L DESIGN FEATURES

NDRV

GNDPGNDVSLMT

UVLO

LTC3725

Q1

FDC2512

D1

CMPSH1-4

GATE IS

T2

183,4

5,6

1µF

162k

L1: VISHAY IHLP2525CZER0M01

L2: PULSE PA1294.910

33nF

0.03Ω

1W

HAT2165H

×2

HAT2165H

×2

T1

23.4mm × 20.1mm × 9.4mm

PLANAR

• •

• •

V

CC

33nF

15k

365k

100k

1µF

SSFLT

FB/IN

+

FS/IN

–

V

IN

+

36V

TO

72V

V

IN

–

L1

1µH

470pF

47nF

3.3k

2.2µF

FG SW IS–IS

+

1nF

2.2nF

200V

0.0012Ω

2W

SG VINNDRV

Q2

FCX491A

V

CC

GND PGND

REGSD PHASE

SLP

MODE

PT

+

PT

–

FS

FB

RUN/SS

LTC3706

ITH

2.74k

604Ω

10µF

100µF

6.3V

×2

220µF

6.3V

100k

V

OUT

+

3.3V

30A

V

OUT

–

0.1µF

5.1k

••

L2

0.85µH

1µF

100V

1µF

100V

×2

Si7450DP

5

2

4

3

10

11

7

9

1.2Ω

1/4W

T1: PULSE PA0815 (6:6:2:1)

T2: PULSE PA0297 (2:1:1)

+

VCC, PRI

VCC, SEC

V

GATE

LOAD CURRENT (A)

5

EFFICIENCY (%)

90

48V

72V

36V

92

94

25

88

86

84

10

15

20

30

Isolated Forward Controllers Offer

Buck Simplicity and Performance

Introduction

Buck converter designers have long

benefited from the simplicity, high

efficiency and fast transient response

made possible by the latest buck

controller ICs, which feature synchronous rectification and PolyPhase®

operat i o n. Unfortunately, these

same features have been difficult or

impossible to implement in the buck

converter’s close relative, the forward

converter. That is, until now. The

LTC3706/26 secondary-side synchronous controller and its companion

smart gate driver, the LTC3705/25,

make it possible to create an isolated

forward converter with the simplicity

and performance of the familiar buck

converter.

The Benefits of SecondarySide Control Made Accessible

Many isolated supplies place the

controller IC on the input (primary)

side and rely on indirect synchronous

by Charles Hawkes and Arthur Kelley

rectifier timing and optoisolator feedback to control the output (secondary).

This architecture is commonly known

as primary-side control. By contrast,

secondary-side control places the

controller IC on the secondary side,

and uses a gate-drive transformer

to directly control the primary-side

MOSFETs. This approach eliminates

the need for an optoisolator and

puts the controller where it is really

needed: with the load. This results in

a significantly faster response, taming

large-signal overshoot and reducing

output capacitance requirements.

In addition, secondary-side control

simplifies the design of the loop compensation to that of a simple buck

converter.

With the apparent advantages of

secondary-side control, why is it not

used in more isolated applications?

