FEATURES

■

Step-Up/Direct-Connect Fractional Charge Pump

Provides Up to 92% Efficiency

■

Up to 400mA Continuous Output Current

■

Independent Current and Dimming Control for

1-6 LED MAIN, 1-4 LED SUB and RGB LED Displays

■

LED Currents Programmable Using 2-Wire I2C™

Serial Interface

■

1% LED Current Matching

■

Low Noise Constant Frequency Operation*

■

Minimal Component Count

■

Automatic Soft-Start Limits Inrush Current

■

16 Exponentially Spaced Dimming States Provides

128:1 Brightness Range for MAIN and SUB Displays

■

Up to 4096 Color Combinations for RGB Display

■

Low Operating Current: I

■

Tiny, Low Profile 24-Lead (4mm × 4mm × 0.75mm)

= 180µA

VIN

QFN Package

U

APPLICATIO S

■

Cellular Phones

■

Wireless PDAs

■

Multidisplay Handheld Devices

, LTC and LT are registered trademarks of Linear Technology Corporation.

I2C is a trademark of Philips Electronics N.V.

* U.S. Patent 6,411,531

LTC3206

I2C Multidisplay

LED Controller

U

DESCRIPTIO

The LTC®3206 is a highly integrated multidisplay LED controller. The part contains a high efficiency, low noise fractional step-up/direct-connect charge pump to provide

power for both main and sub white LED displays plus an

RGB color LED display. The LTC3206 requires only four

small ceramic capacitors plus two resistors to form a

complete 3-display LED power supply and current

controller.

Maximum currents for the main/sub displays and RGB

display are set independently. Current for each LED is

controlled with an internal current source. Dimming and

ON/OFF control for all displays is achieved via a 2-wire

serial interface. Two auxiliary LED pins can be individually

assigned to either the MAIN or SUB displays. 16 individual

dimming states exist for both the MAIN and SUB displays.

Each of the RED, GREEN and BLUE LEDs have 16 dimming

states as well, resulting in up to 4096 color combinations.

The LTC3206 charge pump optimizes efficiency based on

V

and LED forward voltage conditions. The part powers

IN

up in direct-connect mode and automatically switches to

1.5x step-up mode once any enabled LED current source

begins to enter dropout. Internal circuitry prevents inrush

current and excess input noise during start-up and mode

switching. The LTC3206 is available in a 24-lead (4mm ×

4mm) QFN package.

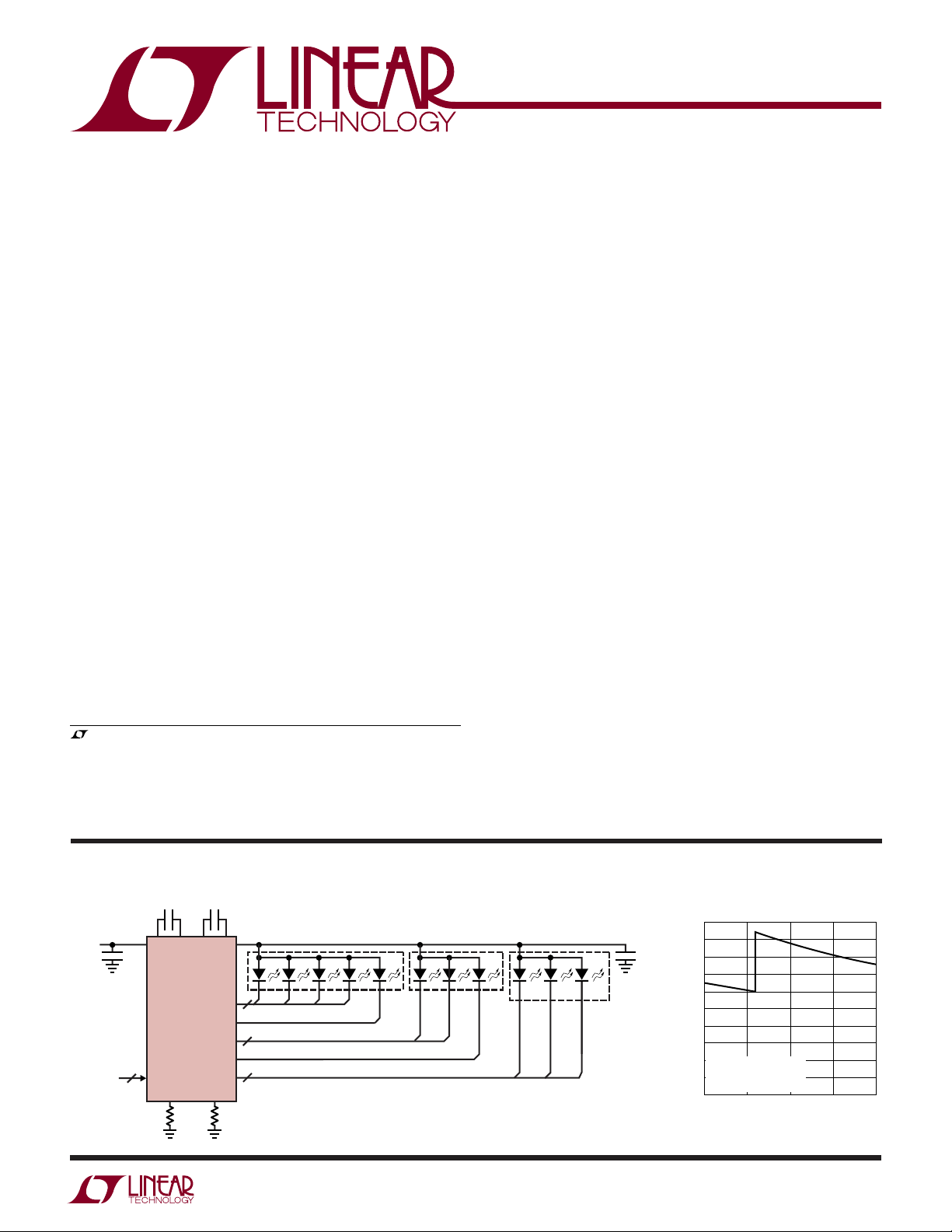

TYPICAL APPLICATIO

2.2µF 2.2µF

V

IN

2.7V TO

4.5V

I2C SERIAL

INTERFACE

V

IN

2.2µF 2.2µF

2

SERIAL PORT

I

RGB

LTC3206

CPO

MAIN1-4

AUX 1

SUB1-2

AUX 2

RGB

I

MS

4

2

3

U

MAIN DISPLAY SUB DISPLAY RGB ILLUMINATOR

RED GREEN BLUE

3206 TA01a

5-LED Main Display Efficiency

vs Input Voltage

100

90

80

) (%)

70

IN

/P

60

LED

50

40

30

EFFICIENCY (P

20

FIVE LEDs AT 15mA/LED

AT 15mA = 3.2V)

(TYP V

F

10

= 25°C

T

A

0

3.0

3.6

3.3

INPUT VOLTAGE (V)

