FEATURES

LTC2970/LTC2970-1

Dual I2C Power

Supply Monitor and

Margining Controller

U

DESCRIPTIO

■

Less Than ±0.5% Total Unadjusted Error 14-Bit ΔΣ

ADC with On-Chip Reference

■

Dual, 8-Bit IDACs with 1x Voltage Buffers

■

Linear, Voltage Servo Adjusts Supply Voltages by

Ramping IDAC Outputs Up/Down

■

I2C™ Bus Interface (SMBus Compatible)

■

Extensive, User Confi gurable Fault Monitoring

■

On-Chip Temperature Sensor

■

Available in 24-Lead 4mm × 5mm QFN Package

U

APPLICATIO S

■

Dual Power Supply Voltage Servo

■

Monitoring Supply Voltage and Current

■

Programmable Power Supplies

■

Programmable Reference

The LTC®2970 is a dual power supply monitor and

2

margining controller with an SMBus compatible I

C bus

interface. A low-drift, on-chip reference and 14-bit ΔΣ A/D

converter allow precise measurements of supply voltages,

load currents or internal die temperature. Fault manage-

⎯A⎯L⎯E⎯R⎯

ment allows

T to be asserted for confi gurable over

and under voltage fault conditions. Two voltage buffered,

8-bit IDACs allow highly accurate programming of DC/DC

converter output voltages. The IDACs can be confi gured

to automatically servo the power supplies to the desired

voltages using the ADC. The LTC2970-1 adds a tracking

feature that can be used to turn multiple power supplies

on or off in a controlled manner.

The bus address is set to 1 of 9 possible combinations by

pin strapping the ASEL0 and ASEL1 pins. The LTC2970/

LTC2970-1 are packaged in the 24-lead, 4mm × 5mm

QFN package.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

U

TYPICAL APPLICATIO

Dual Power Supply Monitor and Controller (One of Two Channels Shown)

8V TO 15V

12V

IN

V

IN

IN

DC/DC

CONVERTER

RUN/SS

SGND

GND

OUT

1/2 LTC2970

I+

I–

FB

LOAD

V

IN0_BM

V

IN0_BP

V

OUT0

V

IN0_AP

I

OUT0

V

IN0_AM

GND

ASEL0 ASEL1

V

GPIO_CFG

ALERT

SCL

SDA

GPIO_0

REF

ADC Total Unadjusted Error

vs Temperature

0.50

0.1μF

DD

0.1μF

2

C BUS

I

SMBUS

()

COMPATIBLE

0.1μF

29701 TA01

15 PARTS MOUNTED ON PCB

0.25

0

ERROR (%)

–0.25

–0.50

–25 0 50

–50

25

TEMPERATURE (°C)

ADC VIN = 5V

75

29701 TA01b

100

29701fc

1

LTC2970/LTC2970-1

WW

W

U

ABSOLUTE AXI U RATI GS

(Notes 1 and 2)

Supply Voltages:

......................................................... –0.3V to 6V

V

DD

.................................................... –0.3V to 15V

12V

IN

Digital Input/Output Voltages:

ASEL0, ASEL1 ............................ –0.3V to V

SDA, SCL, GPIO_CFG,

⎯A⎯L⎯E⎯R⎯

T, GPIO_0, GPIO_1 .......................... –0.3V to 6V

Analog Voltages:

V

IN0_AP

V

IN0_BM

V

IN1_BP

I

OUT0

, I

, V

, V

, V

OUT1

IN0_AM

IN1_AP

IN1_BM

, V

, V

, V

IN0_BP

IN1_AM

, V

OUT0

,

,

.............. –0.3V to 6V

OUT1

, REF ......................... –0.3V to V

RGND .................................................... –0.3V to 0.3V

Operating Temperature Range:

LTC2970C ................................................ 0°C to 70°C

LTC2970I ............................................. –40°C to 85°C

Storage Temperature Range ...................–65°C to 125°C

Lead Temperature (Soldering, 10 sec) .................. 300°C

+ 0.3V

DD

+ 0.3V

DD

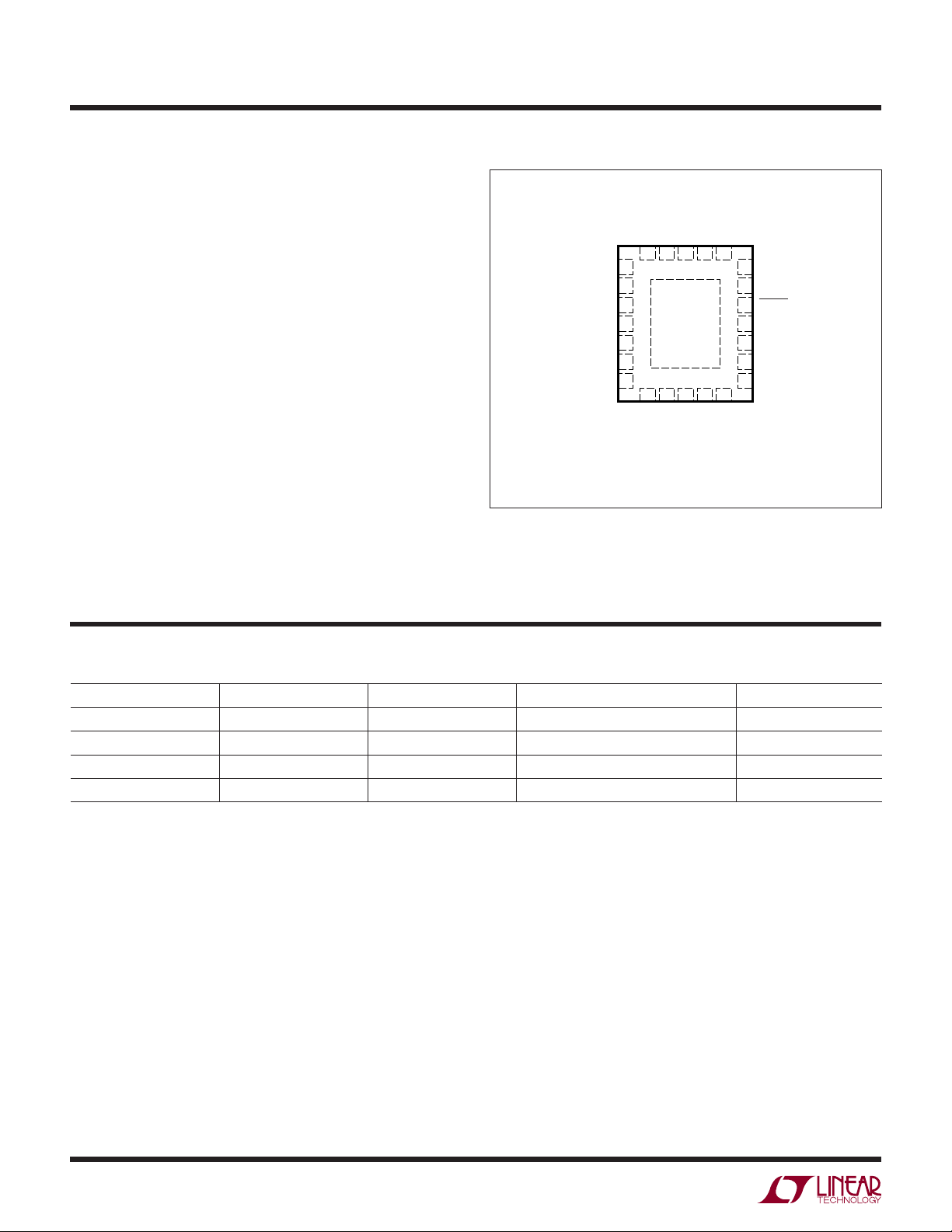

PIN CONFIGURATION

TOP VIEW

RGND

REF

ASEL0

ASEL1

24 23 22 21 20

1

V

IN0_AP

V

2

IN0_AM

V

3

IN0_BP

4

V

IN0_BM

V

5

IN1_AP

6

V

IN1_AM

7

V

IN1_BP

24-LEAD (4mm × 5mm) PLASTIC QFN

T

EXPOSED PAD (PIN 25) IS GND MUST BE SOLDERED TO PCB

JMAX

25

8 9

10 11 12

IN

DD

V

OUT0VOUT1

12V

IN1_BM

V

UFD PACKAGE

= 125°C, θJA = 37°C/W

V

GPIO_CFG

19

SDA

18

SCL

17

ALERT

16

GPIO_0

15

GPIO_1

14

I

13

I

OUT0

OUT1

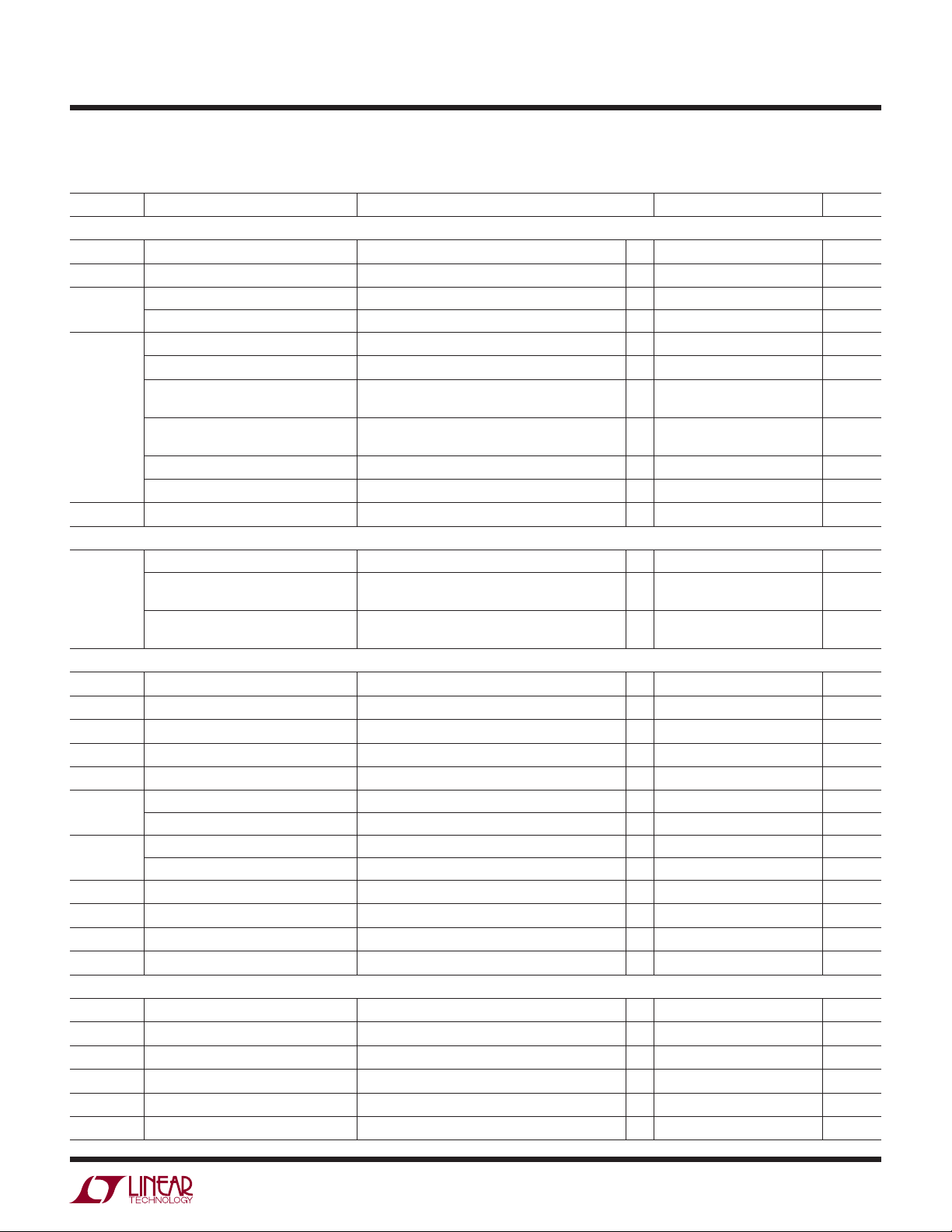

ORDER INFORMATION

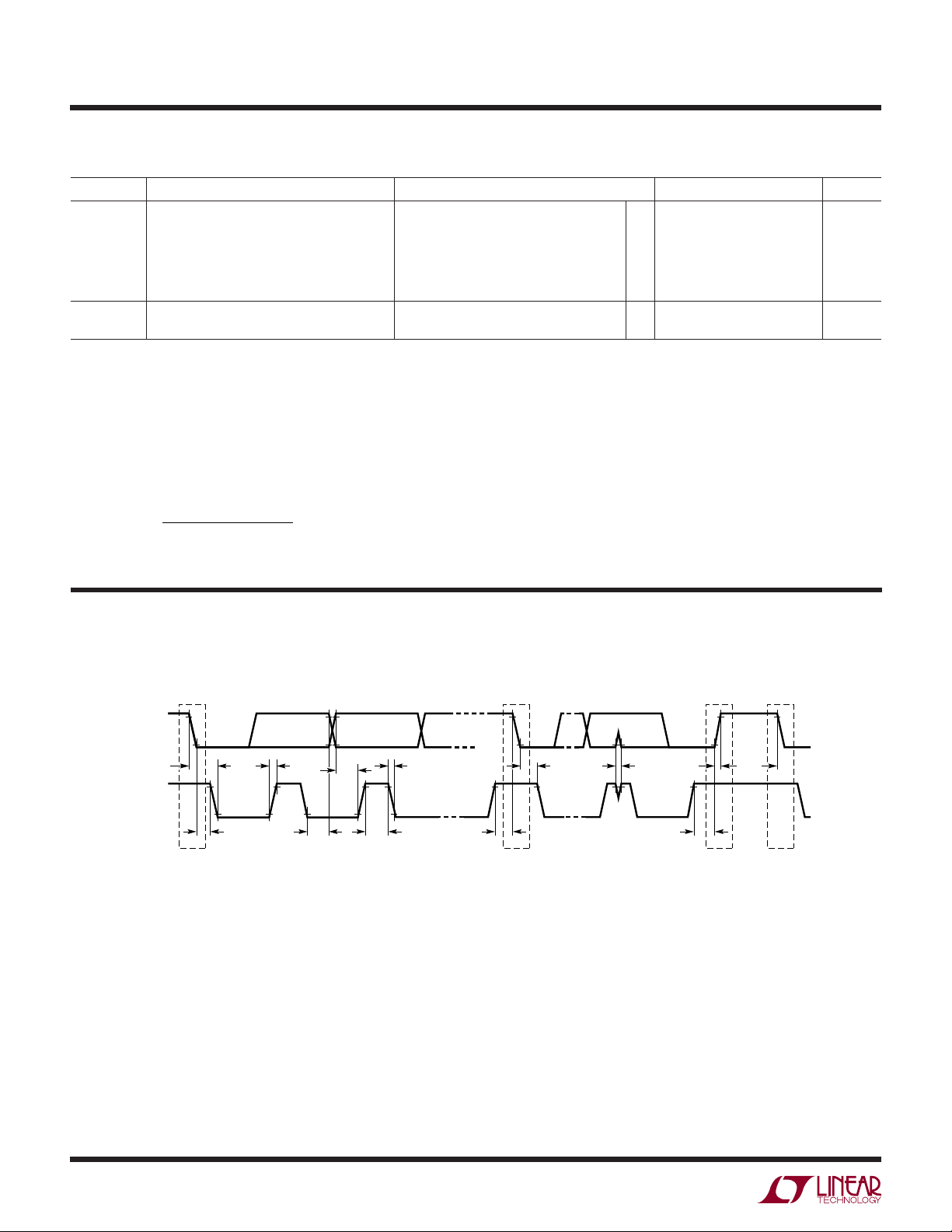

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC2970CUFD#PBF LTC2970CUFD#TRPBF 2970 24-Lead (4mm × 5mm) Plastic DFN 0°C to 70°C

LTC2970CUFD-1#PBF LTC2970CUFD-1#TRPBF 29701 24-Lead (4mm × 5mm) Plastic DFN 0°C to 70°C

LTC2970IUFD#PBF LTC2970IUFD#TRPBF 2970 24-Lead (4mm × 5mm) Plastic DFN –40°C to 85°C

LTC2970IUFD-1#PBF LTC2970IUFD-1#TRPBF 29701 24-Lead (4mm × 5mm) Plastic DFN –40°C to 85°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. *The temperature grade is identifi ed by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

2

29701fc

LTC2970/LTC2970-1

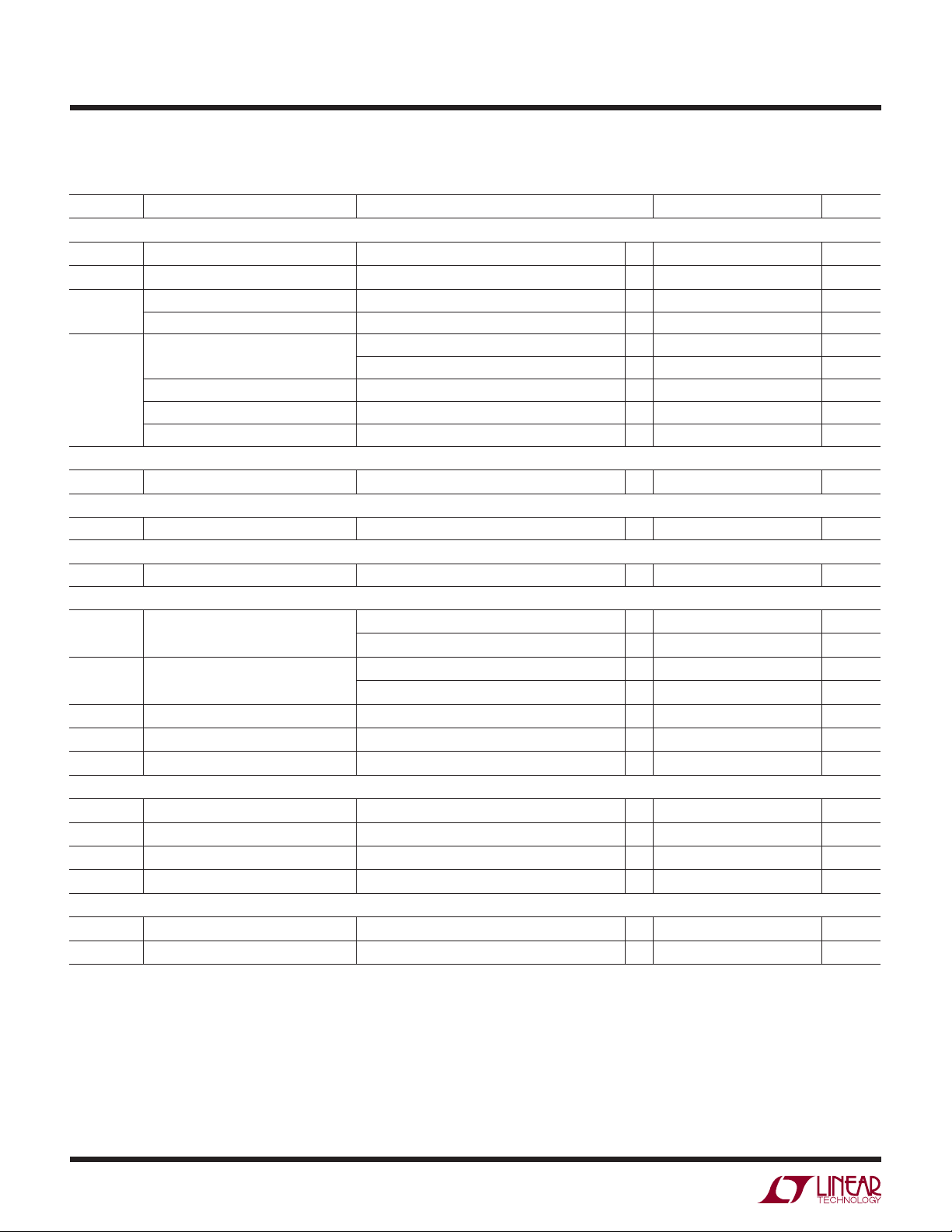

The ● denotes the specifi cations which apply over the full operating

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

C

= 100nF and C

VDD

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Power-Supply Characteristics

I

I

V

V

V12

DD

LKO

DD

12VIN Supply Current V

VDD Supply Current VDD = 5V, V

VDD Undervoltage Lockout VDD Ramping-Down, V

V

DD

Supply Input Operating Range

Regulator Output Voltage 8V ≤ V

Regulator Output Voltage

Temperature Coeffi cient

Regulator Output Voltage Load

Regulation

Regulator Line Regulation 8V ≤ V

Regulator Output Short-Circuit Current V

V

12VIN

12VIN Supply Operating Range

Voltage Reference Characteristics

V

REF

Reference Output Voltage 1.229 V

Reference Voltage Temperature

Coeffi cient

Reference Overdrive Voltage Input

Range

ADC Characteristics

N_ADC Resolution N_ADC = 8.192V/16384 500 μV/LSB

TUE_ADC Total Unadjusted Error V

INL_ADC Integral Nonlinearity (Note 4)

DNL_ADC Differential Nonlinearity (Note 7)

V

IN_ADC

V

OS_ADC

Input Voltage Range

Offset Error

Offset Error Drift 0.19 μV/°C

GAIN_ADC Gain Error Full-Scale V

Gain Error Drift 3 ppm/°C

T

CONV_ADC

C

IN_ADC

F

IN_ADC

I

LEAK_ADC

Conversion Time 33.3 ms

Input Sampling Capacitance 3pF

Input Sampling Frequency 61.4 kHz

Input Leakage Current 0V < VIN < 6V

IDAC Output Current Characteristics

N_I

OUT

INL_I

OUT

DNL_I

I

FS-IOUT

I

DRIFT-IOUT

I

OS-IOUT

Resolution (Guaranteed Monotonic) 8 Bits

Integral Nonlinearity V

Differential Nonlinearity V

OUT

Full-Scale Output Current V

Output Current Drift DAC Code = 'hff 32 ppm/°C

Offset Current DAC Code = 'h00

= 100nF.

REF

Undervoltage Lockout Hysteresis 118 mV

= 25°C. V

A

= 12V, VDD Floating

12VIN

12VIN

–1mA ≤ I

12VIN

= 12V, VDD = 0V

12VIN

= 3V, VIN = V

IN

< VDD – 1.5V

IOUTn

< VDD – 1.5V

IOUTn

< VDD – 1.5V, DAC Code = 'hff

IOUTn

12VIN

= V

12VIN

DD

≤ 15V, –1mA ≤ I

≤ 0 160 ppm/mA

VDD

≤ 15V, I

VDD

INn_xP

= 6V

IN

= 12V, VDD and REF pins fl oating unless otherwise indicated,

●

●

12VIN

= V

VDD

DD

≤ 0

●

3.7 4.14 4.4 V

●

4.5 5.75 V

●

4.75 4.95 5.25 V

= 0mA 80 ppm/V

●

–5 –34 –63 mA

●

815V

●

11.5V

– V

INn_xM

(Note 3)

●

●

–4.5 2 4.5 LSB

●

●

06V

●

–1000 –316 1000 μV

●

●

●

●

●

–236 –255 –276 μA

●

4.24 7.5 mA

3.7 5 mA

10 ppm/°C

2 ppm/°C

±0.5 %

±0.5 LSB

±0.4 %

±0.1 μA

±1 LSB

±1 LSB

±0.1 μA

29701fc

3

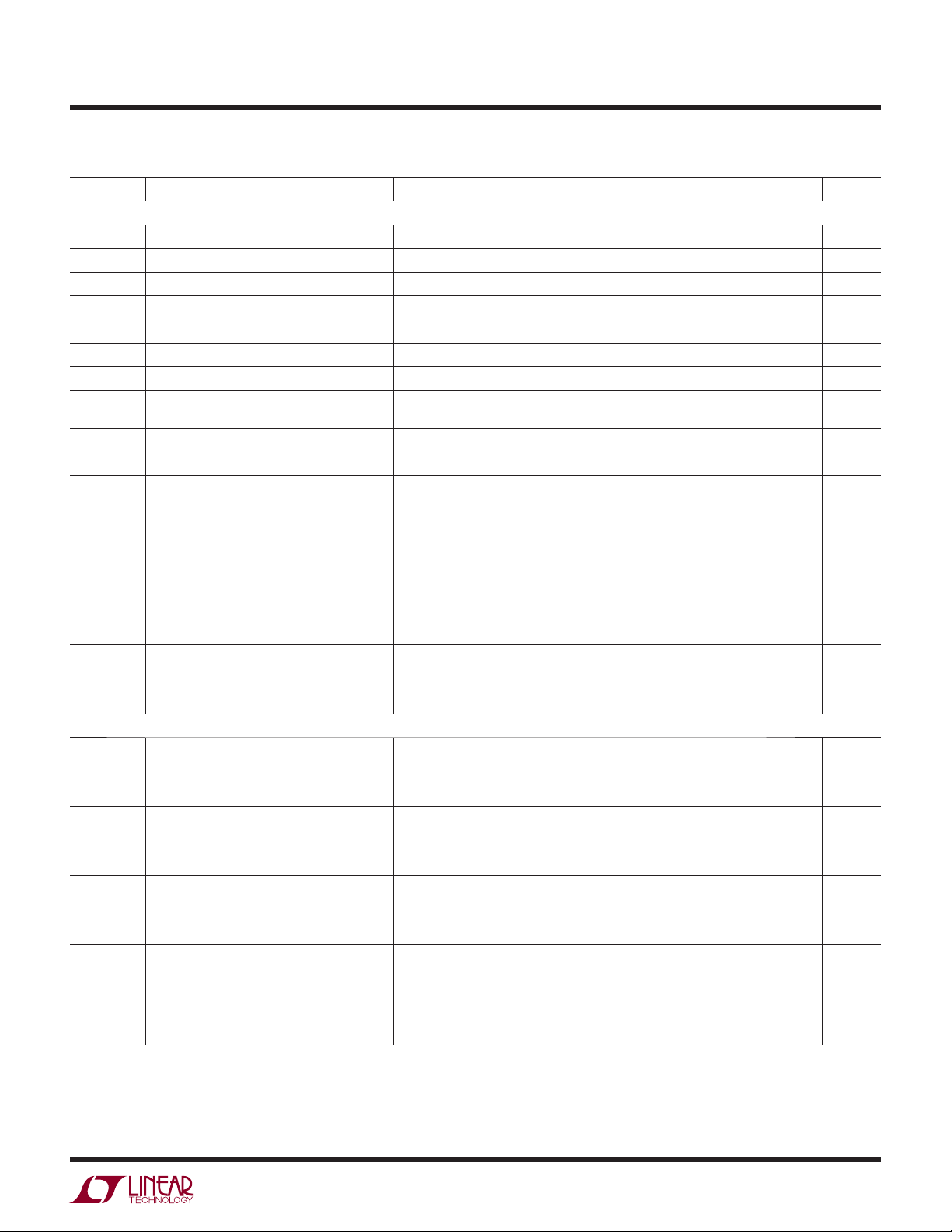

LTC2970/LTC2970-1

The ● denotes the specifi cations which apply over the full operating

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

= 100nF and C

C

VDD

= 100nF.