This is primarily because of the need

for a separate bias supply to power

up the controller on the secondary

side, since there is initially no voltage

present there. With the introduction

of the LTC3706/26 and LTC3705/25,

however, this barrier has now been

completely eliminated. All of the complex issues associated with start-up

and fault monitoring in a secondaryside control forward converter have

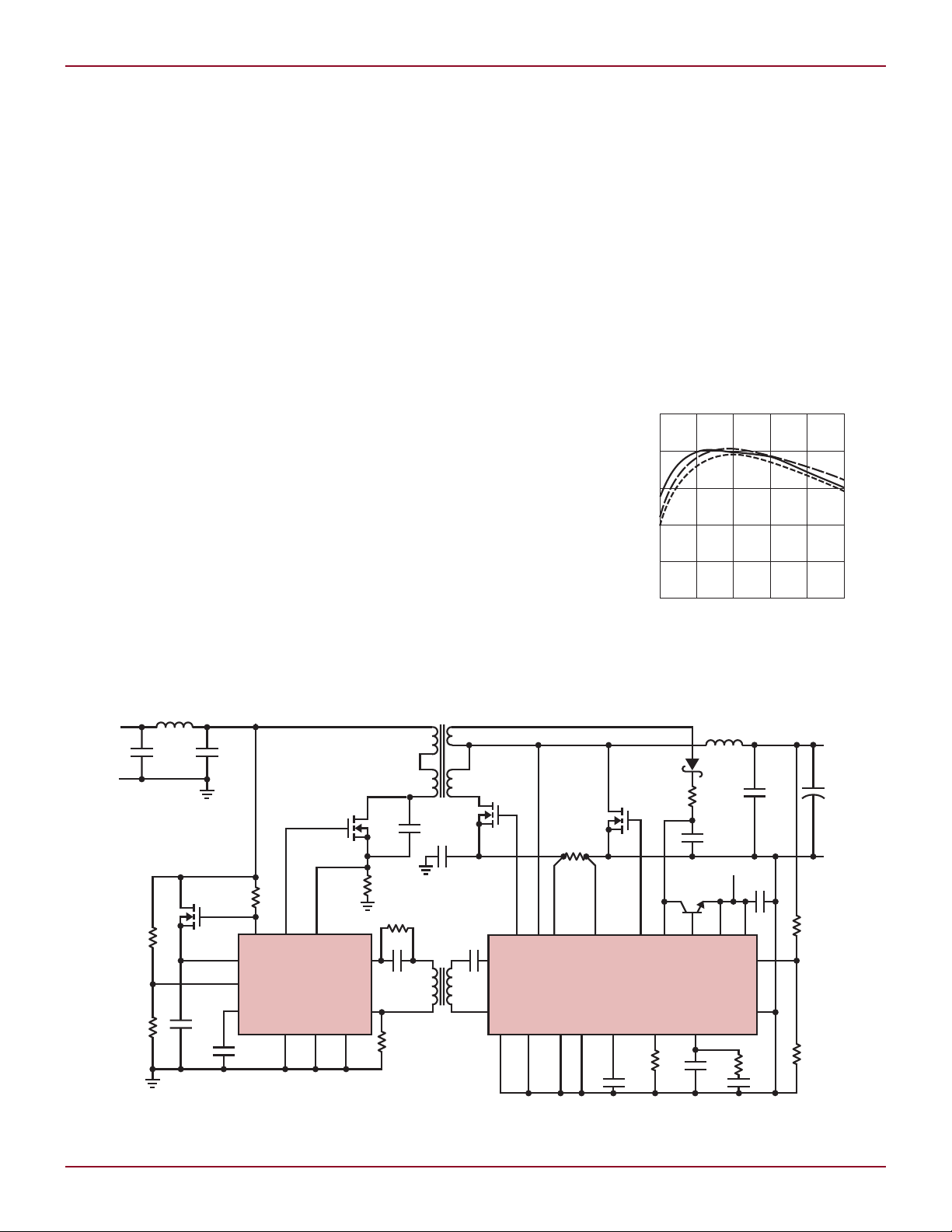

Figure 2. Efficiency of the converter

shown in Figure 1

10

Figure 1. Complete 100W single-switch high efficiency, low cost, minimum part count, isolated

telecom converter. Other output voltages and power levels require only simple component changes.

