Input Current Cancellation and I

FEATURES

■

Easy Drive Technology Enables Rail-to-Rail Inputs

with Zero Differential Input Current

■

Directly Digitizes High Impedance Sensors with

Full Accuracy

■

600nV RMS Noise, Independent of V

■

GND to VCC Input/Reference Common Mode Range

■

2-Wire I2C Interface

■

Simultaneous 50Hz/60Hz Rejection

■

2ppm (0.25LSB) INL, No Missing Codes

■

1ppm Offset and 15ppm Full-Scale Error

■

No Latency: Digital Filter Settles in a Single Cycle

■

Single Supply 2.7V to 5.5V Operation

■

Internal Oscillator

■

Six Addresses Available

■

Available in a Tiny (3mm × 3mm) 10-Lead

REF

DFN Package

U

APPLICATIO S

■

Direct Sensor Digitizer

■

Weight Scales

■

Direct Temperature Measurement

■

Strain Gauge Transducers

■

Instrumentation

■

Industrial Process Control

■

DVMs and Meters

LTC2483

16-Bit ∆Σ ADC with Easy Drive

2

C Interface

U

DESCRIPTIO

The LTC®2483 combines a 16-bit plus sign No Latency ∆Σ

analog-to-digital converter with patented Easy DriveTM technology and I

scheme eliminates dynamic input current errors and the

shortcomings of on-chip buffering through automatic

cancellation of differential input current. This allows large

external source impedances and input signals, with rail-torail input range to be directly digitized while maintaining

exceptional DC accuracy.

The LTC2483 allows a wide common mode input range

(0V to V

reference can be as low as 100mV or can be tied directly

. The noise level is 600nV RMS independent of V

to V

CC

This allows direct digitization of low level signals with 16bit accuracy. The LTC2483 includes an on-chip trimmed

oscillator, eliminating the need for external crystals or

oscillators and provides 87dB rejection of 50Hz and 60Hz

line frequency noise. Absolute accuracy and low drift are

automatically maintained through continuous, transparent, offset and full-scale calibration.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

No Latency ∆Σ and Easy Drive are trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

Patent Pending.

2

C digital interface. The patented sampling

) independent of the reference voltage. The

CC

REF

TM

.

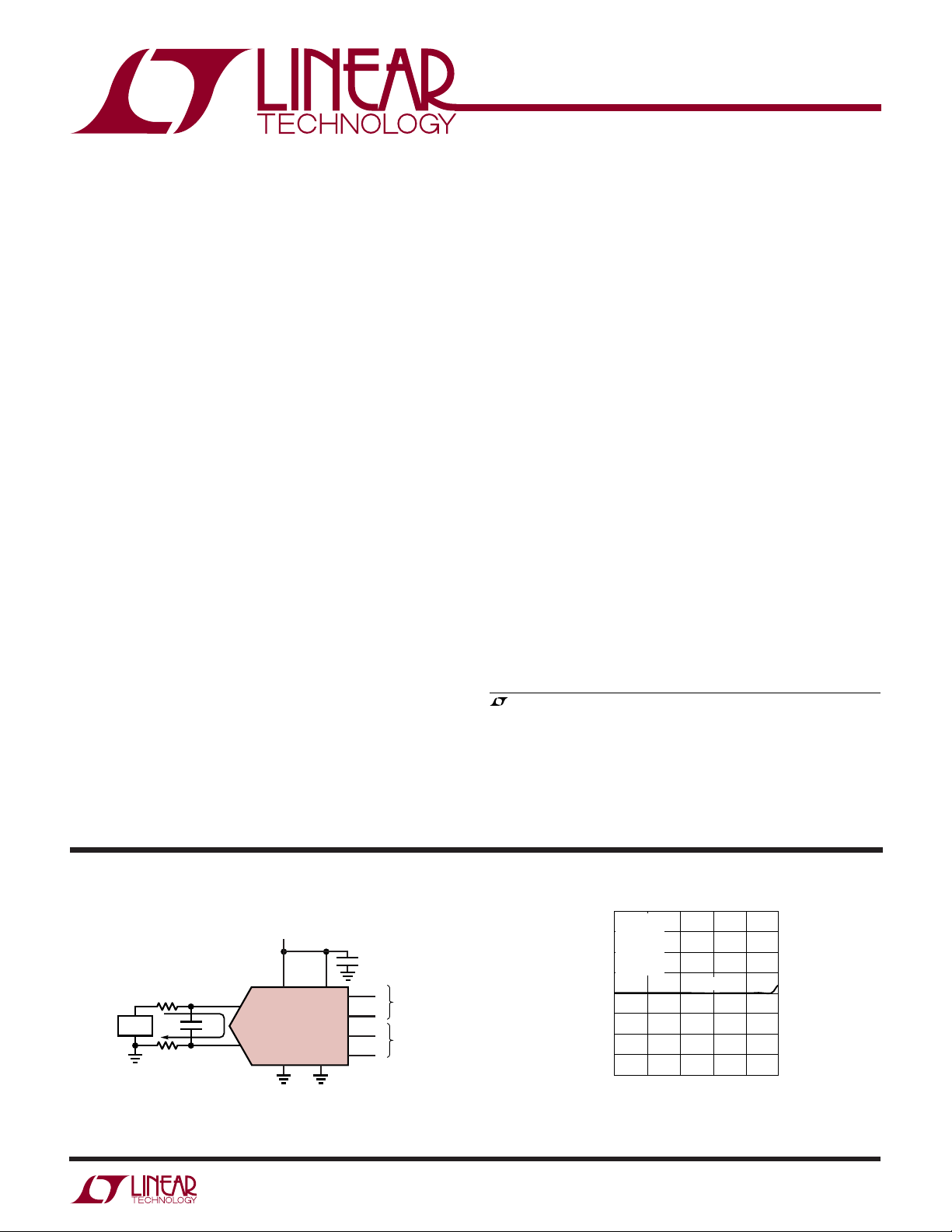

TYPICAL APPLICATIO

V

CC

SENSE

10k

10k

= 0

I

DIFF

1µF

V

IN

V

IN

REF+V

+

LTC2483

–

GND

REF

U

+FS Error vs R

80

VCC = 5V

= 5V

V

REF

60

+

= 3.75V

V

IN

–

= 1.25V

V

IN

40

= GND

F

1µF

SCL

SDA

CA0/F

CA1

2483 TA01

2-WIRE

2

I

C INTERFACE

0

6 ADDRESSES

CC

–

O

= 25°C

T

A

20

0

–20

+FS ERROR (ppm)

–40

–60

–80

1

10 100 10k

SOURCE

R

SOURCE

at IN+ and IN

CIN = 1µF

1k

(Ω)

–

100k

2483 TA02

2483fa

1

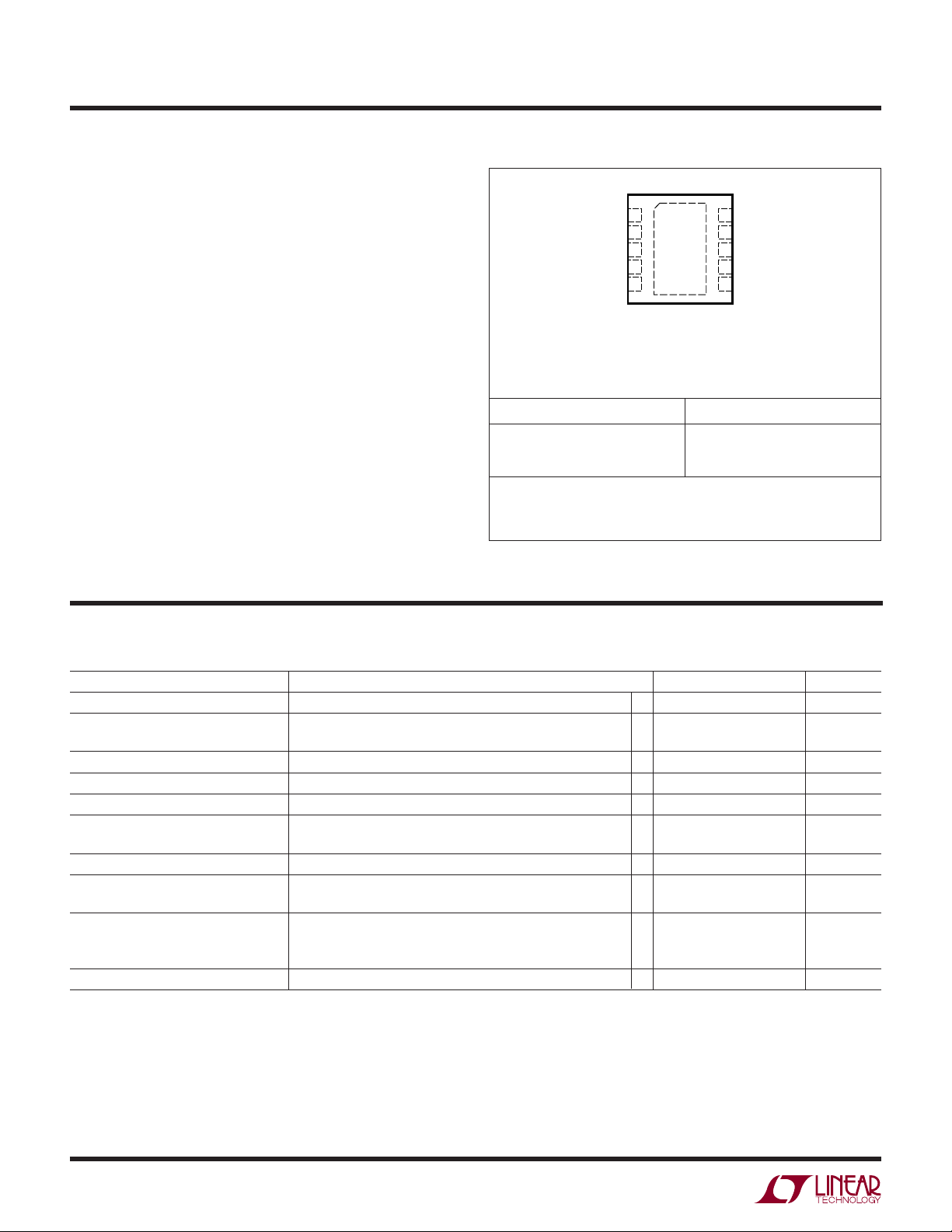

LTC2483

TOP VIEW

11

DD PACKAGE

10-LEAD (3mm × 3mm) PLASTIC DFN

10

9

6

7

8

4

5

3

2

1

CA0/F

0

CA1

GND

SDA

SCL

REF

+

V

CC

REF

–

IN

+

IN

–

WWWU

ABSOLUTE AXI U RATI GS

(Notes 1, 2)

Supply Voltage (VCC) to GND...................... –0.3V to 6V

Analog Input Voltage to GND ....... –0.3V to (V

Reference Input Voltage to GND .. – 0.3V to (V

Digital Input Voltage to GND ........ – 0.3V to (V

Digital Output Voltage to GND ..... – 0.3V to (V

Operating Temperature Range

LTC2483C ................................................... 0°C to 70°C

LTC2483I ................................................ – 40°C to 85°C

Storage Temperature Range ................ –65°C to 125°C

+ 0.3V)

CC

+ 0.3V)

CC

+ 0.3V)

CC

+ 0.3V)

CC

UU

W

PACKAGE/ORDER I FOR ATIO

T

= 125°C, θJA = 43°C/ W

JMAX

EXPOSED PAD (PIN 11) IS GND

MUST BE SOLDERED TO PCB

ORDER PART NUMBER

LTC2483CDD

LTC2483IDD

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

*The temperature grade is identified by a label on the shipping container.