REF

= 25°C. V

A

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Voltage Buffered IDAC Output Characteristics

INL_V

DNL_V

V

OS-VOUT

V

OUT

OUT

Integral Nonlinearity R

Differential Nonlinearity R

OUT

Offset Voltage VOS = V

Output Voltage Drift No Load on V

Load Regulation 0.1V < V

Leakage Current V

Short-Circuit Current Low V

Short-Circuit Current High V

= 10kΩ, No Load on V

IOUTn

= 10kΩ, No Load on V

IOUTn

– V

OUTn

OUTn

< VDD – 1.5V, I

OUTn

0.1V < V

OUTn

OUTn

OUTn

< VDD – 1.5V, I

OUTn

High-Z, 0V ≤ V

Shorted to GND

Shorted to V

Soft Connect Comparator Characteristics (CMP0, CMP1)

V

OS

Offset Voltage ±3 mV

Temperature Sensor Characteristics

TMP Gain 0.25 °C/LSB

Voltage Divider Characteristics

12V

IN

GAIN_12V

Gain

IN

Digital Inputs SCL, SDA, GPIO_CFG, GPIO_0, GPIO_1

V

IH

Input High Threshold Voltage SDA, SCL

GPIO_CFG, GPIO_0, GIPO_1

V

IL

Input Low Threshold Voltage SDA, SCL

GPIO_CFG, GPIO_0, GIPO_1

V

I

LEAK

C

HYST

IN

Input Hysteresis 0.08 V

Input Leakage Current 0V ≤ VIN ≤ 6V

Input Capacitance 10 pF

Three State Inputs ASEL[1:0]

V

IH_ASEL

V

IL_ASEL

I

IN,HL

I

IN,Z

Open Drain Outputs SDA, GPIO_CFG, GPIO_0, GPIO_1,

V

OL

I

OH

Input High Threshold Voltage

Input Low Threshold Voltage

High, Low Input Current ASEL[1:0] = 0, V

High Z Input Current

⎯A⎯L⎯E⎯R⎯

T

Output Low Voltage I

SINK

= 3mA

Input Leakage Current 0V ≤ VIN ≤ 6V

= 12V, VDD and REF pins fl oating unless otherwise indicated,

12VIN

●

●

●

1.6 ±10 mV

, No Load on V

IOUTn

OUTn

OUTn

(Note 5)

(Note 5)

OUTn

0.17 μV/°C

Source = 1mA –57 ppm/mA

VOUTn

Sink = 1mA 100 ppm/mA

VOUTn

●

●

●

●

0.329 0.333 0.335 V/V

●

●

●

1.5 V

●

1.0 V

●

●

●

0.5 V

●

●

±2 μA

●

●

1 ±100 nA

VDD – 0.5 V

DD

DD

OUTn

≤ V

DD

±1 LSB

±1 LSB

–50 mA

50 mA

2.1 V

1.6 V

±1 μA

±20 μA

0.4 V

±1 μA

4

29701fc

LTC2970/LTC2970-1

The ● denotes the specifi cations which apply over the full operating

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

2

C Interface Timing Characteristics

I

f

SCL

t

LOW

t

HIGH

t

BUF

t

HD,STA

t

SU,STA

t

SU,STO

t

HD,DAT

t

SU,DAT

t

SP

t

SETUP_GPIO

t

HOLD_GPIO

t

OUT_GPIO

Internal Timers

t

TIMEOUT_SMB

t

SETUP_ADC

t

TIMEOUT_

SYNC

t

HOLD_TRACK

Serial Clock Frequency (Note 6)

Serial Clock Low Period (Note 6)

Serial Clock High Period (Note 6)

Bus Free Time Between Stop and Start (Note 6)

Start Condition Hold Time (Note 6)

Start Condition Setup Time (Note 6)

Stop Condition Setup Time (Note 6)

Data Hold Time (LTC2970 Receiving Data)

Data Hold Time (LTC2970 Transmitting Data)

Data Setup Time (LTC2970 Receiving Data) (Note 6)

Pulse Width of Spike Suppressed (Note 6)

GPIO_0 and GPIO_1 Setup Time GPIO_0 and GPIO_1 input setup time

GPIO_0 and GPIO_1 Hold Time GPIO_0 and GPIO_1 input hold time

GPIO_0 and GPIO_1 Output Time GPIO_0 and GPIO_1 output delay after

Stuck BUS Timer The LTC2970 will release the I2C bus and

ADC Channel Setup Time After selecting a new ADC channel, the

Tracking SYNC Failure Timer LTC2970-1 Only: The LTC2970-1 will

Tracking IDAC Disconnect Delay LTC2970-1 Only: After the tracking

= 25°C.

A

(Note 6)

prior to the 26th rising SCL of an IO()

2

I

C read. These inputs must be valid and

stable by this time to be returned in the

IO() read result. (Note 6)

after the 26th rising SCL of an IO() I

read. These inputs must be held until

this amount of time has elapsed to be

returned in the IO() read result. (Note 6)

the 35th rising SCL of an I

2

C write. These

outputs will become high impedance or

begin driving low by this time. (Note 6)

terminate the current command if the

command is not completed before this

amount of time has elapsed.

LTC2970 will wait this amount of time

to allow the analog input to settle before

beginning an ADC conversion.

abort a pending SYNC() command if a

tracking command is not received before

this amount of time has elapsed.

algorithm asserts CPIO_CFG low, the

LTC2970-1 will delay disconnecting the

IDACs from the power supply feedback

nodes by this amount of time. Used while

tracking power supplies on.

●

10 400 kHz

●

1.3 μs

●

0.6 μs

●

1.3 μs

●

600 ns

●

600 ns

●

600 ns

●

0

300 900

●

100 ns

●

●

2.5 μs

●

2

C

2.5 μs

●

98 ns

2.5 μs

ns

ns

24 32 39 ms

304 μs

255 ms

32 ms

29701fc

5

LTC2970/LTC2970-1

The ● denotes the specifi cations which apply over the full operating

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

t

SETUP_TRACK

t

DEC_TRACK

Tracking IDAC Disconnect Delay LTC2970-1 Only: After the tracking

Tracking IDAC Decrement Rate LTC2970-1 Only: The LTC2970-1 changes

= 25°C.

A

algorithm asserts CPIO_CFG high, the

LTC2970-1 will wait this amount of time

before starting to decrement Chn_a_

delay_track[9:0]. Used while tracking

power supplies off.

Chn_a_delay_track[9:0] at this rate.

32 ms

88 μs/LSB

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specifi ed.

Note 3: TUE (%) is defi ned as:

%

INL V LSB V

+

+500

μ

V

IN

OS

•Gain Error

100

(• / )

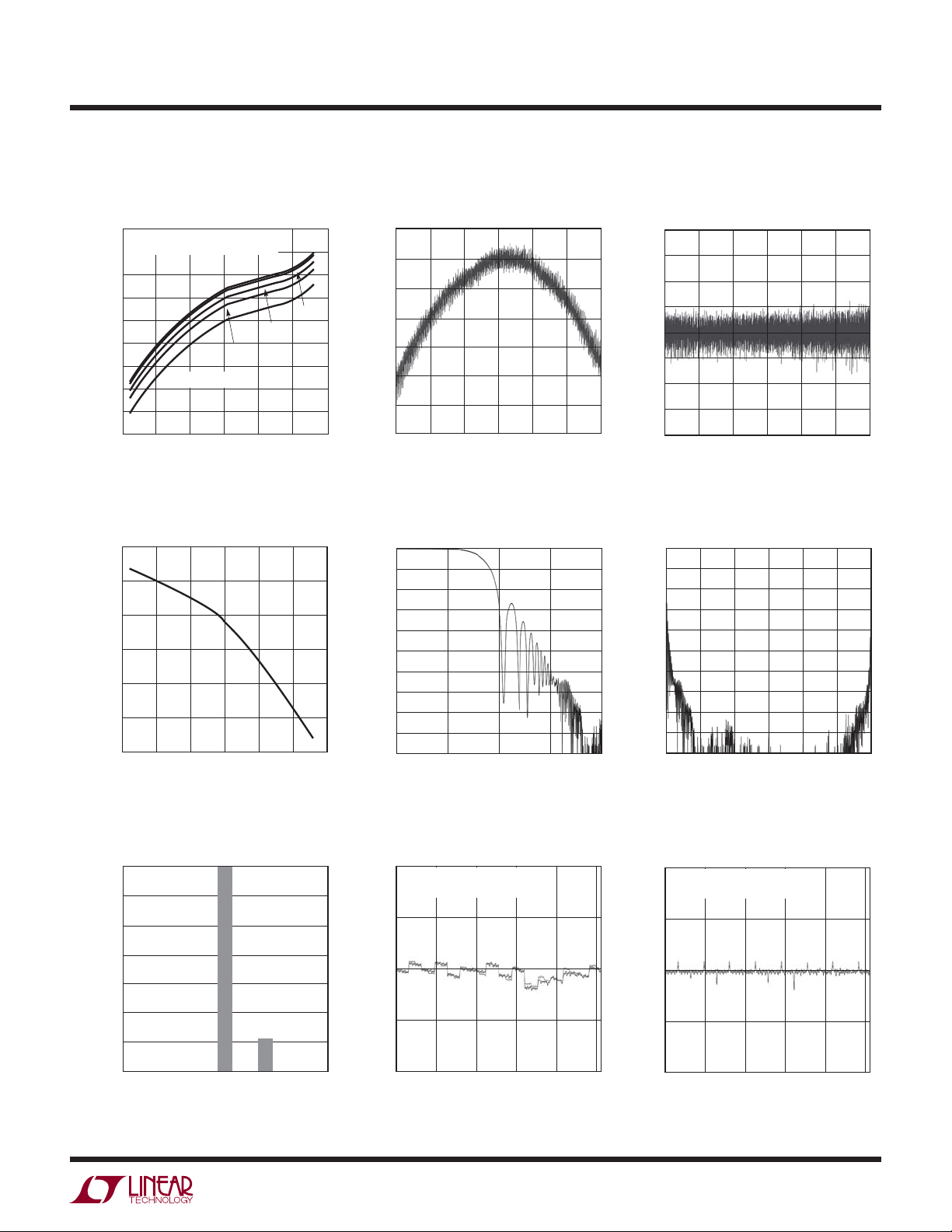

TIMING DIAGRAM

The I2C Bus Specifi cation

SDA

t

SU;DAT

t

f

SCL

t

f

t

LOW

t

r

Note 4: Integral nonlinearity (INL) is defi ned as the deviation of a code

from a straight line passing through the actual endpoints (0V and 6V)

of the transfer curve. The deviation is measured from the center of the

quantization band.

Note 5: Nonlinearity is defi ned from the fi rst code that is greater than or

equal to the maximum offset specifi cation to code 255 (full-scale).

Note 6: Maximum capacitive load, C

clock risetime (t

(20 + 0.1 • C

) and falltime (tf) are: (20 + 0.1 • CB)(ns) < tr < 300ns and

r

)(ns) < tf < 300ns. CB = capacitance of one bus line in pF.

B

SCL and SDA external pull-up voltage, V

, for SCL and SDA is 400pF. Data and

B

, is 3V < VIO < 5.5V.