Linear Technology Magazine • March 2007

DESIGN FEATURES L

NDRV

GND PGND VSLMT

UVLO

BOOST

LTC3705

BAS21

FQT7N10

0.22µF

10µF

25V

CMPSH1-4

1.2Ω

L1

1.2µH

TG TS BG IS

T2

1µF

162k

L1: COILCRAFT SER2010-122

T1: PULSE PA0807

T2: PULSE PA0297

33nF

30mΩ

1W

2mΩ

2W

Si7336ADP

Si7336ADP

×2

T1

••

MURS120

Si7852DP

Si7852DP

MURS120

V

CC

33nF

15k

1%

365k

1%

100k

2.2µF

25V

SS/FLT

FB/IN

+

FS/IN

–

V

IN

–

V

IN

+

330µF

6.3V

×3

2.2µF

16V

680pF

CZT3019

22.6k

1%

20k

102k

1%

V

OUT

–

V

OUT

+

••

1µF

100V

x3

FG SW SG VINNDRV V

CC

GND PGND PHASE SLP MODE REGSD

PT

+

I

S

+

I

S

–

PT

–

RUN/SS

LTC3706

ITH

FB

FS/SYNC

been seamlessly integrated into these

powerful new products. Moreover, a

proprietary scheme is used to multiplex gate drive signals and DC bias

power across the isolation barrier

through a single, tiny pulse transformer. This eliminates the primary-side

bias winding that is otherwise needed.

The result is an isolated supply that

has been architected from the ground

up to achieve unprecedented simplicity

and performance. Figure 1 illustrates

how this remarkable new architecture

is used to make a complete 100W forward converter with minimal design

effort and complexity.

Family of Products Supports

Single or Dual Switch

Topologies

Ta ble 1 s u mm a ri zes how the

LTC3706/26 and LTC3705/25 products can be combined to cover a broad

range of applications. The LTC3706

is a full-featured product available

in a 24-lead SSOP package. For high

precision applications, the LTC3706

includes a 1% accuracy output voltage,

a remote-sense differential amplifier

and a power good output voltage monitor. The high voltage linear regulator

controller simplifies the design of the

bias supply, and PLL frequency synchronization with selectable phase

angle enables PolyPhase operation

with up to twelve phases. In addition,

the flexible current-sense inputs allow

Table 1. LTC3705/06/25/26 combinations

LTC3706 LTC3726

LTC3705

LTC3725

Dual-Switch,

PolyPhase

Single-Switch,

PolyPhase

Dual-Switch,

Single Phase

Single-Switch,

Single Phase

for the use of either resistive or current transformer sensing techniques.

Protection features include an output

overvoltage crowbar as well as currentlimiting and over-current protection.

The 16-lead LTC3726 does not include

the remote voltage sensing or linear

regulator features, so it is more suitable for a single phase application.

Both the LTC3706 and the LTC3726

have a selectable maximum duty cycle

limit of either 75% or 50% to support a

single or dual-switch forward converter

application, respectively.

The LTC3725 primary driver is

intended for use in single-switch

forward converter. The LTC3725 includes a start-up linear regulator and

an integrated bridge rectifier for bias

generation. Protection features include

volt-second limit, over-current protection and a fault monitoring system that

detects a loss of encoded gate-drive

signal from the signal transformer.