DD PART MARKING*

LBSR

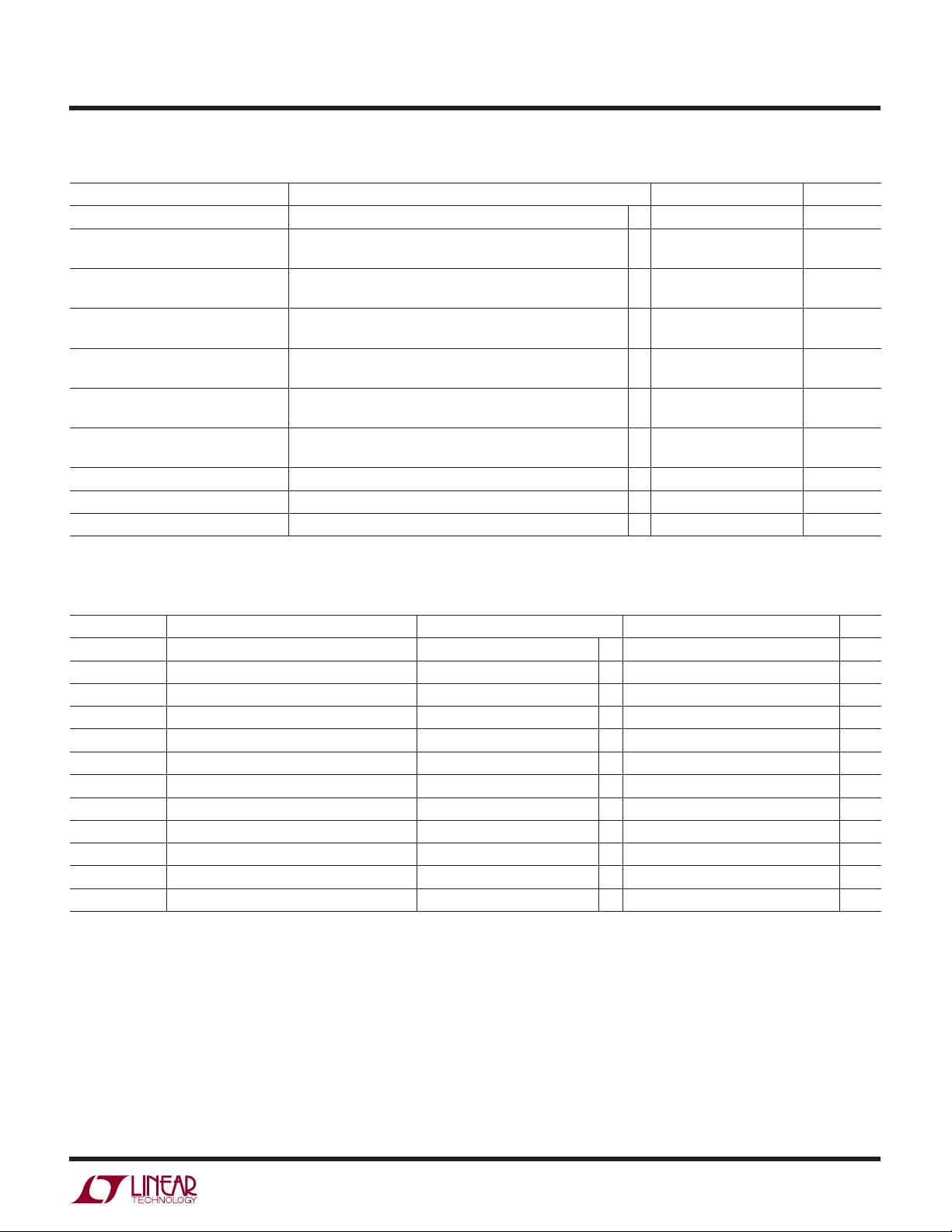

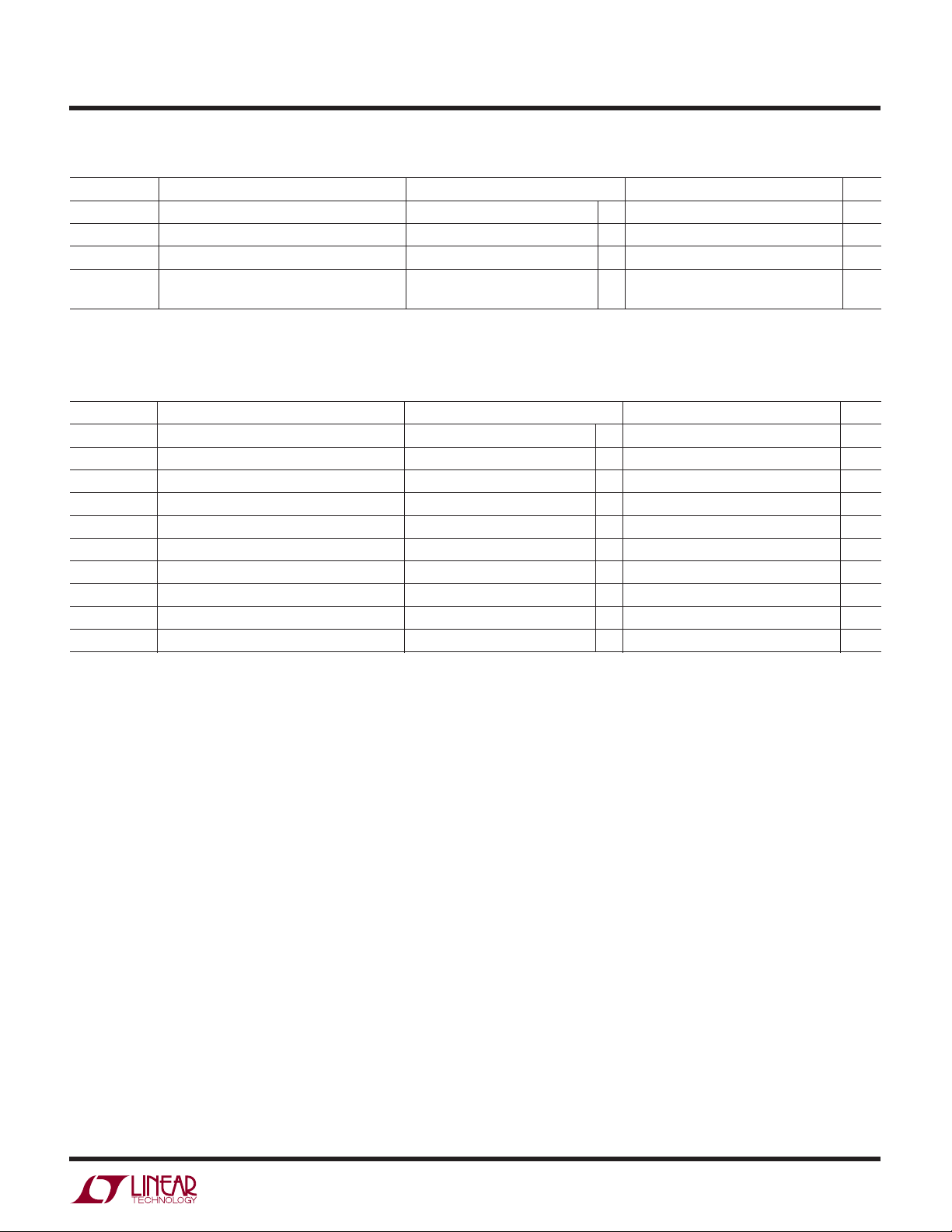

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes the specifications which apply over the full operating

= 25°C. (Notes 3, 4)

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) 0.1 ≤ V

Integral Nonlinearity 5V ≤ VCC ≤ 5.5V, V

2.7V ≤ VCC ≤ 5.5V, V

Offset Error 2.5V ≤ V

Offset Error Drift 2.5V ≤ V

Positive Full-Scale Error 2.5V ≤ V

Positive Full-Scale Error Drift 2.5V ≤ V

≤ VCC, –FS ≤ VIN ≤ +FS (Note 5)

REF

= 5V, V

REF

= 2.5V, V

REF

≤ VCC, GND ≤ IN+ = IN– ≤ VCC (Note 13)

REF

≤ VCC, GND ≤ IN+ = IN– ≤ V

REF

≤ VCC, IN+ = 0.75V

REF

≤ VCC, IN+ = 0.75V

REF

= 2.5V (Note 6)

IN(CM)

IN(CM)

, IN– = 0.25V

REF

, IN– = 0.25V

REF

= 1.25V (Note 6) 1 ppm of V

CC

REF

REF

●

16 Bits

●

●

2 10 ppm of V

0.5 2.5 µV

10 nV/°C

●

25 ppm of V

0.1 ppm of

V

Negative Full-Scale Error 2.5V ≤ V

Negative Full-Scale Error Drift 2.5V ≤ V

≤ VCC, IN– = 0.75V

REF

≤ VCC, IN– = 0.75V

REF

, IN+ = 0.25V

REF

, IN+ = 0.25V

REF

REF

REF

●

25 ppm of V

0.1 ppm of

V

Total Unadjusted Error 5V ≤ VCC ≤ 5.5V, V

5V ≤ VCC ≤ 5.5V, V

2.7V ≤ VCC ≤ 5.5V, V

Output Noise 5V ≤ VCC ≤ 5.5V, V

= 2.5V, V

REF

= 5V, V

REF

= 2.5V, V

REF

= 5V, GND ≤ IN– = IN+ ≤ VCC (Note 12) 0.6 µV

REF

= 1.25V (Note 6) 15 ppm of V

IN(CM)

= 2.5V (Note 6) 15 ppm of V

IN(CM)

= 1.25V (Note 6) 15 ppm of V

IN(CM)

REF

REF

REF

REF

REF

/°C

REF

/°C

REF

REF

REF

RMS

2

2483fa

LTC2483

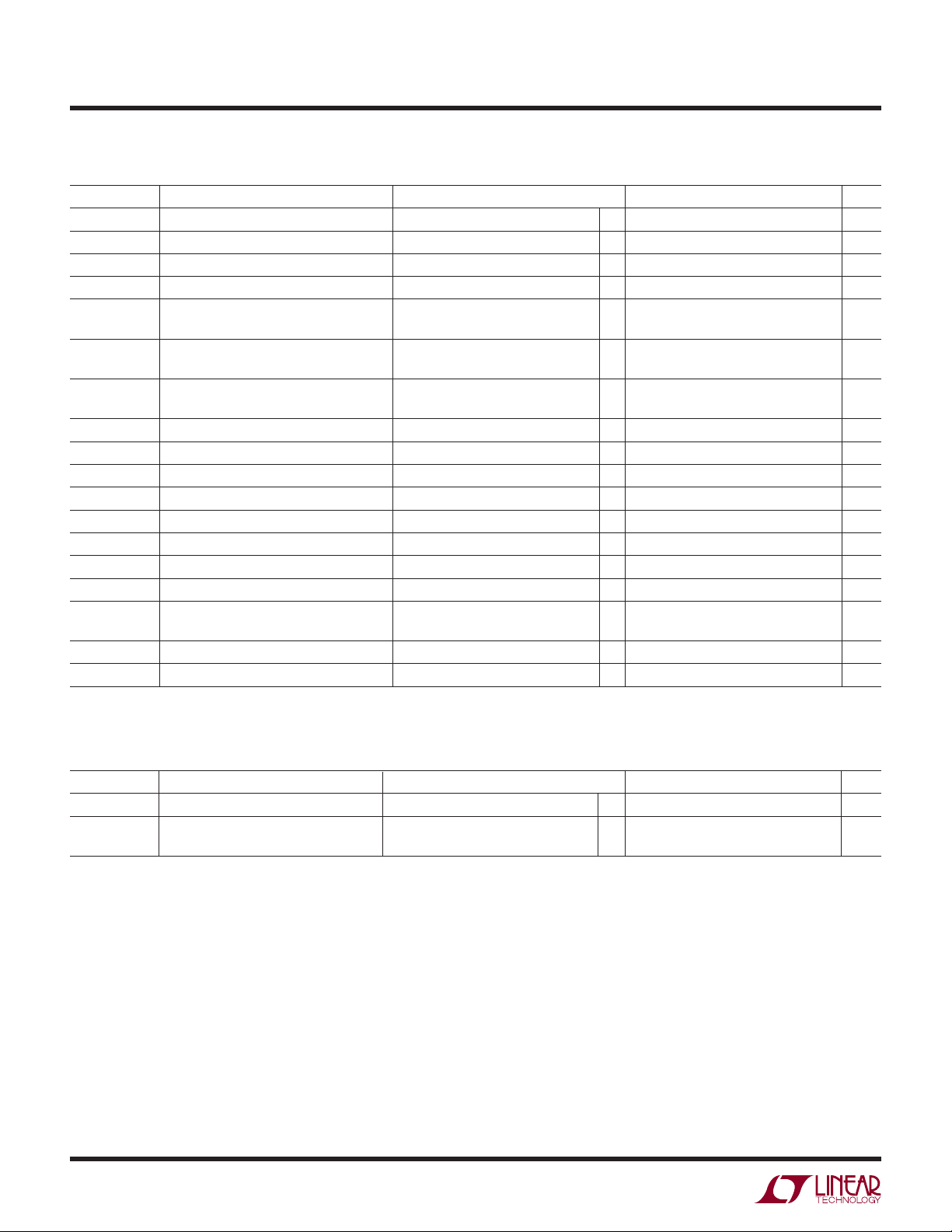

U

CO VERTER CHARACTERISTICS

temperature range, otherwise specifications are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Common Mode Rejection DC 2.5V ≤ V

