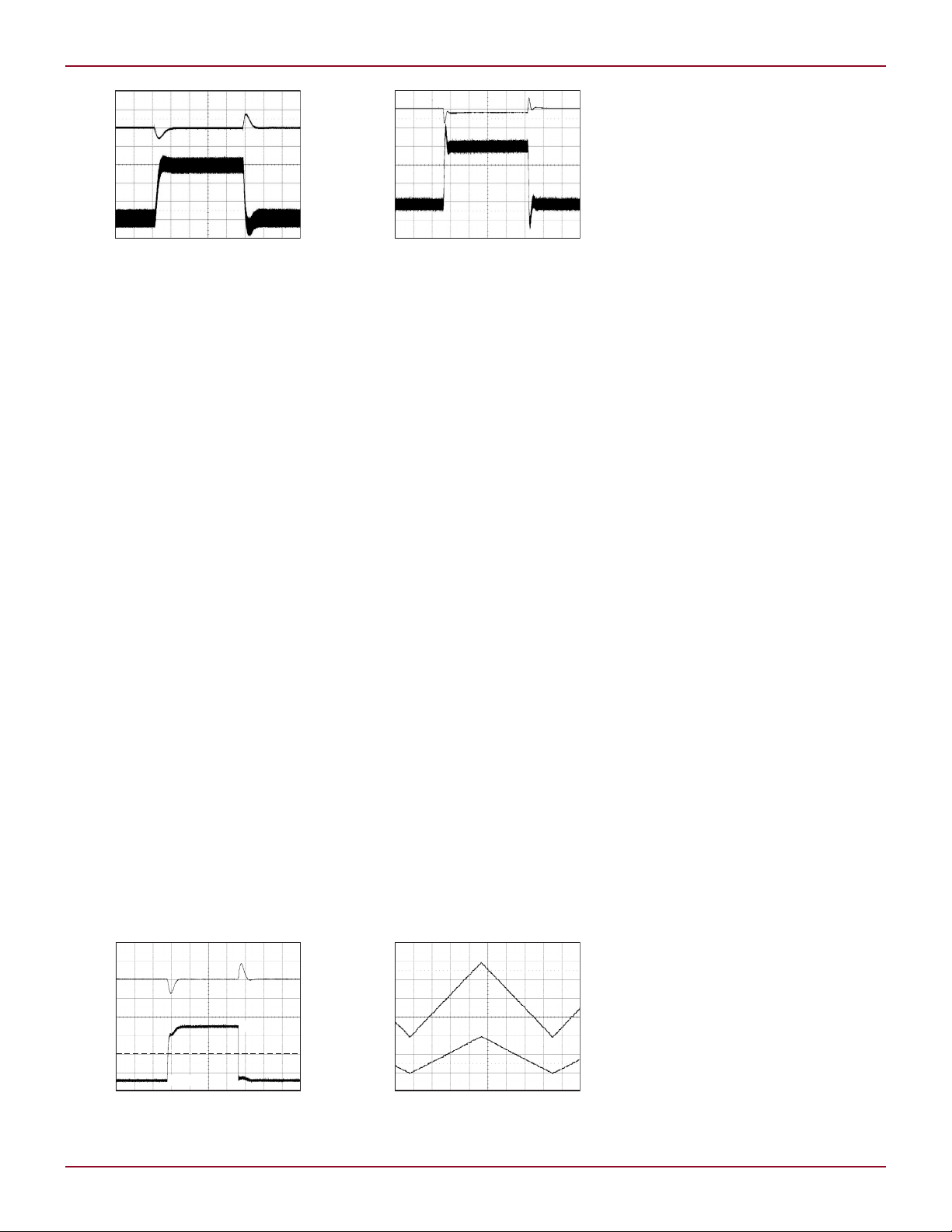

LOAD CURRENT (mA)

1

10010 1k

EFFICIENCY (%)

