LTC2440

24-Bit High Speed

FEATURES

n

Up to 3.5kHz Output Rate

n

Selectable Speed/Resolution

n

2μV

n

200nV

Noise at 880Hz Output Rate

RMS

Noise at 6.9Hz Output Rate with

RMS

Simultaneous 50/60Hz Rejection

n

0.0005% INL, No Missing Codes

n

Autosleep Enables 20μA Operation at 6.9Hz

n

<5μV Offset (4.5V < VCC < 5.5V, –40°C to 85°C)

n

Differential Input and Differential Reference with

GND to V

n

No Latency, Each Conversion is Accurate Even After

Common Mode Range

CC

an Input Step

n

Internal Oscillator—No External Components

n

Pin Compatible with the LTC2410

n

24-Bit ADC in Narrow 16-Lead SSOP Package

APPLICATIONS

n

High Speed Multiplexing

n

Weight Scales

n

Auto Ranging 6-Digit DVMs

n

Direct Temperature Measurement

n

High Speed Data Acquisition

Differential

Δ∑

ADC with

Selectable Speed/Resolution

DESCRIPTION

The LTC®2440 is a high speed 24-bit No Latency Δ∑TM

ADC with 5ppm INL and 5μV offset. It uses proprietary

delta-sigma architecture enabling variable speed and resolution with no latency. Ten speed/resolution combinations

(6.9Hz/200nV

to 3.5kHz/25μV

RMS

through a simple serial interface. Alternatively, by tying a

single pin HIGH or LOW, a fast (880Hz/2μV

noise (6.9Hz, 200nV

, 50/60Hz rejection) speed/reso-

RMS

lution combination can be easily selected. The accuracy

(offset, full-scale, linearity, drift) and power dissipation

are independent of the speed selected. Since there is no

latency, a speed/resolution change may be made between

conversions with no degradation in performance.

Following each conversion cycle, the LTC2440 automatically enters a low power sleep state. Power dissipation

may be reduced by increasing the duration of this sleep

state. For example, running at the 3.5kHz conversion speed

but reading data at a 100Hz rate draws 240μA average

current (1.1mW) while reading data at a 7Hz output rate

draws only 25μA (125μW).The LTC2440 communicates

through a fl exible 3-wire or 4-wire digital interface that is

compatible with the LTC2410 and is available in a narrow

16-lead SSOP package.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

No Latency Δ∑ is a trademark of Linear Technology Corporation. All other trademarks are

the property of their respective owners.

) are programmed

RMS

) or ultralow

RMS

TYPICAL APPLICATION

Simple 24-Bit 2-Speed Acquisition System

4.5V TO 5.5V

V

BUSY

CC

LTC2440

+

REFERENCE VOLTAGE

0.1V TO V

ANALOG INPUT

TO 0.5V

–0.5V

REF

REF

REF

4

CC

REF

IN

IN

GND

f

O

–

SCK

+

SDO

–

CS

SDI

EXT

3-WIRE

SPI INTERFACE

2440 TA01

V

CC

6.9Hz, 200nV NOISE,

50/60Hz REJECTION

10-SPEED SERIAL

PROGRAMMABLE

880Hz OUTPUT RATE,

2μV NOISE

2440 TA01

Speed vs RMS Noise

100

VCC = 5V

V

= 5V

REF

+

V

= V

IN

10

200nV AT 6.9Hz

RMS NOISE (μV)

1

(50/60Hz REJECTION)

0.1

1

–

= 0V

IN

2μV AT 880Hz

10 100

CONVERSION RATE (Hz)

1000 10000

2440 TA02

2440fc

1

LTC2440

(Notes 1,2)

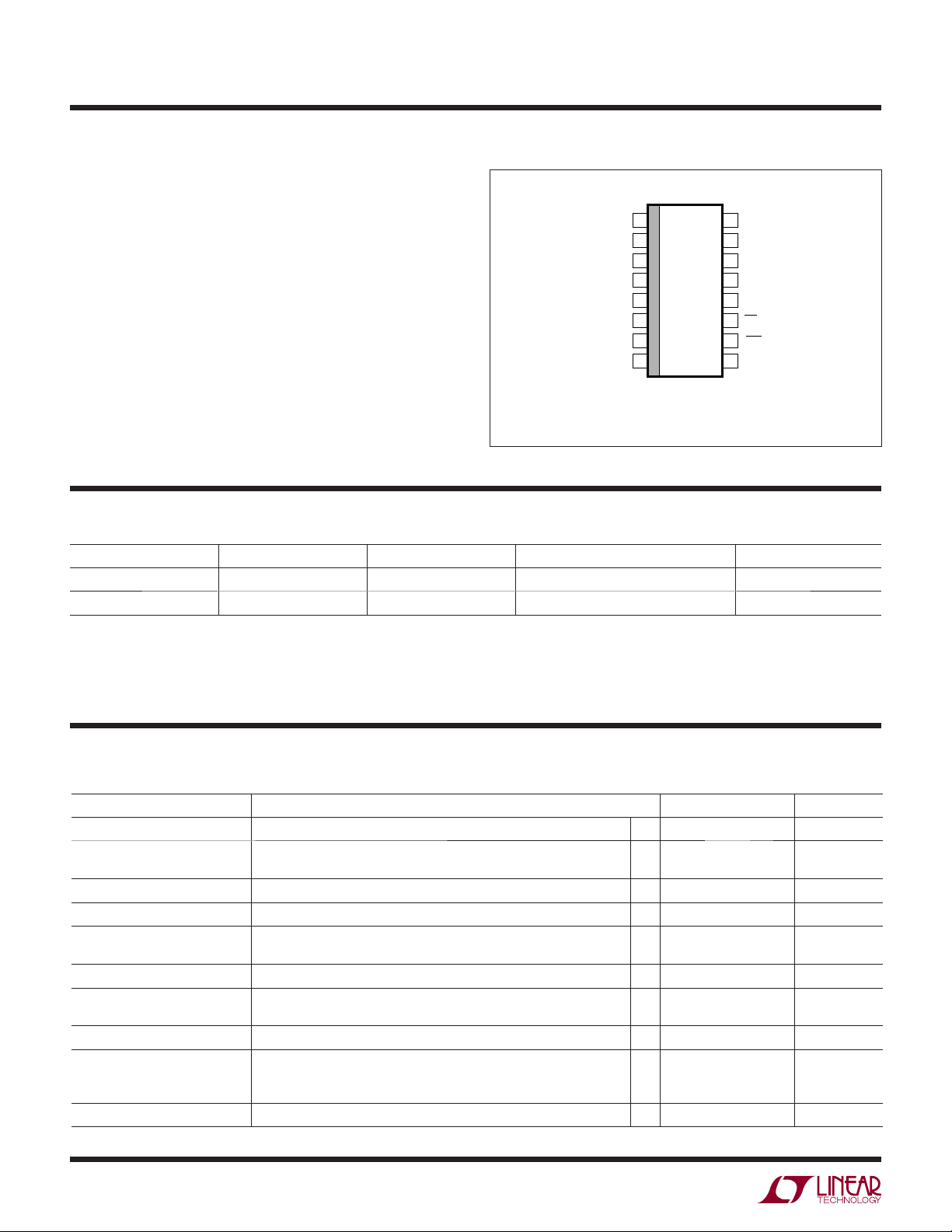

PIN CONFIGURATION ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VCC) to GND ....................... –0.3V to 6V

Analog Input Pins Voltage

to GND ......................................–0.3V to (V

+ 0.3V)

CC

Reference Input Pins Voltage

to GND ......................................–0.3V to (V

Digital Input Voltage to GND .........–0.3V to (V

Digital Output Voltage to GND .......–0.3V to (V

+ 0.3V)

CC

+ 0.3V)

CC

+ 0.3V)

CC

Operating Temperature Range

LTC2440C ............................................... 0°C to 70°C

LTC2440I ............................................. –40°C to 85°C

Storage Temperature Range ...................–65°C to 150°C

Lead Temperature (Soldering, 10 sec) ..................300°C

GND

REF

REF

GND

V

IN

IN

SDI

CC

TOP VIEW

1

2

+

3

–

4

+

5

–

6

7

8

GN PACKAGE

16-LEAD PLASTIC SSOP

T

= 125°C, θJA = 110°C/W

JMAX

16

GND

15

BUSY

14

f

O

13

SCK

12

SDO

11

CS

10

EXT

9

GND

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC2440CGN#PBF LTC2440CGN#TRPBF 2440 Narrow 16-Lead SSOP 0°C to 70°C

LTC2440IGN#PBF LTC2440IGN#TRPBF 2440I Narrow 16-Lead SSOP –40°C to 85°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

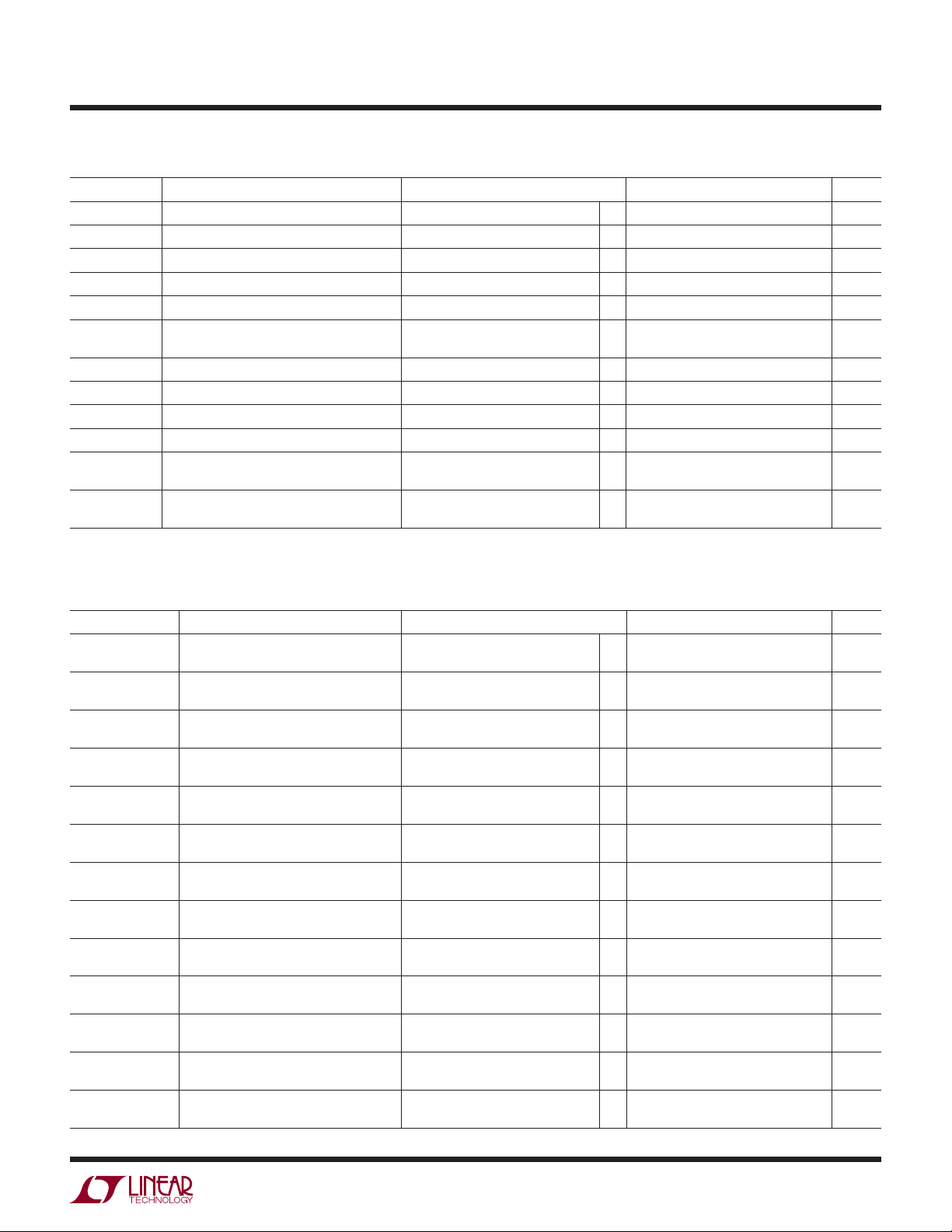

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at TA = 25°C. (Notes 3, 4)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) 0.1V ≤ V