Input Common Mode Rejection 2.5V ≤ V

50Hz ±2%

Input Common Mode Rejection 2.5V ≤ V

60Hz ±2%

Input Normal Mode Rejection 2.5V ≤ V

50Hz ±2%

Input Normal Mode Rejection 2.5V ≤ V

60Hz ±2%

Input Normal Mode Rejection 2.5V ≤ V

50Hz/60Hz ±2%

Reference Common Mode 2.5V ≤ V

Rejection DC

Power Supply Rejection DC V

Power Supply Rejection, 50Hz ±2% V

Power Supply Rejection, 60Hz ±2% V

REF

REF

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

≤ VCC, GND ≤ IN– = IN+ ≤ V

REF

= 2.5V, IN– = IN+ = GND 120 dB

= 2.5V, IN– = IN+ = GND (Notes 7, 9) 120 dB

= 2.5V, IN– = IN+ = GND (Notes 8, 9) 120 dB

The ● denotes the specifications which apply over the full operating

= 25°C. (Notes 3, 4)

A

(Note 5)

CC

(Note 5)

CC

(Note 5)

CC

(Notes 5, 7)

CC

(Notes 5, 8)

CC

(Notes 5, 9)

CC

(Note 5)

CC

●

140 dB

●

140 dB

●

140 dB

●

110 120 dB

●

110 120 dB

●

87 dB

●

120 140 dB

UUU

A ALOG I PUT AUD REFERE CE

temperature range, otherwise specifications are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

IN

–

IN

FS Full Scale of the Differential Input (IN+ – IN–)

LSB Least Significant Bit of the Output Code

V

IN

V

REF

CS (IN+)IN

CS (IN–)IN

CS (V

)V

REF

I

(IN+)IN+ DC Leakage Current Sleep Mode, IN+ = GND

DC_LEAK

I

(IN–)IN– DC Leakage Current Sleep Mode, IN– = GND

DC_LEAK

I

DC_LEAK (VREF

Absolute/Common Mode IN+ Voltage GND – 0.3V VCC + 0.3V V

Absolute/Common Mode IN– Voltage GND – 0.3V VCC + 0.3V V

Input Differential Voltage Range (IN+ – IN–)

Reference Voltage Range (REF+ – REF–)

+

Sampling Capacitance 11 pF

–

Sampling Capacitance 11 pF

Sampling Capacitance 11 pF

REF

)REF+, REF– DC Leakage Current Sleep Mode, V

The ● denotes the specifications which apply over the full operating

●

0.5V

REF

16

FS/2

–FS +FS V

0.1 V

CC

–10 1 10 nA

–10 1 10 nA

–100 1 100 nA

REF

= V

CC

●

●

●

●

●

●

V

V

2483fa

3

LTC2483

UU

I2C DIGITAL I PUTS A D DIGITAL OUTPUTS

the full operating temperature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

V

IL(CA1)

V

IH(CA0/F0,CA1)

R

INH

R

INL

R

INF

I

I

V

HYS

V

OL

t

OF

t

SP

I

IN

C

I

C

B

C

CAX

V

IH(EXT,OSC)

V

IL(EXT,OSC)

High Level Input Voltage

Low Level Input Voltage

Low Level Input Voltage for Address Pin

High Level Input Voltage for Address Pins

Resistance from CA0/F0,CA1 to VCC to Set

Chip Address Bit to 1

Resistance from CA1 to GND to Set

Chip Address Bit to 0

Resistance from CA0/F0, CA1 to VCC or

GND to Set Chip Address Bit to Float

Digital Input Current

Hysteresis of Schmitt Trigger Inputs (Note 5) 0.05V

Low Level Output Voltage SDA I = 3mA

Output Fall Time from V

IHMIN

to V

ILMAX

Bus Load CB 10pF to 400pF (Note 14)

Input Spike Suppression

Input Leakage 0.1V

CC

≤ V

IN

Capacitance for Each I/O Pin

Capacitance Load for Each Bus Line

External Capacitive Load on Chip

Address Pins (CA0/F

High Level CA0/F0 External Oscillator 2.7V ≤ V

Low Level CA0/F0 External Oscillator 2.7V ≤ V

,CA1) for Valid Float

0

CC

CC

= 25°C. (Note 3)

A

≤ V

CC

< 5.5V

< 5.5V

The ● denotes the specifications which apply over

●

0.7V

CC

●

●

●

0.95V

CC

●

●

●

●

●

●

●

●

●

●

●

●

●

2MΩ

–10 10 µA

CC

20+0.1C

B

10 pF

V

– 0.5V V

CC

0.3V

CC

0.05V

CC

10 kΩ

10 kΩ

0.4 V

250 ns

50 ns

1 µA

400 pF

10 pF

0.5 V

V

V

V

V

V

WU

POWER REQUIRE E TS

range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

Supply Voltage

Supply Current Conversion Mode (Note 11)

A

The ● denotes the specifications which apply over the full operating temperature

= 25°C. (Note 3)

Sleep Mode (Note 11)

●

●

●

2.7 5.5 V

160 250 µA

12 µA

2483fa

4

LTC2483

WU

TI I G CHARACTERISTICS

range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

EOSC

t

HEO

t

LEO

t

CONV_1

External Oscillator Frequency Range

External Oscillator High Period

External Oscillator Low Period

Conversion Time Simultaneous 50Hz/60Hz

= 25°C. (Note 3)

A

The ● denotes the specifications which apply over the full operating temperature

External Oscillator (Note 10)

●

●

●

●

●

10 4000 kHz

0.125 100 µs

0.125 100 µs

144.1 146.9 149.9 ms

41036/f

EOSC

ms

UW

I2C TI I G CHARACTERISTICS

temperature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

SCL

t

HD(SDA)

t

LOW

t

HIGH

t

SU(STA)

t

HD(DAT)

t

SU(DAT)

t

r

t

f

t

SU(STO)

SCL Clock Frequency

Hold Time (Repeated) START Condition

LOW Period of the SCL Clock Pin

HIGH Period of the SCL Clock Pin

Set-Up Time for a Repeated START Condition

Data Hold Time

Data Set-Up Time

Rise Time for Both SDA and SCL Signals (Note 14)

Fall Time for Both SDA and SCL Signals (Note 14)

Set-Up Time for STOP Condition

The ● denotes the specifications which apply over the full operating

= 25°C. (Notes 3, 15)

A

●

●

●

●

●

●

●

●

●

●

0 400 kHz

0.6 µs

1.3 µs

0.6 µs

0.6 µs

0 0.9 µs

100 ns

20+0.1C

B

20+0.1C

B

0.6 µs

300 ns

300 ns

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: All voltage values are with respect to GND.

Note 3: V

= 2.7V to 5.5V unless otherwise specified.

CC

= REF+ – REF–, V

V

REF

= IN+ – IN–, V

V

IN

INCM

= (REF+ + REF–)/2, FS = 0.5V

REFCM

= (IN+ + IN–)/2.

REF

;

Note 4: Use internal conversion clock or external conversion clock source

with f

= 307.2kHz unless otherwise specified.

EOSC

Note 5: Guaranteed by design, not subject to test.

Note 6: Integral nonlinearity is defined as the deviation of a code from a

straight line passing through the actual endpoints of the transfer curve.

The deviation is measured from the center of the quantization band.

Note 7: 50Hz f

Note 8: 60Hz f

Note 9: Simultaneous 50Hz/60Hz (internal oscillator) or f

= 256kHz ±2% (external oscillator).

EOSC

= 307.2kHz ±2% (external oscillator).

EOSC

EOSC

= 280kHz

±2% (external oscillator).

Note 10: The external oscillator is connected to the CA0/F

external oscillator frequency, f

, is expressed in kHz.

EOSC

pin. The

0

Note 11: The converter uses the internal oscillator.

Note 12: The output noise includes the contribution of the internal

calibration operations.

Note 13: Guaranteed by design and test correlation.

Note 14: C

Note 15: All values refer to V

= capacitance of one bus line in pF.

B

and V

IH(MIN)

IL(MAX)

levels.

2483fa

5

LTC2483

INPUT VOLTAGE (V)

–12

TUE (ppm OF V

REF

)

–4

4

12

–8

0

8

–0.75 –0.25 0.25 0.75

2483 G06

1.25–1.25

VCC = 2.7V

V

REF

= 2.5V

V

IN(CM)

= 1.25V

85°C

25°C

–45°C

UW

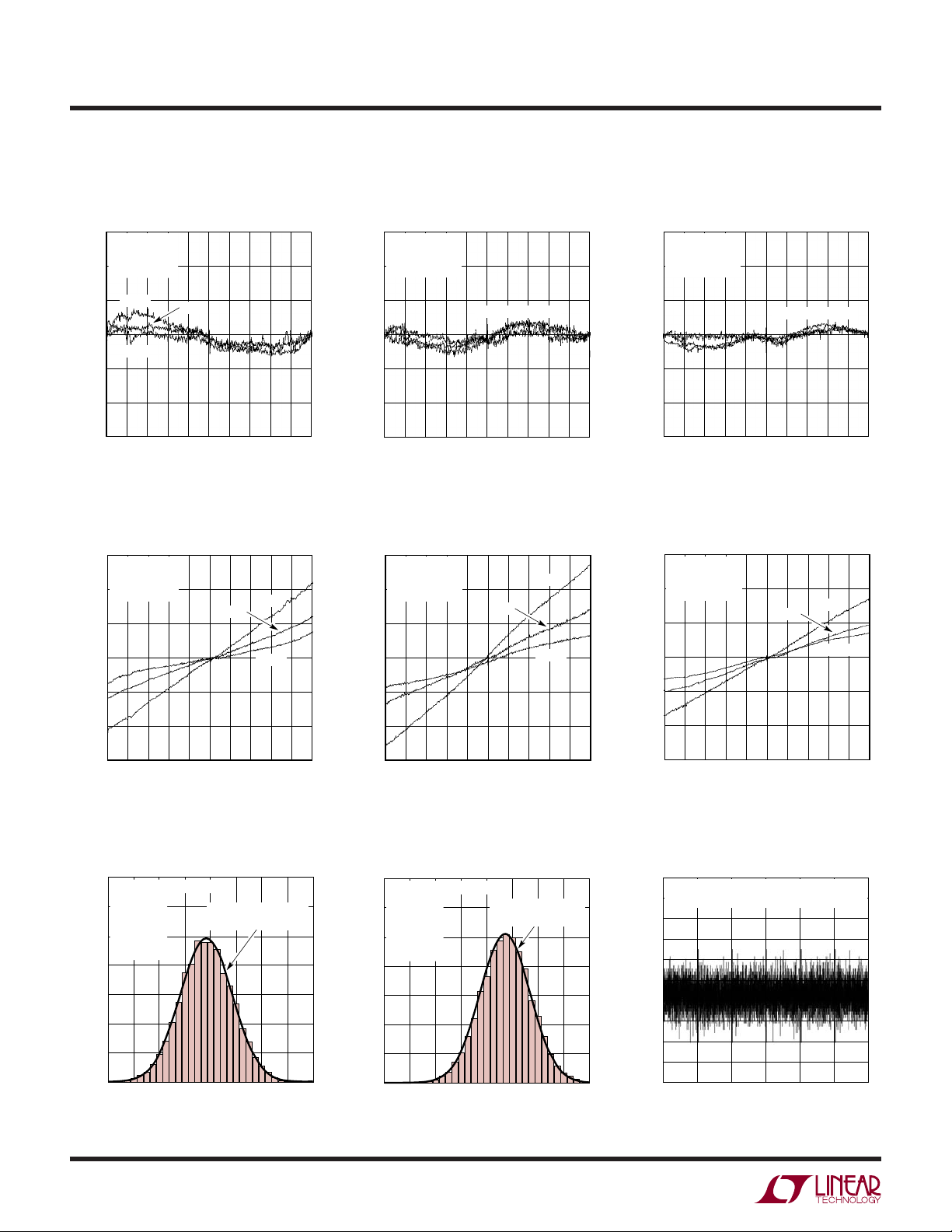

TYPICAL PERFOR A CE CHARACTERISTICS

Integral Nonlinearity

(V

= 5V, V

CC

3

VCC = 5V

= 5V

V

REF

2

)

1

REF

0

–1

INL (ppm OF V

–2

–3

= 2.5V

V

IN(CM)

–45°C

85°C

–1.5 –0.5 0.5 1.5

INPUT VOLTAGE (V)

Total Unadjusted Error

(V

= 5V, V

CC

12

VCC = 5V

= 5V

V

REF

8

)

