L DESIGN FEATURES

L1

15µH

L4

10µH

I

FB3

EN/SS3

EN/SS1

FLT

SW2 GND FB2

CAP1

FB1

V

OUT1

LT3587

V

FB3VOUT3

CAP3 SW3 V

IN

SW1

C6

1µF

C1

10µF

C

FB1

2.7pF

R

FB1

1M

CCD POSITIVE

15V

50mA

V

VIN

2.5V TO 6V

C2

2.2µF

L2

15µH

L3

15µH

R

FB2

1M

CCD NEGATIVE

–8V

100mA

LED DRIVER

20mA UP TO 24V

V

VIN

2.5V TO 6V

C7

22µF

D

S2

D

S3

C4

2.2µF

R

VFB3

1.65M

(OPTIONAL)

D

S1

R

IFB3

8.06k

C5

100nF

C3

100nF

C1: MURATA GRM21BR61C106KE15L

C2: MURATA GRM188R61C225KE15D

C3, C5: MURATA GRM033R60J104KE19D

C4: MURATA GRM21BR71E225KA73L

C6: MURATA GRM155R61A105KE15D

C7: TAIYO YUDEN LMK212BJ226MG-T

C

FB1

: MURATA GRM1555C1H2R7BZ01D

C

FB2

: MURATA GRM1555C1H6R8BZ01D

L1, L2, L3: SUMIDA CDRH2D18/HP-150N

L4: TOKO 1071AS-100M

DS1, DS2, DS3: IR IR05H40CSPTR

C

FB2

6.8pF

±32V Triple-Output Supply for LCDs,

CCDs and LEDs Includes Fault

Protection in a 3mm × 3mm QFN

by Eko T. Lisuwandi

Introduction

The task of designing a battery powered system with multiple high voltage

supplies is a daunting one. In such

systems board space is at a premium

and high efficiency is required to

extend battery life. Supplies must be

sequenced in start-up and shut-down,

and multiple supplies must be able to

maintain regulation without interaction across supplies.

The LT3587 is a 1-chip solution

that combines three switching regulators and three internal high voltage

switches to produce two high voltage

boost converters and a single high voltage inverter. The LT3587 is designed to

run from inputs ranging from 2.5V to

6V, making it ideal for battery powered

systems. Small package size and low

component count produces a small,

efficient solution. Typical applications

include digital still and video cameras,

high performance portable scanners

and display systems, PDAs, cellular

phones and handheld computers that

have high voltage peripherals such as

CCD sensors, LED backlights, LCD

displays or OLED displays.

Features

To keep the component count low, the

LT3587 integrates three high voltage

power switches capable of switching

0.5A, 1A and 1.1A at up to 32V in

a 3mm × 3mm QFN package. Each

of the positive channels includes an

output disconnect to prevent a direct

DC path from input to output when

the switches are disabled. The LT3587

also includes a bidirectional fault pin

(FLT), which can be used for fault

indication (output) or for emergency

shutdown (input).

The LT3587 offers a wide output

range, up to 32V for the positive channels (channels 1 and 3) and –32V for

the inverter (channel 2). Channel 3

is configurable as either a voltage or

current regulator. When configured as

a current regulator, channel 3 uses a

1-wire output that requires no current

sense or high current ground return

lines, easing board layout. A single

resistor programs each of the three

channels output voltage levels and/or

the channel 3 output current level.

Intelligent soft-start allows for

sequential soft-start of channel 1 followed by the inverter negative output

using a single capacitor. Internal

sequencing circuitry disables the

inverter until channel 1 output has

reached 87% of its final value.

