LTC3714

Intel Compatible,

Wide Operating Range, Step-Down Controller

FEATURES

■

True Current Mode with Ultrafast Transient

Response

■

Stable with Ceramic C

■

t

ON(MIN)

< 100ns for Operation from High Input

OUT

Ranges

■

Supports Active Voltage Positioning

■

No Sense Resistor Required

■

5-Bit VID Programmable Output Voltage: 0.6V to 1.75V

■

Dual N-Channel MOSFET Synchronous Drive

■

Programmable Output Offsets

■

Power Good Output Voltage Monitor

■

Wide VIN Range: 4V to 36V

■

±1% 0.6V Reference

■

Adjustable Frequency

■

Programmable Soft-Start

■

Output Overvoltage Protection

■

Optional Short-Circuit Shutdown Timer

■

Forced Continuous Control Pin

■

Logic Controlled Micropower Shutdown: IQ ≤ 30µA

■

Available in 0.209" Wide 28-Lead SSOP Package

U

APPLICATIO S

■

Power Supply for Mobile Pentium® Processors and

Transmeta Processors

■

Notebook and Portable Computers

with Internal Op Amp

U

DESCRIPTIO

The LTC®3714 is a synchronous step-down switching

regulator controller for CPU power. An output voltage

between 0.6V and 1.75V is selected by a 5-bit code (Intel

mobile VID specification). The controller uses a constant

on-time, valley current control architecture to deliver very

low duty cycles without requiring a sense resistor. Operating frequency is selected by an external resistor and is

compensated for variations in VIN and V

Discontinuous mode operation provides high efficiency

operation at light loads. A forced continuous control pin

reduces noise and RF interference and can assist secondary winding regulation by disabling discontinuous mode

when the main output is lightly loaded. Internal op amp

allows programmable offsets to the output voltage during

power saving modes.

Fault protection is provided by internal foldback current

limiting, an output overvoltage comparator and optional

short-circuit shutdown timer. Soft-start capability for supply sequencing is accomplished using an external timing

capacitor. The regulator current limit level is user programmable. Wide supply range allows operation from 4V

to 36V at the input.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Pentium is a registered trademark of Intel Corporation.

OUT

.

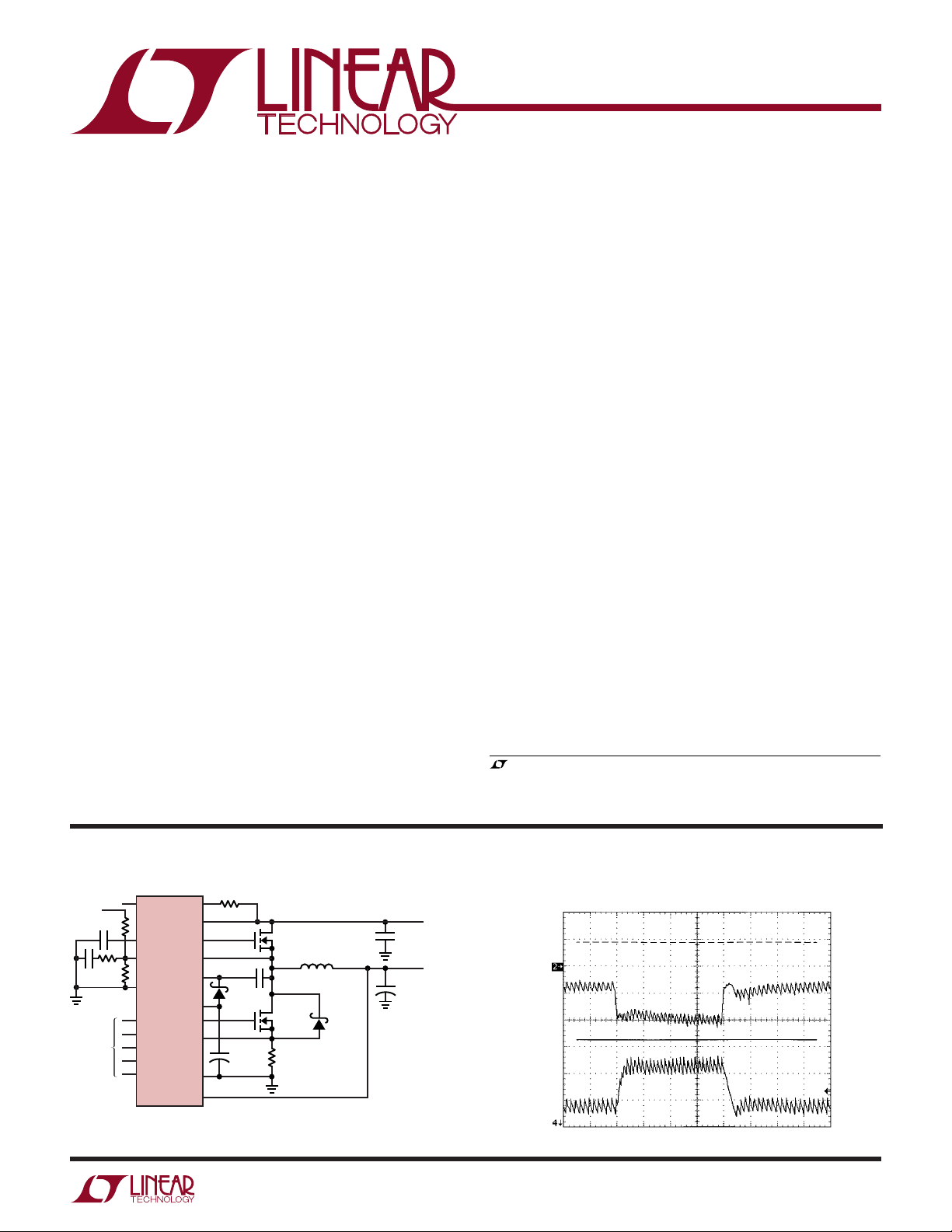

TYPICAL APPLICATIO

INTV

CC

C

SS

0.1µF

C

C

5-BIT

VID

*OPTIONAL

LTC3714

PGOOD

RUN/SS

I

TH

R

C

SGND

VID4

VID3

VID2

VID1

VID0

BOOST

INTV

SENSE

V

OSENSE

Figure 1. High Efficiency Step-Down Converter

PGND

R

ON

I

ON

V

IN

TG

SW

CB, 0.22µF

D

CMDSH-3

CC

BG

+

B

C

VCC

4.7µF

M1

IRF7811

×2

M2

IRF7811

×3

0.003Ω*

L1

0.68µH

U

D1*

UPS840

+

3714 F01

10µF

35V

×4

C

OUT

270µF

2V

×4

V

IN

5V TO 24V

V

OUT

0.6V TO 1.75V

23A

Transient Response of 8A to 23A Output Load Step

1.395V

V

OUT

(1.35V)

50mV/DIV

1.213V

23A

I

LOAD

10A/DIV

8A

20µs/DIV

3714 TA03

3714f

1

LTC3714

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Input Supply Voltage (VIN), ION..................36V to –0.3V

Boosted Topside Driver Supply Voltage

(BOOST) ................................................... 42V to –0.3V

SW, SENSE Voltages ................................... 36V to –5V

EXTVCC, (BOOST – SW), RUN/SS, VID0-VID4,

PGOOD, FCB Voltages ............................... 7V to –0.3V

VON, V

ITH, VFB, V

TG, BG, INTVCC, EXTVCC Peak Currents.................... 2A

TG, BG, INTVCC, EXTVCC RMS Currents .............. 50mA

OPVIN, OP+, OP

Operating Ambient Temperature Range

LTC3714EG (Note 2) .......................... –40°C to 85°C

Junction Temperature (Note 3)............................ 125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

Voltages ................(INTVCC + 0.3V) to –0.3V

RNG

Voltages....................... 2.7V to –0.3V

OSENSE

–

.......................................................

