L DESIGN IDEAS

V

OUT

1.2V

8A

C

OUT

100µF

s2

L1

0.5µH

V

IN

5V TO 18V

C

IN

10µF

25V

3s

+

C1

0.22µF

C

SS

0.1µF

4.7µF

6.3V

V

IN

0.47µF

25V

7.68k

1%

1500pF

R

ON

187k

1%

30.1k

1%

30.1k

1%

100k

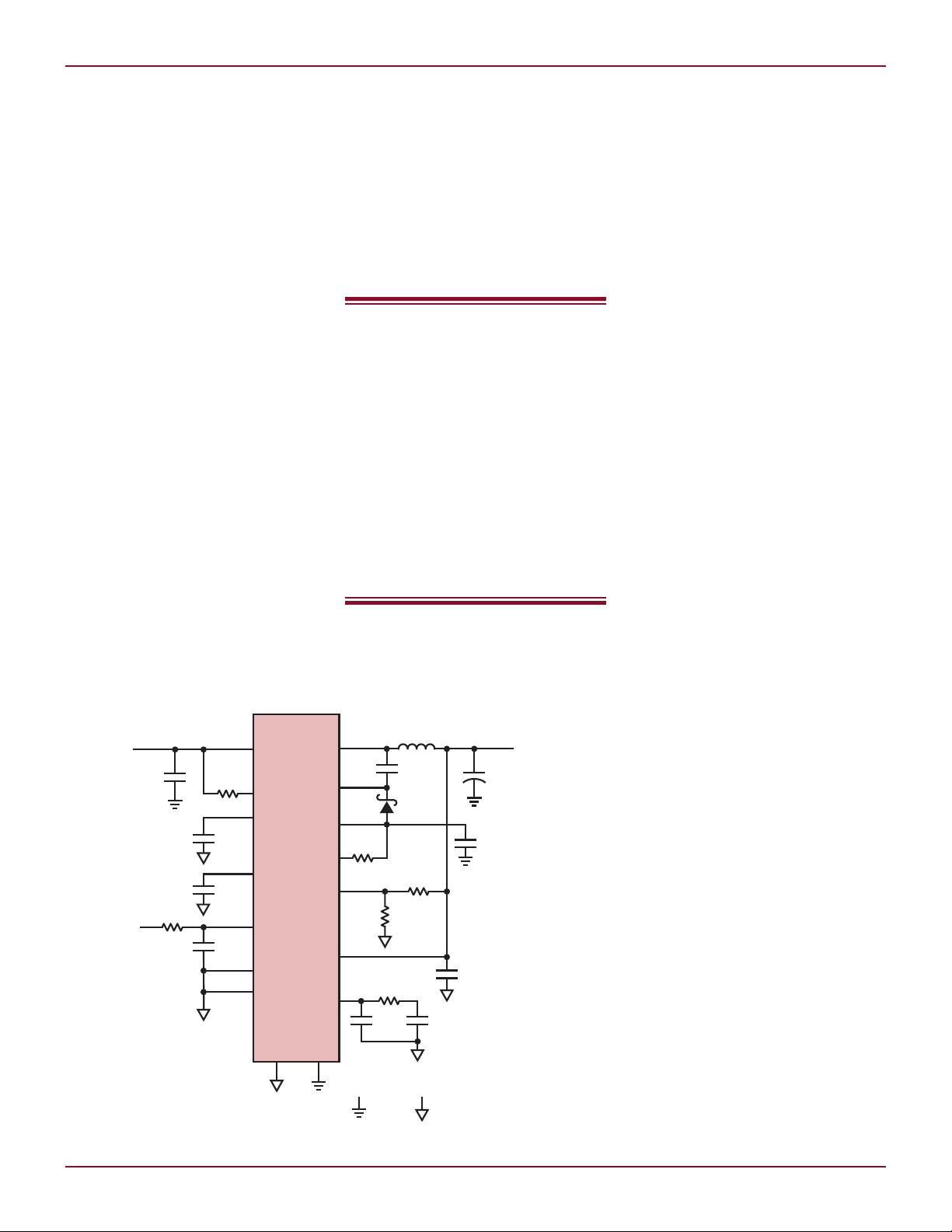

LTC3608

V

FB

I

ON

FCB

I

TH

V

RNG

PGOOD

SGND

BOOST

RUN/SS

V

ON

INTV

CC

SW

PV

IN

0.1µF

100pF

CMDSH-3

1Ω

KEEP POWER GROUND AND SIGNAL GROUND SEPARATE.

CONNECT AT ONE POINT.

= SGND

= PGND

PGND

SV

IN

0.01µF

EXTV

CC

C1: TAIYO YUDEN JMK316BJ226ML-T

CIN: TAIYO YUDEN TMK432BJ106MM

C

OUT

: TDK C4532X5R107M

L1: SUMIDA CDEP85NP-R50MC-125

32V

with Integrated FETs Deliver up to 12A

from Sub-1mm Height Packages

Introduction

Monolithic buck regulators are easy

to hook up and they make it possible

to squeeze an entire DC/DC converter

into very tight spaces. Although monolithics are an easy fit, they aren’t the

perfect fit for every application. For

instance, they typically lack the capability to efficiently convert high input

voltages (>12V) to low voltages at high

output currents (>4A), thus leaving the

job to a traditional controller IC and

external MOSFETs.

