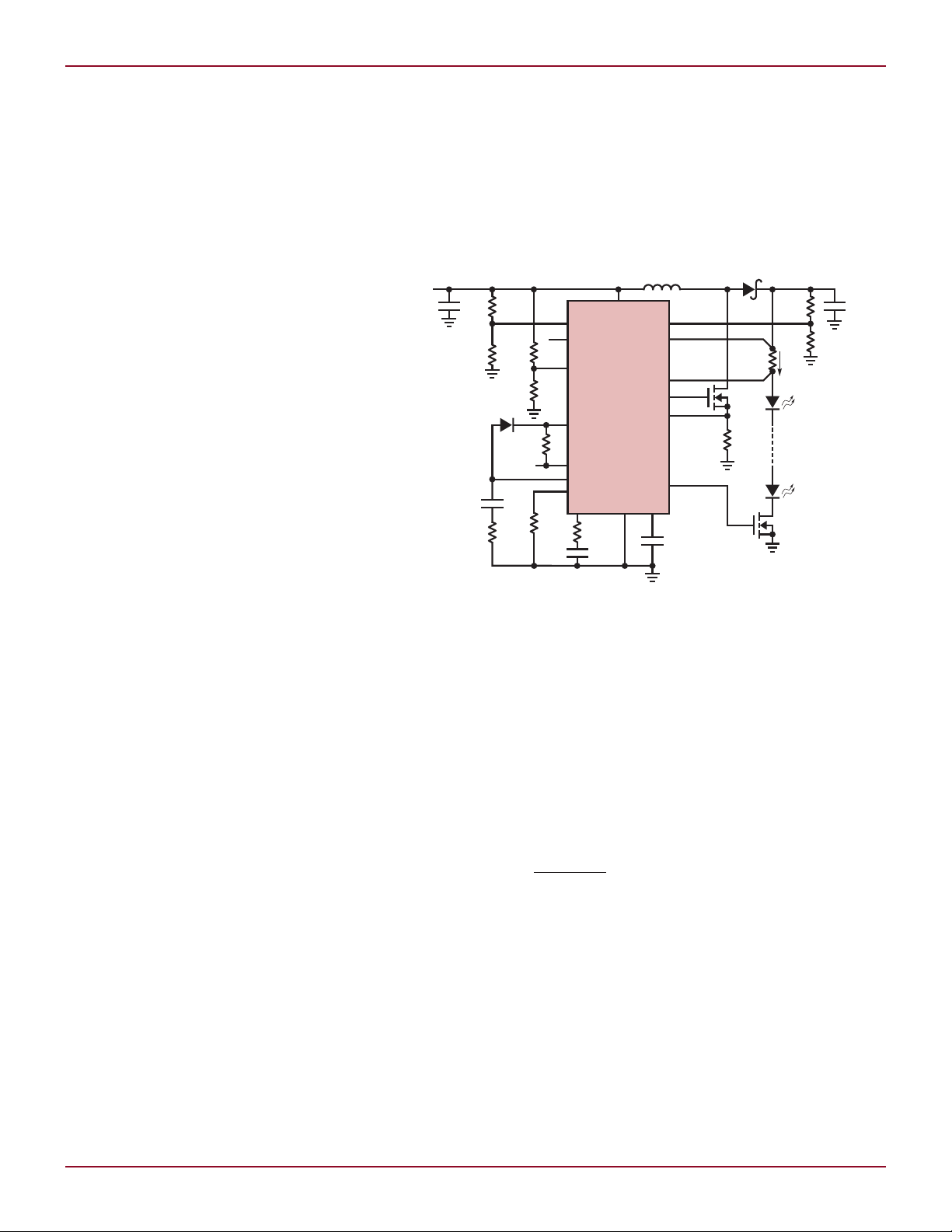

DESIGN IDEAS L

V

IN

LT3756

L1A, B

22µH 2×

OVP = 95V

GNDV

C

INTV

CC

INTV

CC

SHDN/UVLO FB

V

REF

ISP

1M

499k

2.2µF

100V

×2

2.2µF

100V

×5

4700pF

0.1µF

10k

23.2k

10k

42.2k

250kHz

1%

4.7µF

30.9k

100k

CTRL

0.018Ω

Si7322DN

0.068Ω

1.8M

24.3k

I

LED

1.5A

83V

LED

STRING

OPENLED

PWM

SS

R

T

ISN

GATE

SENSE

PWMOUT

PDS5100

Q1A, B

L1 = 2× SERIES SLF12575T-220M4R0

Q1 = 2× PARALLEL Si7322DN

VIN= PV

IN

40V TO 60V

(LED CURRENT

REDUCED WHEN

VIN< 40V)

