L DESIGN FEATURES

C

B

0.1µF

C

F

220pF

L1

0.36µH

C

OUT

470µF

2.5V

×2

C

IN1

330µF

35V

V

IN

5V TO 26V

V

OUT

1.2V

15A

C

VCC

4.7µF

C2

330pF

C1

3.9nF

R

ILIMB

57.6k

R

SET

38.3k

R2

4.7k

R

B

10k

C

OUT

: SANYO 2R5TPD470M5

D

B

: CMDSH4E

L1: IHLP-4040DZ-ER-R36-M11

Q

B

: RJK0301DPB-00-J0

Q

T

: RJK0305DPB-00-J0

R

A

10k

R

SENSE

0.003Ω

R

ILIMT

732Ω

D

B

C

SS

0.01µF

TG Q

T

Q

B

V

IN

LTC3775

SGND

SENSE

I

LIMT

I

LIMB

INTV

CC

SS

BG

PGND

MODE/SYNC

RUN/SHDNCOMP

BOOST

SW

FREQ

FB

+

+

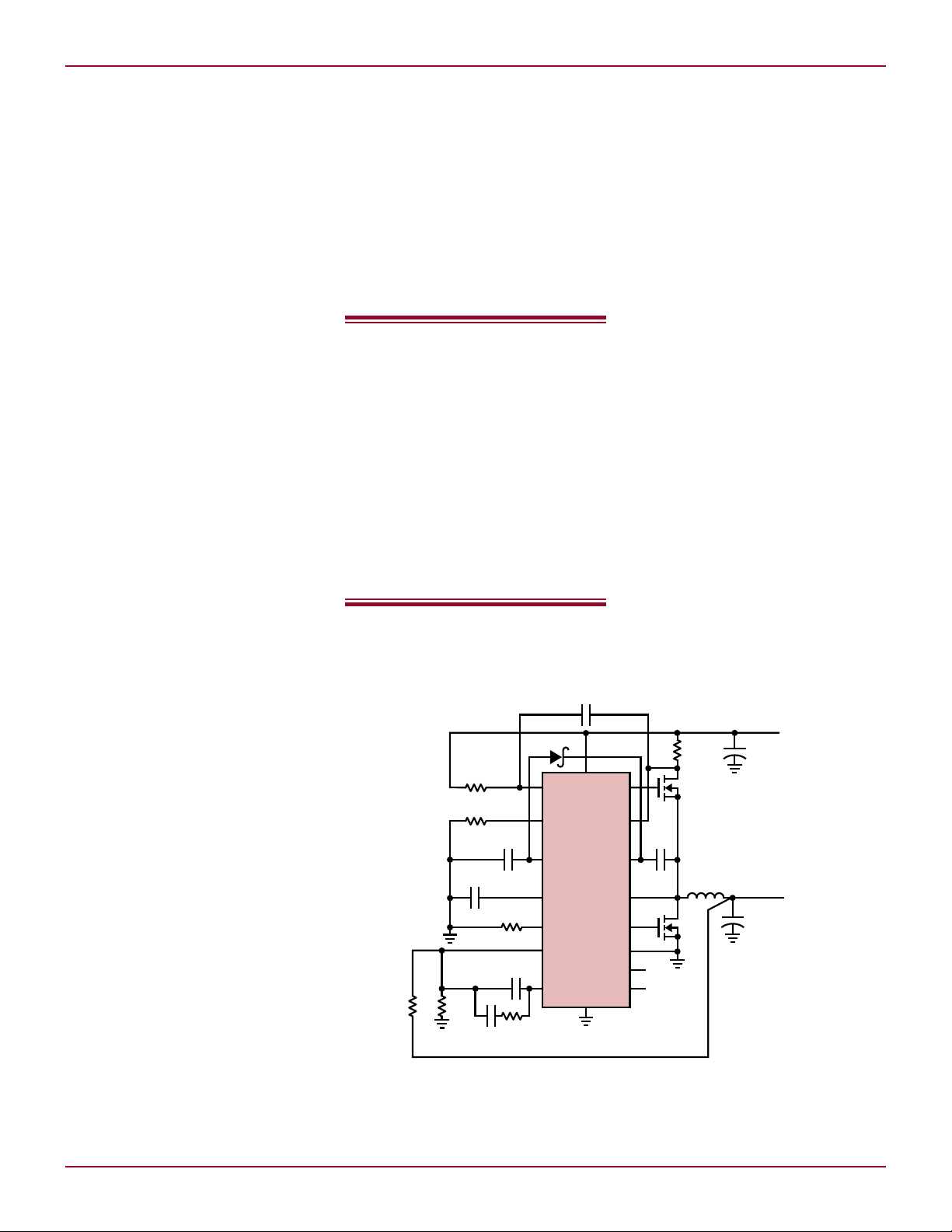

Produce High DC/DC Step-Down

Ratios in Tight Spaces with 30ns

Minimum On-Time Controller in

3mm × 3mm QFN

Introduction

It can be a challenge to design a DC/

DC converter that takes a high voltage

automotive or industrial power supply

down to the 1.5V or lower voltages

required by today’s microprocessors

and programmable logic chips.