0V to 18V

UU

W

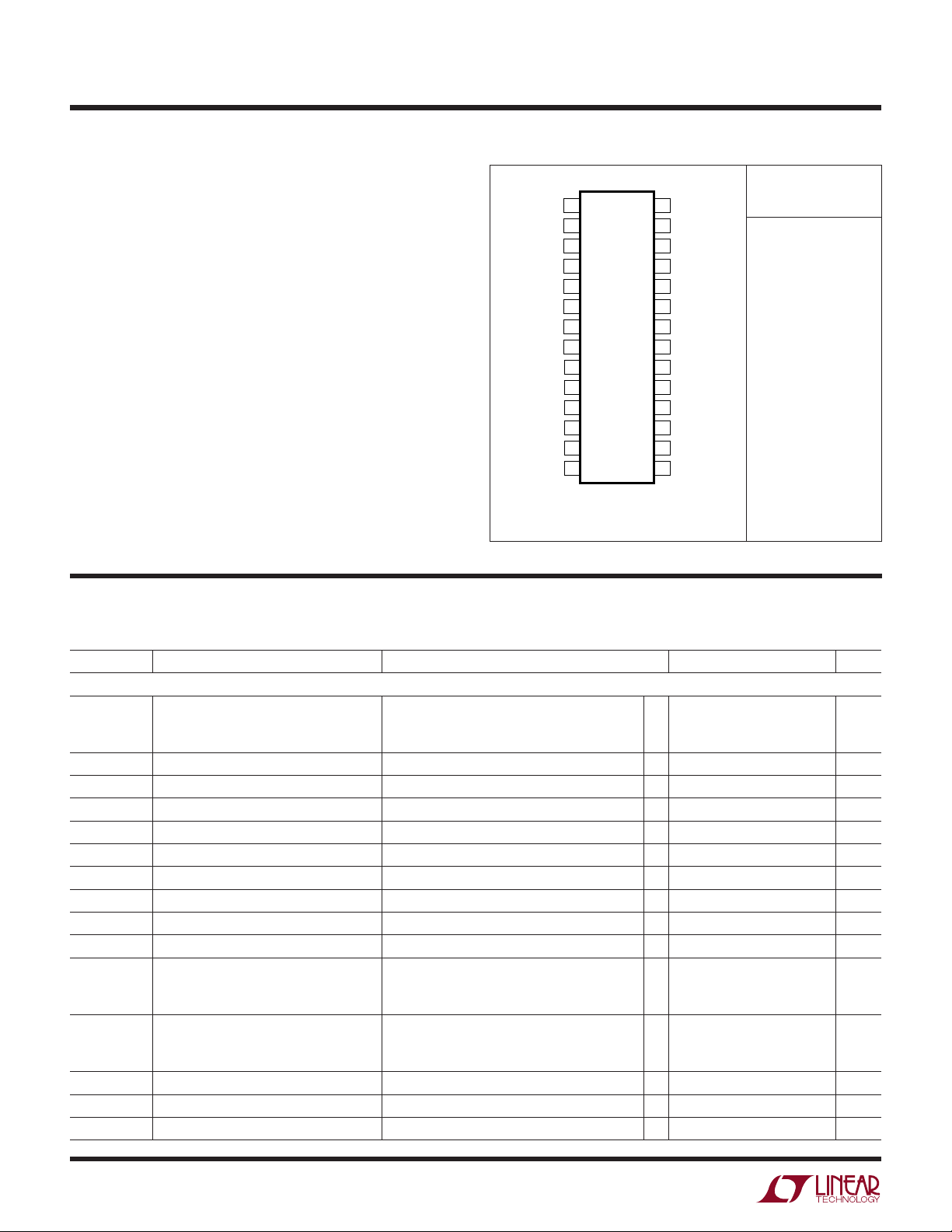

PACKAGE/ORDER I FOR ATIO

TOP VIEW

1

BG

2

PGND

3

SENSE

4

SW

5

TG

6

BOOST

7

VID0

8

VID1

9

VID2

10

RUN/SS

11

V

ON

12

PGOOD

13

V

RNG

14

I

TH

28-LEAD PLASTIC SSOP

T

JMAX

G PACKAGE

= 125°C, θJA = 130°C/W

INTV

28

CC

V

27

IN

EXTV

26

CC

VID4

25

VID3

24

V

23

OSENSE

VFB

22

I

21

ON

FCB

20

SGND

19

OPOUT

18

+

OP

17

–

OP

16

OPV

15

IN

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ORDER PART

NUMBER

LTC3714EG

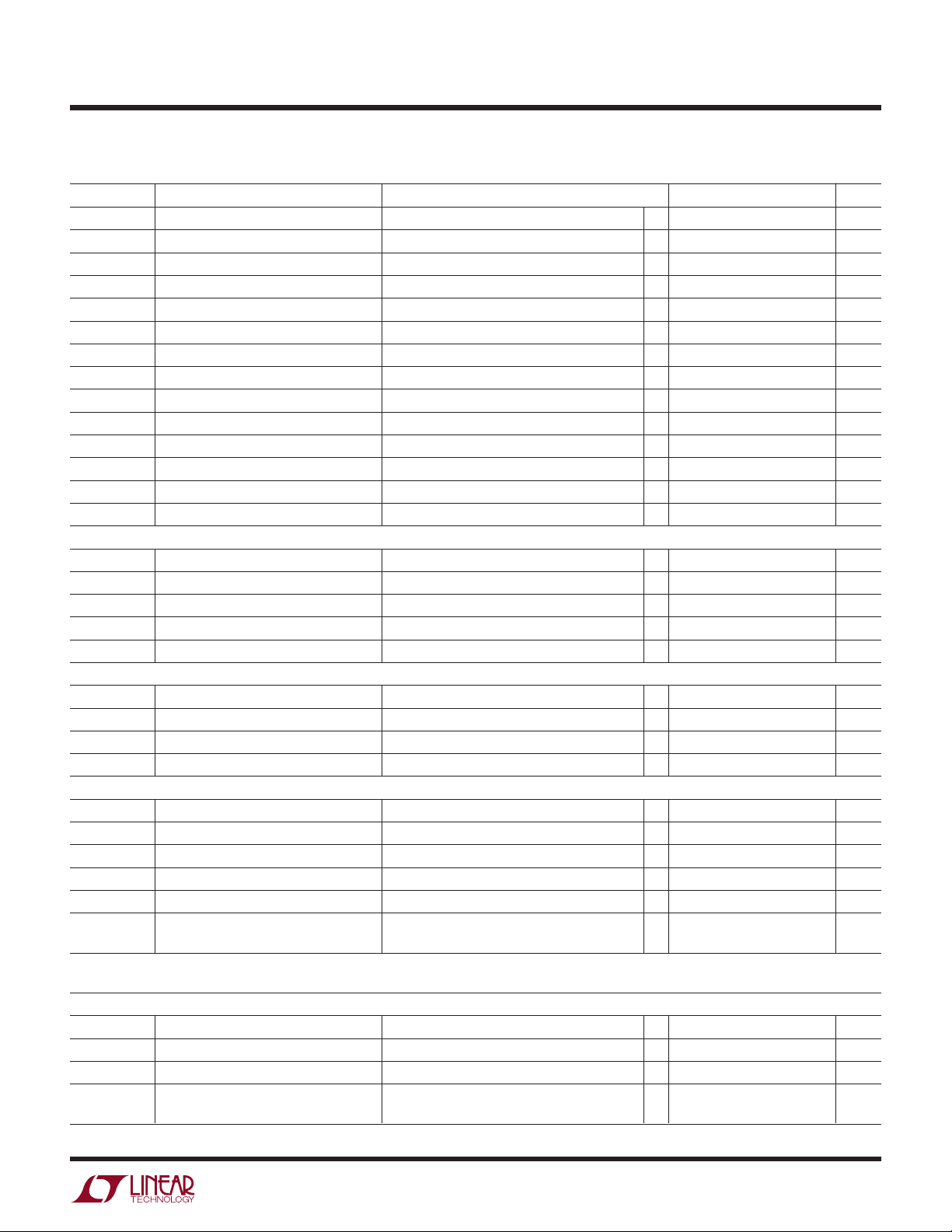

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are TA = 25°C. VIN = 15V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loop

I

Q

V

FB

∆V

FB(LINEREG)

∆V

FB(LOADREG)

g

m(EA)

V

FCB

I

FCB

t

ON

t

ON(MIN)

t

OFF(MIN)

V

SENSE(MAX)

V

SENSE(MIN)

∆V

FB(OV)

∆V

FB(UV)

V

RUN/SS(ON)

Input DC Supply Current

Normal 900 2000 µA

Shutdown Supply Current 15 30 µA

Feedback Reference Voltage ITH = 1.2V (Note 4) ● 0.594 0.600 0.606 V

Feedback Voltage Line Regulation VIN = 4V to 30V (Note 4), ITH = 1.2V 0.002 %/V

Feedback Voltage Load Regulation ITH = 0.5V to 1.9V (Note 4) ● –0.05 –0.3 %

Error Amplifier Transconductance ITH = 1.2V (Note 4) ● 1.4 1.7 2 ms

Forced Continuous Threshold ● 0.57 0.6 0.63 V

Forced Continuous Current V

= 0.6V –1 –2 µA

FCB

On-Time ION = 60µA, VON = 1.5V 200 250 300 ns

Minimum On-Time ION = 180µA, VON = 0V 50 100 ns

Minimum Off-Time ION = 60µA, VON = 1.5V 250 400 ns

Maximum Current Sense Threshold V

Minimum Current Sense Threshold V

= 1V, VFB = 0.56V ● 113 133 153 mV

RNG

= 0V, VFB = 0.56V ● 79 93 107 mV

V

RNG

= INTVCC, VFB = 0.56V ● 158 186 214 mV

V

RNG

= 1V, VFB = 0.64V –67 mV

RNG

V

= 0V, VFB = 0.64V –33 mV

RNG

= INTVCC, VFB = 0.64V –93 mV

V

RNG

Output Overvoltage Fault Threshold 7.5 10 12.5 %

Output Undervoltage Fault Threshold 340 400 460 mV

RUN Pin Start Threshold ● 0.8 1.5 2 V

3714f

2

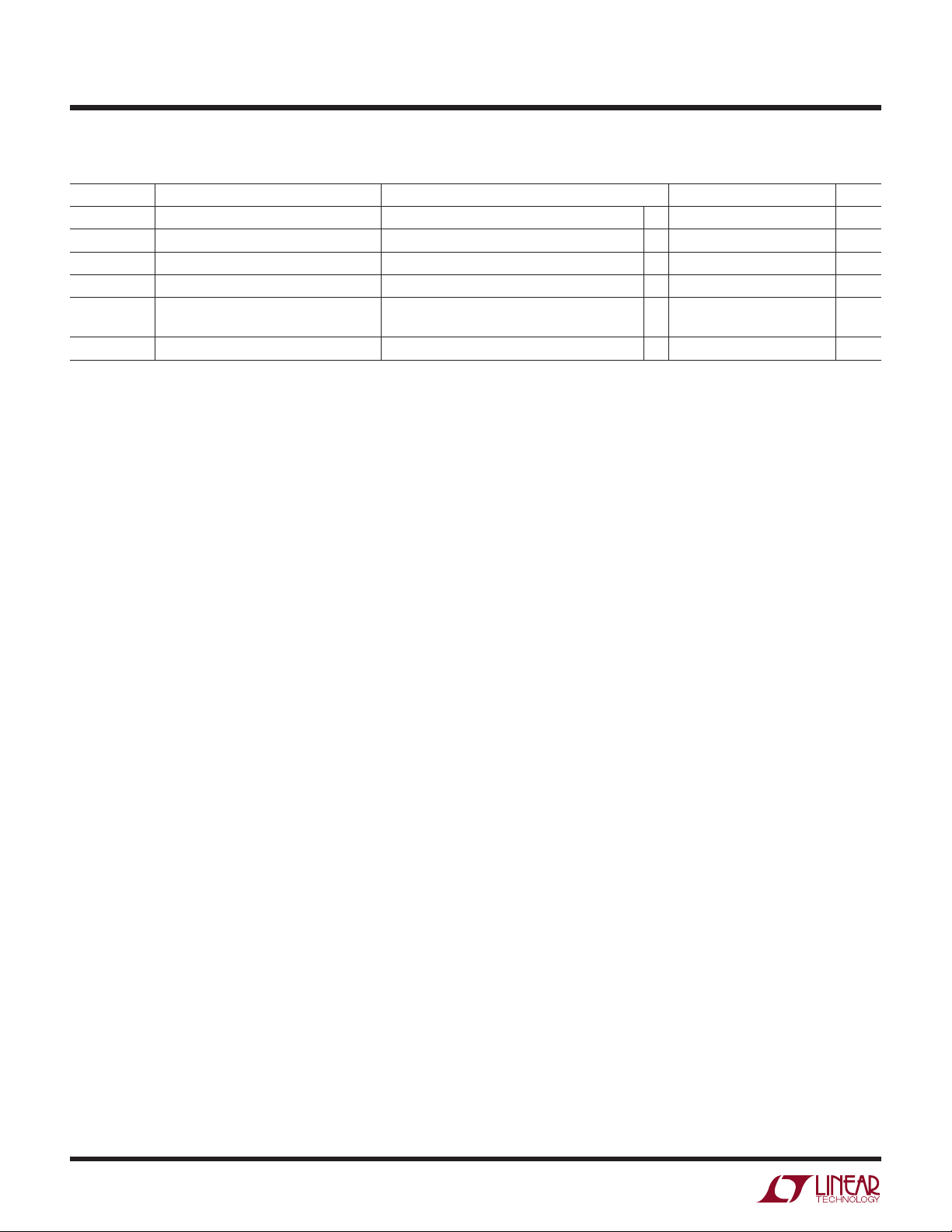

LTC3714

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are TA = 25°C. VIN = 15V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

RUN/SS(LE)

V

RUN/SS(LT)

I

RUN/SS(C)

I

RUN/SS(D)

V

IN(UVLO)

V

IN(UVLOR)

TG R

UP

TG R

DOWN

BG R

UP

BG R

DOWN

TG t

r

TG t

f

BG t

r

BG t

f

Internal VCC Regulator

V

INTVCC

∆V

LDO(LOADREG)

V

EXTVCC

∆V

EXTVCC

∆V

EXTVCC(HYS)

PGOOD Output

∆V

FBH

∆V

FBL

∆V

FB(HYS)

V

PGL

VID DAC

V

VID(T)

I

VID(PULLUP)

V

VID(PULLUP)

I

VID(LEAK)

R

VID

∆V

OSENSE

RUN Pin Latchoff Enable Threshold RUN/SS Pin Rising 4 4.5 V

RUN Pin Latchoff Threshold RUN/SS Pin Falling 3.5 4.2 V

Soft-Start Charge Current –0.5 –1.2 –3 µA

Soft-Start Discharge Current 0.8 1.8 3 µA

Undervoltage Lockout Threshold VIN Falling ● 3.4 3.9 V

Undervoltage Lockout Threshold VIN Rising ● 3.5 4 V

TG Driver Pull-Up On Resistance TG High 2 3 Ω

TG Driver Pull-Down On Resistance TG Low 2 3 Ω

BG Driver Pull-Up On Resistance BG High 3 4 Ω

BG Driver Pull-Down On Resistance BG Low 1 2 Ω

TG Rise Time C

TG Fall Time C

BG Rise Time C

BG Fall Time C

Internal VCC Voltage 6V < VIN < 30V, V

Internal VCC Load Regulation ICC = 0mA to 20mA, V

EXTVCC Switchover Voltage ICC = 20mA, V

EXTVCC Switch Drop Voltage ICC = 20mA, V

= 3300pF 20 ns

LOAD

= 3300pF 20 ns

LOAD

= 3300pF 20 ns

LOAD

= 3300pF 20 ns

LOAD

= 4V ● 4.7 5 5.3 V

EXTVCC

= 4V –0.1 ±2%

EXTVCC

Rising ● 4.5 4.7 V

EXTVCC

= 5V 150 300 mV

EXTVCC

EXTVCC Switchover Hysteresis 200 mV

PGOOD Upper Threshold VFB Rising 7.5 10 12.5 %

PGOOD Lower Threshold VFB Falling –7.5 –10 –12.5 %

PGOOD Hysteresis VFB Returning 1 2.5 %

PGOOD Low Voltage I

= 1mA 0.15 0.4 V

PGOOD

VID0-VID4 Logic Threshold Voltage 0.4 1.2 2 V

VID0-VID4 Pull-Up Current V

VID0-VID4 Pull-Up Voltage V

VID0-VID4 Leakage Current V

Resistance from V

OSENSE

to V

FB

DAC Output Accuracy V

to V

VID0

VID0

VID0

= 0V –2.5 µA

VID4

to V

Open 4.5 V

VID4

to V

VID4

= 5V, V

= 0V 0.01 1 µA

RUN/SS

61014 KΩ

Programmed from –0.45 0 0.25 %

OSENSE

0.6V to 1.75V (Note 5)

VIN = 5V unless otherwise noted.

