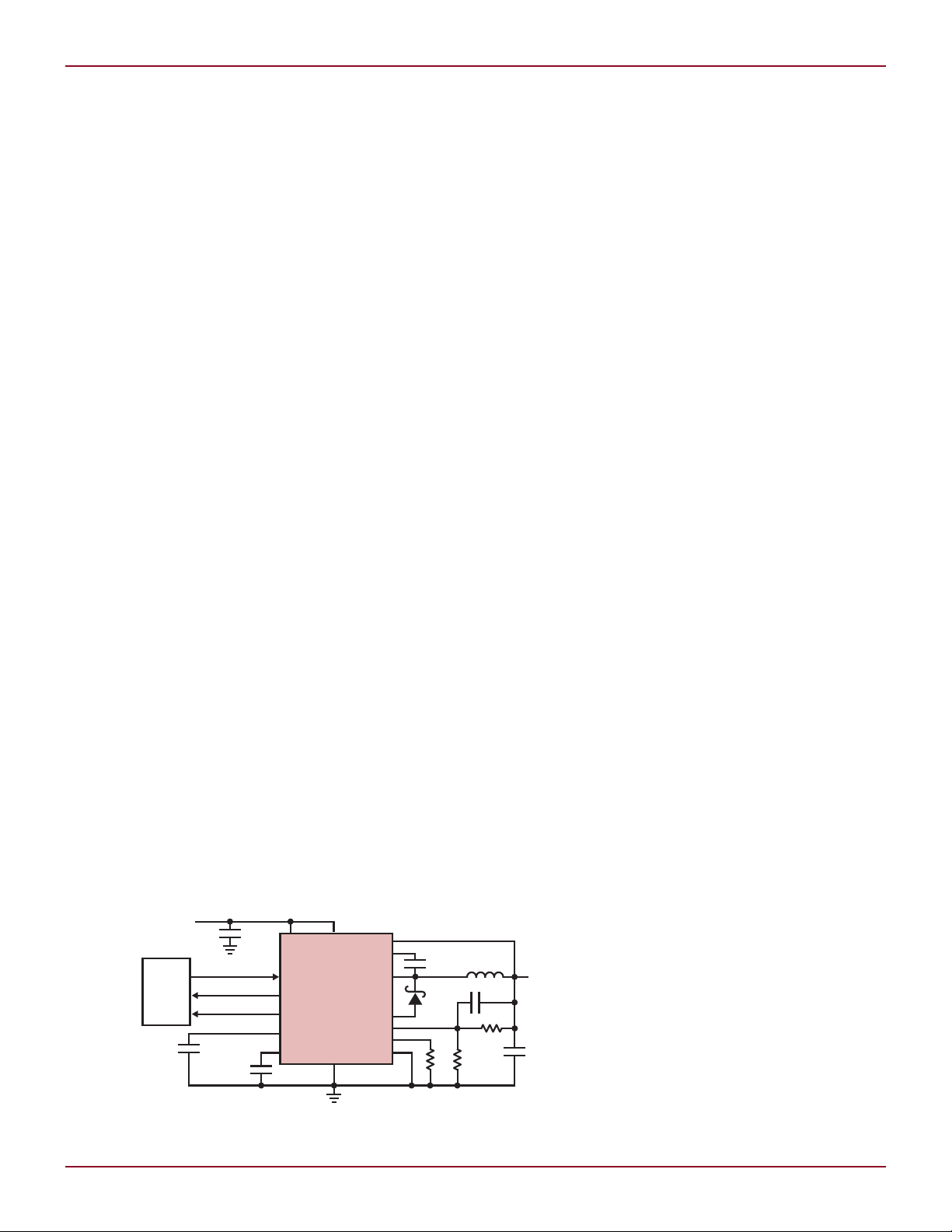

L DESIGN FEATURES

SWI/O

I/O

RESET

DA

FB

R

T

SYNC

fSW = 700kHz

WDI

RST

WDO

V

IN

µP

EN/UVLO

V

IN

4.5V TO 36V

TRANSIENT TO 60V

3.3V

800mA

100k

C

WDT

10nF

t

WDU

= 182ms

t

WDL

= 5.9ms

12µH

10pF

22µF

0.1µF

MBRM140

316k

GND

21k

LT3689

BST

OUT

C

POR

C

WDT

2.2µF

C

POR

68nF

t

RST

= 157ms

Industrial/Automotive Step-Down

Regulator Accepts 3.6V to 36V

and Includes Power-On Reset and

Watchdog Timer in 3mm × 3mm QFN

Introduction

As the number of microprocessors in

automotive and industrial applications continues to expand, so does the

need for rugged step-down regulators

that can operate over a wide input

voltage range and withstand high

voltage transients and output shorts.