4

REF

0

V

IN(CM)

= 2.5V

REF

25°C

REF

= 5V)

= 5V)

25°C

85°C

–45°C

2483 G01

Integral Nonlinearity

(VCC = 5V, V

3

VCC = 5V

= 2.5V

V

REF

2

)

1

REF

0

–1

INL (ppm OF V

–2

2.5–2–2.5 –1 0 1 2

–3

= 1.25V

V

IN(CM)

–0.75 –0.25 0.25 0.75

= 2.5V)

REF

–45°C, 25°C, 90°C

INPUT VOLTAGE (V)

1.25–1.25

2483 G02

Total Unadjusted Error

(VCC = 5V, V

12

8

)

4

REF

0

VCC = 5V

= 2.5V

V

REF

V

IN(CM)

= 1.25V

REF

= 2.5V)

85°C

25°C

–45°C

Integral Nonlinearity

(VCC = 2.7V, V

3

VCC = 2.7V

= 2.5V

V

REF

2

)

1

REF

0

–1

INL (ppm OF V

–2

–3

= 1.25V

V

IN(CM)

–0.75 –0.25 0.25 0.75

INPUT VOLTAGE (V)

Total Unadjusted Error

(VCC = 2.7V, V

= 2.5V)

REF

–45°C, 25°C, 90°C

= 2.5V)

REF

1.25–1.25

2483 G03

–4

TUE (ppm OF V

–8

–12

–1.5 –0.5 0.5 1.5

INPUT VOLTAGE (V)

2.5–2–2.5 –1 0 1 2

2483 G04

–4

TUE (ppm OF V

–8

–12

–0.75 –0.25 0.25 0.75

INPUT VOLTAGE (V)

Noise Histogram (6.8sps) Long-Term ADC ReadingsNoise Histogram (7.5sps)

14

10,000 CONSECUTIVE

READINGS

12

= 5V

V

CC

= 5V

V

REF

= 0V

V

10

IN

= 25°C

T

A

8

6

4

NUMBER OF READINGS (%)

2

0

–3

–1.8 –0.6

–2.4 1.2

–1.2 0 1.8

OUTPUT READING (µV)

RMS = 0.60µV

AVERAGE = –0.69µV

0.6

2483 G07

14

10,000 CONSECUTIVE

READINGS

12

= 2.7V

V

CC

= 2.5V

V

REF

= 0V

V

10

IN

= 25°C

T

A

8

6

4

NUMBER OF READINGS (%)

2

0

–3

–1.8 –0.6

–2.4 1.2

–1.2 0 1.8

OUTPUT READING (µV)

2483 G05

RMS = 0.59µV

AVERAGE = –0.19µV

0.6

2483 G08

1.25–1.25

5

VCC = 5V, V

= 25°C, RMS NOISE = 0.60µV

T

4

A

3

2

1

0

–1

ADC READING (µV)

–2

–3

–4

–5

0

10

= 5V, VIN = 0V, V

REF

30 40

20

TIME (HOURS)

IN(CM)

= 2.5V

50

60

2483 G09

2483fa

6

UW

V

IN(CM)

(V)

–1

OFFSET ERROR (ppm OF V

REF

)

0.1

0.2

0.3

24

2483 G15

0

–0.1

01

356

–0.2

–0.3

VCC = 5V

V

REF

= 5V

V

IN

= 0V

T

A

= 25°C

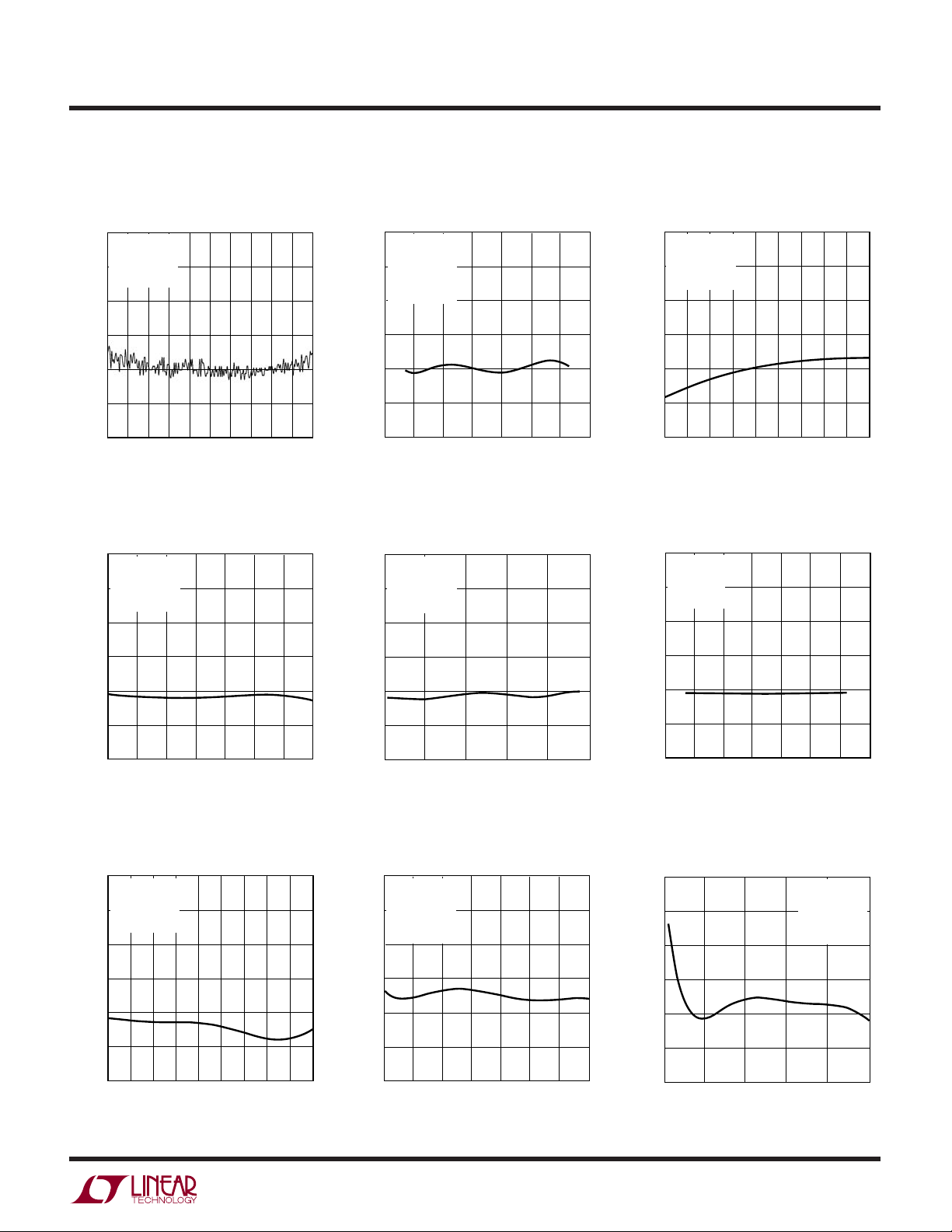

TYPICAL PERFOR A CE CHARACTERISTICS

RMS Noise

vs Input Differential Voltage RMS Noise vs V

1.0

VCC = 5V

V

= 5V

REF

0.9

)

REF

0.8

V

IN(CM)

T

A

= 2.5V

= 25°C

1.0

0.9

0.8

VCC = 5V

= 5V

V

REF

= 0V

V

IN

V

IN(CM)

= 25°C

T

A

= GND

IN(CM)

LTC2483

RMS Noise vs Temperature (TA)

1.0

VCC = 5V

= 5V

V

REF

0.9

= 0V

V

IN

= GND

V

IN(CM)

0.8

0.7

0.6

RMS NOISE (ppm OF V

0.5

0.4

–1.5 –0.5 0.5 1.5

INPUT DIFFERENTIAL VOLTAGE (V)

RMS Noise vs V

1.0

V

= 2.5V

REF

= 0V

V

IN

= GND

V

0.9

IN(CM)

= 25°C

T

A

0.8

0.7

RMS NOISE (µV)

0.6

0.5

0.4

2.7

3.1 3.5

CC

4.3 5.1 5.5

3.9 4.7

VCC (V)

2483 G10

2483 G13

0.7

RMS NOISE (µV)

0.6

0.5

0.4

–1

2.5–2–2.5 –1 0 1 2

01

RMS Noise vs V

1.0

VCC = 5V

= 0V

V

IN

0.9

0.8

0.7

RMS NOISE (µV)

0.6

0.5

0.4

= GND

V

IN(CM)

= 25°C

T

A

0

1234

356

24

V

(V)

IN(CM)

REF

V

(V)

REF

2483 G11

5

2483 G14

0.7

RMS NOISE (µV)

0.6

0.5

0.4

–45

–30 –15 15

Offset Error vs V

0304560

TEMPERATURE (°C)

IN(CM)

75 90

2483 G12

Offset Error vs Temperature Offset Error vs V

0.3

VCC = 5V

V

REF

0.2

V

)

IN

V

REF

IN(CM)

0.1

0

–0.1

OFFSET ERROR (ppm OF V

–0.2

–0.3

–30 0

–45

= 5V

= 0V

= GND

–15

TEMPERATURE (°C)

30 90

15

CC

0.3

REF+ = 2.5V

–

= GND

REF

)

REF

OFFSET ERROR (ppm OF V

60

45

75

2483 G16

–0.1

–0.2

–0.3

0.2

0.1

0

2.7

= 0V

V

IN

V

IN(CM)

= 25°C

T

A

3.1 3.5

= GND

4.3 5.1 5.5

3.9 4.7

VCC (V)

2483 G17

Offset Error vs V

0.3

0.2

)

REF

0.1

0

–0.1

OFFSET ERROR (ppm OF V

–0.2

–0.3

0

1234

REF

VCC = 5V

–

= GND

REF

= 0V

V

IN

= GND

V

IN(CM)

= 25°C

T

A

V

(V)

REF

5

2483.G18

2483fa

7

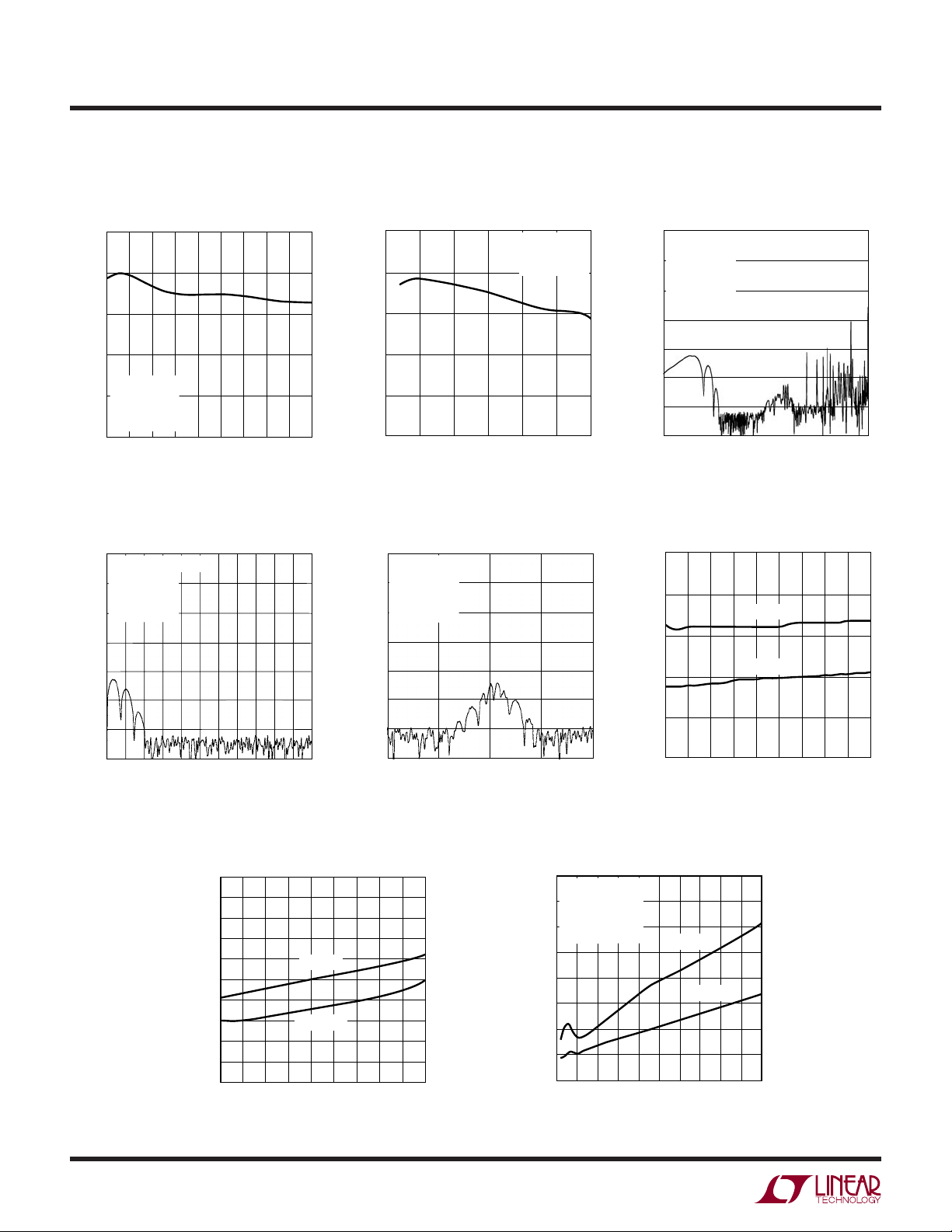

LTC2483

FREQUENCY AT VCC (Hz)