20

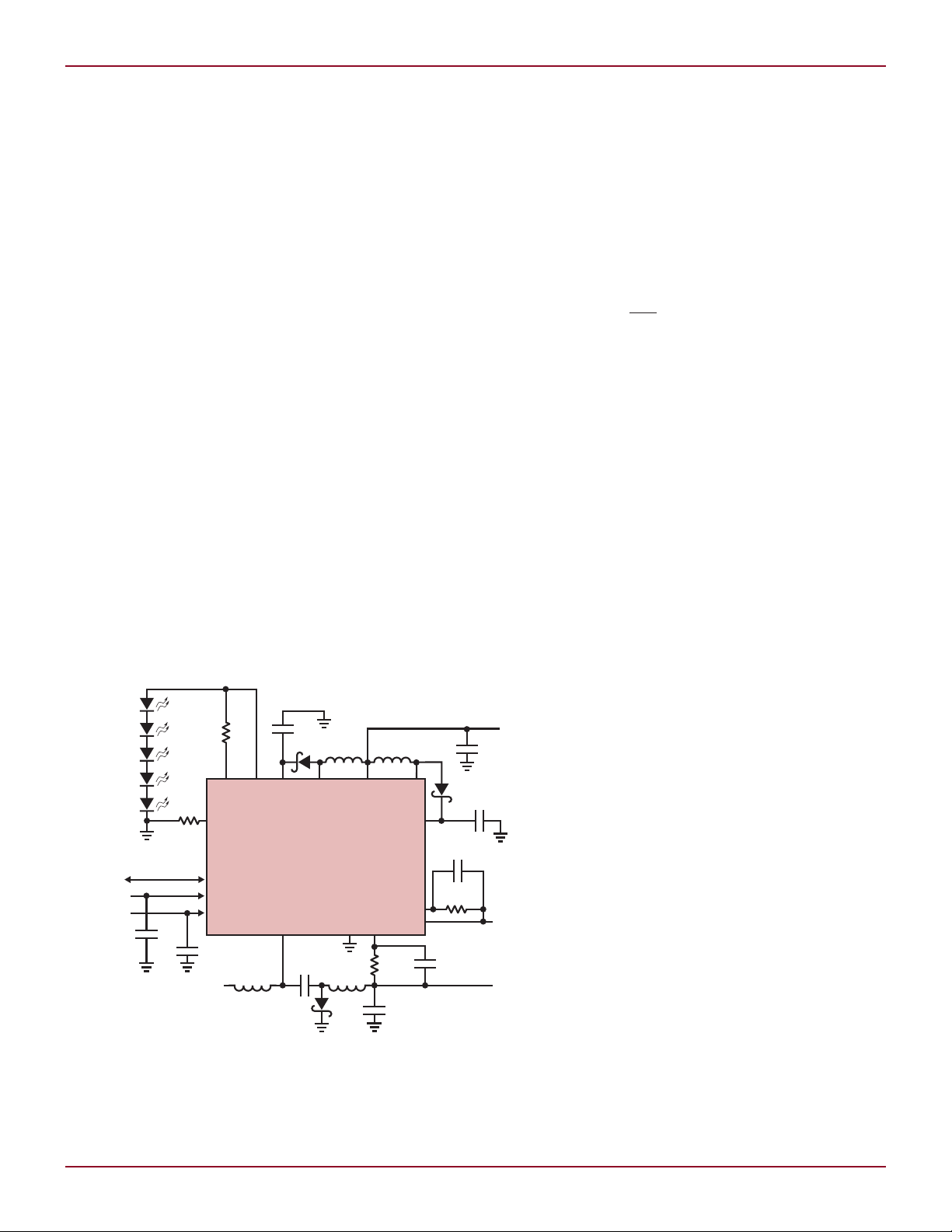

Figure 1. Solution for a Li-Ion powered camera provides positive and negative

supplies for biasing a CCD imager and an LED driver for a 5-LED backlight

Triple-Output Supply for CCD

Imager and LED Backlight

Figure 1 shows a typical application

providing a positive and negative voltage bias for a CCD imager and a 20mA

current bias for an LED backlight. All

three channels of the LT3587 use a

constant frequency, current mode control scheme to provide voltage and/or

current regulation at the output.

The positive CCD bias is configured as a simple non-synchronous

boost converter. Its output voltage is

set to 15V via the feedback resistor

R

. The 15µH inductor (L1) is sized

FB1

for a maximum load of 50mA. The

negative CCD bias is configured as a

non-synchronous ´Cuk converter. Its

output voltage is set at –8V using the

feedback resistor R

Linear Technology Magazine • January 2009

. The two 15µH

FB2

DISCONNECT

CONTROL

TO INTERNAL

CIRCUIT

LT3587

M2

M3

CAP3

V

OUT3

V

OUT1

CAP1

C1

C4

OVERVOLTAGE

PROTECTION

DISCONNECT

CONTROL

SHDN3

SHDN1

M1

I

FB3

R

IFB3

I

VIN

500mA/DIV

V

VOUT1

10V/DIV

V

NEG

10V/DIV

V

EN/SS1

2V/DIV

400µs/DIV

0V

0V

0V

0mA

I

VIN

500mA/DIV

V

VOUT1

10V/DIV

V

NEG

10V/DIV

V

EN/SS1

2V/DIV

4ms/DIV

0mA

0V

0V

Figure 2. Start-up waveforms with no soft-start capacitor, and with a 10nF soft-start capacitor

(L2 and L3) inductors are sized for a

maximum load of 100mA.

