L DESIGN FEATURES

LTC3101

BUCK-BOOST

LDO

ON/OFF

AC

ADAPTER

USB

or

HOT SWAP OUT

3.xV AT 300 to 800mA

1.xV AT 350mA

1.xV AT 350mA

1.8V AT 50mA

3.xV AT 100mA

x.xV AT 200mA

TRACKING OUT

LI-ION

USB

BAT

Power Management IC with

Pushbutton Control Generates Six

Voltage Rails from USB or 2 AA Cells

Via Low Loss PowerPath Topology

Introduction

As the complexity of portable electronic

devices continues to increase, the demands placed on power supplies, and

their designers, expand dramatically.

Not only must typical power systems

accommodate multiple input sources,

with voltages as low as 1.8V for two

AA cells, but they must also provide

an increasing number of independent

output rails to support a wide range

of requirements—for memory, microprocessors, backlights, audio and RF

components. To further complicate

matters, expanding feature sets add up

to increased power dissipation, making

it important to optimize overall power

system efficiency. This is particularly

challenging given that the constant

drive to minimize the required board

area and profile height of the power

system is at direct odds with improving efficiency.

The LTC3101 addresses all of these

challenges with a single-IC power

management solution that allows a

designer to easily maximize overall

power system efficiency while minimizing space requirements. The LTC3101

can generate six power rails by integrating three synchronous switching

converters, two protected switched

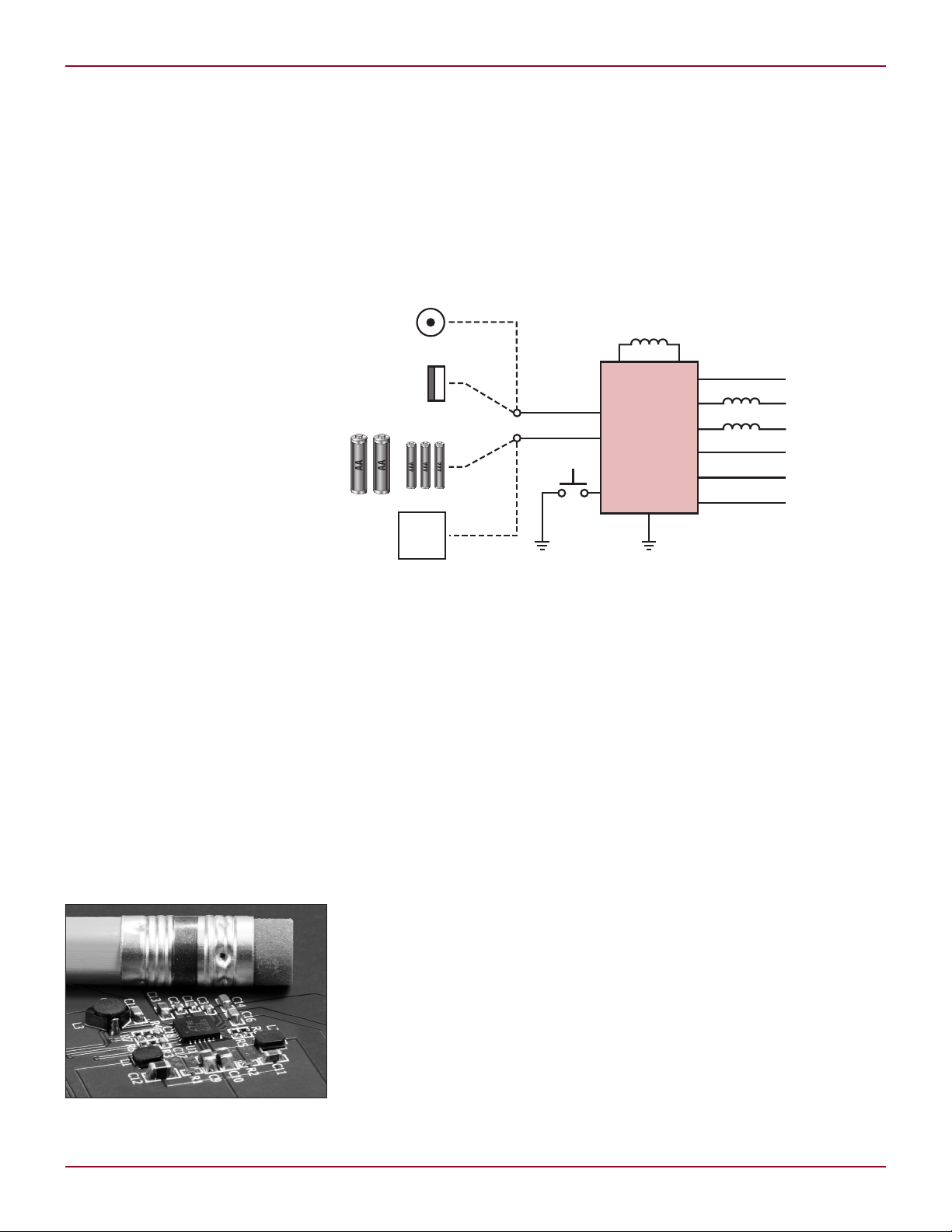

Figure 2. Complete portable power

solution with a 16mm × 19mm footprint

12

by John Canfield

Figure 1. Six output rails, a low loss PowerPath and integrated pushbutton control

power outputs, and an LDO. Its integrated low loss PowerPath™ topology

allows each switching converter to

run directly from either of two input

power sources.