3.9

4.2

3206 TA01b

3206f

1

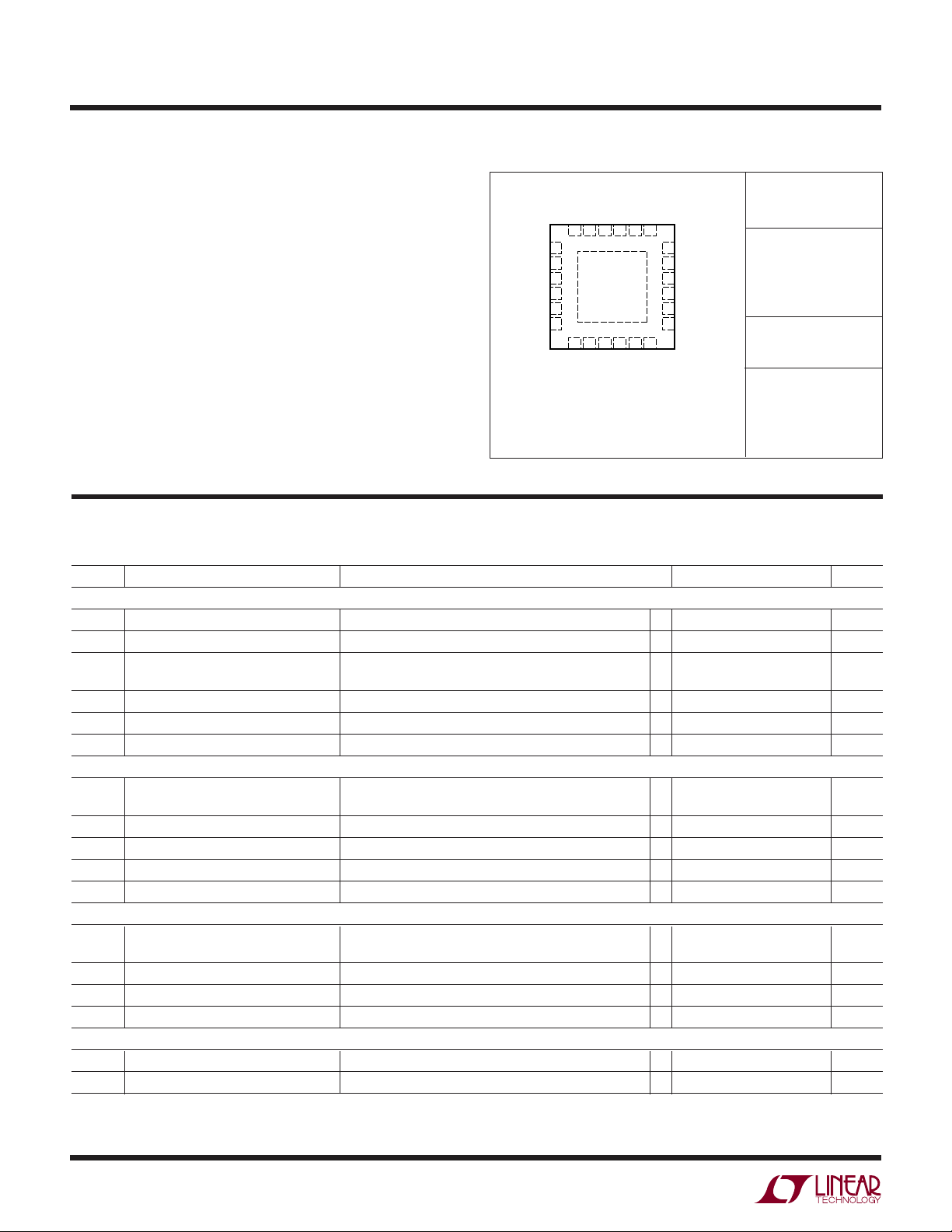

LTC3206

24 23 22 21 20 19

7 8 9

TOP VIEW

25

UF PACKAGE

24-LEAD (4mm × 4mm) PLASTIC QFN

10 11 12

13

14

15

16

17

18

6

5

4

3

2

1

SUB1

SUB2

C2

–

C1

–

C1

+

C2

+

BLUE

GREEN

RED

V

IN

CPO

SGND

AUX2

AUX1

MAIN1

MAIN2

MAIN3

MAIN4

DV

CC

SDA

SCL

ENRGB/S

I

MS

I

RGB

ABSOLUTE AXI U RATI GS

(Note 1)

VIN, DVCC, CPO to GND............................... –0.3V to 6V

SDA, SCL, ENRGB/S ................. – 0.3V to (DV

I

(Continuous) (Note 4) ................................ 400mA

CPO

(Pulsed at 10% Duty Cycle) (Note 4)..................... 1A

I

MAIN1-4, ISUB1,2

(Pulsed at 10% Duty Cycle) (Note 4).............. 125mA

I

RED,GREEN,BLUE

(Pulsed at 10% Duty Cycle) (Note 4).............. 125mA

I

, I

MS

CPO Short-Circuit Duration ............................ Indefinite

Operating Temperature Range (Note 2) .. – 40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 3.6V, DVCC = 3V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Power Supply

White LED Current (MAIN1-MAIN4, SUB1, SUB2, AUX1, AUX2)

RGB LED Current (RED, GREEN, BLUE)

Charge Pump (CPO)

2

WW

W

U

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

+ 0.3V)

CC

, I

AUX 1, 2

(Note 4) ..................... 100mA

(Note 4) ..................................... 100mA

(Note 4) .................................................. 1mA

RGB

T

= 125°C, θJA = 37°C/W, θJC = 2°C/W

JMAX

EXPOSED PAD IS PGND (PIN 25)

MUST BE SOLDERED TO PCB

Consult LTC Marketing for parts specified with wider operating temperature ranges.

The ● denotes the specifications which apply over the full operating

VIN Operating Voltage ● 2.7 4.5 V

DVCC Operating Voltage ● 1.5 5.5 V

VIN Operating Current I

DVCC Operating Current Serial Port Idle 1 µA

VIN Shutdown Current 7.3 10 µA

DVCC Shutdown Current 1 µA

IMS Servo Voltage 25µA < IMS < 75µA 0.585 0.6 0.615 V

Full-Scale LED Current Ratio (I

LED/IMS

LED Dropout Voltage 1.5x Mode Switch Threshold, I

LED Brightness Range 0.78 100 %

LED Current Matching MAIN-MAIN, MAIN-AUX, SUB-SUB, SUB-AUX 1 %

I

Servo Voltage 25µA < I

RGB

LED Current Ratio (I

) RED, GREEN, BLUE Voltage = 1V 360 400 440 mA/mA

LED/IRGB

RGB LED Dropout Voltage 1.5x Mode Switch Threshold, I

RGB PWM (Duty Factor) Range 0/15 15/15 %

1x Mode Output Impedance 0.68 Ω

1.5x Mode Output Impedance VIN = 3V, V

I

CPO

CPO

= IMS = I

= IMS = I

= 0µA, Direct-Connect Mode 180 µA

RGB

= 0µA, 1.5x Step-Up Mode 3.9 mA

RGB

● 0.582 0.6 0.618 V

) MAIN1-MAIN4, SUB1, SUB2, AUX1, AUX2, Voltage = 1V ● 368 400 432 mA/mA

= 20mA 80 mV

LED

< 75µA 0.585 0.6 0.615 V

RGB

= 20mA 80 mV

LED

= 4.2V (Note 3) 1.90 Ω

CPO

● 0.582 0.6 0.618 V

NUMBER

LTC3206EUF

UF PART

MARKING

3206

3206f

LTC3206

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes the specifications which apply over the full operating

= 25°C. VIN = 3.6V, DVCC = 3V unless otherwise noted.

A

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

CPO Regulation Voltage I

= 20mA, 1.5x Mode 4.75 V

CPO

CLK Frequency 0.68 0.96 1.36 MHz

SDA, SCL, ENRGB/S

V

IL

V

IH

I

IH

I

IL

V

OL

Low Level Input Voltage ● 0.3 • DV

High Level Input Voltage ● 0.7 • DV

Input Current SDA, SCL, ENRGB/S = DV

CC

CC

–1 1 µA

CC

Input Current SDA, SCL, ENRGB/S = 0V –1 1 µA

Digital Output Low (SDA) I

= 3mA ● 0.4 V

PULLUP

Timing Characteristics (Note 5)

t

SCL

t

BUF

t

HD, STA

t

SU, STA

t

SU, STD

t

HD, DAT(OUT)

t

HD, DAT(IN)

t

SU, DAT

t

LOW

t

HIGH

t

f

t

r

t

SP

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3206E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

Clock Operating Frequency 400 kHz

Bus Free Time Between Stop and Start Condition 1.3 µs

Hold Time After (Repeated) Start Condition 0.6 µs

Repeated Start Condition Setup Time 0.6 µs

Stop Condition Setup Time 0.6 µs

Data Hold Time 225 900 ns

Input Data Hold Time 0 900 ns

Data Setup Time 100 ns

Clock Low Period 1.3 µs

Clock High Period 0.6 µs

Clock Data Fall Time 20 300 ns

Clock Data RiseTime 20 300 ns

Spike Suppression Time 50 ns

with statistical process controls.

Note 3: 1.5x mode output impedance is defined as (1.5VIN – V

CPO

)/I

OUT

.

Note 4: Based on long term current density limitations.

Note 5: All values are referenced to V

and V

IH

levels.

