Tiny 2-Cell Solar Panel Charges Batteries in Compact,

Off-Grid Devices

Design Note 491

Fran Hoffart

Introduction

Advances in low power electronics now allow placement

of bat tery-powered sensors a nd other devices in locatio ns

far from the power grid. Ide ally, for true grid independen ce,

the batteries should not need replacement, but instead be

recharged using locally available renewable energy, such

as solar power. This Design Note shows how to produce

a compact battery charger that operates from a small

2-cell solar panel. A unique feature of this design is that

the DC/DC converter uses power point control to extract

maximum power from the solar panel.

The Importance of Maximum Power Point Control

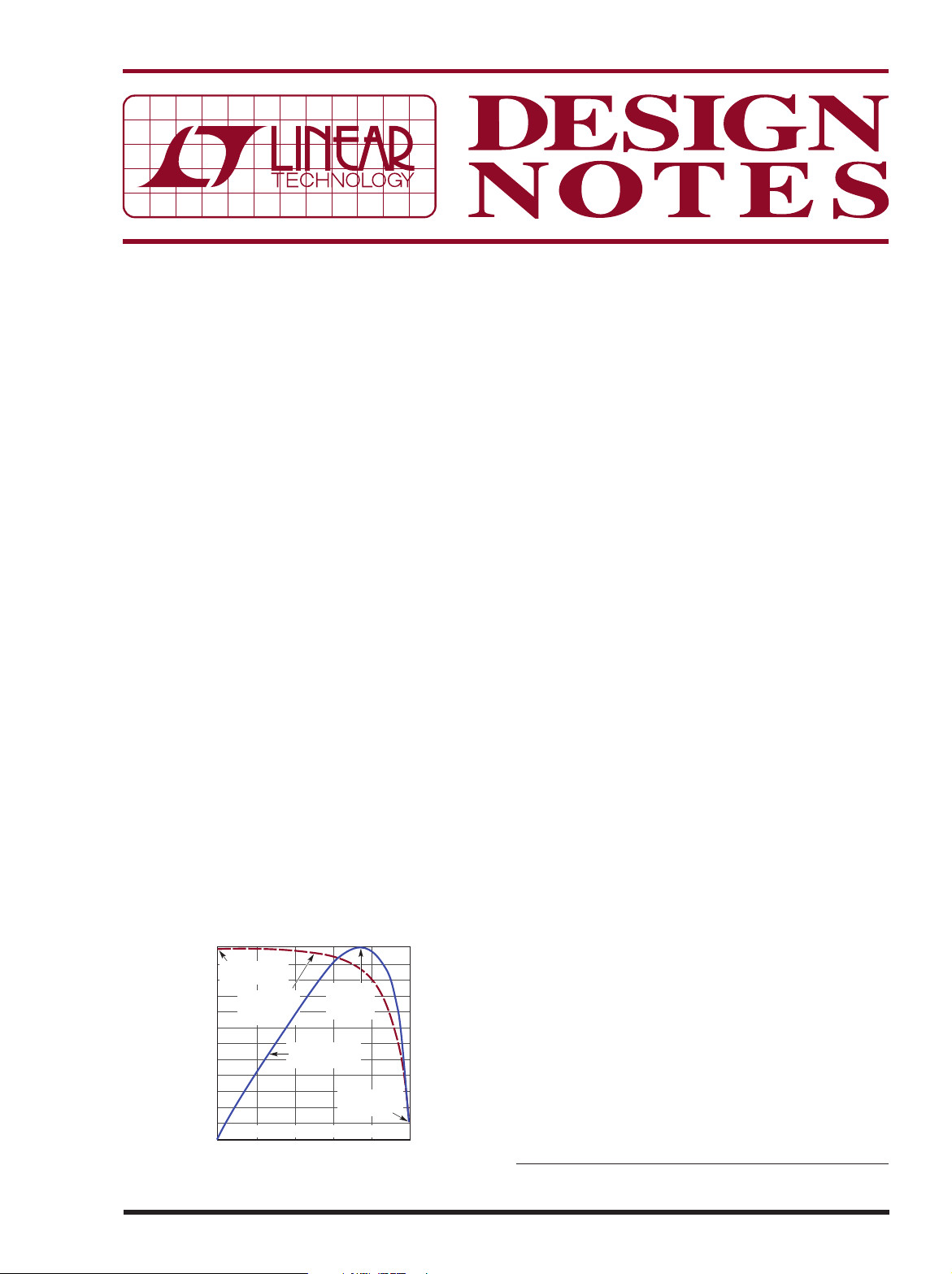

Although solar cells or solar panels are rated by power

output, a panel’s available power is hardly constant. Its

output power dep ends heavily on illumination, t emperature

and on the load current drawn from the panel. To illustrate

this, Figure 1 shows the V-I characteristic of a 2-cell solar

panel at a const ant illumination. The I-vs-V curve features

a relatively constant-current characteristic from shortcircuit (at the far left) to around 550mA load current, at

which point it bends to a constant-voltage characteristic

at lower currents, approaching maximum voltage at open

circuit (far right). The panel’s power output curve shows

a clear peak in power output around 750mV/530mA, at

the knee of the I-vs-V curve. If the load current increases

600

SHORT-CIRCUIT

CURRENT

500

SOLAR PANEL

400

300

200

100

SOLAR PANEL OUTPUT CURRENT (mA)

OUTPUT

CURRENT

2 SERIES POLYCRYSTALLINE CELLS

0

SOLAR PANEL OUTPUT VOLTAGE (mV)

MAXIMUM

POWER

POINT

SOLAR PANEL

OUTPUT POWER

OPEN-CIRCUIT

VOLTAGE

Figure 1. Solar Panel Output Voltage, Current and Power

06/11/491

400

SOLAR PANEL OUTPUT POWER (mW)

300

200

100

0

10008006004002000

DN F01

beyond the power peak, the power curve quickly drops

to zero (far left). Likewise, light loads push power toward