Two 350mA, high efficiency low

voltage rails, typically used to power

processors and memory, are generated

by synchronous buck converters. Each

converter is able to operate down to an

input voltage of 1.8V thereby enabling

single stage conversion from any input

power source.

A single inductor buck-boost

converter generates a high efficiency

intermediate output rail, typically at

3V or 3.3V, and is able to operate from

either input power source and with

input voltages that are above, below,

or even equal to the output regulation

voltage. The buck-boost converter

can supply a 300mA load at 3.3V for

battery voltages down to 1.8V and an

800mA load for input voltages of 3.0V

and greater.

Two always-alive outputs—MAX,

which tracks the higher voltage input

power source and LDO, a fixed 1.8V

output—provide power to critical

functions that must remain powered

under all conditions. An integrated

pushbutton controller with programmable µP reset generator provides

complete ON/OFF control using only

a minimal number of external components while independent enables allow

total power-up sequencing flexibility.

This complete portable power solution

is packaged in a single low profile 24lead 4mm × 4mm QFN package and

the entire power supply, including

all external components, occupies a

PCB area of less than 3cm2 as shown

in Figure 2.

Zero Loss PowerPath

Topology Maximizes

Efficiency

Although rechargeable Li-Ion and

Li-Polymer batteries are the leading

chemistries for powering portable

devices due to their high energy density and long cycle life, many portable

devices continue to be powered by

alkaline and NiMH cells. This allows

indefinite periods of use away from a

Linear Technology Magazine • June 2009

BAT1

USB1

C

RS

ENA1

ENA2

ENA3

PWRKEY

PWRON

PWM

PBSTAT

RESET

USB2

FB3

LDO

SW2

FB2

HSO

MAX

10µF

10µF

2 AA

CELLS

USB/WALL

ADAPTER

1.8V TO 5.5V

10µF

1M

V

OUT3

= 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

221k

Hot Swap OUTPUT: 3.3V AT 100mA

TRACKING OUTPUT: 200mA

4.7µH

4.7µF

1.8V AT 50mA

V

OUT2

1.8V

350mA

V

OUT1

1.5V

350mA

10µF

221k

110k

4.7µH

SW1

FB1

10µF

221k

147k

4.7µH

0.1µF

ON/OFF

BAT2 SW3A

LTC3101

GND

µP

SW3B OUT3

DIS ENA

+

USB

BAT

+

BUCK

V

OUT

USB

BAT

+

BUCK-BOOST

V

OUT

charging socket—which is particularly

important for devices intended for use

in remote locales such as handheld

personal navigation devices or portable

medical devices. Voice recorders, digital still cameras and ultra-small video

recorders are additional examples of

devices that benefit from the ability to

operate from a pair of commonly available batteries, rather than requiring

the lengthy recharging cycle needed

for an internal Li-Ion battery.

Even in portable devices where the

primary power source is restricted

to AA or AAA form factor cells, there

still exist a wide variety of compatible chemistries including alkaline,

rechargeable alkaline, NiMH and

single-use lithium. As a result, the

AA/AAA powered device must accommodate a wide range of input voltages,

from 1.8V for two series alkaline cells

near end of life, to approximately 3.7V

for a pair of fresh non-rechargeable

lithium cells. With its wide 1.8V to

5.5V input voltage range, the LTC3101

can easily support all of these battery chemistries. In addition, the

LTC3101 is able to operate from a

single standard Li-Ion/Polymer cell in

cases where recharging is performed

independently.

Although rechargeable cells are

usually charged outside these types

of devices, the power supply must

accommodate a secondary tethered

power source such as USB or a regulated wall adapter. Consequently, the

power supply must include a means to

generate every power rail from either of

two input sources, and the ubiquitous

3.3V rail must be generated from input

power sources that can be higher or

lower voltage.

In many devices, the capability to

handle dual power sources is provided

by using discrete power MOSFETs to

switch regulator inputs between the

two input power sources or by utilizing

two regulators for generation of each

rail (for example, a buck converter

that generates a 3.3V rail from the

USB input in conjunction with a boost

converter that generates the 3.3V rail

from the battery input).

Both of these approaches suffer

from significant drawbacks. The par-

Linear Technology Magazine • June 2009

allel converter approach increases

system cost and size given that only

one converter is ever active at any given

time and often suffers from glitches

and disruptions to the output rails

during the transition between the

two input power sources. Similarly,

the discrete power switch technique

reduces efficiency due to the addition

of extra series elements in the power

path, increases component count,

and can also lead to disruptions in

the output rails unless the supply

crossover is carefully controlled.

