Page 1

DESIGN FEATURES L

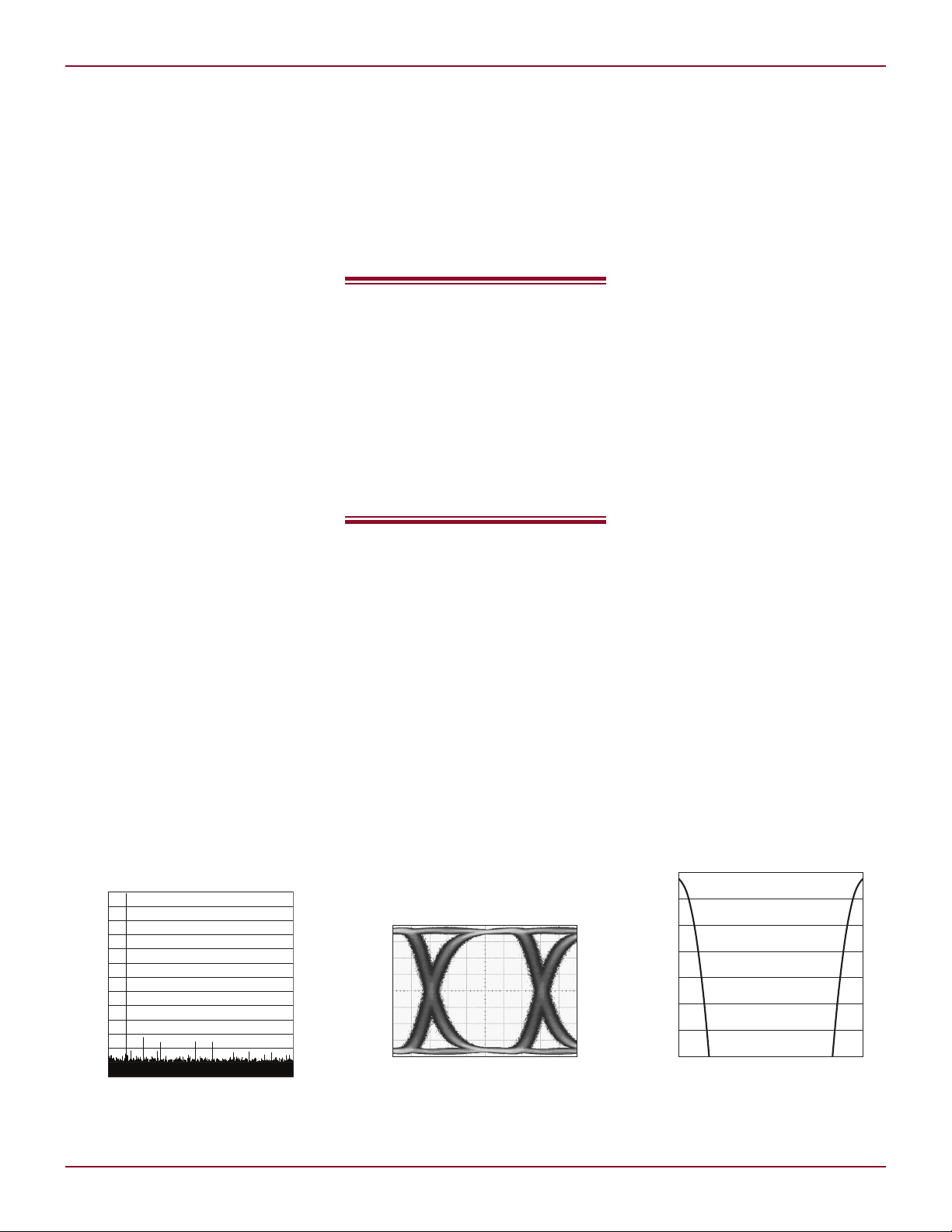

FREQUENCY (MHz)

0

AMPLITUDE (dBFS)

10 20 30 40 50

–130

–120

–110

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

79.4ps/DIV

100mV/DIV

UNIT INTERVAL (UI)

0

BIT ERROR RATE (BER)

0.80.4 1.00.60.2

1.0E–14

1.0E–12

1.0E–10

1.0E–08

1.0E–06

1.0E–04

1.0E–02

1.0E+00

Serial Interface for High Speed Data

Converters Simplifies Layout over

Traditional Parallel Devices

by Clarence Mayott

Introduction

The LTC2274 is a 105Msps, 16-bit

ADC that simplifies the digital connection between the ADC and FPGA by

replacing the usual parallel interface

with a novel high speed serial interface,

thus reducing the typical number of

required data input/output (I/O) lines

from 16 CMOS or 32 LVDS parallel

data lines to a single, self-clocking,

differential pair communicating at

2.1Gbps. This frees up valuable FPGA

pins and board space. It also allows

flexibility to route across analog and

digital boundaries—in noise sensitive applications, the serial interface

provides an effective isolation barrier

between digital and analog circuitry

and serves to eliminate coupling between the digital outputs and analog

inputs to reduce digital feedback.