100V Controller in 3mm × 3mm QFN

or MSE Drives High Power LED Strings

from Just About Any Input

Introduction

Strings of high power solid-state

LEDs are replacing traditional lighting

technologies in large area and high

lumens light sources because of their

high quality light output, unmatched

durability, relatively low lifetime cost,

constant-color dimming and energy efficiency. The list of applications grows

daily, including LCD television backlights and projection system bulbs,

industrial and architectural lighting

systems, automotive headlamps, taillights and indicator lights, computer

monitors, street lights, billboards and

even stadium lights.

As the number of applications expands, so does the complexity of input

requirements for the LED drivers.

LED drivers must be able to handle

wide ranging inputs, including the

harsh transient voltage environment

presented by automotive batteries,

the wide voltage range of the Li-ion

cells and wallwart voltages. For LED

lighting manufacturers and designers, applying a different LED driver

for each application means stocking,

testing and designing with a wide

variety of LED controllers. This can

be an expensive and time-consuming

proposition. It would be far better to

use a controller that can be applied

to many solutions.

The LT3756 high voltage LED driver

features a unique topological versatility that allows it to be used in boost,

buck-boost mode, buck mode, SEPIC,

flyback and other topologies. Its high

power capability provides potentially

hundreds of watts of steady-state LED

power over a very wide input voltage

range. Its 100V floating LED current

sense inputs allow the LED string to

float above ground, as shown in the

buck mode and buck-boost mode topologies in this article. Excellent PWM

dimming architecture produces high

dimming ratios, up to 3000:1.

Linear Technology Magazine • January 2009

Figure 1. A 125W, 83V at 1.5A, 97% efficient boost LED driver for stadium lighting

A number of features protect the

LEDs and surrounding components.

Shutdown and undervoltage lockout,

when combined with analog dimming

derived from the input, provide the

standard ON/OFF feature as well as

a reduced LED current should the

battery voltage drop to unacceptably

low levels. Analog dimming is accurate and can be combined with PWM

dimming for an extremely wide range

of brightness control. The soft-start

feature prevents spiking inrush currents during start-up. The OPENLED

pin informs of open or missing LEDs

and the SYNC (LT3756-1) pin can be

used to sync switching to an external

clock.

The 16-pin IC is available in a

tiny QFN (3mm × 3mm) and an MSE

package, both thermally enhanced.

For applications with lower input voltage requirements, the 40VIN, 75V

LT3755 LED controller is a similar

option to the LT3756.

Although it is typically used as an

OUT

LED driver, the LT3756’s voltage FB

pin provides a well-regulated output

by Keith Szolusha

voltage if the constant current sense

voltage is not used. This is a side benefit

of the LT3756’s overvoltage protection

feature, in which the current control

loop is superceded by the FB voltage

loop in the case of an open LED string,

thus preventing the controller from a

running up the voltage in an effort to

maintain current.

125W Boost LED Driver for

Stadium Lights or Billboards

Lighting systems for stadiums, spotlights and billboards require huge

strings of LEDs running at high power.

The LT3756 controller can drive up

to 100V LED strings with its floating

sense resistor inputs ISP and ISN.

The 125W LED driver in Figure 1

accepts a wide-range 40V–60V input

taken from the output of a high power

transformer.