Internal Op Amp

V

OS

I

OS

I

B

Input Offset Voltage 400 1000 µV

Input Offset Current 410 nA

Input Bias Current 45 80 nA

CMRR Common Mode Rejection Ratio VCM = 0V to (VCC – 1V) 100 dB

= 0V to 18V 80 dB

V

CM

3714f

3

LTC3714

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are TA = 25°C. VIN = 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

PSRR Power Supply Rejection Ratio OPVIN = 3V to 12.5V, OP

A

VOL

V

OL

V

OH

I

SC

I

S

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3714E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: T

dissipation P

LTC3714EG: TJ = TA + (PD • 130°C/W)

Large-Signal Voltage Gain OPVIN = 5V, OP

Output Voltage Swing LOW OPVIN = 5V, I

Output Voltage Swing HIGH OPVIN = 5V, I

Short-Circuit Current Short to GND 30 mA

Short to OPV

Supply Current 170 300 µA

is calculated from the ambient temperature TA and power

J

as follows:

D

= 500mV to 4.5V, RL = 10k 1500 V/mV

OUT

= 5mA ● 165 500 mV

SINK

SOURCE

IN

= VO = 1V 100 dB

OUT

= 5mA ● 4.5 4.87 V

40 mA

Note 4: The LTC3714 is tested in a feedback loop that adjusts V

achieve a specified error amplifier output voltage (I

Note 5: The LTC3714 VID DAC is tested in a feedback loop that adjusts

V

to achieve a specified feedback voltage (VFB = 0.6V) for each DAC

OSENSE

VID code.

).

TH

to

FB

4

3714f

UW

TYPICAL PERFOR A CE CHARACTERISTICS

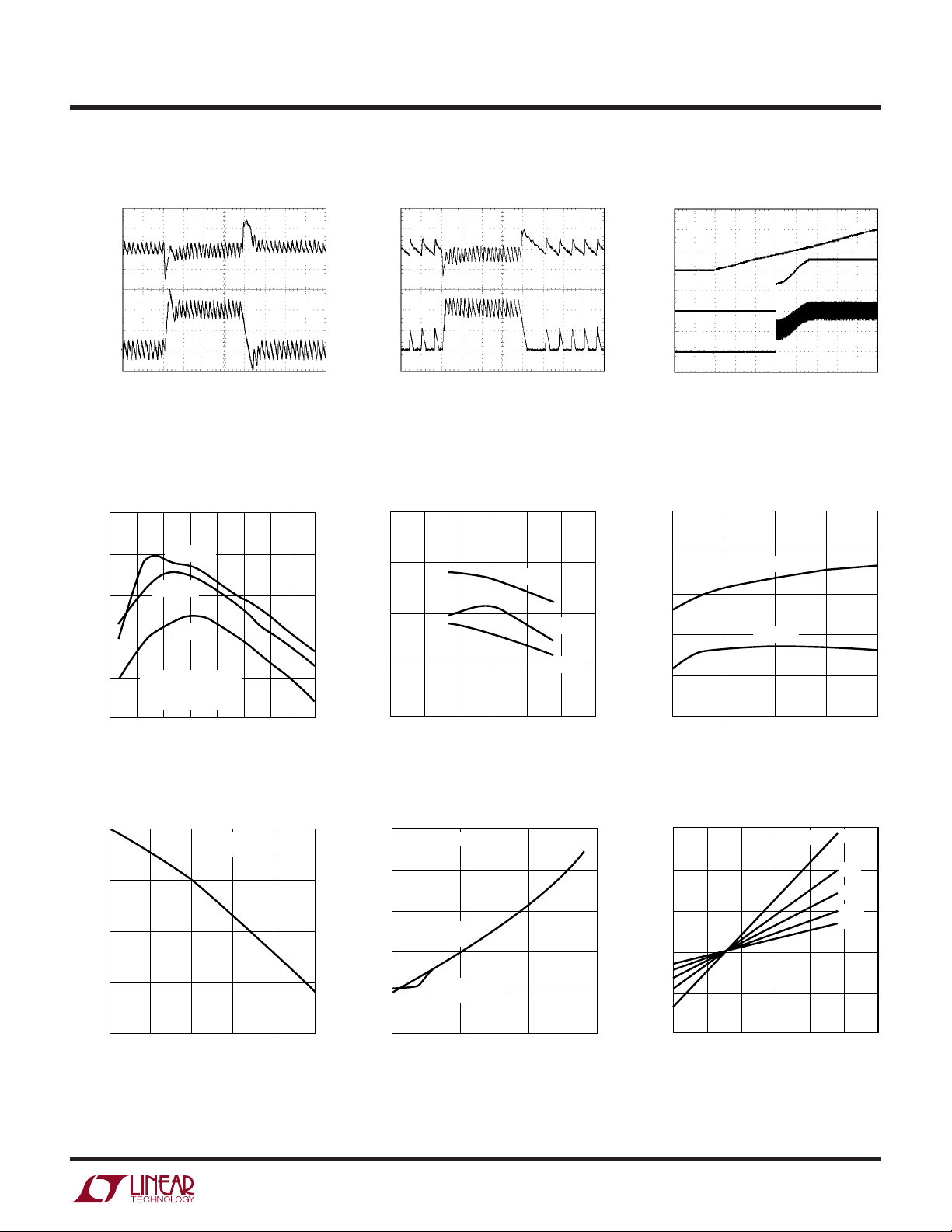

Transient Response

Transient Response

(Discontinuous Mode)

LTC3714

Start-Up

V

OUT

50mV/DIV

I

L

5A/DIV

LOAD STEP 0A TO 10A

V

= 15V

IN

= 1.5V

V

OUT

FCB = 0V

FIGURE 1 CIRCUIT

Efficiency vs Load Current

95

90

85

80

EFFICIENCY (%)

75

70

0

VIN = 8.5V

VIN = 15V

VIN = 24V

V

= 1.35V

OUT

FREQUENCY = 300kHz

FIGURE 1 CIRCUIT

3 6 9 12 15 18 21

LOAD CURRENT (A)

20µs/DIV

3714 G03

3714 G01

V

OUT

50mV/DIV

5A/DIV

I

L

LOAD STEP 1A TO 10A

V

= 15V

IN

= 1.5V

V

OUT

FCB = INTV

FIGURE 1 CIRCUIT

CC

20µs/DIV

3714 G02

RUN/SS

2V/DIV

V

OUT

500mV/DIV

5A/DIV

I

L

VIN = 15V

V

R

OUT

LOAD

= 1.25V

= 0.125Ω

Efficiency vs Input Voltage Frequency vs Input Voltage

100

90

80

EFFICIENCY (%)

70

60

0

I

= 10A

OUT

I

OUT

I

OUT

5101520

INPUT VOLTAGE (V)

= 1A

= 23A

25 30

3714 G04

300

FCB = 0V

FIGURE 1 CIRCUIT

280

260

240

FREQUENCY (kHz)

220

200

5

10

INPUT VOLTAGE (V)

50ms/DIV 3714 G19

I

= 10A

OUT

I

= 0A

OUT

15

20

3714 G05

25

Load Regulation

0

–0.1

(%)

–0.2

OUT

∆V

–0.3

–0.4

0

2

4

LOAD CURRENT (A)

FIGURE 1 CIRCUIT

NO AVP

6

8

3714 G06

Current Sense Threshold

ITH Voltage vs Load Current

2.5

FIGURE 1 CIRCUIT

2.0

1.5

CONTINUOUS

VOLTAGE (V)

1.0

TH

I

0.5

0

10

0

MODE

DISCONTINUOUS

MODE

5

LOAD CURRENT (A)

10

15

3714 G07

vs ITH Voltage

300

200

100

0

–100

CURRENT SENSE THRESHOLD (mV)

–200

0

1.0 1.5 2.0

0.5

ITH VOLTAGE (V)

RNG

=

2V

1.4V

1V

0.7V

0.5V

2.5 3.0

3714 G08

3714f

V

5

LTC3714

TEMPERATURE (°C)

–50

ON-TIME (ns)

200

250

300

25 75

3714 G22

150

100

–25 0

50 100 125

50

0

I

ION

= 30µA

V

VON

= 0V

UW

TYPICAL PERFOR A CE CHARACTERISTICS

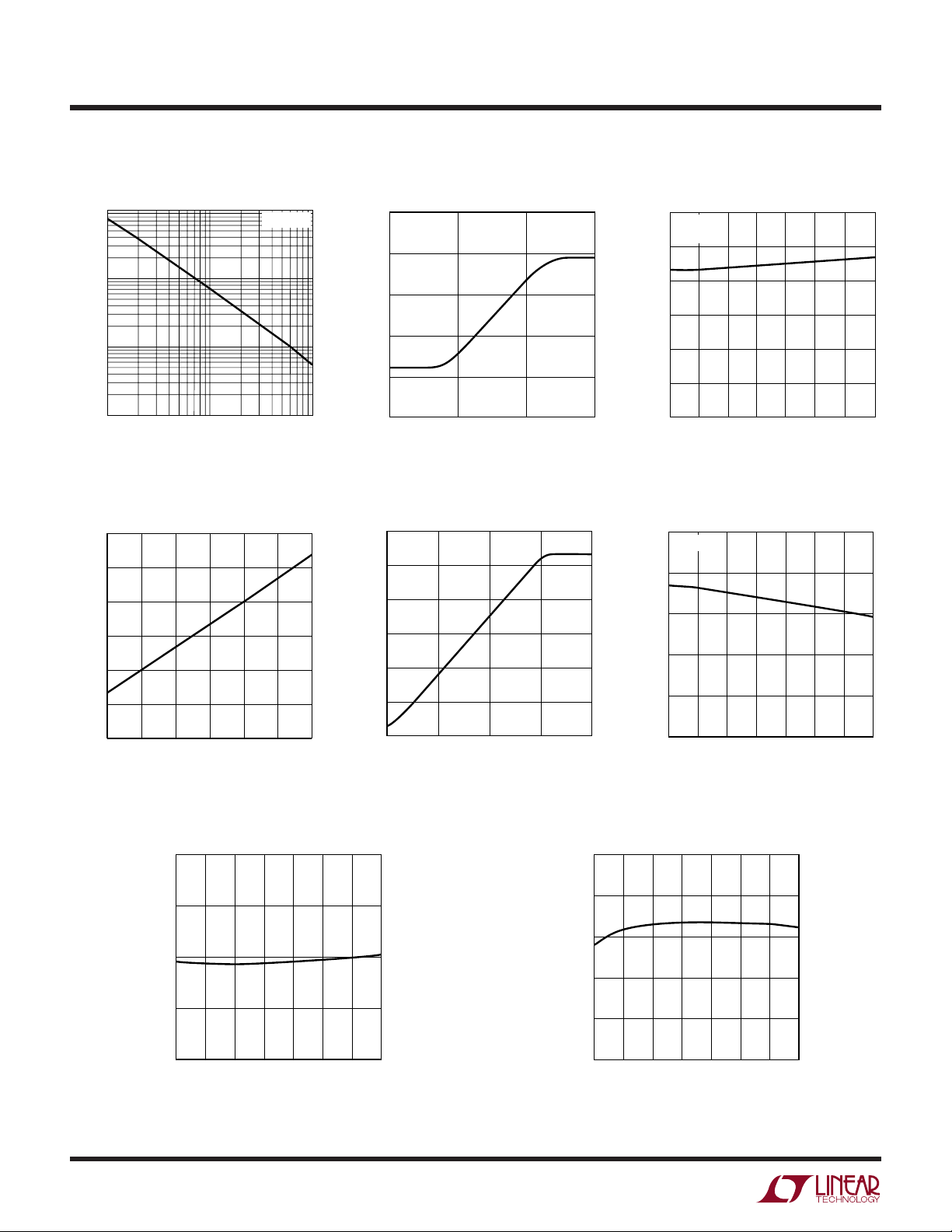

On-Time vs ION Current

10k

1k

ON-TIME (ns)