The LED backlight driver is configured as an output-current-regulated

boost converter. Its output current is

set at 20mA using the current programming resistor R

. The 10µH

IFB3

inductor (L4) is sized for a typical load

of 20mA at up to 24V. Note the optional

voltage feedback resistor, R

VFB3

, on

the LED driver. This resistor acts as

a voltage clamp on the LED driver

output, so that if one of the LED fails

open, the voltage on the LED driver

output is clamped to 24V.

voltage on the EN/SS1 pin is at least

600mV. This ensures that channel 2

starts up after channel 1. Channel 1

and channel 2 regulation loops are

free running with full inductor current

when the voltage at the EN/SS1 pin

is above 2.5V.

In a similar fashion, a capacitor

from the EN/SS3 pin to ground (C5

in Figure 1) sets up a soft-start ramp

for channel 3. When the voltage at the

EN/SS3 pins goes above 200mV, regulation loop for channel 3 is enabled.

When the voltage at the EN/SS3 pin

is above 2V, the regulation loop for

channel 3 is free running with full

Soft-Start

inductor current.

All channels feature soft-start (a slow

voltage ramp from zero to regulation)

to prevent potentially damaging large

inrush currents at start-up. Softstart is implemented via two separate

soft-start control pins: EN/SS1 and

EN/SS3. The EN/SS1 pin controls

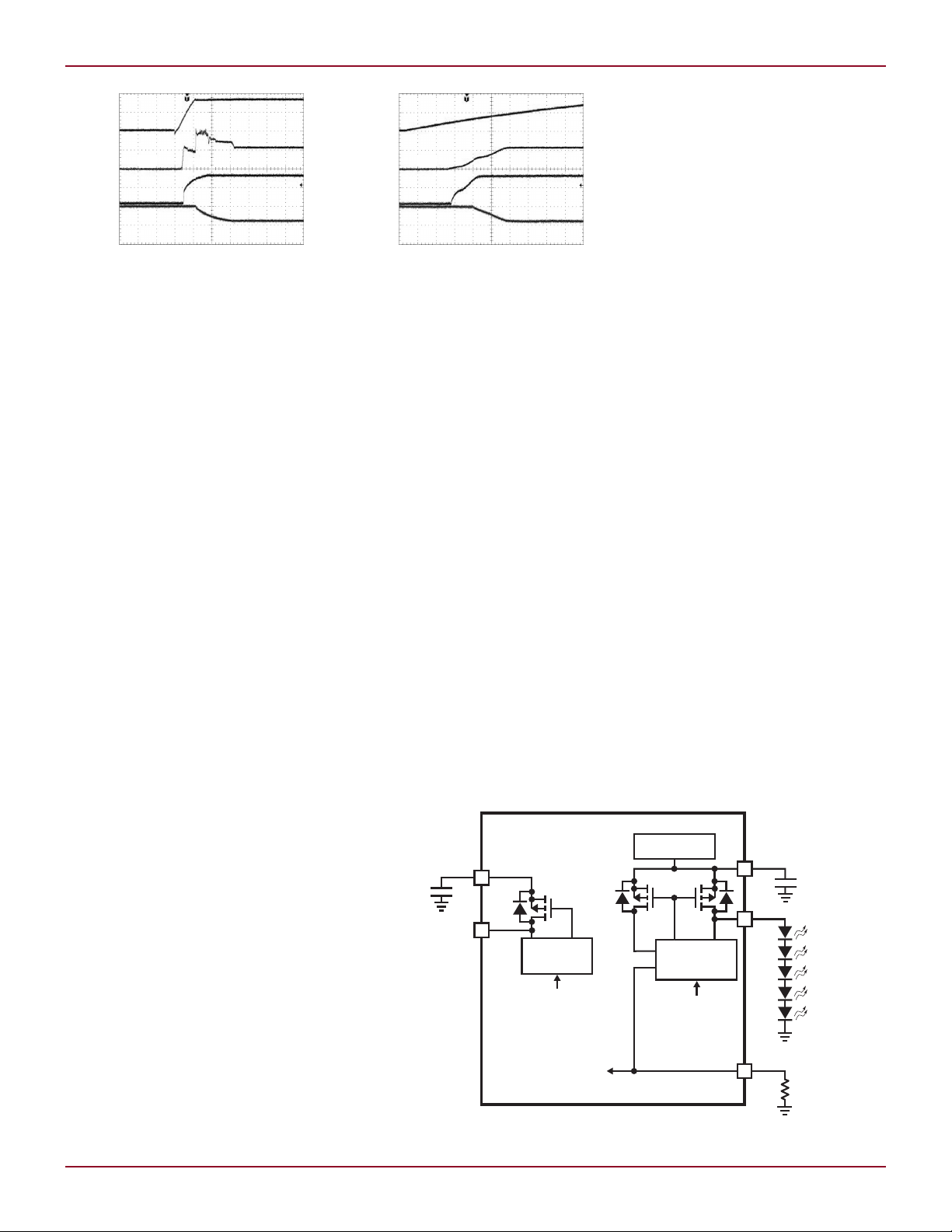

Start-Up Sequencing

The LT3587 also includes internal

sequencing circuitry that inhibits the

channel 2 from operating until the

feedback voltage of channel 1 (at the

FB1 pin) reaches about 1.1V (about

the soft-start for channel 1 and the

inverter, while the EN/SS3 pin controls

the soft-start for channel 3. Both of

these soft-start pins are pulled up with

a 1µA internal current source.

A capacitor from the EN/SS1 pin

to ground (C3 in Figure 1) programs

a soft-start ramp for channel 1 and

channel 2 (the inverter). As the 1µA