The LT3756’s high power GATE

driver switches two 100V MOSFETs

at 250kHz. This switching frequency

minimizes the size of the discrete components while maintaining high 97%

efficiency, thus producing a less-than-

3737

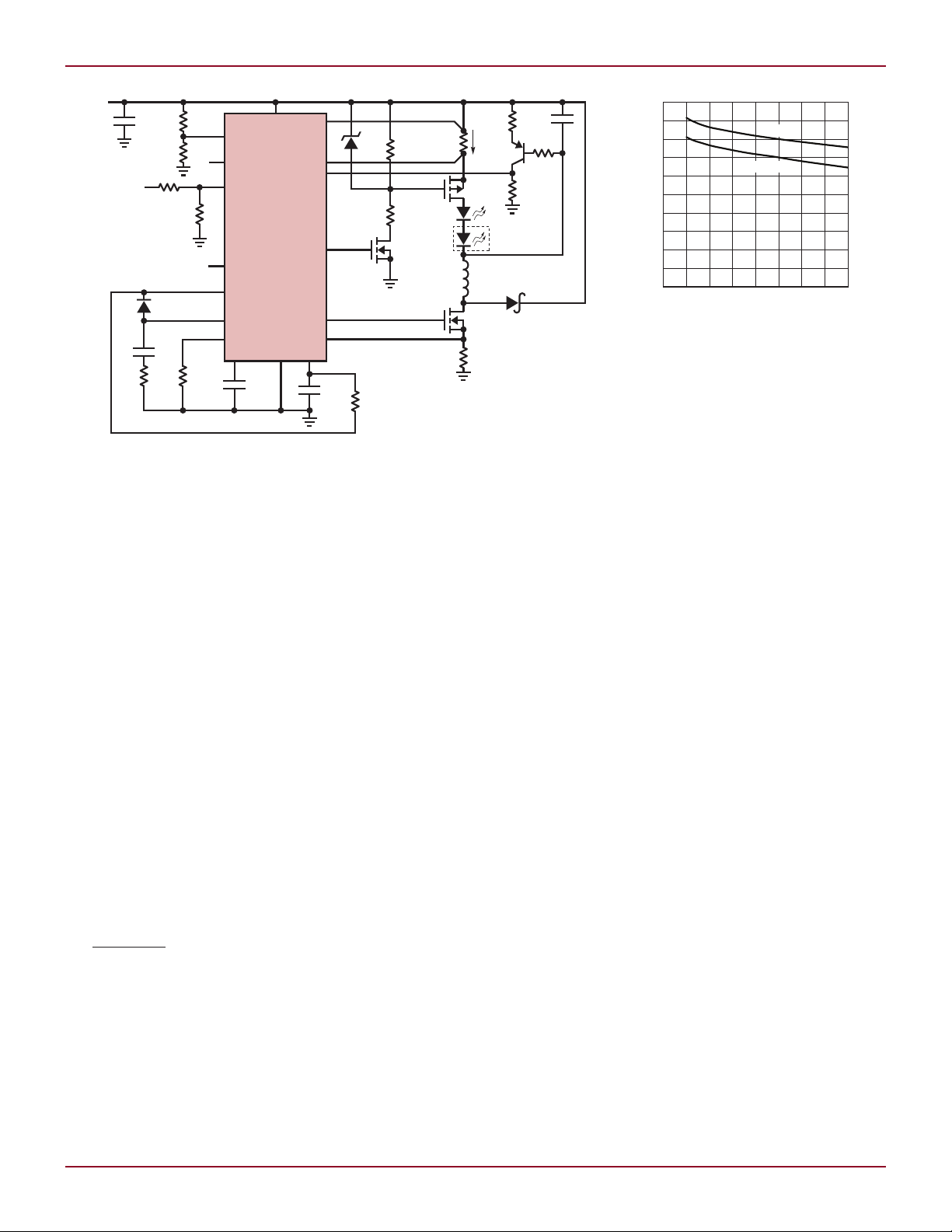

V

IN

LT3756

GNDV

C

INTV

CC

SHDN/UVLO

FB

V

REF

ISP

0.01µF

0.1µF

V

IN

10V TO

80V

PWM

69.8k

150kHz

100k

4.7µF

CTRL

0.05Ω

0.1Ω

M1

10µF

16V

6.2V

L1

33µH

D1

I

LED

1A

OPENLED

PWM

SS

R

T

ISN

GATE

PWMOUT

SENSE

196k

30.9k

D1: DIODES INC B2100

L1: SUMIDA CDRH8D38-330

M1: VISHAY SILICONIX Si4484EY

M2: VISHAY SILICONIX Si2307BDS

M3: VISHAY SILICONIX Si2328DS

Q1: MMBT5401

4.7k

12.4k

1 OR 2 LEDs

3.5V–7V

0A–1A

147k

1k

OPTIONAL

0V–12V FOR

0A–1A I

LED

Q1

51k

120k

M3

1N4448HWT

M2

10k

2.2µF

100V

×2

9.1k

EFFICIENCY (%)