IL

V

V

UW

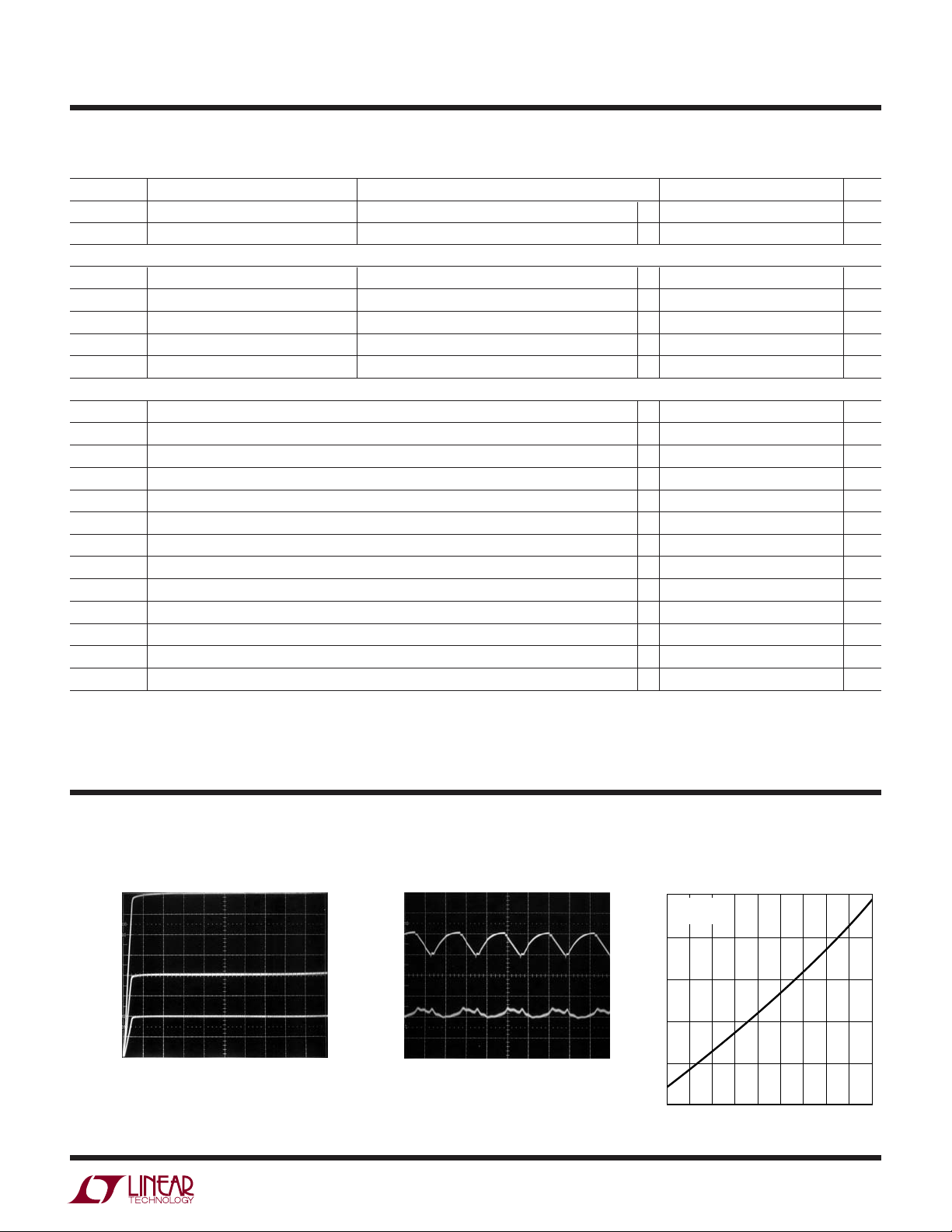

TYPICAL PERFOR A CE CHARACTERISTICS

I

LED

2.5mA/DIV

0mA

LED Pin Sink Current

vs LED Pin Voltage

100%

50%

25%

200mV/DIV 3206 G01 I

V

AT CURRENT SOURCE PIN

LED

AC COUPLED

(50mV/DIV)

AC COUPLED

(50mV/DIV)

Input and Output

Charge Pump Noise

CPO

V

IN

= 200mA 500ns/DIV 3206 G02

CPO

VIN = 3.6V

= C

= 1.6µF

C

IN

CPO

LED Pin Dropout Voltage

vs LED Pin Current

500

VIN = 3.6V

= 25°C

T

A

400

300

200

100

LED PIN DROPOUT VOLTAGE (mV)

0

10 30

20

50 90

60

40

LED CURRENT (mA)

70

80

100

3206 GO3

3206f

3

LTC3206

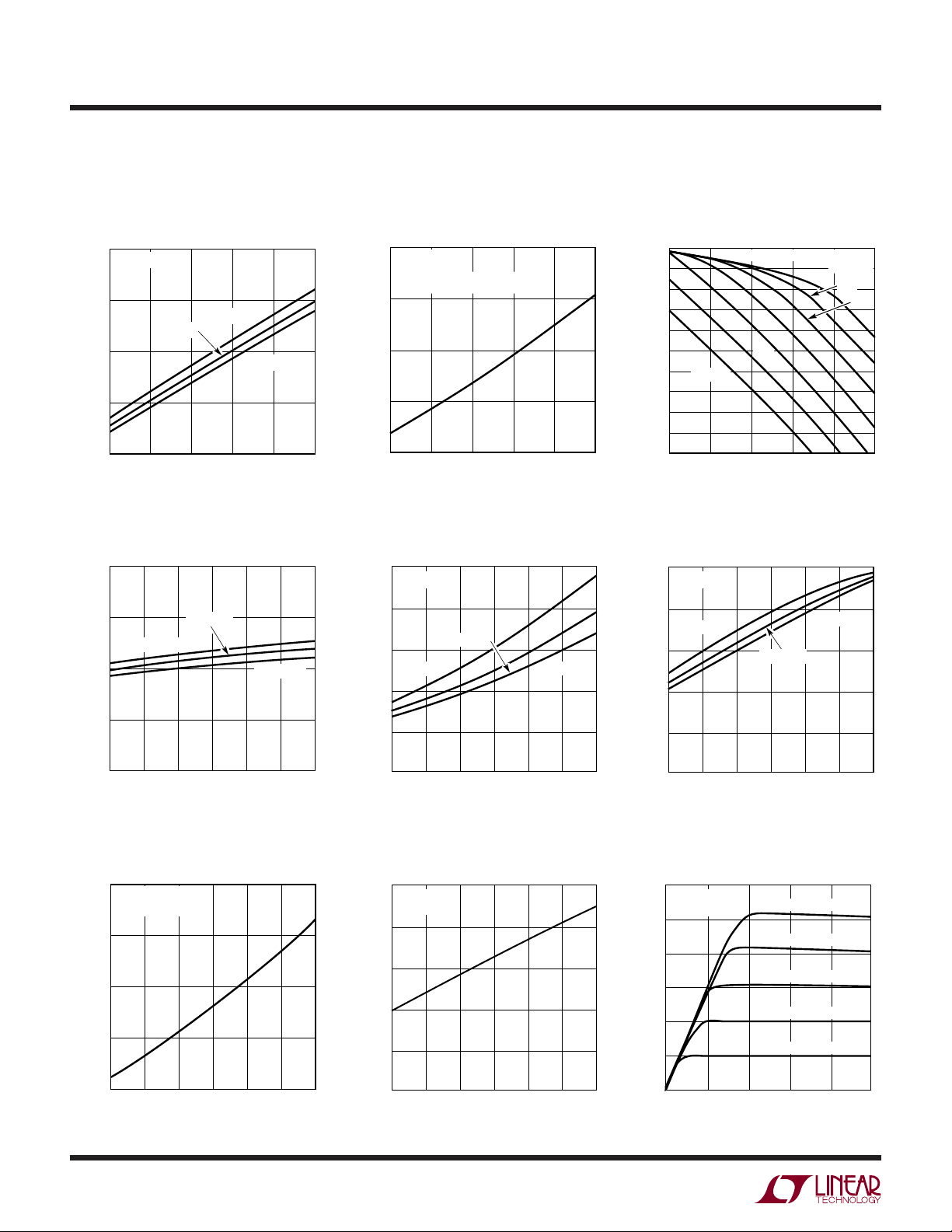

UW

TYPICAL PERFOR A CE CHARACTERISTICS

1.5x Mode Charge Pump Open1x Mode Switch Resistance

vs Temperature

0.9

I

= 100mA

CPO

0.8

VIN = 3.6V

0.7

0.6

SWITCH RESISTANCE (Ω)

