Linear Technology LTC2410 Datasheet

LTC2410

Final Electrical Specifications

FEATURES

■

Differential Input and Differential Reference with

GND to VCC Common Mode Range

■

2ppm INL, No Missing Codes

■

2.5ppm Full-Scale Error

■

0.1ppm Offset

■

0.16ppm Noise

■

Single Conversion Settling Time for Multiplexed

Applications

■

Internal Oscillator—No External Components

Required

■

110dB Min, 50Hz/60Hz Notch Filter

■

24-Bit ADC in Narrow SSOP-16 Package

(SO-8 Footprint)

■

Single Supply 2.7V to 5.5V Operation

■

Low Supply Current (200µA) and Auto Shutdown

■

Fully Differential Version of LTC2400

U

APPLICATIO S

■

Direct Sensor Digitizer

■

Weight Scales

■

Direct Temperature Measurement

■

Gas Analyzers

■

Strain-Gage Transducers

■

Instrumentation

■

Data Acquisition

■

Industrial Process Control

■

6-Digit DVMs

24-Bit No Latency ∆Σ

ADC

with Differential Input and

Differential Reference

U

TM

DESCRIPTIO

The LTC®2410 is a 2.7V to 5.5V micropower 24-bit

differential ∆Σ analog to digital converter with an inte-

grated oscillator, 2ppm INL and 0.16ppm RMS noise. It

uses delta-sigma technology and provides single cycle

settling time for multiplexed applications. Through a

single pin, the LTC2410 can be configured for better than

110dB input differential mode rejection at 50Hz or 60Hz

±2%, or it can be driven by an external oscillator for a user

defined rejection frequency. The internal oscillator requires no external frequency setting components.

The converter accepts any external differential reference

voltage from 0.1V to VCC for flexible ratiometric and

remote sensing measurement configurations. The fullscale differential input range is from –0.5V

The reference common mode voltage, V

input common mode voltage, V

dently set anywhere within the GND to VCC range of the

LTC2410. The DC common mode input rejection is better

than 140dB.

The LTC2410 communicates through a flexible 3-wire

digital interface which is compatible with SPI and

MICROWIRETM protocols.

, LTC and LT are registered trademarks of Linear Technology Corporation.

No Latency ∆Σ is a trademark of Linear Technology Corporation.

MICROWIRE is a trademark of National Semiconductor Corporation.

INCM

April 2000

to 0.5V

REF

REFCM

REF

, and the

, may be indepen-

.

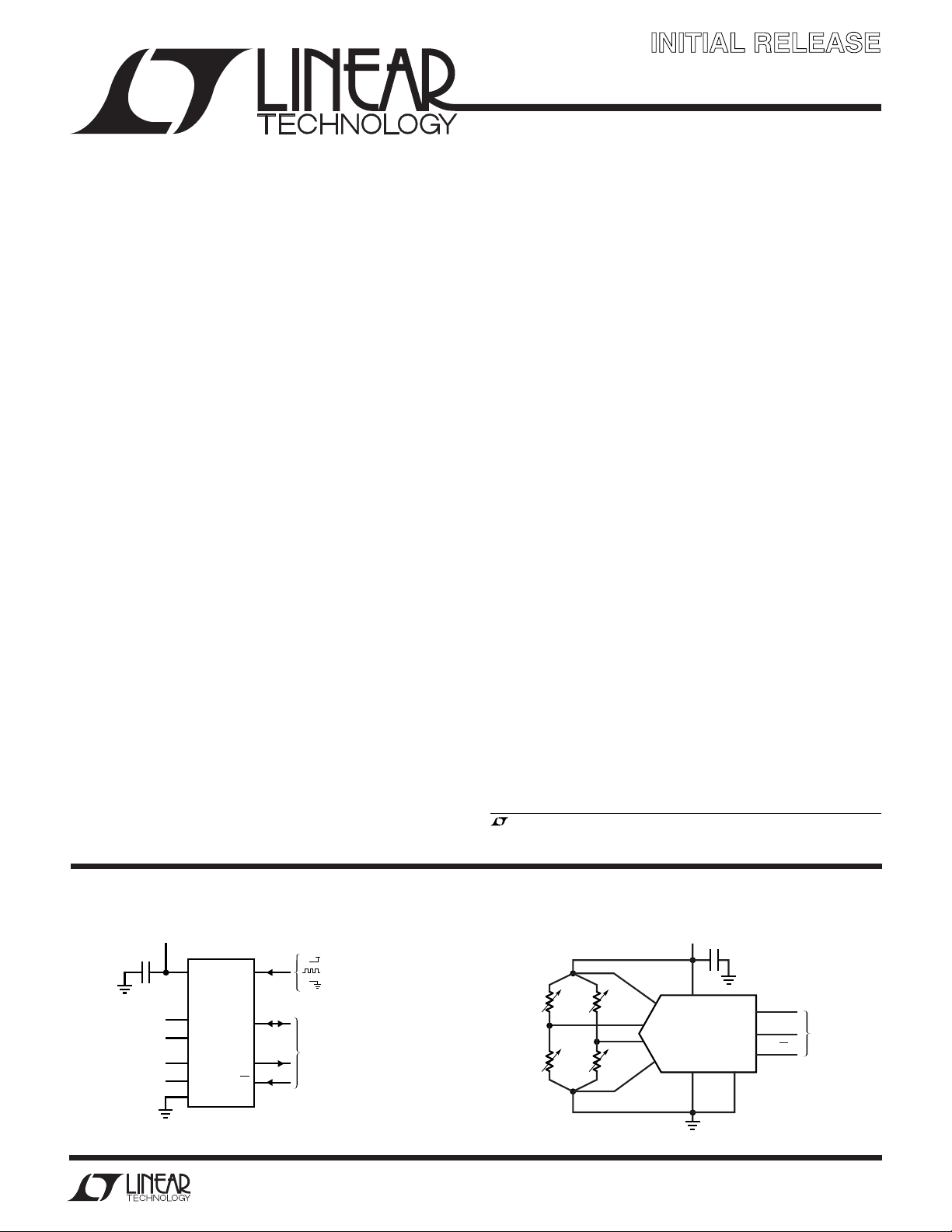

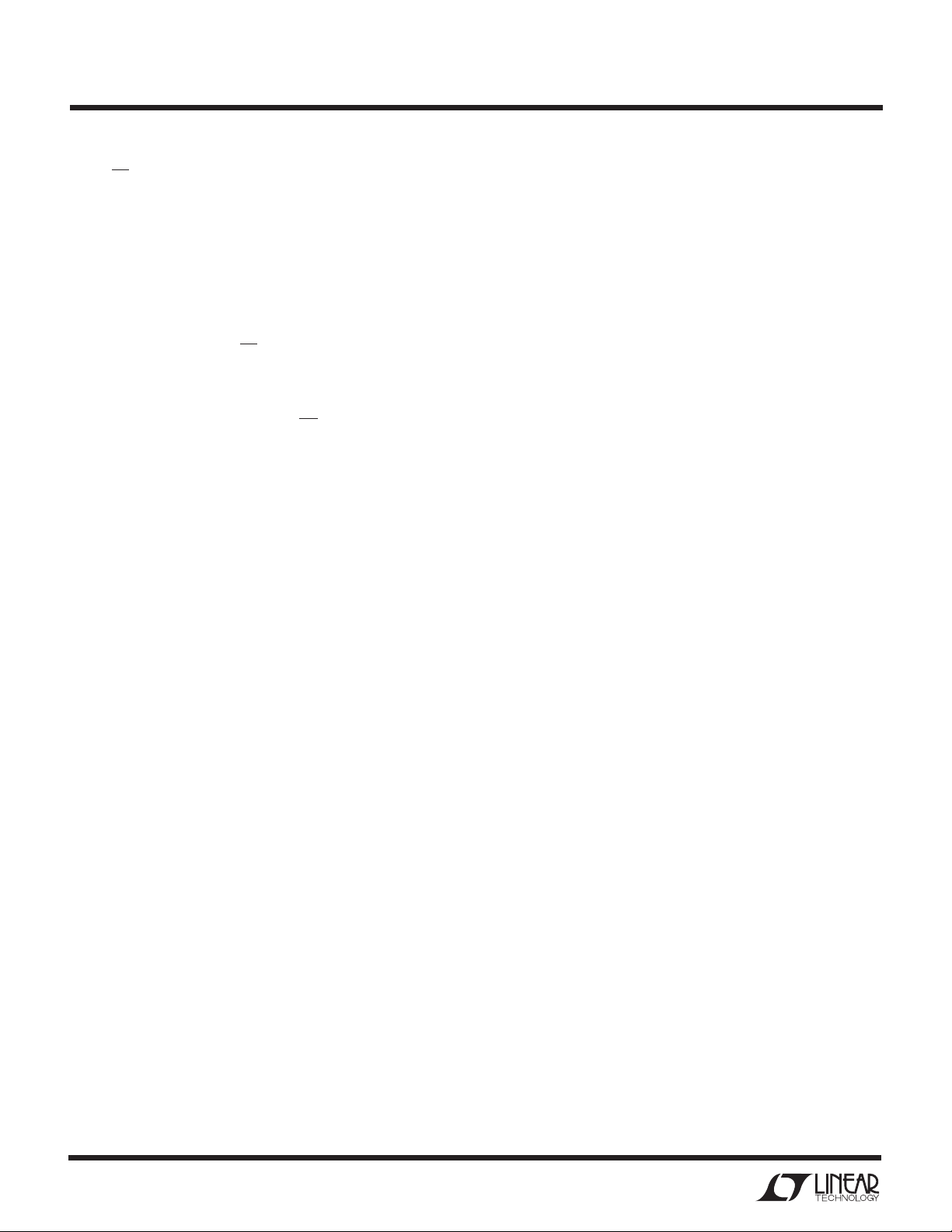

TYPICAL APPLICATIO S

2.7V TO 5.5V

1µF

214

V

CC

LTC2410

3

REFERENCE

VOLTAGE

0.1V TO V

CC

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

REF

1, 7, 8, 9, 10, 15, 16

+

REF

REF

IN

IN

GND

SCK

–

+

SDO

–

4

5

6

U

V

CC

= INTERNAL OSC/50Hz REJECTION

F

O

13

12

11

CS

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

= EXTERNAL CLOCK SOURCE

= INTERNAL OSC/60Hz REJECTION

3-WIRE

SPI INTERFACE

2410 TA01

BRIDGE

IMPEDANCE

100Ω TO10k

V

CC

1µF

2

3

REF+V

IN

IN

+

–

REF

CC

LTC2410

–

GND F

1, 7, 8

9, 10,

15, 16

5

6

4

12

SDO

3-WIRE

SCK

13

11

O

14

2410 TA02

CS

SPI INTERFACE

1

LTC2410

WW

W

ABSOLUTE AXI U RATI GS

U

UUW

PACKAGE/ORDER I FOR ATIO

(Notes 1, 2)