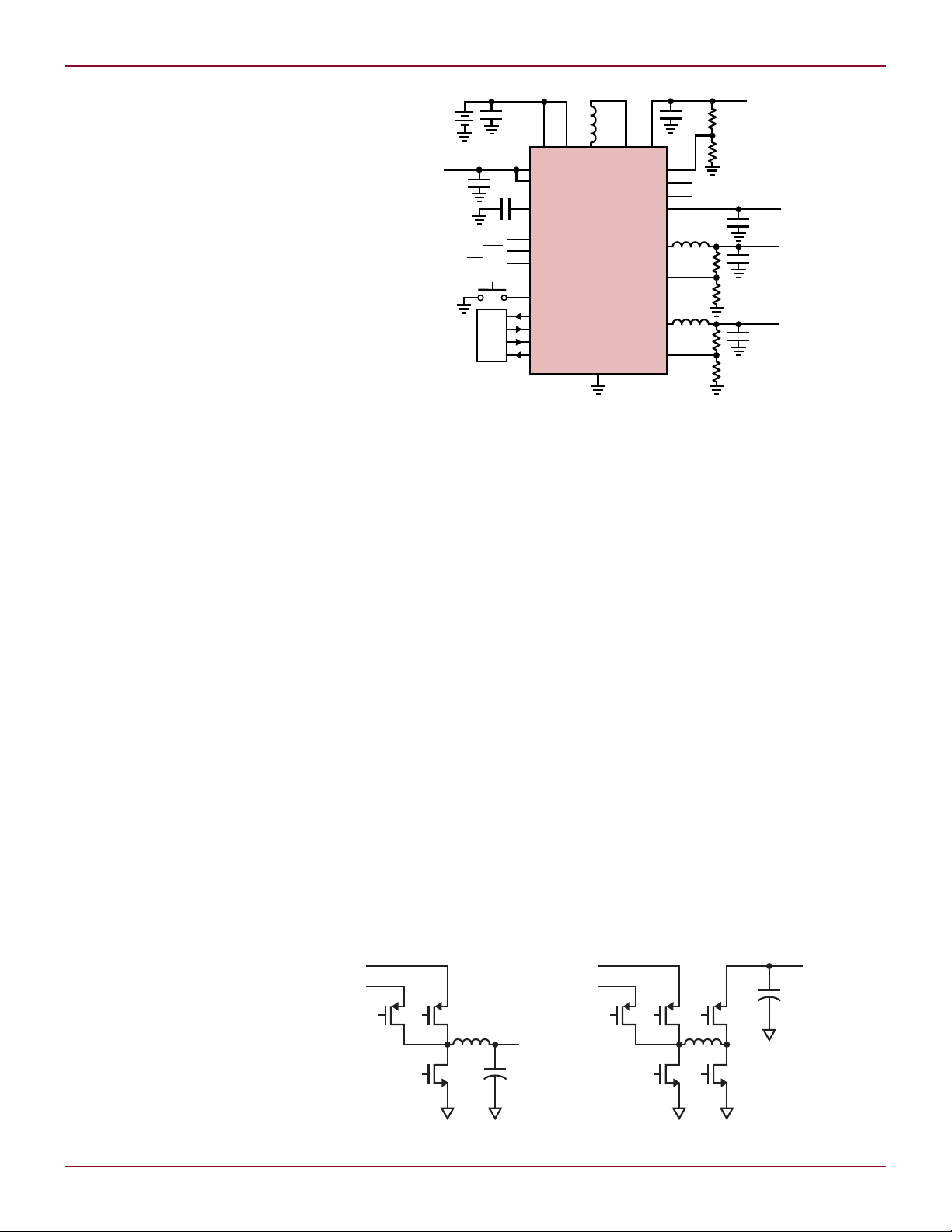

The LTC3101 avoids these problems by using a low loss PowerPath

topology as shown in Figure 4, where

each converter is able to operate directly from either input power source.

In this architecture, each switching

converter utilizes an additional power

switch, which is connected to the

alternate power input. As a result,

each converter is able to run with

maximum efficiency from either input

power source so no efficiency penalty

DESIGN FEATURES L

Figure 3. Typical application

is incurred in supporting dual input

power sources.

The total solution area is minimized

by the fact that the same inductor is

used in either case. In addition, the

automatic transition between the

two input power sources is seamless—there is no interruption to any

of the output rails. Figure 5 shows the

transient response of the buck-boost

converter as the input power source

transitions from battery power to USB

power in response to a live cable plug

into a USB port.

Integrated Buck-Boost

Provides High Efficiency

3V/3.3V Rail from

Any Power Source

In many portable devices an intermediate supply rail, typically regulated to

3.3V, is required to power an RF stage

or audio amplifiers. Often this rail is

generated from the two series AA cells

using a boost converter. However, the

higher cell voltage of single-use lithium

Figure 4. The low loss PowerPath architecture

13

Loading...

Loading...