VIN (V)

V

LED

= 7V

V

LED

= 3.5V

800

100

0

10 20 30 40 50 60 70

10

20

30

40

50

60

70

80

90

L DESIGN IDEAS

Figure 2. An 80VIN buck mode LED driver with PWM dimming for single or double LEDs

50°C discrete component temperature

rise—far more manageable than the

potential heat produced by the 83V

string of 1.5A LEDs.

Even if PWM dimming is not

required, the PWMOUT dimming

MOSFET is useful for LED disconnect

during shutdown. This prevents current from running through the string

of ground-connected LEDs—possible

under certain input conditions.

If an LED fails open or if the LED

string is removed from the high power

driver, the FB constant voltage loop

takes over and regulates the output at

95V until a proper string is attached

between LED+ and LED–. Without

overvoltage protection, the LED sense

resistor would see zero LED current

and the control loop would work hard

to increase its output. Eventually, the

output capacitor voltage would go over

100V, exceeding the maximum rating

of several components. While in OVP

the OPENLED status flag goes low.

High Voltage Buck Mode

LED Driver with High

PWM Dimming Ratio

When the input voltage is higher than

the LED string voltage, the LT3756

can serve equally well as a constant

current buck mode converter. For example, an automotive battery’s voltage

can present a wildly moving target,

38

38

from drooping voltages to dizzyingly

high voltage spikes, The buck mode

LED driver in Figure 2 is perfect for

such harsh environments. It operates

with a wide 10V-to-80V input range

to drive one or two 3.5V LEDs (7V) at

1A. In this case, both the V

IN

ISP and ISN current sense inputs can

go as high as 80V.

PWM dimming requires a level-shift

from the PWMOUT pin to the high

side LED string as shown in Figure 2. The maximum PWM dimming

ratio increases with higher switching frequency, lower PWM dimming

frequency, higher input voltage and

lower LED power. In this case, a 100:1

dimming ratio is possible with a 100Hz

dimming frequency, a 48V input, a

3.5V or 7V LED at 1A, and a 150kHz

switching frequency. Although higher

switching frequency is possible with

the LT3756, the duty cycle eventually

has its limits. Generous minimum

on-time and minimum off-time restrictions require a frequency on the lower

end of its range (150kHz) to meet both

the harsh high-VIN-to-low-V

to one 3.5V LED) and low-VIN-dropout

requirements (10V

particular converter.

The overvoltage protection of the

to 7V

IN

LED

LED

buck mode LED driver has a level

shift as well. Q1, a pnp transistor,

helps regulate the maximum allowable

pin and

(80VIN

) of this

Figure 3. Efficiency for the

buck mode converter in Figure 2

output capacitor voltage to a level just

beyond that of the LED string. Without

the level-shifted OVP network tied to

FB, an open LED string would result

in the output capacitor charging up to

the input voltage. Although the buck

mode components will survive this

scenario, the LEDs may not survive

being plugged back into a potential

equal to the input voltage. That is,

a single 3.5V LED might not survive

being connected directly to 80V.

Single Inductor Buck-Boost

Mode LED Driver

One increasingly common LED driver

requirement is that the ranges of both

the LED string voltage and the input

voltage are wide and overlapping. In

fact, some designers prefer to use the

same LED driver circuit for several

different battery sources and several

different LED string types. Such a

versatile configuration trades some

efficiency, component cost, and board

space for design simplicity, but the

tradeoffs are usually mitigated by the

significantly reduced time-to-market

by producing an essentially off-theshelf multipurpose LED driver.

The buck-boost mode topology

shown in Figure 4 uses a single

inductor and can both step-up and

step-down the input voltage to the LED

string voltage. It accepts inputs from

6V to 36V to drive 10V–50V LED strings

at up to 400mA. The PWM dimming

and OVP are level-shifted in a manner

similar to the buck mode for optimal

performance of these features.