To maintain efficiency and performance, designers are often forced to

create a 2-stage solution, which first

steps down to an intermediate voltage

and uses another converter to produce

the low voltage from there. 2-stage

solutions can perform well, and are

handy if the application can use the

intermediate voltage elsewhere, but

2-stage solutions always take more

space and are more costly than a single

stage solution.

Many regulators can produce high

step-down ratios in a single stage if the

switching frequency of the step-down

converter is slowed considerably. However, this option sacrifices efficiency

and requires larger, more expensive

external components, doing little to

solve the space and cost problems

incurred in 2-stage solutions.

The LTC3775 is a voltage mode

DC/DC regulator with a very low

minimum on-time of 30ns, allowing

very wide step-down ratios at high

switching frequencies without sacrificing performance. Unlike most voltage

mode controllers, the LTC3775 offers

cycle-by-cycle programmable current

limit, excellent short circuit protection

and fast transient response over a wide

input voltage range.

A 1.2V Converter Operating

from 5V–28VIN at 350kHz

The LTC3775 is ideal for generating

low output voltages from high input

voltages, a common requirement for

powering CPUs from wide-ranging

20

by Theo Phillips

application providing a continuous

Current mode controllers

are often favored for their

continuous monitoring of

current through the inductor

or switches. While a typical

voltage mode controller

requires additional circuitry

to monitor current in the

power stage, the LTC3775

requires no ancillary

circuits to oversee the entire

switching cycle.

rails such as those found in automotive applications. Figure 1 shows an

Figure 1. A 1.2V, 15A converter

15A from an 5V–26V input.

Current mode controllers are often

favored for their continuous monitoring of current through the inductor or

switches, protecting these components

and the load against short circuits and

pre-biased outputs during start-up.

To avoid these difficulties, a typical

voltage mode controller requires additional circuitry to monitor current in

the power stage. The LTC3775 requires

no ancillary circuits to oversee the

entire switching cycle.