10k

0

10

20

30

40

50

60

70

80

90

100

BURST MODE OPERATION

PULSE SKIPPING MODE

FORCED CONTINUOUS

MODE

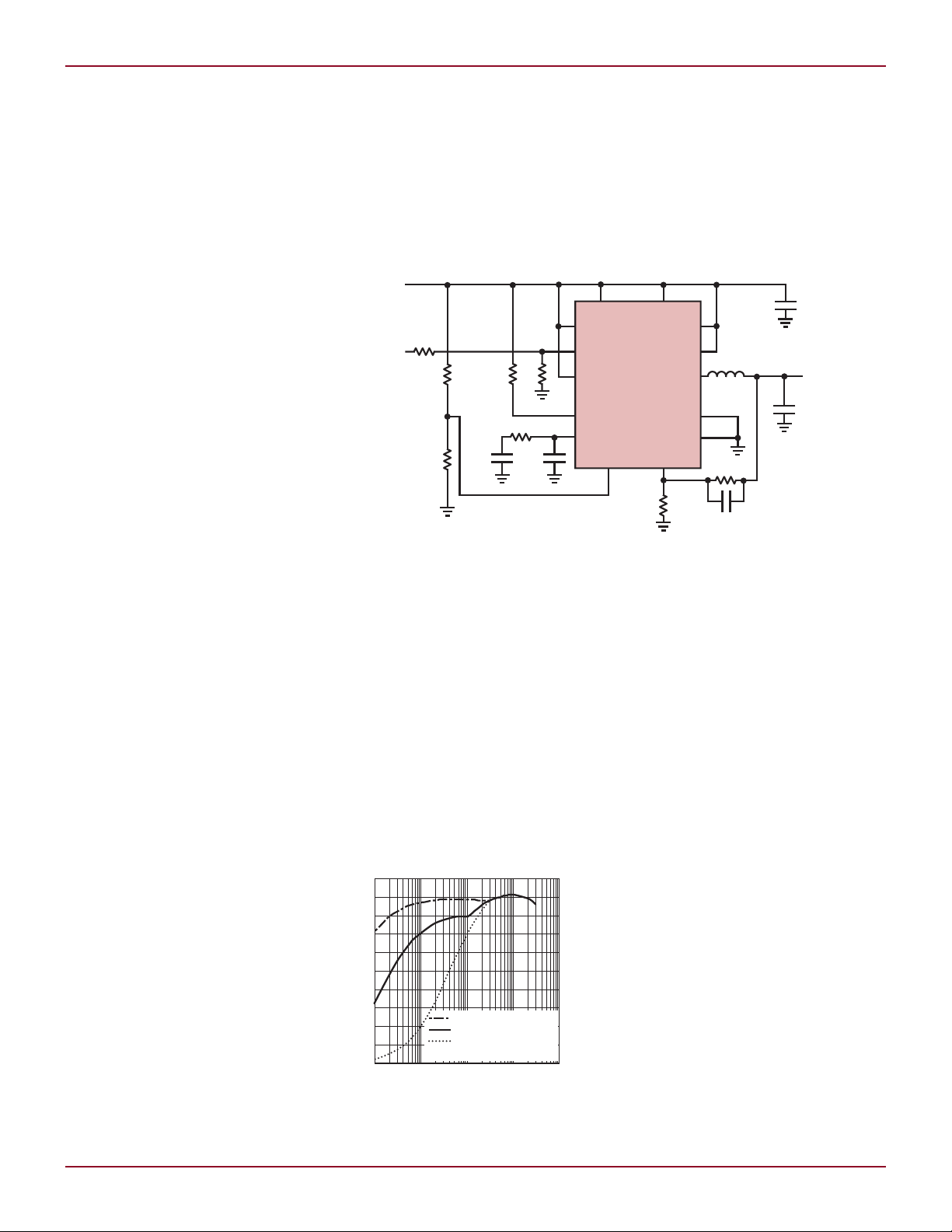

LT3612

PWN_DRIVER

DDR

SVIN PVIN

MODE VFB

RUN

TRACKSS

RT_SYNC

PGOOD

ITH

SW

SGROUND

PGROUND

VTT=VDD/2

1.25V

±1.5A

22pF

110k

470pF 10pF

12.1k

100k

402k

V

IN

3.3V

V

DD

2.5V

100k

1M

165k

L1

470nH

33µF

=2

22µF

=2

1M

L DESIGN FEATURES

Monolithic Synchronous Step-Down

Regulator Sources 3A or Sinks 1.5A

in TSSOP or 3mm × 4mm QFN

by Genesia Bertelle

Introduction

The LTC3612 monolithic synchronous

buck regulator can source 3A and

sink 1.5A from a tiny 3mm × 4mm

QFN or 20-lead TSSOP package with

exposed pads for improved thermal

performance. This device saves space,

minimizes external components and is

highly efficient. It employs a constant

frequency, current mode architecture

that operates from an input range of

2.25V to 5.5V—suitable for a single

Li-Ion battery or low voltage input

applications. The LTC3612 provides

an adjustable regulated output down

to 0.6V.