The LTC3705 is a dual-switch forward

driver, and includes an 80V (100V

transient) high side gate driver. The

integration of this high side driver into

the LTC3705 greatly facilitates the use

of the simple and robust dual switch

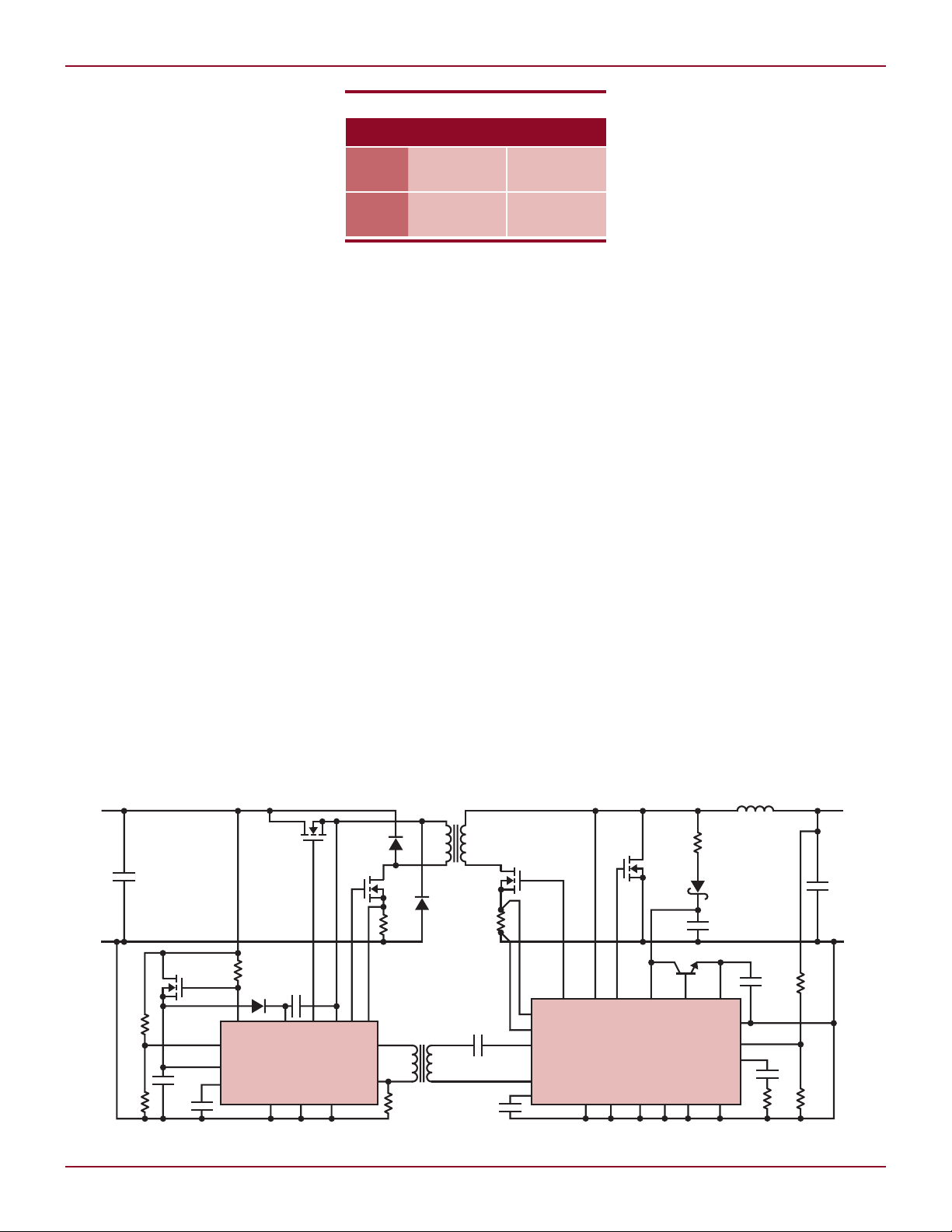

forward converter topology. Figure 3

shows a typical dual-switch converter

application using the LTC3705 and

the LTC3706.

Table 2 highlights some of the relative merits of using either single or dual

switch forward converter topologies.

In general, for applications that have

a limited input voltage variation, or

where a robust and simple design is

a priority, the dual-switch forward

converter may be preferred. For a wide

input voltage application (greater than

2:1), or whenever a lower cost or size

justifies the complication of the transformer reset design, a single-switch

forward should be used.

Bringing the Power of

PolyPhase to Isolated Supplies

The LTC3706/26 defies typical forward

converter limits by allowing simple

implementation of a PolyPhase current

share design. PolyPhase operation

allows two or more phase-interleaved

power stages to accurately share the

load. The advantages of PolyPhase

current sharing are numerous, including much improved efficiency, faster

transient response and reduced input

and output ripple.