Current Mode Logic and

8B/10B Encoding Allows

High Speed Serial Data

Transfer

The LTC2274 achieves excellent signal

to noise ratio (SNR) performance of

77.6dBFS and spurious free dynamic

range (SFDR) of 100dB at baseband,

as shown in Figure 1. The input topology of the LTC2274 family is based on

its predecessor, the LTC2207 family,

The LTC2274 ADC replaces

the usual parallel interface

with a novel high speed

serial interface, thus

reducing the typical number

of required data input/

output lines from 16 CMOS

or 32 LVDS to a single, self-

clocking, differential pair

communicating at 2.1Gbps.

and achieves similar AC performance.

However, the LTC2274 differs from the

LTC2207 in its output structure. The

LTC2274 uses an 8B/10B encoder to

encode and serialize the data before it

is transmitted. 8B/10B encoding is a

process that takes 8 bits of data and

encodes them into 10 bits to ensure

zero DC offset and a limited run length.

To encode a 16-bit word, the LTC2274

must transmit 20 bits of serial data.

This requires that the serial data must

be transmitted at 20 times the clock

frequency of the ADC. Sampling at

105Msps requires the LTC2274 to

transmit serial data at 2.1GHz. This

is beyond the usable range of LVDS

signaling, and therefore requires a

faster, more robust differential signaling scheme. The LTC2274’s differential

signaling uses current mode logic

(CML), which is capable of transmitting

data in excess of 10GHz.

Current mode logic uses a differential output transistor pair (usually

N-type) to steer current into resistive

loads. The output swing and offset

depends on the bias current and

termination resistance. The output

driver bias current is typically 16mA,

generating a signal swing potential

of 400mV

(800mV

P–P

differential)

P–P

across the combined internal and

external termination resistance of 25Ω

on each output. LVDS typically uses

3.5mA to develop its signal swing, and

the capacitance of the ESD protection

diodes becomes a limiting factor for

transmission speed. CML uses more

current, and therefore this capacitance

becomes less of a limiting factor to

data throughput.

CML is typically faster than LVDS.