The LTC3612 uses Burst Mode®

operation to increase efficiency at light

loads, consuming less than 100µA of

supply current at no load. Adjustable

compensation allows the transient

response to be optimized over a wide

range of loads and output capacitors.

The internal synchronous switch

increases efficiency and eliminates

the need for an external catch diode,

saving external components and board

space.

Design Versatility

Depending on the application requirements, a designer can either prioritize

light load efficiency or minimize supply noise by choosing from three light

load operating modes: Burst Mode

operation, pulse-skipping, or forced

continuous modes. Burst Mode operation provides high efficiency over

the entire load range by reducing gate

charge losses at light loads. Burst

Mode operation is an efficient solution

for low current applications, but in

some applications noise suppression

is a higher priority. Forced continuous

operation, though not as efficient as

Burst Mode operation at light loads,

maintains a constant switching frequency, making it easier to reduce

10

Figure 1. High efficiency and very compact 1.5A LTC3612 VTT power supply with 3.3V input

noise and RF interference. In forced

continuous operation, the LTC3612

can source and sink current. Pulseskipping mode is similar to Burst Mode

operation. It reduces output voltage

ripple, but incurs more gate charge

losses, compromising light load efficiency. Although not as efficient as

Burst Mode operation at low currents,

pulse-skipping mode still provides

high efficiency for moderate loads.

The default frequency of 2.25MHz is

chosen by tying the RT/SYNC pin to

VIN. This high frequency allows the use

of tiny inductors and ceramic output

capacitors without compromising efficiency. The switching frequency can

be set from 300kHz to 4MHz with an

external resistor or synchronized to

an external clock, where each switching cycle begins at the falling edge of

the external clock signal. All operating modes (Burst Mode operation,

pulse-skipping and forced continuous

mode) can be selected in combination

with the default 2.25MHz frequency,

a frequency defined by an external

resistor or synchronization with external clock.

The LTC3612 offers a power good

indicator (PGOOD pin), which monitors the output voltage. The PGOOD

pin is an open-drain output which is

pulled down to ground during shut

down, start-up and while the output

voltage is outside the power good

voltage window (±7.5% of the final

programmed output voltage). If the

output voltage stays inside the power

good window for more than 100µs, the

PGOOD pin is released. If the output

Figure 2. Efficiency vs load current, 2.25MHz

switching frequency, in various operating

modes

voltage remains outside the power

good window for more than 100µs,

the PGOOD pin is pulled down.

The 100% duty cycle capability for

low dropout conditions allows maxi-

Linear Technology Magazine • December 2009

V

DD

100mV/DIV

V

TT

100mV/DIV

1ms/DIV

V

OUT

200mV/DIV

I

LOAD

1A/DIV

0A

50µs/DIV

–1.5V

1.5V

V

OUT

200mV/DIV

I

L

1A/DIV

50µs/DIV

V

OUT

= 1.8V

I

LOAD

= 100mA TO 3A

V

MODE

= 1.5V

V

OUT

100mV/DIV

I

L

1A/DIV

50µs/DIV

V

OUT

= 1.8V

I

LOAD

= 100mA TO 3A

V

MODE

= 1.5V

V

ITH

= V

IN

Figure 3. Load step transient in forced continuous mode

mum energy to be extracted from a

Li-Ion battery. In dropout, the output

voltage is determined by the input

voltage minus the voltage drop across

the internal P-channel MOSFET (only

70mΩ) and the inductor resistance.

Power Supply Tracking and

DDR Applications

The LTC3612 supports coincidental or

ratiometric ramp-up and ramp-down

tracking of another supply via the

TRACK/SS pin. For TRACK/SS voltages lower than 0.2V, the switching

frequency is reduced to ensure that

the minimum duty cycle limit does

not prevent the output voltage from

following the TRACK/SS pin.