0.5

–40

–15

10

TEMPERATURE (°C)

V

IN

= 3.3V

VIN = 3.9V

35

60

85

3206 G04

Loop Output Resistance vs

Temperature (1.5V

2.50

VIN = 3V

= 4.2V

V

CPO

= C

= C

= C

FLY1

TEMPERATURE (°C)

OUTPUT RESISTANCE (Ω)

2.25

2.00

1.75

1.50

C

IN

CPO

–15 10 35 60

–40

FLY2

– V

IN

= 1.6µF

CPO

)/I

CPO

3206 G05

1.5x Mode CPO Voltage

vs Load Current

4.8

4.7

4.6

4.5

4.4

4.3

4.2

CPO VOLTAGE (V)

4.1

4.0

3.9

85

3.8

0

CIN = C

3.1V

VIN = 3V

100

LOAD CURRENT (mA)

200

CPO

3.2V

= C

3.3V

FLY1 CFLY2

3.6V

300

400

T

A

= 1.6µF

= 25°C

3.5V

3.4V

3206 G06

500

Oscillator Frequency

vs Supply Voltage

1100

1000

TA = –40°C

900

FREQUENCY (kHz)

800

700

2.7

3.0 3.3 3.6 3.9

TA = 25°C

VIN SUPPLY VOLTAGE (V)

1x Mode No Load Supply Current

vs Input Voltage

300

TA = 25°C

= I

= 0µA

I

MS

RGB

250

200

SUPPLY CURRENT (µA)

150

TA = 85°C

4.2 4.5

3206 G07

DVCC Shutdown Current

vs Input Voltage

0.5

VIN = 3.6V

0.4

TA = –40°C

3.0

TA = 25°C

3.3 3.6 3.9

DVCC VOLTAGE (V)

SHUTDOWN CURRENT (µA)

DV

0.3

0.2

CC

0.1

0

2.7

1.5x Mode Supply Current

vs I

(IIN – 1.5I

CPO

10

VIN = 3.6V

= 25°C

T

A

8

6

4

SUPPLY CURRENT (mA)

2

CPO

)

TA = 85°C

4.2 4.5

3206 G08

VIN Shutdown Current

vs Input Voltage

10

DVCC = 3V

8

TA = –40°C

6

4

SHUTDOWN CURRENT (µA)

IN

2

V

0

2.7

3.0

TA = 25°C

3.3 3.6 3.9

INPUT VOLTAGE (V)

LED Pin Voltage for Higher LED

Currents

120

VIN = 3.6V

= 25°C

T

A

100

80

60

40

LED CURRENT (mA)

20

IMS, I

IMS, I

IMS, I

IMS, I

IMS, I

TA = 85°C

= 250µA

RGB

= 200µA

RGB

= 150µA

RGB

= 100µA

RGB

= 50µA

RGB

4.2 4.5

3206 G09

4

100

2.7

3.0 3.3 3.6 3.9

INPUT VOLTAGE (V)

4.2 4.5

3206 G10

0

0

100 150 200

50

LOAD CURRENT (mA)

250 300

3206 G11

0

0

0.4 0.6 0.8

0.2

LED PIN VOLTAGE (V)

1.0

3206 G12

3206f

LTC3206

U

UU

PI FU CTIO S

SUB1, SUB2 (Pins 1, 2): Current Source Outputs for the

SUB Display White LEDs. The current for the SUB display

is controlled by the resistor on the I

SUB display can be set to exponentially increasing brightness levels from 0.78% to 100% of full-scale. See Table 1.

C1+, C1–, C2+, C2– (Pins 5, 4, 6, 3): Charge Pump Flying

Capacitor Pins. A 2.2µF X7R or X5R ceramic capacitor

should be connected from C1

+

to C2–.

C2

DV

(Pin 7): This pin sets the logic reference level of the

CC

SDA, SCL and ENRGB/S pins.

SDA (Pin 8): Input Data for the I2C Serial Port. Serial data

is shifted in one bit per clock to control the LTC3206 (see

Figures 3 and 4). The logic level for SDA is referenced to

DVCC.

SCL (Pin 9): Clock Input for the I2C Serial Port (see Figures

3 and 4). The logic level for SCL is referenced to DVCC.

ENRGB/S (Pin 10): This pin is used to enable and disable

either the RED, GREEN and BLUE current sources or the

SUB display depending on which is programmed to respond via the I2C port. Once ENRGB/S is brought high, the

LTC3206 illuminates the RGB or SUB display with the

color combination or intensity that was previously programmed via the I2C port. The logic level for ENRGB/S is

referenced to DVCC.

IMS (Pin 11): This pin controls the maximum amount of

LED current in both the MAIN and SUB LED displays. The

IMS pin servos to 0.6V when there is a resistor to ground.

The full scale (100%) currents in the MAIN and SUB

display LEDs will be 400 times the current at the IMS pin.

I

(Pin 12): This pin controls the amount of LED current

RGB

at the RED, GREEN and BLUE LED pins. The I

servos to 0.6V when there is a resistor to ground. The

current in the RED, GREEN and BLUE LEDs will be 400

times the current at the I

scale.

+

pin when programmed to full

RGB

pin.The LEDs on the

MS

to C1– and another from

pin

RGB

CPO (Pin 14): Output of the Charge Pump. This output

should be used to power white, blue and “true” green

LEDs. Red LEDs can be powered from V

or X7R low impedance (ceramic) 2.2µF charge storage

capacitor is required on CPO.

VIN (Pin 15): Supply Voltage for the Charge Pump. The V

pin should be connected directly to the battery and bypassed with a 2.2µF X5R or X7R ceramic capacitor.

RED, GREEN, BLUE (Pins 16, 17, 18): Current Source

Outputs for the RGB Illuminator LEDs. The currents for the

RGB LEDs are controlled by the resistor on the I

The RGB LEDs can independently be set to any duty cycle

from 0/15 through 15/15 under software control giving a

total of 16 shades per LED and 4096 colors for the

illuminator. See Table 1. The RGB LEDs are modulated at

1/240 the speed of the charge pump oscillator (approximately 4kHz).

MAIN1-MAIN4 (Pins 22, 21, 20, 19): Current Source

Outputs for the Main Display White LEDs. The current for

the main display is controlled by the resistor on the I

pin. The LEDs on the MAIN display can be set to 16

exponentially increasing brightness steps from 0.78% to

100% of full scale. See Table 1.

AUX1, AUX2 (Pins 23, 24): Current source outputs for the

auxiliary white LEDs. The auxiliary current sources can be

individually assigned to be either MAIN display or SUB

display LEDs via the I2C serial port. When either AUX1 and/

or AUX2 are assigned to the MAIN display they will have

the same power setting as the other MAIN LEDs. Likewise,

when either AUX1 and/or AUX2 are assigned to the SUB

display they will have the same power setting as the other

SUB LEDs. The currents for the AUX1 and AUX2 pins are

controlled by the resistor on the IMS pin.

PGND (Pin 25, Exposed Pad): Power Ground for the

Charge Pump. This pin should be connected directly to a

low impedance ground plane.

or CPO. An X5R

IN

pin.

RGB

IN

MS

SGND (Pin 13): Ground for the control logic. This pin

should be connected directly to a low impedance ground

plane.

3206f

5

LTC3206

BLOCK DIAGRA

W

I

I

RGB

SGND

C1+C1–C2+C2

5 4 6 3

960kHz

OSCILLATOR

V

15

IN

1x AND 1.5x CHARGE PUMP

–

PGND

25

CPO

14

–

+

+

–

11

MS

+

–

12

13

ENABLECP

MAIN1

22

MAIN2

21

MAIN3

20

MAIN4

19

AUX1

23

AUX2

24

2

2

SUB1

1

SUB2

2

2

DV

7

ENRGB/S

SDA

SCL

CC

10

8

9

STOP

CONTROL

LOGIC

4 4 4244 4

COMMAND LATCH

I2C SERIAL PORT

PWM

U

OPERATIO

Power Management

To optimize efficiency, the power management section of

the LTC3206 provides two methods of supplying power to

the CPO pin: 1x direct connect mode or 1.5x boost mode.