1

0

–20

–40

–60

–80

–100

–120

–140

1k 100k

2483 G23

10 100

10k 1M

REJECTION (dB)

VCC = 4.1V DC

V

REF

= 2.5V

IN

+

= GND

IN

–

= GND

T

A

= 25°C

UW

TYPICAL PERFOR A CE CHARACTERISTICS

On-Chip Oscillator Frequency

vs Temperature

310

308

306

304

FREQUENCY (kHz)

VCC = 4.1V

= 2.5V

V

302

REF

= 0V

V

IN

= GND

V

IN(CM)

300

–45 –30

–15

TEMPERATURE (°C)

30

150

PSRR vs Frequency at V

0

VCC = 4.1V DC ±1.4V

= 2.5V

V

REF

–20

+

= GND

IN

–

= GND

IN

–40

= 25°C

T

A

–60

–80

REJECTION (dB)

–100

–120

On-Chip Oscillator Frequency

vs V

CC

310

308

306

304

FREQUENCY (kHz)

302

300

60 75

90

2483 G21

45

2.5

3.5 4.0 4.5

3.0

VCC (V)

V

REF

V

IN

V

IN(CM)

= 2.5V

= 0V

= GND

5.0 5.5

2483 G22

PSRR vs Frequency at V

CC

Conversion Current

CC

PSRR vs Frequency at V

0

VCC = 4.1V DC ±0.7V

= 2.5V

V

REF

–20

+

= GND

IN

–

= GND

IN

–40

= 25°C

T

A

–60

–80

REJECTION (dB)

–100

–120

CC

vs Temperature

200

180

160

140

CONVERSION CURRENT (µA)

120

VCC = 5V

VCC = 2.7V

–140

8

0

60

80

40

20

FREQUENCY AT VCC (Hz)

100

SLEEP MODE CURRENT (µA)

140

120 160

180

2483 G24

Sleep Mode Current

vs Temperature

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

–30 0

–15

–45

TEMPERATURE (°C)

220200

VCC = 5V

VCC = 2.7V

30 90

45

15

–140

30600

60

30650 30700 30800

FREQUENCY AT VCC (Hz)

75

2483 G27

30750

500

450

400

350

300

250

SUPPLY CURRENT (µA)

200

150

100

100

–30 0

–45

2483 G25

Conversion Current

vs Output Data Rate

V

= V

REF

CC

IN+ = GND

–

= GND

IN

= EXT OSC

CA0/F

0

= 25°C

T

A

0

20 40 60 1007010 30 50 90

OUTPUT DATA RATE (READINGS/SEC)

VCC = 5V

–15

TEMPERATURE (°C)

VCC = 3V

80

30 90

15

2483 G28

60

75

45

2483 G26

2483fa

LTC2483

U

UU

PI FU CTIO S

REF+ (Pin 1), REF– (Pin 3): Differential Reference Input.

The voltage on these pins can have any value between GND

and V

more positive than the reference negative input, REF

at least 0.1V.

V

(Pin 8) with a 1µF tantalum capacitor in parallel with 0.1µF

ceramic capacitor as close to the part as possible.

IN+ (Pin 4), IN– (Pin 5): Differential Analog Input. The

voltage on these pins can have any value between

GND – 0.3V and V

converter bipolar input range (V

from –0.5 • V

the converter produces unique overrange and underrange

output codes.

SCL (Pin 6): Serial Clock Pin of the I2C Interface. The

LTC2483 can only act as a slave and the SCL pin only

accepts external serial clock. Data is shifted out the SDA

pin on the falling edges of the SCL clock.

as long as the reference positive input, REF+, is

CC

(Pin 2): Positive Supply Voltage. Bypass to GND

CC

+ 0.3V. Within these limits the

CC

= IN+ – IN–) extends

IN

to 0.5 • V

REF

. Outside this input range

REF

–

, by

SDA (Pin 7): Serial Data Output Line of the I2C Interface.

In the transmitter mode (Read), the conversion result is

output through the SDA pin. It is an open-drain N-channel

driver and therefore an external pull-up resistor or current

source to V

GND (Pin 8): Ground. Connect this pin to a ground plane

through a low impedance connection.

CA1 (Pin 9): Chip Address Control Pin. The CA1 pin is

configured as a three state (LOW, HIGH, or Floating)

address control bit for the device I

CA0/F

0

Input Pin. When no transition is detected on the CA0/F

pin, it is a two state (HIGH or Floating) address control bit

for the device I

external clock signal with a frequency f

10kHz, the converter uses this signal as its system clock

and the fundamental digital filter rejection null is located at

a frequency f

internally to a HIGH.

is needed.

CC

2

C address.

(Pin 10): Chip Address Control Pin/External Clock

0

2

C address. When the pin is driven by an

of at least

EOSC

/5120 and sets the Chip Address CA0

EOSC

2483fa

9

LTC2483

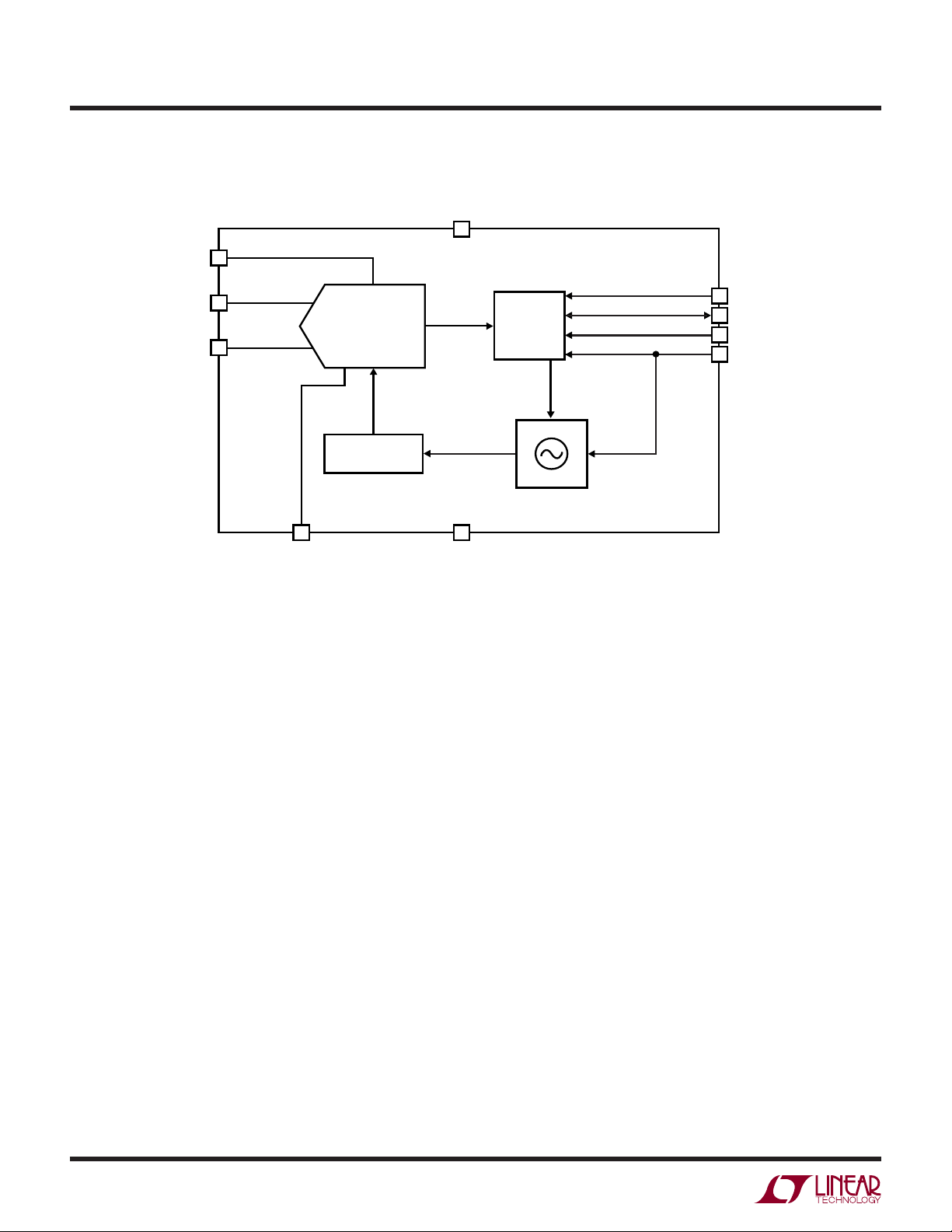

UU

W

FU CTIO AL BLOCK DIAGRA

+

REF

1

+

IN

4

–

IN

5

+

IN

–

IN

AUTOCALIBRATION

–

REF

3

REF

3RD ORDER

∆Σ ADC

–

REF

AND CONTROL

+

V

GND

2

CC

SCL

6

CA0/F

SDA

CA1

0

2483 FB

7

9

10

I2C

SERIAL

INTERFACE

INTERNAL

OSCILLATOR

8

10

2483fa

WUUU

APPLICATIO S I FOR ATIO

LTC2483

CONVERTER OPERATION

Converter Operation Cycle

The LTC2483 is a low power, ∆Σ analog-to-digital con-

2

verter with an I

C interface. After power on reset, its

operation is made up of three states. The converter

operating cycle begins with the conversion, followed by

the low power sleep state and ends with the data output

(see Figure 1).

POWER ON RESET

CONVERSION

SLEEP

NO

ACKNOWLEDGE

YES

DATA OUTPUT

STOP

NO

OR READ

24-BITS

YES

2483 F01

Figure 1. LTC2483 State Transition Diagram

Initially, the LTC2483 performs a conversion. Once the

conversion is complete, the device enters the sleep state.

While in this sleep state, power consumption is reduced

by two orders of magnitude. The part remains in the sleep

state as long as it is not addressed for a read operation.

The conversion result is held indefinitely in a static shift

register while the converter is in the sleep state.

LTC2483 is addressed for a read operation, the device

begins outputting the conversion result under control of

the serial clock (SCL). There is no latency in the conversion result. The data output is 24 bits long and contains a

16-bit plus sign conversion result. This result is shifted

out on the SDA pin under the control of the SCL. Data is

updated on the falling edges of SCL allowing the user to

reliably latch data on the rising edge of SCL. A new

conversion is initiated at the conclusion of a data read

operation (read out all 24 bits).

2

I

C INTERFACE

The LTC2483 communicates through an I2C interface.

2

The I

C interface is a 2-wire open-drain interface supporting multiple devices and masters on a single bus. The

connected devices can only pull the bus wires LOW and

they never drive the bus HIGH. The bus wires are externally connected to a positive supply voltage via a currentsource or pull-up resistor. When the bus is free, both

lines are HIGH. Data on the I2C-bus can be transferred at

rates of up to 100kbit/s in the Standard-mode and up to

400kbit/s in the Fast-mode.

Each device on the I2C bus is recognized by a unique

address stored in that device and can operate as either a

transmitter or receiver, depending on the function of the

device. In addition to transmitters and receivers, devices

can also be considered as masters or slaves when performing data transfers. A master is the device which

initiates a data transfer on the bus and generates the clock

signals to permit that transfer. At the same time any device

addressed is considered a slave.

The LTC2483 can only be addressed as a slave. Once

addressed, it can transmit the last conversion result.

Therefore the serial clock line SCL is an input only and the

data line SDA is bidirectional (data out/address in). The

device supports the Standard-mode and the Fast-mode

for data transfer speeds up to 400kbit/s. Figure 2 shows

the definition of timing for Fast/Standard-mode devices

2

on the I

C-bus.