100

10

1

ION CURRENT (µA)

Maximum Current Sense

Threshold vs V

300

250

200

150

100

50

V

= 0V

VON

10 100

3714 G20

Voltage

RNG

On-Time vs VON Voltage On-Time vs Temperature

1000

I

= 30µA

ION

800

600

400

ON-TIME (ns)

200

0

0

1

VON VOLTAGE (V)

Maximum Current Sense

Threshold vs RUN/SS Voltage

150

125

100

= 1V

V

RNG

75

50

25

2

3

3714 G21

Maximum Current Sense

Threshold vs Temperature

150

V

= 1V

RNG

140

130

120

110

MAXIMUM CURRENT SENSE THRESHOLD (mV)

0

0.5

0.75

1.0 1.25 1.5

V

VOLTAGE (V)

RNG

Feedback Reference Voltage

vs Temperature

0.62

0.61

0.60

6

0.59

FEEDBACK REFERENCE VOLTAGE (V)

0.58

–50

–25 0 25 50

TEMPERATURE (°C)

1.75 2.0

3714 G10

MAXIMUM CURRENT SENSE THRESHOLD (mV)

0

75 100 125

3714 G12

1.5

2 2.5 3 3.5

RUN/SS VOLTAGE (V)

MAXIMUM CURRENT SENSE THRESHOLD (mV)

3714 G23

100

–50 –25

0

TEMPERATURE (°C)

Error Amplifier gm vs Temperature

2.0

1.8

1.6

(mS)

m

g

1.4

1.2

1.0

–50 –25

0

TEMPERATURE (°C)

50

25

50

25

75

100

75

125

3714 G13

100

125

3714 G11

3714f

TEMPERATURE (°C)

–50 –25

0

EXTV

CC

SWITCH RESISTANCE (Ω)

4

10

0

50

75

3714 G14

2

8

6

25

100

125

UW

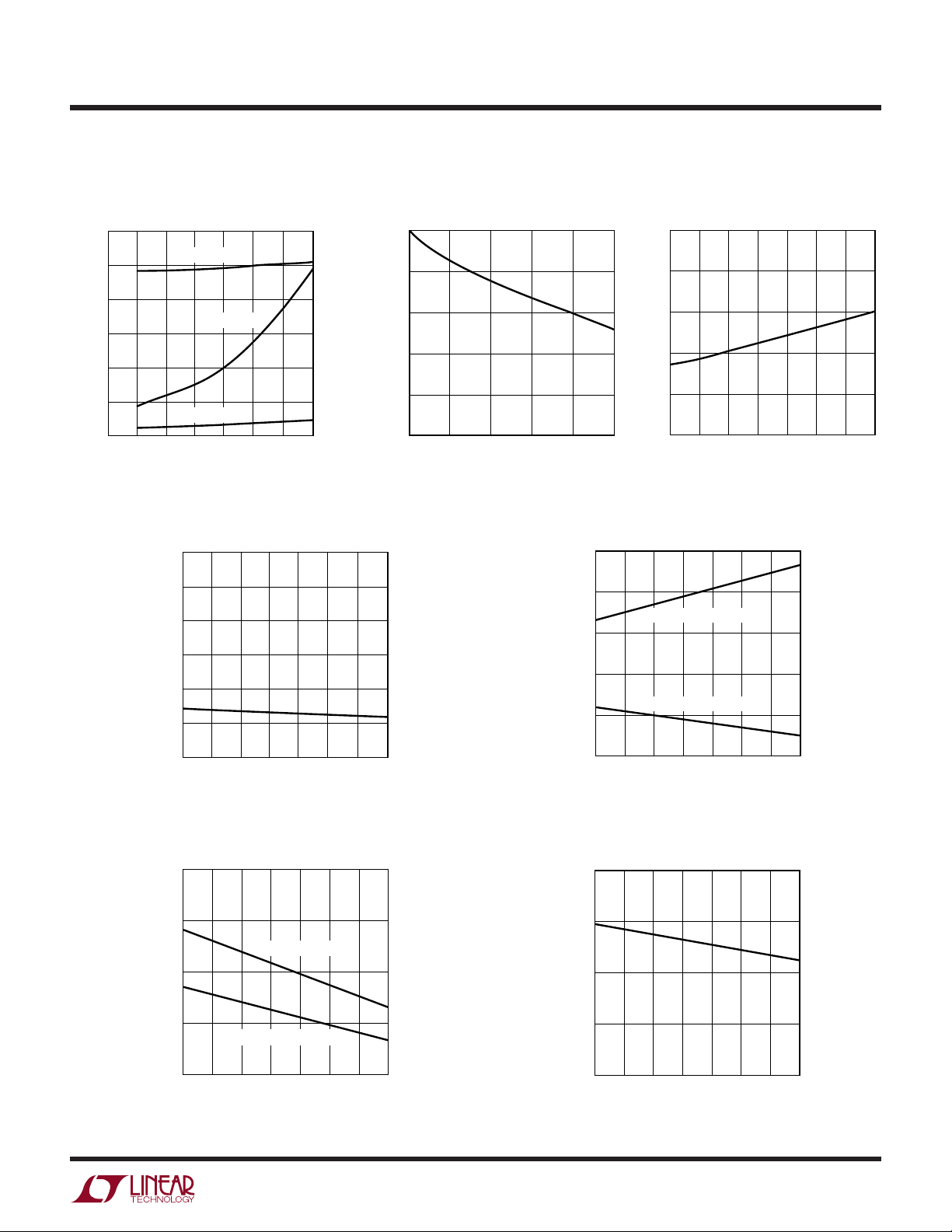

TYPICAL PERFOR A CE CHARACTERISTICS

LTC3714

Input and Shutdown Currents

vs Input Voltage

1200

1000

INPUT CURRENT (µA)

800

600

400

200

0

0

510

EXTVCC OPEN

SHUTDOWN

EXTVCC = 5V

15 25

INPUT VOLTAGE (V)

FCB Pin Current vs Temperature

0

–0.25

–0.50

–0.75

–1.00

FCB PIN CURRENT (µA)

–1.25

20 30 35

3714 G24

EXTVCC Switch Resistance

INTVCC Load Regulation

–0.1

–0.2

(%)

CC

–0.3

∆INTV

–0.4

–0.5

0

10

0

INTVCC LOAD CURRENT (mA)

30

40

20

50

3714 G25

60

50

SHUTDOWN CURRENT (µA)

40

30

20

10

0

vs Temperature

RUN/SS Pin Current

vs Temperature

3

2

PULL-DOWN CURRENT

1

0

FCB PIN CURRENT (µA)

–1

PULL-UP CURRENT

–1.50

5.0

4.5

4.0

3.5

RUN/SS THRESHOLD (V)

3.0

50 100 125

–50

–25 0

25 75

TEMPERATURE (°C)

RUN/SS Latchoff Thresholds

vs Temperature

LATCHOFF ENABLE

LATCHOFF THRESHOLD

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125

3714 G15

3714 G17

–2

–50 –25

0

TEMPERATURE (°C)

50

25

75

Undervoltage Lockout Threshold

vs Temperature

4.0

3.5

3.0

2.5

UNDERVOLTAGE LOCKOUT THRESHOLD (V)

2.0

–50

–25 0 25 50

TEMPERATURE (C)

75 100 125

100

125

3714 G16

3714 G18

3714f

7

LTC3714

UUU

PI FU CTIO S

BG (Pin 1): Bottom Gate Drive. Drives the gate of the

bottom N-channel MOSFET between ground and INTVCC.

PGND (Pin 2): Power Ground. Connect this pin closely to

the bottom of the sense resistor or if no sense resistor is

used, to the source of the bottom N-channel MOSFET, the

(–) terminal of C

SENSE (Pin 3): Current Sense Comparator Input. The (+)

input to the current comparator is normally connected to

the SW node unless using a sense resistor (see Applications Information).

SW (Pin 4): Switch Node. The (–) terminal of the bootstrap

capacitor CB connects here. This pin swings from a diode

voltage drop below ground up to VIN.

TG (Pin 5): Top Gate Drive. Drives the top N-channel

MOSFET with a voltage swing equal to INTVCC superimposed on the switch node voltage SW.

BOOST (Pin 6): Boosted Floating Driver Supply. The (+)

terminal of the bootstrap capacitor CB connects here. This

pin swings from a diode voltage drop below INTVCC up to

V

+ INTVCC.

IN

VID0-VID4 (Pins 7, 8, 9, 24, 25): VID Digital Inputs. The

voltage identification (VID) code sets the internal feedback

resistor divider ratio for different output voltages as shown

in Table 1. If unconnected, the pins are pulled high by

internal 2.5µA current sources.

RUN/SS (Pin 10): Run Control and Soft-Start Input. A

capacitor to ground at this pin sets the ramp time to full

output current (approximately 3s/µF) and the time delay

for overcurrent latchoff (see Applications Information).

Forcing this pin below 0.8V shuts down the device.

and the (–) terminal of CIN.

VCC

mum output current and can be set from 0.5V to 2V by a

resistive divider from INTVCC. The sense voltage defaults

to 70mV when this pin is tied to ground, 140mV when tied

to INTVCC.

I

(Pin 14): Current Control Threshold and Error Ampli-

TH

fier Compensation Point. The current comparator threshold increases with this control voltage. The voltage ranges

from 0V to 2.4V with 0.8V corresponding to zero sense

voltage (zero current).

OPVIN (Pin 15): Internal Op Amp Supply. Connect to

INTVCC or a separate supply greater than 5V.

OP– (Pin 16): Negative Input of the Internal Op Amp.

OP+ (Pin 17): Positive Input of the Internal Op Amp.

OPOUT (Pin 18): Output of the Internal Op Amp.

SGND (Pin 19): Signal Ground. All small-signal compo-

nents and compensation components should connect to

this ground, which in turn connects to PGND at one point.

FCB (Pin 20): Forced Continous Input. Tie this pin to

ground to force continuous synchronous operation at low

load, to INTVCC to enable discontinuous mode operation

at low load or to a resistive divider from a secondary output

when using a secondary winding.

ION (Pin 21): On-Time Current Input. Tie a resistor from

VIN to this pin to set the one-shot timer current and thereby

set the switching frequency.

VFB (Pin 22): Error Amplifier Feedback Input. This pin

connects to both the error amplifier input and to the output

of the internal resistive divider. It can be used to attach

additional compensation components if desired.

VON (Pin 11): On-Time Voltage Input. Voltage trip point for

the on-time comparator. Tying this pin to the output

voltage makes the on-time proportional to V

comparator input defaults to 0.7V when the pin is grounded,

2.4V when the pin is tied to INTVCC.

PGOOD (Pin 12): Power Good Output. Open drain logic

output that is pulled to ground when the output voltage is

not within ±10% of the regulation point.

V

(Pin 13): Sense Voltage Range Input. The voltage at

RNG

this pin is ten times the nominal sense voltage at maxi-

OUT

. The

8

V

OSENSE

voltage connects here to the input of the internal resistive

feedback divider.

EXTVCC (Pin 26): External V

ceeds 4.7V, an internal switch connects this pin to INTV

and shuts down the internal regulator so that controller

and gate drive power is drawn from EXTVCC. Do not exceed

7V at this pin and ensure that EXTVCC < VIN.

VIN (Pin 27): Main Input Supply. Decouple this pin to

SGND with an RC filter (1Ω, 0.1µF).