current source charges up the capacitor, the regulation loops for channel

1 and channel 2 are enabled when

the EN/SS1 pin voltage rises above

200mV. During start-up, the peak

switch current for channel 1 proportionally rises with the soft-start voltage

ramp at the EN/SS1 pin. The inverter

switch current also follows the voltage

ramp at the EN/SS1 pin, but its switch

current ramp does not start until the

Linear Technology Magazine • January 2009

Figure 3. Partial block diagram of the LT3587 showing the disconnect PMOS for channels 1 and 3

DESIGN FEATURES L

87% of the final voltage). The size of the

soft-start capacitor controls channel

2 start-up behavior.

If there is no soft-start capacitor,

or a very small capacitor, then the

negative channel starts up immediately with full inductor current when

the positive output reaches 87% of its

final value. If a large soft-start capacitor is used, then the EN/SS1 voltage

controls the inverter channel past

the point of regulation of the positive

channel. Figure 2 shows the start-up

sequencing without soft-start and with

a 10nF soft-start capacitor.

Output Disconnect

Both of the positive channels (channels

1 and 3) have an output disconnect

between their respective CAP and V

pins. This disconnect feature prevents

a DC path from forming between V

and V

through the inductors when

OUT

switching is disabled (Figure 1).

For channel 1, this output disconnect feature is implemented using a

PMOS (M1) as shown in the partial block

diagram in Figure 3. When turned on,

M1 normally provides a low resistance,

low power dissipation path for delivering output current between the CAP1

pin and the V

pin. M1 is on as long

OUT1

as the voltage difference between CAP1

and V

is greater than 2.5V. This al-

IN

lows the positive bias to stay high as

long as possible while the negative bias

discharges during turn off.