When any display of the LTC3206 is enabled, the power

management system connects the CPO pin directly to V

with a low impedance switch. If the voltage supplied at V

is high enough to power all of the LEDs with the programmed current, the system will remain in this “direct

connect” mode providing maximum efficiency. Internal

IN

IN

RED

16

GREEN

17

BLUE

18

3206 BD

circuits monitor all current sources for the onset of “dropout,” the point at which the current sources can no longer

supply programmed current. As the battery voltage falls,

the LED with the largest forward voltage will reach the dropout threshold first. When any of the LED pins reach the dropout threshold, the LTC3206 will switch to boost mode and

automatically soft-start the 1.5x boost charge pump. The

constant frequency charge pump is designed to minimize

the amount of noise generated at the VIN supply.

3206f

6

OPERATIO

LTC3206

U

The 1.5x step-up charge pump uses a patented constant

frequency architecture to combine the best efficiency with

the maximum available power at the lowest noise level.

The charge pump of the LTC3206 can be forced to come

on even if no LEDs are programmed for current. Setting bit

2

A3 in the I

C serial port forces the charge pump on (see

Figure 3).

Soft-Start

To prevent excessive inrush current and supply droop

when switching into step-up mode, the LTC3206 employs

a soft-start feature on its charge pump. The current

available to the CPO pin is increased linearly over a period

of about 400µs.

Charge Pump Strength

When the LTC3206 operates in 1.5x boost mode, the

charge pump can be modeled as a Thevenin-equivalent

circuit to determine the amount of current available from

the effective input voltage, 1.5V

and the effective open-

IN

loop output resistance, ROL (Figure 1).

ROL is dependent on a number of factors including the

switching term, 1/(2f

OSC

• C

), internal switch resis-

FLY

tances and the non-overlap period of the switching circuit.

However, for a given ROL, the amount of current available

will be directly proportional to the advantage voltage 1.5V

– V

. Consider the example of driving white LEDs from

CPO

IN

a 3.1V supply. If the LED forward voltage is 3.8V and the

current sources require 100mV, the advantage voltage is

3.1V • 1.5 – 3.8V – 0.1V or 750mV. Notice that if the input

voltage is raised to 3.2V, the advantage voltage jumps to

900mV—a 20% improvement in available strength.

From Figure 1, the available current is given by:

VV

15.–

I

OUT

=

IN CPO

R

OL

R

OL

+

1.5V

IN

–

3206 F01

Figure 1. Equivalent Open-Loop Circuit

+

CPO

–

Typical values of ROL as a function of temperature are

shown in Figure 2.

2.50

VIN = 3V

= 4.2V

V

CPO

= C

= C

= C

C

IN

CPO

2.25

2.00

1.75

OUTPUT RESISTANCE (Ω)

1.50

–40

Figure 2. Typical ROL vs Temperature

FLY1

–15 10 35 60

TEMPERATURE (°C)

FLY2

= 1.6µF

85

3206 F02

I2C Interface

The LTC3206 communicates with a host (master) using

the standard I2C 2-wire interface. The Timing Diagram

(Figure 4) shows the timing relationship of the signals on

the bus. The two bus lines, SDA and SCL, must be high

when the bus is not in use. External pull-up resistors or

current sources, such as the LTC1694 SMBus accelerator,

are required on these lines. The LTC3206 is a receive-only

(slave) device.

Bus Speed

The I2C port is designed to be operated at speeds of up to

400kHz. It has built-in timing delays to ensure correct

operation when addressed from an I2C compliant master

device. It also contains input filters designed to suppress

glitches should the bus become corrupted.

START and STOP Conditions

A bus-master signals the beginning of a communication to

a slave device by transmitting a START condition. A

START condition is generated by transitioning SDA from

high to low while SCL is high. When the master has

finished communicating with the slave, it issues a STOP

condition by transitioning SDA from low to high while SCL

is high. The bus is then free for communication with

another I2C device.

3206f

7

LTC3206

OPERATIO

U

Byte Format

Each byte sent to the LTC3206 must be 8 bits long followed

by an extra clock cycle for the Acknowledge bit to be

returned by the LTC3206. The data should be sent to the

LTC3206 most significant bit (MSB) first.

Acknowledge

The Acknowledge bit is used for handshaking between the

master and the slave. An Acknowledge (active LOW)

generated by the slave (LTC3206) lets the master know

that the latest byte of information was received. The

Acknowledge related clock pulse is generated by the

master. The master releases the SDA line (HIGH) during

the Acknowledge clock cycle. The slave-receiver must pull

down the SDA line during the Acknowledge clock pulse so

that it remains a stable LOW during the HIGH period of this

clock pulse.

Slave Address

The LTC3206 responds to only one 7-bit address which

has been factory programmed to 0011011. The eighth bit

of the address byte (R/W) must be 0 for the LTC3206 to

recognize the address since it is a write only device. This

is equivalent to an 8-bit address where the least significant

bit of the address is always 0. If the correct seven bit

address is given but the R/W bit is 1, the LTC3206 will not

respond.

Bus Write Operation

The master initiates communication with the LTC3206

with a START condition and a 7-bit address followed by the

Write Bit R/W = 0. If the address matches that of the

LTC3206, the LTC3206 returns an Acknowledge. The

master should then deliver the most significant data byte.

Again the LTC3206 acknowledges and the cycle is repeated two more times for a total of one address byte and

three data bytes. Each data byte is transferred to an

internal holding latch upon the return of an Acknowledge.

After all three data bytes have been transferred to the

LTC3206, the master may terminate the communication

with a STOP condition. Alternatively, a REPEAT-START

condition can be initiated by the master and another chip

on the I2C bus can be addressed. This cycle can continue

indefinitely and the LTC3206 will remember the last input

of valid data that it received. Once all chips on the bus have

been addressed and sent valid data, a STOP condition can

be sent and the LTC3206 will update its command latch

with the data that it had received.

In certain circumstances, the data on the I

become corrupted. In these cases the LTC3206 responds

appropriately by preserving only the last set of complete

data that it has received. For example, assume the LTC3206

has been successfully addressed and is receiving data

when a STOP condition mistakenly occurs. The LTC3206

will ignore this stop condition and will not respond until a

new START condition, correct address, new set of data

and STOP condition are transmitted.

Likewise, if the LTC3206 was previously addressed and

sent valid data but not updated with a STOP, it will respond

to any STOP that appears on the bus independent of the

number of REPEAT-STARTs that have occurred. An exception occurs if a REPEAT-START is given and the

LTC3206 successfully acknowledges its addressed. In

this case, it will not respond to a STOP after the first data

byte is acknowledged. It will, however, respond after the

third data byte is acknowledged.