Supply Voltage (VCC) to GND.......................– 0.3V to 7V

Analog Input Pins Voltage

to GND.................................... –0.3V to (VCC + 0.3V)

Reference Input Pins Voltage

to GND.................................... –0.3V to (VCC + 0.3V)

Digital Input Voltage to GND........ –0.3V to (VCC + 0.3V)

Digital Output Voltage to GND ..... –0.3V to (VCC + 0.3V)

Operating Temperature Range

GND

REF

REF

GND

GND

V

CC

IN

IN

LTC2410C ............................................... 0°C to 70°C

LTC2410I............................................ –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

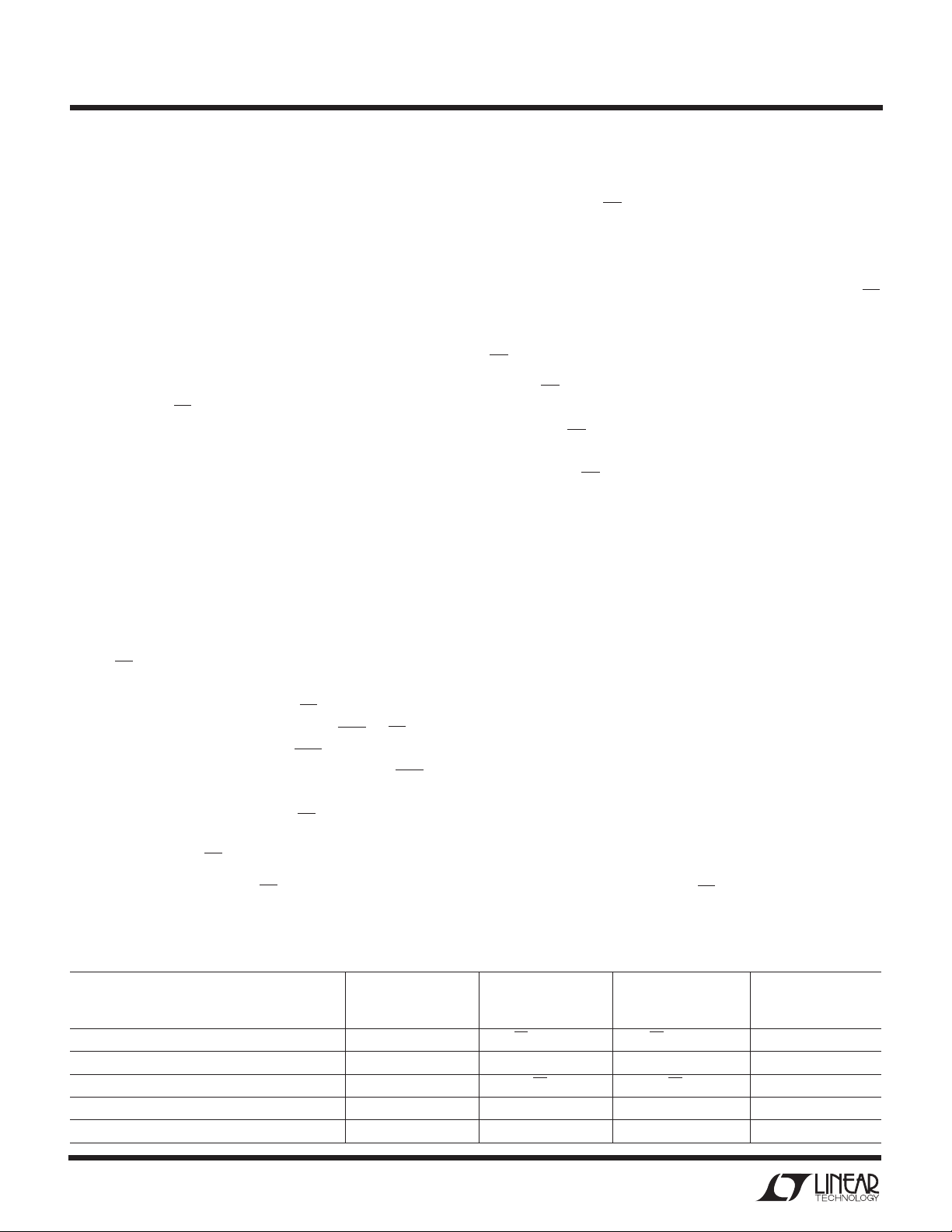

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) 0.1V ≤ V

Integral Nonlinearity REF+ = 2.5V, REF– = GND, V

5V ≤ VCC ≤ 5.5V, REF+ = 5V, REF– = GND, V

Offset Error 2.5V ≤ REF+ ≤ VCC, REF– = GND, ● 0.5 2.5 µV

GND ≤ IN

Offset Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, 10 nV/°C

GND ≤ IN

Positive Full-Scale Error 2.5V ≤ REF+ ≤ VCC, REF– = GND, ● 2.5 12 ppm of V

IN+ = 0.75REF+, IN– = 0.25 • REF

Positive Full-Scale Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, 0.04 ppm of V

Negative Full-Scale Error 2.5V ≤ REF+ ≤ VCC, REF– = GND, ● 2.5 12 ppm of V

Negative Full-Scale Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, 0.04 ppm of V

Total Unadjusted Error REF+ = 2.5V, REF– = GND, V

Output Noise 5V ≤ VCC ≤ 5.5V, REF+ = 5V, V

+

IN

IN+ = 0.25 • REF+, IN– = 0.75 • REF

+

IN

5V ≤ VCC ≤ 5.5V, REF+ = 5V, REF– = GND, V

GND ≤ IN– = IN+ ≤ 5V, (Note 13)

≤ VCC, –0.5 • V

REF

+

= IN– ≤ VCC, (Note 14)

+

= IN– ≤ V

= 0.75REF+, IN– = 0.25 • REF

= 0.25 • REF+, IN– = 0.75 • REF

The ● denotes specifications which apply over the full operating

= 25°C. (Notes 3, 4)

A

≤ VIN ≤ 0.5 • V

REF

= 1.25V, (Note 6) ● 1 ppm of V

INCM

CC

= 1.25V 5 ppm of V

INCM

REF

Consult factory for Military grade parts.

REF

= 2.5V, (Note 6) ● 2 14 ppm of V

INCM

+

+

+

+

= 2.5V 10 ppm of V

INCM

– = GND, 0.8 µV

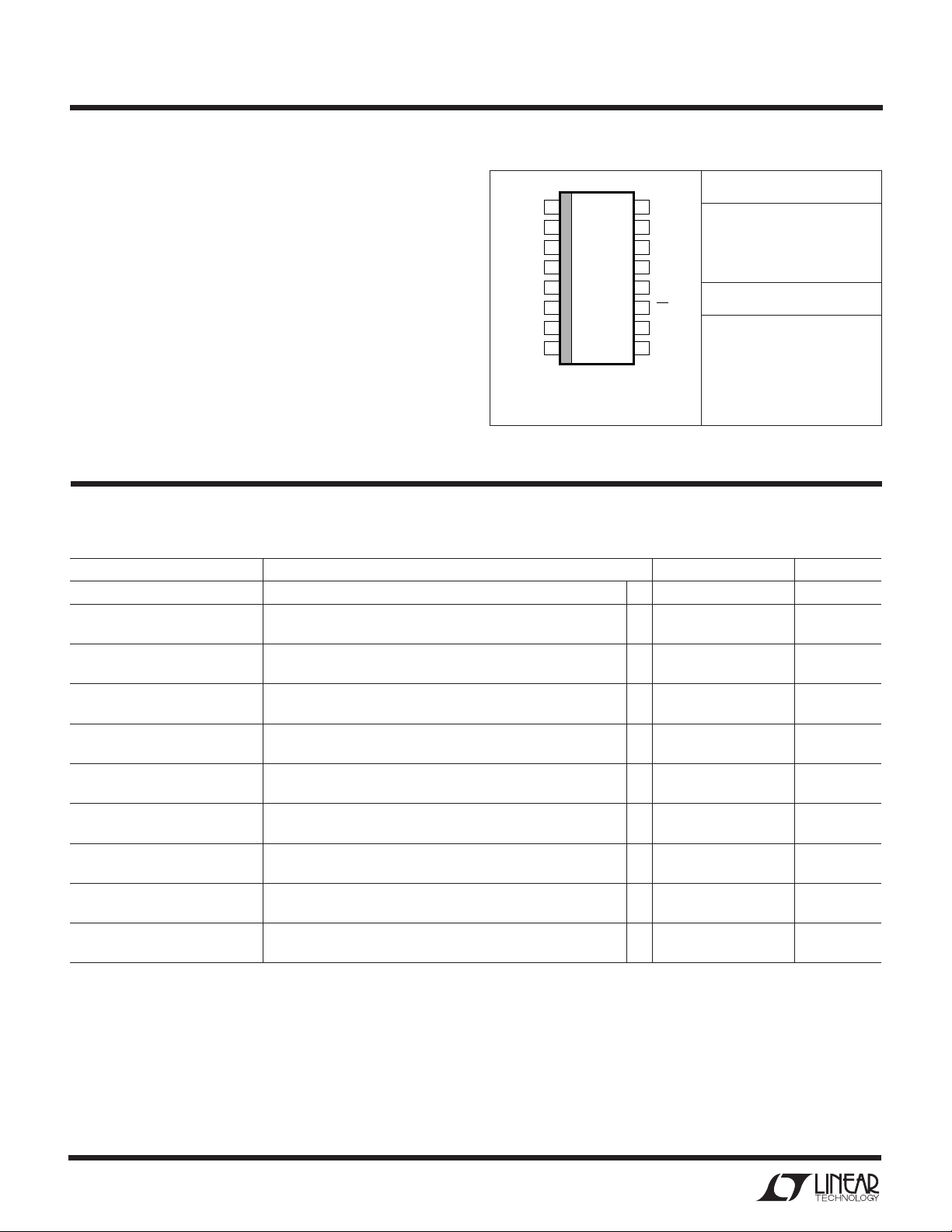

TOP VIEW

1

2

+

3

–

4

+

5

–

6

7

8

GN PACKAGE

16-LEAD PLASTIC SSOP

T

= 125°C, θJA = 95°C/W

JMAX

, (Note 5) ● 24 Bits

16

GND

15

GND

14

F

O

13

SCK

12

SDO

11

CS

10

GND

9

GND

ORDER PART NUMBER

LTC2410CGN

LTC2410IGN

GN PART MARKING

2410

2410I

REF

REF

REF

/°C

REF

REF

/°C

REF

REF

REF

RMS

2

LTC2410

U

CO VERTER CHARACTERISTICS

temperature range, otherwise specifications are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Common Mode Rejection DC 2.5V ≤ REF+ ≤ VCC, REF– = GND, ● 130 140 dB