The device will not acknowledge an external request

during the conversion state. After a conversion is finished,

the device is ready to accept a read request. Once the

2483fa

11

LTC2483

WUUU

APPLICATIO S I FOR ATIO

The START and STOP Conditions

A START condition is generated by transitioning SDA from

HIGH to LOW while SCL is HIGH. The bus is considered to

be busy after the START condition. When the data transfer

is finished, a STOP condition is generated by transitioning

SDA from LOW to HIGH while SCL is HIGH. The bus is free

again a certain time after the STOP condition. START and

STOP conditions are always generated by the master.

When the bus is in use, it stays busy if a repeated START

(Sr) is generated instead of a STOP condition. The

repeated START (Sr) conditions are functionally identical

to the START (S).

SDA

t

SU;DAT

t

r

SCL

t

f

t

LOW

t

r

Data Transferring

2

After the START condition, the I

C bus is busy and data

transfer is set between a master and a slave. Data is

2

transferred over I

C in groups of nine bits (one byte)

followed by an acknowledge bit, therefore each group

takes nine SCL cycles. The transmitter releases the SDA

line during the acknowledge clock pulse and the receiver

issues an Acknowledge (ACK) by pulling SDA LOW or

leaves SDA HIGH to indicate a Not Acknowledge (NAK)

condition. Change of data state can only happen while SCL

is LOW.

t

HD;STA

t

SP

t

t

r

BUF

t

HD;STA

SSrPS

t

HD;DAT

Figure 2. Definition of Timing for F/S-Mode Devices on the I2C-Bus

t

HIGH

t

SU;STA

t

SU;STO

2483 F02

12

2483fa

WUUU

APPLICATIO S I FOR ATIO

LTC2483

LTC2483 Data Format

After a START condition, the master sends a 7-bit address

followed by a R/W bit. The bit R/W is 1 for a Read request

and 0 for a Write request. If the 7-bit address agrees with

an LTC2483’s address, that device is selected. When the

device is in the conversion state, it does not accept the

request and issues a Not-Acknowledge (NAK) by leaving

SDA HIGH. A write operation will also generate an NAK

signal. If the conversion is complete, it issues an acknowledge (ACK) by pulling SDA LOW.

The output register contains the last conversion result.

After each conversion is completed, the device automatically enters the sleep state where the supply current is

reduced to 1µA. When the LTC2483 is addressed for a

Read operation, it acknowledges (by pulling SDA LOW)

and acts as a transmitter. The master and receiver can read

up to three bytes from the LTC2483. After a complete Read

operation (3 bytes), the output register is emptied, a new

conversion is initiated, and a following Read request in the

same output phase will be NAKed. The LTC2483 output

data stream is 24 bits long, shifted out on the falling edges

of SCL. The first bit is the conversion result sign bit (SIG),

see Tables 1 and 2. This bit is HIGH if V

<0. The second bit is the most significant bit (MSB) of

V

IN

≥ 0. It is LOW if

IN

the result. The first two bits (SIG and MSB) can be used to

indicate over range conditions. If both bits are HIGH, the

differential input voltage is above +FS and the following 16

bits are set to LOW to indicate an overrange condition. If

both bits are LOW, the input voltage is below –FS and the

following 16 bits are set to HIGH to indicate an underrange

condition. The function of these two bits is summarized in

Table 1. The next 16 bits contain the conversion results in

binary two’s complement format. The remaining six bits

are LOW.

Table 1. LTC2483 Status Bits

BIT 23 BIT 22

INPUT RANGE SIG MSB

VIN ≥ 0.5 • V

0V ≤ VIN < 0.5 • V

–0.5 • V

VIN < –0.5 • V

REF

≤ VIN < 0V 0 1

REF

REF

REF

11

10

00

As long as the voltage on the IN+ and IN– pins is maintained within the – 0.3V to (V

+ 0.3V) absolute maximum

CC

operating range, a conversion result is generated for any

differential input voltage

= 0.5 • V

. For differential input voltages greater than

REF

from –FS = –0.5 • V

VIN

REF

to +FS

+FS, the conversion result is clamped to the value corresponding to the +FS + 1LSB. For differential input voltages

below –FS, the conversion result is clamped to the value

corresponding to –FS – 1LSB.

Table 2. LTC2483 Output Data Format

DIFFERENTIAL INPUT VOLTAGE BIT 23 BIT 22 BIT 21 BIT 20 BIT 19 … BIT 6

* SIG MSB

V

IN

VIN* ≥ FS** 1 1 0 0 0 … 0

FS** – 1LSB 1 0 1 1 1 … 1

0.5 • FS** 1 0 1 0 0 … 0

0.5 • FS** – 1LSB 1 0 0 1 1 … 1

010000…0

–1LSB 0 1 1 1 1 … 1

– 0.5 • FS** 0 1 1 0 0 … 0

– 0.5 • FS** – 1LSB 0 1 0 1 1 … 1

– FS** 0 1 0 0 0 … 0

VIN* < –FS** 0 0 1 1 1 … 1

*The differential input voltage VIN = IN+ – IN–. **The full-scale voltage FS = 0.5 • V

REF

.

2483fa

13

LTC2483

WUUU

APPLICATIO S I FOR ATIO

Initiating a New Conversion

When the LTC2483 finishes a conversion, it automatically

enters the sleep state. Once in the sleep state, the device

is ready for a Read operation. After the device acknowledges a Read request, the device exits the sleep state and

enters the data output state. The data output state concludes and the LTC2483 starts a new conversion once a

STOP condition is issued by the master or all 24-bits of

data are read out of the device.

During the data read cycle, a stop command may be issued

by the master controller in order to start a new conversion

and abort the data transfer. This stop command must be

issued during the 9th clock cycle of a byte read when the

bus is free (the ACK/NAK cycle).

LTC2483 Address

The LTC2483 has two address pins, enabling one in 6

possible addresses, as shown in Table 3.

Table 3. LTC2483 Address Assignment

CA1 CA0/F0 * Address

LOW HIGH 001 01 00

LOW Floating 001 01 01

Floating HIGH 001 01 11

Floating Floating 010 01 00

HIGH HIGH 010 01 10

HIGH Floating 010 01 11

* CA0/F0 is treated as HIGH when driven by a valid external clock.

Data Read

The data read operation sequence is shown in Figure 5.

When the conversion is finished, the device may be

addressed for a read operation. At the end of a read

operation, a new conversion begins. At the conclusion

of the conversion cycle, the next result may be read

using the method described above. If the conversion

cycle is not concluded and a valid address selects the

device, the LTC2483 generates a NAK signal indicating

the conversion cycle is in progress.

Easy Drive Input Current Cancellation

The LTC2483 combines a high precision delta-sigma ADC

with an automatic differential input current cancellation

front end. A proprietary front-end passive sampling

network transparently removes the differential input current. This enables external RC networks and high impedance sensors to directly interface to the LTC2483 without

external amplifiers. The remaining common mode input

current is eliminated by either balancing the differential

input impedances or setting the common mode input

equal to the common mode reference (see Automatic

Input Current Cancellation section). This unique architecture does not require on-chip buffers enabling input

signals to swing all the way to ground and up to V

Furthermore, the cancellation does not interfere with the

transparent offset and full-scale auto-calibration and the

absolute accuracy (full scale + offset + linearity) is maintained even with external RC networks.

Conversion Clock

A major advantage the delta-sigma converter offers over

conventional type converters is an on-chip digital filter

(commonly implemented as a SINC or Comb filter). For high

resolution, low frequency applications, this filter is typically

designed to reject line frequencies of 50Hz and 60Hz plus

their harmonics. The filter rejection performance is directly

related to the accuracy of the converter system clock. The

LTC2483 incorporates a highly accurate on-chip oscillator.

This eliminates the need for external frequency setting components such as crystals or oscillators.

CC

.

14

2483fa

WUUU

APPLICATIO S I FOR ATIO

LTC2483

Frequency Rejection Selection (CA0/F0)

The LTC2483 internal oscillator provides better than 87dB

normal mode rejection at line frequencies of 50Hz and

60Hz and all of their harmonics (up to the 255th) from

48Hz to 62.4Hz.

When a fundamental rejection frequency different from

50Hz/60Hz is required or when the converter must be

synchronized with an outside source, the LTC2483 can

operate with an external conversion clock. The converter

7 … …89 1 2 9

1

7-BIT

ADDRESS

START BY

MASTER

ACK BY

LTC2483

SLEEP DATA OUTPUT

ACK BY

MASTER

automatically detects the presence of an external clock

signal at the CA0/F

pin and turns off the internal oscilla-

0

tor. The chip address for CA0 is internally set HIGH. The

frequency f

of the external signal must be at least

EOSC

10kHz to be detected. The external clock signal duty cycle

is not significant as long as the minimum and maximum

specifications for the high and low periods t

HEO

and t

LEO

are observed.

While operating with an external conversion clock of a

frequency f

1 2 3 4 5 6 7 8 9

LSBR MSBSGN D15

, the LTC2483 provides better than 110dB

EOSC

NAK BY

MASTER

2483 F03

Figure 3. Timing Diagram for Reading from the LTC2483

S ACK DATA Sr DATA TRANSFERRING P

CONVERSION CONVERSION

7-BIT ADDRESS

SLEEP DATA INPUT/OUTPUT CONVERSION

7-BIT ADDRESS

SLEEP SLEEPDATA OUTPUT DATA OUTPUT

R/W

2483 F04

Figure 4. The LTC2483 Conversion Sequence

7-BIT ADDRESSSSRRACK ACKREAD READPP

CONVERSION

2483 F05

Figure 5. Consecutive Reading at the Same Configuration

2483fa

15

LTC2483

WUUU

APPLICATIO S I FOR ATIO

normal mode rejection in a frequency range of f

EOSC

/5120

± 4% and its harmonics. The normal mode rejection as a

function of the input frequency deviation from f

EOSC

/5120

is shown in Figure 6.

–80

–85

–90

–95

–100

–105

–110

–115

–120

–125

NORMAL MODE REJECTION (dB)

–130

–135

–140

–12 –8 –4 0 4 8 12

DIFFERENTIAL INPUT SIGNAL FREQUENCY

DEVIATION FROM NOTCH FREQUENCY f

Figure 6. LTC2483 Normal Mode Rejection When

Using an External Oscillator

Whenever an external clock is not present at the CA0/F

EOSC

/5120(%)

2483 F06

0

pin, the converter automatically activates its internal oscillator and enters the Internal Conversion Clock mode.

CA0/F

may be tied HIGH or left floating in order to set the

0

chip address. The LTC2483 operation will not be disturbed if the change of conversion clock source occurs

during the sleep state or during the data output state while

the converter uses an external serial clock. If the change

occurs during the conversion state, the result of the

conversion in progress may be outside specifications but

the following conversions will not be affected.

Table 4 summarizes the duration of the conversion state of

each state and the achievable output data rate as a function

of f

EOSC

.

Ease of Use

The

LTC2483

data output has no latency, filter settling

delay or redundant data associated with the conversion

cycle. There is a one-to-one correspondence between the

conversion and the output data. Therefore, multiplexing

multiple analog voltages is easy.

The LTC2483 performs offset and full-scale calibrations

every conversion cycle. This calibration is transparent to the

user and has no effect on the cyclic operation described

above. The advantage of continuous calibration is extreme

stability of offset and full-scale readings with respect to

time, supply voltage change and temperature drift.

Power-Up Sequence

The LTC2483 automatically enters an internal reset state

when the power supply voltage V

drops below approxi-

CC

mately 2V. This feature guarantees the integrity of the conversion result.

When the VCC voltage rises above this critical threshold,

the converter creates an internal power-on-reset (POR)

signal with a duration of approximately 4ms. The POR

signal clears all internal registers. Following the POR

signal, the LTC2483 starts a normal conversion cycle and

follows the succession of states described in Figure 1. The

first conversion result following POR is accurate within the

specifications of the device if the power supply voltage is

restored within the operating range (2.7V to 5.5V) before

the end of the POR time interval.

