advertisement

Power Supply Sequencing Made Simple – Design Note 401

Bob Jurgilewicz

Introduction

System designers face a number of problems when it

comes to controlling multiple power supplies. Turn-on

and turn-off characteristics, supply monitoring, fault

management and reset generation are a few issues that

affect both the short term system performance and

long-term reliability. Design is further complicated by

a process that often puts fi nal decisions about supply

requirements at the end of the design phase. So, a good

supervisor/control solution allows for easy design and

adjustment anywhere in the design process.

Firmware solutions place a daunting hurdle directly in

the critical path of the design. Every change involves

software engineers, a load of testing and worst of all,

w a it i ng . L o ad in g co de d ur i n g p r od u c t io n i s ti m e c o n su m ing and costly.

A better solution uses hardware, but easy-to-change,

relatively inexpensive hardware. How about generic reusable circuit blocks that are added early in the system

d e s i g n w i t h l i t t l e r e g a r d t o t h e fi nal specifi c power requir ements? The existing blocks are left unfi nished, simply

waiting for passive component values to be determined.

When fi nal decisions about the power supplies’ operating

specifi cations are determined, calculate the values for a

few passive components and populate the empty spaces

in the circuit. Fortunately, such a solution exists.

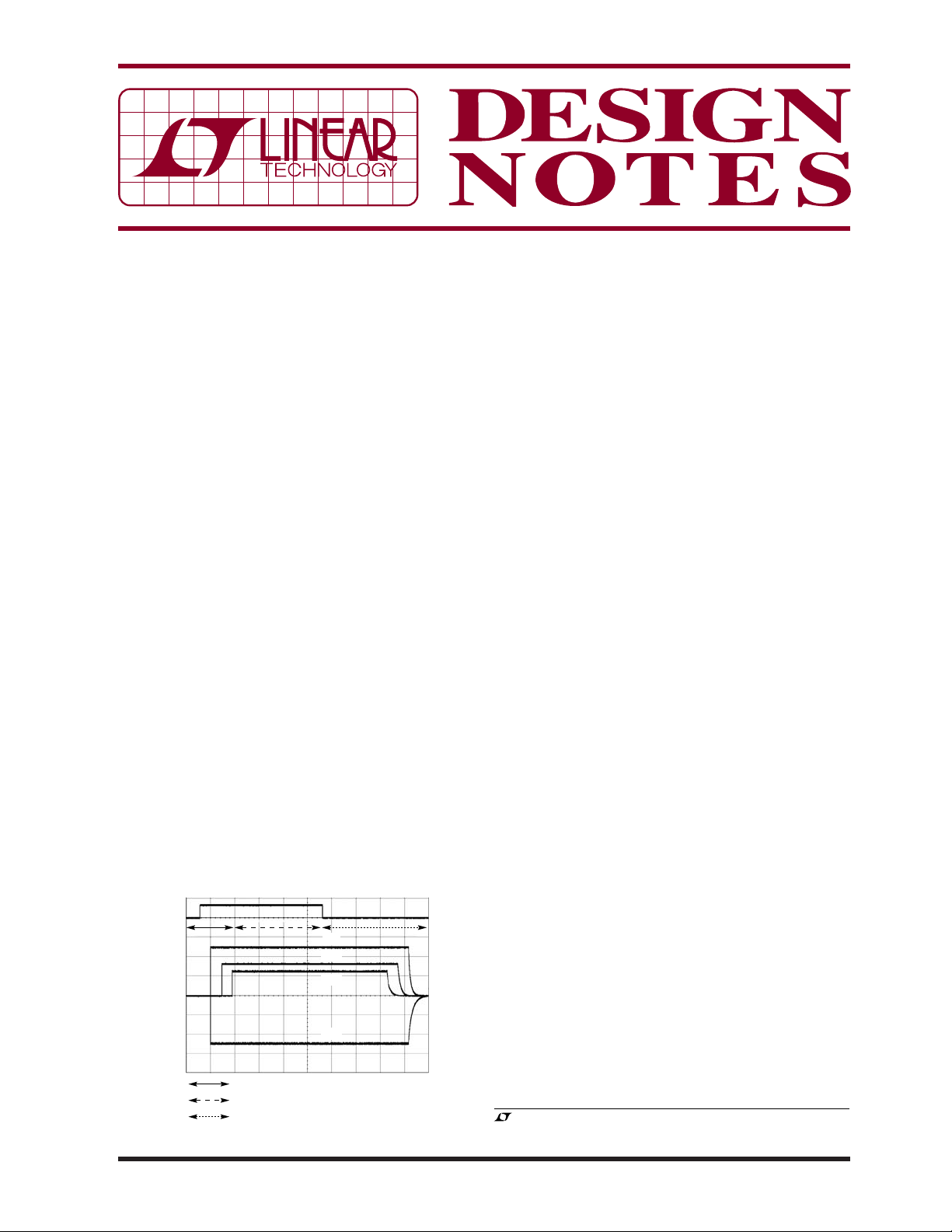

ON

5V

3.3V

2.5V

–5V

SEQUENCE-UP PHASE

SUPPLY MONITOR PHASE

SEQUENCE-DOWN PHASE

Figure 1. Sequencing Application Waveforms

The LTC2928 is a 4-channel cascadable power supply sequencer and high accuracy supervisor. Multiple

LTC2928s can be easily connected to sequence an

unlimited number of power supplies. Cascade action is