IO

Note 7: This specifi cation is guaranteed by design.

t

HD;STA

t

SP

t

t

r

BUF

6

START

CONDITION

t

HD;STA

t

HD;DAT

t

HIGH

t

SU;STA

REPEATED START

CONDITION

t

SU;STO

STOP

CONDITION

START

CONDITION

29701 TD

29701fc

0

UW

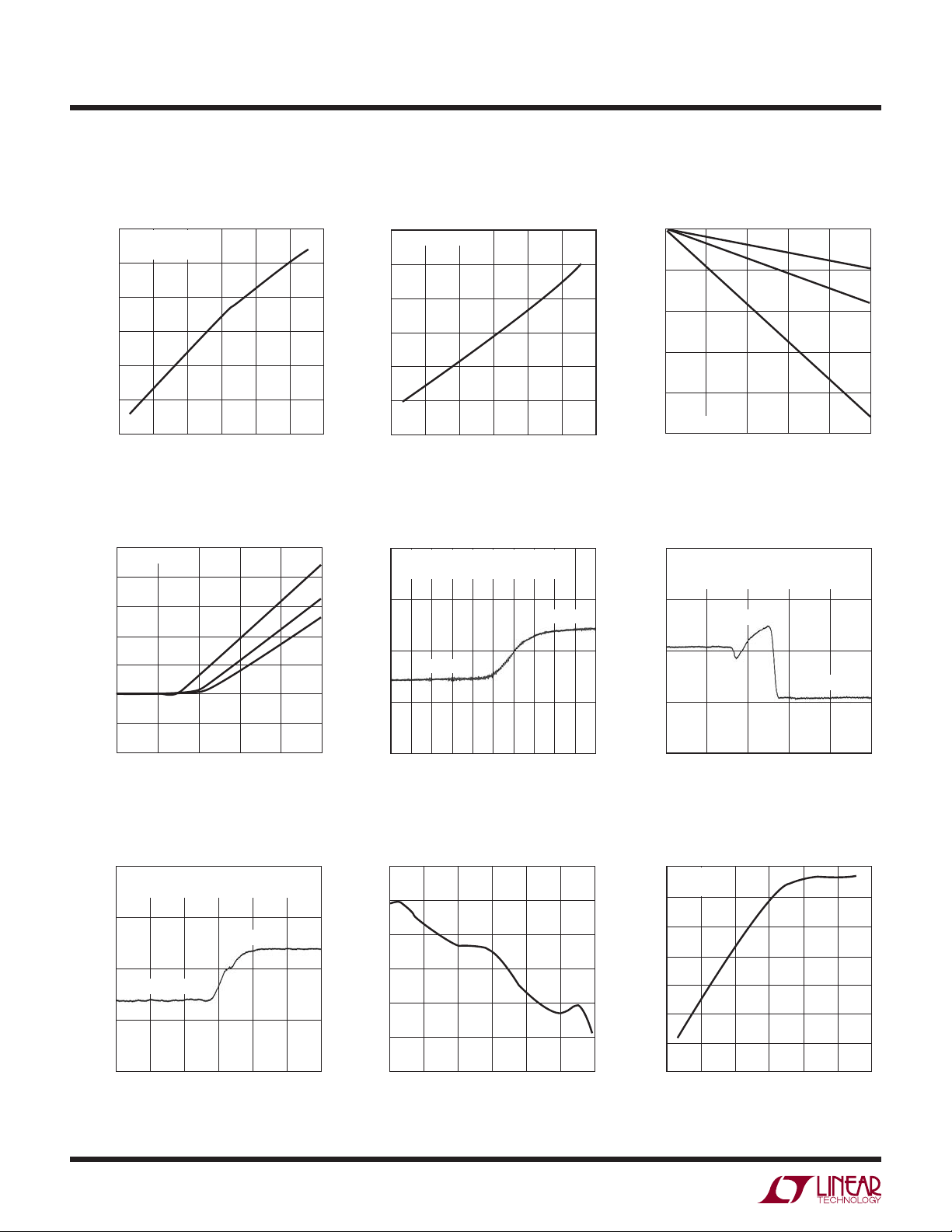

TYPICAL PERFOR A CE CHARACTERISTICS

ADC Total Unadjusted Error

vs Temperature ADC INL ADC DNL

0.050

0.025

0

–0.025

–0.050

–0.075

ERROR (%)

–0.100

–0.125

–0.150

–0.175

BASED ON AVERAGE OF 15 PARTS

ASSEMBLED ON 1/8" THICK PCB

3.3V

ADC VIN = 5V

0

–50

–25

25 10

TEMPERATURE (oC)

1V

1.8V

2.5V

50

75

29701 G01

2.5

2.0

1.5

1.0

0.5

ERROR (LSBs)

0

–0.5

–1.0

0

12

INPUT VOLTAGE (V)

46

35

LTC2970/LTC2970-1

1.00

0.75

0.50

0.25

0

–0.25

ERROR (LSBs)

–0.50

–0.75

–1.00

29701 G02

12 4

0

INPUT VOLTAGE (V)

3

5

6

29701 G03

ADC Zero Code Center Offset

Voltage vs Temperature

–305

–310

–315

(MV)

–320

OS

V

–325

–330

–335

–50

–25

ADC Noise Histogram

10,000,000

1,000,000

NUMBER OF READINGS

VIN = 0V

100000

10,000

1000

100

10

02550

TEMPERATURE (oC)

75 100

29701 G04

ADC Rejection vs Frequency

at V

IN

0

–10

–20

–30

–40

–50

–60

REJECTION (dB)

–70

–80

–90

–100

1

10

100

FREQUENCY AT VIN (Hz)

Voltage Buffered IDAC INL

0.50

CHANNELS 0 AND 1 SHOWN

= R

IOUT1

= 10k7

R

IOUT0

0.25

0

ERROR (LSBs)

–0.25

1000

10000

29701 G05

ADC Rejection vs Frequency

at V

IN

0

–10

–20

–30

–40

–50

–60

REJECTION (dB)

–70

–80

–90

–100

5000

0

15000 20000

10000

FREQUENCY AT VIN (Hz)

Voltage Buffered IDAC DNL

0.50

CHANNELS 0 AND 1 SHOWN

= R

R

IOUT0

0.25

0

ERROR (LSBs)

–0.25

IOUT1

= 10k7

25000

30000

29701 G06

1

–1 0 2

–2

OUTPUT CODE (LSBs)

1

29701 G07

–0.50

50

0

100

DAC CODE

150

200

29701 G08

250

–0.50

50

0

100

DAC CODE

150

200

250

29701 G09

29701fc

7

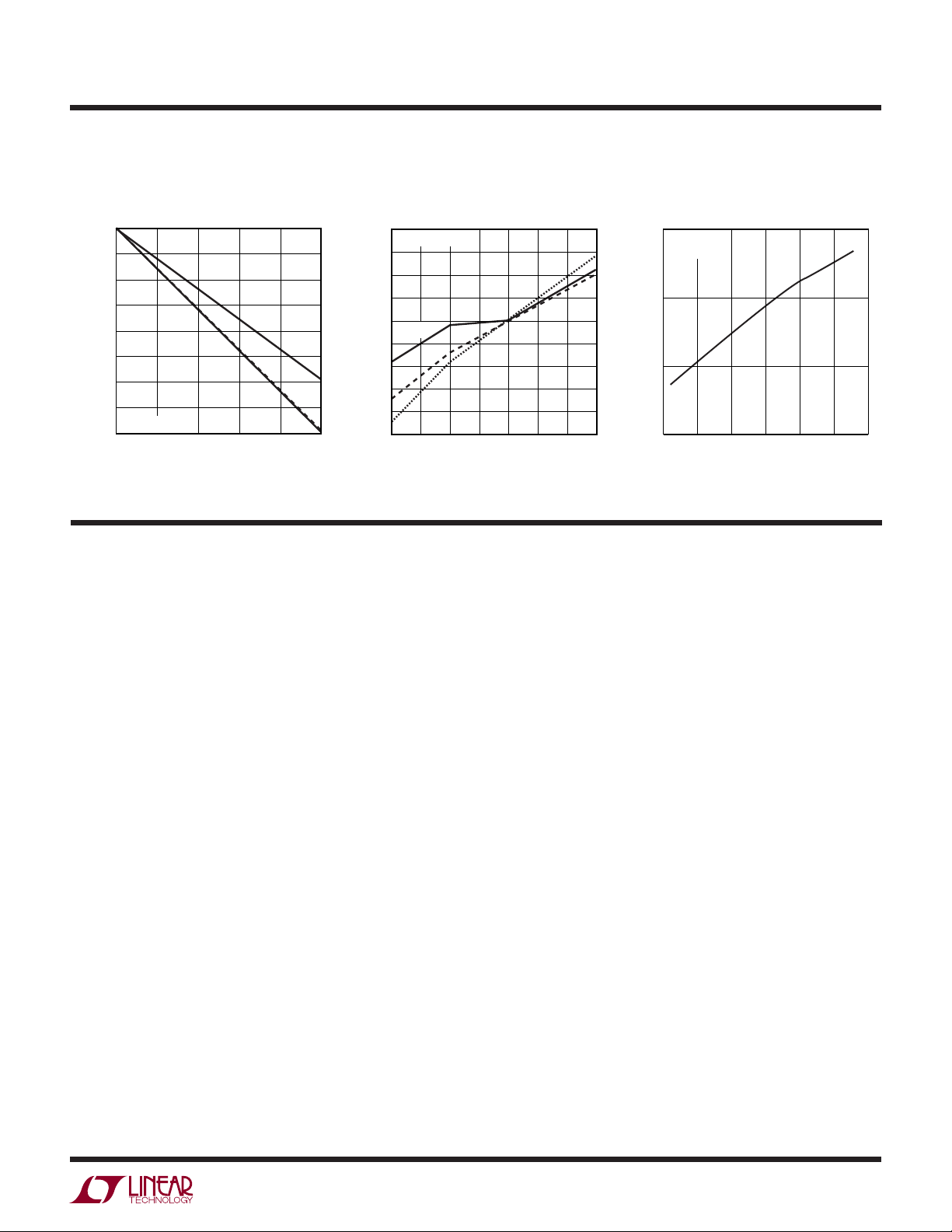

LTC2970/LTC2970-1

0

UW

TYPICAL PERFOR A CE CHARACTERISTICS

IDAC Output Current

vs Temperature

257.4

IDAC CODE = 'hff

= 13kΩ

R

IOUT

257.2

257.0

256.8

256.6

OUTPUT CURRENT (μA)

256.4

256.2

–50

02550

–25

TEMPERATURE (°C)

Voltage Buffered IDAC Load

Regulation Sinking

0.35

V

= 0.1V

IOUT

0.30

0.25

0.20

0.15

0.10

OUTPUT VOLTAGE (V)

75 10

29701 G10

90oC

25oC

–45oC

V

Offset Voltage

OUTn

vs Temperature

1.620

IDAC CODE = 'h00

1.615

1.610

1.605

1.600

OFFSET VOLTAGE (mV)

1.595

1.590

–50

02550

–25

TEMPERATURE (oC)

Voltage Buffered IDAC Transient

Response to 1LSB DAC Code Change

100k7 SERIES RESISTANCE ON V

R

= 10k7

IOUT

CODE 'h7f

10mV PER DIVISION

75 100

29701 G11

OUTn

CODE 'h80

Voltage Buffered IDAC Load

Regulation Sourcing

3.500

3.498

3.496

3.494

OUTPUT VOLTAGE (V)

3.492

V

= 3.5V

IOUTn

3.490

–2

0

–4

CURRENT (mA)

Voltage Buffered IDAC SoftConnect Transient Response

100k7 SERIES RESISTANCE ON V

R

= 10k7

IOUT

CODE 'h80

HIGH-Z

10mV PER DIVISION

–6

CONNECTED

–8

OUTn

25oC

–45oC

90oC

–10

29701 G12

0.05

0

246 10

0

CURRENT (mA)

Voltage Buffered IDAC Transient

Response During Transition from

On State to High-Z State

100k7 SERIES RESISTANCE ON V

R

= 10k7

IOUT

HIGH-Z

CONNECTED

10mV PER DIVISION

10Ms PER DIVISION

OUTn

8

5Ms PER DIVISION

Regulator Output Voltage

= 12V

= 0A

50 100

–25 0

25 75

TEMPERATURE (oC)

29701 G15

29701 G18

29701fc

29701 G13

29701 G16

1Ms PER DIVISION

Temperature Sensor Error

vs Temperature

1.5

1.0

0.5

0

ERROR (oC)

–0.5

–1.0

–1.5

–50

02550

–25

TEMPERATURE (oC)

29701 G14

75 100

29701 G17

V

vs Temperature

4.945

V

I

VDD

4.944

4.943

4.942

(V)

DD

V

4.941

4.940

4.939

4.938

–50

DD

12VIN

8

UW

TYPICAL PERFOR A CE CHARACTERISTICS

VDD Regulator Load Regulation

0

–100

–200

–300

(ppm)

–400

DD

ΔV

–500

–600

–700

V

= 12V

12VIN

–800

–1 –2 –4

0

CURRENT (mA)

–45°C

25°C90°C

–3

29701 G19

(ppm)

DD

–100

ΔV

–200

–300

–400

–500

–5

Regulator Line Regulation

V

DD

400

NO LOAD ON V

300

200

100

0

25°C

8

–45°C

9

90°C

DD

10 15

10

V

12VIN

(V)

12

13 14

UUU

PI FU CTIO S

LTC2970/LTC2970-1

VDD Regulator Short-Circuit

Current vs Temperature

–25

V

= 12V

12VIN

= 0V

V

DD

–30

–35

SHORT-CIRCUIT CURRENT (mA)

–40

–50

–25 0 25 50

TEMPERATURE (°C)

29701 G20

75 100

29701 G21

V

(Pin 1): Positive CH0_A ADC Multiplexer Input.

IN0_AP

The output of the differential, 7:1 multiplexer connects to

the input of the ADC. CH0_A can be confi gured to servo

IDAC0.

V

(Pin 2): Negative CH0_A ADC Multiplexer Input.

IN0_AM

The output of the differential, 7:1 multiplexer connects to

the input of the ADC. CH0_A can be confi gured to servo

IDAC0.

V

(Pin 3): Positive CH0_B ADC Multiplexer Input. The

IN0_BP

output of the differential, 7:1 multiplexer connects to the

input of the ADC. CH0_B is a voltage monitor input only.

V

(Pin 4): Negative CH0_B ADC Multiplexer Input.

IN0_BM

The output of the differential, 7:1 multiplexer connects to the

input of the ADC. CH0_B is a voltage monitor input only.

V

(Pin 5): Positive CH1_A ADC Multiplexer Input.

IN1_AP

The output of the differential, 7:1 multiplexer connects to

the input of the ADC. CH1_A can be confi gured to servo

IDAC1.

V

(Pin 6): Negative CH1_A ADC Multiplexer Input.

IN1_AM

The output of the differential, 7:1 multiplexer connects to

the input of the ADC. CH1_A can be confi gured to servo

IDAC1.

V

(Pin 7): Positive CH1_B ADC Multiplexer Input. The

IN1_BP

output of the differential, 7:1 multiplexer connects to the

input of the ADC. CH1_B is a voltage monitor input only.