The LTC3706/26 supports standard output voltages such as 5V, 12V,

28V and 52V as well as low voltages

down to 0.6V. Figure 4 shows how

11

Linear Technology Magazine • March 2007

Figure 3. Isolated forward converter for 36V–72V input to 3.3V/20A out

L DESIGN FEATURES

SSP

V

IN

+

V

IN

–

V

IN

+

V

IN

–

V

OUT

+

1.2V/100A

V

OUT

–

V

OUT

+

V

OUT

–

SYNC

LTC3705/LTC3706

36V-72VIN TO 1.2V

OUT

50A SUPPLY

ITH SSSV

BIAS

SSP

V

IN

+

V

IN

–

V

OUT

+

V

OUT

–

SYNC

LTC3705/LTC3706

36V-72VIN TO 1.2V

OUT

50A SUPPLY

ITH SSSV

BIAS

I

LOUT1

I

LOUT2

10A/DIV

10µs/DIV

V

OUT

0.5V/DIV

2ms/DIV

SECONDARY-SIDE MODE

PRIMARY-

SIDE MODE

V

IN

V

CCPRI

V

CCPRI

SUPPLIED BY Q1

V

GATE

CONTROLLED BY LTC3706

V

GATE

CONTROLLED BY LTC3725

V

CCPRI

SUPPLIED BY

TRANSFORMER T2

V

GATE

V

OUT

V

CC,SEC

V

PT+,VPT–

easy it is to parallel two 1.2V supplies

to achieve a 100A supply. Figure 5

shows excellent output inductor current tracking during a 0A to 100A load

current step and the smooth handoff

during start-up to secondary-side control at approximately V

= 0.25V.

OUT

Anatomy of a Start-Up:

A Simple Isolated 3.3V,

30A Forward Converter

The circuit of Figure 1 shows a

complete 100W, one-switch forward

converter. In this example, the

LTC3706 controller is used on the

secondary and the LTC3725 driver

with self-starting capability is used

on the primary. This design features

off-the-shelf magnetics and high efficiency (see Figure 2). The start-up

behavior of this supply is illustrated

in Figure 6. When input voltage is

first applied, the LTC3725 uses Q1

to generate a bias voltage V

begins a controlled soft-start of the

output voltage. As the output voltage

begins to rise, the LTC3706 secondary controller is quickly powered up

by using T1, D1 and Q2 to generate

V

V

. As shown in Figure 6, the

CC,SEC

voltage rises very quickly as

CC,SEC

compared with the output voltage

V

of the converter. The LTC3706

OUT

CC,PRI

, and

Table 2. Single and dual switch forward converter relative merits

Requirement Single-Switch Dual-Switch

Simple Design

Requires Design

Transformer Reset Circuit

to Prevent Saturation

Wide Input Supply Range

(>2:1)

High Efficiency

Low Switch Voltage Stress

Low Cost

Small Size

75% Max Duty

Good

Can be 2 × VIN or Greater

One FET

One FET and Better

Transformer Utilization

then assumes control of the output

voltage by sending encoded PWM gate

pulses to the LTC3725 primary driver

via signal transformer T2. As soon as

the LTC3725 begins decoding these

PWM gate pulses, it shuts down the

linear regulator by tying NDRV to VCC

and begins extracting bias power for

V

from the signal transformer T2.

CC,PRI

This complete transition from primary

to secondary control occurs seamlessly

at a fraction of the output voltage. From

–

+

Reset Circuit not

Required—Can’t Saturate

+

–

50% Max Duty

+

+

Good

–

+

+

Limited to V

–

IN

Two FETs

+

–

Two FETs and 50%

Transformer Utilization

that point on, operation and design

simplifies to that of a simple buck

converter. Even the design and optimization of the feedback loop makes use

of the familiar and proven OPTI-LOOP®

compensation techniques.

A 10V–30V Input, 15V Output

at 5A Forward Converter

Figure 7 highlights the flexibility of

the LTC3706 and LTC3725 by illustrating a 12V/24V input application.

