805 allows selection of

the optimum frequency for any given

design.

Programming the VIN Thresholds

The rising threshold on VIN, which is

independent of the thresholds on VCC,

is set by the 221kΩ and 8.86kΩ resistors connected to the RUN pin. The

rising threshold on the RUN pin is 1.2V

while its absolute maximum voltage is

18V—a 15:1 ratio. Therefore the RUN

pin accommodates designs with a wide

range of input voltages and still has a

high enough voltage rating to survive

a transient overvoltage on VIN. Once

started, the LTC3805 sources a 5µA

current from the RUN pin. Multiplied

by the 221kΩ resistor, this current

sets the hysteresis on VIN to 1.1V. A

different hysteresis, with the same

rising threshold, can be selected by

changing the values of the 221kΩ and

8.86k

ratio constant.

Setting the Soft-Start

The rate of change of V

is programmed by the capacitor on the

SSFLT pin—0.1µF in this case. A major

consideration in the selection of the

SSFLT capacitor is the filter capacitor used to bypass V

larger output filter capacitor requires

a slower soft-start to limit the inrush

current caused by the charging filter

capacitor. Conversely, if the converter

has a small output filter capacitor, the

SSFLT capacitor can be omitted and

the LTC3805 internal soft-start ramps

up the output voltage in 1.8ms.

Programming Slope Compensation

and Overcurrent Operation

The 68m

rent through the main NMOS switch

and implements both current mode

control and overcurrent protection via

the I

The I

through the main switch and turns it

off when the current exceeds a level

Linear Technology Magazine • March 2007

Ω resistors while keeping their

at start-up

OUT

. Generally, a

OUT

Ω resistor monitors the cur-

and OC pins, respectively.

SENSE

pin monitors the current

SENSE

set by the voltage on the ITH pin. The

3.01kΩ resistor sets the amount of

slope compensation using a ramp

of current that is sourced by the

LTC3805.

The overcurrent protection level is

set by the 1.33kΩ resistor in series

with the OC pin using a constant 10µA

current sourced by the OC pin. Several

behaviors can be programmed using

this resistor. This particular design

is set to regulate output voltage up

present before the LTC3805 begins

operation or it can be applied after

the LTC3805 has begun operation

using the frequency programmed by

the resistor on the FS pin. When the

synchronization signal is applied,

the LTC3805 locks on to the signal

within two cycles of operation. When

the synchronization signal is removed,

the LTC3805 takes no more than two

cycles to jump back to the frequency

programmed by the FS pin.

to 3A and then overcurrent trip just

above that. An alternate strategy,

using a smaller resistor, would be to

allow the output voltage to sag as the

converter goes into current limiting

and then trip on overcurrent only

to prevent damage. In either case,

once there is an overcurrent trip the

LTC3805 shuts down, waits for a time

out interval determined by discharging the capacitor on the SSFLT pin

and then restarts if the overcurrent

fault has been removed. If the fault

is not removed, the LTC3805 enters

a hiccup mode in which it periodically

tries to restart with the period determined by the capacitor on the SSFLT

pin. Thusly, the LTC3805 completely

protects a flyback converter from short

circuits on the output.