Integral Nonlinearity V

= 5V, REF+ = 5V, REF– = GND, V

CC

+

REF

= 2.5V, REF– = GND, V

≤ VCC, –0.5 • V

REF

≤ VIN ≤ 0.5 • V

REF

INCM

= 1.25V, (Note 6)

INCM

, (Note 5)

REF

= 2.5V, (Note 6)

Offset Error 2.5V ≤ REF+ ≤ VCC, REF– = GND, GND ≤ IN+ = IN– ≤ VCC (Note 12)

+

Offset Error Drift 2.5V ≤ REF

Positive Full-Scale Error REF

REF

≤ VCC, REF– = GND, GND ≤ IN+ = IN– ≤ V

+

= 5V, REF– = GND, IN+ = 3.75V, IN– = 1.25V

+

= 2.5V, REF– = GND, IN+ = 1.875V, IN– = 0.625V

CC

Positive Full-Scale Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, IN+ = 0.75REF+, IN– = 0.25 • REF

+

Negative Full-Scale Error REF

= 5V, REF– = GND, IN+ = 1.25V, IN– = 3.75V

+

REF

= 2.5V, REF– = GND, IN+ = 0.625V, IN– = 1.875V

Negative Full-Scale Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, IN+ = 0.25 • REF+, IN– = 0.75 • REF

Total Unadjusted Error 5V ≤ V

5V ≤ V

REF

≤ 5.5V, REF+ = 2.5V, REF– = GND, V

CC

≤ 5.5V, REF+ = 5V, REF– = GND, V

CC

+

= 2.5V, REF– = GND, V

= 1.25V, (Note 6)

INCM

Input Common Mode Rejection DC 2.5V ≤ REF+ ≤ VCC, REF– = GND, GND ≤ IN– = IN+ ≤ V

INCM

INCM

= 1.25V

= 2.5V

CC

l

24 Bits

l

l

5

15 ppm of V

3

ppm of V

REF

REF

2.5 5 μV

20 nV/ °C

l

l

+

l

l

+

101030

50

ppm of V

ppm of V

0.2 ppm of V

101030

50

ppm of V

ppm of V

0.2 ppm of V

15

15

15

ppm of V

ppm of V

ppm of V

REF

REF

REF

REF

/°C

REF

REF

/°C

REF

REF

REF

120 dB

2440fc

2

LTC2440

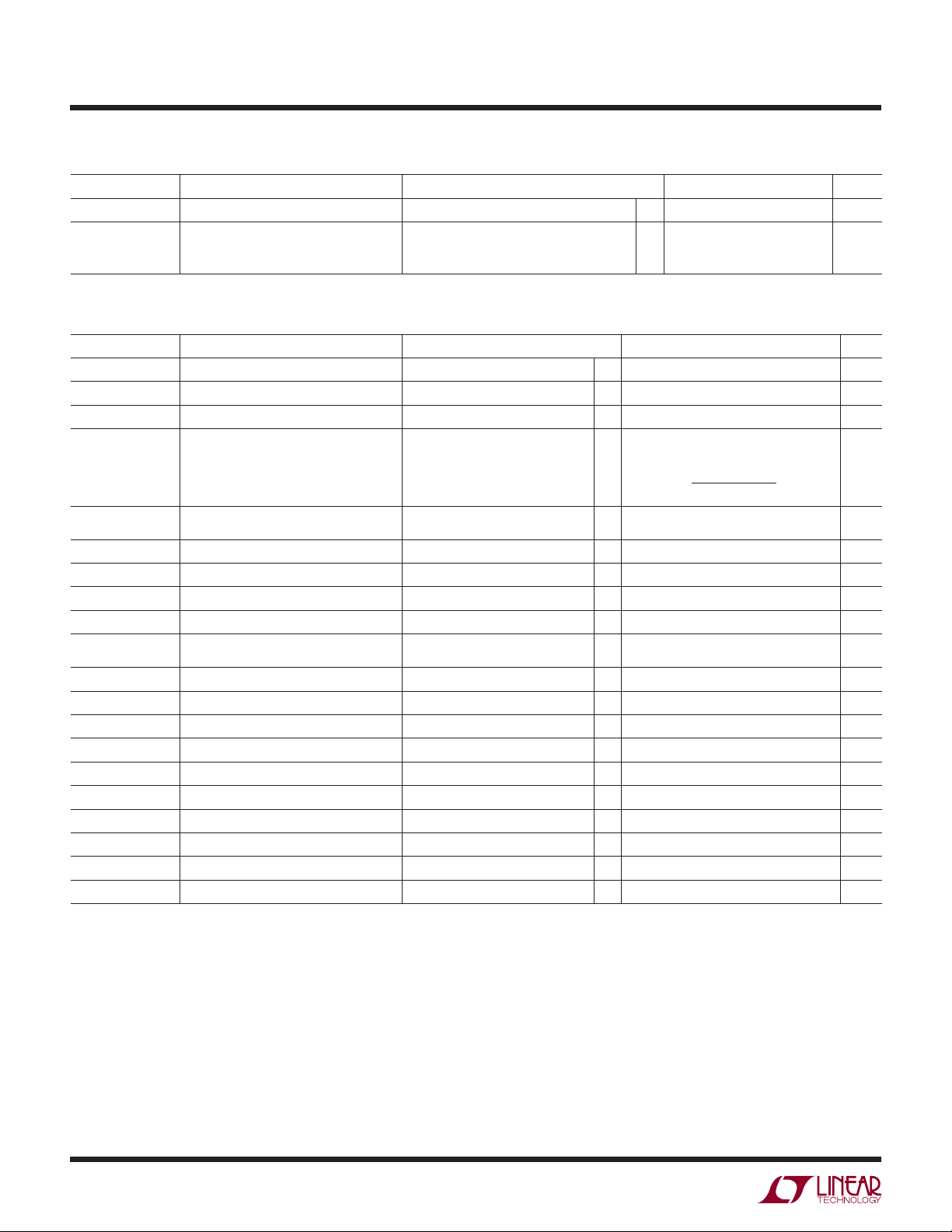

ANALOG INPUT AND REFERENCE

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

IN

–

IN

V

IN

+

REF

–

REF

V

REF

C

S(IN+)

C

S(IN–)

C

S(REF+)

C

S(REF–)

I

DC_LEAK(IN+, IN–,

+

, REF–)

REF

I

SAMPLE(IN+, IN–,

+

, REF–)

REF

Absolute/Common Mode IN+ Voltage

Absolute/Common Mode IN– Voltage

Input Differential Voltage Range (IN+ – IN–)

Absolute/Common Mode REF+ Voltage

Absolute/Common Mode REF– Voltage

Reference Differential Voltage Range (REF+

–

– REF

)

IN+ Sampling Capacitance 3.5 pF

IN– Sampling Capacitance 3.5 pF

REF+ Sampling Capacitance 3.5 pF

REF– Sampling Capacitance 3.5 pF

Leakage Current, Inputs and Reference CS = VCC, IN+ = GND, IN– = GND,

Average Input/Reference Current During

Sampling

= 25°C. (Note 3)

A

+

REF

= 5V, REF– = GND

l

GND – 0.3V VCC + 0.3V V

l

GND – 0.3V VCC + 0.3V V

l

–V

/2 V

REF

l

l

l

l

0.1 V

GND VCC – 0.1V V

0.1 V

–100 10 100 nA

/2 V

REF

CC

CC

Varies, See Applications Section

V

V

DIGITAL INPUTS AND DIGITAL OUTPUTS

The l denotes the specifi cations which apply over the full

operating temperature range, otherwise specifi cations are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

V

IL

V

IN

High Level Input Voltage

CS, f

O

Low Level Input Voltage

CS, f

O

High Level Input Voltage

4.5V ≤ VCC ≤ 5.5V

4.5V ≤ VCC ≤ 5.5V

4.5V ≤ VCC ≤ 5.5V (Note 8)

SCK

V

IL

Low Level Input Voltage

4.5V ≤ VCC ≤ 5.5V (Note 8)

SCK

I

IN

I

IN

Digital Input Current

CS, f

O

Digital Input Current

0V ≤ VIN ≤ V

CC

0V ≤ VIN ≤ VCC (Note 8)

SCK

C

IN

C

IN

Digital Input Capacitance

CS, f

O

Digital Input Capacitance

(Note 8) 10 pF

SCK

V

OH

High Level Output Voltage

IO = –800μA

SDO, BUSY

V

OL

Low Level Output Voltage

IO = 1.6mA

SDO, BUSY

V

OH

High Level Output Voltage

IO = –800μA (Note 9)

SCK

V

OL

Low Level Output Voltage

IO = 1.6mA (Note 9)

SCK

I

OZ

Hi-Z Output Leakage

SDO

l

l

l

l

l

l

25 V

0.8 V

25 V

0.8 V

–10 10 μA

–10 10 μA

10 pF

l

VCC – 0.5V V

l

l

VCC – 0.5V V

l

l

–10 10 μA

0.4V V

0.4V V

2440fc

3

LTC2440

POWER REQUIREMENTS

The l denotes the specifi cations which apply over the full operating temperature

range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

Supply Voltage

Supply Current

Conversion Mode

Sleep Mode

TIMING CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating temperature

range, otherwise specifi cations are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

EOSC

t

HEO

t

LEO

t

CONV

f

ISCK

D

ISCK

f

ESCK

t

LESCK

t

HESCK

t

DOUT_ISCK

t

DOUT_ESCK

t

1

t

2

t

3

t

4

t

KQMAX

t

KQMIN

t

5

t

7

t

8

Note 1: Stresses beyond those listed under Absolute Maximum Ratings may

cause permanent damage to the device. Exposure to any Absolute Maximum

Rating condition for extended periods may affect device reliability and lifetime.

Note 2: All voltage values are with respect to GND.

Note 3: V

V

REF

V

IN

Note 4: f

f

EOSC

= 4.5 to 5.5V unless otherwise specifi ed.

CC

= REF+ – REF–, V

= IN+ – IN–, V

pin tied to GND or to external conversion clock source with

O

= 10MHz unless otherwise specifi ed.

Note 5: Guaranteed by design, not subject to test.

Note 6: Integral nonlinearity is defi ned as the deviation of a code from a

straight line passing through the actual endpoints of the transfer curve.

The deviation is measured from the center of the quantization band.

External Oscillator Frequency Range

External Oscillator High Period

External Oscillator Low Period

Conversion Time OSR = 256 (SDI = 0)

Internal SCK Frequency Internal Oscillator (Note 9)

Internal SCK Duty Cycle (Note 9)

External SCK Frequency Range (Note 8)

External SCK Low Period (Note 8)

External SCK High Period (Note 8)

Internal SCK 32-Bit Data Output Time Internal Oscillator (Notes 9, 11)

External SCK 32-Bit Data Output Time (Note 8)

↑

CS to SDO Low Z (Note 12)

CS ↑ to SDO High Z

↑

CS to SCK (Note 9)

↑

CS to SCK ↑

SCK to SDO Valid

↑

↑

SDO Hold After SCK (Note 5)

SCK Set-Up Before CS

SDI Setup Before SCK ↑

SDI Hold After SCK ↑

= (REF+ + REF–)/2;

REFCM

= (IN+ + IN–)/2.