V

(Pin 8): Negative CH1_B ADC Multiplexer Input.

IN1_BM

The output of the differential, 7:1 multiplexer connects to the

input of the ADC. CH1_B is a voltage monitor input only.

(Pin 9): VDD Power Supply, Voltage Monitor Input,

V

DD

and Internal 5V Regulator Output. The supply input range

is 4.5V to 5.75V. The V

to the ADC through an internal mux. Bypass the V

to device ground with a 100nF capacitor (C

input voltage supply is available, fl oat the V

power the LTC2970 from the 12V

(Pin 10): 12V Power Supply and Voltage Monitor

12V

IN

Input. An internal regulator generates 5V from 12V

input range for 12V

pin voltage can be connected

DD

pin

DD

). If no 5V

VDD

pin and

DD

pin.

IN

. The

IN

is 8V to 15V. Bypass this pin with a

IN

100nF capacitor. The regulator’s output is connected to the

pin. The 12VIN pin voltage can also be monitored by

V

DD

the ADC through a 3:1 attenuator and the internal mux. If

no 12V supply input is available, tie the 12V

to the VDD

IN

pin and operate from 4.5V to 5.75V.

(Pin 11): CH0 Voltage Output. Buffered version of

V

OUT0

IDAC0 output voltage.

29701fc

9

LTC2970/LTC2970-1

UUU

PI FU CTIO S

V

(Pin 12): CH1 Voltage Output. Buffered version of

OUT1

IDAC1 output voltage.

(Pin 13): IDAC1 Current Output. Connect a resistor

I

OUT1

between this pin and the point-of-load ground for channel

1. The IDAC sources between 0 and 255μA.

(Pin 14): IDAC0 Current Output. Connect a resistor

I

OUT0

between this pin and the point-of-load ground for channel

0. The IDAC sources between 0 and 255μA.

GPIO_1 (Pin 15): General Purpose Input or Open Drain

Digital Output. GPIO_1 can be confi gured as the IDAC

Fault or Faults output, a digital input, or an open-drain

digital output.

GPIO_0 (Pin 16): General Purpose Input or Open Drain

Digital Output. GPIO_0 can be confi gured as the voltage

monitor power-good or power-good bar output, a digital

input, or a programmable open-drain output. Power good

is the NOR of all instantaneous OV and UV faults; it does

not include IDAC faults.

⎯A⎯L⎯E⎯R⎯

T (Pin 17): Open Drain Digital Output. Connect the

⎯A⎯L⎯E⎯R⎯

SMBALERT signal to this pin.

either IDAC0 or IDAC1 rails out (optional), or when one

of the monitored voltages ventures outside its UV and OV

thresholds (also optional).

SCL (Pin 18): Serial Bus Clock Input.

T is asserted low when

SDA (Pin 19): Serial Bus Data Input and Output.

GPIO_CFG (Pin 20): GPIO Confi guration Digital Input and

Open Drain Output. Pulling GPIO_CFG high will cause the

GPIO_0 and GPIO_1 open-drain outputs to automatically

assert low after a power-on reset. If GPIO_CFG is pulled

low, then GPIO_0 and GPIO_1 do not assert low after

power-up.

ASEL1 (Pin 21): Slave Address Select Bit 1. Tie this pin to

the V

location (see Table 2).

ASEL0 (Pin 22): Slave Address Select Bit 0. Tie this pin to

the V

location (see Table 2).

REF (Pin 23): Internal Reference Output or ADC Reference

Overdrive Input. The voltage at this pin determines the

full-scale input voltage of the delta-sigma ADC (V

SCALE

decouples the reference output from this pin. Bypass this

pin to RGND with a 100nF capacitor (C

RGND (Pin 24): Reference Ground. Connect to device

ground.

GND (Pin 25): Device Ground. Must be soldered to

ground.

pin, ground, or fl oat in order to select the address

DD

pin, ground, or fl oat in order to select the address

DD

= 6.65 • V

, typically). An internal 3.5k resistor

REF

).

REF

FULL-

10

29701fc

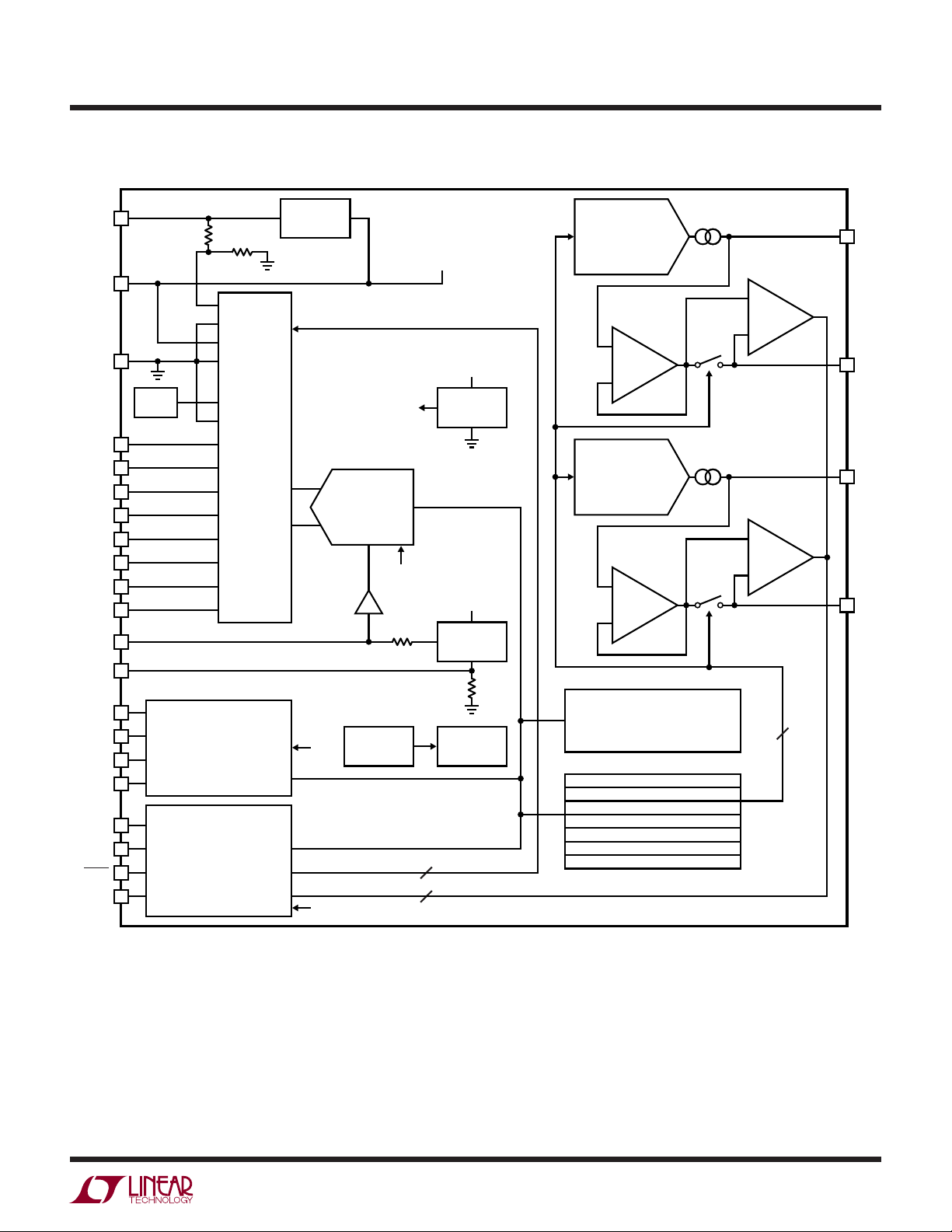

BLOCK DIAGRA

LTC2970/LTC2970-1

W

IN0_AP

IN0_AM

IN0_BP

IN0_BM

IN1_AP

IN1_AM

IN1_BP

IN1_BM

1012V

IN

9V

DD

25GND

2R

R

12V

P

12V

M

V

DDP

V

DDM

5V REGULATOR

V

V

OUT

IN

IDAC0

8 BITS

V

DD

+

V

DD

VBUF0

0μA TO 255μA

+

CMP0

–

14 I

11 V

OUT0

OUT0

–

TEMP

SENSOR

1V

2V

3V

4V

5V

6V

7V

8V

23REF

24RGND

18SCL

19SDA

(400kHz, SMBUS COMPATIBLE)

22ASEL0

21ASEL1

16GPIO_0

DAC SOFT CONNECT FUNCTION

15GPIO_1

17ALERT

20GPIO_CFG

MANAGE FAULT REPORTING

TRACKING CONTROL (LT2970-1)

TSNSP

TSNSM

CH0_AP

CH0_AM

CH0_BP

CH0_BM

CH1_AP

CH1_AM

CH1_BP

CH1_BM

7:1 MUX

I2C BUS INTERFACE

SERVO CONTROLLER

SERVO FUNCTION

MONITOR FUNCTION

WATCH DOG

POR

POR

+

DELTA-SIGMA

–

6.65X

(TYP)

OSCILLATOR

14-BIT

A/D

POR

ADC

CLOCKS

3.5k

7

2

UVLO

V

DD

REFERENCE

1.229V (TYP)

20Ω

CLOCK

GENERATION

IDAC1

8 BITS

+

VBUF1

–

RAM

ADC_Results

MONITOR LIMITS

SERVO TARGETS

REGISTERS

I/O CONFIGURATION

IDAC0

IDAC1

ADC MONITOR

FAULT ENABLE

INSTANTANEOUS FAULTS

LATCHED FAULTS

0μA TO 255μA

+

CMP1

–

13 I

OUT1

12 V

OUT1

18

29701 BD

29701fc

11

LTC2970/LTC2970-1

UU

TABLE OF CO TE TS

1. LTC2970 Operation Overview .............................................................................................................................13

2

C Serial Digital Interface .................................................................................................................................14

2. I

3. Register Command Set .......................................................................................................................................15

2

4. Detailed I

5. Soft Connecting the LTC2970 to the Power Supply Feedback Node ..................................................................20

6. Hard Connecting the LTC2970 to the Power Supply Trim Pin ............................................................................20

7. Programming a Previously Connected IDAC ......................................................................................................21

8. Disconnecting the LTC2970 from the Power Supply Trim Pin ...........................................................................21

9. Tracking Power Supplies Overview (LTC2970-1 Only) .......................................................................................21

10. Tracking Power Supplies On (LTC2970-1 Only) .................................................................................................21

11. Tracking Power Supplies Off (LTC2970-1 Only) .................................................................................................22

12. Continuous Power Supply Voltage Servo ...........................................................................................................23

C Command Register Descriptions ...................................................................................................16

(For Operations Sections)

13. One Time Power Supply Voltage Servo .............................................................................................................24

14. One Time Power Supply Voltage Servo with Repeat On Fault ..........................................................................24

15. Confi guring ADC to Monitor Input Channels and Internal Temperature Sensor ................................................24

16. Generating and Monitoring Instantaneous Faults ..............................................................................................25

17. Generating and Monitoring Latched Faults ........................................................................................................26

18. General Purpose Input/Output Pins ....................................................................................................................27

19. Advanced Development Features .......................................................................................................................27

12

29701fc

OPERATIO

LTC2970/LTC2970-1

U

1. LTC2970 Operation Overview

The LTC2970 is designed to control and monitor two

power supplies. The LTC2970’s superior accuracy allows

it to precisely servo each supply’s output voltage over a

wide range of operating conditions; increasing accuracy,

reducing power requirements and component costs. Margining may be performed with equal ease and precision.

The monitoring functions allow for increased reliability

by alerting a system host about incipient failures before

they occur. The seven channel ADC may also be used to

monitor current, temperature, and the 5V or optional 12V

supply.

The LTC2970’s unique architecture and control algorithm

have been especially tailored for power supply management. The soft connect feature allows the LTC2970 to begin

controlling a power supply without perturbing its initial

value. The delta-sigma ADC architecture was specifi cally

chosen to average out power-supply noise and allow the

LTC2970 to ignore fast transients. Unlike discrete time

DACs, the LTC2970’s continuous time, voltage buffered

IDAC is ideal for noise sensitive applications. The servo

algorithm limits the IDAC step size to one LSB per iteration

in order to minimize power supply transients. The point

of load ground reference for the IDAC outputs minimize

errors that would otherwise occur in a power system that

experiences ground bounce. By selecting two resistor

values, the user can choose the appropriate resolution

while providing an important hardware range limit beyond

which the supply may not be driven. The servo on fault

option allows the LTC2970 to further reduce output voltage

disturbances by only stepping the IDAC when the output

voltage drifts outside of a user programmable window.

The LTC2970 powers up in a high impedance state and

will not interfere with default power supply operation.

Similarly, powering down the LTC2970 will restore its

high impedance state.

All communication with the LTC2970 is performed over

an industry standard I

also meets all SMBus setup times, hold times, and timeout

requirements. The ALERT pin may be used to signal that

one or more of the fourteen confi gurable fault limits have

been reached. Each fault may be individually masked. The

2

C interface supports word reads, word writes and the

I

SMBus Alert Response Address protocol. Two general

purpose IO pins may be used to provide additional fault

information or user defi ned system control. Powering down

the LTC2970 will not interfere with I

The LTC2970-1 enables power supply tracking and sequencing with the addition of a few external components.

A special global address and synchronization command

allow multiple LTC2970-1’s to track and sequence multiple

pairs of power supplies.