via a single pin connection and is functional during sequence-up and sequence-down operations. Sequencing

thresholds, order and timing are confi gured with just a

few external components, eliminating the need for PC

board layout or software changes during system development. Sequence outputs control supply enable pins

or N-channel pass gates. Precision input comparators

with individual outputs monitor power supply voltages

to 1.5% accuracy. Supervisory functions include under

and overvoltage monitoring and reporting as well as

reset generation. The reset output may be forced high

to complement margin testing.

Application faults, whether generated by the LTC2928 or

communicated by a host, can shut down all controlled

supplies. The type and source of faults are reported for

diagnosis. Individual channel controls are available to

independently exercise enable outputs and supervisory

functions. A high voltage input allows the LTC2928 to be

powered from voltages as high as 16.5V. A buffered reference output permits negative power supply sequencing

and monitoring operations.

Three Phases of the Power Management Cycle

A complete power management c ycle is divided in to three

phases as shown in Figure 1. The sequence-up phase

initiates by transitioning the ON pin above threshold with

a logic signal or power supply. The controlled supplies

sequence-up with user confi gured order and timing.

All supplies must exceed a user defi ned sequence-up

threshold within the confi gured “power-good” time. If

any supply fails to turn on properly, a sequence fault

occurs and all controlled supplies are shut down. Once

all supplies reach their sequence-up thre shold, the supply

monitor phase begins.

, LT, LTC and LTM are registered trademarks of Linear Technology

Corporation. All other trademarks are the property of their respective owners.