GND ≤ IN

Input Common Mode Rejection 2.5V ≤ REF+ ≤ VCC, REF– = GND, ● 140 dB

60Hz ±2% GND ≤ IN

Input Common Mode Rejection 2.5V ≤ REF+ ≤ VCC, REF– = GND, ● 140 dB

50Hz ±2% GND ≤ IN

Input Normal Mode Rejection (Note 7) ● 110 140 dB

60Hz ±2%

Input Normal Mode Rejection (Note 8) ● 110 140 dB

50Hz ±2%

Reference Common Mode 2.5V ≤ REF+ ≤ VCC, GND ≤ REF– ≤ 2.5V, ● 130 140 dB

Rejection DC V

Power Supply Rejection, DC REF+ = 2.5V, REF– = GND, IN– = IN+ = GND 100 dB

Power Supply Rejection, 60Hz ±2% REF+ = 2.5V, REF– = GND, IN– = IN+ = GND, (Note 7) 110 dB

Power Supply Rejection, 50Hz ±2% REF+ = 2.5V, REF– = GND, IN– = IN+ = GND, (Note 8) 110 dB

–

= IN+ ≤ 5V

–

= IN+ ≤ 5V, (Note 7)

–

= IN+ ≤ 5V, (Note 8)

= 2.5V, IN– = IN+ = GND

REF

The ● denotes specifications which apply over the full operating

= 25°C. (Notes 3, 4)

A

UUU

A ALOG I PUT AUD REFERE CE

temperature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

IN

–

IN

V

IN

+

REF

–

REF

V

REF

CS (IN+)IN

CS (IN–)IN

CS (REF+)REF

CS (REF–)REF

I

I

I

I

(IN+)IN+ DC Leakage Current CS = VCC, IN+ = GND ● –10 1 10 nA

DC_LEAK

(IN–)IN– DC Leakage Current CS = VCC, IN– = GND ● –10 1 10 nA

DC_LEAK

(REF+)REF+ DC Leakage Current CS = VCC, REF+ = 5V ● –10 1 10 nA

DC_LEAK

(REF–)REF– DC Leakage Current CS = VCC, REF– = GND ● –10 1 10 nA

DC_LEAK

Absolute/Common Mode IN+ Voltage ● GND – 0.3V VCC + 0.3V V

Absolute/Common Mode IN– Voltage ● GND – 0.3V VCC + 0.3V V

Input Differential Voltage Range ● –V

+

(IN

– IN–)

Absolute/Common Mode REF+ Voltage ● 0.1 V

Absolute/Common Mode REF– Voltage ● GND VCC – 0.1V V

Reference Differential Voltage Range ● 0.1 V

+

– REF–)

(REF

+

Sampling Capacitance 18 pF

–

Sampling Capacitance 18 pF

+

Sampling Capacitance 18 pF

–

Sampling Capacitance 18 pF

= 25°C. (Note 3)

A

The ● denotes specifications which apply over the full operating

/2 V

REF

/2 V

REF

CC

CC

V

V

3

LTC2410

UU

DIGITAL I PUTS A D DIGITAL OUTPUTS

operating temperature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

V

IH

V

IL

I

IN

I

IN

C

IN

C

IN

V

OH

V

OL

V

OH

V

OL

I

OZ

High Level Input Voltage 2.7V ≤ VCC ≤ 5.5V ● 2.5 V

CS, F

O

Low Level Input Voltage 4.5V ≤ VCC ≤ 5.5V ● 0.8 V

CS, F

O

High Level Input Voltage 2.7V ≤ VCC ≤ 5.5V (Note 9) ● 2.5 V

SCK 2.7V ≤ V

Low Level Input Voltage 4.5V ≤ VCC ≤ 5.5V (Note 9) ● 0.8 V

SCK 2.7V ≤ V

Digital Input Current 0V ≤ VIN ≤ V

CS, F

O

Digital Input Current 0V ≤ VIN ≤ VCC (Note 9) ● –10 10 µA

SCK

Digital Input Capacitance 10 pF

CS, F

O

Digital Input Capacitance (Note 9) 10 pF

SCK

High Level Output Voltage IO = –800µA ● VCC – 0.5V V

SDO

Low Level Output Voltage IO = 1.6mA ● 0.4V V

SDO

High Level Output Voltage IO = –800µA (Note 10) ● VCC – 0.5V V

SCK

Low Level Output Voltage IO = 1.6mA (Note 10) ● 0.4V V

SCK

Hi-Z Output Leakage ● –10 10 µA

SDO

2.7V ≤ VCC ≤ 3.3V 2.0 V

2.7V ≤ VCC ≤ 5.5V 0.6 V

= 25°C. (Note 3)

A

≤ 3.3V (Note 9) 2.0 V

CC

≤ 5.5V (Note 9) 0.6 V

CC

CC

The ● denotes specifications which apply over the full

● –10 10 µA

WU

POWER REQUIRE E TS

otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

Supply Voltage ● 2.7 5.5 V

Supply Current

Conversion Mode CS = 0V (Note 12)

Sleep Mode CS = V

= 25°C. (Note 3)

A

The ● denotes specifications which apply over the full operating temperature range,

● 200 300 µA

(Note 12) ● 20 30 µA

CC

4

LTC2410

WU

TI I G CHARACTERISTICS

range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

EOSC

t

HEO

t

LEO

t

CONV

f

ISCK

D

ISCK

f

ESCK

t

LESCK

t

HESCK

t

DOUT_ISCK

t

DOUT_ESCK

t

1

t2 CS ↑ to SDO High Z ● 0 200 ns

t3 CS ↓ to SCK ↓ (Note 10) ● 0 200 ns

t4 CS ↓ to SCK ↑ (Note 9) ● 50 ns

t

KQMAX

t

KQMIN

t

5

t

6

Note 1: Absolute Maximum Ratings are those values beyond which the

life of the device may be impaired.

Note 2: All voltage values are with respect to GND.

Note 3: V

= REF+ – REF–, V

V

REF

V

= IN+ – IN–, V

IN

Note 4: F

source with f

Note 5: Guaranteed by design, not subject to test.

Note 6: Integral nonlinearity is defined as the deviation of a code from

a straight line passing through the actual endpoints of the transfer

curve. The deviation is measured from the center of the quantization

band.

Note 7: FO = 0V (internal oscillator) or f

(external oscillator).

External Oscillator Frequency Range ● 2.56 2000 kHz

External Oscillator High Period ● 0.25 390 µs

External Oscillator Low Period ● 0.25 390 µs

Conversion Time FO = 0V ● 130.86 133.53 136.20 ms

Internal SCK Frequency Internal Oscillator (Note 10) 19.2 kHz

Internal SCK Duty Cycle (Note 10) ● 45 55 %

External SCK Frequency Range (Note 9) ● 2000 kHz

External SCK Low Period (Note 9) ● 250 ns

External SCK High Period (Note 9) ● 250 ns

Internal SCK 32-Bit Data Output Time Internal Oscillator (Notes 10, 12) ● 1.64 1.67 1.70 ms

External SCK 32-Bit Data Output Time (Note 9) ● 32/f

CS ↓ to SDO Low Z ● 0 200 ns

SCK ↓ to SDO Valid ● 220 ns

SDO Hold After SCK ↓ (Note 5) ● 15 ns

SCK Set-Up Before CS ↓ ● 50 ns

SCK Hold After CS ↓ ● 50 ns

= 2.7 to 5.5V unless otherwise specified.

CC

INCM

pin tied to GND or to VCC or to external conversion clock

O

= 153600Hz unless otherwise specified.

EOSC

= (REF+ + REF–)/2;

REFCM

= (IN+ + IN–)/2.

= 25°C. (Note 3)

A

= 153600Hz ±2%

EOSC

The ● denotes specifications which apply over the full operating temperature

F

= V

O

CC

External Oscillator (Note 11)

External Oscillator (Notes 10, 11) f

External Oscillator (Notes 10, 11)

Note 8: FO = VCC (internal oscillator) or f

(external oscillator).

Note 9: The converter is in external SCK mode of operation such that

the SCK pin is used as digital input. The frequency of the clock signal

driving SCK during the data output is f

Note 10: The converter is in internal SCK mode of operation such that

the SCK pin is used as digital output. In this mode of operation the

SCK pin has a total equivalent load capacitance C

Note 11: The external oscillator is connected to the FO pin. The external

oscillator frequency, f

Note 12: The converter uses the internal oscillator.

= 0V or FO = VCC.

F

O

Note 13: The output noise includes the contribution of the internal

calibration operations.

Note 14: Guaranteed by design and test correlation.

● 157.03 160.23 163.44 ms

● 20510/f

● 256/f

, is expressed in kHz.

EOSC

(in kHz) ms

EOSC

/8 kHz

EOSC

(in kHz) ms

EOSC

(in kHz) ms

ESCK

= 128000Hz ±2%

EOSC

and is expressed in kHz.

ESCK

= 20pF.

LOAD

5

LTC2410

UUU

PI FU CTIO S

GND (Pins 1, 7, 8, 9, 10, 15, 16): Ground. Multiple

ground pins internally connected for optimum ground

current flow and VCC decoupling. Connect each one of

these pins to a ground plane through a low impedance

connection.

VCC (Pin 2): Positive Supply Voltage. Bypass to GND

(Pin␣ 1) with a 10µF tantalum capacitor in parallel with

0.1µF ceramic capacitor as close to the part as possible.

REF+ (Pin 3), REF– (Pin 4): Differential Reference Input.

The voltage on these pins can have any value between GND

and VCC as long as the reference positive input, REF+, is

maintained more positive than the reference negative

input, REF–, by at least 0.1V.

IN+ (Pin 5), IN– (Pin 6): Differential Analog Input. The

voltage on these pins can have any value between

GND – 0.3V and VCC + 0.3V. Within these limits the

converter bipolar input range (VIN = IN+ – IN–) extends

from – 0.5 • (V

the converter produces unique overrange and underrange

output codes.

CS (Pin 11): Active LOW Digital Input. A LOW on this pin

enables the SDO digital output and wakes up the ADC.