OUT

21

IN

L DESIGN FEATURES

I

L4

500mA/DIV

V

CAP3

10V/DIV

V

VOUT3

10V/DIV

I

VOUT3

500mA/DIV

40µs/DIV

0mA

24V

I

L4

500mA/DIV

V

CAP3

10V/DIV

V

VOUT3

10V/DIV

I

VOUT3

500mA/DIV

40µs/DIV

24V

0mA

V

VIN

= 3.6V

C4 = 1µF

I

L1

500mA/DIV

V

CAP1

10V/DIV

V

VOUT1

10V/DIV

I

VOUT1

500mA/DIV

40µs/DIV

V

VIN

= 3.6V

C1 = 4.7µF

0mA

15V

15V

ENSS1/ENSS3

5V/DIV

V

NEG

10V/DIV

V

VOUT3

20V/DIV

V

VOUT1

10V/DIV

V

FLT

5V/DIV

100ms/DIV

PART RESET

SHORT

AT V

OUT1

ENSS1/ENSS3

5V/DIV

V

NEG

10V/DIV

V

VOUT3

20V/DIV

V

VOUT1

10V/DIV

V

FLT

5V/DIV

100ms/DIV

PART RESET

FLT FORCED LOW

Figure 4. Channel 1 short circuit event

Figure 6. Fault detection

of a short circuit event

The disconnect transistor M1 is

current limited to provide a maximum

output current of 155mA. There is also

a protection circuit for M1 that limits

the voltage drop across CAP1 and

V

to about 10V. When the voltage

OUT1

at CAP1 is greater than 10V, such as

during an output overload or short

circuit to ground, then M1 is set fully

on, without any current limit, to allow

for the voltage on CAP1 to discharge

as fast as possible. When the voltage

across CAP1 and V

reduces to

OUT1

less than 10V, the output current is

then again limited to 155mA. Figure 4

shows the output voltage and current

during an overload event with V

initially at 15V.

The output disconnect feature on

channel 3 is implemented similarly

using M3 (Figure 3). However, in this

case M3 is only turned off when the

EN/SS3 pin voltage is less than 200mV

and the regulation loop for channel 3

is disabled.

The disconnect transistor M3 is also

current limited, providing a maximum

output current at V

also has a similar protection circuit as

of 100mA. M3

OUT3

M1 that limits the voltage drop across

CAP3 and V

22

to about 10V. Figure 5

OUT3

Figure 5. Channel 3 short circuit condition with and without 20mA current limit

Figure 7. Waveforms for when the

FLT pin is externally forced low

The LT3587 is a versatile,

highly integrated device

that provides a compact

solution for devices such

as cameras, handheld

computers and terminals

requiring multiple high

voltage supplies. A low part

count and a 3mm × 3mm

package keep the solution

size small. High efficiency

conversion makes it

CAP1

applications. Adjustable

suitable for battery powered

output voltage and wide

output range of up to 32V for

the positive boosts, and –32V

for the inverter, make it a

flexible solution for systems

that require high voltage

supplies.

shows the output voltage and current

during an overload event with V

initially at 24V.

Fault Detection and Indicator

The LT3587 features fault detection on

all outputs and a fault indicator pin,

FLT. The fault detection circuitry is

enabled only when at least one of the

channels has completed the soft-start

process and is free running with full

inductor current. Once fault detection is enabled, if any of the enabled

channel feedback voltages (V

or the greater of V

below its regulation value for more

than 16ms, the FLT pin pulls low.

One particularly important case is

an overload or short circuit condition

on any of the outputs. In this case, if

the corresponding loop is unable to

bring the output back into regulation

within 16ms, a fault is detected and

the FLT pin pulls low.

Note that the fault condition is

latched—once activated all three channels are disabled. Enabling any of the

channels requires resetting the part

by shutting it down (forcing both the

EN/SS1 and EN/SS3 pins low below

200mV) and then on again. Figure 6

shows the waveforms when a short

circuit condition occurs at channel 1

for more than 16ms and the subse-

CAP3

quent resetting of the part.

Linear Technology Magazine • January 2009

VFB3

and V

FB1

IFB3

, V

FB2

) falls

DESIGN FEATURES L

ENSS3

5V/DIV

I

L4

200mA/DIV

I

VOUT3

13mA/DIV

2ms/DIV

V

VIN

= 3.6V

6 LEDs

0mA

0mA

0V

PWM

FREQ

2.5V

0V

MN1

Si1304BDL

10µH

V

OUT3

CAP3

I

FB3

LT3587

R

IFB3

8.06k

EN/SS3

SW3

V

IN

LED DRIVER

1µF

V

VIN

2.5V TO 5V

10µH

V

OUT3

CAP3

I

FB3

LT3587

R

IFB3

8.06k

EN/SS3

SW3

V

IN

LED DRIVER

1µF

V

VIN

2.5V TO 5V

V

DAC-OUT

DAC

LTC2630

Figure 8. Analog dimming using a DAC and a resistor

Besides acting as a fault output

indicator, the FLT pin is also an input

pin. If this pin is externally forced

below 400mV, the LT3587 behaves

as if a fault event has occurred and

all the channels turn off. In order to

turn the part back on, remove the

external voltage that forces the pin low

and reset the part. Figure 7 shows the

waveforms when the FLT pin is externally forced low and the subsequent

resetting of the part.

Dimming Control for

Channel 3 as a CurrentRegulated LED Driver

As shown in Figure 1, one of the most

common applications for the channel

3 is as a current regulator for a backlight LED driver. In many high end

display applications requiring an LED

backlight, the ability to dim the display

brightness is crucial for implementing

a power saving mode or to maintain

contrast in different ambient lighting

conditions.