(Pin 23): Output Voltage Sense. The output

Input. When EXTVCC ex-

CC

CC

3714f

UUU

PI FU CTIO S

LTC3714

INTVCC (Pin 28): Internal 5V Regulator Output. The driver

and control circuits are powered from this voltage. De-

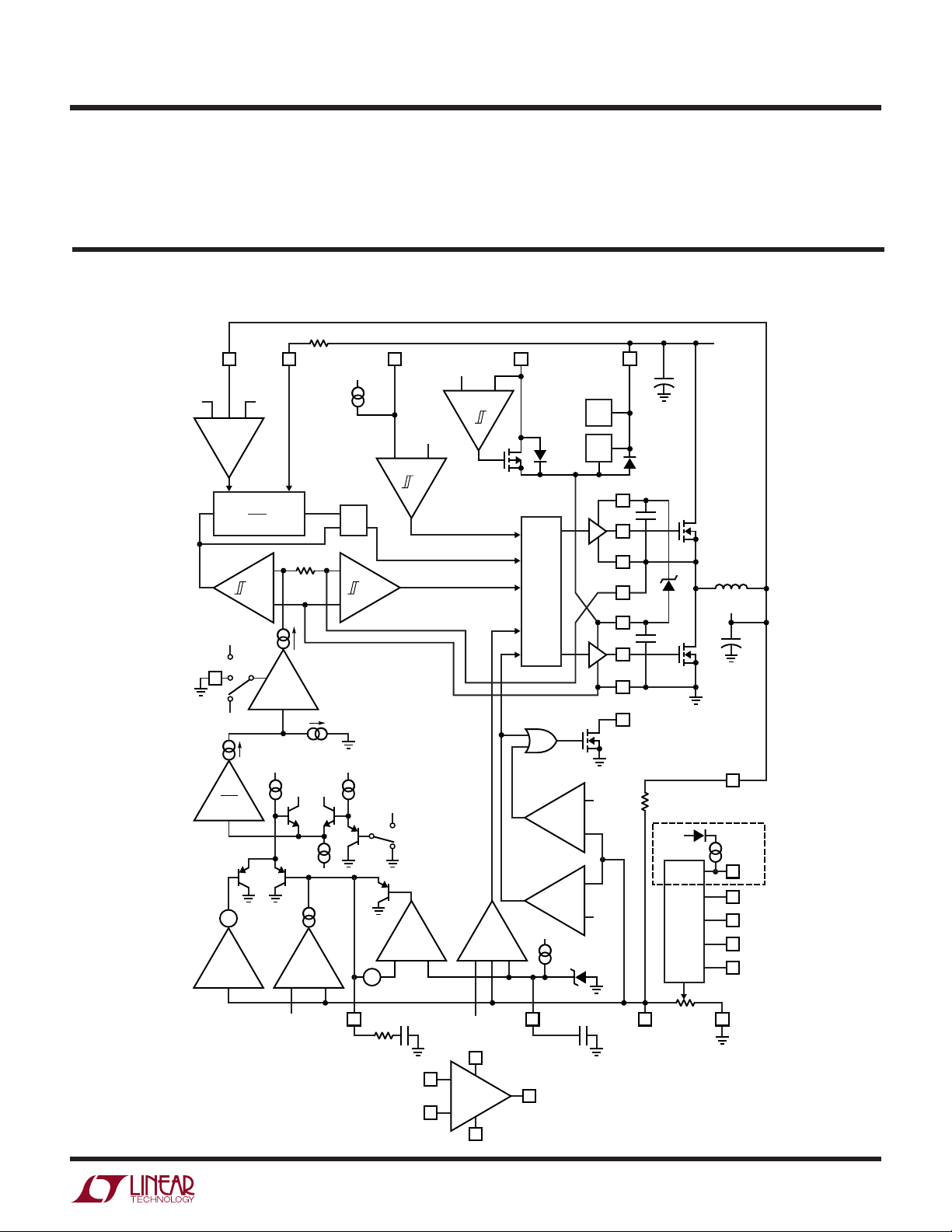

U

U

W

FU CTIO AL DIAGRA

R

ON

0.7V

11

1

tON = (10pF)

1.4V

V

RNG

13

0.7V

V

OST

ON

V

I

I

CMP

VON

ION

2.4V

21

+

–

X

(0.5 TO 2)

I

20k

FCB

1µA

20

4.7V

+

0.6V

+

–

F

ON

R

SQ

+

I

REV

–

couple this pin to power ground with a minimum of 4.7µF

tantalum or other low ESR capacitor.

V

IN

C

IN

M1

L1

V

OUT

+

C

M2

OUT

–

FCNT

SHDN

V

0.6V

REF

REG

27

IN

+

5V

BOOST

6

C

TG

B

5

SW

4

SENSE

3

INTV

CC

28

C

VCC

BG

1

PGND

2

PGOOD

12

EXTV

26

CC

ON

SWITCH

LOGIC

OV

240k

×5.3

3.3µA

V

OSENSE

1

Q4

Q2

Q6

Q3

Q1

+

0.8V

–

EA

–

+

0.6V

1V

Q5

+

OP AMP

–

0.4V

RUN

SHDN

RUN/SS

10

OPV

15

IN

OPOUT

18

SGND

19

SS

–

+

+

–

0.6V

C

C1

I

14

TH

R

C

+

OP

17

–

OP

16

UV

OV

1.2µA

0.54V

+

–

+

0.66V

–

6V

C

SS

R2

10k

5× (ALL VID PINS)

INTV

CC

VID

DAC

R1

22 19

FB

23

2.5µA

7

8

9

24

25

SGNDV

3714 FD

VID0

VID1

VID2

VID3

VID4

3714f

9

LTC3714

OPERATIO

U

Main Control Loop

The LTC3714 is a constant on-time, current mode controller for DC/DC step-down converters. In normal operation,

the top MOSFET is turned on for a fixed interval determined by a one-shot timer OST. When the top MOSFET is

turned off, the bottom MOSFET is turned on until the

current comparator I

timer and initiating the next cycle. Inductor current is

determined by sensing the voltage between the PGND and

SENSE pins using either the bottom MOSFET on-resistance or a separate sense resistor. The voltage on the I

pin sets the comparator threshold corresponding to inductor valley current. The error amplifier EA adjusts this

voltage by comparing the feedback signal VFB from the

output voltage with an internal 0.6V reference. The feedback voltage is derived from the output voltage by a

resistive divider DAC that is set by the VID code pins VID0VID4. If the load current increases, it causes a drop in the

feedback voltage relative to the reference. The ITH voltage

then rises until the average inductor current again matches

the load current.

At low load currents, the inductor current can drop to zero

and become negative. This is detected by current reversal

comparator I

discontinuous operation. Both switches will remain off

with the output capacitor supplying the load current until

the ITH voltage rises above the zero current level (0.8V) to

initiate another cycle. Continuous synchronous operation

can be forced in the LTC3714 by bringing the FCB pin

below 0.6V. The benefit of forced continuous operation is

lower output voltage ripple, faster transient response to

current load steps and a much quieter frequency spectrum

so that it won’t interfere with any neighboring noise

sensitive components.

which then shuts off M2, resulting in

REV

trips, restarting the one-shot

CMP

TH

The operating frequency is determined implicitly by the

top MOSFET on-time and the duty cycle required to

maintain regulation. The one-shot timer generates an ontime that is proportional to the ideal duty cycle, thus

holding frequency approximately constant with changes

in VIN and V

with an external resistor RON.

Overvoltage and undervoltage comparators OV and UV

pull the PGOOD output low if the output feedback voltage

exits a ±10% window around the regulation point. Furthermore, in an overvoltage condition, M1 is turned off and M2

is turned on and held on until the overvoltage condition

clears.

Foldback current limiting is provided if the output is

shorted to ground. As VFB drops, the buffered current

threshold voltage I

level set by Q2 and Q6. This reduces the inductor valley

current level to one sixth of its maximum value as V

approaches ground.

Pulling the RUN/SS pin low forces the controller into its

shutdown state, turning off both M1 and M2. Releasing

the pin allows an internal 1.2µA current source to charge

up an external soft-start capacitor CSS. When this voltage

reaches 1.5V, the controller turns on and begins switching, but with the ITH voltage clamped at approximately

0.6V below the RUN/SS voltage. As CSS continues to

charge, the soft-start current limit is removed.

. The nominal frequency can be adjusted

OUT

is pulled down by clamp Q3 to a 1V

THB

FB

10

3714f

OPERATIO

LTC3714

U

Internal Op Amp

The internal op amp allows the user to program accurate

offsets to the output voltage during power saving modes.

By connecting the OP+ pin to the output, the OPOUT pin to

the V

OSENSE

pin and an external resistor R1 between the

OP–and OPOUT pins, the op amp is hooked up as a unitygain feedback amplifier. Resistors R2 and R3, together

with series switches, can then be placed on the OP– pin to

allow negative offsets to be switched onto the output

voltage (see Figures 2a and 2b). The accuracy of the offset

will depend on the matching of the external resistors R1 to

R2 and R3.*

For applications that require less accurate output offsets,

or none at all, the user can use the internal op amp for true

differential remote sensing of the output voltage by connecting OPOUT to V

OSENSE

and using OP+ and OP– for

differential sensing across the output capacitor as shown

in Figure 2c.

INTVCC/EXTVCC Power

Power for the top and bottom MOSFET drivers and most

of the internal controller circuitry is derived from the

INTVCC pin. The top MOSFET driver is powered from a

floating bootstrap capacitor CB. This capacitor is recharged from INTVCC through an external Schottky diode

DB when the top MOSFET is turned off. When the EXTV

CC

pin is grounded, an internal 5V low dropout regulator

supplies the INTVCC power from VIN. If EXTVCC rises

above 4.7V, the internal regulator is turned off, and an

internal switch connects EXTVCC to INTVCC. This allows

a high efficiency source connected to EXTVCC, such as an

external 5V supply or a secondary output from the

converter, to provide the INTVCC power. Voltages up to

7V can be applied to EXTVCC for additional gate drive. If

the input voltage is low and INTVCC drops below 3.5V,

undervoltage lockout circuitry prevents the power

switches from turning on.

*An alternate configuration, shown in Figure 2b, can be used to program

offsets as well. Either configuration can be used, depending upon the logic

of control signals. If offsets are not required, the op amp can be used to

remotely sense the output voltage, proving true differential sense.

V

V

OUT

OPV

15

+

OP

–

OP

+

17

16

–

SLEEP

MODE

OFFSET

IN

18

R1

BATTERY

MODE

OFFSET

V

OSENSE

23

VID DAC

BATTERY

V

FB

22

R3

3714 F02b

MODE

OFFSET

OPOUT

R2

Figure 2a

+

R

+

V

OUT

V

OUT

R

R

–

OP

–

OP

+

17

16

–

OUT

OPV

15

R1

R2

SLEEP

MODE

OFFSET

+

OP

–

OP

R2

R3

+

17

16

–

IN

18

R1

VID DAC

23

V

FB

22

3714 F02b

Figure 2b

OPV

15

IN

OPOUT V

OSENSE

18R23

3714 F02c

Figure 2c

3714f

11

LTC3714

WUUU

APPLICATIO S I FOR ATIO

The basic LTC3714 application circuit is shown in

Figure 1. External component selection is primarily determined by the maximum load current and begins with

the selection of the sense resistance and power MOSFET

switches. The LTC3714 can use either a sense resistor or

the on-resistance of the synchronous power MOSFET for

determining the inductor current. The desired amount of

ripple current and operating frequency largely determines the inductor value. Finally, CIN is selected for its

ability to handle the large RMS current into the converter

and C

is chosen with low enough ESR to meet the

OUT

output voltage ripple and transient specification.

Maximum Sense Voltage and V

RNG

Pin

Inductor current is determined by measuring the voltage

across a sense resistance that appears between the PGND

and SENSE pins. The maximum sense voltage is set by the

voltage applied to the V

mately (0.133)V

. The current mode control loop will

RNG

pin and is equal to approxi-

RNG

not allow the inductor current valleys to exceed

(0.133)V

RNG/RSENSE

. In practice, one should allow some

margin for variations in the LTC3714 and external component values and a good guide for selecting the sense

resistance is:

V

R

SENSE

=

10 •

RNG

I

()

OUT MAX

An external resistive divider from INTVCC can be used to

set the voltage of the V

pin between 0.5V and 2V

RNG

resulting in nominal sense voltages of 50mV to 200mV.