Following each conversion the ADC automatically enters

the Sleep mode and remains in this low power state as

long as CS is HIGH. A LOW-to-HIGH transition on CS

during the Data Output transfer aborts the data transfer

and starts a new conversion.

) to 0.5 • (V

REF

). Outside this input range

REF

SDO (Pin 12): Three-State Digital Output. During the Data

Output period this pin is used as serial data output. When

the chip select CS is HIGH (CS = VCC) the SDO pin is in a

high impedance state. During the Conversion and Sleep

periods this pin is used as the conversion status output.

The conversion status can be observed by pulling CS LOW.

SCK (Pin 13): Bidirectional Digital Clock Pin. In Internal

Serial Clock Operation mode, SCK is used as digital output

for the internal serial interface clock during the Data

Output period. In External Serial Clock Operation mode,

SCK is used as digital input for the external serial interface

clock during the Data Output period. A weak internal pullup is automatically activated in Internal Serial Clock Operation mode. The Serial Clock Operation mode is determined by the logic level applied to the SCK pin at power up

or during the most recent falling edge of CS.

FO (Pin 14): Frequency Control Pin. Digital input that

controls the ADC’s notch frequencies and conversion

time. When the FO pin is connected to VCC (FO = VCC), the

converter uses its internal oscillator and the digital filter

first null is located at 50Hz. When the FO pin is connected

to GND (FO = OV), the converter uses its internal oscillator

and the digital filter first null is located at 60Hz. When F

is driven by an external clock signal with a frequency f

the converter uses this signal as its system clock and the

digital filter first null is located at a frequency f

EOSC

EOSC

/2560.

O

,

6

LTC2410

1.69k

SDO

2410 TA04

Hi-Z TO V

OL

VOH TO V

OL

VOL TO Hi-Z

C

LOAD

= 20pF

V

CC

CONVERT

SLEEP

DATA OUTPUT

2410 F01

TRUE

FALSE

CS = LOW

AND

SCK

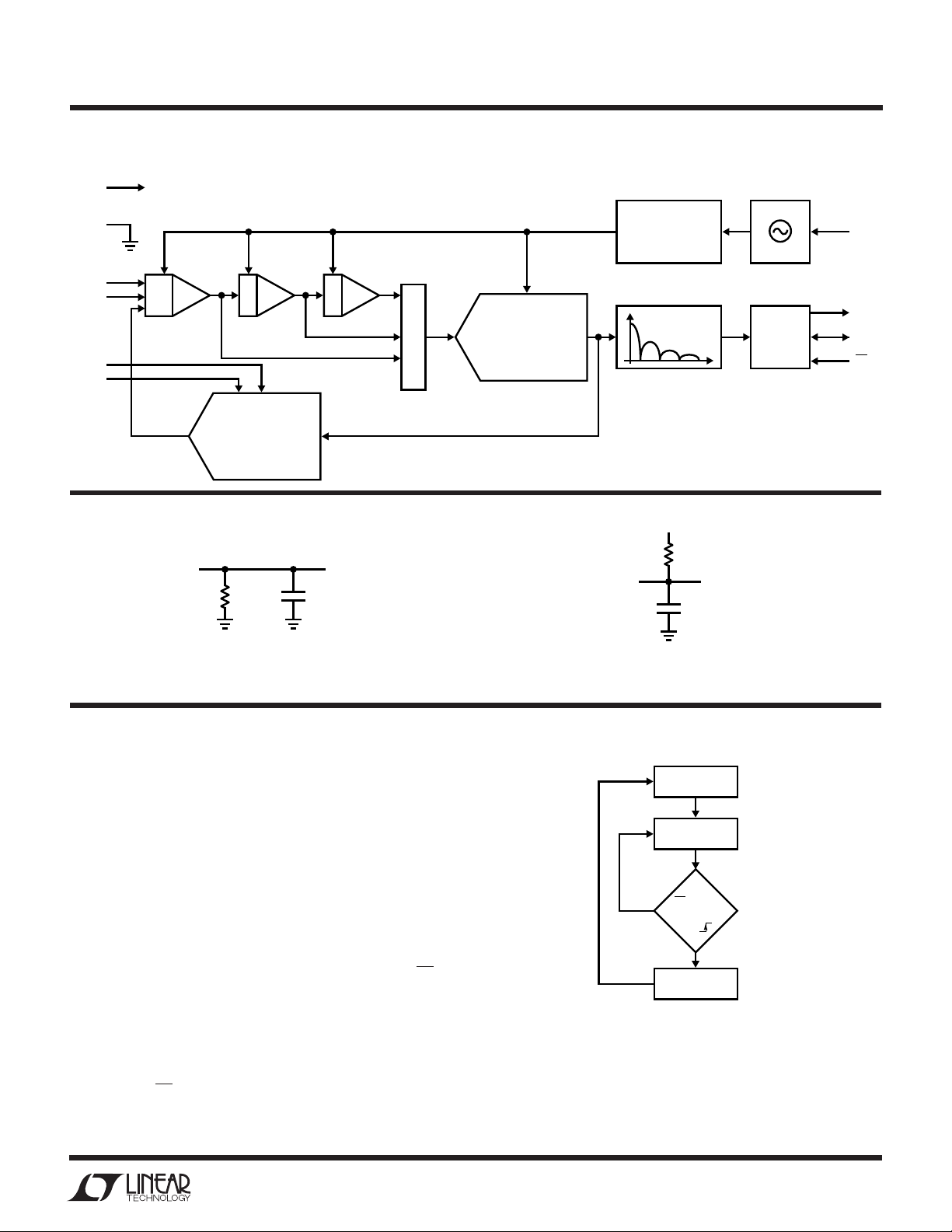

UU

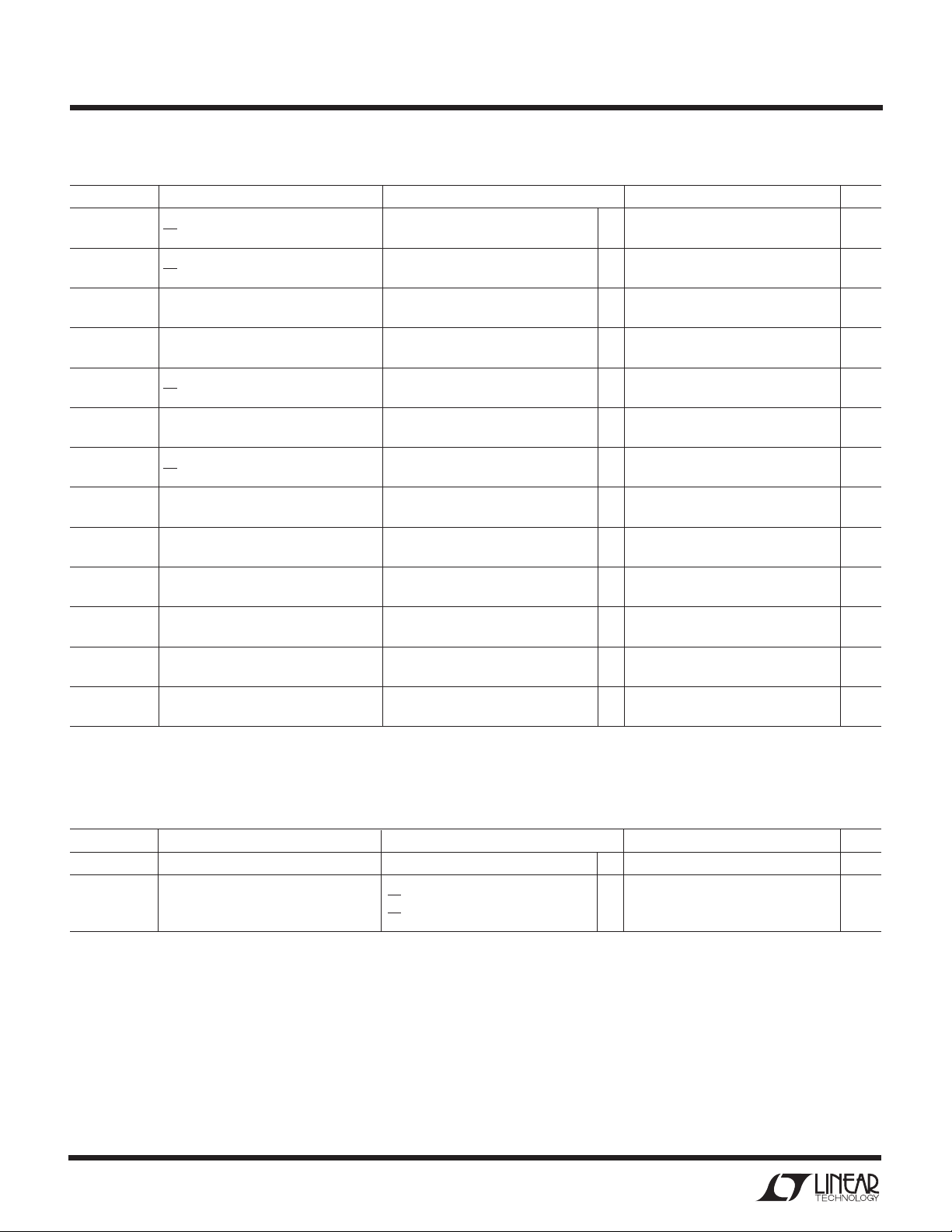

W

FU CTIO AL BLOCK DIAGRA

V

CC

GND

+

IN

–

IN

+

–

∫∫∫

∑

+

REF

–

REF

–+

DAC

TEST CIRCUITS

SDO

ADC

AUTOCALIBRATION

AND CONTROL

DECIMATING FIR

INTERNAL

OSCILLATOR

SERIAL

INTERFACE

(INT/EXT)