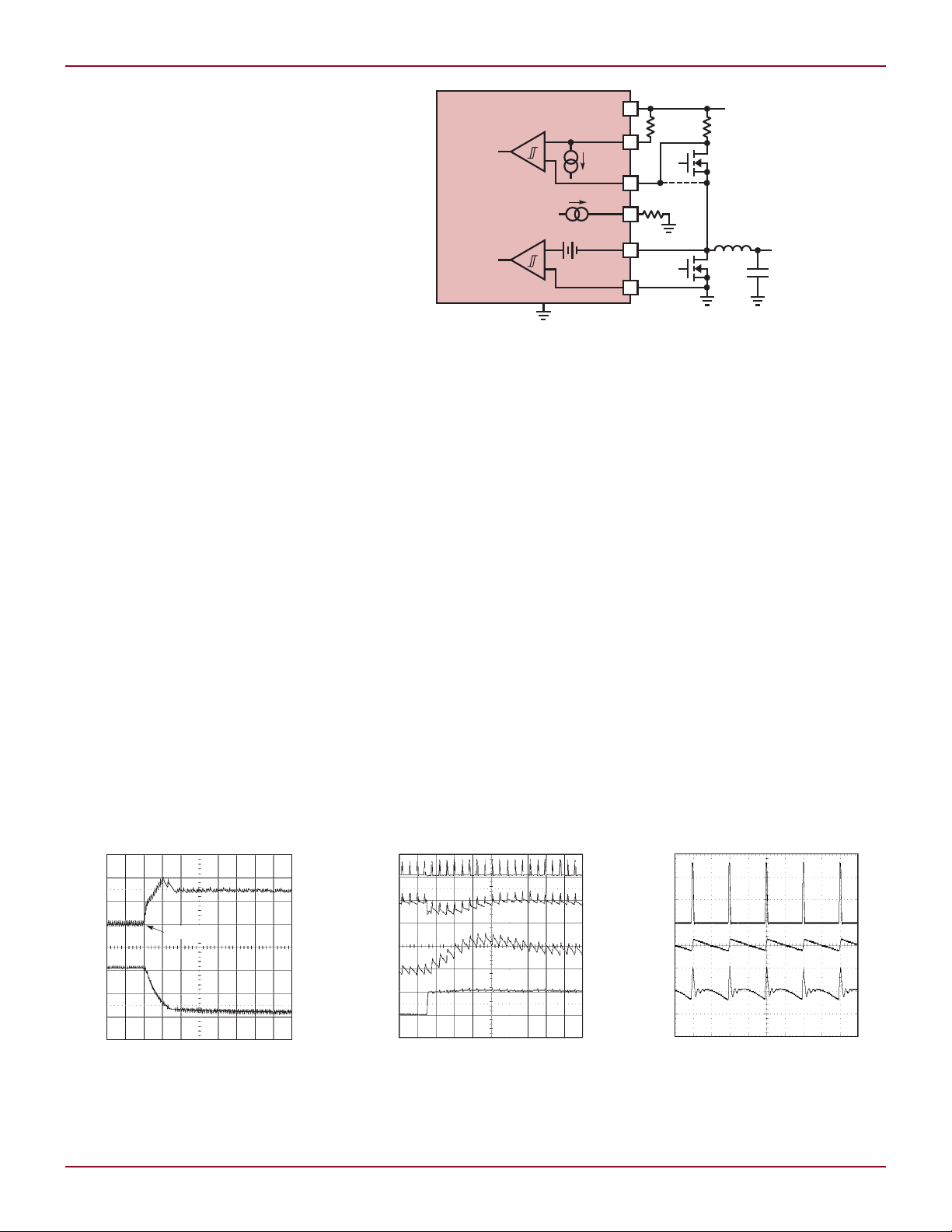

The current limit is programmed

with two resistors (as shown in the

block diagram of Figure 2), corre

sponding to the current measured

through the top and bottom switches

Linear Technology Magazine • December 2009

during their respective on times. This

V

OUT(AC)

RIPPLE

20mV/DIV

V

SW

10V/DIV

I

L

10A/DIV

1µs/DIVVIN = 26V

V

OUT

= 1.2V

NO LOAD

R

SET

= 38.3k

V

OUT(AC)

100mV/DIV

V

SW

20V/DIV

I

L

10A/DIV

I

LOAD

10A/DIV

5µs/DIVV

IN

= 12V

V

OUT

= 1.2V

LOAD STEP = 0A TO 10A

MODE/SYNC = 0V

SW FREQ = 500kHz

I

L

20A/DIV

V

SS

1V/DIV

20µs/DIVV

IN

= 12V

V

OUT

= 1.2V

C

SS

= 0.01µF

0A LOAD

+

+

–

100µA

R

ILIMB

(OPT)

10µA

t7

ILIMB

R

ILIMT

7

IN

LTC3775

R

SENSE

SENSE

CTLIM

TURN OFF TG

+

–

CBLIM

EXTEND BG

I

LIMB

SW

I

LIMT

TG Q

T

7

IN

BG Q

B

7

OUT

PGND

SGND

arrangement allows cycle-by-cycle

current limit, regardless of the duty

cycle, and ensures that the inductor

is not saturated.

In a current mode converter, the

voltage on the output of the error

amplifier controls the peak switch

current, such that the switch current

must always be monitored, allowing

the introduction of noise. This may be

most pronounced around 50% duty

cycle in some current mode designs.

Contrast this with a voltage mode

converter, where the error voltage

on V

is compared to a saw-tooth

OUT

ramp, which in turn controls duty

cycle; the larger the error voltage, the

longer the top switch stays on. The

LTC3775 senses current through both

MOSFETs to assure that they do not

exceed programmed limits. During

normal operation, these limits do not

come into play, and noise-free operation is assured.

A high side current limit would be of

little value if the circuit was operated

at its maximum VIN, since the bottom

switch would be on most of the time,

and nothing would protect the synchronous MOSFET. Fortunately, the

low side current limit, programmed by

I

, can limit the current through

LIMB

the bottom switch. Conversely, a fault

at low VIN during the on-time of the

top switch requires a high side current limit for immediate response. The

LTC3775 uses both top- and bottomside current limit circuits to provide

DESIGN FEATURES L

Figure 2. The LTC3775 features high and low side programmable current limits, for cycle-by-cycle

short circuit protection.

optimum protection for the MOSFETs

and inductor.

This current limit approach is effective, as shown by the short circuit

behavior in Figure 3. A hard short

could spell disaster for an unprotected

voltage mode converter. But here, the

inductor does not saturate, and the

input rail maintains its integrity while

the output gracefully drops.

Output voltage is monitored using

an inverting summing amplifier topology, with the FB pin configured as a

virtual ground. The reference voltage

is accurate to within ±0.75% over

temperature. The LTC3775 uses a true

operational error amplifier with 80dB

of open loop gain, and a 25MHz gainbandwidth product. Feedback gain

can be tightly controlled by external

components, allowing the use of “Type

3” compensation, which provides a

phase boost at the LC double pole

frequency and significantly improves

control loop phase margin. Figure 4

shows a characteristically fast load

transient response.

The modulator consists of the

PWM generator, the output MOSFET

drivers and the external MOSFETs

themselves. The modulator gain varies linearly with the input voltage. The

line feedforward circuit compensates

for this change in gain, and provides a

constant gain from the error amplifier

output to the inductor input regardless

of input voltage.

The application in Figure 1 de

mands a minimum on time of just

86ns at the maximum input voltage

of 28V. Many controllers turn the top

gate on at the beginning of the clock

cycle and must wait for the response

time of the PWM comparator before

turning off the top gate. This response

time is typically around 100ns or more.

In addition, those controllers would

make the decision at a noisy interval,

Figure 3. Short circuit behavior for the

converter of Figure 1

Linear Technology Magazine • December 2009

Figure 4. Load transient response for the

converter of Figure 1

Figure 5. The converter of Figure 1

demonstrates a clean switching waveform

with a razor-thin on-time.

21

Loading...

Loading...