The LTC2970 can perform the following operations:

• Accept all programming commands and report status

over the I

• Command each voltage buffered IDAC to connect to the

corresponding power supply’s feedback node through

an external resistor using the IDAC code that most

closely approximates the feedback node’s regulation

voltage (Soft Connect).

• Command each voltage buffered IDAC output to connect

to the corresponding power supply’s feedback node

through an external resistor with a user-selected IDAC

code (Hard Connect).

• Change the code of a previously connected IDAC.

• Disconnect each voltage buffered IDAC output from the

power supply’s feedback node.

• LTC2970-1 Only: Track two power supplies up or down.

Multiple LTC2970-1’s can be confi gured to track simultaneously or in a sequence.

2

C or SMBus bus.

2

C bus. The LTC2970 I2C interface

2

C operation.

29701fc

13

LTC2970/LTC2970-1

U

OPERATIO

• Continuously servo one or both supplies to a programmed voltage.

• Perform a one-time servo of one or both supplies to a

programmed voltage and hold the servo codes in the

controlling IDAC.

• Perform a one time servo of one or both supplies to

a programmed voltage and hold the code(s) in the

controlling IDAC(s) until over/under voltage monitoring detects a fault, at which point a control bit may be

used to allow the LTC2970 to servo back to the initial

voltage target.

• Select any combination of seven possible ADC channels

to be monitored by the ADC.

• Generate instantaneous faults based on user programmable over-voltage and under-voltage limits and fi xed

IDAC limits. The status of OR’d voltage limit faults and

IDAC faults may be output over GPIO_0 and GPIO_1,

respectively.

• Enable instantaneous faults to set associated latched

faults using the FAULT_EN register. The status of OR’d

latched faults may be signalled using ALERT.

• Confi gure the GPIO_0 and GPIO_1 pins to act as inputs

or outputs.

2

C Serial Digital Interface

2. I

The LTC2970 communicates with a host (master) using

the 2-wire, I

shows the timing relationship of the signals on the bus.

2

C serial bus interface. The Timing Diagram

The two bus lines, SDA and SCL, must be high when the

bus is not in use. External pull-up resistors or current

sources are required on these lines.

2

The LTC2970 I

all SMBus setup times, hold times and timeout requirements.

The LTC2970 is a receive-only (slave) device. The LTC2970

can signal the host through the SMBALERT protocol that it

wants to talk by asserting ALERT low. The LTC2970 supports the three I

Slave Address

The LTC2970 can respond to one of nine 7-bit addresses.

The two slave address select pins (ASEL1 and ASEL0) are

programmed by the user and determine the slave address,

as shown in Table 2.

The LTC2970 also supports the ARA address and a global

address that allows multiple LTC2970s to be programmed

with the same data simultaneously, as shown in Table 3.

Table 1. Supported I2C Command Types

READ DATA WORD:

S:ADR:W:A:CMD:A:Sr:ADR:R:A:DATA:A:DATA:NACK:P

WRITE DATA WORD:

S:ADR:W:A:CMD:A:DATA:A:DATA:A:P

ALERT RESPONSE

S:ARA:R:A:ADR:NACK:P:

C interface is SMBus compatible; it meets

2

C protocols summarized in Table 1.

14

29701fc

OPERATIO

LTC2970/LTC2970-1

U

Table 2. LTC2970 Address Table

ADDRESS[7:0]

(R/W = 0)

8’hB8 7’h5C L L

8’hBA 7’h5D L F

8’hBC 7’h5E L H

8’hBE 7’h5F F L

8’hD6 7’h6B F F

8’hD8 7’h6C F H

8’hDA 7’h6D H L

8’hDC 7’h6E H F

8’hDE 7’h6F H H

ASELn

< V

IL_ASEL

L: V

ADDRESS[7:1] ASEL1 ASEL0

F: ASELn Floating H: V

ASELn

> V

IH_ASEL

Table 3. Special LTC2970 Addresses

ADDRESS[7:0]

(R/W = 0)

ARA 8’h18 7’h0C This is the standard Alert

Global 8’hB6 7’h5B This a global address to which

ADDRESS[7:1] FUNCTION

Response Address for all

SMBus devices. This address is

independent of the value of the

ASEL1 and ASEL0 pins.

all LTC2970s will respond. This

address is independent of the

value of the ASEL1 and ASEL0

pins.

3. Register Command Set

COMMAND FUNCTION DESCRIPTION R/W DATA

FAULT() Instantaneous Fault Status For All Channels Read Only 16 Bits ‘h00

FAULT_EN() Enable For All Latched Faults and Servo On Fault Read/Write 16 Bits ‘h08

FAULT_LA_INDEX() Index to All Latched Faults Read Only 16 Bits ‘h10

FAULT_LA() Latched Fault Status For All Channels Read Only 16 Bits ‘h11

IO() IO Control and Status Register Read/Write 16 Bits ‘h17

ADC_MON() Control Register For Selecting ADC Channels to Monitor Read/Write 16 Bits ‘h18

*SYNC() Control Register For Synchronizing Tracking Across Multiple Devices Read/Write 16 Bits ‘h1F

VDD_ADC() V

VDD_OV() V

VDD_UV() V

V12_ADC() 12V

V12_OV() 12V

V12_UV() 12V

CH0_A_ADC() CH0_A ADC Conversion Result Register Read Only 16 Bits ‘h40

CH0_A_OV() CH0_A Over-Voltage Monitor Control Register Read/Write 16 Bits ‘h41

CH0_A_UV() CH0_A Under-Voltage Monitor Control Register Read/Write 16 Bits ‘h42

CH0_A_SERVO() CH0_A Voltage Servo Control Register Read/Write 16 Bits ‘h43

CH0_A_IDAC() CH0_A IDAC Control Register Read/Write 16 Bits ‘h44

*CH0_A_IDAC_TRACK() CH0_A IDAC Track Final Value Register Read/Write 16 Bits ‘h45

*CH0_A_DELAY_TRACK() CH0_A IDAC Track Delay Register Read/Write 16 Bits ‘h46

CH0_B_ADC() CH0_B ADC Conversion Result Register Read Only 16 Bits ‘h48

CH0_B_OV() CH0_B Over-Voltage Monitor Control Register Read/Write 16 Bits ‘h49

CH0_B_UV() CH0_B Under-Voltage Monitor Control Register Read/Write 16 Bits ‘h4A

CH1_A_ADC() CH1_A ADC Conversion Result Register Read Only 16 Bits ‘h50

CH1_A_OV() CH1_A Over-Voltage Monitor Control Register Read/Write 16 Bits ‘h51

CH1_A_UV() CH1_A Under-Voltage Monitor Control Register Read/Write 16 Bits ‘h52

ADC Conversion Result Register Read Only 16 Bits ‘h28

DDIN

Over-Voltage Monitor Control Register Read/Write 16 Bits ‘h29

DDIN

Under-Voltage Monitor Control Register Read/Write 16 Bits ‘h2A

DDIN

ADC Conversion Result Register Read Only 16 Bits ‘h38

IN

Over-Voltage Monitor Control Register Read/Write 16 Bits ‘h39

IN

Under-Voltage Monitor Control Register Read/Write 16 Bits ‘h3A

IN

LENGTH

COMMAND

BYTE VALUE

29701fc

15

LTC2970/LTC2970-1

U

OPERATIO

3. Register Command Set (Cont.)

COMMAND FUNCTION DESCRIPTION R/W DATA

CH1_A_SERVO() CH1_A Voltage Servo Control Register Read/Write 16 Bits ‘h53

CH1_A_IDAC() CH1_A IDAC Control Register Read/Write 16 Bits ‘h54

*CH1_A_IDAC_TRACK() CH1_A IDAC Track Control Register Read/Write 16 Bits ‘h55

*CH1_A_DELAY_TRACK() CH1_A IDAC Track Delay Register Read/Write 16 Bits ‘h56

CH1_B_ADC() CH1_B ADC Conversion Result Register Read Only 16 Bits ‘h58

CH1_B_OV() CH1_B Over-Voltage Monitor Control Register Read/Write 16 Bits ‘h59

CH1_B_UV() CH1_B Under-Voltage Monitor Control Register Read/Write 16 Bits ‘h5A

TEMP_ADC() Temperature ADC Conversion Result Register Read/Write 16 Bits ‘h68

RESERVED() All other commands are reserved for future expansion and should not be

written or read.

*LTC2970-1 Only. LTC2970 will not acknowledge these commands.

Read/Write 16 Bits ‘hXX

LENGTH

COMMAND

BYTE VALUE

4. Detailed I2C Command Register Descriptions

FAULT: Instantaneous Fault Register – Read

BIT(s) SYMBOL OPERATION

b[0]

b[1]

b[2]

b[3]

b[4]

b[5]

b[6]

b[7]

b[8]

b[9]

b[10]

b[11]

b[12]

b[13]

b[15:14] Reserved Always Returns 0

Fault_ch0_a_ov

Fault_ch0_a_uv

Fault_ch0_a_idac

Fault_ch0_b_ov

Fault_ch0_b_uv

Fault_ch1_a_ov

Fault_ch1_a_uv

Fault_ch1_a_idac

Fault_ch1_b_ov

Fault_ch1_b_uv

Fault_vdd_ov

Fault_vdd_uv

Fault_v12_ov

Fault_v12_uv

0 = The associated channel is clear of

instantaneous faults.

1 = The associated channel has an

instantaneous fault.

The reported faults are instantaneous

and not latched. When used in

conjunction with latched faults they

may indicate faults that are transient in

nature.

FAULT_EN: Fault Enabling Register – Read/Write

BIT(s) SYMBOL OPERATION

b[0]

b[1]

b[2]

b[3]

b[4]

b[5]

b[6]

b[7]

b[8]

b[9]

b[10]

b[11]

b[12]

b[13]

b[14] Fault_en_ch0_a_servo 0 = Do not re-servo CH0_A in

b[15] Fault_en_ch1_a_servo 0 = Do not re-servo CH1_A in

Fault_en_ch0_a_ov

Fault_en_ch0_a_uv

Fault_en_ch0_a_idac

Fault_en_ch0_b_ov

Fault_en_ch0_b_uv

Fault_en_ch1_a_ov

Fault_en_ch1_a_uv

Fault_en_ch1_a_idac

Fault_en_ch1_b_ov

Fault_en_ch1_b_uv

Fault_en_vdd_ov

Fault_en_vdd_uv

Fault_en_v12_ov

Fault_en_v12_uv

0 = The associated bit in the

FAULT_LA register will always be 0.

(default)

1 = Instantaneous faults reported in

the FAULT register will set associated

bit in the FAULT_LA register.

response to instantaneous OV or UV

fault.

1 = Repeat a one time servo of CH0_A

in response to instantaneous OV or

UV fault. CH0_A must have servo

operation enabled with Ch0_a_idac_

servo_repeat set low, and Adc_mon_

ch0_a set high.

response to instantaneous OV or UV

fault.

1 = Repeat a one time servo of CH1_A

in response to instantaneous OV or

UV fault. CH1_A must have servo

operation enabled with Idac_ch1_a_

servo_repeat set low, and Adc_mon_

ch1_a set high.

29701fc

16

OPERATIO

LTC2970/LTC2970-1

U

4. Detailed I2C Command Register Descriptions

(Cont.)

FAULT_INDEX: Latched Fault Index Register – Read

BIT(s) SYMBOL OPERATION

b[0] Fault_la_index 0 = All faults indicated by FAULT_LA

b[15:1] Reserved Always Returns 0

FAULT_LA: Latched Fault Register – Read

BIT(s) SYMBOL OPERATION

b[0]

b[1]

b[2]

b[3]

b[4]

b[5]

b[6]

b[7]

b[8]

b[9]

b[10]

b[11]

b[12]

b[13]

b[15:14] Reserved Always Returns 0

Fault_la_ch0_a_ov

Fault_la_ch0_a_uv

Fault_la_ch0_a_idac

Fault_la_ch0_b_ov

Fault_la_ch0_b_uv

Fault_la_ch1_a_ov

Fault_la_ch1_a_uv

Fault_la_ch1_a_idac

Fault_la_ch1_b_ov

Fault_la_ch1_b_uv

Fault_la_vdd_ov

Fault_la_vdd_uv

Fault_la_v12_ov

Fault_la_v12_uv

are clear.

1 = One or more faults indicated by

FAULT_LA are set.

This register allows a summary of all

latched faults to be viewed in a single

read without resetting latched faults.

0 = The associated channel is clear of

faults.

1 = The associated channel has faulted

and is enabled.

The latched faults are set and held

when the associated channel's

instantaneous fault has occured with

faults enabled. Clearing the enable bit

for the associated channel in FAULT_EN

will immediately clear its corresponding

latched fault bit.

All latched channel faults are cleared

when this register is read. They may

be set again if the instantaneous

fault condition and fault_en have not

changed.

IO: Input/Output Data and General Purpose Control Register

– Read/Write unless specifi ed otherwise.

BIT(s) SYMBOL OPERATION

b[1:0] Io_cfg_0[1:0] Io_cfg_0[1:0] is used to confi gure the function of

b[3:2] Io_cfg_1[1:0] Io_cfg_1[1:0] is used to confi gure the function

b[4] Io_gpio_0 See Io_cfg_0.

b[5] Io_gpio_1 See Io_cfg_1.

b[6] Io_alertb Mirrors the value of the ALERT pin.

b[7] Io_alertb_enb 1 = ALERT pin never asserts (default).

b[8] Io_i2c_adc_

wen

b[9] Io_gpio_cfg Read only. GPIO_CFG digital input and open-

b[10] Io_track_start Writing a 1 to this bit will start tracking all

b[15:11] Reserved Always Returns 0

the GPIO_0 pin and IO(Io_gpio_0).