F

O

SDO

SCK

CS

2410 FD

1.69k

Hi-Z TO V

VOL TO V

OH

VOH TO Hi-Z

U

OH

= 20pF

C

LOAD

2410 TA03

WUU

APPLICATIO S I FOR ATIO

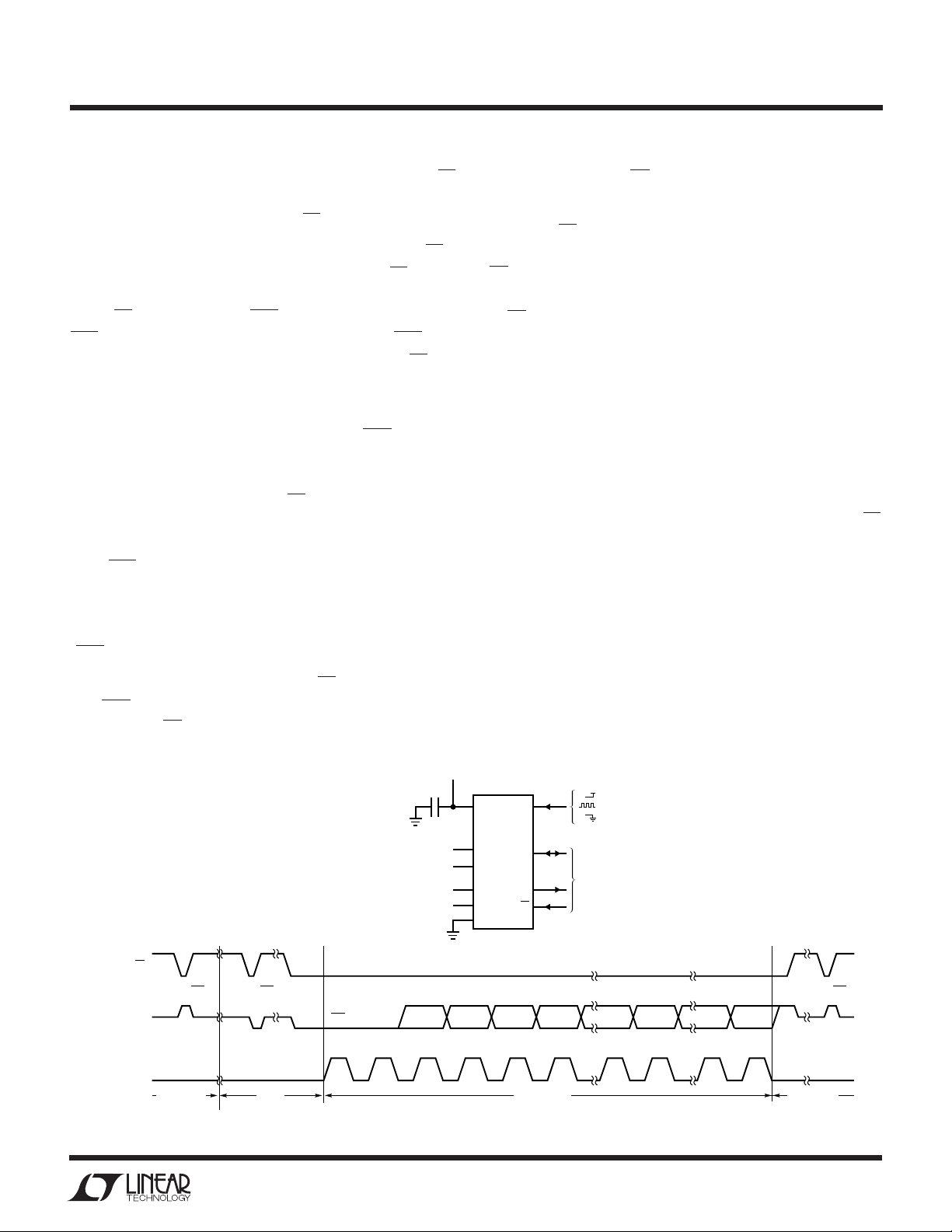

CONVERTER OPERATION

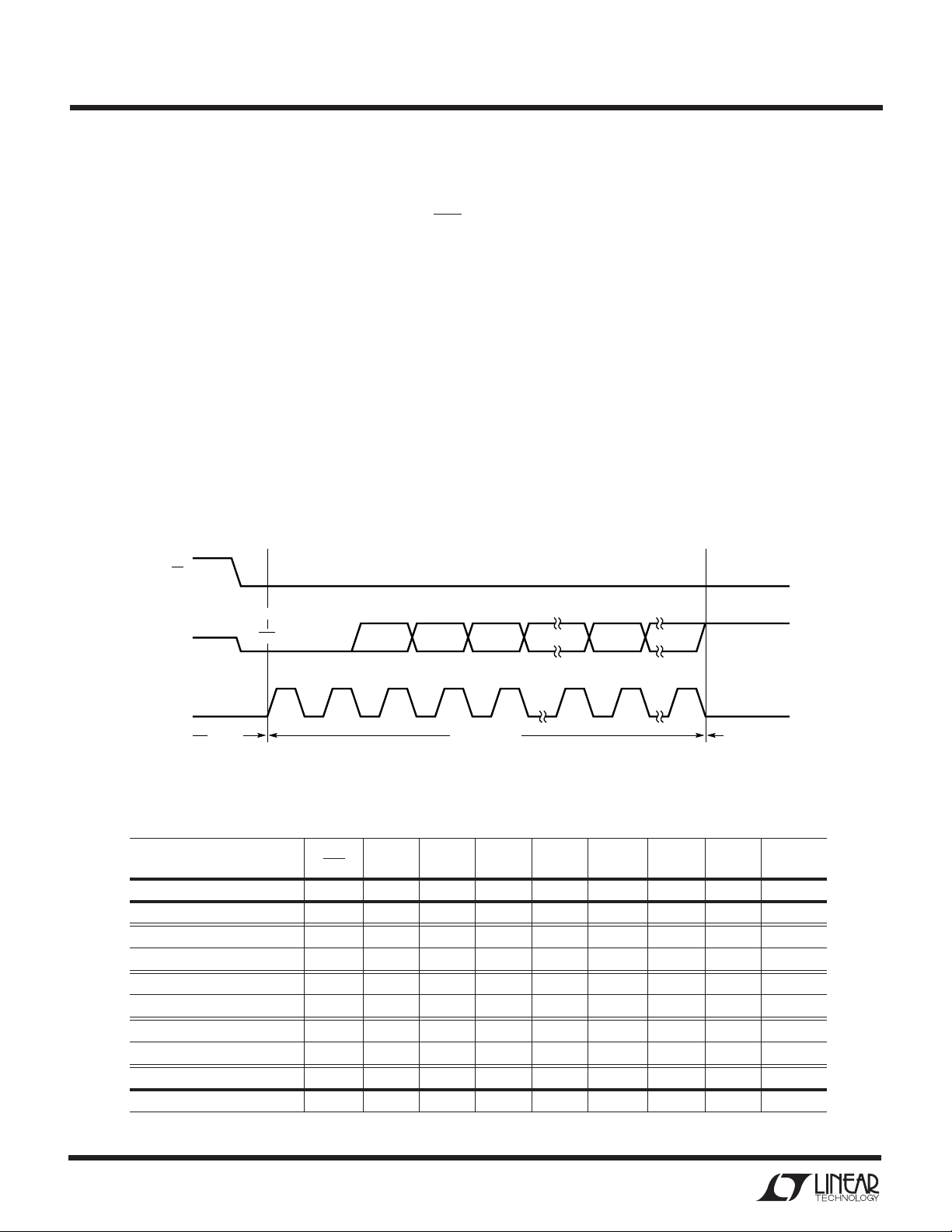

Converter Operation Cycle

The LTC2410 is a low power, delta-sigma analog-todigital converter with an easy to use 3-wire serial interface.

Its operation is made up of three states. The converter

operating cycle begins with the conversion, followed by

the low power sleep state and ends with the data output

(see Figure 1). The 3-wire interface consists of serial data

output (SDO), serial clock (SCK) and chip select (CS).

Initially, the LTC2410 performs a conversion. Once the

conversion is complete, the device enters the sleep state.

While in this sleep state, power consumption is reduced by

an order of magnitude. The part remains in the sleep state

as long as CS is HIGH. The conversion result is held

indefinitely in a static shift register while the converter is

in the sleep state.

Figure 1. LTC2410 State Transition Diagram

7

LTC2410

U

WUU

APPLICATIO S I FOR ATIO

Once CS is pulled LOW, the device begins outputting the

conversion result. There is no latency in the conversion

result. The data output corresponds to the conversion just

performed. This result is shifted out on the serial data out

pin (SDO) under the control of the serial clock (SCK). Data

is updated on the falling edge of SCK allowing the user to

reliably latch data on the rising edge of SCK (see Figure 3).

The data output state is concluded once 32 bits are read

out of the ADC or when CS is brought HIGH. The device

automatically initiates a new conversion and the cycle

repeats.

Through timing control of the CS and SCK pins, the

LTC2410 offers several flexible modes of operation

(internal or external SCK and free-running conversion

modes). These various modes do not require programming configuration registers; moreover, they do not disturb the cyclic operation described above. These modes of

operation are described in detail in the Serial Interface

Timing Modes section.

Conversion Clock

A major advantage the delta-sigma converter offers over

conventional type converters is an on-chip digital filter

(commonly implemented as a Sinc or Comb filter). For

high resolution, low frequency applications, this filter is

typically designed to reject line frequencies of 50 or 60Hz

plus their harmonics. The filter rejection performance is

directly related to the accuracy of the converter system

clock. The LTC2410 incorporates a highly accurate onchip oscillator. This eliminates the need for external frequency setting components such as crystals or oscillators. Clocked by the on-chip oscillator, the LTC2410

achieves a minimum of 110dB rejection at the line frequency (50Hz or 60Hz ±2%).

Ease of Use

The LTC2410 data output has no latency, filter settling

delay or redundant data associated with the conversion

cycle. There is a one-to-one correspondence between the

conversion and the output data. Therefore, multiplexing

multiple analog voltages is easy.

The LTC2410 performs offset and full-scale calibrations

every conversion cycle. This calibration is transparent to

the user and has no effect on the cyclic operation described above. The advantage of continuous calibration is

extreme stability of offset and full-scale readings with respect to time, supply voltage change and temperature drift.

Power-Up Sequence

The LTC2410 automatically enters an internal reset state

when the power supply voltage VCC drops below approximately 2.2V. This feature guarantees the integrity of the

conversion result and of the serial interface mode selection. (See the 2-wire I/O sections in the Serial Interface

Timing Modes section.)

When the VCC voltage rises above this critical threshold,

the converter creates an internal power-on-reset (POR)

signal with a duration of approximately 0.5ms. The POR

signal clears all internal registers. Following the POR

signal, the LTC2410 starts a normal conversion cycle and

follows the succession of states described above. The first

conversion result following POR is accurate within the

specifications of the device if the power supply voltage is

restored within the operating range (2.7V to 5.5V) before

the end of the POR time interval.

Reference Voltage Range

This converter accepts a truly differential external reference voltage. The absolute/common mode voltage specification for the REF+ and REF– pins covers the entire range

from GND to VCC. For correct converter operation, the

REF+ pin must always be more positive than the REF– pin.

The LTC2410 can accept a differential reference voltage

from 0.1V to VCC. The converter output noise is determined by the thermal noise of the front-end circuits, and

as such, its value in nanovolts is nearly constant with

reference voltage. A decrease in reference voltage will not

significantly improve the converter’s effective resolution.