zero (far right), but this tends to be less of an issue.

Of course, panel illumination affects available power—

less light means lower power output; more light, more

power. Although illumination directly affects the

value

of peak power output, it does not do much to affect the

peak’s

location

on the voltage scale. That is, regardless

of illumination, the panel output voltage at which peak

power occurs remains relatively constant. Thus, it makes

sense to moderate the output current so that the solar

panel volt age remains at or above this peak power volt age,

in this case 750mV. Doing so is called maximum power

point control (MPPC).

Figure 2 shows the effects of varying sunlight on the

charge current, with maximum power point control and

without. T he simulated sunlight is varied from 100% down

to approximately 20%, then back up to 100%. Note that as

the sunlight intensity drops about 20%, the solar panel’s

output voltage and current also drop, but the LTC3105

maximum power point control prevents the panel’s

output voltage from dropping below the programmed

750mV. It accomplishes this by reducing the LTC3105

output charge current to prevent the solar panel from

collapsing to near zero volts, as is shown in the plot on

the right side of Figure 2. Without power point control,

a small reduction in sunlight can completely stop charge

current from flowing.

LTC3105 Boost Converter with Input Power Control

The LTC3105 is a synchronous step-up DC/DC converter

designed primarily to convert power from ambient energy

sources, such as low vol tage solar cells and thermoele ctric

generators, to battery charging power. The LTC3105 uses

MPPC to deliver ma ximum available power from the source.

It accomplishes this by reducing the LTC3105 output current to prevent the solar panel from collapsing to near zero

L, LT, LTC, LTM, Linear Technology, the Linear logo and Burst Mode are registered

trademarks of Linear Technology Corporation. All other trademarks are the property of

their respective owners.