Reference Voltage Range

The LTC2483 external reference voltage range is 0.1V to

VCC. The converter output noise is determined by the

Table 4. LTC2483 State Duration

STATE OPERATING MODE DURATION

CONVERSION Internal Oscillator 50Hz/60Hz Rejection 147ms, Output Data Rate ≤ 6.8 Readings/s

External Oscillator CA0/F0 = External Oscillator with Frequency 41036/f

f

EOSC

Hz (f

/5120 Rejection)

EOSC

s, Output Data Rate ≤ f

EOSC

/41036 Readings/s

EOSC

16

2483fa

WUUU

IIN IIN

VV

R

I REF

VV V

R

V

VR

VD

R

VV V

R

V

VR

where

AVG AVG

IN CM REF CM

EQ

AVG

REF INCM REFCM

EQ

IN

REF EQ

REF T

EQ

REF REF CM IN CM

EQ

IN

REF EQ

+

+

REF+REF

–

()=()

=

−

•

()

=

• − +

•

−

•

−≅

+

()

–

() ()

() ()

.

.

.

.• •

.–

.•

–

•

05

15

05

05

15

05

2

2

:

V

VININ

V

IN IN

REFCM

IN

INCM

=

= −

=

+

−

⎛

⎝

⎜

⎞

⎠

⎟

= Ω

=•

()

+ −

+ −

V,

REF

=

REF

+

REF–+

⎛

⎝

⎜

⎞

⎠

⎟

2

2

R 2.98M INTERNAL OSCILLATOR

R 0.833 10 / f EXTERNAL OSCILLATOR

D IS THE DENSITY OF A DIGITAL TRANSITION AT THE MODULATOR OUTPUT

EQ

EQ

12

EOSC

T

WHERE REF– IS INTERNALLY TIED TO GND

APPLICATIO S I FOR ATIO

LTC2483

thermal noise of the front-end circuits, and as such, its

value in nanovolts is nearly constant with reference voltage. Since the transition noise (600nV) is much less than

the quantization noise (V

/217), a decrease in the refer-

REF

ence voltage will increase the converter resolution. A

reduced reference voltage will also improve the converter

performance when operated with an external conversion

clock (external F

signal) at substantially higher output

O

data rates (see the Output Data Rate section).

The reference input is differential. The differential reference input range (V

the common mode reference input range is 0V to V

= REF+ – REF–) is 100mV to VCC and

REF

CC

.

Input Voltage Range

The analog input is truly differential with an absolute/

common mode range for the IN

extending from GND – 0.3V to V

+

and IN– input pins

+ 0.3V. Outside

CC

these limits, the ESD protection devices begin to turn on

and the errors due to input leakage current increase rapidly.

Within these limits, the LTC2483 converts the bipolar

differential input signal, V

where FS = 0.5 • V

REF

= IN+ – IN–, from –FS to +FS

IN

. Beyond this range, the converter

indicates the overrange or the underrange condition using

distinct output codes. Since the differential input current

cancellation does not rely on an on-chip buffer, current

cancellation and DC performance is maintained rail-to-rail.

nput signals applied to IN+ and IN– pins may extend by

I

300mV below ground and above V

. In order to limit any

CC

fault current, resistors of up to 5k may be added in series

+

with the IN

and IN– pins without affecting the performance of the devices. The effect of the series resistance on

the converter accuracy can be evaluated from the curves

presented in the Input Current/Reference Current sections. In addition, series resistors will introduce a temperature dependent offset error due to the input leakage

current. A 1nA input leakage current will develop a 1ppm

offset error on a 5k resistor if V

= 5V. This error has a

REF

very strong temperature dependency.

Driving the Input and Reference

The input and reference pins of the LTC2483 converter are

directly connected to a network of sampling capacitors.

Depending upon the relation between the differential input

voltage and the differential reference voltage, these capacitors are switching between these four pins transferring

small amounts of charge in the process. A simplified equivalent circuit is shown in Figure 7.

For a simple approximation, the source impedance R

S

driving an analog input pin (IN+, IN–, REF+ or REF–) can be

considered to form, together with R

and CEQ (see

SW

Figure 7), a first order passive network with a time constant

τ = (R

+ RSW) • CEQ. The converter is able to sample the

S

V

CC

+

I

REF

V

REF

+

I

IN

+

V

IN

–

I

IN

–

V

IN

SWITCHING FREQUENCY

f

SW

f

SW

I

REF

V

REF

= 123kHz INTERNAL OSCILLATOR

= 0.4 • f

+

V

CC

–

–

EXTERNAL OSCILLATOR

EOSC

I

LEAK

I

LEAK

V

CC

I

LEAK

I

LEAK

V

CC

RSW (TYP)

10k

RSW (TYP)

I

LEAK

10k

I

LEAK

RSW (TYP)

10k

RSW (TYP)

I

LEAK

10k

I

LEAK

C

EQ

12pF

(TYP)

2483 F07

Figure 7. LTC2483 Equivalent Analog Input Circuit

2483fa

17

LTC2483

WUUU

APPLICATIO S I FOR ATIO

input signal with better than 1ppm accuracy if the sampling

period is at least 14 times greater than the input circuit time

constant τ. The sampling process on the four input analog

pins is quasi-independent so each time constant should be

considered by itself and, under worst-case circumstances,

the errors may add.

When using the internal oscillator, the LTC2483’s frontend switched-capacitor network is clocked at 123kHz

corresponding to an 8.1µs sampling period. Thus, for

settling errors of less than 1ppm, the driving source

impedance should be chosen such that τ ≤ 8.1µs/14 =

580ns. When an external oscillator of frequency f

used, the sampling period is 2.5/f

error of less than 1ppm, τ ≤ 0.178/f

and, for a settling

EOSC

.

EOSC

Automatic Differential Input Current Cancellation

In applications where the sensor output impedance is low

(up to 10kΩ with no external bypass capacitor or up to

500Ω with 0.001µF bypass), complete settling of the input

occurs. In this case, no errors are introduced and direct

digitization of the sensor is possible.

For many applications, the sensor output impedance combined with external bypass capacitors produces RC time

constants much greater than the 580ns required for 1ppm

accuracy. For example, a 10kΩ bridge driving a 0.1µF

bypass capacitor has a time constant an order of magnitude greater than the required maximum. Historically,

settling issues were solved using buffers. These buffers

led to increased noise, reduced DC performance (Offset/

Drift), limited input/output swing (cannot digitize signals

near ground or V

), added system cost and increased

CC

power. The LTC2483 uses a proprietary switching algorithm that forces the average differential input current to

zero independent of external settling errors. This allows

accurate direct digitization of high impedance sensors

without the need of buffers (see Figures 8 to 10). Additional errors resulting from mismatched leakage currents

must also be taken into account.

The switching algorithm forces the average input current

on the positive input (I

current on the negative input (I

+

) to be equal to the average input

IN

–

). Over the complete

IN

conversion cycle, the average differential input current

(I

IN+

–

– I

) is zero. While the differential input current is

IN

EOSC

is

R

SOURCE

V

V

INCM

INCM

+ 0.5V

– 0.5V

IN

R

SOURCE

IN

C

EXT

C

EXT

Figure 8. An RC Network at IN+ and IN

80

VCC = 5V

= 5V

V

REF

60

+

= 3.75V

V

IN

–

= 1.25V

V

IN

40

= 25°C

T

A

20

0

–20

+FS ERROR (ppm)

–40

–60

–80

1

C

= 1nF, 0.1µF, 1µF

EXT

10 100 10k

R

SOURCE

Figure 9. +FS Error vs R

80

VCC = 5V

= 5V

V

REF

60

+

= 1.25V

V

IN

–

= 3.75V

V

IN

40

= 25°C

T

A

20

0

–20

–FS ERROR (ppm)

–40

–60

–80

1

C

= 1nF, 0.1µF, 1µF

EXT

10 100 10k

R

SOURCE

Figure 10. –FS Error vs R

C

C

EXT

1k

(Ω)

SOURCE

= 100pF

C

EXT

1k

(Ω)

SOURCE

IN

C

PAR

≅20pF

LTC2483

IN

C

PAR

≅20pF

= 0pF

EXT

= 100pF

2483 F09

at IN+ and IN

C

= 0pF

EXT

100k

2483 F10

at IN+ and IN

+

–

2483 F08

–

100k

–

–

2483fa

18

WUUU

APPLICATIO S I FOR ATIO

+

zero, the common mode input current (I

IN

proportional to the difference between the common mode

input voltage (V

voltage (V

REFCM

) and the common mode reference

INCM

).

In applications where the input common mode voltage is

equal to the reference common mode voltage, as in the

case of a balance bridge type application, both the differential and common mode input current are zero. The

accuracy of the converter is unaffected by settling errors.

Mismatches in source impedances between IN

also do not affect the accuracy.

+ I

IN

+

and IN

–

)/2 is

–

LTC2483

Table 5. Suggested Input Configuration for LTC2483

BALANCED INPUT UNBALANCED INPUT

RESISTANCES RESISTANCES

Constant C

V

– V

IN(CM)

Varying C

V

IN(CM)

– V

REF(CM)

REF(CM)

> 1nF at Both C

EXT

IN+ and IN–. Can Take and IN–. Can Take Large

Large Source Resistance Source Resistance.

with Negligible Error Unbalanced Resistance

> 1nF at Both IN+Minimize IN+ and IN

EXT

and IN–. Can Take Large Capacitors and Avoid

Source Resistance with Large Source Impedance

Negligible Error (<5k Recommended)

> 1nF at Both IN

EXT

Results in an Offset

Which Can be Calibrated

+

–

In applications where the input common mode voltage is

constant but different from the reference common mode

voltage, the differential input current remains zero while

the common mode input current is proportional to the

difference between V

INCM

and V

. For a reference

REFCM

common mode of 2.5V and an input common mode of

1.5V, the common mode input current is approximately

0.74µA. This common mode input current has no effect on

the accuracy if the external source impedances tied to IN

+

and IN– are matched. Mismatches in these source impedances lead to a fixed offset error but do not affect the

linearity or full-scale reading. A 1% mismatch in 1kΩ

source resistances leads to a 15ppm shift (74µV) in offset

voltage.

In applications where the common mode input voltage

varies as a function of input signal level (single-ended

input, RTDs, half bridges, current sensors, etc.), the

common mode input current varies proportionally with

input voltage. For the case of balanced input impedances,

the common mode input current effects are rejected by the

large CMRR of the LTC2483 leading to little degradation in

accuracy. Mismatches in source impedances lead to gain

errors proportional to the difference between the common

mode input voltage and the common mode reference

voltage. 1% mismatches in 1kΩ source resistances lead

to worst-case gain errors on the order of 15ppm or 1LSB

(for 1V differences in reference and input common mode

voltage). Table 5 summarizes the effects of mismatched

source impedance and differences in reference/input common mode voltages.

The magnitude of the dynamic input current depends upon

the size of the very stable internal sampling capacitors and

upon the accuracy of the converter sampling clock. The

accuracy of the internal clock over the entire temperature

and power supply range is typically better than 0.5%. Such

a specification can also be easily achieved by an external

clock. When relatively stable resistors (50ppm/°C) are

used for the external source impedance seen by IN

–

IN

, the expected drift of the dynamic current and offset

+

and

will be insignificant (about 1% of their respective values

over the entire temperature and voltage range). Even for

the most stringent applications, a one-time calibration

operation may be sufficient.

In addition to the input sampling charge, the input ESD

protection diodes have a temperature dependent leakage

current. This current, nominally 1nA (±10nA max), results

in a small offset shift. A 1k source resistance will create a

1µV typical and 10µV maximum offset voltage.

Reference Current

In a similar fashion, the LTC2483 samples the differential

reference pins REF

+

and REF– transferring small amount

of charge to and from the external driving circuits thus

producing a dynamic reference current. This current does

not change the converter offset, but it may degrade the

gain and INL performance. The effect of this current can be

analyzed in two distinct situations.

For relatively small values of the external reference capacitors (C

< 1nF), the voltage on the sampling capacitor

REF

settles almost completely and relatively large values for the

source impedance result in only small errors. Such values

for C

will deteriorate the converter offset and gain

REF

2483fa

19

LTC2483

WUUU

APPLICATIO S I FOR ATIO

performance without significant benefits of reference filtering and the user is advised to avoid them.

Larger values of reference capacitors (C

> 1nF) may be

REF

required as reference filters in certain configurations. Such

capacitors will average the reference sampling charge and

the external source resistance will see a quasi constant

reference differential impedance.