Additionally, the V

pin can be tied to SGND or INTV

RNG

CC

in which case the nominal sense voltage defaults to 70mV

or 140mV, respectively. The maximum allowed sense

voltage is about 1.33 times this nominal value.

MOSFET as the current sense element by simply connecting the SENSE pin to the switch node SW at the drain of the

bottom MOSFET. This improves efficiency, but one must

carefully choose the MOSFET on-resistance as discussed

below.

Power MOSFET Selection

The LTC3714 requires two external N-channel power

MOSFETs, one for the top (main) switch and one for the

bottom (synchronous) switch. Important parameters for

the power MOSFETs are the breakdown voltage V

threshold voltage V

transfer capacitance C

, on-resistance R

(GS)TH

and maximum current I

RSS

DS(ON)

(BR)DSS

, reverse

DS(MAX)

,

.

The gate drive voltage is set by the 5V INTVCC supply.

Consequently, logic-level threshold MOSFETs must be

used in LTC3714 applications. If the input voltage is

expected to drop below 5V, then sub-logic level threshold

MOSFETs should be considered.

When the bottom MOSFET is used as the current sense

element, particular attention must be paid to its onresistance. MOSFET on-resistance is typically specified

with a maximum value R

DS(ON)(MAX)

at 25°C. In this case,

additional margin is required to accommodate the rise in

MOSFET on-resistance with temperature:

R

R

DS ON MAX

()( )

=

SENSE

ρ

T

The ρT term is a normalization factor (unity at 25°C)

accounting for the significant variation in on-resistance

with temperature, typically about 0.4%/°C as shown in

Figure 3. Junction-to-case temperature is about 30°C in

most applications. For a maximum ambient temperature

of 70°C, using a value ρ

= 1.3 is reasonable.

100°C

Connecting the SENSE Pin

The LTC3714 can be used with or without a sense resistor.

When using a sense resistor, it is placed between the

source of the bottom MOSFET M2 and ground. Connect

the SENSE pin to the source of the bottom MOSFET so that

the resistor appears between the SENSE and PGND pins.

Using a sense resistor provides a well defined current

limit, but adds cost and reduces efficiency. Alternatively,

one can eliminate the sense resistor and use the bottom

12

The power dissipated by the top and bottom MOSFETs

strongly depends upon their respective duty cycles and

the load current. When the LTC3714 is operating in

continuous mode, the duty cycles for the MOSFETs are:

V

D

D

TOP

BOT

OUT

=

V

IN

–

VV

IN OUT

=

V

IN

3714f

WUUU

APPLICATIO S I FOR ATIO

LTC3714

2.0

1.5

1.0

0.5

NORMALIZED ON-RESISTANCE

T

ρ

0

–50

0

JUNCTION TEMPERATURE (°C)

Figure 3. R

50

vs Temperature

DS(ON)

100

150

3714 F02

The resulting power dissipation in the MOSFETs at maximum output current are:

P

TOP

+ k V

P

BOT

= D

TOP IOUT(MAX)

2

I

IN

OUT(MAX) CRSS

= D

BOT IOUT(MAX)

2

ρ

T(TOP) RDS(ON)(MAX)

f

2

ρ

T(BOT) RDS(ON)(MAX)

Tying a resistor RON from VIN to the ION pin yields an ontime inversely proportional to VIN. For a step-down converter, this results in approximately constant frequency

operation as the input supply varies:

V

f

=

VR pF

OUT

VON ON

()10

To hold frequency constant during output voltage changes,

tie the VON pin to V

. The VON pin has internal clamps

OUT

that limit its input to the one-shot timer. If the pin is tied

below 0.7V, the input to the one-shot is clamped at 0.7V.

Similarly, if the pin is tied above 2.4V, the input is clamped

at 2.4V.

Because the voltage at the ION pin is about 0.7V, the

current into this pin is not exactly inversely proportional to

VIN, especially in applications with lower input voltages.

To correct for this error, an additional resistor R

ON2

connected from the ION pin to the 5V INTVCC supply will

further help to stabilize the frequency.

Both MOSFETs have I2R losses and the top MOSFET

includes an additional term for transition losses, which are

largest at high input voltages. The constant k = 1.7A–1 can

be used to estimate the amount of transition loss. The

bottom MOSFET losses are greatest when the bottom duty

cycle is near 100%, during a short-circuit or at high input

voltage.

Operating Frequency

The choice of operating frequency is a tradeoff between

efficiency and component size. Low frequency operation

improves efficiency by reducing MOSFET switching losses

but requires larger inductance and/or capacitance in order

to maintain low output ripple voltage.

The operating frequency of LTC3714 applications is determined implicitly by the one-shot timer that controls the

on-time tON of the top MOSFET switch. The on-time is set

by the current into the ION pin and the voltage at the V

ON

pin according to:

V

t

ON

VON

= ()10

I

ION

pF

V

07=.

5

R

V

R

ON ON2

Changes in the load current magnitude will also cause

frequency shift. Parasitic resistance in the MOSFET

switches and inductor reduce the effective voltage across

the inductance, resulting in increased duty cycle as the

load current increases. By lengthening the on-time slightly

as current increases, constant frequency operation can be

maintained. This is accomplished with a resistive divider

from the ITH pin to the VON pin and V

. The values

OUT

required will depend on the parasitic resistances in the

specific application. A good starting point is to feed about

25% of the voltage change at the ITH pin to the VON pin as

shown in Figure 4a. Place capacitance on the VON pin to

filter out the ITH variations at the switching frequency. The

resistor load on ITH reduces the DC gain of the error amp

and degrades load regulation, which can be avoided by

using the PNP emitter follower of Figure 4b.

3714f

13

LTC3714

14

WUUU

APPLICATIO S I FOR ATIO

LTC3714

The selection of C

is primarily determined by the ESR

OUT

required to minimize voltage ripple and load step

transients. The output ripple ∆V

is approximately

OUT

bounded by:

∆≤∆ +

V I ESR

OUT L

8

fC

1

OUT

Since ∆IL increases with input voltage, the output ripple is

highest at maximum input voltage. Typically, once the ESR

requirement is satisfied, the capacitance is adequate for

filtering and has the necessary RMS current rating.

Multiple capacitors placed in parallel may be needed to

meet the ESR and RMS current handling requirements.

Dry tantalum, special polymer, POSCAP aluminum electrolytic and ceramic capacitors are all available in surface

mount packages. Special polymer capacitors offer very

low ESR but have lower capacitance density than other

types. Tantalum capacitors have the highest capacitance

density but it is important to only use types that have been

surge tested for use in switching power supplies. Aluminum electrolytic capacitors have significantly higher ESR,

but can be used in cost-sensitive applications providing

that consideration is given to ripple current ratings and

long term reliability. Ceramic capacitors have excellent

low ESR characteristics but can have a high voltage

coefficient and audible piezoelectric effects. The high Q of

ceramic capacitors with trace inductance can also lead to

significant ringing. When used as input capacitors, care

must be taken to ensure that ringing from inrush currents

and switching does not pose an overvoltage hazard to the

power switches and controller. High performance throughhole capacitors may also be used, but an additional

ceramic capacitor in parallel is recommended to reduce

the effect of their lead inductance.

Top MOSFET Driver Supply (CB, DB)

An external bootstrap capacitor CB connected to the BOOST

pin supplies the gate drive voltage for the topside MOSFET.

This capacitor is charged through diode DB from INTV

CC

when the switch node is low. When the top MOSFET turns

on, the switch node rises to VIN and the BOOST pin rises

to approximately VIN + INTVCC. The boost capacitor needs

to store about 100 times the gate charge required by the

top MOSFET. In most applications 0.1µF to 0.47µF is

adequate.

Discontinuous Mode Operation and FCB Pin

The FCB pin determines whether the bottom MOSFET

remains on when current reverses in the inductor. Tying

this pin above its 0.6V threshold (typically to INTVCC)

enables discontinuous operation where the bottom

MOSFET turns off when inductor current reverses. The

load current at which current reverses and discontinuous

operation begins, depends on the amplitude of the inductor ripple current. The ripple current depends on the

choice of inductor value and operating frequency as well

as the input and output voltages.

Tying the FCB pin below the 0.6V threshold forces continuous synchronous operation, allowing current to reverse at

light loads.

In addition to providing a logic input to force continuous

operation, the FCB pin provides a means to maintain a

flyback winding output when the primary is operating in

discontinuous mode. The secondary output V

SEC

is normally set as shown in Figure 5 by the turns ratio N of the

transformer. However, if the controller goes into discontinuous mode and halts switching due to a light primary

load current, then V

divider from V

V

SEC(MIN)

until V

SEC

VV

SEC MIN()

OPTIONAL

EXTV

CONNECTION

< 7V

5V < V

SEC

SEC

below which continuous operation is forced

has risen above its minimum.

.=+

06 1

CC

EXTV

R4

FCB

R3

SGND

will droop. An external resistor

SEC

to the FCB pin sets a minimum voltage

R

4

LTC3714

CC

SENSE

V

TG

SW

BG

PGND

R

3

V

IN

+

C

IN

IN

1N4148

V

C

OUT

3714 F05

C

1µF

SEC

SEC

V

OUT

•

T1

1:N

+

•

+

Figure 5. Secondary Output Loop and EXTVCC Connection

15

3714f

LTC3714

WUUU

APPLICATIO S I FOR ATIO

Fault Conditions: Current Limit and Foldback

The maximum inductor current is inherently limited in a

current mode controller by the maximum sense voltage. In

the LTC3714, the maximum sense voltage is controlled by

the voltage on the V

pin. With valley current control,

RNG

the maximum sense voltage and the sense resistance

determine the maximum allowed inductor valley current.

The corresponding output current limit is:

V

SNS MAX

I

=+∆

LIMIT

()

R

* ρ

DS ON T

()

1

I

L

2

The current limit value should be checked to ensure that

I

LIMIT(MIN)

> I

OUT(MAX)

. The minimum value of current limit

generally occurs with the lowest VIN at the highest ambient

temperature. Note that it is important to check for selfconsistency between the assumed junction temperature

and the resulting value of I

which heats the MOSFET

LIMIT

switches.

Caution should be used when setting the current limit

based upon the R

of the MOSFETs. The maximum

DS(ON)

current limit is determined by the minimum MOSFET onresistance. Data sheets typically specify nominal and

maximum values for R

reasonable assumption is that the minimum R

, but not a minimum. A

DS(ON)

DS(ON)

lies

the same amount below the typical value as the maximum

lies above it. Consult the MOSFET manufacturer for further

guidelines.

To further limit current in the event of a short circuit to

ground, the LTC3714 includes foldback current limiting. If

the output falls by more than 50%, then the maximum

sense voltage is progressively lowered to about one sixth

of its full value.

Minimum Off-Time and Dropout Operation

The minimum off-time t

OFF(MIN)

is the smallest amount of

time that the LTC3714 is capable of turning on the bottom

MOSFET, tripping the current comparator and turning the

MOSFET back off. This time is generally about 250ns. The

minimum off-time limit imposes a maximum duty cycle of

tON/(tON + t

OFF(MIN)

). If the maximum duty cycle is reached,

due to a dropping input voltage for example, then the

output will drop out of regulation. The minimum input

voltage to avoid dropout is:

tt

+

VV

IN MIN OUT

=

()

ON OFF MIN

t

ON

()

Output Voltage Programming

The output voltage is digitally set to levels between 0.6V

and 1.75V using the voltage identification (VID) inputs

VID0-VID4. An internal 5-bit DAC configured as a precision resistive voltage divider sets the output voltage in

increments according to Table 1. The VID codes are

compatible with Intel Mobile Pentium® III processor specifications. Each VID input is pulled up by an internal 2.5µA

current source from the INTVCC supply and includes a

series diode to prevent damage from VID inputs that

exceed the supply.