On the other hand, a reduced reference voltage will improve the converter’s overall INL performance. A reduced

reference voltage will also improve the converter performance when operated with an external conversion clock

(external FO signal) at substantially higher output data

rates (see the Output Data Rate section).

8

LTC2410

U

WUU

APPLICATIO S I FOR ATIO

Input Voltage Range

The analog input is truly differential with an absolute/

common mode range for the IN+ and IN– input pins

extending from GND – 0.3V to VCC + 0.3V. Outside

these limits the ESD protection devices begin to turn on

and the errors due to input leakage current increase

rapidly. Within these limits the LTC2410 converts the

bipolar differential input signal, VIN = IN+ – IN–, from

–FS = – 0.5 • V

REF+ – REF–. Outside this range the converter indicates the

overrange or the underrange condition using distinct

output codes.

Input signals applied to IN+ and IN– pins may extend by

300mV below ground and above VCC. In order to limit any

fault current, resistors of up to 5k may be added in series

with the IN+ and IN– pins without affecting the performance of the device. In the physical layout, it is important

to maintain the parasitic capacitance of the connection

between these series resistors and the corresponding pins

as low as possible; therefore, the resistors should be

located as close as practical to the pins. The effect of the

series resistance on the converter accuracy can be evaluated from the curves presented in the Input Current/

Reference Current sections. In addition, series resistors

will introduce a temperature dependent offset error due to

the input leakage current. A 1nA input leakage current will

develop a 1ppm offset error on a 5k resistor if V

This error has a very strong temperature dependency.

Output Data Format

The LTC2410 serial output data stream is 32 bits long. The

first 3 bits represent status information indicating the sign

and conversion state. The next 24 bits are the conversion

result, MSB first. The remaining 5 bits are sub LSBs

beyond the 24-bit level that may be included in averaging

or discarded without loss of resolution. The third and

fourth bit together are also used to indicate an underrange

condition (the differential input voltage is below –FS) or an

overrange condition (the differential input voltage is above

+FS).

Bit 31 (first output bit) is the end of conversion (EOC)

indicator. This bit is available at the SDO pin during the

conversion and sleep states whenever the CS pin is LOW.

to +FS = 0.5 • V

REF

where V

REF

REF

=

REF

= 5V.

This bit is HIGH during the conversion and goes LOW

when the conversion is complete.

Bit 30 (second output bit) is a dummy bit (DMY) and is

always LOW.

Bit 29 (third output bit) is the conversion result sign indicator (SIG). If VIN is >0, this bit is HIGH. If VIN is <0, this

bit is LOW.

Bit 28 (fourth output bit) is the most significant bit (MSB)

of the result. This bit in conjunction with Bit 29 also

provides the underrange or overrange indication. If both

Bit 29 and Bit 28 are HIGH, the differential input voltage is

above +FS. If both Bit 29 and Bit 28 are LOW, the

differential input voltage is below –FS.

The function of these bits is summarized in Table 1.

Table 1. LTC2410 Status Bits

Bit 31 Bit 30 Bit 29 Bit 28

Input Range EOC DMY SIG MSB

VIN ≥ 0.5 • V

0V ≤ VIN < 0.5 • V

–0.5 • V

VIN < –0.5 • V

REF

≤ VIN < 0V 0 0 0 1

REF

REF

REF

0011

0010

0000

Bits 28-5 are the 24-bit conversion result MSB first.

Bit 5 is the least significant bit (LSB).

Bits 4-0 are sub LSBs below the 24-bit level. Bits 4-0 may

be included in averaging or discarded without loss of

resolution.

Data is shifted out of the SDO pin under control of the serial

clock (SCK), see Figure 3. Whenever CS is HIGH, SDO

remains high impedance and any externally generated

SCK clock pulses are ignored by the internal data out shift

register.

In order to shift the conversion result out of the device, CS

must first be driven LOW. EOC is seen at the SDO pin of the

device once CS is pulled LOW. EOC changes real time from

HIGH to LOW at the completion of a conversion. This

signal may be used as an interrupt for an external

microcontroller. Bit 31 (EOC) can be captured on the first

rising edge of SCK. Bit 30 is shifted out of the device on the

first falling edge of SCK. The final data bit (Bit 0) is shifted

out on the falling edge of the 31st SCK and may be latched

9

LTC2410

U

WUU

APPLICATIO S I FOR ATIO

on the rising edge of the 32nd SCK pulse. On the falling

edge of the 32nd SCK pulse, SDO goes HIGH indicating the

initiation of a new conversion cycle. This bit serves as EOC

(Bit 31) for the next conversion cycle. Table 2 summarizes

the output data format.

As long as the voltage on the IN+ and IN– pins is maintained

within the –0.3V to (VCC + 0.3V) absolute maximum

operating range, a conversion result is generated for any

differential input voltage VIN from –FS = –0.5 • V

+FS = 0.5 • V

. For differential input voltages greater than

REF

+FS, the conversion result is clamped to the value corresponding to the +FS + 1LSB. For differential input voltages

below –FS, the conversion result is clamped to the value

corresponding to –FS – 1LSB.

CS

REF

to

Frequency Rejection Selection (FO)

The LTC2410 internal oscillator provides better than 110dB

normal mode rejection at the line frequency and all its

harmonics for 50Hz ±2% or 60Hz ±2%. For 60Hz rejection, FO should be connected to GND while for 50Hz

rejection the FO pin should be connected to VCC.

The selection of 50Hz or 60Hz rejection can also be made

by driving FO to an appropriate logic level. A selection

change during the sleep or data output states will not

disturb the converter operation. If the selection is made

during the conversion state, the result of the conversion in

progress may be outside specifications but the following

conversions will not be affected.

When a fundamental rejection frequency different from

50Hz or 60Hz is required or when the converter must be

BIT 31

SDO

Hi-Z

SCK

SLEEP DATA OUTPUT CONVERSION

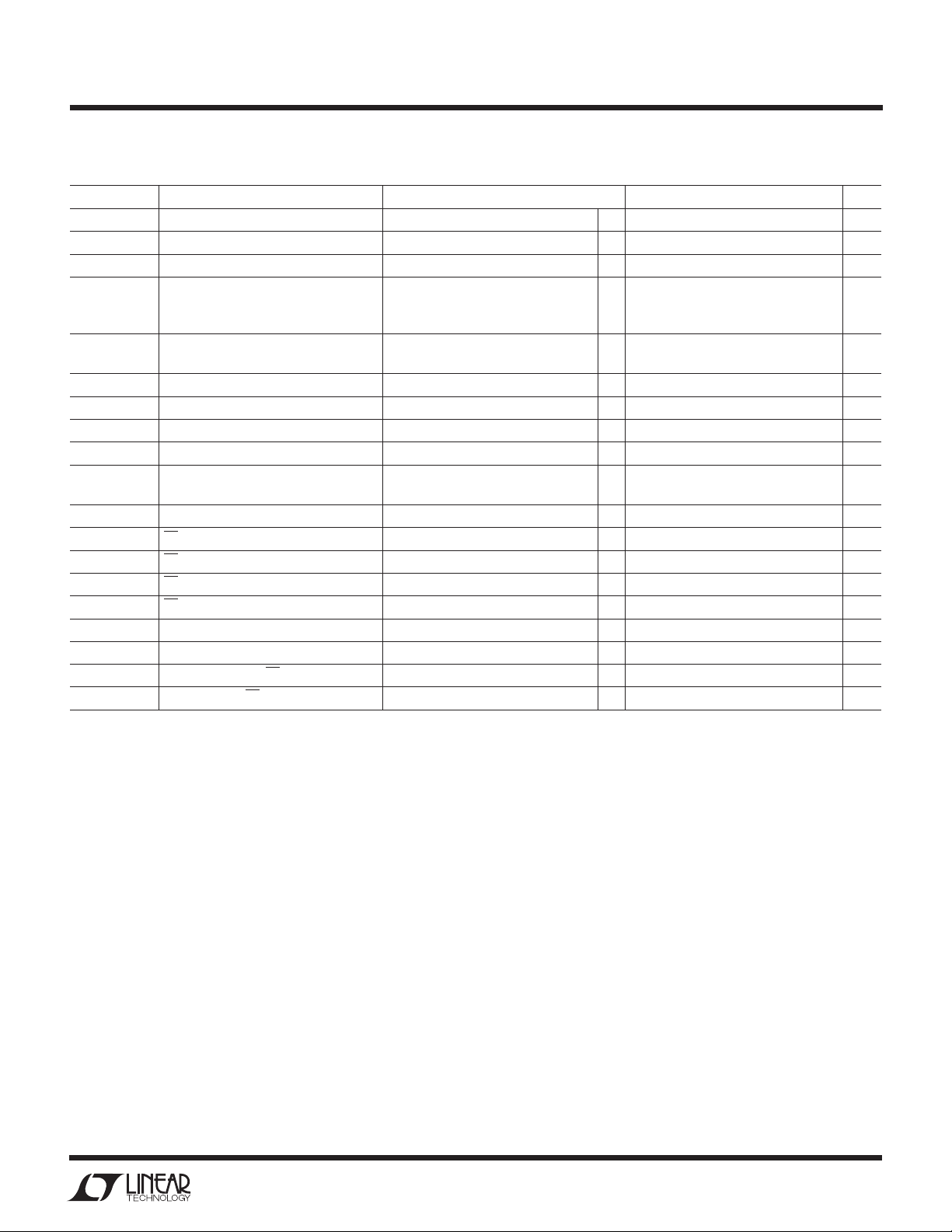

Table 2. LTC2410 Output Data Format

Differential Input Voltage Bit 31 Bit 30 Bit 29 Bit 28 Bit 27 Bit 26 Bit 25 … Bit 0

* EOC DMY SIG MSB

V

IN

VIN* ≥ 0.5 • V

0.5 • V

0.25 • V

0.25 • V

0 00100 0 0…0

–1LSB 0 0011 1 1…1

–0.25 • V

–0.25 • V

–0.5 • V

VIN* < –0.5 • V

*The differential input voltage VIN = IN+ – IN–.

**The differential reference voltage V

REF

** – 1LSB 0 0101 1 1…1

REF

** 00101 0 0…0

REF

** – 1LSB 00100 1 1…1

REF

** 00011 0 0…0

REF

** – 1LSB 00010 1 1…1

REF

** 00010 0 0…0

REF

REF

EOC

12345 262732

** 00110 0 0…0

** 00001 1 1…1

= REF+ – REF–.