There are two different ways to

implement a dimming control of

the LED string. LED current can be

adjusted by either using a digital to

analog converter (DAC) and a resistor

R

IFB3

Analog Dimming Using

a DAC and a Resistor

For some applications, the preferred

method of brightness control is using

a DAC and a resistor. This method

Linear Technology Magazine • January 2009

or by using a PWM signal.

Figure 9. Driver for six LEDs with PWM dimming

is more commonly known as analog

dimming. This method is shown in

Figure 8.

Since the programmed V

OUT3

cur -

rent is proportional to the current

through R

, the LED current can be

IFB3

adjusted by changing the DAC output

voltage. A higher DAC output voltage

level results in lower LED current and

hence lower overall brightness. For

accurate dimming control, keep the

DAC output impedance low enough

to sink approximately 1/200 of the

desired maximum LED current. Note

the maximum possible output current

is limited by the output disconnect

current limit to 100mA.

PWM Dimming

One problem with analog dimming as

described above is that changing the

forward current flowing in the LEDs

not only changes the brightness intensity of the LEDs, it also changes the

color. This is a problem for applications

Figure 10. PWM dimming waveforms

that cannot tolerate any shift in the

LED chromaticity.

Controlling the LED intensity with

a direct PWM signal allows dimming

of the LEDs without changing the

color. A PWM frequency of ~80Hz or

higher guarantees that there is no

visible flicker. The amount of on-time

in the PWM signal is proportional to

the intensity of the LEDs. The color of

the LEDs remains unchanged in this

scheme since the LED current value is

either zero or a constant value (I

= 160V/R

IFB3

).

VOUT3

Figure 9 shows an LED driver for

six white LEDs. If the voltage at the

CAP3 pin is higher than 10V when

the LED is on, direct PWM dimming

method requires an external NMOS.

This external NMOS is tied between

the cathode of the lowest LED in the

string and ground.

The output disconnect feature

and the external NMOS ensure that

the LEDs quickly turn off without

discharging the output capacitor.

This allows the LEDs to turn on

faster. Figure 10 shows the PWM

dimming waveforms for the circuit in

Figure 9.

The time it takes for the LED current

to reach its programmed value sets the

achievable dimming range for a given

PWM frequency. At extreme lower end

of the duty cycle, the linear relation

between the average LED current

and the PWM duty cycle is no longer

preserved. The minimum on time is

23

L DESIGN FEATURES

V

VIN

= 3.6V

WITHOUT PROGRAMMED OUTPUT VOLTAGE

CLAMP: V

FB3

CONNECTED TO GND

I

L4

200mA/DIV

V

VOUT3

10V/DIV

200µs/DIV

20V

OUTPUT LOAD

DISCONNECTED

V

VIN

= 3.6V

WITH PROGRAMMED OUTPUT

VOLTAGE CLAMP AT 24V

I

L4

200mA/DIV

V

VOUT3

10V/DIV

200µs/DIV

20V

OUTPUT LOAD

DISCONNECTED

V

VIN

= 3.6V

WITHOUT CURRENT LIMIT: I

FB3

CONNECTED TO GND

V

OUT3

STAYS AT 15V, OUTPUT CURRENT

INCREASES FROM 20mA TO 40mA

I

L4

200mA/DIV

V

VOUT3

5V/DIV

I

VOUT3

13mA/DIV

200µs/DIV

15V

20mA

LOAD STEP

V

VIN

= 3.6V

WITH 20mA CURRENT LIMIT: R

IFB3

= 8.06k

OUTPUT CURRENT STAYS AT 20mA,

V

OUT3

DROPS FROM 15V TO 7.5V

I

L4

200mA/DIV

V

VOUT3

5V/DIV

I

VOUT3

13mA/DIV

200µs/DIV

15V

20mA

LOAD STEP

chosen based on how much linearity

is required for the average LED current. For example for the circuit in

Figure 9, to produce approximately

10% deviation from linearity at the

lower duty cycle, the minimum on

time of the LED current is approximately 320µs (3.2% duty cycle) for a

3.6V input voltage and a 100Hz PWM

frequency. The achievable dimming

range for this application is then 30

to 1 (approximately the reciprocal of

the minimum duty cycle).