INCM

= 25°C. (Note 3)

A

↑

↑

CS = 0V (Note 7)

CS = V

(Note 7)

CC

OSR = 32768 (SDI = 1)

External Oscillator (Note 10, 13)

External Oscillator (Notes 9, 10)

External Oscillator (Notes 9, 10)

(Note 12)

(Notes 8, 12)

(Note 5)

(Note 5)

Note 7: The converter uses the internal oscillator.

Note 8: The converter is in external SCK mode of operation such that the

SCK pin is used as a digital input. The frequency of the clock signal driving

SCK during the data output is f

Note 9: The converter is in internal SCK mode of operation such that the

SCK pin is used as a digital output. In this mode of operation, the SCK pin

has a total equivalent load capacitance of C

Note 10: The external oscillator is connected to the f

oscillator frequency, f

Note 11: The converter uses the internal oscillator. fO = 0V.

Note 12: Guaranteed by design and test correlation.

Note 13: There is an internal reset that adds an additional 1μs (typical) to

the conversion time.

l

4.5 5.5 V

l

l

l

0.1 20 MHz

l

25 10000 ns

l

25 10000 ns

l

0.99

l

126

l

l

0.8 0.9

l

45 55 %

l

l

25 ns

l

25 ns

l

30.9 35.3

l

l

l

l

l

25 ns

l

l

15 ns

l

50 ns

l

10 ns

l

10 ns

, is expressed in kHz.

EOSC

40 • OSR + 170

025ns

025ns

and is expressed in Hz.

ESCK

f

EOSC

8

8

1.13

145

(kHz)

11

30

1.33

170

mA

μA

ms

ms

ms

1

f

/10

EOSC

20 MHz

41.6 μs

320/f

EOSC

32/f

ESCK

5μs

25 ns

= 20pF.

LOAD

pin. The external

O

2440fc

s

s

4

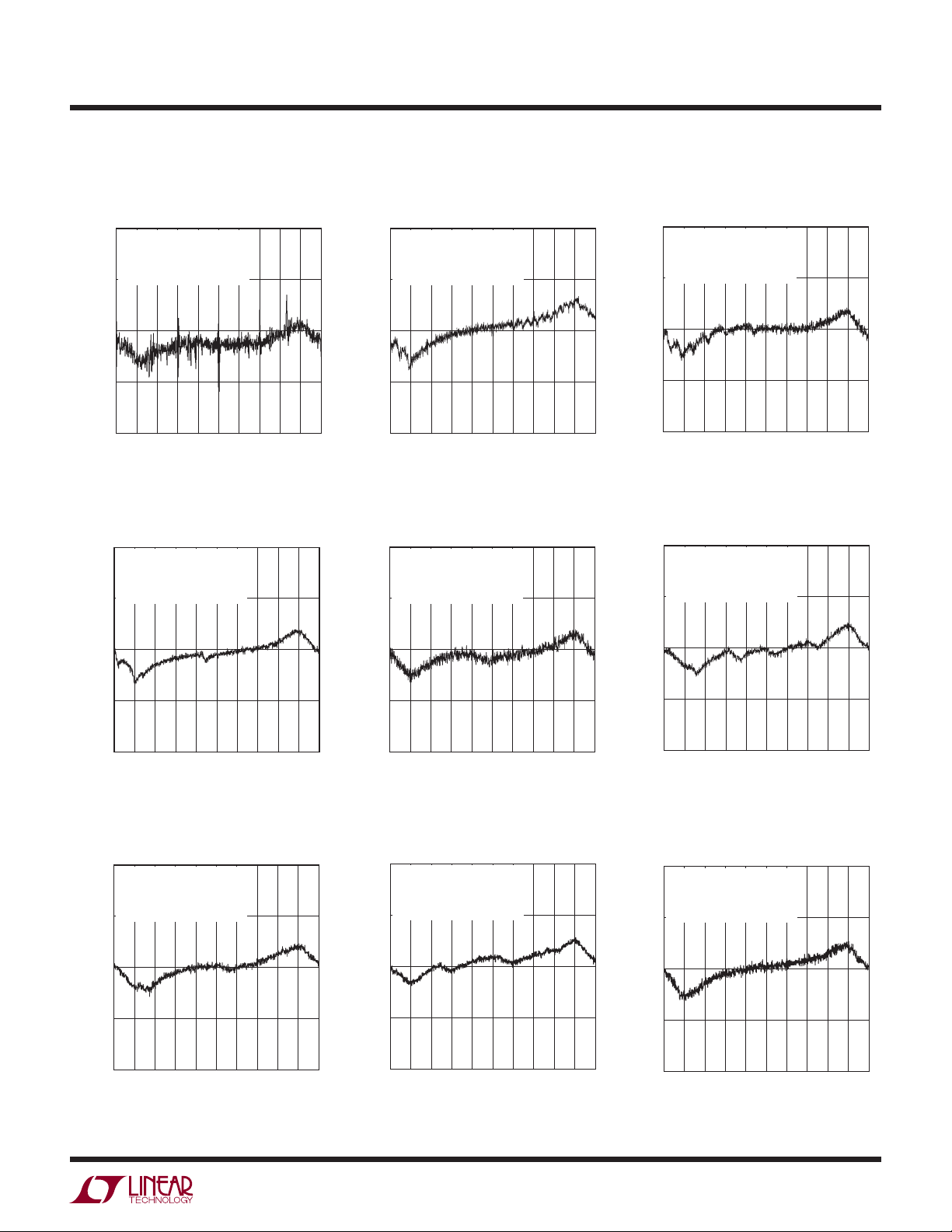

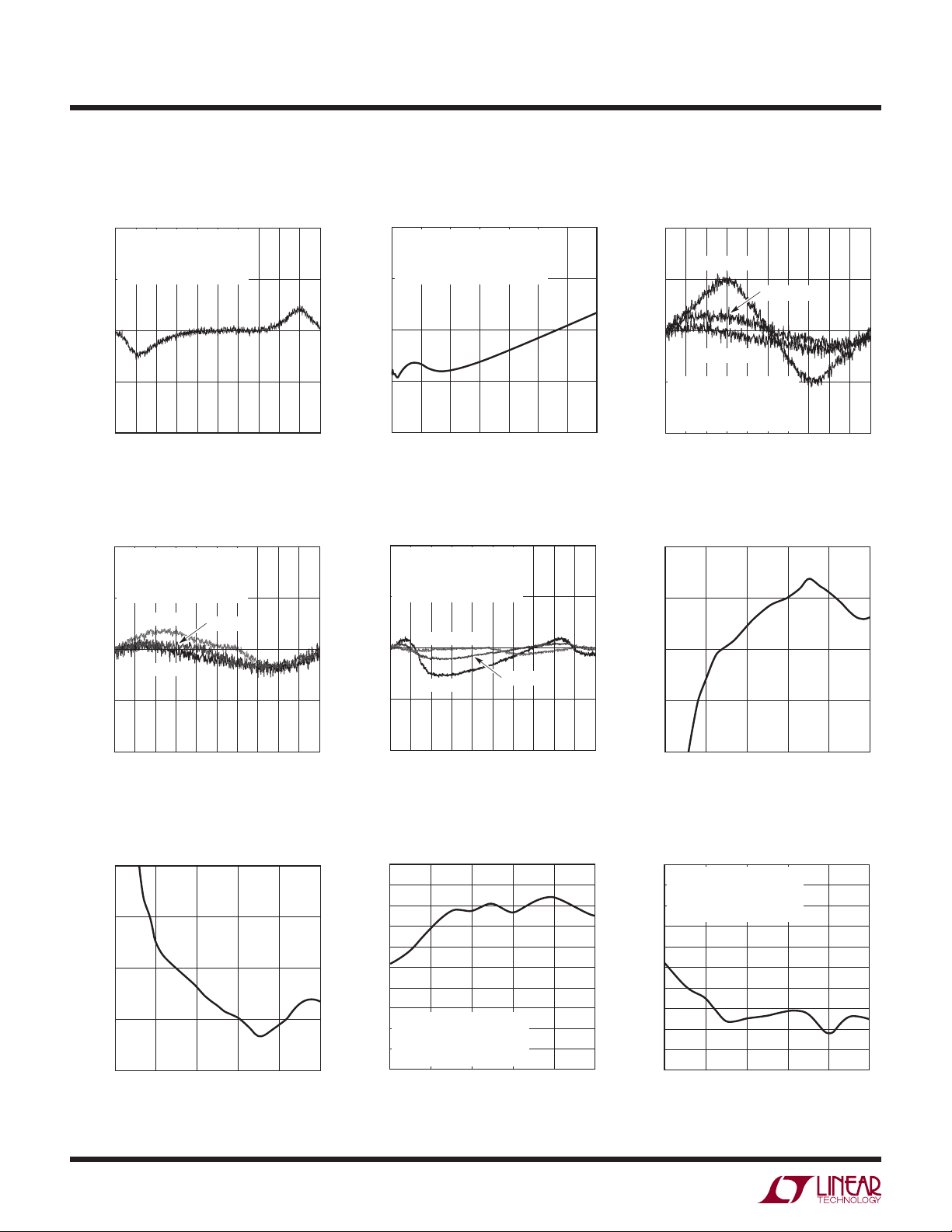

TYPICAL PERFORMANCE CHARACTERISTICS

Integral Nonlinearity

Integral Nonlinearity f

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

)

REF

–

= GND

V

REF

5

V

f

T

INCM

O

A

= 2.5V

= GND

= 25°C

= 3.5kHz

OUT

f

= 1.76kHz Integral Nonlinearity f

OUT

10

VCC = 5V

= 5V

V

REF

+

V

REF

)

REF

–

V

REF

5

= 5V

= GND

V

INCM

= GND

f

O

= 25°C

T

A

= 2.5V

)

REF

10

5

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

–

= GND

V

REF

LTC2440

OUT

V

= 2.5V

INCM

= GND

f

O

= 25°C

T

A

= 880Hz

0

–5

INL ERROR (ppm OF V

–10

–2.5

–1.5

–2

–1

Integral Nonlinearity f

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

–10

–

= GND

V

REF

5

0

–5

–2

–1.5

–2.5

–1

)

REF

INL ERROR (ppm OF V

–0.5

V

INCM

= GND

f

O

T

A

–0.5

0

VIN (V)

= 2.5V

= 25°C

0

VIN (V)

0

–5

INL ERROR (ppm OF V

1.5

0.5

1

= 440Hz Integral Nonlinearity f

OUT

2

2440 G01

2.5

–10

10

)

REF

–2.5

5

–2

VCC = 5V

= 5V

V

REF

+

V

REF

–

V

REF

–1.5

= 5V

= GND

0

–5

INL ERROR (ppm OF V

–10

–2

–1.5

0.5

1.5

1

2

2440 G04

2.5

–2.5

0

–5

INL ERROR (ppm OF V

–10

–2

–1.5

0

–0.5

–1

0.5

1.5

1

2.5

2

–2.5

VIN (V)

2440 G02

= 220Hz Integral Nonlinearity f

V

INCM

= GND

f

O

T

= 25°C

A

OUT

= 2.5V

)

REF

10

5

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

–

= GND

V

REF

0

–1

–0.5

0.5

1.5

1

2.5

2

VIN (V)

2440 G03

= 110Hz

OUT

V

= 2.5V

INCM

= GND

f

O

= 25°C

T

A

0

–5

INL ERROR (ppm OF V

–10

–2

–1.5

0

–1

–0.5

0.5

1.5

1

2.5

2

–2.5

VIN (V)

2440 G05

0

0.5

1

1.5

2.5

–1

–0.5

2

VIN (V)

2440 G06

Integral Nonlinearity f

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

)

REF

INL ERROR (ppm OF V

–10

–

= GND

V

REF

5

0

–5

–2

–1.5

–2.5

–1

V

INCM

= GND

f

O

= 25°C

T

A

–0.5

= 2.5V

0

VIN (V)

= 55Hz Integral Nonlinearity f

OUT

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

)