REF

BIT 28BIT 29BIT 30

MSBSIG“0”

Figure 3. Output Data Timing

LSB

BIT 0BIT 27 BIT 5

24

2410 F03

10

LTC2410

U

WUU

APPLICATIO S I FOR ATIO

synchronized with an outside source, the LTC2410 can

operate with an external conversion clock. The converter

automatically detects the presence of an external clock

signal at the FO pin and turns off the internal oscillator. The

frequency f

2560Hz (1Hz notch frequency) to be detected. The external clock signal duty cycle is not significant as long as the

minimum and maximum specifications for the high and

low periods t

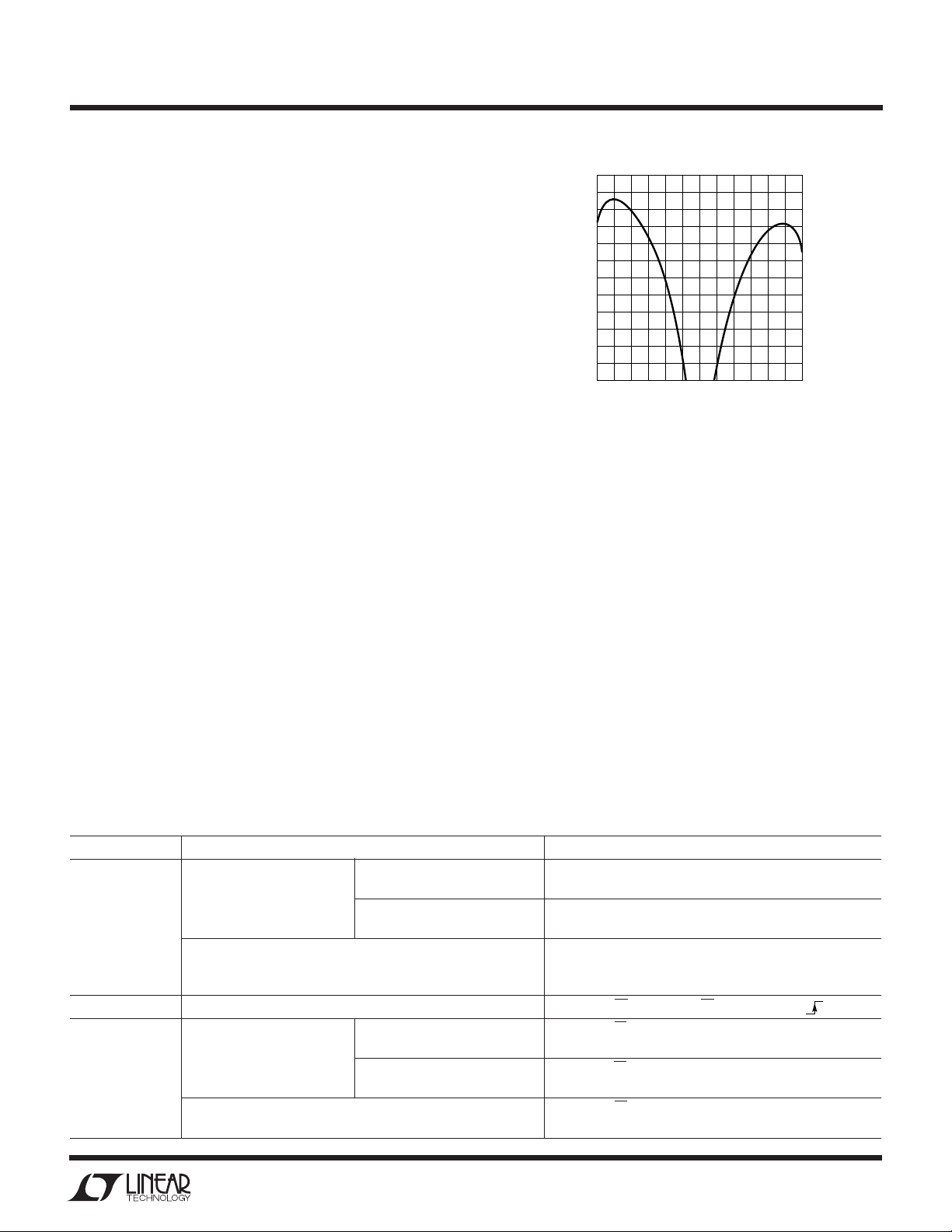

While operating with an external conversion clock of a

frequency f

normal mode rejection in a frequency range f

±4% and its harmonics. The normal mode rejection as a

function of the input frequency deviation from f

is shown in Figure 4.

Whenever an external clock is not present at the FO pin the

converter automatically activates its internal oscillator and

enters the Internal Conversion Clock mode. The LTC2410

operation will not be disturbed if the change of conversion

clock source occurs during the sleep state or during the

data output state while the converter uses an external

serial clock. If the change occurs during the conversion

state, the result of the conversion in progress may be

outside specifications but the following conversions will

not be affected. If the change occurs during the data output

state and the converter is in the Internal SCK mode, the

serial clock duty cycle may be affected but the serial data

stream will remain valid.

of the external signal must be at least

EOSC

and t

HEO

, the LTC2410 provides better than 110dB

EOSC

are observed.

LEO

EOSC

EOSC

/2560

/2560

–80

–85

–90

–95

–100

–105

–110

–115

–120

–125

NORMAL MODE REJECTION (dB)

–130

–135

–140

–12–8–404812

DIFFERENTIAL INPUT SIGNAL FREQUENCY

DEVIATION FROM NOTCH FREQUENCY f

Figure 4. LTC2410 Normal Mode Rejection When

Using an External Oscillator of Frequency f

EOSC

/2560(%)

2410 F04

EOSC

Table 3 summarizes the duration of each state and the

achievable output data rate as a function of FO.

SERIAL INTERFACE PINS

The LTC2410 transmits the conversion results and receives the start of conversion command through a synchronous 3-wire interface. During the conversion and

sleep states, this interface can be used to assess the

converter status and during the data output state it is used

to read the conversion result.

Table 3. LTC2410 State Duration

State Operating Mode Duration

CONVERT Internal Oscillator FO = LOW 133ms, Output Data Rate ≤ 7.5 Readings/s

(60Hz Rejection)

FO = HIGH 160ms, Output Data Rate ≤ 6.2 Readings/s

(50Hz Rejection)

External Oscillator FO = External Oscillator 20510/f

with Frequency f

/2560 Rejection)

(f

EOSC

SLEEP As Long As CS = HIGH Until CS = LOW and SCK

DATA OUTPUT Internal Serial Clock FO = LOW/HIGH As Long As CS = LOW But Not Longer Than 1.67ms

(Internal Oscillator) (32 SCK cycles)

FO = External Oscillator with As Long As CS = LOW But Not Longer Than 256/f

Frequency f

External Serial Clock with As Long As CS = LOW But Not Longer Than 32/f

Frequency f

kHz (32 SCK cycles)

SCK

EOSC

kHz

EOSC

kHz (32 SCK cycles)

s, Output Data Rate ≤ f

EOSC

/20510 Readings/s

EOSC

SCK

EOSC

ms

ms

11

LTC2410

U

WUU

APPLICATIO S I FOR ATIO

Serial Clock Input/Output (SCK)

The serial clock signal present on SCK (Pin 13) is used to

synchronize the data transfer. Each bit of data is shifted out

the SDO pin on the falling edge of the serial clock.

In the Internal SCK mode of operation, the SCK pin is an

output and the LTC2410 creates its own serial clock by

dividing the internal conversion clock by 8. In the External

SCK mode of operation, the SCK pin is used as input. The

internal or external SCK mode is selected on power-up and

then reselected every time a HIGH-to-LOW transition is

detected at the CS pin. If SCK is HIGH or floating at powerup or during this transition, the converter enters the internal SCK mode. If SCK is LOW at power-up or during this

transition, the converter enters the external SCK mode.

Serial Data Output (SDO)

The serial data output pin, SDO (Pin 12), provides the

result of the last conversion as a serial bit stream (MSB

first) during the data output state. In addition the SDO pin

is used as an end of conversion indicator during the

conversion and sleep states.

When CS (Pin 11) is HIGH, the SDO driver is switched to

a high impedance state. This allows sharing the serial

interface with other devices. If CS is LOW during the

convert or sleep state, SDO will output EOC. If CS is LOW

during the conversion phase, the EOC bit appears HIGH on

the SDO pin. Once the conversion is complete, EOC goes

LOW. The device remains in the sleep state until the first

rising edge of SCK occurs while CS = LOW.

Chip Select Input (CS)

The active LOW chip select, CS (Pin 11), is used to test the

conversion status and to enable the data output transfer as

described in the previous sections.

In addition, the CS signal can be used to trigger a new

conversion cycle before the entire serial data transfer has

been completed. The LTC2410 will abort any serial data

transfer in progress and start a new conversion cycle

anytime a LOW-to-HIGH transition is detected at the CS

pin after the converter has entered the data output state

(i.e., after the first rising edge of SCK occurs with

CS␣=␣LOW).

Finally, CS can be used to control the free-running modes

of operation, see Serial Interface Timing Modes section.

Grounding CS will force the ADC to continuously convert

at the maximum output rate selected by FO. Tying a

capacitor to CS will reduce the output rate and power

dissipation by a factor proportional to the capacitor’s

value, see Figures 12 to 14.

SERIAL INTERFACE TIMING MODES

The LTC2410’s 3-wire interface is SPI and MICROWIRE

compatible. This interface offers several flexible modes of

operation. These include internal/external serial clock,

2- or 3-wire I/O, single cycle conversion and autostart. The

following sections describe each of these serial interface

timing modes in detail. In all these cases, the converter

can use the internal oscillator (FO = LOW or FO = HIGH) or

an external oscillator connected to the FO pin. Refer to

Table␣ 4 for a summary.

External Serial Clock, Single Cycle Operation

(SPI/MICROWIRE Compatible)

This timing mode uses an external serial clock to shift out

the conversion result and a CS signal to monitor and

control the state of the conversion cycle, see Figure 5.

Table 4. LTC2410 Interface Timing Modes

Conversion Data Connection

SCK Cycle Output and

Configuration Source Control Control Waveforms

External SCK, Single Cycle Conversion External CS and SCK CS and SCK Figures 5, 6

External SCK, 2-Wire I/O External SCK SCK Figure 7

Internal SCK, Single Cycle Conversion Internal CS ↓ CS ↓ Figures 8, 9

Internal SCK, 2-Wire I/O, Continuous Conversion Internal Continuous Internal Figure 10

Internal SCK, Autostart Conversion Internal C

EXT

Internal Figure 11

12

LTC2410

U

WUU

APPLICATIO S I FOR ATIO

The serial clock mode is selected on the falling edge of CS.