Start-up behavior can be programmed in one of three ways via the

TRACK/SS pin. Tying TRACK/SS to

SVIN selects the internal soft-start

circuit (1ms ramp time). Alternately,

external soft-start timing can be programmed with a TRACK/SS capacitor

to ground and a resistor to SVIN. Finally, the TRACK/SS pin can be used to

force the LTC3612 to track the start-up

behavior of another supply.

When running in DDR mode, the

TRACK/SS pin can be used as an

external reference input, allowing the

Figure 4. Load transient response for ±1.5A

load applied to the circuit shown in Figure 1

Linear Technology Magazine • December 2009

DESIGN FEATURES L

LTC3612 to power DDR memory. In

this mode, the power good window

moves in relation to the actual TRACK/

SS pin voltage.

Typically DDR memory needs at

least two main power supplies: V

and VTT, where V

the V

supply with VTT = V

DD

must always track

TT

Since the termination resistors can

carry current in either direction, the

V

power supply must be able to both

TT

source and sink current while tracking

the V

supply.

DD

Two LTC3612 converters can be

used to generate both V

and V

DD

as shown in the circuit in Figure 1.

V

voltages range from 1.25V down

TT

to 0.75V for different DDR standards.

LTC3612 can be used for all DDR

standards because the TRACK/SS

voltage can accept a reference voltage

from 0.6V down to 0.3V (although

TRACK/SS voltage values from 0.4V

to 0.5V are the most accurate).

Optional AVP Mode with

Internal Compensation

Fast load current transient response is

an important feature in microprocessor power supplies. Normally, several

capacitors in parallel are required to

meet microprocessor transient re-

Figure 5. VTT responding to a change in VDD

for the circuit shown in Figure 1

DD

DD

/2.

,

TT

quirements, where capacitor ESR and

ESL primarily determine the amount

of droop or overshoot in the output

voltage. If a load step with very fast

slew rate occurs, an output voltage

excursion is seen for transients in

both directions: that is for full load to

minimum load and for the minimum

load to full load.

If the ITH pin is tied to SVIN, the active voltage positioning (AVP) mode and

internal compensation are selected.

AVP mode intentionally compromises

output voltage regulation by reducing

the gain of the feedback circuit, resulting in an output voltage that varies

with load current.

When the load current suddenly

increases, the output voltage starts

from a level slightly higher than nominal so the output voltage can droop

and stay within the specified voltage

range. When the load current suddenly

decreases the output voltage starts

at a level lower than nominal so the

output voltage can overshoot and stay

within the specified voltage range. In

AVP mode the external compensation

at ITH pin is not needed, reducing

external components.

Short-Circuit Protection

The LTC3612 is protected against

an output short to ground. When

the output is shorted to ground, the

inductor current decays very slowly

during a single switching cycle. The

LTC3612 uses two techniques to prevent inductor current runaway from

occurring.

First, if the output voltage drops below 50% of its nominal value, the peak

current clamp is decreased, reducing

the maximum inductor current. When

the output voltage reaches 0V, the

clamp voltage at the ITH pin drops to

40% of the clamp voltage during normal operation. The short-circuit peak

inductor current is determined by the

minimum on-time of the LTC3612, the

input voltage and the inductor value.

This foldback behavior helps in limiting the peak inductor current when the

output is shorted to ground.

Secondly, a limit is also imposed

on the valley inductor current. If the

continued on page 15

11

DESIGN FEATURES L

V V V

V

V

BAT PRE BAT MIN BAT FLOAT( ) ( ) ( )

•

.

.

< =

2 3

3 3

V V V

V

V

BAT PRE BAT MIN BAT FLOAT( ) ( ) ( )

•

.

.