REF

–

= GND

V

REF

5

0

–5

INL ERROR (ppm OF V

–10

–2

–1.5

0.5

1

1.5

2.5

2

2440 G07

–2.5

Integral Nonlinearity

= 27.5Hz

OUT

V

= 2.5V

INCM

= GND

f

O

= 25°C

T

A

0

0.5

1

1.5

2.5

–1

–0.5

2

VIN (V)

2440 G08

f

= 13.75Hz

OUT

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

)

REF

–

= GND

V

REF

5

0

–5

INL ERROR (ppm OF V

–10

–2

–1.5

–2.5

V

= 2.5V

INCM

= GND

f

O

= 25°C

T

A

0

0.5

1

1.5

2.5

–1

–0.5

2

VIN (V)

2440 G09

2440fc

5

LTC2440

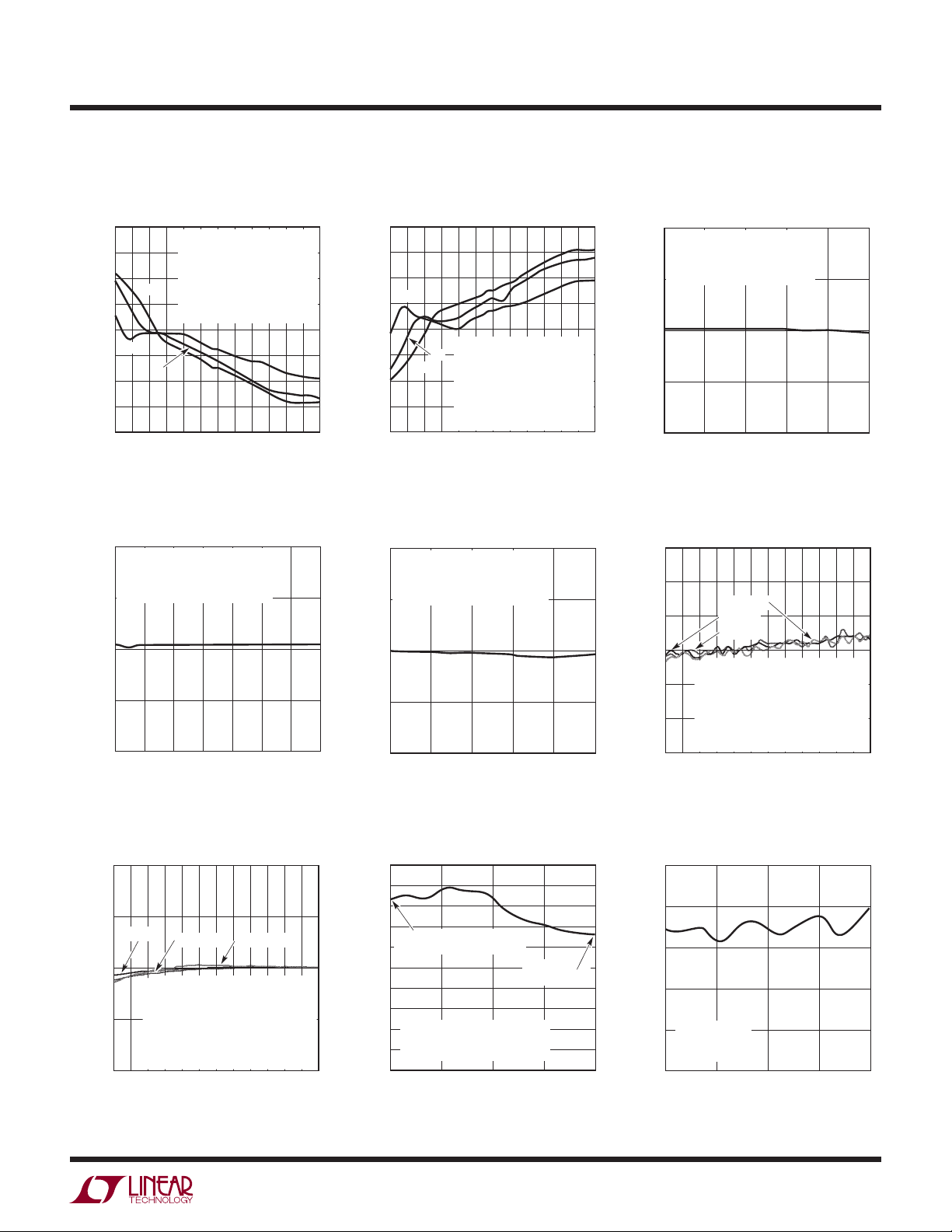

TYPICAL PERFORMANCE CHARACTERISTICS

Integral Nonlinearity

f

= 6.875Hz

OUT

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

)

REF

–

= GND

V

REF

5

0

–5

INL ERROR (ppm OF V

–10

–2

–1.5

–2.5

–1

Integral Nonlinearity

vs Temperature

10

VCC = 5V

= 2.5V

V

REF

+

= 2.5V

V

REF

–5

5

0

–1.25

V

REF

–

= GND

TA = –55°C

TA = 25°C

–0.75

)

REF

INL ERROR (ppm OF V

–10

V

= 2.5V

INCM

= GND

f

O

= 25°C

T

A

0

–0.5

VIN (V)

V

= 1.25V

INCM

OSR = 32768

= GND

f

O

TA = 125°C

–0.25

VIN (V)

0.5

0.25

Integral Nonlinearity

vs Conversion Rate Integral Nonlinearity vs V

10

V

= 3.75V

)

REF

INCM

5

0

V

= 1.25V

INCM

–5

VCC = 5V

INL ERROR (ppm OF V

–10

–1.25

= 2.5V

V

REF

+

= 2.5V

V

REF

–

= GND

V

REF

–0.75

V

INCM

OSR = 32768

= GND

f

O

= 25°C

T

A

–0.25

VIN (V)

)

10.0

REF

7.5

VCC = 5V

= 5V

V

REF

+

V

REF

–

V

REF

= 5V

= GND

–2.5V ≤ V

= 2.5V

V

INCM

= GND

f

O

= 25°C

T

A

≤ 2.5V

IN

5.0

2.5

INL ERROR (ppm OF V

0

0

1.5

1

2.5

2

500 1000 1500 2000

2500 3000 3500

CONVERSION RATE (Hz)

2440 G10

2440 G11

0.25

= 2.5V

INCM

0.75

1.25

2440 G12

Integral Nonlinearity

0.75

2440 G13

1.25

vs Temperature –Full-Scale Error vs V

10

VCC = 5V

= 5V

V

REF

+

= 5V

V

REF

)

REF

–

= GND

V

REF

5

0

TA = 125°C

TA = –25°C

–5

INL ERROR (ppm OF V

–10

–2

–1.5

–2.5

V

INCM

OSR = 32768

= GND

f

O

–1

–0.5

= 2.5V

0

VIN (V)

TA = 25°C

0.5

1

1.5

2

2440 G14

2.5

20

)

REF

10

0

–10

–FULL-SCALE ERROR (ppm OF V

–20

1

0

2

V

REF

(V)

REF

3

4

5

2440 G15

+Full-Scale Error vs V

20

)

REF

10

0

–10

+FULL-SCALE ERROR (ppm OF V

–20

1

0

6

REF

–Full-Scale Error vs V

10

9

)

REF

8

CC

7

6

5

4

3

V

= 2.5V

REF

+

2

V

REF

FULL-SCALE ERROR (ppm OF V

3

4

2

V

(V)

REF

5

2440 G16

–

V

REF

1

V

INCM

0

4.5

= 2.5V

= GND

= 1.25V

4.7

OSR = 32768

fO = GND

= 25°C

T

A

5.1

4.9

VCC (V)

5.3

5.5

2440 G17

+Full-Scale Error vs V

0

V

= 2.5V

REF

+

–1

V

)

REF

–

V

REF

REF

–2

V

INCM

–3

–4

–5

–6

–7

–8

FULL-SCALE ERROR (ppm OF V

–9

–10

4.5

= 2.5V

= GND

= 1.25V

4.7

OSR = 32768

= GND

f

O

= 25°C

T

A

4.9

VCC (V)

5.1

CC

5.3

5.5

2440 G18

2440fc

TYPICAL PERFORMANCE CHARACTERISTICS

LTC2440

Negative Full-Scale Error

vs Temperature

20

)

15

REF

10

5

0

5.5V

–5

–10

FULL-SCALE ERROR (ppm OF V

–15

–20

–55

4.5V

5V

–25 5

VCC = 4.5V

= 4.5V

V

REF

+

= 4.5V

V

REF

–

= GND

V

REF

= 2.25V

V

INCM

OSR = 32768

= GND

f

O

35

= 5.5V, 5V

V

CC

= 5V

V

REF

+

= 5V

V

REF

–

= GND

V

REF

= 2.5V

V

INCM

OSR = 32768

= GND

f

O

65 95

125

Positive Full-Scale Error

vs Temperature Offset Error vs V

20

)

15

REF

10

5.5V

5

0

–5

4.5V

–10

FULL-SCALE ERROR (ppm OF V

–15

–20

–55

–25 5

TEMPERATURE (°C)

2440 G19

Offset Error vs Conversion Rate Offset Error vs V

5.0

VCC = 5V

= 5V

V

REF

+

V

)

REF

–

V

REF

REF

2.5

= 5V

= GND

V

f

T

0

–2.5

OFFSET ERROR (ppm OF V

–5.0

0

500 1000 1500 2000

CONVERSION RATE (Hz)

+

IN

= GND

O

= 25°C

A

= V

IN

–

= GND

2500 3000 3500

2440 G22

5.0

VCC = 5V

= 5V

V

REF

2.5

+

V

REF

–

V

REF

)

REF

0

–2.5

OFFSET ERROR (ppm OF V

–5.0

0

INL vs Output Rate

(OSR = 128) External Clock Sweep

Offset Error vs Temperature

5.0

2.5

VCC = 5V

0

OFFSET ERROR (μV)

–2.5

–5.0

–55

VCC = 5.5V

VCC = 4.5V

= 2.5V

V

REF

+

= 2.5V

V

REF

–

= GND

V

REF

+

= V

V

IN

IN

OSR = 256

= GND

f

O

53565

–25

TEMPERATURE (°C)

–

= GND

VCC = 4.5V

= 5.5V, 5V

V

CC

= 5V

V

REF

+

= 5V

V

REF

–

= GND

V

REF

+

= V

V

IN

OSR = 256

= GND

f

O

–

= GND

IN

95 125

2440 G25

10MHz to 20MHz

20

18

16

14

EXTERNAL CLOCK 10MHz

12

(OR INTERNAL OSCILLATOR)

10

8

LINEARITY (BITS)

6

V

4

REF

TEMP = 25°C

2

SWEEP (V

0

2000

5V

VCC = 4.5V

= 4.5V

V

REF

+

= 4.5V

V

REF

–

= GND

V

REF

= 2.25V

V

INCM

OSR = 32768

= GND

f

O

35

= 5.5V, 5V

V

CC

= 5V

V

REF

+

= 5V

V

REF

–

= GND

V

REF

= 2.5V

V

INCM

OSR = 32768

= GND

f

O

65 95

TEMPERATURE (°C)

2440 G20

INCM

+

–

V

= V

= V

IN

IN

(V)

/2) TO V

INCM

3

EXTERNAL

CLOCK 20MHz

/2

REF

4

2440 G23

2440 G26

OSR = 32768

= 5V

= GND

= GND

f

O

= 25°C

T

A

1

2

V

INCM

= VCC = 5V

– V

IN

REF

2500 3000 3500 4000

OUTPUT RATE (Hz)

125

5.0

)

REF

2.5

0

–2.5

OFFSET ERROR (ppm OF V

–5.0

3.5

3.0

2.5

2.0

RMS NOISE (μV)

1.5

1.0

5

0.5

5

4

3

2

RMS NOISE (μV)

1

0

2000

CC

–

= GND

OSR = 32768

= GND

f

O

= 25°C

T

A

4.9

VCC (V)

5.1

4.5

V

= 2.5V

REF

+

= 2.5V

V

REF

–

= GND

V

REF

+

= V

V

IN

IN

4.7

RMS Noise vs Temperature

VCC = 4.5V

VCC = 5V

VCC = 5.5V

–55

VCC = 4.5V

= 2.5V

V

REF

+

= 2.5V

V

REF

–

= GND

V

REF

+

–

= V

V

IN

IN

OSR = 256

= GND

f

O

53565

–25

= GND

= 5.5V, 5V

V

CC

= 5V

V

REF

+

= 5V

V

REF

–

= GND

V

REF

+

= V

V

IN

OSR = 256

= GND

f

O

TEMPERATURE (°C)

RMS Noise vs Output Rate

(OSR = 128) External Clock

Sweep 10MHz to 20MHz

V

= VCC = 5V

REF

TEMP = 25°C

±V

/2

V

IN

REF

2500 3000 3500 4000

OUTPUT RATE (Hz)

5.3

2440 G21

–

= GND

IN

95 125

5.5

2440 G24

2440 G27

2440fc

7

LTC2440

PIN FUNCTIONS

GND (Pins 1, 8, 9, 16): Ground. Multiple ground pins

internally connected for optimum ground current fl ow and

decoupling. Connect each one of these pins to a ground

V

CC

plane through a low impedance connection. All four pins

must be connected to ground for proper operation.