Figure 4. Paralleling supplies for higher power operation

12

Figure 5. 1.2V, 100A load current step

(top trace) and start-up (bottom trace)

Figure 6. Anatomy of a start-up

Linear Technology Magazine • March 2007

DESIGN FEATURES L

NDRV

GND PGND VSLMT

UVLO

GATE

LTC3725

2.2nF

250VAC

C3

2.2nF

100V

220pF

200V

68pF

L1

13µH

10Ω

0.5W

150Ω

174Ω

IS

T2

1µF

68pF

68pF

162k

470pF

L1: PULSE PA1961.133

T1: PULSE PA0810

T2: PULSE PA0297

C1: NIPPON CHIMICON EMZA500ADA221MUA0G

C2: TAIYO YUDEN GMK325BJ106MN

C3: TAIYO YUDEN TMK325BJ106MM

C4: SANYO OSCON 16SVP180MX

Q1: FMMT38C

Q2: MMBFJ201

Q3: ZVN3320F

Q4: FDMS2572 ×2

Q5: FMMT 618

Q6: FMMT 718

Q7: MMBT 2907A

33nF

5mΩ

2W

6mΩ

1W

Si7852DP

Q7

Q5

Q4

Q6

T1

1:3

2:1

V

CC

68nF

383k

75k

Q1

R1

10k

1µF

25V

SS/FLT

FB/IN

+

FS/IN

–

V

IN

–

V

IN

+

C4

180µF

16V

C6

10µF

200V

C3

10µF

25V

×2

10µF

16V

R2

8.66k

1nF

470pF

FG SW SG VINNDRV V

CC

GND PGND PHASE SLP MODE REGSD

PT

+

I

S

+

I

S

–

PT

–

RUN/SS

LTC3706

ITH

100k

43.2k

1.07k

1%

25.5k

1%

V

OUT

–

V

OUT

+

330pF

33pF

D2 BAT54

C5

0.1µF

R3

33k

0.5W

D1

ES1C

FCX1051A

FB

FS/SYNC

0.1µF

1nF

••

C1

220µF

50V

×2

C2

10µF

35V

×5

100Ω100Ω

100Ω

5.1kΩ

301Ω

IRF6648

×2

Q3

100Ω

Q2

LOAD CURRENT (A)

0

85

90

95

4

2 6

75

80

EFFICIENCY (%)

VIN = 12V

VIN = 24V

V

OUT

200mV/DIV

I

OUT

5A/DIV

20µs/DIV

VIN = 12V

V

OUT

= 15V

LOAD STEP = 0A TO 5A

Figure 7. Isolated forward converter for 10V–30V input to 15V/5A out

In this circuit, the main transformer

T1 is used to step up the voltage so

that the output can be either higher

or lower than the input. This circuit

is an excellent alternative to a flyback

converter where higher efficiency or

lower noise is a priority.

The UVLO on the LTC3725 has been

set to turn on at V

V

= 7.5V, and a linear regulator (Q1)

IN

= 9.5V and off at

IN

is used to establish bias for start-up.

Note that the LTC3725 requires that

the NDRV pin be at least 1V above

the VCC pin for proper linear regulator

operation. To meet this requirement,

while providing the lowest possibly

dropout voltage, a darlington transistor is used (Q1). JFET Q2 is used to

provide adequate bias current for the

NDRV pin at low input voltage, while

limiting the maximum current seen at

high input voltage. R11 is needed to

prevent back-feeding of current from

the NDRV pin into base of Q1 (and

Linear Technology Magazine • March 2007

gate of Q2) during normal operation

when V

less than 12V.

On the secondary side, the output

voltage is used directly as a source

of bias voltage for the LTC3706. This

is possible for output voltages of 9V

or greater. Q3 is used to limit the

CC

= V

= 12V and VIN is

NDRV

peak voltage seen by the SW pin on

Figure 8. Transient response

of the circuit in Figure 7

the LTC3706, while still allowing the

detection circuits in the LTC3706 to

function normally. Capacitor C3 is

used to establish the resonant reset

of the main transformer T1 during the

off-time of the primary-side switches.