A new family of devices, though,

offers the advantages of monolithics

with the low duty cycle and high efficiency of discrete components. The

LTC3608, LTC3609, LTC3610 and

LTC3611 are synchronous buck converters that bring high power density

and simplified design to point-of-load

applications. With a maximum input of

32

32

Synchronous Buck Regulators

IN

by Stephanie Dai and Theo Phillips

are packaged in thermally enhanced

packages less than 1mm in height. A

typical application of the LTC3608 is

shown in Figure 1.

Features

The LTC3608, LTC3609, LTC3610 and

LTC3611 integrate high performance

synchronous buck controllers with

super-low R

to produce compact high efficiency

converters (Figure 2). Two package

sizes are available, each having a

high voltage or high current option

(Table 1). Each device features a sub100ns on-time, allowing very low duty

cycle operation and high switching

frequency. The current-mode control

architecture of these parts simplifies

tuning of loop stability and allows

excellent transient response with a

variety of output capacitor types, including all-ceramic output capacitor

applications.

The LTC3610 can operate in forced

continuous mode, which provides the

lowest possible output ripple and EMI,

or discontinuous mode, which has

better light load efficiency because

inductor current is not allowed to

reverse.

Current into the ION pin sets the

on-time—a resistor RON from VIN to the

ION pin reduces on-time as V

thus limiting changes in switching

frequency. Furthermore, response to a

load step can be very fast since the loop

does not have to wait for an oscillator

pulse before the top switch is turned

on and current begins increasing.

The current limit, which is inferred

from the maximum allowable sense

voltage across the on-resistance of

the bottom FET, can be adjusted by

applying a voltage to the V

Maximum load current limits for each Figure 1. Typical application of the LTC3608

Linear Technology Magazine • September 2008

DS(ON)

A new family of devices

offers the advantages of

monolithic DC/DC converters

with the low duty cycle and

high efficiency of discrete

components. The LTC3608,

LTC3609, LTC3610 and

LTC3611 are synchronous

buck converters that bring

high power density and

simplified design to point-of-

load applications.

32V they utilize current-mode control

up to a 2MHz switching frequency,

deliver up to 12A of load current, and

DMOS MOSFETs

rises,

IN

pin.