00: Io_gpio_0 = GPIO_0 = Power_good. Power_

good asserts high if there are no instantaneous

over-voltage or under-voltage faults.

01: Io_gpio_0 = GPIO_0 = Power_good_bar.

Power_good_bar is the complement of

Power_good.

10: GPIO_0 is a general-purpose open-drain

output and mirrors the value written to Io_gpio_0

(default).

11: GPIO_0 is a general-purpose digital input

with Io_gpio_0 = GPIO_0

of the GPIO_1 pin and IO(Io_gpio_1).

00: Io_gpio_1 = GPIO_1 = Idac_fault.

Idac_fault asserts if either IDAC value is faulted

(Chn_idac[7:0] = 8’h00 or 8’hff)

01: Io_gpio_1 = GPIO_1 = Idac_fault_bar.

Idac_fault_bar is the complement of Idac_fault.

10 = GPIO_1 is a general-purpose opendrain output and mirrors the value written to

Io_gpio_1 (default).

11 = GPIO_1 is a general-purpose digital input

with Io_gpio_1 = GPIO_1

If the GPIO_CFG pin is pulled-high during a

power on reset, Io_gpio_0 is cleared and the

GPIO_0 open-drain output will assert low.

If the GPIO_CFG pin is pulled-high during a

power on reset, Io_gpio_1 is cleared and the

GPIO_1 open-drain output will assert low.

Read only.

0 = ALERT pin asserts low when one or more

FAULT_LA bits are set.

1 = Special test mode that inhibits ADC from

writing to ADC result register and allows user

to update registers over the I

0 = Normal operation (default).

drain output. Reading this bit returns the

current state of the GPIO_CFG pin voltage.

enabled channels. Returns a 1 when tracking

is pending (LTC2970-1). Reserved on LTC2970

and always returns 0.

2

C serial interface.

29701fc

17

LTC2970/LTC2970-1

U

OPERATIO

4. Detailed I2C Command Register Descriptions

(Cont.)

ADC_MON: ADC Monitoring Mux Control Register – Read/Write

BIT(s) SYMBOL OPERATION

b[0]

b[1]

b[2]

b[3]

b[4]

b[5]

b[6]

b[15:7] Reserved Always Returns 0

SYNC: Tracking Synchronization Control Register – Read/Write

LTC2970-1 Only

BIT(s) SYMBOL OPERATION

b[0] Sync_track Write

b[15:1] Reserved Always Returns 0

Adc_mon_vdd

Adc_mon_v12

Adc_mon_ch0_a

Adc_mon_ch0_b

Adc_mon_ch1_a

Adc_mon_ch1_b

Adc_mon_temp

0 = ADC will not convert associated

channel. (Default)

1 = ADC will continuously convert

associated channel.

0 = Do not synchronize.

1 = Synchronize all tracking enabled

registers to the same starting point.

Read

0 = The LTC2970-1 is not synchronized

for tracking (default).

1 = The LTC2970-1 is synchronized for

tracking.

Use of the global address will allow

the synchronization status of multiple

LTC2970-1s to be verifi ed in a single

read; since a one can only be returned

if all LTC2970-1s are synchronized. The

IO_track_start command may then be

issued with the same global address

to begin synchronized tracking across

multiple ICs.

VDD_ADC, V12_ADC, CH0_A_ADC, CH0_B_ADC, CH1_A_ADC,

CH1_B_ADC, and TEMP_ADC: ADC Conversion Result Registers

– Read Only Unless Specifi ed Otherwise

BIT(s) SYMBOL OPERATION

b[14:0] Vdd_adc[14:0]

V12_adc[14:0]

Ch0_a_adc[14:0]

Ch0_b_adc[14:0]

Ch1_a_adc[14:0]

Ch1_b_adc[14:0]

Temp_adc[14:0]

b[15] Vdd_adc_new

V12_adc_new

Ch0_a_adc_new

Ch0_b_adc_new

Ch1_a_adc_new

Ch1_b_adc_new

Temp_adc_new

Measured data from ADC conversion.

'h4000 corresponds to negative full-

scale input voltage.

'h0000 corresponds to 0V.

'h3fff corresponds to full-scale input

voltage.

2’s complement format, b[14] = sign.

Read/Write when Io_i2c_adc_wen = 1.

Default value is undefi ned.

1 = The ADC has updated the

associated result register since the last

time the data was read.

0 = Previously read data. (Default)

VDD_OV, V12_OV, CH0_A_OV, CH0_B_OV, CH1_A_OV, CH1_B_

OV: Over Voltage Limit Registers – Read/Write

BIT(s) SYMBOL OPERATION

b[14:0] Vdd_ov[14:0]

V12_ov[14:0]

Ch0_a_ov[14:0]

Ch0_b_ov[14:0]

Ch1_a_ov[14:0]

Ch1_b_ov[14:0]

b[15] Reserved Always Returns 0

ADC over-voltage threshold limit.

The associated instantaneous over

voltage fault is asserted if the channel’s

ADC result is greater than this limit.

Code 'h3fff disables OV threshold

detect feature for that channel.

2’s complement format, b[14] = sign.

Default value is undefi ned.

VDD_UV, V12_UV, CH0_A_UV, CH0_B_UV, CH1_A_UV, CH1_B_

UV: Under Voltage Limit Registers – Read/Write

BIT(s) SYMBOL OPERATION

b[14:0] Vdd_uv[14:0]

V12_uv[14:0]

Ch0_a_uv[14:0]

Ch0_b_uv[14:0]

Ch1_a_uv[14:0]

Ch1_b_uv[14:0]

b[15] Reserved Always Returns 0

ADC under-voltage threshold limit.

The associated instantaneous under

voltage fault is asserted if the channel’s

ADC result is greater than this limit.

Code 'h4000 disables UV threshold

detect feature for that channel.

2’s complement format, b[14] = sign.

Default value is undefi ned.

18

29701fc

OPERATIO

LTC2970/LTC2970-1

U

4. Detailed I2C Command Register Descriptions

(Cont.)

CH0_A_SERVO, CH1_A_SERVO: Voltage Servo Control

Registers – Read/Write

BIT(s) SYMBOL OPERATION

b[14:0] Ch0_a_servo[14:0]

Ch1_a_servo[14:0]

b[15] Ch0_a_servo_en

Ch1_a_servo_en

CH0_A_IDAC, CH1_A_IDAC: IDAC Control/Data Registers –

Read/Write

BIT(s) SYMBOL OPERATION

b[7:0] Ch0_a_idac[7:0]

Ch1_a_idac[7:0]

b[8] Ch0_a_idac_en

Ch1_a_idac_en

b[9] Ch0_a_idac_con

Ch1_a_idac_con

During servo operation

Chn_a_idac[7:0] output current is

stepped to force Chn_a_adc[14:0]

code to equal target code stored in

Chn_a_servo[14:0].

2’s complement format, b[14] = sign

Default value is undefi ned.

0 = Chn_a servo disabled (default).

1 = Chn_a servo enabled.

Chn_a IDAC data value.

0 = V

1 = V

There are two ways to enable

V

1) When Chn_a_idac_en is set

high with Chn_a_idac_con low,

the LTC2970 will perform a soft

connect. During a soft connect,

the V

will not be connected to the V

pin until the internal algorithm

has servo’d the voltage at the

IDACn pin to match the V

pin voltage. Resolution is one

Chn_a_idac LSB.

2) When Chn_a_idac_en is

enabled with Chn_a_idac_con

high, the LTC2970 will perform

a hard connect. The V

voltage buffer will be immediately

connected to the V

0 = V

has been enabled but is not yet

connected to the output of the

CHn voltage buffer. (Default)

1 = V

connected to the output of the

CHn voltage buffer.

See Chn_a_idac_en for additional

information.

output tri-stated.

OUTn

output enabled.

OUTn

.

OUTn

voltage buffer output

OUTn

is not enabled or

OUTn

is enabled and has been

OUTn

OUTn

OUTn

pin.

OUTn

OUTn

b[10] Ch0_a_idac_pol

Ch1_a_idac_pol

b[11] Ch0_a_idac_servo_repeat

Ch1_a_idac_servo_repeat

b[15:12] Reserved Always Returns 0

0 = Use this setting when

increasing V

(VINn_AP-VINn_AM) to decrease.

Inverting confi guration common

to DC/DC converters with external

feedback networks.

1 = Use this setting when

increasing V

(VINn_AP-VINn_AM) to increase.

Non-inverting confi guration

common to DC/DC converters

with trim pins.

0 = During servo operation, servo

Chn_a until the measured result

is stable and matches the target

code.

1 = During servo operation,

continuously servo Chn_a to the

target code.

OUTn

OUTn

causes

causes

CH0_A_IDAC_TRACK and CH1_A_IDAC_TRACK: IDAC Tracking

data and control registers – Read/Write

LTC2970-1 Only

BIT(s) SYMBOL OPERATION

b[7:0] Ch0_a_idac_

b[8] Ch0_a_idac_track_en

b[15:9] Reserved Always Returns 0

track[7:0]

Ch1_a_idac_

track[7:0]

Ch1_a_idac_track_en

Final target value for of Chn_a_

idac[7:0]. During tracking, Chn_a_

idac[7:0] is incremented/decremented

by 1 until it is equal to this value.

0 = inhibit tracking of Chn_a_idac[7:0].

1 = enable tracking of Chn_a_idac[7:0]

CH0_A_DELAY_TRACK and CH1_A_DELAY_TRACK: IDAC

Tracking delay register – Read/Write

LTC2970-1 Only

BIT(s) SYMBOL OPERATION

b[9:0] Ch0_a_delay_track[9:0]

Ch1_a_delay_track[9:0]

b[1510] Reserved Always Returns 0

Delay used to synchronize or offset

tracking events.

29701fc

19

LTC2970/LTC2970-1

U

OPERATIO

5. Soft Connecting the LTC2970 to the Power Supply

Feedback Node

The soft connect feature allows the LTC2970 to connect to

the power supply’s feedback node with minimal disturbance

to the supply’s output voltage. This is accomplished by

comparing the buffered voltage of I

and incrementing or decrementing Chn_a_idac[7:0]

V

n

OUT

until the comparator output (COMPn) changes. The value

of Chn_a_idac[7:0] when the comparator transitions is the

appropriate value for a soft connect. The voltage buffer

output is only connected to V

soft connect value without generating an instantaneous

IDAC fault (Fault_chn_a_idac).

Soft-Connect Procedure:

Determine the appropriate polarity for Chn_a_idac_pol.

Select Chn_a_idac_pol = 1 if incrementing V

differential voltage (VINn_AP – VINn_AM) to increase.

When properly programmed, lowering the value in Chn_

a_idac[7:0] will always cause the output of the controlled

power supply to decrease.

Ensure that the channel’s IDAC is not currently enabled for

connection, i.e., the Chn_a_idac_en bit must be 0.

Update CHn_A_IDAC() with Chn_a_idac_pol, Chn_a_idac_

con = 0, Chn_a_idac_en = 1, and Chn_a_idac[7:0] = 0x80.

The value programmed into Chn_a_idac[7:0] is ignored

and Chn_a_idac[7:0] is initially set to 8’h80.

The LTC2970 will now ramp Chn_a_idac[7:0] while monitoring the output of the soft connect comparator. If the soft

connect comparator trips, the LTC2970 will connect the

output of V

If the soft connect comparator does not trip before the

IDAC value reaches ‘h00 or ‘hFF, then the soft connection

will fail, an IDAC fault will be indicated (Fault_chn_a_idac),

and Chn_a_idac_con will remain low.

Soft-Connect Rules:

When both channels are requesting a soft connect, channel 0 has priority.

Soft connect requests will be ignored and the user will not

be able to change Chn_a_idac_pol or Chn_a_idac[7:0] if

the LTC2970 is servicing a previously issued soft connect

BUFn

to V

and set Chn_a_idac_con high.

OUTn

if the IDAC reaches this

OUTn

to the voltage at

OUTn

OUTn

causes

on that channel or the previously issued soft connect failed

with an IDAC fault (Fault_chn_a_idac = 1). Recall that the

Chn_a_idac_en bit must initially have been set to 0.

LTC2970-1 Only: Soft connect requests will be ignored

and the user will not be able to change Chn_a_idac_pol or

Chn_a_idac[7:0] if GPIO_CFG is high and either GPIO_0

or GPIO_1 are high.

LTC2970-1 Only: Soft connect requests will be ignored and

the user will not be able to change the Chn_a_idac_pol bit

if there is a pending tracking operation.

6. Hard Connecting the LTC2970 to the Power Supply

Trim Pin

The hard connect feature allows the LTC2970 to bypass the

soft connect algorithm and connect directly to the power

supply’s feedback node using the value programmed into

Chn_a_idac[7:0]. This feature is useful for systems that

have calculated or measured an acceptable voltage at which

to connect the IDAC’s buffered voltage V

Hard Connect Procedure:

Determine the appropriate polarity for Chn_a_idac_pol.

Select Chn_a_idac_pol = 1 if incrementing V

(VINn_AP – VINn_AP) to increase. When properly programmed, lowering the value in the IDAC will always cause

the output of the controlled power supply to decrease.

Determine the value for Chn_a_idac[7:0]. The values ‘h00

or ‘hff are allowed, but they will trip the IDAC’s fault bit

(Fault_chn_a_idac = 1).