*Use R

value here if a sense resistor is connected between SENSE and PGND.

SENSE

16

3714f

WUUU

APPLICATIO S I FOR ATIO

LTC3714

INTVCC Regulator

An internal P-channel low dropout regulator produces the

5V supply that powers the drivers and internal circuitry

within the LTC3714. The INTVCC pin can supply up to

50mA RMS and must be bypassed to ground with a

minimum of 4.7µF tantalum or other low ESR capacitor.

Good bypassing is necessary to supply the high transient

currents required by the MOSFET gate drivers. Applications using large MOSFETs with a high input voltage and

high frequency of operation may cause the LTC3714 to

exceed its maximum junction temperature rating or RMS

current rating. Most of the supply current drives the

MOSFET gates unless an external EXTVCC source is used.

In continuous mode operation, this current is I

f(Q

g(TOP)

+ Q

). The junction temperature can be

g(BOT)

GATECHG

=

estimated from the equations given in Note 2 of the

Electrical Characteristics. For example, the LTC3714EG is

limited to less than 14mA from a 30V supply:

TJ = 70°C + (14mA)(30V)(130°C/W) = 125°C

For larger currents, consider using an external supply with

the EXTVCC pin.

Table 1. VID Output Voltage Programming

VID4 VID3 VID2 VID1 VID0 V

000001.75V

000011.70V

000101.65V

000111.60V

001001.55V

001011.50V

001101.45V

001111.40V

010001.35V

010011.30V

010101.25V

010111.20V

011001.15V

011011.10V

011101.05V

01111 1.00V

100000.975V

100010.950V

100100.925V

100110.900V

101000.875V

101010.850V

101100.825V

101110.800V

110000.775V

110010.750V

110100.725V

110110.700V

111000.675V

111010.650V

111100.625V

11111 0.600V

OUT

(V)

3714f

17

LTC3714

WUUU

APPLICATIO S I FOR ATIO

EXTVCC Connection

The EXTVCC pin can be used to provide MOSFET gate drive

and control power from the output or another external

source during normal operation. Whenever the EXTV

CC

pin is above 4.7V the internal 5V regulator is shut off and

an internal 50mA P-channel switch connects the EXTV

CC

pin to INTVCC. INTVCC power is supplied from EXTVCC until

this pin drops below 4.5V. Do not apply more than 7V to

the EXTVCC pin and ensure that EXTVCC ≤ VIN. The following list summarizes the possible connections for EXTVCC:

1. EXTVCC grounded. INTV

is always powered from the

CC

internal 5V regulator.

2. EXTVCC connected to an external supply. A high efficiency supply compatible with the MOSFET gate drive

requirements (typically 5V) can improve overall

efficiency.

3. EXTVCC connected to an output derived boost network.

The low voltage output can be boosted using a charge

pump or flyback winding to greater than 4.7V. The system

will start-up using the internal linear regulator until the

boosted output supply is available.

External Gate Drive Buffers

The LTC3714 drivers are adequate for driving up to about

60nC into MOSFET switches with RMS currents of 50mA.

Applications with larger MOSFET switches or operating at

frequencies requiring greater RMS currents will benefit

from using external gate drive buffers such as the LTC1693.

Alternately, the external buffer circuit shown in Figure 6

can be used. Note that the bipolar devices reduce the

signal swing at the MOSFET gate, and benefit from increased EXTVCC voltage of about 6V.

10Ω

INTV

PGND

CC

Q3

FMMT619

Q4

FMMT720

GATE

OF M2

3714 F06

BOOST

Q1

FMMT619

10Ω

TG

Q2

FMMT720

SW

Figure 6. Optional External Gate Driver

GATE

OF M1

BG

18

3714f

WUUU

APPLICATIO S I FOR ATIO

LTC3714

Soft-Start and Latchoff with the RUN/SS Pin

The RUN/SS pin provides a means to shut down the

LTC3714 as well as a timer for soft-start and overcurrent

latchoff. Pulling the RUN/SS pin below 1.5V puts the

LTC3714 into a low quiescent current shutdown (IQ ≤

30µA). Releasing the pin allows an internal 1.2µA internal

current source to charge up the external timing capacitor

CSS. If RUN/SS has been pulled all the way to ground, there

is a delay before starting of about:

15

.

t

DELAY SS SS

V

=

12

CsFC

.

A

µ

13

./

=µ

()

When the voltage on RUN/SS reaches 1.5V, the LTC3714

begins operating with a clamp on ITH of approximately

0.9V. As the RUN/SS voltage rises to 3V, the clamp on I

TH

is raised until its full 2.4V range is available. This takes an

additional 1.3s/µF, during which the load current is folded

back until the output reaches 50% of its final value. The pin

can be driven from logic as shown in Figure 7. Diode D1

reduces the start delay while allowing CSS to charge up

slowly for the soft-start function.

After the controller has been started and given adequate

time to charge up the output capacitor, CSS is used as a

short-circuit timer. After the RUN/SS pin charges above

4V, if the output voltage falls below 75% of its regulated

value, then a short-circuit fault is assumed. A 1.7µA cur-

rent then begins discharging CSS. If the fault condition

persists until the RUN/SS pin drops to 3.5V, then the con-

troller turns off both power MOSFETs, shutting down the

converter permanently. The RUN/SS pin must be actively

pulled down to ground in order to restart operation.

The overcurrent protection timer requires that the softstart timing capacitor CSS be made large enough to guarantee that the output is in regulation by the time CSS has

reached the 4V threshold. In general, this will depend upon

the size of the output capacitance, output voltage and load

current characteristic. A minimum soft-start capacitor can

be estimated from:

CSS > C

OUT VOUT RSENSE

(10–4 [F/Vs])

Generally 0.1µF is more than sufficient.

Overcurrent latchoff operation is not always needed or

desired. Load current is already limited during a shortcircuit by the current foldback circuitry and latchoff

operation can prove annoying during troubleshooting.

The feature can be overridden by adding a pull-up current

of >5µA to the RUN/SS pin. The additional current prevents the discharge of CSS during a fault and also shortens

the soft-start period. Using a resistor to VIN as shown in

Figure 7a is simple, but slightly increases shutdown

current. Connecting a resistor to INTVCC as shown in

Figure 7b eliminates the additional shutdown current, but

requires a diode to isolate CSS. Any pull-up network must

be able to pull RUN/SS above the 4.5V maximum threshold that arms the latchoff circuit and overcome the 4µA

maximum discharge current.

INTV

CC

V

3.3V OR 5V RUN/SS

Figure 7. RUN/SS Pin Interfacing with Latchoff Defeated

IN

RSS*

D1

C

SS

*OPTIONAL TO OVERRIDE

OVERCURRENT LATCHOFF

(7a) (7b)

RSS*

D2*

RUN/SS

C

SS

3714 F07

3714f

19

LTC3714

WUUU

APPLICATIO S I FOR ATIO

Efficiency Considerations

The percent efficiency of a switching regulator is equal to

the output power divided by the input power times 100%.

It is often useful to analyze individual losses to determine

what is limiting the efficiency and which change would

produce the most improvement. Although all dissipative

elements in the circuit produce losses, four main sources

account for most of the losses in LTC3714 circuits:

1. DC I2R losses. These arise from the resistances of the

MOSFETs, inductor and PC board traces and cause the

efficiency to drop at high output currents. In continuous

mode the average output current flows through L, but is

chopped between the top and bottom MOSFETs. If the two

MOSFETs have approximately the same R

resistance of one MOSFET can simply be summed with the

resistances of L and the board traces to obtain the DC I2R

loss. For example, if R

loss will range from 15mW up to 1.5W as the output

current varies from 1A to 10A for a 1.5V output.

2. Transition loss. This loss arises from the brief amount

of time the top MOSFET spends in the saturated region

during switch node transitions. It depends upon the input

voltage, load current, driver strength and MOSFET capacitance, among other factors. The loss is significant at input

voltages above 20V and can be estimated from:

Transition Loss ≅ (1.7A–1) V

3. INTVCC current. This is the sum of the MOSFET driver

and control currents. This loss can be reduced by supplying INTVCC current through the EXTVCC pin from a high

efficiency source, such as an output derived boost network or alternate supply if available.

4. CIN loss. The input capacitor has the difficult job of

filtering the large RMS input current to the regulator. It

must have a very low ESR to minimize the AC I2R loss and

sufficient capacitance to prevent the RMS current from

causing additional upstream losses in fuses or batteries.

Other losses, including C

conduction loss during dead time and inductor core loss

generally account for less than 2% additional loss.

= 0.01Ω and RL = 0.005Ω, the

DS(ON)

2

I

IN

OUT CRSS

ESR loss, Schottky diode D1

OUT

DS(ON)

f

, then the

When making any adjustments to improve efficiency, the

final arbiter is the total input current for the regulator at

your operating point. If you make a change and the input

current decreases, then you improved the efficiency. If

there is no change in input current, then there is no change

in efficiency.

Checking Transient Response

The regulator loop response can be checked by looking at

the load transient response. Switching regulators take

several cycles to respond to a step in load current. When

a load step occurs, V

equal to ∆I

resistance of C

discharge C

the regulator to return V

During this recovery time, V

overshoot or ringing that would indicate a stability problem. The ITH pin external components shown in Figure 8

will provide adequate compensation for most applications. For a detailed explanation of switching control loop

theory see Linear Technology Application Note 76.

Design Example

As a design example, take a supply with the following

specifications: VIN = 7V to 24V (15V nominal),

V

= 1.15V ±100mV, I

OUT

calculate the timing resistor with VON = V

R

=

ON

and choose the inductor for about 40% ripple current at

the maximum VIN:

L

300 0 4 15

()()()

Choosing a standard value of 0.68µH results in a maxi-

mum ripple current of:

∆=

L

(ESR), where ESR is the effective series

LOAD

OUT

generating a feedback error signal used by

OUT

kHz pF

300 10

()()

115

.

kHz A

115

kHz H

300 0 68

()

immediately shifts by an amount

OUT

. ∆I

1

V

.

V

.

.

()

also begins to charge or

LOAD

to its steady-state value.

OUT

can be monitored for

OUT

OUT(MAX)

µ

= 15A, f = 300kHz. First,

OUT

k

=

330

V

115

.

−

1

1

–

V

24

115

.

24

=µ

06

V

=I

V

:

.

54

.

H=

A

20

3714f

WUUU

P

VVVA

W

BOT

=

()

Ω

()

=

24 1 152420

2

16 0013 198

2

–.

.. .

APPLICATIO S I FOR ATIO

LTC3714

Next, choose the synchronous MOSFET switch. Because

of the narrow duty cycle and large current, a single SO-8

MOSFET will have difficulty dissipating the power lost in

the switch. Choosing two IRF7811s (R

C

= 60pF) yields a nominal sense voltage of:

RSS

V

SNS(NOM)

Tying V

= (15A)(0.5)(1.3)(0.013Ω) = 127mV

to INTVCC will set the current sense voltage

RNG

DS(ON)

= 0.013Ω,

range for a nominal value of 140mV with current limit

occurring at 186mV. To check if the current limit is

acceptable, assume a junction temperature of about 100°C

above a 50°C ambient with ρ

C

SS

0.1µF

R

100k

C

C1

R

2.2nF

C

20k

C

C2

100pF

C

0.01µF

ION

C

100pF

FB

R

ON

330k

150°C

PG

9

10

11

12

13

14

19

21

22

20

23

24

15

16

= 1.6:

VID2

RUN/SS

V

ON

PGOOD

V

RNG

I

TH

LTC3714

SGND

I

ON

V

FB

FCB

V

OSENSE

VID3

OPV

IN

–

OP

VID1

VID0

BOOST

SW

SENSE

PGND

INTV

EXTV

VID4

OPOUT

OP

8

7

C

B

0.33µF

C

VCC

4.7µF

CMDSH-3

C

0.1µF

6

5

TG

4

3

2

1

BG

28

CC

27

V

IN

26

5V

CC

25

18

17

+

I

LIMIT

≥

186

05 16 0013

...

()()

()

Ω

1

+

AA

=

54 20

.