(Pin 2): Positive Supply Voltage. Bypass to GND

V

CC

(Pin 1) with a 10μF tantalum capacitor in parallel with 0.1μF

ceramic capacitor as close to the part as possible.

+

(Pin 3), REF– (Pin 4): Differential Reference Input.

REF

The voltage on these pins can have any value between

GND and V

as long as the reference positive input, REF+,

CC

is maintained more positive than the reference negative

–

input, REF

+

IN

(Pin 5), IN– (Pin 6): Differential Analog Input. The

, by at least 0.1V.

voltage on these pins can have any value between GND

– 0.3V and V

bipolar input range (V

• (V

) to 0.5 • (V

REF

+ 0.3V. Within these limits the converter

CC

= IN+ – IN–) extends from –0.5

IN

). Outside this input range the

REF

converter produces unique overrange and underrange

output codes.

SDI (Pin 7): Serial Data Input. This pin is used to select

the speed/resolution of the converter. If SDI is grounded

(pin compatible with LTC2410) the device outputs data at

880Hz with 21 bits effective resolution. By tying SDI HIGH,

the converter enters the ultralow noise mode (200nV

RMS

)

with simultaneous 50/60Hz rejection at 6.9Hz output

rate. SDI may be driven logic HIGH or LOW anytime during the conversion or sleep state in order to change the

speed/resolution. The conversion immediately following

the data output cycle will be valid and performed at the

newly selected output rate/resolution. SDI may also be

programmed by a serial input data stream under control of

SCK during the data output cycle. One of ten speed/resolution ranges (from 6.9Hz/200nV

to 3.5kHz/21μV

RMS

RMS

)

may be selected. The fi rst conversion following a new

selection is valid and performed at the newly selected

speed/resolution.

EXT (Pin 10): Internal/External SCK Selection Pin. This pin

is used to select internal or external SCK for outputting

data. If EXT is tied low (pin compatible with the LTC2410),

the device is in the external SCK mode and data is shifted

out the device under the control of a user applied serial

clock. If EXT is tied high, the internal serial clock mode

is selected. The device generates its own SCK signal and

outputs this on the SCK pin. A framing signal BUSY (Pin 15)

goes low indicating data is being output.

CS (Pin 11): Active LOW Digital Input. A LOW on this pin

enables the SDO digital output and wakes up the ADC.

Following each conversion the ADC automatically enters

the Sleep mode and remains in this low power state as

long as CS is HIGH. A LOW-to-HIGH transition on CS

during the Data Output transfer aborts the data transfer

and starts a new conversion.

SDO (Pin 12): Three-State Digital Output. During the Data

Output period, this pin is used as serial data output. When

the chip select CS is HIGH (CS = V

) the SDO pin is in a

CC

high impedance state. During the Conversion and Sleep

periods, this pin is used as the conversion status output. The

conversion status can be observed by pulling CS LOW.

SCK (Pin 13): Bidirectional Digital Clock Pin. In Internal

Serial Clock Operation mode, SCK is used as digital output

for the internal serial interface clock during the Data Output

period. In External Serial Clock Operation mode, SCK is used

as digital input for the external serial interface clock during

the Data Output period. The Serial Clock Operation mode is

determined by the logic level applied to the EXT pin.

fO (Pin 14): Frequency Control Pin. Digital input that controls the internal conversion clock. When fO is connected to

VCC or GND, the converter uses its internal oscillator running

at 9MHz. The conversion rate is determined by the selected

OSR such that t

(t

= 1.137ms at OSR = 256, t

CONV

32768). The fi rst null is located at 8/ t

(in ms) = (40 • OSR + 170)/9000

CONV

= 146ms at OSR =

CONV

, 7kHz at OSR =

CONV

256 and 55Hz (simultaneous 50/60Hz) at OSR = 32768.

When f

kHz), the conversion time becomes t

170)/f

is driven by an oscillator with frequency f

O

= (40 • OSR +

CONV

(in ms) and the fi rst null remains 8/t

EOSC

EOSC

CONV

(in

.

BUSY (Pin 15): Conversion in Progress Indicator. For

compatibility with the LTC2410, this pin should not be

tied to ground. This pin is HIGH while the conversion

is in progress and goes LOW indicating the conversion

is complete and data is ready. It remains low during the

sleep and data output states. At the conclusion of the data

output state, it goes HIGH indicating a new conversion

has begun.

2440fc

8

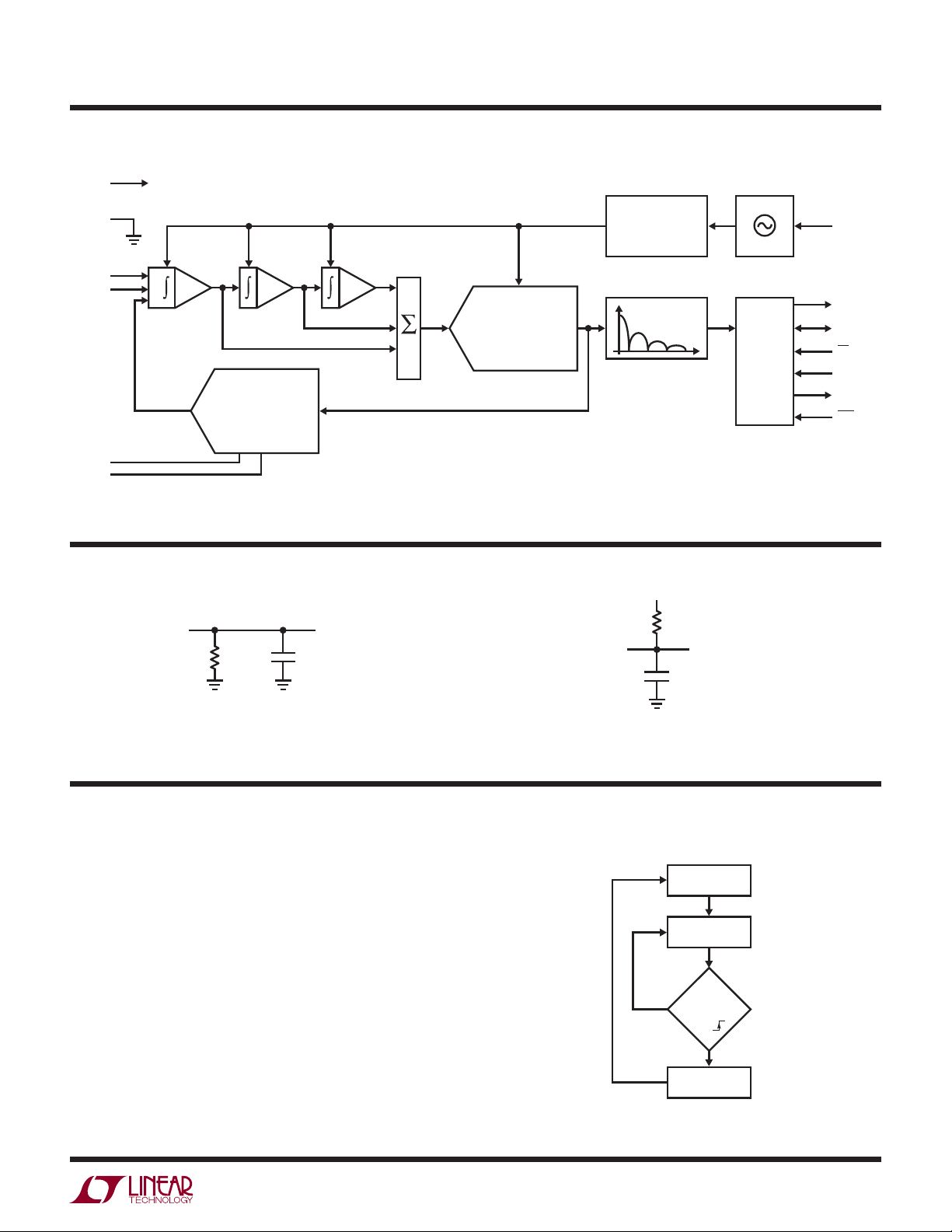

FUNCTIONAL BLOCK DIAGRAM

LTC2440

V

CC

GND

+

REF

REF

IN

–

IN

+

–

+

–

TEST CIRCUITS

SDO

DAC

1.69k

Hi-Z TO V

VOL TO V

VOH TO Hi-Z

–+

OH

OH

C

LOAD

= 20pF

2440 TA03

ADC

Figure 1. Functional Block Diagram

AUTOCALIBRATION

AND CONTROL

DECIMATING FIR

2440 F01

SDO

Hi-Z TO V

VOH TO V

VOL TO Hi-Z

INTERNAL

OSCILLATOR

f

O

(INT/EXT)

SDO

SCK

SERIAL

INTERFACE

V

CC

1.69k

= 20pF

C

LOAD

OL

OL

2440 TA04

CS

SDI

BUSY

EXT

APPLICATIONS INFORMATION

CONVERTER OPERATION

Converter Operation Cycle

The LTC2440 is a high speed, delta-sigma analog-to-digital

converter with an easy to use 4-wire serial interface (see

Figure 1). Its operation is made up of three states. The

converter operating cycle begins with the conversion,

followed by the low power sleep state and ends with the

data output (see Figure 2). The 4-wire interface consists

of serial data input (SDI), serial data output (SDO), serial

clock (SCK) and chip select (CS). The interface, timing,

operation cycle and data out format is compatible with

the LTC2410.

CONVERT

SLEEP

FALSE

CS = LOW

AND

SCK

TRUE

DATA OUTPUT

2440 F02

Figure 2. LTC2440 State Transition Diagram

2440fc

9

LTC2440

APPLICATIONS INFORMATION

Initially, the LTC2440 performs a conversion. Once the

conversion is complete, the device enters the sleep state.

While in this sleep state, power consumption is reduced

below 10μA. The part remains in the sleep state as long

as CS is HIGH. The conversion result is held indefi nitely

in a static shift register while the converter is in the sleep

state.

Once CS is pulled LOW, the device begins outputting the

conversion result. There is no latency in the conversion

result. The data output corresponds to the conversion

just performed. This result is shifted out on the serial data

out pin (SDO) under the control of the serial clock (SCK).

Data is updated on the falling edge of SCK allowing the

user to reliably latch data on the rising edge of SCK (see

Figure 3). The data output state is concluded once 32-bits

are read out of the ADC or when CS is brought HIGH. The

device automatically initiates a new conversion and the

cycle repeats.

Through timing control of the CS, SCK and EXT pins,

the LTC2440 offers several fl exible modes of operation

(internal or external SCK). These various modes do not

require programming confi guration registers; moreover,

they do not disturb the cyclic operation described above.