The dimming range can be significantly extended by combining PWM

dimming with analog dimming. The

color of the LEDs no longer remains

constant because the forward current

of the LED changes with the output

voltage of the DAC. For the six LED

application described above, the LEDs

can be dimmed first by modulating the

duty cycle of the PWM signal with the

DAC output at 0V. Once the minimum

duty cycle is reached, the value of the

DAC output voltage can be increased

to further dim the LEDs. The use of

both techniques together allows the

average LED current for the six LED

application to be varied from 20mA

down to less than 1µA (a 20000:1

dimming ratio).

Channel 3 can be configured

either as a voltage-regulated

boost converter or as a

current-regulated boost

converter. The regulation

loop of channel 3 uses the

greater of the two voltages

at V

FB3

and I

as feedback

FB3

to set the peak current

of its power switch. This

architecture allows for a

programmable current limit

on voltage regulation or a

voltage limit on

current regulation.

the V

load current is less than I

3 regulates the voltage at the V

to 0.8V. If there is an increase in load

current beyond I

V

FB3

I

FB3

loop then regulates the voltage at the

I

FB3

pin. In this case, when the

OUT3

, the voltage at

LIMIT

, channel

LIMIT

FB3

pin

starts to drop and the voltage at

rises above 0.8V. The channel 3

pin to 0.8V, limiting the output

current at V

OUT3

to I

. Figure 11

LIMIT

compares the transient responses

with and without current limit when

a current overload occurs.

The channel 3 CAP3 pin has over

voltage protection. When the voltage at

CAP3 is driven above 29V, the channel 3 loop is disabled and SW3 pin

stops switching. When configured as

a boost current regulator, a feedback

resistor from the I

sets the output current at V

a fixed level. In this case, if the V

pin to ground

FB3

OUT3

at

FB3

pin is grounded then the over voltage

protection defaults to 29V.

On the other hand a resistor can

be connected from the V

the V

clamp (V

pin to set an output voltage

FB3

) level lower than 29V.

CLAMP

OUT3

pin to

In this case, when the voltage level is

less than V

regulates the voltage at the I

the channel 3 loop

CLAMP

,

FB3

pin

to 0.8V. On the other hand, when

the output load fails open circuit or

disconnected, the voltage at I

FB3

drops

to reflect the lower output current

and the voltage at V

When the voltage at V

V

, the voltage at the V

CLAMP

starts to rise.

FB3

rises beyond

OUT3

pin goes

FB3

Channel 3 Overvoltage and

Overcurrent Protection

Channel 3 can be configured either as

a voltage regulated boost converter or

as a current regulated boost converter.

The regulation loop of channel 3 uses

the greater of the two voltages at V

and I

current of its power switch. This architecture allows for a programmable

current limit on voltage regulation or

voltage limit on current regulation.

age regulator, a feedback resistor

from the output pin V

pin sets the voltage level at V

a fixed level. In this case, the I

can either be grounded if no current

limiting is desired or be connected to

ground with a resistor to set an output

current limit value (I

noted before, the pull up current on

the I

1/200 of the output load current at

as feedback to set the peak

FB3

When configured as a boost volt-

to the V

OUT3

pin is controlled to be typically

FB3

). As briefly

LIMIT

OUT3

pin

FB3

FB3

Figure 11. Channel 3 in an output current overload event with and without output current limit

FB3

at

Figure 12. Channel 3 in an output open circuit with

and without programmed output voltage clamp

24

Linear Technology Magazine • January 2009

DESIGN FEATURES L

L1

15µH

L4

10µH

V

OUT3

CAP3

V

FB3

I

FB3

SW2

GND

FB2

CAP1

FB1

V

OUT1

LT3587

FLT

EN/SS1

EN/SS3

SW3 SW1V

IN

C6

1µF

CCD POSITIVE

15V

50mA

V

VIN

2.5V TO 6V

C2

2.2µF

D3

R

FB2

1M

CCD NEGATIVE

–8V

100mA

R

IFB3

7.15k

(OPTIONAL)