RNG

part are shown in Table 1. Soft-start

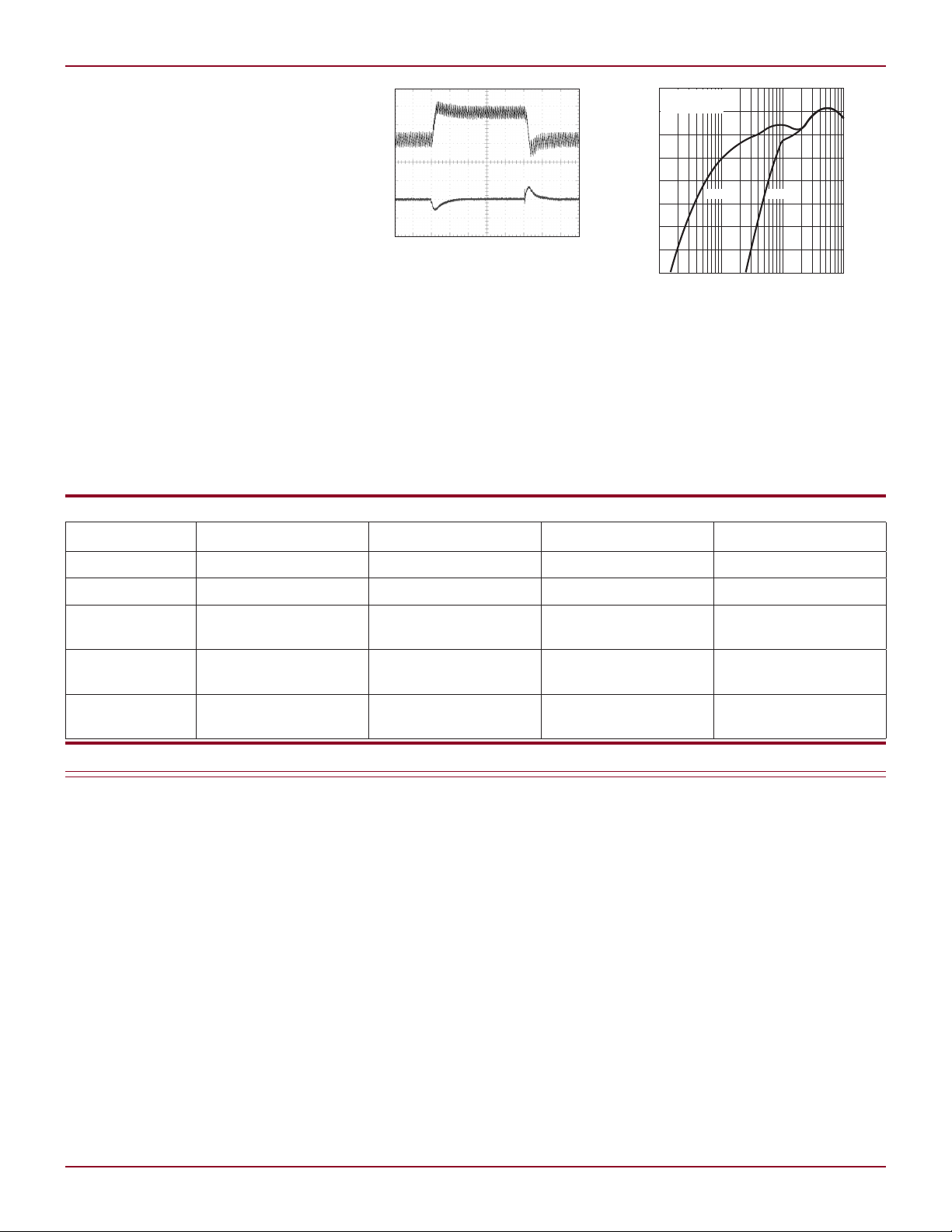

LOAD STEP 1A-8A

VIN = 12V

V

OUT

= 1.2V

FCB = 0V

200mV

V

OUT

200mV/DIV

I

L

5A/DIV

LOAD CURRENT (A)

0.01

50

EFFICIENCY (%)

55

65

75

60

70

80

85

90

0.1 1 10

VIN = 12V

FREQ = 550kHz

CCMDCM

and latch off functions are controlled

by the RUN/SS pin, preventing inrush

current and current overshoot during

startup, and providing the option of

latch-off if an under voltage or short

circuit is presented. An open drain

power-good pin monitors the output

and pulls low if the output voltage is

±10% from the regulation point.

Conclusion

The LTC3608, LTC3609, LTC3610

and LTC3611 buck regulators offer the efficiency and power output

capability of separate (controller +

discrete) MOSFET solutions with

the ease-of-use and space-saving

advantages of traditional MOSFETon-the-die monolithics. These parts

also yield higher efficiencies than

Figure 3. Transient response for the typical

LTC3608 application represented in Figure 1

with a load step of 1A to 8A

traditional monolithic solutions.

They conserve power, save space, and

simplify power designs. They reduce

discrete components over controller-based solutions, making them a

DESIGN IDEAS L

Figure 2. Efficiencies for a typical

LTC3608 application in discontinuous

conduction mode (DCM) and continuous

conduction mode (CCM)

good fit in everything from low power

portable device applications such as

notebook and palmtop computers

to high-power industrial distributed

power systems.

L

LTC3610 LTC3611 LTC3608 LTC3609

PVIN Max 24V 32V 18V 32V

I

Max 12A 10A 8A 6A

LOAD

Package

R

DS(ON)

Top FET

R

DS(ON)

Bottom FET

LTC4009, continued from page 20

9mm × 9mm × 0.9mm

64-pin

12mΩ 15mΩ 14mΩ 19mΩ

6.5mΩ 9mΩ 8mΩ 12mΩ

LTC4009 family monitors the voltage

across the input blocking diode for

unexpected voltage reversal. Initial

startup, restarts from fault conditions,

and charge current reduction during

input current limit are also carefully

controlled to avoid producing reverse

current.

All members of the family provide

an input current limit flag to tell the

system when the adapter is running

at over 95% of its current capacity.

Finally, each IC features internal

over-temperature protection to prevent silicon damage during elevated

thermal operation.

Recovery from all fault conditions is

under full control of the analog feed-

Linear Technology Magazine • September 2008

Table 1. Integrated MOSFET buck regulators

9mm × 9mm × 0.9mm

64-pin

7mm × 8mm × 0.9mm

52-pin

back loops, which guarantees charging

remains suspended until the internal

feedback loops respond coherently and

report the need to supply current to

the load to maintain proper voltage or

current regulation.

Conclusion

The LTC4009 family integrates a full

set of charger building blocks in a small

PCB footprint. The result is a high

power battery charger IC with high

precision and a full set of monitoring

and fault handling features.

The LTC4009 provides adjustable

output voltage control with a simple,

external, user-programmed resistive

voltage divider. As such, it is suitable as

a general purpose charger that works

7mm × 8mm × 0.9mm

52-pin

with multiple battery chemistries and

supercaps. It offers direct control over

the entire charge process, facilitating

implementation of a wide range of

charge termination algorithms with

an external microprocessor.

The LTC4009-1 and LTC4009-2

feature pin-programmable output

voltage for common lithium-ion or

lithium-polymer battery pack configurations with one to four series cells.

For these chemistries, the number of

precision external application components is reduced without sacrificing

accuracy. Both 4.1V/cell (LTC4009-1)

and 4.2V/cell (LTC4009-2) options are

available, allowing the user to balance

capacity and safety per the demands

of the application.

L

3333

Loading...

Loading...