These modes of operation are described in detail in the

Serial Interface Timing Modes section.

Ease of Use

The LTC2440 data output has no latency, fi lter settling

delay or redundant data associated with the conversion

cycle. There is a one-to-one correspondence between the

conversion and the output data. Therefore, multiplexing

multiple analog voltages is easy. Speed/resolution adjustments may be made seamlessly between two conversions

without settling errors.

The LTC2440 performs offset and full-scale calibrations

every conversion cycle. This calibration is transparent to

the user and has no effect on the cyclic operation described

above. The advantage of continuous calibration is extreme

stability of offset and full-scale readings with respect to

time, supply voltage change and temperature drift.

Power-Up Sequence

The LTC2440 automatically enters an internal reset state

when the power supply voltage V

proximately 2.2V. This feature guarantees the integrity

of the conversion result and of the serial interface mode

selection.

When the V

converter creates an internal power-on-reset (POR) signal

with a duration of approximately 0.5ms. The POR signal

clears all internal registers. Following the POR signal, the

LTC2440 starts a normal conversion cycle and follows the

succession of states described above. The fi rst conversion

result following POR is accurate within the specifi cations

of the device if the power supply voltage is restored within

the operating range (4.5V to 5.5V) before the end of the

POR time interval.

Reference Voltage Range

This converter accepts a truly differential external reference

voltage. The absolute/common mode voltage specifi cation

for the REF

GND to V

must always be more positive than the REF

The LTC2440 can accept a differential reference voltage

from 0.1V to V

by the thermal noise of the front-end circuits, and as such,

its value in microvolts is nearly constant with reference

voltage. A decrease in reference voltage will not signifi cantly improve the converter’s effective resolution. On the

other hand, a reduced reference voltage will improve the

converter’s overall INL performance.

Input Voltage Range

The analog input is truly differential with an absolute/common mode range for the IN

from GND – 0.3V to V

ESD protection devices begin to turn on and the errors

due to input leakage current increase rapidly. Within these

limits, the LTC2440 converts the bipolar differential input

signal, V

voltage rises above this critical threshold, the

CC

+

and REF– pins covers the entire range from

. For correct converter operation, the REF+ pin

CC

. The converter output noise is determined

CC

+

and IN– input pins extending

+ 0.3V. Outside these limits, the

CC

= IN+ – IN–, from –FS = –0.5 • V

IN

drops below ap-

CC

–

pin.

to +FS =

REF

10

2440fc

APPLICATIONS INFORMATION

LTC2440

0.5 • V

where V

REF

= REF+ – REF–. Outside this range,

REF

the converter indicates the overrange or the underrange

condition using distinct output codes.

Output Data Format

The LTC2440 serial output data stream is 32-bits long.

The fi rst 3-bits represent status information indicating

the sign and conversion state. The next 24-bits are the

conversion result, MSB fi rst. The remaining 5-bits are

sub LSBs beyond the 24-bit level that may be included in

averaging or discarded without loss of resolution. In the

case of ultrahigh resolution modes, more than 24 effective bits of performance are possible (see Table 3). Under

these conditions, sub LSBs are included in the conversion

result and represent useful information beyond the 24-bit

level. The third and fourth bit together are also used to

indicate an underrange condition (the differential input

voltage is below –FS) or an overrange condition (the differential input voltage is above +FS). For input conditions

in excess of twice full scale (|V

IN

| ≥ V

), the converter

REF

may indicate either overrange or underrange. Once the

input returns to the normal operating range, the conversion

result is immediately accurate within the specifi cations of

the device.

Bit 31 (fi rst output bit) is the end of conversion (EOC)

indicator. This bit is available at the SDO pin during the

conversion and sleep states whenever the CS pin is LOW.

This bit is HIGH during the conversion and goes LOW

when the conversion is complete.

Bit 30 (second output bit) is a dummy bit (DMY) and is

always LOW.

Bit 29 (third output bit) is the conversion result sign

indicator (SIG). If VIN is >0, this bit is HIGH. If VIN is <0,

this bit is LOW.

Bit 28 (fourth output bit) is the most signifi cant bit (MSB) of

the result. This bit in conjunction with Bit 29 also provides

the underrange or overrange indication. If both Bit 29 and

Bit 28 are HIGH, the differential input voltage is above +FS.

If both Bit 29 and Bit 28 are LOW, the differential input

voltage is below –FS.

The function of these bits is summarized in Table 1.

Table 1. LTC2440 Status Bits

Input Range

≥ 0.5 • V

V

IN

< 0.5 • V

0V ≤ V

IN

–0.5 • V

REF

< –0.5 • V

V

IN

Bit 31

EOC

REF

REF

≤ VIN < 0V 0001

REF

0011

0010

0000

Bit 30

DMY

Bit 29

SIG

Bit 28

MSB

Bits ranging from 28 to 5 are the 24-bit conversion result

MSB fi rst.

Bit 5 is the Least Signifi cant Bit (LSB).

Bits ranging from 4 to 0 are sub LSBs below the 24-bit

level. Bits 4 to bit 0 may be included in averaging or discarded without loss of resolution.

Data is shifted out of the SDO pin under control of the

serial clock (SCK), see Figure 3. Whenever CS is HIGH,

SDO remains high impedance.

In order to shift the conversion result out of the device,

CS must fi rst be driven LOW. EOC is seen at the SDO pin

of the device once CS is pulled LOW. EOC changes real

time from HIGH to LOW at the completion of a conversion.

This signal may be used as an interrupt for an external

CS

BIT 31

SDO

SCK

BUSY

EOC

Hi-Z

1 2 3 4 5 262732

SLEEP DATA OUTPUT CONVERSION

BIT 28BIT 29BIT 30

MSBSIG“0”

Figure 3. Output Data Timing

LSB

BIT 0BIT 27 BIT 5

24

2440 F03

2440fc

11

LTC2440

APPLICATIONS INFORMATION

microcontroller. Bit 31 (EOC) can be captured on the fi rst

rising edge of SCK. Bit 30 is shifted out of the device on

the fi rst falling edge of SCK. The fi nal data bit (Bit 0) is

shifted out on the falling edge of the 31st SCK and may

be latched on the rising edge of the 32nd SCK pulse. On

the falling edge of the 32nd SCK pulse, SDO goes HIGH

indicating the initiation of a new conversion cycle. This

bit serves as EOC (Bit 31) for the next conversion cycle.

Table 2 summarizes the output data format.

+

As long as the voltage on the IN

tained within the –0.3V to (V

and IN– pins is main-

+ 0.3V) absolute maximum

CC

operating range, a conversion result is generated for any

differential input voltage V

+FS = 0.5 • V

. For differential input voltages greater

REF

from –FS = –0.5 • V

IN

REF

to

than +FS, the conversion result is clamped to the value

corresponding to the +FS + 1LSB. For differential input

voltages below –FS, the conversion result is clamped to

the value corresponding to –FS – 1LSB.

SERIAL INTERFACE PINS

The LTC2440 transmits the conversion results and receives

the start of conversion command through a synchronous

2-wire, 3-wire or 4-wire interface. During the conversion

and sleep states, this interface can be used to assess

the converter status and during the data output state it

is used to read the conversion result and program the

speed/resolution.

Serial Clock Input/Output (SCK)

The serial clock signal present on SCK (Pin 13) is used to

synchronize the data transfer. Each bit of data is shifted out

the SDO pin on the falling edge of the serial clock.

In the Internal SCK mode of operation, the SCK pin is an

output and the LTC2440 creates its own serial clock. In

the External SCK mode of operation, the SCK pin is used

as input. The internal or external SCK mode is selected

by tying EXT (Pin 10) LOW for external SCK and HIGH

for internal SCK.

Serial Data Output (SDO)

The serial data output pin, SDO (Pin 12), provides the

result of the last conversion as a serial bit stream (MSB

fi rst) during the data output state. In addition, the SDO

pin is used as an end of conversion indicator during the

conversion and sleep states.

When CS (Pin 11) is HIGH, the SDO driver is switched

to a high impedance state. This allows sharing the serial

interface with other devices. If CS is LOW during the

convert or sleep state, SDO will output EOC. If CS is LOW

during the conversion phase, the EOC bit appears HIGH

on the SDO pin. Once the conversion is complete, EOC

goes LOW. The device remains in the sleep state until the

fi rst rising edge of SCK occurs while CS = LOW.

Table 2. LTC2440 Output Data Format

Differential Input Voltage

VIN*

* ≥ 0.5 • V

V

IN

0.5 • V

REF

0.25 • V

0.25 • V

0 0010000…0

–1LSB 0001111…1

–0.25 • V

–0.25 • V

–0.5 • V

VIN* < –0.5 • V

*The differential input voltage V

** 0011000…0

REF

** – 1LSB 0 0 1 0 1 1 1 … 1

** 0010100…0

REF

** – 1LSB 0 0 1 0 0 1 1 … 1

REF

** 0001100…0

REF

** – 1LSB 0 0 0 1 0 1 1 … 1

REF

** 0001000…0

REF

** 0000111…1

REF

Bit 31

EOC

= IN+ – IN–. **The differential reference voltage V

IN

Bit 30

DMY

Bit 29

SIG

Bit 28

MSB Bit 27 Bit 26 Bit 25 … Bit 0

= REF+ – REF–.

REF

2440fc

12

APPLICATIONS INFORMATION

LTC2440

Chip Select Input (CS)

The active LOW chip select, CS (Pin 11), is used to test the

conversion status and to enable the data output transfer

as described in the previous sections.

In addition, the CS signal can be used to trigger a new conversion cycle before the entire serial data transfer has been

completed. The LTC2440 will abort any serial data transfer

in progress and start a new conversion cycle anytime a

LOW-to-HIGH transition is detected at the CS pin after the

converter has entered the data output state (i.e., after the

fi fth falling edge of SCK occurs with CS = LOW).

Serial Data Input (SDI)—Logic Level Speed Selection

The serial data input (SDI, Pin 7) is used to select the

speed/resolution of the LTC2440. A simple 2-speed control

is selectable by either driving SDI HIGH or LOW. If SDI

is grounded (pin compatible with LTC2410) the device

outputs data at 880Hz with 21 bits effective resolution. By

tying SDI HIGH, the converter enters the ultralow noise

mode (200nV

6.9Hz output rate. SDI may be driven logic HIGH or LOW

anytime during the conversion or sleep state in order to

change the speed/resolution. The conversion immediately

following the data output cycle will be valid and performed

at the newly selected output rate/resolution.

Changing SDI logic state during the data output cycle

should be avoided as speed resolution other than 6.9Hz

or 880Hz may be selected. For example, if SDI is changed

from logic 0 to logic 1 after the second rising edge of SCK,

the conversion rate will change from 880Hz to 55Hz (the

following values are listed in Table 3: OSR4 = 0, OSR3 = 0,

OSR2 = 1, OSR1 = 1 and OSR0 = 1). If SDI remains HIGH,

the conversion rate will switch to the desired 6.9Hz speed

immediately following the conversion at 55Hz. The 55Hz

rate conversion cycle will be a valid result as well as the

fi rst 6.9Hz result. On the other hand, if SDI is changed to a

1 anytime before the fi rst rising edge of SCK, the following

conversion rate will become 6.9Hz. If SDI is changed to

a 1 after the 5th rising edge of SCK, the next conversion

will remain 880Hz while all subsequent conversions will

be at 6.9Hz.

) with simultaneous 50/60Hz rejection at

RMS

Serial Data Input (SDI)—Serial Input Speed Selection

SDI may also be programmed by a serial input data

stream under control of SCK during the data output cycle,

see Figure 4. One of ten speed/resolution ranges (from

6.9Hz/200nV

Table 3. The conversion following a new selection is valid

and performed at the newly selected speed/resolution.