Frequency Synchronization

to an External Source

Although shown grounded in Figure 1,

the SYNC pin is used to synchronize

the frequency of operation of the

LTC3805 to an external source. The

synchronization signal can be applied

and removed without any particular

sequencing requirement—it can be

Isolated Converter Design

The basic design shown in Figure 1

can be modified to provide DC isola-

tion between the input and output by

the addition of a reference, such as

the LT4430, on the secondary side of

the transformer and an optoisolator

to provide feedback from the isolated

secondary to the LTC3805. Figure

shows a photo of the DC1045 demon-

stration circuit, which is an isolated

converter with the same basic design

and performance as the converter

in Figure 1, and is representative of

the size of both the isolated and non-

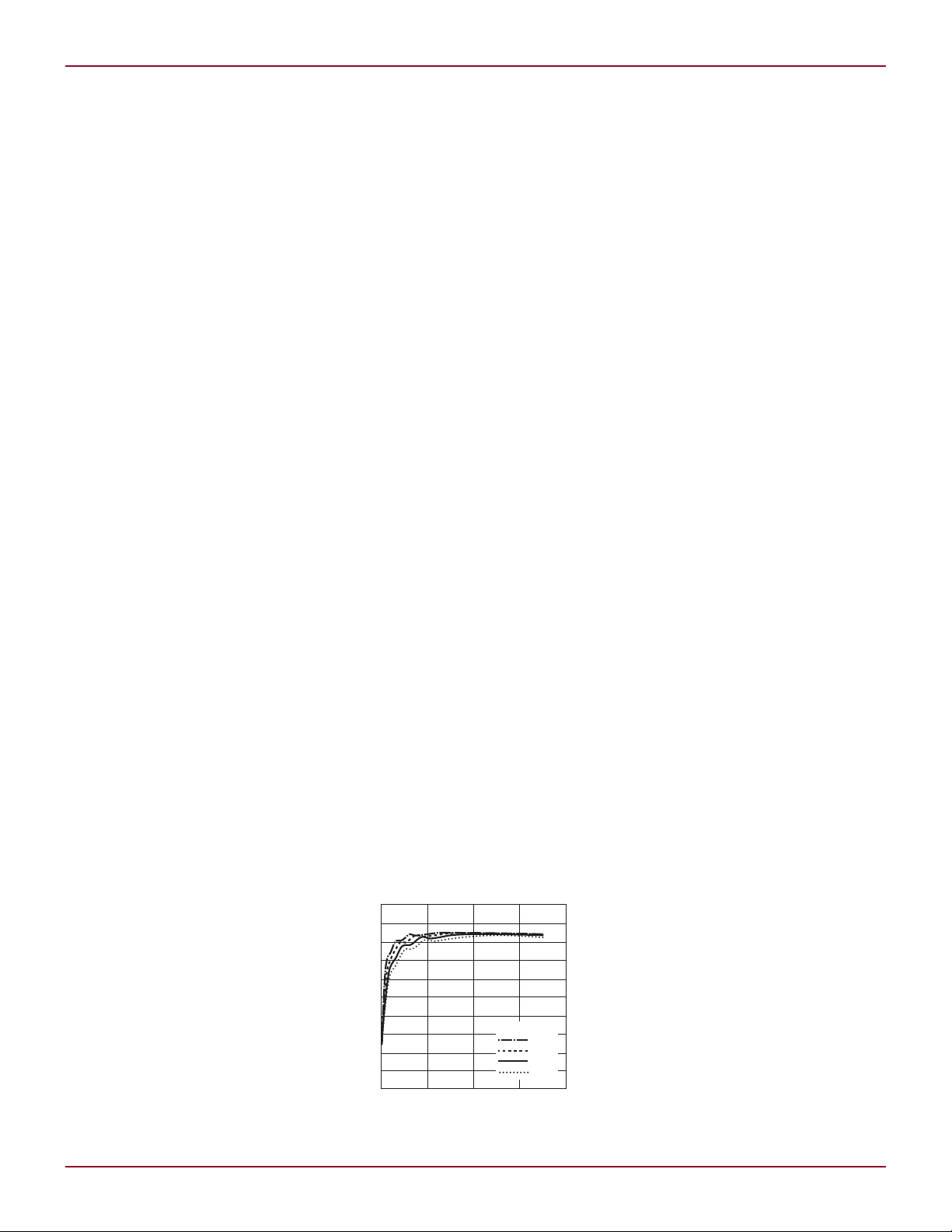

isolated designs. Figure 3 shows the

efficiency of the isolated converter

and is also representative of the non-

isolated converter.