The inductor current is the sum of

the input current and the LED string

Linear Technology Magazine • January 2009

V

IN

LT3756

GND

SHDN/UVLO

INTV

CC

499k

110k

2.49k

130k

1M

140k

0.25Ω

10V–50V

2.2µF

50V

s2

V

IN

9V TO 36V

(6V UVLO)

L1

22µH

M1: VISHAY SILICONIX Si7454DP

D1: DIODES INC. PDS3100

L1: SUMIDA CDRH127-220

4.7k

LED

–

LED

+

0.1µF

4.7µF

CTRL

V

C

5.1k

10k

100k

4700pF

OPENLED

SS

FB

ISN

ISP

PWMOUT

PWM

V

REF

SENSE

R

T

GATE

C

OUT

2.2µF

100V

s2

M1

D1

28.7k

400kHz

0.025Ω

V

IN

3906

I

LED

400mA

EFFICIENCY (%)

VIN (V)

V

LED

= 10V

V

LED

= 50V

3010

100

0

15 20 25

10

20

30

40

50

60

70

80

90

Figure 4. A buck-boost mode LED driver with wide-ranging V

current; the peak inductor current

is also equal to the peak switching

current—higher than either a buck

mode or boost topology LED driver

with similar specs due to the nature

of the hookup. The 4A peak switch

current and inductor rating reflects

the worst-case 9V input to 50V LED

string at 400mA.

Below 9V input, the CTRL analog

dimming input pin is used to scale back

LT3782A, continued from page 36

other out, thus reducing the total

output ripple by 50%, which in turn

reduces output capacitance requirements. The input current ripple is also

halved, which reduces the required

input capacitance and reduces EMI.

Finally, the power dissipated as heat is

spread out over two phases, reducing

the size of heat sinks or eliminating

them altogether.

24V at 8A from

a 10V–15V Input

Figure 1 shows a high power boost

application that efficiently produces a

24V/8A output from a 10V–15V input.

The LTC4440 high side driver is used

Linear Technology Magazine • January 2009

and V

IN

LED

the LED current to keep the inductor

current under control if the battery

voltage drops too low. The LEDs turn

off below 6V input due to undervoltage

lockout and will not turn back on until

the input rises above 7V, to prevent

flickering. In buck-boost mode, the

output voltage is the sum of the input

voltage and the LED string voltage. The

output capacitor, the catch diode, and

small) strings of high power LEDs.

It can be used in boost, buck-boost

mode, buck mode, SEPIC and flyback

topologies. Its high voltage rating, optimized LED driver architecture, high

performance PWM dimming, host of

protection features and accurate high

side current sensing make the LT3756

a single-IC choice for a variety of high

voltage input and high power lighting

systems.

to level shift the SGATE signals and

drive the synchronous MOSFETs. The

250kHz switching frequency optimizes

efficiency and component size/board

area. Figure 2 shows the layout. Proper

routing and filtering of the sense pins,

placement of the power components

and isolation using ground and supply planes ensure an almost jitter free

operation, even at 50% duty cycle.

Figure 3 shows the efficiency of the

circuit in Figure 1 with synchronous

MOSFETs (measured to 8A) and the

efficiency of an equivalent non-synchronous circuit using boost diodes

(measured to 6A). The 1% improvement

in peak efficiency may not seem significant, but take a look at the difference

in heat dissipation shown in Figure 4,

which shows thermal images of both

circuits under equivalent operating

conditions. The thermal advantages

of using synchronous switches are

clear.

Conclusion

The 2-phase synchronous boost

topology possible with the LT3782A

offers several advantages over a nonsynchronous or a single-phase boost

topology. Its combination of high efficiency, small footprint, heat sink-free

thermal characteristics and low input/output capacitance requirements

make it an easy fit in automotive and

industrial applications.

DESIGN IDEAS L

Figure 5. Efficiency for the buck-boost

mode converter in Figure 4

the power MOSFET can see voltages

as high as 90V for this design.

Conclusion

The 100V LT3756 controller is ostensibly a high power LED driver, but its

architecture is so versatile, it can be

used in any number of high voltage

input applications. Of course, it has

all the features required for large (and

L

L

3939

Loading...

Loading...