< =

2 3

3 3

∆ •

• ∆

•

( )

V

V

R

R R

R R

IN NTC

REGINNTC NTC

IN NTC

=

2 1

mode and maximum charge current

is determined as follows:

V

BAT(MIN)

V

BAT(PRE)

V

CHRG(PRE)

V

CHRG(PRE)

= 5.7V

< 5.7V

= 0.15 • I

= 0.3A

CHRG

Using and efficiency of 0.85, plot PIN

over the range of VIN that is current

controlled. This is the regulated VIN,

or V

of the V

, power line. The intersection

REG

power line with the solar

REG

panel power curve is the operating

point. As the battery charges, the

slope of the V

power line increases,

REG

indicating the increase in input power

required to support the increasing

output power. The intersection of the

V

power line continues to follow

REG

up the solar panel’s power curves

until the charger exits constant cur rent mode.

The resulting plots are shown in

Figure 4.

The Circuit in Action

Figure 4 shows the power output of the

solar panel plotted at light intensity

levels from 100W/m2 to 1000W/m2

in 100W/m2 steps. At maximum light

intensity (top curve in Figure 4) and

the battery voltage just above the preconditioning level (V

BAT(MIN)

solar panel is producing more power

than the charger needs. The solar

panel voltage rises above the V

control voltage and travels across the

constant power line until it intersects

the light-power-intensity curve for

that intensity level (point A in Figure

4). As the battery charges, the input

power increases and the solar panel

operating point moves up the lightpower-intensity curve until the battery

at 2A), the

REG

approaches full charge (point B). The

LT3652 transitions from constant current mode to constant voltage mode

and the charging current is reduced.

The solar panel operating point moves

back down the light-power-intensity

curve to the open circuit voltage (point

C) when the battery reaches its final

float voltage.

During the charging of the battery, if

the light intensity diminishes, the operation point moves across a constant

The input voltage regulation

loop of the LT3652 has

the ability to seek out the

maximum power operating

point of a solar panel’s

power characteristic, thus

utilizing the full capacity of

the solar panel.

power line for the battery voltage until

it reaches the new power-intensity

curve. If the light intensity level continues to diminish, the operating point

travels along this constant power line

until it reaches the V

At this point the charging current is

reduced until the operating point is at

the intersection of the light-power-intensity curve and the V

(point D for constant current charging

at V

BAT(FLOAT)

with 800W/m2 illumination). As the battery continues to

charge at this light intensity level, the

operating point moves along the new

light-power-intensity curve until the

battery approaches full charge.

As darkness approaches, the operating point moves down the V

power line until charging current

ceases (point E) and the solar panel

output voltage drops below the SHDN

power line.

REG

power line

REG

REG

falling threshold at which point the

LT3652 turns off.

The remaining elements of the

design, selection of output inductor,

catch rectifier and timer capacitor,

are outlined in the design procedure

in the LT3652 datasheet along with

PCB layout considerations.

The maximum power voltage, for

a monocrystalline solar cell, has a

temperature coefficient of –0.37%/K

while the maximum power level is

–0.47%/K. This may be compensated

for by letting R

be a combination

IN1

of a series resistor and a series NTC

thermistor. The ratio of the two elements that comprise R

of R

need to be adjusted to achieve

IN2

and the value

IN1

the correct negative temperature of

VIN while still maintaining the control

range of VIN.

Conclusion

The input voltage regulation loop of

the LT3652 has the ability to seek out

the maximum power operating point

of a solar panel’s power characteristic,

thus utilizing the full capacity of the

solar panel. The float voltage regulation loop and its adjustable charging

current enable the LT3652 to be used

with many battery chemistries, making

it a versatile battery charger. The added

features of a wide input voltage range,

an auto-recharge cycle to maintain a

fully charged battery, a battery preconditioning mode, NTC temperature

sensing, selectable C/10 or timed

charging termination, a FAULT and

a charging status pins fills out the

full feature set of the LT3652. The

LT3652 is available in a 3mm × 3mm

12-lead plastic DFN, package with an

exposed pad.

L

LTC3612, continued from page 11

inductor current measured through

the bottom MOSFET increases beyond

6A, the top power MOSFET is held off

and switching cycles are skipped until

the inductor current is reduced.

Linear Technology Magazine • December 2009

Conclusion

The LTC3612 is well suited for a wide

range of low voltage step-down converter applications, including DDR

memory termination applications

requiring ±1.5A of output current. Its

high switching frequency and internal

low R

power switches allow the

DS(ON)

LTC3612 to offer a compact, high efficiency design solution supplying up

to 3A output current.

L

15

Loading...

Loading...