2

C bus may

8

3206f

UWW

ACK ACK

123

ADDRESS WR

456789123456789123456789123456789

00110 110

00110110

A7 A6 A5 A4 A3 A2 A1 A0

A7 A6 A5 A4 A3 A2 A1 A0 B7 B6 B5 B4 B3 B2 B1 B0

B7 B6 B5 B4 B3 B2 B1 B0

C7 C6 C5 C4 C3 C2 C1 C0

C7 C6 C5 C4 C3 C2 C1 C0

ACK

STOPSTART

SDA

SCL

ACK

FORCE

CHARGE PUMP

ENSUB_ENRGB

AUXSEL1

AUXSEL0

RED

BLUE

GREEN

MAIN

SUB

3206 FO3

t

SU, DAT

t

HD, STA

t

HD, DAT

SDA

SCL

t

SU, STA

t

HD, STA

t

SU, STO

3206 F04

t

BUF

t

LOW

t

HIGH

START

CONDITION

REPEATED START

CONDITION

STOP

CONDITION

START

CONDITION

t

r

t

f

t

SP

RED

GREEN

BLUE

MAIN

SUB

HEX

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

A7

B3

B7

C7

C3

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

A4

B0

B4

C4

C0

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

A6

B2

B6

C6

C2

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

A5

B1

B5

C5

C1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

4-BIT CODE SUB-RANGE

NA

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/2

1/2

1

1

DUTY CYCLE

NA

3.13%

4.42%

6.25%

8.80%

12.50%

17.70%

25.00%

35.35%

50.00%

70.70%

100.00%

70.70%

100.00%

70.70%

100.00%

BRIGHTNESS

LEVEL

OFF

0.78%

1.07%

1.56%

2.25%

3.13%

4.40%

6.25%

8.90%

12.50%

17.70%

25.00%

35.35%

50.00%

70.70%

100.00%

BRIGHTNESS

LEVEL

OFF

1/15(6.7%)

2/15(13.3%)

3/15(20.0%)

4/15(26.7%)

5/15(33.3%)

6/15(40.0%)

7/15(46.7%)

8/15(53.3%)

9/15(60.0%)

10/15(66.6%)

11/15(73.3%)

12/15(80.0%)

13/15(86.7%)

14/15(93.3%)

15/15(100.0%)

MAIN

SUB

AUX

RED

GREEN

BLUE

A0

0

0

1

1

A1

0

1

0

1

AUX1

MAIN

MAIN

SUB

SUB

AUX2

MAIN

SUB

MAIN

SUB

A2

0

1

CONTROL

RGB DISPLAY

SUB DISPLAY

TI I G DIAGRA

LTC3206

Figure 3. Bit Assignments

Table 3. ENRGB/S Assignment

Table 2. Auxilliary LED Pin Assignments

Figure 4. Timing Parameters

Table 1. Serial Port Bit Assignments

3206f

9

LTC3206

WUUU

APPLICATIO S I FOR ATIO

White LED Brightness Control

The White LED displays (MAIN, SUB and AUX) have 16

individual brightness settings. The settings are exponentially spaced to compensate for the nearly logarithmic

characteristic of human vision perception. The base of the

power settings is √2 . The off setting (0 power) is a special

case needed for shutdown.

The LTC3206 uses a subranging technique to control the

LED brightness with a combination of both DC level

control and pulse width modulation. Table 1 summarizes

the level control operation. The DC level of the LEDs will be

one of either three sub-range settings, 100%, 50% or 25%

of full scale. For example, if the full scale LED current is

programmed (via the IMS pin) to be 20mA, then the “on”

level of the LED will be either 20mA, 10mA or 5mA

respectively. The power to the LED will be the product of

the subrange (DC current) and the PWM setting. For

example, if an LED power of 2.25% is desired, then the

LTC3206 sets the sub range to 25% and the duty cycle to

8.8%. These settings are designed to optimize the efficiency of the dual-mode LTC3206 power management

system while preserving LED color accuracy at low power

levels.

To achieve brightness control by purely DC means, only

the 100%, 50% or 25% power settings should be selected.

The DC current levels of the MAIN, SUB and AUX LEDs are

controlled by a precisely mirrored multiple of the current

at the IMS pin. The IMS pin servos to a fixed level of 0.6V so

the current is programmed simply by adding a resistor

from IMS to ground.

The current that flows during the “on” time will follow the

relationship:

V

IS

= 40006••

LED

where S is the subrange for the given power setting (it will

be either 25%, 50% or 100%, see Table 1) and RMS is the

value of the resistor at the IMS pin.

The average LED current (LED power level) will follow the

relationship:

.

R

MS

D

AVG I

() •.•=−400

LED

06

R

MS

V

15

2

where D is the decimal equivalent of the 4-bit digital code

programmed for the given display (0 to 15).

The PWM frequency is 1/1024 of the frequency of the

charge pump oscillator (typically 938Hz). During PWM,

the LED currents are soft-switched to minimize noise.

AUX LEDs

The AUX1 and AUX2 LEDs can be arbitrarily assigned to

either the MAIN or SUB display. Table 2 summarizes the

assignment possibilities. When an AUX pin is assigned to

a display, it will follow the power level (both DC and PWM)

set for that display.

Unused White LED Pins

The LTC3206 can power up to eight white LEDs (four for

the MAIN display, two for the SUB display and the two

flexible AUX pins), however, it is not necessary to use all

eight in each application.

Any of these LED pins can cause the LTC3206 to switch

from 1x mode to 1.5x charge pump mode if they drop out.

In fact, if an unused LED pin is left unconnected or

grounded, it

will

drop out and force the LTC3206 into

charge pump mode.

To avoid this problem, unused MAIN, SUB or AUX LED

pins can be disabled by connecting them to CPO. Power is

not wasted in this configuration. When the LED pin voltage

is within approximately 1V of CPO, its LED current is

switched off and only a small 10µA test current remains.

Figure 5 shows a block diagram of each of the MAIN, SUB

and AUX LED pins.

CPO

1V

+

+

–

MAIN1-MAIN4

SUB1, SUB2, AUX1, AUX2

–

ENABLE

I

LED

Figure 5. Internal MAIN, SUB and AUX LED Disable Circuit

10µA

3206 F05

3206f

10

WUUU

APPLICATIO S I FOR ATIO

LTC3206

The RED, GREEN and BLUE pins can also enable the

charge pump, however, since they each have individual

disable control they can be left floating or grounded if

unused.

RGB Illuminator Brightness Control

The RED, GREEN and BLUE LEDs can be individually set

to have a linear duty cycle ranging from 0/15 (off) to

15/15 (full on) with 1/15 increments in between. The

combination of 16 possible brightness levels gives the

RGB indicator LED a total of 4096 colors. Table 1 indicates

the decoding of the RED, GREEN and BLUE LEDs.

The full-scale currents in the RED, GREEN and BLUE LEDs

are controlled by the current at the I

pin in a similar

RGB

manner to those in the MAIN, SUB and AUX LEDs. The

I

pin also servos to 0.6V and the RGB LED currents are

RGB

a precise multiple of the I

current. The DC value of the

RGB

RGB display LED currents will follow the relationship:

.

06

R

RGB

V

pin.

RGB

I

RED GREENBLUE

,,

where R

RGB

= 400

is the value of the resistor at the I

The average value of the current in the RED, GREEN and

BLUE LEDs will be:

(see Figure 3 and Table 3) determines which display

ENRGB/S controls. When bit A2 is 0, the ENRGB/S pin

controls the RGB display. If it is set to 1, ENRGB/S controls

the SUB display.

To use the ENRGB/S pin, the I2C port must first be

configured to the desired setting. For example, if ENRGB/S

will be used to control the SUB display, then a non-zero

code must reside in the C3-C0 nibble of the I2C port and bit

A2 must be set to 1 (see Table 1). Now when ENRGB/S is

high (DVCC), the SUB display will be on with the C3-C0

setting. When ENRGB/S is low, the SUB display will be off.

If no other displays are programmed to be on, the entire

chip will be in shutdown.

Likewise, if ENRGB/S will be used to enable the RGB

display, then a non-zero code must reside in one of the

RED, GREEN or BLUE nibbles of the serial port (A4-A7 or

B0-B7), and bit A2 must be 0. Now when ENRGB/S is high

(DVCC), the RGB display will light with the programmed

color. When ENRGB/S is low, the RGB display will be off.

If no other displays are programmed to be on, the entire

chip will be in shutdown.

If bit A2 is set to 1 (SUB display control), then ENRGB/S

will have no effect on the RGB display. Likewise, if bit A2

is set to 0 (RGB display control), then ENRGB/S will have

no effect on the SUB display.

DV

.

AVG I

()••

RED GREENBLUE

,,

= 400

15

06

R

RGB

where D is the decimal equivalent of the 4-bit digital code

programmed for the given LED(0 to 15). Table 1 summarizes the RED, GREEN and BLUE LED power settings.

The RED, GREEN and BLUE LEDs are pulse width modulated at a frequency of 1/240 of the frequency of the charge

pump oscillator or about 4kHz.

ENRGB/S Pin

The ENRGB/S pin can be used to enable or disable the

LTC3206 without re-accessing the I2C port. This might be

useful to indicate an incoming phone call without waking

the microcontroller. ENRGB/S can be software programmed as an independent control for either the RGB

display or the SUB display. Control bit A2 in the serial port

If the ENRGB/S pin is not used, it should be connected to

DVCC. It should not be grounded or left floating.