In the following discussion, it is assumed the input and

reference common mode are the same. For the internal

oscillator, the related difference resistance is 1.1MΩ and

90

VCC = 5V

80

= 5V

V

REF

+

= 3.75V

V

IN

70

–

= 1.25V

V

IN

= 25°C

T

A

60

50

40

30

+FS ERROR (ppm)

20

10

0

–10

C

= 0.01µF

REF

= 0.001µF

C

REF

= 100pF

C

REF

= 0pF

C

REF

10

0

100

R

SOURCE

(Ω)

1k

10k

100k

2483 F11

the resulting full-scale error is 0.46ppm for each ohm of

source resistance driving the REF

CA0/F

f

is driven by an external oscillator with a frequency

0

(external conversion clock operation), the typical

EOSC

differential reference resistance is 0.30 • 10

each ohm of source resistance driving the REF

–6

will result in 1.67 • 10

• f

EOSC

+

and REF– pins. When

12

/f

Ω and

EOSC

+

or REF– pins

ppm gain error. The typical

+FS and –FS errors for various combinations of source

resistance seen by the REF

+

or REF– pins and external

capacitance connected to that pin are shown in Figures

11-14.

10

0

C

C

REF

VCC = 5V

= 5V

V

REF

+

= 1.25V

V

IN

–

= 3.75V

V

IN

= 25°C

T

A

= 0.01µF

REF

= 0.001µF

= 100pF

C

REF

C

REF

10

= 0pF

100

R

SOURCE

1k

(Ω)

10k

100k

2483 F12

–10

–20

–30

–40

–50

–FS ERROR (ppm)

–60

–70

–80

–90

0

Figure 11. +FS Error vs R

500

VCC = 5V

= 5V

V

REF

+

= 3.75V

V

IN

400

–

= 1.25V

V

IN

= 25°C

T

A

300

200

+FS ERROR (ppm)

100

0

200

0

Figure 13. +FS Error vs R

20

at REF+ or REF– (Small C

SOURCE

C

= 1µF, 10µF

REF

C

REF

C

= 0.01µF

REF

600

400

R

SOURCE

at REF+ or REF– (Large C

SOURCE

800

(Ω)

= 0.1µF

2483 F13

1000

REF

REF

)

)

Figure 12. –FS Error vs R

0

–100

–200

C

= 1µF, 10µF

REF

–300

–FS ERROR (ppm)

VCC = 5V

= 5V

V

REF

+

–400

–500

0

V

IN

V

IN

T

A

= 1.25V

–

= 3.75V

= 25°C

200

Figure 14. –FS Error vs R

at REF+ or REF– (Small C

SOURCE

C

= 0.01µF

REF

C

= 0.1µF

REF

600

400

R

SOURCE

at REF+ or REF– (Large C

SOURCE

800

(Ω)

1000

2483 F14

REF

REF

2483fa

)

)

WUUU

APPLICATIO S I FOR ATIO

LTC2483

In addition to this gain error, the converter INL performance is degraded by the reference source impedance.

The INL is caused by the input dependent terms

2

–V

/(V

IN

• REQ) – (0.5 • V

REF

• DT)/REQ in the reference

REF

pin current as expressed in Figure 7. When using internal

oscillator, every 100Ω of reference source resistance

translates into about 0.61ppm additional INL error. When

CA0/F

f

REF

is driven by an external oscillator with a frequency

0

, every 100Ω of source resistance driving REF+ or

EOSC

–

translates into about 2.18 • 10–6 • f

EOSC

ppm additional INL error. Figure 15 shows the typical INL error due

to the source resistance driving the REF

when large C

values are used. The user is advised to

REF

minimize the source impedance driving the REF

–

REF

pins.

+

or REF– pins

+

and

In applications where the reference and input common

mode voltages are different, extra errors are introduced.

For every 1V of the reference and input common mode

voltage difference (V

REFCM

– V

) and a 5V reference,

INCM

each Ohm of reference source resistance introduces an

extra (V

REFCM

– V

INCM

)/(V

• REQ) full-scale gain error,

REF

which is 0.067ppm when using internal oscillator. If an

external clock is used, the corresponding extra gain error

is 0.24 • 10

–6

• f

EOSC

ppm.

The magnitude of the dynamic reference current depends

upon the size of the very stable internal sampling capacitors and upon the accuracy of the converter sampling

clock. The accuracy of the internal clock over the entire

temperature and power supply range is typically better

than 0.5%. Such a specification can also be easily achieved

by an external clock. When relatively stable resistors

(50ppm/°C) are used for the external source impedance

seen by REF

+

and REF–, the expected drift of the dynamic

current gain error will be insignificant (about 1% of its

value over the entire temperature and voltage range). Even

for the most stringent applications a one-time calibration

operation may be sufficient.

In addition to the reference sampling charge, the reference

pins ESD protection diodes have a temperature dependent

leakage current. This leakage current, nominally 1nA

(±10nA max), results in a small gain error. A 100Ω source

resistance will create a 0.05µV typical and 0.5µV maxi-

mum full-scale error.

10

VCC = 5V

8

= 5V

V

REF

= 2.5V

V

IN(CM)

6

= 25°C

T

A

= 10µF

C

)

REF

4

REF

2

0

–2

INL (ppm OF V

–4

–6

–8

–10

Figure 15. INL vs DIFFERENTIAL Input Voltage and

Reference Source Resistance for C

–0.5

–0.3

–0.1

VIN/V

REF

0.1

(V)

R = 1k

R = 500Ω

R = 100Ω

0.3

REF

0.5

2483 F15

> 1µF

2483fa

21

LTC2483

WUUU

APPLICATIO S I FOR ATIO

Output Data Rate

When using its internal oscillator, the LTC2483 produces

up to 6.82sps with simultaneous 50Hz/60Hz rejection. The

actual output data rate will depend upon the length of the

sleep and data output phases which are controlled by the

user and which can be made insignificantly short. When

operated with an external conversion clock (CA0/F

con-

0

nected to an external oscillator), the LTC2483 output data

rate can be increased as desired. The duration of the

conversion phase is 41036/f

EOSC

. If f

= 307.2kHz, the

EOSC

converter notch is set at 60Hz.

An increase in f

over the nominal 307.2kHz will

EOSC

translate into a proportional increase in the maximum

50

V

= V

IN(CM)

VCC = V

40

V

)

CA0/F

REF

30

20

10

OFFSET ERROR (ppm OF V

0

–10

REF(CM)

= 5V

REF

= 0V

IN

= EXT CLOCK

0

TA = 85°C

TA = 25°C

20 40 60 80

OUTPUT DATA RATE (READINGS/SEC)

10010030507090

2483 F16

output data rate. The increase in output rate is nevertheless accompanied by three potential effects, which must

be carefully considered.

First, a change in f

will result in a proportional change

EOSC

in the internal notch position and in a reduction of the

converter differential mode rejection at the power line

frequency. In many applications, the subsequent performance degradation can be substantially reduced by relying

upon the LTC2483’s exceptional common mode rejection

and by carefully eliminating common mode to differential

mode conversion sources in the input circuit. The user

should avoid single-ended input filters and should maintain a very high degree of matching and symmetry in the

circuits driving the IN

3500

V

VCC = V

3000

CA0/F

)

REF

2500

2000

1500

1000

+FS ERROR (ppm OF V

500

0

0

+

and IN– pins.

= V

IN(CM)

REF(CM)

= 5V

REF

= EXT CLOCK

0

TA = 85°C

T

= 25°C

A

50

60 80

70

30

40

20

10

OUTPUT DATA RATE (READINGS/SEC)

90

2483 F17

100

Figure 16. Offset Error vs Output Data Rate and Temperature Figure 17. +FS Error vs Output Data Rate and Temperature

0

–500

)

REF

–1000

–1500

–2000

–2500

–FS ERROR (ppm OF V

V

= V

IN(CM)

–3000

VCC = V

REF

= EXT CLOCK

CA0/F

–3500

0

0

20

10

OUTPUT DATA RATE (READINGS/SEC)

TA = 85°C

REF(CM)

= 5V

30

40

60 80

50

T

A

= 25°C

70

90

2483 F18

100

Figure 18. –FS Error vs Output Data Rate and Temperature

22

24

22

TA = 85°C

20

18

16

V

RESOLUTION (BITS)

14

12

10

= V

IN(CM)

VCC = V

V

CA0/F

RES = LOG 2 (V

0

REF(CM)

= 5V

REF

= 0V

IN

= EXT CLOCK

0

30

20

10

OUTPUT DATA RATE (READINGS/SEC)

Figure 19. Resolution (Noise

REF

40

/NOISE

50

= 25°C

T

A

)

RMS

70

60 80

RMS

90

2483 F19

≤ 1LSB)

vs Output Data Rate and Temperature

100

2483fa

WUUU

APPLICATIO S I FOR ATIO

LTC2483

Second, the increase in clock frequency will increase

proportionally the amount of sampling charge transferred through the input and the reference pins. If large

external input and/or reference capacitors (CIN, C

REF

) are

used, the previous section provides formulae for evaluating the effect of the source resistance upon the converter

performance for any value of f

and/or reference capacitors (C

. If small external input

EOSC

, C

IN

) are used, the

REF

effect of the external source resistance upon the LTC2483

typical performance can be inferred from Figures 9, 10,

11 and 12 in which the horizontal axis is scaled by

307200/f

EOSC

22

20

.

18

T

TA = 85°C

16

= 25°C

A

Third, an increase in the frequency of the external oscillator

above 1MHz (a more than 3

+

increase in the output data

rate) will start to decrease the effectiveness of the internal

autocalibration circuits. This will result in a progressive

degradation in the converter accuracy and linearity.

Typical measured performance curves for output data

rates up to 100 readings per second are shown in Figures 16 to 23. In order to obtain the highest possible level

of accuracy from this converter at output data rates above

20 readings per second, the user is advised to maximize

the power supply voltage used and to limit the maximum

ambient operating temperature. In certain circumstances,

a reduction of the

differential reference voltage may

be beneficial.

20

V

= V

IN(CM)

= 25°C

A

0

REF(CM)

= EXT CLOCK

VCC = V

REF

= 5V

VIN = 0V

CA0/F

)

15

T

REF

10

5

14

RESOLUTION (BITS)

V

= V

IN(CM)

VCC = V

12

CA0/F

RES = LOG 2 (V

10

0

Figure 20. Resolution (INL

REF(CM)

= 5V

REF

= EXT CLOCK

0

20

10

OUTPUT DATA RATE (READINGS/SEC)

/INL

40

MAX

60 80

50

)

70

MAX

≤ 1LSB)

REF

30

90

2483 F20

100

vs Output Data Rate and Temperature

24

22

VCC = 5V, V

20

18

16

V

RESOLUTION (BITS)

14

VIN = 0V

CA0/F

12

T

RES = LOG 2 (V

10

0

REF

= V

IN(CM)

REF(CM)

= EXT CLOCK

0

= 25°C

A

30

20

10

OUTPUT DATA RATE (READINGS/SEC)

Figure 22. Resolution (Noise

= 2.5V

/NOISE

REF

40

V

CC

RMS

60 80

50

= V

REF

)

70

RMS

= 5V

90

2483 F22

≤ 1LSB)

100

vs Output Data Rate and Reference Voltage

0

OFFSET ERROR (ppm OF V

–5

–10

VCC = 5V, V

0

30

20

10

OUTPUT DATA RATE (READINGS/SEC)

40

REF

50

= 2.5V

60 80

90

2483 F21

100

70

Figure 21. Offset Error vs Output

Data Rate and Reference Voltage

22

20

18

16

VCC = 5V, V

14

V

RESOLUTION (BITS)

12

10

= V

IN(CM)

VIN = 0V

= EXT CLOCK

CA0/F

0

= 25°C

T

A

RES = LOG 2 (V

0

20

10

OUTPUT DATA RATE (READINGS/SEC)

REF

REF(CM)

30

= 2.5V

REF

40

/INL

VCC = V

MAX

50

Figure 23. Resolution (INL

REF

)

70

60 80

≤ 1LSB)

MAX

= 5V

90

2483 F23

100

vs Output Data Rate and Reference Voltage

2483fa

23

LTC2483

WUUU

APPLICATIO S I FOR ATIO

Input Bandwidth

The combined effect of the internal SINC

4

digital filter and

of the analog and digital autocalibration circuits determines the LTC2483 input bandwidth. When the internal

oscillator is used, the 3dB input bandwidth is 3.3Hz. If an

external conversion clock generator of frequency f

connected to the CA0/F

11.8 • 10

–6

• f

EOSC

pin, the 3dB input bandwidth is

0

.

EOSC

is

Due to the complex filtering and calibration algorithms

utilized, the converter input bandwidth is not modeled

very accurately by a first order filter with the pole located

at the 3dB frequency. When the internal oscillator is

used, the shape of the LTC2483 input bandwidth is

shown in Figure 24. When an external oscillator of frequency f

is used, the shape of the LTC2483 input

EOSC

bandwidth can be derived from Figure 24, in which the

horizontal axis is scaled by f

The conversion noise (600nV

/279.2kHz.

EOSC

typical for V

RMS

= 5V) can

REF