Modifications for Different

Input or Output Voltages

The two applications described above

represent typical non-isolated and

isolated 10W flyback converters. It is

fairly easy to take this basic design

and change the input or output voltage

by scaling the external components in

direct proportion to the change in volt-

age. These changes are transparent to

the LTC3805 and can be accomplished

with a circuit no more complex than

that of Figure 1 and a board no bigger

than that shown in Figure 2.

increase of the input current, mainly

involves selecting a NMOS power

switch with a lower voltage and higher

current rating and selecting a trans-

former primary winding with a reduced

number of turns and a proportionally

larger wire size. For the input filter

Figure 3. Efficiency for isolated and nonisolated 36V–72V to 3.3V 3A flyback converter

capacitor, the voltage rating can be

2

A decrease of the input voltage, and

continued on page 17

9

100ns/DIV

2V/DIV

B

A

DI

RO

Figure 8. The LTC2854 driver delivering a

single 50ns pulse through 100ft of Cat 5 cable,

which is received by another LTC2854. Both

parts have their on-chip termination enabled.

Top trace is the input to the transmitting

device and the middle and bottom traces are

observed at the receiving part.

to +15V, with typical peak current

not exceeding 180mA. Additionally,

thermal shutdown protection disables

the driver, receiver, and terminator if

excessive power dissipation causes

the device to heat to temperatures

above 160°C. When the temperature

drops below 140°C, normal operation

resumes.

Extreme ESD Protection

The driver output pins and receiver

input pins on the LTC2854 are pro

tected to ESD levels of ±25kV HBM

with respect to ground or VCC. The fullduplex LTC2855 withstands ±15kV

ESD. These protection levels exist for

all modes of device operation including

power-down, standby, receive, transmit, termination and all combinations

of these. Furthermore, the protection

level is valid whether VCC is on, shorted

to ground, or disconnected.

When a line I/O pin on the

LTC2854/LTC2855 is hit with an

-

DESIGN FEATURES L

Figure 9. The LTC2854 sending data (see scope traces in background)

while hit with multiple 30kV ESD strikes on the ‘A’ pin.

ESD strike during operation, the part

undergoes a short disturbance of duration similar to the ESD event and

then fully recovers. The device does

not latch up and there is no need to

toggle states or cycle the supply to

recover. This is true whether the part

is in a static state or sending/receiving

data and for the full range of ground

common mode voltages called out in

the RS485 standard. The photo in Fig

ure 9 shows the LTC2854 absorbing

the energy from an ESD gun (configured for IEC air discharge) delivering

repeated 30kV strikes to the ‘A’ pin

while transmitting data. The oscilloscope traces in the background show

data toggling happily on the A and B

pins before and after a strike, with a

positive glitch only during the ESD

-

event. This device can handle many

such strikes without damage.

Conclusion

The LTC2854 and LTC2855 break

new ground in the world of 3.3V

RS485/RS422 transceivers. The in

clusion of a selectable termination

resistor provides a complete solution

to RS485 networking with the ability

to remotely configure the network

for optimal data transfer. Unparal-

leled ESD performance provides

outstanding ruggedness while a bal-

anced-threshold receiver with full

failsafe capability makes this family

of small-footprint devices a natural

choice for modern RS485/RS422

systems.

L

-

LTC3805, continued from page 9

reduced and the capacitance increased

in proportion. Also, the resistor divider

connected to the RUN pin must be

adjusted for the new input voltage.

Finally, the 68m

Ω current sense resistor should be reduced in value to

account for the higher input current.

For an increase in input voltage, everything is changed proportionally in

the opposite direction.

Similarly, a change in the output

voltage involves a change in the diode,

Linear Technology Magazine • March 2007

the number of turns in the secondary

winding of the transformer and the

voltage rating and value of the output

filter capacitor along with the appropriate change to the voltage divider

that senses the output voltage. If the

output voltage is between 4V and 9V,

the design of non-isolated converters

is very simple because VCC can be provided by a diode connected directly to

the output instead of the third winding

on the transformer.

Conclusion

Because of its flexibility, the flyback

converter is the most widely used

transformer-based converter. The

LTC3805 maximizes the flexibility of

the flyback converter by making it possible to use the same basic circuit for a

wide range of converter input and output voltages. Simply scale component

values to match voltage and current

conditions, greatly simplifying board

design and updates.

L

17

Loading...

Loading...