To select the external serial clock mode, the serial clock pin

(SCK) must be LOW during each CS falling edge.

The serial data output pin (SDO) is Hi-Z as long as CS is

HIGH. At any time during the conversion cycle, CS may be

pulled LOW in order to monitor the state of the converter.

While CS is pulled LOW, EOC is output to the SDO pin.

EOC␣ =␣ 1 while a conversion is in progress and EOC = 0 if

the device is in the sleep state. Independent of CS, the

device automatically enters the low power sleep state once

the conversion is complete.

When the device is in the sleep state (EOC = 0), its

conversion result is held in an internal static shift register. The device remains in the sleep state until the first

rising edge of SCK is seen while CS is LOW. Data is

out the SDO pin on each falling edge of SCK. This enables

external circuitry to latch the output on the rising edge of

SCK. EOC can be latched on the first rising edge of SCK

and the last bit of the conversion result can be latched on

the 32nd rising edge of SCK. On the 32nd falling edge of

SCK, the device begins a new conversion. SDO goes HIGH

(EOC = 1) indicating a conversion is in progress.

At the conclusion of the data cycle, CS may remain LOW

and EOC monitored as an end-of-conversion interrupt.

Alternatively, CS may be driven HIGH setting SDO to Hi-Z.

shifted

As described above, CS may be pulled LOW at any time in

order to monitor the conversion status.

Typically, CS remains LOW during the data output state.

However, the data output state may be aborted by pulling

CS HIGH anytime between the first rising edge and the

32nd falling edge of SCK, see Figure 6. On the rising edge

of CS, the device aborts the data output state and immediately initiates a new conversion. This is useful for systems not requiring all 32 bits of output data, aborting an

invalid conversion cycle or synchronizing the start of a

conversion.

External Serial Clock, 2-Wire I/O

This timing mode utilizes a 2-wire serial I/O interface. The

conversion result is shifted out of the device by an externally generated serial clock (SCK) signal, see Figure 7. CS

may be permanently tied to ground, simplifying the user

interface or isolation barrier.

The external serial clock mode is selected at the end of the

power-on reset (POR) cycle. The POR cycle is concluded

approximately 0.5ms after VCC exceeds 2.2V. The level

applied to SCK at this time determines if SCK is internal or

external. SCK must be driven LOW prior to the end of POR

in order to enter the external serial clock timing mode.

SDO

SCK

(EXTERNAL)

CS

CONVERSION

2.7V TO 5.5V

1µF

214

V

F

CC

O

LTC2410

3

+

REFERENCE

VOLTAGE

0.1V TO V

ANALOG INPUT RANGE

TO 0.5V

–0.5V

REF

1, 7, 8, 9, 10, 15, 16

TEST EOCTEST EOC

SLEEP DATA OUTPUT CONVERSION

BIT 31

EOC

REF

4

REF

CC

5

+

IN

REF

6

–

IN

GND

13

SCK

–

12

SDO

11

CS

V

CC

= 50Hz REJECTION

= EXTERNAL OSCILLATOR

= 60Hz REJECTION

3-WIRE

SPI INTERFACE

BIT 5BIT 27 BIT 26BIT 28BIT 29BIT 30

LSB

BIT 0

SUB LSBMSBSIG

Figure 5. External Serial Clock, Single Cycle Operation

TEST EOC

Hi-ZHi-ZHi-Z

2410 F05

13

LTC2410

U

WUU

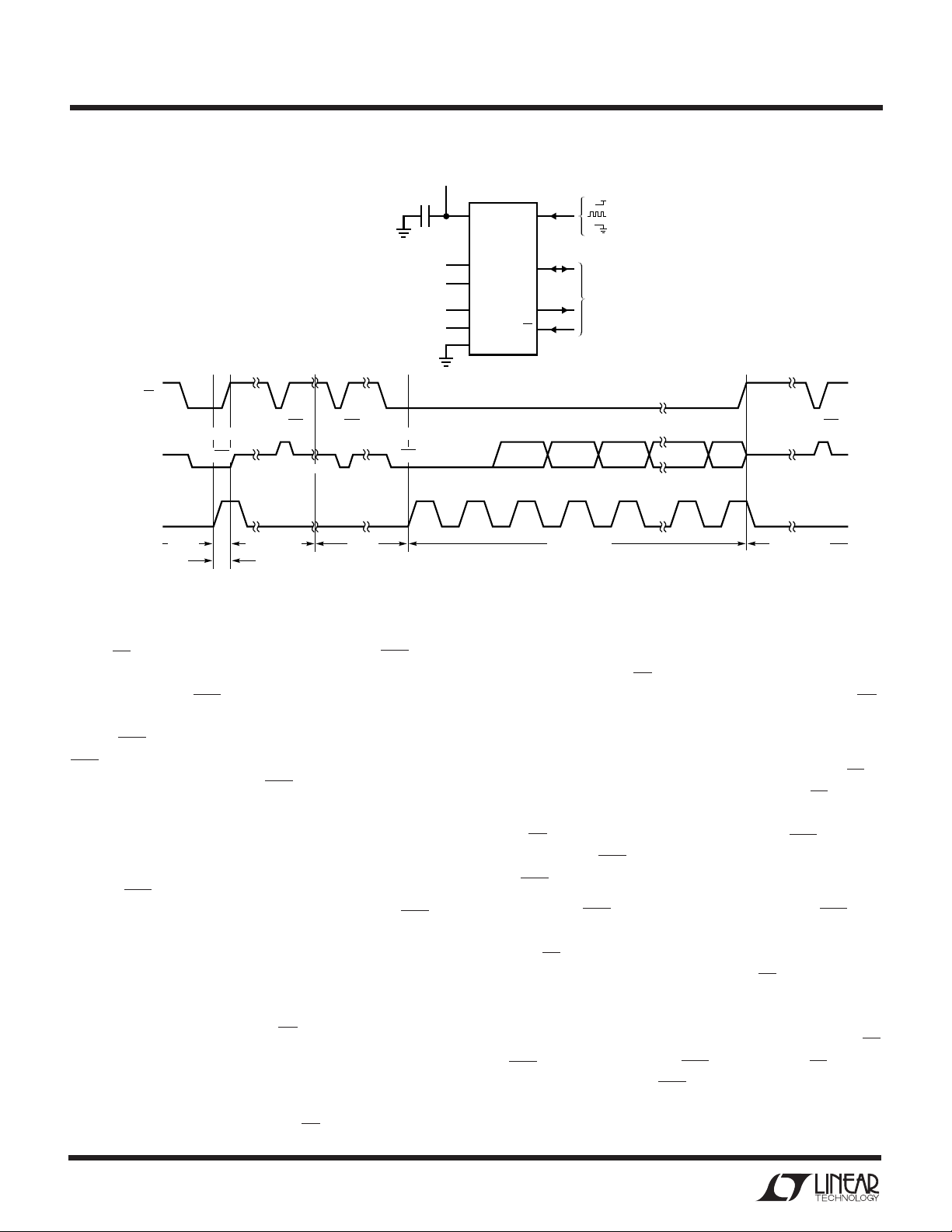

APPLICATIO S I FOR ATIO

ANALOG INPUT RANGE

–0.5V

REF

CS

TEST EOC TEST EOC

SDO

SCK

(EXTERNAL)

EOC

CONVERSIONSLEEP SLEEP

DATA OUTPUT

Hi-Z

Hi-Z Hi-ZHi-Z

2.7V TO 5.5V

1µF

REFERENCE

VOLTAGE

0.1V TO V

CC

TO 0.5V

REF

1, 7, 8, 9, 10, 15, 16

BIT 31BIT 0

EOC

V

CC

214

V

3

REF

4

REF

5

IN

6

IN

GND

CC

LTC2410

+

–

+

–

F

SCK

SDO

CS

O

13

12

11

DATA OUTPUT

= 50Hz REJECTION

= EXTERNAL OSCILLATOR

= 60Hz REJECTION

3-WIRE

SPI INTERFACE

MSBSIG

BIT 8BIT 27 BIT 9BIT 28BIT 29BIT 30

TEST EOC

CONVERSION

2410 F06

Figure 6. External Serial Clock, Reduced Data Output Length

Since CS is tied LOW, the end-of-conversion (EOC) can be

continuously monitored at the SDO pin during the convert

and sleep states. EOC may be used as an interrupt to an

external controller indicating the conversion result is

ready. EOC = 1 while the conversion is in progress and

EOC␣ =␣ 0 once the conversion enters the low power sleep

state. On the falling edge of EOC, the conversion result is

loaded into an internal static shift register. The device

remains in the sleep state until the first rising edge of SCK.

Data is shifted out the SDO pin on each falling edge of SCK

enabling external circuitry to latch data on the rising edge

of SCK. EOC can be latched on the first rising edge of SCK.

On the 32nd falling edge of SCK, SDO goes HIGH (EOC␣ =␣ 1)

indicating a new conversion has begun.

Internal Serial Clock, Single Cycle Operation

This timing mode uses an internal serial clock to shift out

the conversion result and a CS signal to monitor and

control the state of the conversion cycle, see Figure 8.

In order to select the internal serial clock timing mode, the

serial clock pin (SCK) must be floating (Hi-Z) or pulled

HIGH prior to the falling edge of CS. The device will not

enter the internal serial clock mode if SCK is driven LOW

on the falling edge of CS. An internal weak pull-up resistor

is active on the SCK pin during the falling edge of CS;

therefore, the internal serial clock timing mode is automatically selected if SCK is not externally driven.

The serial data output pin (SDO) is Hi-Z as long as CS is

HIGH. At any time during the conversion cycle, CS may be

pulled LOW in order to monitor the state of the converter.

Once CS is pulled LOW, SCK goes LOW and EOC is output

to the SDO pin. EOC = 1 while a conversion is in progress

and EOC = 0 if the device is in the sleep state.

When testing EOC, if the conversion is complete (EOC = 0),

the device will exit the sleep state and enter the data output

state if CS remains LOW. In order to prevent the device

from exiting the low power sleep state, CS must be pulled

HIGH before the first rising edge of SCK. In the internal

SCK timing mode, SCK goes HIGH and the device begins

outputting data at time t

(if EOC = 0) or t

after EOC goes LOW (if CS is LOW

EOCtest

during the falling edge of EOC). The value of t

after the falling edge of CS

EOCtest

EOCtest

is 23µs

if the device is using its internal oscillator (F0 = logic LOW

or HIGH). If FO is driven by an external oscillator of

14

Loading...

Loading...