BUSY

The BUSY output (Pin 15) is used to monitor the state of

conversion, data output and sleep cycle. While the part is

converting, the BUSY pin is HIGH. Once the conversion is

complete, BUSY goes LOW indicating the conversion is

complete and data out is ready. The part now enters the

LOW power sleep state. BUSY remains LOW while data is

shifted out of the device. It goes HIGH at the conclusion

of the data output cycle indicating a new conversion has

begun. This rising edge may be used to fl ag the completion of the data read cycle.

SERIAL INTERFACE TIMING MODES

The LTC2440’s 2-wire, 3-wire or 4-wire interface is SPI

and MICROWIRE compatible. This interface offers several

fl exible modes of operation. These include internal/external

serial clock, 2-wire or 3-wire I/O, single cycle conversion

and autostart. The following sections describe each of

these serial interface timing modes in detail. In all these

cases, the converter can use the internal oscillator (f

LOW) or an external oscillator connected to the f

See Table 4 for a summary.

External Serial Clock, Single Cycle Operation

(SPI/MICROWIRE Compatible)

This timing mode uses an external serial clock to shift

out the conversion result and a CS signal to monitor and

control the state of the conversion cycle, see Figure 5.

The serial clock mode is selected by the EXT pin. To select

the external serial clock mode, EXT must be tied low.

The serial data output pin (SDO) is Hi-Z as long as CS is

HIGH. At any time during the conversion cycle, CS may be

pulled LOW in order to monitor the state of the converter.

While CS is pulled LOW, EOC is output to the SDO pin.

to 3.5kHz/21μV

RMS

) may be selected, see

RMS

pin.

O

2440fc

=

O

13

LTC2440

APPLICATIONS INFORMATION

CS

SCK

SDI

Hi-Z

SDO

BUSY

*OSR4 BIT MUST BE AT FIRST SCK RISING EDGE DURING SERIAL DATA OUT CYCLE

OSR4* OSR3 OSR2 OSR1 OSR0

BIT 28 BIT 27 BIT 26 BIT 25 BIT 1 BIT 0

“0”

BIT 29

SIG

MSB

BIT 31

EOC

BIT 30

LSB

Hi-Z

2440 F04

Figure 4. SDI Speed/Resolution Programming

Table 3. SDI Speed/Resolution Programming

CONVERSION RATE

OSR4 OSR3 OSR2 OSR1 OSR0

INTERNAL

9MHz CLOCK

EXTERNAL

10.24MHz CLOCK

X 0 0 0 1 3.52kHz 4kHz 23μV 17 64

X 0 0 1 0 1.76kHz 2kHz 3.5μV 20 128

0 0 0 0 0 880Hz 1kHz 2μV 21.3 256*

X 0 0 1 1 880Hz 1kHz 2μV 21.3 256

X 0 1 0 0 440Hz 500Hz 1.4μV 21.8 512

X 0 1 0 1 220Hz 250Hz 1μV 22.4 1024

X 0 1 1 0 110Hz 125Hz 750nV 22.9 2048

X 0 1 1 1 55Hz 62.5Hz 510nV 23.4 4096

X 1 0 0 0 27.5Hz 31.25Hz 375nV 24 8192

X 1 0 0 1 13.75Hz 15.625Hz 250nV 24.4 16384

X 1 1 1 1 6.875Hz 7.8125Hz 200nV 24.6 32768**

**Address allows tying SDI HIGH *Additional address to allow tying SDI LOW

RMS

NOISE ENOB OSR

Table 4. LTC2440 Interface Timing Modes

Confi guration

SCK

Source

Conversion

Cycle

Control

Data

Output

Control

Connection

and

Waveforms

External SCK, Single Cycle Conversion External CS and SCK CS and SCK Figures 5, 6

External SCK, 2-Wire I/O External SCK SCK Figure 7

Internal SCK, Single Cycle Conversion Internal CS CS Figures 8, 9

↑

↑

Internal SCK, 2-Wire I/O, Continuous Conversion Internal Continuous Internal Figure 10

14

2440fc

APPLICATIONS INFORMATION

REFERENCE VOLTAGE

0.1V TO V

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

CS

4.5V TO 5.5V

1μF

CC

REF

1, 8, 9, 16

LTC2440

2

V

CC

LTC2440

3

+

REF

4

–

REF

5

+

IN

6

–

IN

GND

BUSY

SCK

SDO

SDI

EXT

15

14

f

O

13

12

11

CS

7

10

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

V

CC

200nV NOISE, 50/60Hz REJECTION

10-SPEED/RESOLUTION PROGRAMMABLE

2μV NOISE, 880Hz OUTPUT RATE

SDO

SCK

(EXTERNAL)

BUSY

CONVERSION

TEST EOCTEST EOC

SLEEP DATA OUTPUT CONVERSION

BIT 31

EOC

Figure 5. External Serial Clock, Single Cycle Operation

EOC = 1 (BUSY = 1) while a conversion is in progress

and EOC = 0 (BUSY = 0) if the device is in the sleep state.

Independent of CS, the device automatically enters the low

power sleep state once the conversion is complete.

When the device is in the sleep state (EOC = 0), its conversion result is held in an internal static shift register.

The device remains in the sleep state until the fi rst rising

edge of SCK is seen. Data is shifted out the SDO pin on

each falling edge of SCK. This enables external circuitry

to latch the output on the rising edge of SCK. EOC can be

latched on the fi rst rising edge of SCK and the last bit of

the conversion result can be latched on the 32nd rising

edge of SCK. On the 32nd falling edge of SCK, the device

begins a new conversion. SDO goes HIGH (EOC = 1) and

BUSY goes HIGH indicating a conversion is in progress.

At the conclusion of the data cycle, CS may remain LOW

and EOC monitored as an end-of-conversion interrupt.

Alternatively, CS may be driven HIGH setting SDO to Hi-Z

and BUSY monitored for the completion of a conversion.

As described above, CS may be pulled LOW at any time in

order to monitor the conversion status on the SDO pin.

BIT 5BIT 27 BIT 26BIT 28BIT 29BIT 30

LSB

BIT 0

SUB LSBMSBSIG

TEST EOC

Hi-ZHi-ZHi-Z

2440 F05

Typically, CS remains LOW during the data output state.

However, the data output state may be aborted by pulling

CS HIGH anytime between the fi fth falling edge (SDI must

be properly loaded each cycle) and the 32nd falling edge

of SCK, see Figure 6. On the rising edge of CS, the device

aborts the data output state and immediately initiates a

new conversion. This is useful for systems not requiring

all 32-bits of output data, aborting an invalid conversion

cycle or synchronizing the start of a conversion.

External Serial Clock, 2-Wire I/O

This timing mode utilizes a 2-wire serial I/O interface.

The conversion result is shifted out of the device by an

externally generated serial clock (SCK) signal, see Figure

7. CS may be permanently tied to ground, simplifying the

user interface or isolation barrier. The external serial clock

mode is selected by tying EXT LOW.

Since CS is tied LOW, the end-of-conversion (EOC) can

be continuously monitored at the SDO pin during the

convert and sleep states. Conversely, BUSY (Pin 15) may

be used to monitor the status of the conversion cycle.

EOC or BUSY may be used as an interrupt to an external

2440fc

15

LTC2440

APPLICATIONS INFORMATION

REFERENCE VOLTAGE

0.1V TO V

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

CS

4.5V TO 5.5V

1μF

CC

REF

1, 8, 9, 16

2

V

CC

LTC2440

3

+

REF

4

–

REF

5

+

IN

6

–

IN

GND

BUSY

SCK

SDO

EXT

CS

SDI

15

14

f

O

13

12

11

7

10

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

V

CC

200nV NOISE, 50/60Hz REJECTION

10-SPEED/RESOLUTION PROGRAMMABLE

2μV NOISE, 880Hz OUTPUT RATE

(EXTERNAL)

CS

SDO

SCK

BUSY

TEST EOC TEST EOC

EOC

15

CONVERSIONSLEEP SLEEP

DATA OUTPUT

BIT 31BIT 0

Hi-Z

EOC

Hi-Z Hi-ZHi-Z

MSBSIG

DATA OUTPUT

Figure 6. External Serial Clock, Reduced Data Output Length

4.5V TO 5.5V

1μF

REFERENCE VOLTAGE

0.1V TO V

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

REF

CC

1, 8, 9, 16

2

V

CC

LTC2440

3

+

REF

4

–

REF

5

+

IN

6

–

IN

GND

BUSY

SCK

SDO

SDI

EXT

15

14

f

O

13

12

11

CS

7

10

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

V

CC

200nV NOISE, 50/60Hz REJECTION

10-SPEED/RESOLUTION PROGRAMMABLE

2μV NOISE, 880Hz OUTPUT RATE

BIT 8BIT 27 BIT 9BIT 28BIT 29BIT 30

TEST EOC

CONVERSION

2410 F06

SDO

SCK

(EXTERNAL)

BUSY

16

CONVERSION

BIT 31

EOC

SLEEP DATA OUTPUT CONVERSION

MSBSIG

LSB

BIT 5BIT 27 BIT 26BIT 28BIT 29BIT 30

24

BIT 0

Figure 7. External Serial Clock, CS = 0 Operation (2-Wire)

2440 F07

2440fc

APPLICATIONS INFORMATION

LTC2440

controller indicating the conversion result is ready. EOC

= 1 (BUSY = 1) while the conversion is in progress and

EOC = 0 (BUSY = 0) once the conversion enters the low

power sleep state. On the falling edge of EOC/BUSY, the

conversion result is loaded into an internal static shift

register. The device remains in the sleep state until the

fi rst rising edge of SCK. Data is shifted out the SDO pin

on each falling edge of SCK enabling external circuitry to

latch data on the rising edge of SCK. EOC can be latched

on the fi rst rising edge of SCK. On the 32nd falling edge

of SCK, SDO and BUSY go HIGH (EOC = 1) indicating a

new conversion has begun.

Internal Serial Clock, Single Cycle Operation

This timing mode uses an internal serial clock to shift out

the conversion result and a CS signal to monitor and control

the state of the conversion cycle, see Figure 8.

In order to select the internal serial clock timing mode,

the EXT pin must be tied HIGH.

The serial data output pin (SDO) is Hi-Z as long as CS is

HIGH. At any time during the conversion cycle, CS may be

pulled LOW in order to monitor the state of the converter.

Once CS is pulled LOW, SCK goes LOW and EOC is output

to the SDO pin. EOC = 1 while a conversion is in progress

and EOC = 0 if the device is in the sleep state. Alternatively, BUSY (Pin 15) may be used to monitor the status

of the conversion in progress. BUSY is HIGH during the

conversion and goes LOW at the conclusion. It remains

LOW until the result is read from the device.

When testing EOC, if the conversion is complete (EOC =

0), the device will exit the sleep state and enter the data

output state if CS remains LOW. In order to prevent the

device from exiting the low power sleep state, CS must

be pulled HIGH before the fi rst rising edge of SCK. In the

internal SCK timing mode, SCK goes HIGH and the device

begins outputting data at time t

of CS (if EOC = 0) or t

after EOC goes LOW (if CS is

EOCtest

LOW during the falling edge of EOC). The value of t

is 500ns. If CS is pulled HIGH before time tE

after the falling edge

EOCtest

OCtest

EOCtest

, the

device remains in the sleep state. The conversion result

is held in the internal static shift register.