In order to reduce the inrush current

during start-up, D2, R2 and C5 are

continued on page 39

Figure 9. Efficiency of

the circuit in Figure 7

13

DESIGN IDEAS L

R1

200Ω

R3

200Ω

R4

200Ω

R2

200Ω

5V

PECL LEVELS

1/4 MC10H350

PECL-TTL TRANSLATOR

TTL OUTPUT

OUT

OPTION

700mV

PP

(DIFFERENTIAL)

MINIMUM

(INPUT

CIRCUITRY

OMITTED)

5V

OV

DD

OGND

+

–

LT6411

5V5V

LT1715

20µs/DIV

V

OUT

50mV/DIV

INDUCTOR

CURRENT

5A/DIV

Single-Ended Output

The LT6411 produces a differential

output, but if a single-ended logic

output is needed, there are multiple

options for data conversion. One such

way is shown in Figure 8, in which

the MC10H350 PECL-TTL translator

performs the conversion. To translate

the voltage levels from the LT6411 to

PECL input voltage levels, two resistive dividers level-shift and attenuate

the output signal of the LT6411. Alternatively, a high speed comparator

such as Linear Technology’s LT1715

can also perform this task without the

level-shifting resistors.

Conclusion

The LT6411 is a dual high speed amplifier with flexible features and superb

AC characteristics, making it suitable

for use as a high data rate receiver.

The ability to select different gain

configurations with minimal external

components makes the LT6411 easy

to use. Its small footprint and low

power consumption allow it to fit into

Figure 8. If a single-ended output is needed, there are many options available for translators.

One example is ON Semiconductor’s MC10H350 PECL-TTL translator. The 200Ω resistors shift

the output of the LT6411 up to PECL voltage levels. Alternatively, a level-translating comparator

such as the LT1715 could be used to give a variety of logic output levels.

almost any application without painful

compromises, especially for portable

or peripheral applications where space

and power are at a premium.

L

LT3740, continued from page 36

The LT3740 uses a valley mode current control system that boasts a fast

response to load changes. As shown

in Figure 3, this design responds to

0A–10A step load change in 10µs,

yielding a voltage transient of less

than 50mV.

Soft-Start

The LT3740 is also equipped with a

flexible soft-start design that allows for

either ramped current or tracking. If

the XREF pin is held above 1V, and an

RC timer is applied to the SHDN pin,

the converter soft-starts by ramping

the current available to the load. If the

SHDN pin is high, enabling the chip,

and a 0V to 0.8V tracking signal is

applied to the XREF pin, the internal

reference of the LT3740 follows the

tracking signal.

LTC3706/26, continued from page 13

used to provide a gradual increase

in peak current during the soft-start

interval. The circuit of Figure 7 also

includes an optional falling-edge delay

circuit on the gate of synchronous

switch Q4. This delay has been used

to optimize the dead time for this

specific application, thereby improving

Linear Technology Magazine • March 2007

Conclusion

The LT3740 is a synchronous buck

controller that boasts a rich feature set

which allows the designer to optimize

power and volumetric efficiency by exploiting the advantages of a low input

voltage. Through a combination of its

Figure 3. Output voltage and inductor current response to a

0A–10A step load transient applied to the circuit in Figure 1

the efficiency by about 1%. Figure 8

shows the transient response that is

achieved using the circuit of Figure 7,

and Figure 9 shows the efficiency at

V

IN

Conclusion

The new LTC3706/26 controller and

LTC3705/25 driver bring an un-

= 12V and V

= 24V.

IN

onboard boost regulator, user programmable current limit thresholds,

fast transient response and flexible

soft-start system, the designer can

produce a small, efficient, full featured

converter.

L

precedented level of simplicity and

performance to the design of isolated

power supplies. Each controller-driver

pair works in concert to offer high

efficiency, low cost solutions using

off-the-shelf components. The devices

are versatile and easy to use, covering

a broad range of forward converter

applications.

L

3939

Loading...

Loading...