10/06/401

12V

1/2 LTC1628

V

IN

V

RUN

OUT

5V

LTM4600

V

V

IN

OUT

RUN

1/2 LTC1628

V

V

IN

OUT

RUN

LTC3704

V

V

IN

OUT

RUN

µF

0.1

ON

95.3k

42.2k

24.3k

95.3k

3.32k

V

CC

1µF

ALL RESISTORS 1%

EN1HV

CC

ON

RT1

RT2

RT3

RT4

DONE

SQT1

SQT2

VSEL

V

CC

GND MS1 MS2

EN2 EN4EN3 REF

LTC2928

RTMR

PTMR STMR

47nF 6.8nF

0.15µF

20.5k

OVA

RST

FLT

80.6k

54.9k 42.2k 88.7k

V1

V2

V3

V4

OV

10.7k

60.4k

10k 10k

11.5k

SYSTEM

RESET

FAULT

V

CC

2.5V

3.3V

–5V

10.7k

DN401 F02

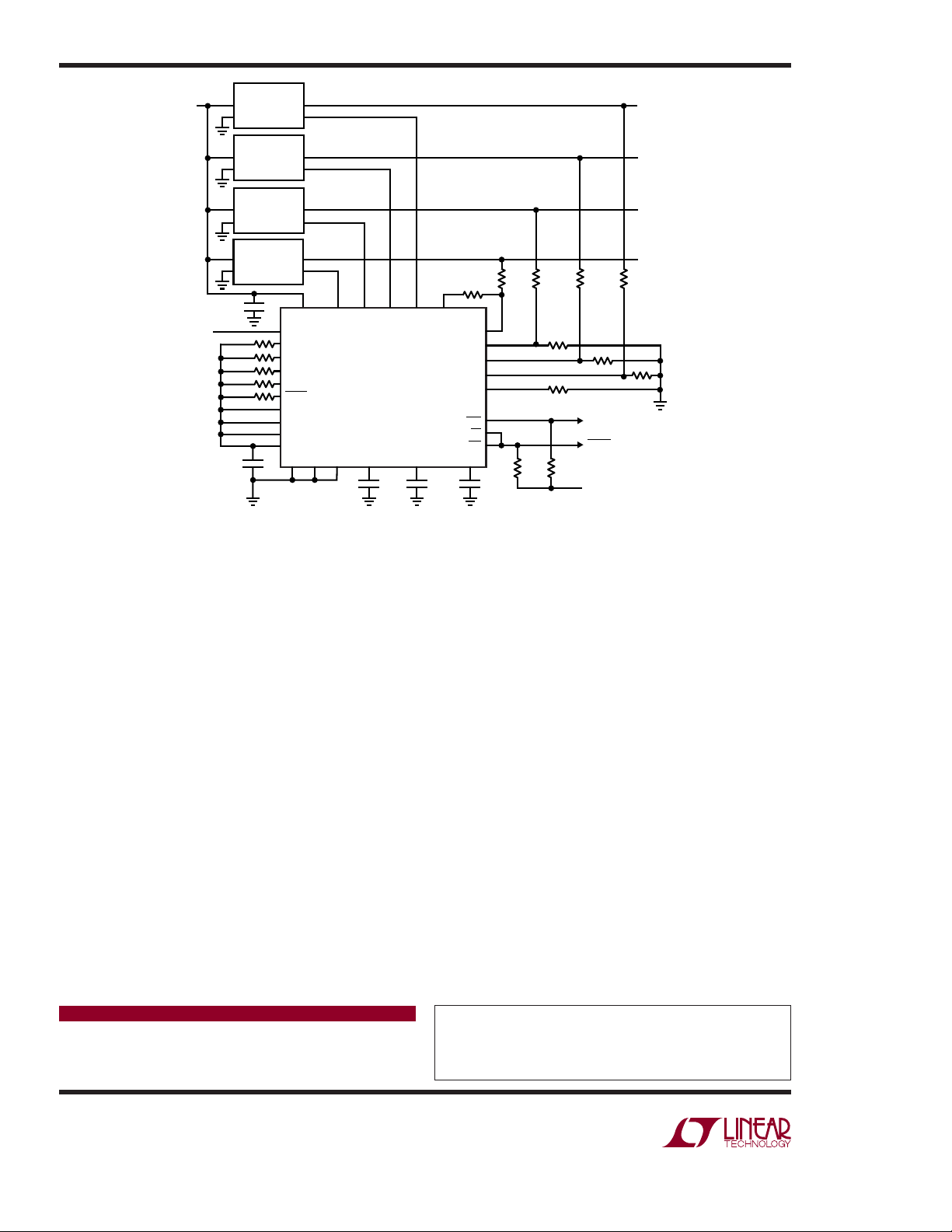

Figure 2. LTC2928 Application Schematic (component values calculated with the LTC2928 Confi gurator Tool)

During the supply monitor pha se, the input signals are continuously compared against user c onfi gured undervoltage

and overvoltage thresholds. The comparators fi lter out

minor glitches coupled to their inputs. If any supply is

out of compliance with suffi cient magnitude and dura-

⎯R⎯S⎯

tion, the reset output (

⎯O⎯

V) pulls low. Once all inputs are within compliance,

(

T) and/or overvoltage output

the respective monitor output pulls high after the user

defi ned reset delay. Users may select whether or not a

fault is generated on the basis of under or overvoltage

events. A generated fault shuts down all controlled supplies. Shut ting down upon an under voltage fault is often

a critical operation. For example, consider a temporary

short on one supply due to a probe slip. Once the short

is removed, the supply may recover, but it might do so

out of sequence if the other supplies are unaffected. A

reset fault shuts off all the supplies, allowing for a new

in-sequence start-up procedure.

The sequence-down phase initiates by transitioning the

ON pin below threshold with a logic signal or power

supply. The controlled supplies sequence-down with

user confi gured order and timing. All supplies must fall

below the user defi ned sequence-down threshold within

the confi gured “power-good” time. If any supply fails to

turn off pr operly, a sequence f ault occurs and all controll ed

supplies are shut down.

LTC2928 Confi guration Software Designs It for You

To make life truly simple, Linear Technology offers free

confi guration software that calculates all resistor values,

capacitor values and required logic connections. The

tool also generates schematics and a passive element

bill-of-materials. All you need to know are your supply

parameters and sequence order. Contact Linear Technology for details.

Conclusion

The LTC2928 greatly reduces the time and cost of power

management design by eliminating the need to develop,

verify and load fi rmware at back end test. System control

issues such as sequence order, timing, reset generation,

supply monitoring and fault management are all handled

with the LTC2928.

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

For applications help,

call (408) 432-1900, Ext. 2452

dn401f LT 1006 409K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2006

Loading...

Loading...