C4

1µF

OLED DRIVER

16V

20mA

V

VIN

2.5V TO 6V

C7

22µF

D

S1

C1

4.7µF

R

FB1

1M

D

S3

C5

100nF

C

FB2

6.8pF

C3

100nF

D

S2

L2

15µH

C1: TAIYO YUDEN TMK212BJ475KG-T

C2: TAIYO YUDEN EMK107BJ225KA-T

C3, C5: TAIYO YUDEN JMK063BJ104KP-F

C4: TAIYO YUDEN GMK107BJ105KA-T

C6: TAIYO YUDEN LMK105BJ105KV-F

C7: TAIYO YUDEN LMK212BJ226MG-T

C

FB1

: TAIYO YUDEN EMK105SK2R7JW-F

C

FB2

: TAIYO YUDEN EMK105SH6R8JW-F

L1, L2: SUMIDA CDRH2D18/HP-150N

L4: TOKO 1071AS-100M

DS1, DS2, DS3, D3: NXP PMEG2005EB

R

VFB3

1.07M

C

FB1

2.7pF

L1

15µH

L4

10µH

I

FB3

EN/SS3

EN/SS1

FLT

SW2 GND FB2

CAP1

FB1

V

OUT1

LT3587

V

FB3VOUT3

CAP3 SW3 SW1

C1

4.7µF

R

FB1

787k

2AA CELLS

2V TO 3.2V

C2

2.2µF

L2

15µH

L3

15µH

R

FB2

1M

LED DRIVER

20mA UP TO 12V

2AA CELLS

2V TO 3.2V

C7

10µF

D

S2

V

IN

D

S3

C4

1µF

R

VFB3

787k

(OPTIONAL)

D

S1

R

IFB3

8.06k

C1: MURATA GRM21BR61E475KA12L

C2: MURATA GRM188R61C225KE15D

C4: MURATA GRM188R61E105KA12B

C6: MURATA GRM155R61A105KE15D

C7: MURATA GRM21BR71A106KE51L

C

FB1

: MURATA GRM1555C1H3R3BZ01D

C

FB2

: MURATA GRM1555C1H6R3BZ01D

L1, L2, L3: SUMIDA CDRH2D18/HP-150N

L4: TOKO 1071AS-100M

DS1, DS2, DS3: NXP PMEG2005EB

C6

1µF

3.3V

C

FB1

3.3pF

C

FB2

6.8pF

CCD POSITIVE

15V

10mA

CCD NEGATIVE

–8V

20mA

above 0.8V. The channel 3 loop then

regulates the voltage at the V

FB3

pin

to 0.8V, limiting the voltage level at

V

OUT3

to V

. Figure 12 contrasts

CLAMP

the transient responses with and

without programmed V

CLAMP

when the

output load is disconnected.

Low Input Voltage

While the LT3587’s V

range is 2.5V to 6.0V, the inductors can

run off a lower voltage. Most portable

devices and systems have a separate

3.3V logic supply voltage, which can

be used to power the LT3587. This

allows the outputs to be powered

straight from the lower voltage power

source such as two alkaline cells.

This configuration results in higher

efficiency. Figure 13 shows a typical

digital still camera application powered

this way. It has positive and negative

CCD supplies and an LED backlight

supply.

supply voltage

IN

Adjustable output voltage and wide

output range of up to 32V for the positive boosts, and –32V for the inverter,

make it a flexible solution for systems

that require high voltage supplies.

Channel 3’s ability to work as a voltage

regulator or as a true 1-wire current

regulator give the LT3587 status as a

true all-in-one power supply.

Additional features, such as softstart, supply sequencing, output

disconnect and fault handling also add

to the versatility of this part and further

simplify power supply design.

L

Replace Inductor

with Schottky for

Smaller Footprint

If higher current ripple is tolerable at

the output of the inverter (channel 2),

replace inductor L3 with a Schottky

diode D3 as shown in Figure 14.

Since the Schottky diode footprint

is usually smaller than the inductor

footprint, this alternate topology is

recommended for space constrained

applications. This topology is only

viable if the absolute value of the inverter output is greater than V

Schottky diode is configured with the

anode connected to the output of the

inverter and the cathode to the output

end of the flying capacitor C2 as shown

in Figure 14.

Conclusion

The LT3587 is a versatile, highly integrated device that provides a simple

solution to devices such as cameras,

handheld computers and terminals

requiring multiple high voltage supplies. A low part count and a compact

3mm × 3mm package keep the solution

size small. High efficiency conversion

makes it suitable for battery powered

applications.

Linear Technology Magazine • January 2009

IN

. This

Figure 13. Two AA cells produce CCD positive and

negative supplies and a driver for a 3-LED backlight.

Figure 14. Li-ion driver for an OLED panel and a CCD imager

with a Schottky diode replacing the inverter’s output inductor

25

Loading...

Loading...