Microprocessor-based applications

also require supervisory functions,

such as power-on reset (POR) and

watchdog timing, to ensure high system reliability. The regulator must

have high efficiency at light loads

to increase battery life. The LT3689

delivers all of these features in tiny

16-pin 3mm × 3mm QFN and 16-pin

MSOP packages.

Features of the LT3689

Step-Down Regulator

The LT3689 employs a constant frequency, current mode architecture to

provide 800mA of continuous output

current. The part operates from a

wide 3.6V to 36V input range and can

protect itself from input transients up

to 60V. It is internally compensated,

which helps to lower the external component count. The switching frequency

can be set anywhere between 350kHz

and 2.2MHz by tying a resistor from

24

Figure 1. LT3689 typical application circuit with reset time

set to 157ms and watchdog timeout period set to 182ms

the RT pin to ground, allowing the designer to optimize component size and

efficiency. The switching frequency can

also be synchronized to an external

clock for noise sensitive applications.

An external resistor divider programs

the output voltage to any value above

the part’s 0.8V reference. Also, the

boost diode is integrated into the IC

to minimize solution size and cost.

Figure 1 shows a typical application

of LT3689.

Soft-Start and Output

Short Circuit Protection

The LT3689 includes a soft-start feature that limits the maximum inrush

current during start-up and recovery

from fault conditions. The soft-start

circuit ramps up the peak switch

current limit in approximately 150µs,

reducing the peak input current.

The DA pin is used to monitor the

current in the catch diode. If the catch

diode current at the end of switch

cycle is higher than the DA current

limit then the part delays the switch

turn-on until the catch diode current

drops below the DA current limit. This

protects the LT3689 in the face of

inductor current runaway situations,

by Ramanjot Singh

especially during output overload or

short at high switching frequencies

with high input voltages and small

inductor values. Other protection

features such as frequency foldback,

cycle-by-cycle current limit, and thermal shutdown together ensure that

the part is not damaged by excessive

switch currents during startup, overload or short circuit.

Pin Selectable Modes of

Operation: Low Ripple

Burst Mode Operation

and Pulse-Skipping Mode

Two modes of operation can be selected

through the SYNC pin. Applying a logic

low to the SYNC pin enables the low

ripple Burst Mode® operation, which

maintains high efficiency at light loads

while keeping output ripple low. In

Burst Mode operation, the LT3689

delivers single cycle bursts of current

to the output capacitor followed by

sleep periods. Between bursts, all circuitry associated with controlling the

output switch is shutdown, reducing

the VIN pin and OUT pin currents in

a typical application to a mere 50µA

and 75µA, respectively. As the load

current decreases to a no load condition, the percentage of sleep time

increases, thus decreasing average

input current.

A logic high on SYNC disables Burst

Mode operation, allowing the part to

skip pulses at light loads. The advantage of this pulse-skipping mode over

Burst Mode operation is that the part

continues to switch at the programmed

frequency (set by RT) down to very low

load currents, above 15mA at 12V

in a typical application.

Linear Technology Magazine • March 2009

IN

DESIGN FEATURES L

POR COMPARATOR OVERDRIVE VOLTAGE AS PERCENTAGE

OF RESET THRESHOLD, V

RST

(%)

0.10

400

TRANSIENT DURATION (µs)

500

600

700

800

1.00 10.00 100.00

300

200

100

0

RESET OCCURS

ABOVE THE CURVE

50ms/DIV

V

OUT

2V/DIV

C

POR

1V/DIV

RST

2V/DIV

t

RST

= 165ms

C

POR

= 71.3nF

Programmable

Undervoltage Lockout

The LT3689 can be shutdown by pulling the EN/UVLO pin below 0.3V. In

shutdown, quiescent current is less

than 0.5µA. The EN/UVLO pin can

also be used to perform an accurate

undervoltage lockout (UVLO) function.