If CS remains LOW longer than t

, the fi rst rising

EOCtest

edge of SCK will occur and the conversion result is serially

shifted out of the SDO pin. The data output cycle begins

SDO

SCK

(INTERNAL)

BUSY

4.5V TO 5.5V

1μF

2

V

CC

LTC2440

3

+

REFERENCE VOLTAGE

0.1V TO V

ANALOG INPUT RANGE

–0.5V

TO 0.5V

REF

REF

<t

EOCtest

CS

TEST EOC

Hi-Z Hi-Z Hi-Z Hi-Z

BIT 31

EOC

SLEEP DATA OUTPUT CONVERSIONCONVERSION

CC

1, 8, 9, 16

MSBSIG

REF

4

–

REF

5

+

IN

6

–

IN

GND

15

BUSY

14

f

O

13

SCK

12

SDO

11

CS

7

SDI

10

EXT

BIT 27 BIT 26BIT 28BIT 29BIT 30

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

V

CC

V

CC

200nV NOISE, 50/60Hz REJECTION

10-SPEED/RESOLUTION PROGRAMMABLE

2μV NOISE, 880Hz OUTPUT RATE

BIT 5

LSB

24

BIT 0

TEST EOC

2440 F08

Figure 8. Internal Serial Clock, Single Cycle Operation

2440fc

17

LTC2440

APPLICATIONS INFORMATION

on this fi rst rising edge of SCK and concludes after the

32nd rising edge. Data is shifted out the SDO pin on each

falling edge of SCK. The internally generated serial clock

is output to the SCK pin. This signal may be used to shift

the conversion result into external circuitry. EOC can be

latched on the fi rst rising edge of SCK and the last bit of

the conversion result on the 32nd rising edge of SCK.

After the 32nd rising edge, SDO goes HIGH (EOC = 1),

SCK stays HIGH and a new conversion starts.

Typically, CS remains LOW during the data output state.

However, the data output state may be aborted by pulling CS HIGH anytime between the fi rst and 32nd rising

edge of SCK, see Figure 9. In order to properly select the

OSR for the conversion following a data abort, fi ve SCK

rising edges must be seen prior to performing a data out

abort (pulling CS HIGH). If CS is pulled high prior to the

fi fth SCK falling edge, the OSR selected depends on the

number of SCK signals seen prior to data abort, where

subsequent nonaborted conversion cycles return to the

programmed OSR. On the rising edge of CS, the device

aborts the data output state and immediately initiates a

new conversion. This is useful for systems not requiring

all 32-bits of output data, aborting an invalid conversion

cycle, or synchronizing the start of a conversion.

Internal Serial Clock, 2-Wire I/O,

Continuous Conversion

This timing mode uses a 2-wire, all output (SCK and SDO)

interface. The conversion result is shifted out of the device

by an internally generated serial clock (SCK) signal, see

Figure 10. CS may be permanently tied to ground, simplifying the user interface or isolation barrier. The internal

serial clock mode is selected by tying EXT HIGH.

During the conversion, the SCK and the serial data output

pin (SDO) are HIGH (EOC = 1) and BUSY = 1. Once the

conversion is complete, SCK, BUSY and SDO go LOW (EOC

= 0) indicating the conversion has fi nished and the device

has entered the low power sleep state. The part remains in

the sleep state a minimum amount of time (≈500ns) then

immediately begins outputting data. The data output cycle

begins on the fi rst rising edge of SCK and ends after the

32nd rising edge. Data is shifted out the SDO pin on each

SDO

SCK

(INTERNAL)

BUSY

>t

EOCtest

CS

Hi-Z Hi-Z

BIT 0

EOC

4.5V TO 5.5V

1μF

2

V

CC

LTC2440

3

+

1, 8, 9, 16

REF

4

–

REF

5

+

IN

6

–

IN

GND

REFERENCE VOLTAGE

0.1V TO V

CC

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

REF

<t

EOCtest

TEST EOCTEST EOC

Hi-Z Hi-Z Hi-Z

51

DATA OUTPUT

BIT 31

EOC

SLEEP DATA OUTPUT

BUSY

SCK

SDO

SDI

EXT

15

14

f

O

13

12

11

CS

7

10

MSBSIG

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

V

CC

200nV NOISE, 50/60Hz REJECTION

10-SPEED/RESOLUTION PROGRAMMABLE

2μV NOISE, 880Hz OUTPUT RATE

V

CC

BIT 27 BIT 26BIT 28BIT 29BIT 30

BIT 8

CONVERSIONCONVERSIONSLEEP

TEST EOC

2440 F09

18

Figure 9. Internal Serial Clock, Reduced Data Output Length

2440fc

APPLICATIONS INFORMATION

REFERENCE VOLTAGE

0.1V TO V

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

CS

SDO

SCK

(INTERNAL)

BUSY

BIT 31

EOC

4.5V TO 5.5V

1μF

CC

REF

1, 8, 9, 16

MSBSIG

LTC2440

2

V

CC

LTC2440

3

+

REF

4

–

REF

5

+

IN

6

–

IN

GND

BUSY

SCK

SDO

SDI

EXT

15

14

f

O

13

12

11

CS

7

10

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

2-WIRE

SPI INTERFACE

V

CC

200nV NOISE, 50/60Hz REJECTION

10-SPEED/RESOLUTION PROGRAMMABLE

2μV NOISE, 880Hz OUTPUT RATE

V

CC

BIT 5 BIT 0BIT 27 BIT 26BIT 28BIT 29BIT 30

LSB

24

SLEEP

Figure 10. Internal Serial Clock, Continuous Operation

falling edge of SCK. The internally generated serial clock

is output to the SCK pin. This signal may be used to shift

the conversion result into external circuitry. EOC can be

latched on the fi rst rising edge of SCK and the last bit of

the conversion result can be latched on the 32nd rising

edge of SCK. After the 32nd rising edge, SDO goes HIGH

(EOC = 1) indicating a new conversion is in progress. SCK

remains HIGH during the conversion.

Normal Mode Rejection and Antialiasing

One of the advantages delta-sigma ADCs offer over

conventional ADCs is on-chip digital fi ltering. Combined

with a large oversampling ratio, the LTC2440 signifi cantly

simplifi es antialiasing fi lter requirements.

DATA OUTPUT CONVERSIONCONVERSION

rejection at the frequency f

±14% is better than 80dB,

N

2410 F10

see Figure 12.

is grounded, fS is set by the on-chip oscillator at

If f

O

1.8MHz ±5% (over supply and temperature variations). At

an OSR of 32,768, the fi rst NULL is at f

no latency output rate is f

0

–20

–40

–60

–80

/8 = 6.9Hz. At the maximum

N

= 55Hz and the

N

The LTC2440’s speed/resolution is determined by the

over sample ratio (OSR) of the on-chip digital fi lter. The

OSR ranges from 64 for 3.5kHz output rate to 32,768

for 6.9Hz output rate. The value of OSR and the sample

determine the fi lter characteristics of the device.

rate f

S

The fi rst NULL of the digital fi lter is at f

where fN = fS/OSR, see Figure 11 and Table 5. The

of f

N

and multiples

N

–100

NORMAL MODE REJECTION (dB)

–120

–140

60 120 240

0

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

180

2440 F11

Figure 11. LTC2440 Normal Mode Rejection (Internal Oscillator)

2440fc

19

LTC2440

APPLICATIONS INFORMATION

Table 5. OSR vs Notch Frequency (fN) with Internal Oscillator

Running at 9MHz

OSR NOTCH (fN)

64 28.16kHz

128 14.08kHz

256 7.04kHz

512 3.52kHz

1024 1.76kHz

2048 880Hz

4096 440Hz

8192 220Hz

16384 110Hz

32768* 55Hz

*Simultaneous 50/60 rejection

–80

–90

–100

–110

–120

NORMAL MODE REJECTION (dB)

–130

OSR, the noise performance of the device is 200nV

RMS

with

better than 80dB rejection of 50Hz ±2% and 60Hz ±2%.

Since the OSR is large (32,768) the wide band rejection

is extremely large and the antialiasing requirements are

simple. The fi rst multiple of f

occurs at 55Hz • 32,768 =

S

1.8MHz, see Figure 13.

The fi rst NULL becomes f

(an output rate of 880Hz) and f

= 7.04kHz with an OSR of 256

N

grounded. While the NULL

O

has shifted, the sample rate remains constant. As a result

of constant modulator sampling rate, the linearity, offset

and full-scale performance remains unchanged as does

the fi rst multiple of f

0

–20

–40

–60

–80

–100

NORMAL MODE REJECTION (dB)

–120

.

S

REJECTION > 120dB

1.8MHz

–140

47

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

51 55

49 53

57

59

61

63

2440 F12

–140

0

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

1000000 2000000

1440 F13

Figure 12. LTC2440 Normal Mode Rejection (Internal Oscillator) Figure 13. LTC2440 Normal Mode Rejection (Internal Oscillator)

2440fc

20

APPLICATIONS INFORMATION

LTC2440

The sample rate fS and NULL fN, my also be adjusted by

driving the f

rate is f

clock applied to f

sample rate leads to notch frequencies f

pin with an external oscillator. The sample

O

S

= f

/5, where f

EOSC

. Combining a large OSR with a reduced

O

is the frequency of the

EOSC

near DC while

N

maintaining simple antialiasing requirements. A 100kHz

clock applied to f

results in a NULL at 0.6Hz plus all

O

harmonics up to 20kHz, see Figure 14. This is useful in

applications requiring digitalization of the DC component

of a noisy input signal and eliminates the need of placing

a 0.6Hz fi lter in front of the ADC.

An external oscillator operating from 100kHz to 20MHz can

be implemented using the LTC1799 (resistor set SOT-23

oscillator), see Figure 22. By fl oating pin 4 (DIV) of the

LTC1799, the output oscillator frequency is:

f MHz

=

OSC

10

⎛

⎜

⎝

10••

10

R

k

SET

⎞

⎟

⎠

The normal mode rejection characteristic shown in Figure 14 is achieved by applying the output of the LTC1799

(with R

= 100k) to the fO pin on the LTC2440 with SDI

SET

tied HIGH (OSR = 32768).

Reduced Power Operation

In addition to adjusting the speed/resolution of the

LTC2440, the speed/resolution/power dissipation may

also be adjusted using the automatic sleep mode. During

the conversion cycle, the LTC2440 draws 8mA supply

current independent of the programmed speed. Once the

conversion cycle is completed, the device automatically

enters a low power sleep state drawing 8μA. The device

remains in this state as long as CS is HIGH and data is not

shifted out. By adjusting the duration of the sleep state

(hold CS HIGH longer) and the duration of the conversion

cycle (programming OSR) the DC power dissipation can

be reduced, see Figure 16.

For example, if the OSR is programmed at the fastest rate

(OSR = 64, t

= 0.285ms) and the sleep state is 10ms,

CONV

the effective output rate is approximately 100Hz while the

average supply current is reduced to 240μA. By further

extending the sleep state to 100ms, the effective output

rate of 10Hz draws on average 30μA. Noise, power, and

speed can be optimized by adjusting the OSR (Noise/Speed)

and sleep mode duration (Power).

0

–20

–40

–60

–80

–100

NORMAL MODE REJECTION (dB)

–120

–140

Figure 14. LTC2440 Normal Mode Rejection

(External Oscillator at 90kHz)

246 10

0

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

8

2440 F14

2440fc

21

LTC2440

APPLICATIONS INFORMATION

CONVERTER

STATE

CS

SUPPLY

CURRENT

SLEEP CONVERT SLEEP CONVERT SLEEP

DATA

OUT

Figure 15. Reduced Power Timing Mode

LTC2440 Input Structure

Modern delta sigma converters have switched capacitor

front ends that repeatedly sample the input voltage over

some time period. The sampling process produces a small

current pulse at the input and reference terminals as the

capacitors are charged. The LTC2440 switches the input

and reference to a 5pF sample capacitor at a frequency

of 1.8MHz. A simplifi ed equivalent circuit is shown in

Figure 16.

The average input and reference currents can be expressed

in terms of the equivalent input resistance of the sample

capacitor, where:

DATA

OUT

8μA8μA8mA8μA

When using the internal oscillator, f

is 1.8MHz and the

SW

8mA

2440 F15

equivalent resistance is approximately 110kΩ.

Driving the Input and Reference

Because of the small current pulses, excessive lead length

at the analog or reference input may allow refl ections or

ringing to occur, affecting the conversion accuracy. The