VIN, CPO Capacitor Selection

The style and value of capacitors used with the LTC3206

determine several important parameters such as regulator

control-loop stability, output ripple and charge pump

strength. To reduce noise and ripple, it is recommended

that low equivalent series resistance (ESR) multilayer

ceramic capacitors be used on both VIN and CPO. Tantalum and aluminum capacitors are not recommended because of their high ESR. The value of the capacitor on CPO

directly controls the amount of output ripple for a given

load current. Increasing the size of this capacitor will

reduce the output ripple. The peak-to-peak output ripple is

approximately given by the expression:

I

V

RIPPLE

P-P

≅

CPO

fC

3•

OSC CPO

3206f

11

LTC3206

WUUU

APPLICATIO S I FOR ATIO

where f

960kHz) and C

is the LTC3206’s oscillator frequency (typically

OSC

is the output charge storage capacitor

CPO

on CPO. Both the style and value of the output capacitor

can significantly affect the stability of the LTC3206. The

LTC3206 uses a linear control loop to adjust the strength

of the charge pump to match the current required at the

output. The error signal of this loop is stored directly on

the output charge storage capacitor. The charge storage

capacitor also serves to form the dominant pole for the

control loop. To prevent ringing or instability, it is important for the output capacitor to maintain at least 0.6µF of

capacitance over all conditions. Likewise, excessive ESR

on the output capacitor will tend to degrade the loop

stability of the LTC3206. The closed-loop output resistance of the LTC3206 is designed to be 0.4Ω. For a 100mA

load current change, the error signal will change by about

40mV. If the output capacitor has 0.4Ω or more of ESR,

the closed-loop frequency response will cease to roll off in

a simple one-pole fashion and poor load transient response or instability could result. Multilayer ceramic chip

capacitors typically have exceptional ESR performance.

MLCC capacitors combined with a tight board layout, will

yield very good stability. As the value of C

controls the

CPO

amount of output ripple, the value of CIN controls the

amount of ripple present at the input pin (VIN). The input

current to the LTC3206 will be relatively constant while the

charge pump is on either the input charging phase or the

output charging phase but will drop to zero during the

clock nonoverlap times. Since the non-overlap time is

small (~25ns), these missing “notches” will result in only

a small perturbation on the input power supply line. Note

that a higher ESR capacitor such as tantalum will have

higher input noise due to the input current change times

the ESR. Therefore, ceramic capacitors are again recommended for their exceptional ESR performance. Input

noise can be further reduced by powering the LTC3206

through a very small series inductor as shown in Figure 6.

A 10nH inductor will reject the fast current notches,

thereby presenting a nearly constant current load to the

input power supply. For economy, the 10nH inductor can

be fabricated on the PC board with about 1cm (0.4") of PC

board trace.

Flying Capacitor Selection

10nH

V

IN

Figure 6. 10nH Inductor Used for Input Noise

Reduction (Approximately 1cm of Wire)

V

IN

2.2µF0.1µF

LTC3206

GND

3206 F06

Warning: A polarized capacitor such as tantalum or aluminum should never be used for the flying capacitors since

their voltage can reverse upon start-up of the LTC3206.

Ceramic capacitors should always be used for the flying

capacitors.

The flying capacitor controls the strength of the charge

pump. In order to achieve the rated output current it is

necessary to have at least 1µF of capacitance for each of

the flying capacitors. Capacitors of different materials lose

their capacitance with higher temperature and voltage at

different rates. For example, a ceramic capacitor made of

X7R material will retain most of its capacitance from

–40°C to 85°C whereas a Z5U or Y5V style capacitor will

lose considerable capacitance over that range. Z5U and

Y5V capacitors may also have a very poor voltage coefficient causing them to lose 60% or more of their capacitance when the rated voltage is applied. Therefore, when

comparing different capacitors, it is often more appropriate to compare the amount of achievable capacitance for

a given case size rather than comparing the specified

capacitance value. For example, over rated voltage and

temperature conditions, a 1µF, 10V, Y5V ceramic capaci-

tor in a 0603 case may not provide any more capacitance

than a 0.22µF, 10V, X7R available in the same 0603 case.

The capacitor manufacturer’s data sheet should be consulted to determine what value of capacitor is needed to

ensure minimum capacitances at all temperatures and

voltages.

12

3206f

WUUU

GND

V

IN

CPO

3206 F07

PIN 1

APPLICATIO S I FOR ATIO

Table 4 shows a list of ceramic capacitor manufacturers

and how to contact them:

Table 4. Recommended Capacitor Vendors

AVX www.avxcorp.com

Kemet www.kemet.com

Murata www.murata.com

Taiyo Yuden www.t-yuden.com

Vishay www.vishay.com

For very light load applications, the flying capacitors

may be reduced to save space or cost. The theoretical

minimum output resistance of a 1.5x fractional charge

pump is given by:

.–

15 1

VV

R

OL MIN

where f

C

is the value of the flying capacitors. Note that the

FLY

≡ =

()

is the switching frequency (960kHz typ) and

OSC

charge pump will typically be weaker than the theoretical

limit due to additional switch resistance, however for very

light load applications, the above expression can be used

as a guideline in determining a starting capacitor value.

Layout Considerations and Noise

Due to its high switching frequency and the transient

currents produced by the LTC3206, careful board layout is

necessary. A true ground plane and short connections to

all capacitors will improve performance and ensure proper

regulation under all conditions. Figure 7 shows the recommended layout configuration.

The flying capacitor pins C1+, C2+, C1– and C2– will have

very high edge rate waveforms. The large dv/dt on these pins

can couple energy capacitively to adjacent printed circuit

board runs. Magnetic fields can also be generated if the

flying capacitors are not close to the LTC3206 (i.e., the loop

area is large). To decouple capacitive energy transfer, a

Faraday shield may be used. This is a grounded PC trace

between the sensitive node and the LTC3206 pins. For a high

quality AC ground, it should be returned to a solid ground

plane that extends all the way to the LTC3206.

IN OUT

IfC

OUT OSC FLY

2

LTC3206

Figure 7. Optimum Single Layer PCB Layout

Power Efficiency

To calculate the power efficiency (η) of a white LED driver

chip, the LED power should be compared to the input

power. The difference between these two number represents lost power whether it is in the charge pump or the

current sources. Stated mathematically, the power efficiency is given by:

P

LED

η≡

P

IN

The efficiency of the LTC3206 depends upon the mode in

which it is operating. Recall that the LTC3206 operates as

a pass switch, connecting VIN to CPO until one of the LEDs

drops out. This feature provides the optimum efficiency

available for a given input voltage and LED forward voltage. When it is operating as a switch, the efficiency is

approximated by:

P

LED

η≡ = ≅

P

IN

since the input current will be very close to the LED

current.

At moderate to high output power, the quiescent current

of the LTC3206 is negligible and the expression above is

valid. For example, with VIN = 3.9V, I

and V

equal to 3.6V, the measured efficiency is 92.2%,

LED

which is very close to the theoretical 92.3% calculation.

•

VI

LED LED

•

VIVV

IN IN

LED

IN

= 20mA • 6 LEDs

OUT

3206f

13

LTC3206

WUUU

APPLICATIO S I FOR ATIO

Once an LED pin drops out, the LTC3206 switches into

step-up mode. Employing the fractional ratio 1.5x charge

pump, the LTC3206 provides more efficiency than would

be achieved with a voltage doubling charge pump.

In 1.5x boost mode, the efficiency is similar to that of a

linear regulator with an effective input voltage of 1.5 times

the actual input voltage. This is because the input current

for a 1.5x fractional charge pump is approximately 1.5

times the load current. In an ideal 1.5x charge pump, the

power efficiency would be given by:

P

η

IDEAL

LED

≡ = ≅

P

Thermal Management

For higher input voltages and maximum output current,

there can be substantial power dissipation in the LTC3206.

If the junction temperature increases above approximately

160°C the thermal shutdown circuitry will automatically

deactivate the output. To reduce the maximum junction

temperature, a good thermal connection to the PC board

is recommended. Connecting the PGND pin (exposed

center pad) to a ground plane and maintaining a solid

ground plane under the device can reduce the thermal

resistance of the package and PC board considerably.