A resistor divider from VIN pin can be

used to program the UVLO threshold

of the circuit using the 1.26V accurate

threshold of the EN/UVLO pin. A 4µA

current hysteresis on this pin is also

provided to allow the user to program

desired voltage hysteresis. The LT3689

also has an internal UVLO that prevents the part from switching if VIN

pin ever goes below 3.3V (typical). The

part only starts switching when VIN is

higher than 3.4V and EN/UVLO pin

is above the 1.26V threshold.

Low Dropout

The LT3689 features low dropout for

output voltages above 3V. The minimum operating voltage of the device

is determined either by the LT3689’s

internal undervoltage lockout or

by its maximum duty cycle. Unlike

many buck regulators, the LT3689

can extend its duty cycle by staying

on for multiple cycles, provided that

the boost capacitor is charged above

the minimum voltage of 2.5V. Eventually, after several switching cycles, the

boost capacitor discharges. Internal

circuitry detects this condition and

charges the boost capacitor only when

needed. Also, a bigger boost capacitor

allows even higher duty cycle, allowing extremely low dropout operation.

The dropout voltage for a 5V typical

application is about 400mV at 200mA

load and 900mV at 800mA load.

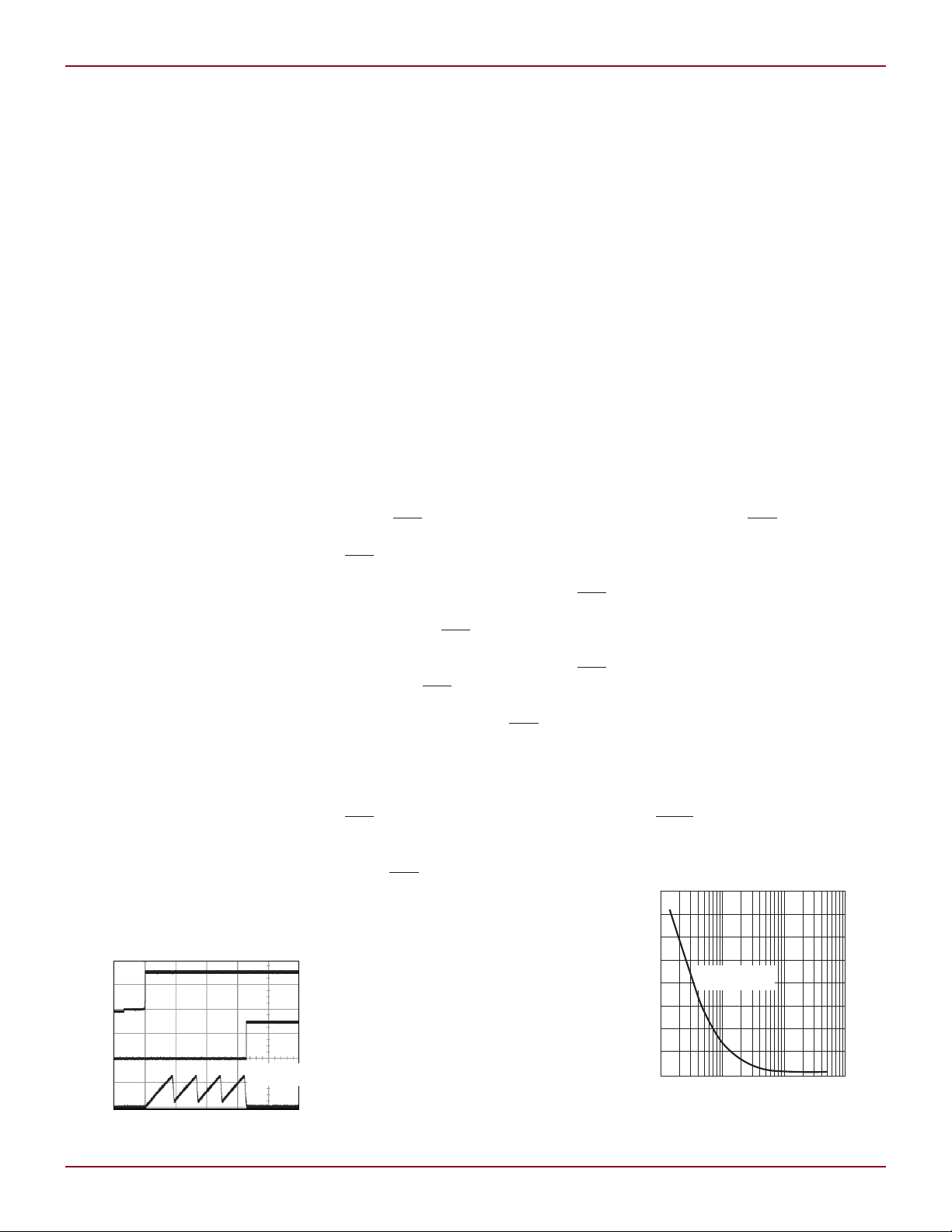

Figure 2. Power-on reset feature of LT3689

Linear Technology Magazine • March 2009

Power-On Reset (POR)

Many microprocessor -based applications powered by the output

of a switching regulator must know

when the regulator output is ready

and stable before the microprocessor

starts operating. Likewise, once running, the electronic system must be

warned when the regulator output has

dropped below a minimum tolerable

threshold, such as during overload or

shutdown conditions. This is required

to prevent unreliable operation and to

allow the microprocessor to perform

housekeeping operations before power

is completely lost.

The LT3689’s accurate internal

voltage reference and glitch immune

precision POR comparator and timer

circuit feed these specific needs of

microprocessor -based applications.

The switcher’s output voltage must

be above 90% of programmed value

for its RST pin to remain high (refer

to Figure 2). The LT3689 asserts

RST during power-up, power-down

and brown-out conditions. Once the

output voltage rises above the RST

threshold, the adjustable reset timer