600

400

100% 100%

200

PANEL

OUTPUT (mA)

0

60

LTC3105

40

CHARGE

CURRENT

20

CHARGE

BATTERY VOLTAGE = 3.6V

CURRENT (mA)

0

(WITH MAXIMUM POWER POINT CONTROL)

SOLAR PANEL

OUTPUT CURRENT

RELATIVE SUNLIGHT

INTENSITY

10 SECONDS

Figure 2. Changing Sunlight Intensity Effects on Charge Current

SOLAR PANEL

OUTPUT VOLTAGE

SOLAR PANEL OUTPUT (V)

1.0

0.8

0.6

0.4

0.2

0

600

400

100%

200

PANEL

OUTPUT (mA)

0

60

LTC3105

40

CHARGE

CURRENT

20

CHARGE

CURRENT (mA)

0

SOLAR PANEL

OUTPUT CURRENT

RELATIVE SUNLIGHT

INTENSITY

SOLAR PANEL

OUTPUT VOLTAGE

BATTERY

VOLT. = 3.6V

(NO MAXIMUM POWER POINT CONTROL)

10 SECONDS

100%

LTC3105

CHARGE

CURRENT

SOLAR PANEL OUTPUT (V)

1.0

0.8

0.6

0.4

0.2

0

DN F02

volts. The LTC3105 is capable of starting up with an input

as low as 250mV, allowing it to be powered by a single

solar cell or up to nine or ten series-connected cells.

Output disconnect eliminates the isolation diode often

required with other solar powered DC/DC converters

and allows the output voltage to be above or below the

input voltage. The 400mA switch current limit is reduced

during start-up to allow operation from relatively high

impedance power sources, but still provides sufficient

power for many low power solar applications once the

converter is in normal operation. Also included are a 6mA

adjustable ou tput low dropout linear regulator, open-drain

power good output, shutdown input and Burst Mode

®

operation to improve ef ficiency in low power applications.

Solar-Powered Li-Ion Battery Charger

Figure 3 shows a compact solar-powered battery charger

using a LTC3105 as a boost converter and a LTC4071 as a

Li-Ion shunt charger. A 2-cell 400mW solar pan el provides

the input power to the LTC3105 to produce over 60mA

of charge current in full sunlight. Maximum power point

control prevents the solar panel voltage from dropping

below the 750mV maximum power point, as shown in

Figure 1. The converter’s output voltage is programmed

for 4.35V, slightly above the 4.2V float voltage of the

Li-Ion battery. The LTC4071 shunt charger limits the

voltage across the battery to 4.2V. Grounding the FBLDO

pin programs the low dropout regulator to 2.2V, which

powers the “charging” LED. This LED is on when charging

and off when the battery voltage is within 40mV of the

float voltage, indicating near full charge. An NTC thermistor senses battery temperature and lowers the LTC4071

float voltage at high ambient temperatures for increased

battery safety. To prevent battery damage from overdischarge, the low bat tery disconnec t feature disconnects

the battery from the load if the battery drops below 2.7V.

Conclusion

Although the circuit described here produces only a

few hundred milliwatts, it can provide enough power to

keep a 400mAhr Li-Ion battery fully charged under most

weather conditions. The low input voltage, combined

with input power control, makes the LTC3105 ideal for

low power solar applications. In addition, the LTC4071

shunt charging system complements the LTC3105 by

providing the precision float voltage, charge status and

temperature safety features to assure long battery life in

outdoor environments.

SOLAR PANEL

(2 CELLS)

ISC = 600mA,

VOC = 1V

MPPC

OPTIONAL MPPC

TEMPERATURE TRACKING,

SEE DATA SHEET FOR DETAILS

+

–

10µH

10µF

75k

ONOFF

1µF

Figure 3. 2-Cell Solar Panel Li-Ion Battery Charger

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

SW

IN

MPPC

SHDN

AUX

LTC3105

PGOOD

GND

OUT

LDO

FBLDO

1M

FB

2.2V

10µF

301k

220Ω

CHARGING

LED STATUS

ON = CHARGING

OFF = V

BAT

OFF = NO BATTERY OR NO V

ADJ

LBSEL

LTC4071

LED

HBO

APPROACHES V

V

BAT

NTC BIAS

NTC

GND

FLOAT

IN

4.2V

+

LOAD

400mAhr

Li-Ion

POLYMER

BATTERY

DN F03

CC

10k

NTC

10k

For applications help,

call (408) 432-1900, Ext. 3725

dn491 LT/AP 0611 226K • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPORATION 2011

Loading...

Loading...