Brightness Control

Although the LTC3206 has many exponentially spaced

brightness settings for the main and sub displays, it is

possible to control the brightness by alternative means.

Figure 8 shows an example of how an external voltage

source can be use to inject a current into the IMS or I

pins to control brightness. For example, if R1 and R2 are

24k, then the LED current would range from 20mA to 0mA

as V

is swept from 0V to 1.2V.

CNTRL

Alternatively, if only digital outputs are available, the

number of settings can be doubled from 15 to 30 by simply

VI

•

LED LED

VIVV

IN

•. .15 15

IN LED

LED

IN

RGB

V

0.6V

CNTRL

–

||

R2

R1

3206 F08

R2

R2

V

CNTRL

R1

LTC3206

I

I

MS

RGB

I

= 400

LED

()

11

12

12k

Figure 8. Alternative Linear Brightness Control

connecting V

to a digital signal. This topology can be

CNTRL

extended to any number of bits and can also be applied to

the RGB display.

Finally, PWM brightness control can be achieved by apply-

LTC3206

I

I

RGB

MS

11

12

12k

Figure 9. Alternative Digital Brightness Control

18.2k

3206 F09

34k

V

DIG

0V TO 0.7V

OR HIGHER

ing a PWM signal to the IMS programming resistor as

shown in Figure 10. The signal should range from 0V (full

on) to any voltage above 0.7V (full off).

LTC3206

I

I

RGB

Figure 10. PWM Brightness Control of the MAIN and SUB Displays

MS

12k

11

12k

12

PWM SIGNAL

0V TO 0.7V OR HIGHER

BRIGHTNESS = 1 – D

3206 F10

14

3206f

TYPICAL APPLICATIO S

2.2µF2.2µF

V

IN

2.7V TO

2.7V TO

4.5V

4.5V

I2C SERIAL

INTERFACE

V

IN

V

IN

2.2µF 2.2µF

LTC3206

MAIN1-4

AUX 1

AUX 2

I

RGB

12k 12k

SUB1-2

RGB

I

MS

2

SERIAL PORT

Main Backlight, Keypad Backlight Plus Motor Controller

2.2µF2.2µF

V

IN

2.2µF 2.2µF

CPO

LTC3206

U

CPO

4-Display Controller

MAIN DISPLAY SUB DISPLAY ILLUMINATOR

4

2

3

MAIN DISPLAY KEYPAD

RED GREEN BLUE

FLASH

CAMERA

LIGHT

3206 TA02

LTC3206

MAIN1-4

AUX 1-2

SUB1-2

R

I

MS

12k 12k

G

I2C SERIAL

INTERFACE

2

SERIAL PORT

I

RGB

PACKAGE DESCRIPTIO

4.50 ± 0.05

3.10 ± 0.05

2.45 ± 0.05

(4 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

B

0.25 ±0.05

0.50 BSC

8

U

UF Package

24-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1692)

4.00 ± 0.10

(4 SIDES)

0.70 ±0.05

PACKAGE

OUTLINE

PIN 1

TOP MARK

(NOTE 5)

NOTE:

1. DRAWING PROPOSED TO BE MADE A JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGD-X)—TO BE APPROVED

2. ALL DIMENSIONS ARE IN MILLIMETERS

3. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE, IF PRESENT

4. EXPOSED PAD SHALL BE SOLDER PLATED

5. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

6. DRAWING NOT TO SCALE

0.75 ± 0.05

2.45 ± 0.10

(4-SIDES)

0.200 REF

0.00 – 0.05

BATT

VIBRATOR

MOTOR

3206 TA04

BOTTOM VIEW—EXPOSED PAD

R = 0.115

TYP

(4 SIDES)

24

23

0.23 TYP

0.38 ± 0.10

1

2

(UF24) QFN 0603

0.25 ± 0.05

0.50 BSC

3206f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

LTC3206

TYPICAL APPLICATIO

U

5-LED Main Plus Low/High Current Camera Light

2.2µF 2.2µF

V

2.7V TO

4.5V

I2C SERIAL

INTERFACE

IN

FLASH

V

IN

2.2µF 2.2µF

LTC3206

ENRGB/S

2

SERIAL PORT

I

RGB

2.4k 12k

CPO

MAIN1-4

AUX 1

AUX 2

SUB1-2

RGB

I

MS

4

3

3

MAIN DISPLAY

TORCH MODE

FLASH MODE

HIGH CURRENT

CAMERA LED

3206 TA03

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT®1618 Constant Current, Constant Voltage, 1.4MHz Up to 16 White LEDs, VIN: 1.6V to 18V, V

High Efficiency Boost Regulator I

LTC1911-1.5 250mA (I

), 1.5MHz High Efficiency 75% Efficiency, VIN: 2.7V to 5.5V, V

OUT

≤1µA, 10-Lead MS Package

SD

OUT(MIN)

Step-Down Charge Pump ISD ≤10µA, MS8 Package

LT1932 Constant Current, 1.2MHz High Efficiency White Up to 8 White LEDs, VIN: 1V to 10V, V

LED Boost Regulator ThinSOT

TM

Package

LT1937 Constant Current, 1.2MHz High Efficiency White Up to 4 White LEDs, VIN: 2.5V to 10V, V

LED Boost Regulator I

≤1µA, ThinSOT, SC70 Packages

SD

LTC3200-5 Low Noise, 2MHz Regulated Charge Pump Up to 6 White LEDs, VIN: 2.7V to 4.5V, V

OUT(MAX)

OUT(MAX)

OUT(MAX)

White LED Driver ThinSOT Package

LTC3201 Low Noise, 1.7MHz Regulated Charge Pump Up to 6 White LEDs, VIN: 2.7V to 4.5V, V

OUT(MAX)

White LED Driver 10-Lead MS

LTC3202 Low Noise, 1.5MHz Regulated Charge Pump Up to 8 White LEDs, VIN: 2.7V to 4.5V, V

OUT(MAX)

White LED Driver 10-Lead MS Package

LTC3205 Multi-Display LED Controller 92% Efficiency, VIN: 2.8V to 4.5V, IQ = 50µA, ISD ≤ 1µA ,

4mm × 4mm QFN Package

LTC3251 500mA (I

Step-Down Charge Pump I

LTC3405/LTC3405A 300mA (I

), 1MHz to 1.6MHz Spread Spectrum 85% Efficiency, VIN: 3.1V to 5.5V, V

OUT

), 1.5MHz Synchronous Step-Down 95% Efficiency, VIN: 2.7V to 6V, V

OUT

≤1µA, 10-Lead MS Package

SD

: 0.9V to 1.6V, IQ = 9µA,

OUT

OUT(MIN)

DC/DC Converter ThinSOT Package

LTC3406/LTC3406B 600mA (I

), 1.5MHz Synchronous Step-Down 95% Efficiency, VIN: 2.5V to 5.5V, V

OUT

OUT(MIN)

DC/DC Converter ThinSOT Package

LTC3440 600mA (I

), 2MHz Synchronous Buck-Boost 95% Efficiency, VIN: 2.5V to 5.5V, V

OUT

OUT(MIN)

DC/DC Converter 10-Lead MS Package

LT3465/LT3465A 1.2MHz/2.7MHz with Internal Schottky Up to 6 White LEDs, VIN: 12.7V to 16V, V

<1µA, ThinSOT Package

I

SD

ThinSOT is a trademark of Linear Technology Corporation.

= 34V, IQ = 1.8mA,

OUT(MAX)

= 1.5V/1.8V, IQ = 180µA,

= 34V, IQ = 1.2mA, IS ≤1µA,

= 34V, IQ = 1.9mA,

= 5V, IQ = 8mA, ISD ≤1µA,

= 5V, IQ = 6.5mA, ISD ≤1µA,

= 5V, IQ = 5mA, ISD ≤1µA,

= 0.8V, IQ = 20µA, ISD ≤1µA,

= 0.6V, IQ = 20µA, ISD ≤1µA,

= 2.5V, IQ = 25µA, ISD ≤1µA,

= 34V, IQ = 1.9mA,

OUT(MAX)

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

3206f

LT/TP 0604 1K • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2004

Loading...

Loading...