When the IDAC is already connected, the value Chn_a_

idac[7:0] and Chn_a_idac_pol will be programmed into the

IDAC provided all other conditions are met. See “Programming a Previously Connected Current DAC” for details

Update CHn_A_IDAC() with Chn_a_idac_pol, Chn_a_idac_

con = 1, Chn_a_idac_en = 1, and Chn_a_idac[7:0].

Hard Connect Rules:

Hard connect requests will be ignored and the user will not

be able to change Chn_a_idac_pol, Chn_a_idac_con or

Chn_a_idac[7:0] if the LTC2970 is servicing a previously

issued soft connect on that channel or the previously issued

BUFn

to V

OUTn

.

OUTn

causes

20

29701fc

OPERATIO

LTC2970/LTC2970-1

U

soft connect failed with an IDAC fault (Fault_chn_a_idac =

1). Recall that a new hard connection requires the previous

value of Chn_a_idac_en = 0.

LTC2970-1 Only: Hard connect requests will be ignored

and the user will not be able to change Chn_a_idac_pol,

Chn_a_idac_con or Chn_a_idac[7:0] if GPIO_CFG is high

and either GPIO_0 or GPIO_1 are high.

LTC2970-1 Only: Hard connect requests will be ignored and

the user will not be able to change Chn_a_idac_pol, Chn_a_

idac_con or Chn_a_idac[7:0] if there is a pending tracking

operation.

7. Programming a Previously Connected IDAC

The LTC2970 IDAC’s may be programmed after they have

been connected with a soft connect or a hard connect

provided a servo operation is not enabled on the associated channel.

Procedure:

Determine the value for Chn_a_idac[7:0]. The values

‘h00 or ‘hff are allowed, but will trip the IDAC’s fault bit

(Fault_chn_a_idac = 1).

8. Disconnecting the LTC2970 from the Power Supply

Trim Pin

can be placed in a high impedance state simply by

V

OUTn

clearing the Chn_a_idac_en bit. In order to minimize the

resulting disturbance to the power supply voltage, the

IDAC code should not be changed from its current value

when clearing the Chn_a_idac_en bit. This is not an issue

if the channel’s associated servo_en bit is high.

Disconnect Procedure:

Update CHn_IDAC() with Chn_a_idac_en set low.

The LTC2970 will immediately disconnect the buffered

from V

I

OUTn

Disconnect Rules:

Clearing Chn_a_idac_con with Chn_a_idac_en high will

not disconnect the IDAC. Only setting Chn_a_idac_en low

will clear Chn_a_idac_con.

LTC2970-1 Only: Chn_a_idac_en may not be changed if

the feedback node connection is confi gured for tracking.

Tracking is enabled when GPIO_CFG is high and either

GPIO_0 or GPIO_1 are high.

OUTn

.

Verify that the IDAC is already connected, and that

Chn_a_idac_con is high.

Ensure that servo mode is not enabled for the channel

being programmed. Chn_a_servo_en must be low. This

requirement prevents the user from interfering with a

previously requested servo operation.

Update the CHn_A_IDAC() register with Chn_a_idac_pol,

Chn_a_idac_con = 1, Chn_a_idac_en = 1, and Chn_a_

idac[7:0].

Note: Care should be taken to preserve the current value

of the Chn_a_idac_pol bit, since the LTC2970 does not

prevent the user from changing this value when writing

to the IDAC control registers.

Rules:

Setting Chn_a_idac_con to zero will not disconnect the

DAC unless Chn_a_idac_en is also set low.

All Hard Connect rules apply.

9. Tracking Power Supplies Overview (LTC2970-1

Only)

2

The LTC2970-1 tracking feature allows the I

to initiate a controlled power up or power down of two

or more supplies (Figure 2 shows a typical LTC2970-1

application circuit). Multiple LTC2970-1’s with different

addresses may be simultaneously programmed using

the LTC2970 group address and the SYNC() command.

Tracking is enabled when GPIO_CFG is pulled high and

either GPIO_0 or GPIO_1 are high.

10. Tracking Power Supplies On (LTC2970-1 Only)

The LTC2970-1 tracking feature allows the I

a controlled power up of two or more supplies.

Procedure: This procedure describes all the steps necessary to track up two or more power supplies. Steps that

require I

command function.

Power-up the LTC2970-1 with GPIO_CFG pulled high.

2

C interaction are prefi xed with the required I2C

C interface

2

C to initiate

29701fc

21

LTC2970/LTC2970-1

U

OPERATIO

This causes open-drain outputs GPIO_1 and GPIO_0 to

automatically pull the power supplies’ run/soft-start pins

to ground.

CHn_A_IDAC(): Hard connect Chn_a_idac[7:0] with a value

that forces the power supplies off when GPIO_CFG = 1.

Verify that Chn_a_idac_pol is at the appropriate value.

CHn_A_IDAC_TRACK(): Set Chn_a_idac_track_en = 1,

and set the Chn_a_idac_track[7:0] target value to the

code that causes V

corresponding power supply’s feedback node voltage

when it is in regulation.

CHn_A_DELAY_TRACK(): Set the value by which the

incrementing of IDACn should be delayed with respect to

the start of tracking event. This controls whether the power

supplies track up coincidentally or sequentially.

IO(): Release the run/soft-start pins by programming

io_gpio_n = 1. This will enable the power supplies without

allowing their outputs to move since these are held low

by Chn_a_idac[7:0]. Wait until power supplies have had

suffi cient time to start running before starting tracking.

SYNC(): Optional command that allows multiple LTC29701’s to be synchronized for tracking. Writing Sync_track

= 1 will allow the LTC2970-1 to fi nish its current ADC

conversion before having it wait to receive io_track_start

= 1. The LTC2970-1 will timeout this wait command after

t

TIMEOUT_SYNC

global address will ensure all LTC2970-1’s are synchronized

before proceeding with the tracking operation.

IO(): Set Io_track_start = 1 and keep the run/soft-start pins

enabled. Use the global I

up power supplies across multiple LTC2970-1’s.

LTC2970-1 response: For each tracking enabled channel,

the LTC2970-1 will decrement the CHn_A_delay_track

counter at a rate of t

tracking counter reaches zero, the LTC2970-1 will begin

stepping the value of Chn_a_idac[7:0] by one count until

the fi nal value of Chn_a_idac_track[7:0] is reached, at which

point Chn_a_idac_track_en is de-asserted. When the fi nal

value is reached for all channels, GPIO_CFG is asserted

low. After a time delay of t

de-asserted.

. Reading back Sync_track = 1 using the

to most closely approximate the

OUTn

2

C address to simultaneously track

DEC_TRACK

. As soon as a channel’s

HOLD_TRACK

, Chn_a_idac_en is

Power-Up Tracking Rules:

Tracking cannot begin if Chn_a_idac_con is not connected.

This condition is met when the previous procedure is

followed.

Chn_a_idac_track_pol, Chn_a_idac_track_en, and ch0_

idac[7:0] updates will be ignored after IO(Io_track_start)

is asserted until tracking is complete or whenever tracking

is pending, i.e., GPIO_CFG pulled high with either GPIO_0

or GPIO_1 asserted pulled high.

11. Tracking Power Supplies Off (LTC2970-1 Only)

2

The LTC2970-1 tracking feature allows the I

a controlled power down of two or more supplies.

Procedure: This procedure describes all steps necessary

to track down two or more power supplies. Steps that

require I

command function.

CHn_IDAC(): Disable the IDAC’s for each tracking enabled

channel (Chn_a_idac_en = 0). Ensure Chn_a_idac_pol is

at the appropriate value.

CHn_IDAC_TRACK(): Select the channels to be tracked

by setting Chn_a_idac_track_en = 1, and set the target

value for each Chn_a_idac_track[7:0] to that which forces

the supply off.

CHn_A_DELAY_TRACK(): Set the value by which the

decrementing of that channel’s DAC should be delayed

with respect to the start of the tracking event. This controls whether the supplies track down coincidentally or

sequentially.

SYNC(): Optional command that allows multiple LTC29701’s to be synchronized for tracking. Writing Sync_track

= 1 will allow the LTC2970-1 to fi nish its current ADC

conversion before having it wait to receive io_track_start

= 1. The LTC2970-1 will timeout this wait command after

t

TIMEOUT_SYNC

global address will ensure all LTC2970’s are synchronized

before proceeding with the tracking operation.

IO(): Set Io_track_start = 1. Use the global I

to simultaneously track down power supplies across

multiple LTC2970’s.

2

C interaction are prefi xed with the required I2C

. Reading back Sync_track = 1 using the

C to initiate

2

C address

22

29701fc

OPERATIO

LTC2970/LTC2970-1

U

LTC2970-1 response: Each tracking enabled channel is soft

connected. The GPIO_CFG pin is released allowing it to be

pulled high. The LTC2970-1 waits t

GPIO_CFG to settle. For each tracking enabled channel,

the Chn_a_delay_track counter is decremented at a rate

of t

DEC_TRACK

reaches zero, the LTC2970-1 will begin stepping the value

of Chn_a_idac[7:0] by one count until the fi nal value of

Chn_a_idac_track[7:0] is reached. The tracking enable bit

is then cleared for both channels (Chn_a_idac_track_en

= 0).

IO(): The I

and GPIO_0 low, disabling the power supplies.

Power Down Tracking Rules:

Power down tracking requests will be ignored until the

user has disabled the IDAC’s by setting Chn_a_idac_en =

0 for each tracking enabled channel.

Chn_a_idac_track_pol, Chn_a_idac_track_en, and ch0_

idac[7:0] updates will be ignored after IO(IO_track_start) is

asserted until tracking is complete and whenever tracking

range is confi gured; (GPIO_CFG high with either GPIO_0

or GPIO_1 asserted high).

12. Continuous Power Supply Voltage Servo

The continuous voltage servo feature allows the LTC2970

to servo an external power supply to a programmed

value. The voltage of the external supply is monitored

over Chn_A_ADC and compared to a target value stored

in Chn_a_servo. After each conversion, Chn_A_IDAC is

incremented by 1, decremented by 1, or held; whichever

brings or keeps the measured voltage closer to the targeted

servo value.

. As soon as a channel’s tracking counter

2

C interface may then be used to set GPIO_1

SETUP_TRACK

to allow

Determine the target servo voltage, Chn_a_servo[14:0].

Update CHn_A_SERVO() with Chn_a_servo_en = 1, and

Chn_a_servo[14:0].

Update CHn_A_IDAC() with Chn_a_idac_servo_repeat =

1. This step may be skipped if Chn_a_idac_servo_repeat

was set high during the soft or hard connect procedure.

LTC2970 response: The LTC2970 will continuously increment, decrement or hold Chn_a_idac[7:0] in order

to match the measured value of (VINn_AP-VINn_AM) to

Chn_a_servo[14:0].

Whenever the CHn_A_SERVO() register is updated an internal fl ag is cleared indicating that a successful servo has

not been completed. This internal fl ag, Chn_a_servo_done,

initially causes the ADC to operate in an accelerated 12-bit

mode. Once the channel reaches the servo target, the ADC

switches back to 14-bit mode for two conversions before

asserting Chn_a_servo_done high.

In continuous voltage servo mode the Chn_a_servo_done

fl ags allow the initial servo target to be reached quickly.

During this time, ADC conversions for all non-servo channels are temporarily inhibited.

Rules:

The IDAC associated with the servo channel must be

enabled. If Chn_a_idac_en is low the servo enable bit

Chn_a_servo_en is always forced low.

The IDAC associated with the servo channel must be connected (Chn_a_idac_con = 1).

An IDAC fault may be generated during a continuous servo

operation. The LTC2970 will report the fault and continue

trying to servo that channel.

Procedure:

Follow procedure for hard connecting or soft connecting

the LTC2970 to power supply trim pin; when updating

CHn_A_IDAC(), Chn_a_idac_servo_repeat should be asserted high. The servo channel’s IDAC must be enabled

before Chn_A_servo_en can be set high.

LTC2970-1 Only: There must be no pending tracking

commands. A pending tracking command will clear

Chn_a_servo_en.

LTC2970-1 Only: The tracking range must not be enabled;

(GPIO_CFG high with either GPIO_0 or GPIO_1 asserted

high). An enabled tracking range will clear Chn

low.

_a_servo_en

29701fc

23

LTC2970/LTC2970-1

U

OPERATIO

13. One Time Power Supply Voltage Servo

The one time voltage servo feature allows the LTC2970 to

servo an external power supply to a programmed value

and then stop updating the IDAC once the target value

has been reached.

Procedure:

Follow procedure for hard connecting or soft connecting

the LTC2970 to power supply trim pin; when updating

CHn_A_IDAC(), Chn_a_idac_servo_repeat should be deasserted low. The servo channel’s IDAC must be enabled

before Chn_a_servo_en may be set high.

Update CHn_A_IDAC() with Chn_a_idac_servo_repeat = 0.

This step may be skipped if Chn_a_idac_servo_repeat was

cleared low during the soft or hard connect procedure.

Update FAULT_EN() with Fault_en_chn_a_servo = 0. This

prevents the LTC2970 from reinitiating a servo after an

over-voltage or under-voltage fault.

Determine the target servo voltage, Chn_a_servo[14:0].

Procedure:

Follow procedure outlined for “One Time Power Supply

Voltage Servo”.

Update FAULT_EN() with Fault_en_chn_a_servo = 1.

Enable detection of the appropriate instantaneous faults

for all servo channels; see “Generating and Monitoring

Instantaneous Faults”.