is started and RST is released after the

reset timeout period. On power-down,

once output voltage drops below RST

threshold, RST is held at a logic low.

The reset timer is adjustable using an

external capacitor. The RST pin has a

weak pull up to the OUT pin.

The POR comparator is designed to

avoid false triggering. High frequency

noise on the FB pin can falsely trip

RST, particularly when the monitored

output is already near the reset threshold. This can cause oscillatory behavior

at the RST pin. The traditional way of

tackling this problem is to add some

DC hysteresis in the comparator input,

which changes the threshold point

once the output flips. The problem

is that the addition of DC hysteresis

makes the trip voltage less accurate,

since the trip point changes once the

output changes. The LT3689 does not

use hysteresis. Instead, it performs an

integration-like function on transient

events at the comparator. In this way

the magnitude and duration of the

event are both important to the comparator threshold. Figure 3 illustrates

the typical transient duration versus

comparator overdrive (as a percentage

of trip threshold) required to trip the

comparator.

Selecting the Reset

Timing Capacitor

The reset timeout period is adjustable

in order to accommodate a variety of

microprocessor applications. The reset

timeout period, t

, is adjusted by

RST

connecting a capacitor between the

C

pin and ground. The value of this

POR

capacitor is determined by:

C

= t

POR

with C

• 432 • 10

RST

in Farads and t

POR

onds. The C

–9

in sec-

value per millisecond

POR

RST

of delay can also be expressed as

C

/ms = 432 (pF/ms).

POR

Leaving the C

pin unconnected

POR

generates a minimum reset timeout

of approximately 25µs with 10kΩ

pull-up to 5V on RST pin. Maximum

reset timeout is limited by the largest

available low leakage capacitor. The

accuracy of the timeout period will

be affected by capacitor leakage (the

nominal charging current is 2µA) and

capacitor tolerance. A low leakage ceramic capacitor is recommended.

Watchdog Modes:

Timeout or Window

The LT3689 also includes an adjustable watchdog timer that monitors a

microprocessor’s activity. If a code

execution error occurs in a µP, the

watchdog detects the error and sets

the WDO pin low. This signal can

be used to interrupt a routine or to

reset a µP.