()

2

mV

and double check the assumed TJ in the MOSFET:

TJ = 50°C + (1.98W)(50°C/W) = 149°C

D

B

V

IN

7V TO 24V

C

IN

M1

IRF7811

M2

IRF7811

×2

R

F

1Ω

F

L1

0.68µH

D1

UPS840

22µF

25V

×3

C

OUT

270µF

2V

×5

V

OUT

1.15V

15A

: UNITED CHEMICON THCR70EIH226ZT

C

IN

: PANASONIC EEFUE0D271

C

OUT

L1: SUMIDA CEP125-4712-T007

Figure 8. CPU Core Voltage Regulator 1.15V/15A at 300kHz without Active Voltage Positioning

3714 F08

3714f

21

LTC3714

WUUU

APPLICATIO S I FOR ATIO

Because the top MOSFET is on for such a short time, a

single IRF7811 will be sufficient. Checking its power

dissipation at current limit with ρ

.

115

P

=

TOP

()( )( )( )( )

TJ = 50°C + (0.652W)(50°C/W) = 82.6°C

The junction temperatures will be significantly less at

nominal current, but this analysis shows that careful

attention to heat sinking will be necessary in this circuit.

CIN is chosen for an RMS current rating of about 6A at

temperature. The output capacitors are chosen for a low

ESR of 0.005Ω to minimize output voltage changes due to

inductor ripple current and load steps. The ripple voltage

will be only:

∆V

OUT(RIPPLE)

= 27mV

However, a 0A to 15A load step will cause an output

change of up to:

∆V

OUT(STEP)

The complete circuit is shown in Figure 8.

V

24

V

.

1 7 24 20 60 300

...

=+=

0 299 0 353 0 652

= ∆I

2

20 1 2 0 013

()()

2

V A pF kHz

WWW

= ∆I

LOAD

..

A

L(MAX)

()

(ESR) = (5.4A) (0.005Ω)

(ESR) = (15A) (0.005Ω) = ±75mV

80°C

= 1.2:

Ω

+

1

∆=

OUT STEP()

By positioning the output voltage 60mV above the regulation point at no load, it will drop 65mV below the regulation

point after the load step. However, when the load disappears or the output is stepped from 15A to 0A, the 65mV

is recovered. This way, a total of 65mV change is observed

on V

150mV is seen on V

Implementing active voltage positioning requires setting a

precise gain between the sensed current and the output

voltage. Because of the variability of MOSFET on-resistance, it is prudent to use a sense resistor with active

voltage positioning. In order to minimize power lost in this

resistor, a low value of 0.003Ω is chosen. The nominal

sense voltage will now be:

To maintain a reasonable current limit, the voltage on the

V

INTVCC and GND, corresponding to a 50mV nominal sense

voltage.

Next, the gain of the LTC3714 error amplifier must be

determined. The change in ITH voltage for a corresponding

change in the output current is:

in all conditions, whereas a total of ±75mV or

OUT

V

SNS(NOM)

pin is reduced to 0.5V by connecting it between

RNG

()

OUT

= (0.003Ω)(15A) = 45mV

()

3

without voltage positioning.

Ω

.15

0 025 125

=VA mV

Active Voltage Positioning

Active voltage positioning (also termed load “deregulation” or droop) describes a technique where the output

voltage varies with load in a controlled manner. It is useful

in applications where rapid load steps are the main cause

of error in the output voltage. By positioning the output

voltage at or above the regulation point at zero load, and

below the regulation point at full load, one can use more

of the error budget for the load step. This allows one to

reduce the number of output capacitors by relaxing the

ESR requirement.

In the design example, Figure 8, five 0.025Ω capacitors

are required in parallel to keep the output voltage within

tolerance. Using active voltage positioning, the same

specification can be met with only three capacitors. In this

case, the load step will cause an output voltage change of:

22

∆=

The corresponding change in the output voltage is determined by the gain of the error amplifier and feedback

divider. The LTC3714 error amplifier has a

transconductance gm that is constant over both temperature and a wide ± 40mV input range. Thus, by connecting

a load resistance RVP to the ITH pin, the error amplifier gain

can be precisely set for accurate voltage positioning.

∆=

I

TH

=

()

TH m VP

12

V

RI

V

RNG

24 0 003 15 1 08..

()()

06.

V

∆

SENSE OUT

Ω

AV

V

∆IgR

V

OUT

OUT

=

3714f

WUUU

APPLICATIO S I FOR ATIO

LTC3714

Solving for this resistance value:

VI

∆

R

VP

==

OUT TH

=

Vg V

(. )

06

(. )(. )( )

06 17 60

∆

m OUT

VV

(. )(. )

115 108

VmSmV

.

20 3

k

The gain setting resistance RVP is implemented with two

resistors, R

connected from ITH to ground and R

VP1

VP2

connected from ITH to INTVCC. The parallel combination of

these resistors must equal RVP and their ratio determines

0.1µF

R

RNG1

10k

2.2nF

C

9

C

SS

R

RNG2

90.1k

C

C1

R

C

20k

0.01µF

ION

R

ON

330k

R

VP2

185k

R

VP1

23k

C

INTV

100pF

FB

CC

0.1µF

R

PG

100k

C

100pF

VID2

10

RUN/SS

11

V

ON

12

PGOOD

13

V

RNG

LTC3714

14

I

TH

C1

19

SGND

21

I

ON

22

V

FB

20

FCB

23

V

OSENSE

24

VID3

15

OPV

IN

16

–

OP

VID1

VID0

BOOST

SENSE

PGND

INTV

EXTV

VID4

OPOUT

OP

SW

BG

V

8

7

6

5

TG

4

3

2

1

28

CC

27

IN

26

5V

CC

25

18

17

+

nominal value of the ITH pin voltage when the error

amplifier input is zero. To set the beginning of the load line

at the regulation point, the ITH pin voltage must be set to

correspond to zero output current. The relation between

voltage and the output current is:

C

B

0.33µF

C

VCC

4.7µF

I

TH NOM

D

B

CMDSH-3

R

1Ω

C

F

0.1µF

=

=

055

=

F

12 1

V

RI I V

V

RNG

12

V

0 003 0

()

05

V

.

V

.

M1

IRF7811

0.68µH

M2

IRF7811

×2

R

SENSE

0.003Ω

SENSE OUT L()

AA V

Ω

.–..

L1

D1

UPS840

–.

∆

2

1

54 075

2

C

IN

10µF

25V

×3

C

OUT

270µF

2V

×3

075

+

+

V

IN

7V TO 24V

V

OUT

1.15V/15A

C

: UNITED CHEMICON THCR70EIH226ZT

IN

: PANASONIC EEFUE0D271

C

OUT

L1: SUMIDA CEP125-4712-T007

Figure 9. CPU Core Voltage Regulator with Active Voltage Positioning 1.15V/15A at 300kHz

3714 F08

3714f

23

LTC3714

WUUU

APPLICATIO S I FOR ATIO

Solving for the required values of the resistors:

V

R

==

VP

1

=

R

===

VP

2

5

VI

5

––.

TH NOM

k

23

V

55

I

TH NOM

()

R

()

R

VP

VP

055

.

V

+

V

C

IN

IN

–

–

C

V

OUT

OUT

+

V

5

VV

5055

20 3 185

.

20 3

kk

V

M1

M2

D1

.

The modified circuit is shown in Figure 9. Refer to Linear

Technology Design Solutions 10 for additional information about output voltage positioning.

k

PC Board Layout Checklist

When laying out the printed circuit board, use the following checklist to ensure proper operation of the controller.

C

VCC

LTC3714

1

BG

PGND

2

3

SENSE

D

B

4

SW

INTV

EXTV

V

VID4

28

CC

27

IN

26

CC

25

C

F

R

F

R

ON

C

C

BOLD LINES INDICATE HIGH CURRENT PATHS

Figure 10. LTC3714 Layout Diagram

V

OSENSE

SGND

OPOUT

OPV

VID3

V

I

FCB

OP

OP

24

23

22

FB

21

ON

20

19

18

17

+

16

–

15

IN

C

ION

C

3714 F10

FB

5

10

11

12

13

14

6

7

8

9

C

TG

BOOST

VID0

VID1

VID2

RUN/SS

V

ON

PGOOD

V

RNG

I

TH

C2

C

B

SS

C1

R

C

24

3714f

WUUU

APPLICATIO S I FOR ATIO

LTC3714

These items are also illustrated in Figures 10 and 11.

• Segregate the signal and power grounds. All small

signal components should return to the SGND pin at

one point which is then tied to the PGND pin close to the

source of M2.

• Place M2 as close to the controller as possible, keeping

the PGND, BG and SENSE traces short.

•

Connect the input capacitor(s) CIN close to the power

MOSFETs. This capacitor carries the MOSFET AC

current.

V

IN

C

IN

C

IN

C

IN

C

IN

SW

• Keep the high dV/dT SW, BOOST and TG nodes away

from sensitive small-signal nodes.

• Connect the INTVCC decoupling capacitor C

VCC

closely

to the INTVCC and PGND pins.

• Connect the top driver boost capacitor CB closely to the

BOOST and SW pins.

• Connect the VIN pin decoupling capacitor CF closely to

the VIN and PGND pins.

• VID0-VID4 interface circuitry must return to SGND.

TO PGND

(PIN 2)

R

SENSE

PGND

M1 M2

C

OUT

SENSE

PGND

C

OUTCOUTCOUT

V

OUT

M1

D1

M2

M2

L1

Figure 11. General Layout of External Power Components

TO SENSE

(PIN 3)

3714 F11

3714f

25

LTC3714

TYPICAL APPLICATIO

Performance Data for Intel Compatible Mobile Microprocessor Power Supply with Active Voltage Positioning

U

Line Transient Reponse from VIN = 9V to 17V Load Transient Reponse for I

V

IN

5V/DIV

V

OUT

50mV/DIV

AC COUPLED

50µs/DIV

3714 TA02

20µs/DIV

Efficiency

95

V

= 1.35V

OUT

90

85

80

EFFICIENCY (%)

VIN = 8.5V

VIN = 15V

VIN = 24V

= 8A to 23A

OUT

3714 TA03

1.395V

V

OUT

(1.35V)

50mV/DIV

1.213V

23A

I

LOAD

10A/DIV

8A

26

75

70

0 3 6 9 12 15 18 21

LOAD CURRENT (A)

3714 TA04

3714f

TYPICAL APPLICATIO

Transmeta CrusoeTM Microprocessor Power Supply with Active Voltage Positioning

3.3V

VRON

V

R22

100k

1k

3.3V

IN

V

OUT

V

IN

POWER GOOD

2k

DPSLP

BAT54C

START

1µF

100Ω

10k

0.1µF

220pF

0.1µF

U

INTV

0.01µF

820pF

13k 1%

1000pF

100pF

1M

1k

CC

3.2k

20k

10k

80.6k 1%

330k

200k

BAT54

BAT54

VID3

200k

START

VID2

U1 LTC3714EG

9

VID2

10

RUN/SS

11

V

ON

12

PGOOD

13

V

RNG

LTC3714EG

14

I

TH

19

SGND

20

FCB

21

I

ON

22

V

FB

23

V

OSENSE

24

VID3

18

OPOUT

15

OPV

IN

0.01µF

100k

1%

DPSLP

BOOST

SENSE

PGND

INTV

EXTV

VID1

VID0

SW

VID4

OP

OP

TG

BG

CC

V

IN

CC

+

–

VID1 VID0 3.3V

CMDSH-3

5V

0.22µF

1Ω

453k

1%

75k

1%

200k

200k

4.7µF

0.1µF

200k

8

7

6

5

4

3

2

1

28

27

25

26

17

16

LTC3714

V

IN

C

IN

IRF7811

L1

1.8µH

IRF7811

0.005Ω

V

IN

3.3V

VID4

V

OUT

MBRS340

10µF

35V

×2

+

C

OUT

270µF

2V

×2

5V TO 24V

V

OUT

0.6V To 1.75V

8A

1µF

6.3V

3714 TA01

PACKAGE DESCRIPTIO

5.20 – 5.38**