Figure 3. Typical transient duration

vs POR comparator overdrive

25

L DESIGN FEATURES

t

WDU

t

WDU

t < t

WDL

t

RST

t

RST

t

RST

WATCHDOG TIMING (W/T = HIGH), TIMEOUT MODE

WDO

WDI

WDI

WDO

WATCHDOG TIMING (W/T = LOW), WINDOW MODE

t

RST

= PROGRAMMED RESET PERIOD

t

WDU

= WATCHDOG UPPER BOUNDARY PERIOD

t

WDL

= WATCHDOG WINDOW MODE LOWER BOUNDARY PERIOD

VUV = OUTPUT VOLTAGE RESET THRESHOLD

The watchdog is operated either

in timeout or window mode (refer to

Figure 4). In timeout mode, the microprocessor needs to toggle the WDI pin

before the watchdog timer expires to

keep the WDO pin high. If the voltage

on the WDI pin does not transition

during the programmed timeout period

then the circuitry pulls WDO low.

In window mode, the WDI pin’s

negative-going pulses must appear

inside a programmed time window to

prevent WDO from going low. If more

than two falling pulses are registered

in the lower boundary period (t

the WDO pin is forced low. The WDO

pin also goes low if no negative edge

is supplied to the WDI pin within the

upper boundary period (t

During a code execution error, the

microprocessor outputs WDI pulses

that are either too fast or too slow.

This condition asserts WDO low and

forces the microprocessor to reset the

program.

In window mode, the WDI signal is

bounded by an upper and lower boundary periods for normal operation. The

period of the WDI input signal should

be longer than the window mode’s lower boundary period and shorter than

the upper boundary period to keep

WDO high under normal conditions.

The window mode’s lower and upper

boundary periods have a fixed ratio

of 31. These times can be increased

or decreased by adjusting an external

capacitor on the C

In both watchdog modes, when

WDO is asserted, the reset timer is

enabled. Any WDI pulses that appear

while the reset timer is running are

ignored. When the reset timer expires,

the WDO is allowed to go back high

again. Therefore, if no input is applied

to the WDI pin then the watchdog

circuitry produces a train of pulses

on the WDO pin. The high time of

this pulse train is equal to the upper

boundary period and low time is equal

to the reset period. Also, WDO and

RST cannot be logic low simultaneously. If WDO is low and there is an

undervoltage lockout fault, RST goes

low and WDO will go high.

The WDE pin allows the user to turn

on or off the watchdog function. This

26

WDT

WDU

pin.

).

WDL

),

Figure 4. Watchdog timing diagram

feature can be used to reliably program

the connected microprocessor in the

factory. During factory programming

of the microprocessor, WDE pin can

be kept high to prevent WDO from

toggling and thus prevents WDO from

interfering with the microprocessor’s

programming procedure.

Tying the WDO and RST pins

together will generate a reset signal

when either the output voltage falls

10% below the regulation value or if

there is a watchdog error.

Selecting the Watchdog

Timing Capacitor

The watchdog upper boundary period

is adjustable and can be optimized

for software execution. The watchdog

upper boundary period is adjusted by

connecting a capacitor between the

C

pin and ground. Given a specified

WDT

watchdog upper boundary period, the

capacitor is determined by:

C

= t

WDT

• 55 (pF/ms)

WDU

The window mode lower boundary

period has a fixed relationship to upper

boundary period for a given capacitor.

The lower boundary period is related

to the upper boundary period by the

following:

t

= 1/31 • t

WDL

WDU

Leaving the C

pin unconnected

WDT

generates a minimum watchdog upper boundary period of approximately

200µs with 10kΩ pull-up to 5V on

WDO pin. Maximum timeout is limited

by the largest available low leakage

capacitor. The accuracy of the upper

and lower boundary periods is affected

by capacitor leakage (the nominal

charging current is 2µA) and capacitor tolerance. A low leakage ceramic

capacitor is recommended.

Conclusion

The wide input range, low quiescent

current, supervisory features, robustness and small size of the LT3689

makes it an ideal candidate to power

automotive and industrial applications. The part withstands 60V VIN

transients and normal operation is

guaranteed for max VIN of 36V, and

the part is robust against inrush and

short circuit conditions. The Burst

Mode circuitry provides high efficiencies at light loads. Programmable

switching frequency allows the designer to trade off between component

size and efficiency. The accurate POR

and Watchdog circuitry of LT3689

allows complete supervisory control

of a microprocessor connected to

the output of the LT3689 switching

regulator.

L

Linear Technology Magazine • March 2009

Loading...

Loading...