A typical LVDS output stage requires

four transistors to steer current into

the load, usually using both P-channel

and N-channel devices. A mixture of

N- and P-channel makes it difficult to

produce devices that have the same

characteristics. P-channel devices are

often slower—that is, if an N-channel

Figure 1. Typical LTC2274 performance

at 105Msps f

Linear Technology Magazine • September 2008

= 4.93MHz

IN

a. CMLOUT eye diagram 2.1GBps

Figure 2. Signal integrity of CMLOUT

b. CMLOUT Dual-Dirac BER

bathtub curve, 2.1GBps

13

Page 2

L DESIGN FEATURES

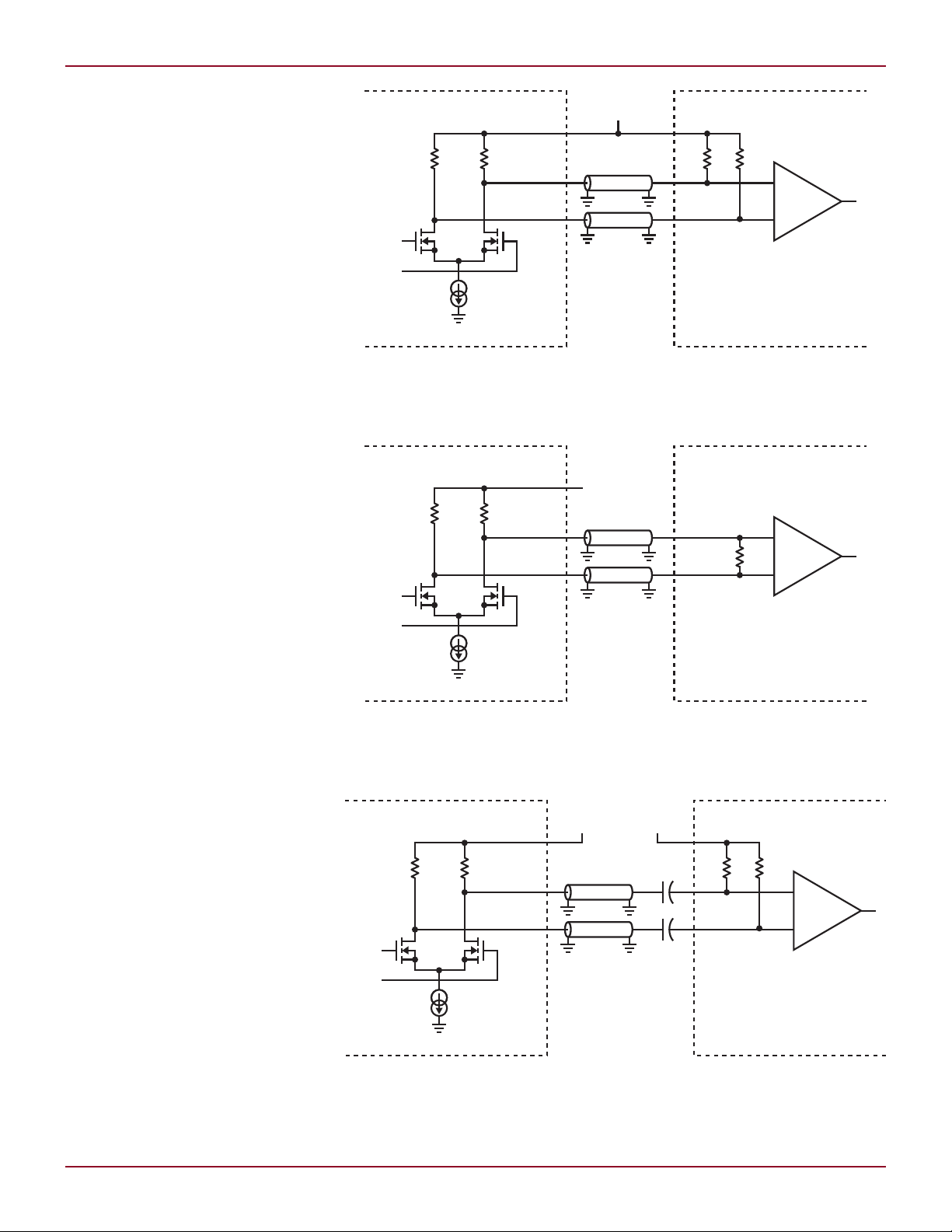

50Ω50Ω50Ω 50Ω

DATA

+

DATA

–

GND

SERIAL CML DRIVER SERIAL CML RECEIVER

1.2V TO 3.3V

16mA

CMLOUT

+

OV

DD

CMLOUT

–

50Ω

TRANSMISSION LINE

50Ω

TRANSMISSION LINE

100Ω

50Ω 50Ω

DATA

+

DATA

–

GND

SERIAL CML DRIVER SERIAL CML RECEIVER

1.4V TO 3.3V

50Ω

TRANSMISSION LINE

50Ω

TRANSMISSION LINE

16mA

CMLOUT

+

OV

DD

CMLOUT

–

50Ω50Ω

0.01µF

0.01µF

50Ω 50Ω

DATA

+

DATA

–

GND

SERIAL CML DRIVER SERIAL CML RECEIVER

1.4V TO 3.3V VTERM

16mA

CMLOUT

+

OV

DD

CMLOUT

–

50Ω

TRANSMISSION LINE

50Ω

TRANSMISSION LINE

and a P-channel device are cascaded,

the P-channel cannot pull up the signal

as fast as the N-channel can pull down.

This causes the output waveform to be

distorted, which can lead to bit errors,

and limits the speed at which LVDS

can transfer data.

The LTC2274 CML driver is implemented with only N-channel devices,

which allows faster throughput rates.

Since CML only sinks current, it has

true differential signal, which improves

signal integrity. The eye diagram and

bathtub curves of the LTC2274 are

shown in Figure 2. The eye diagram

shows very little variation cycle to

cycle of the CML logic output, and the

bathtub curve shows that total jitter

in the signal is less than 0.35UI (unit

interval). This equates into a very clean

uniform signal that can easily received

by a properly terminated receiver.

a. Recommended CML termination, directly-coupled mode

Termination of CML

CML must be terminated for proper

operation. Figure 3a shows a recommended design in which an FPGA

receiver uses internal 50Ω pull up re-

sistors for termination. These resistors

pull up to the OV

OV

must be between 1.2V and 3.3V

DD

to ensure proper operation. The signal

has a common mode voltage of OV

– 0.2V. The directly-coupled differential termination of Figure 3b may be

used in the absence of a receiver termination voltage within the required

range. In this case, the common mode

voltage is shifted down to approximately 400mV below OVDD, requiring

an OV

in the range of 1.4V to 3.3V.

DD

If the serial receiver’s common mode

input requirements are not compatible

with the directly-coupled termination

modes, the DC balanced 8B/10B

encoded data permits the addition of

DC blocking capacitors as shown in

Figure 3c. In this AC-coupled mode,

the termination voltage is determined

by the receiver’s requirements. The

coupling capacitors should be selected appropriately for the intended

operating bit-rate, usually between

1nF and 10nF. In AC coupled mode,

the output common mode voltage is

approximately 400mV below OVDD, so

the OV

14

supply voltage should be in

DD

of the LTC2274.

DD

DD

b. CML termination, directly-coupled differential mode

c. CML termination, AC-coupled mode

Figure 3. CML termination schemes

Linear Technology Magazine • September 2008

Page 3

DESIGN FEATURES L

the range of 1.4V to 3.3V. If possible,

using a lower OV

can reduce power

DD

consumption. The termination scheme

is largely based on the receiver. When

choosing the OV

voltage, refer to the

DD

receiver’s data sheet to terminate the

CML lines properly.

CML uses true double termination.

Generally, LVDS is only terminated at

the receiver, which means that any

signal reflection back to the source

reflects back to the receiver with little

attenuation. This limits the data rate

and trace length that LVDS can drive.

The truly differential nature of CML

radiates less energy than LVDS and

CMOS signals, allowing devices to be

in closer proximity to antennas, mixers or other sensitive analog front end

systems. CML also has common mode

termination. This gives CML a better

common mode behavior than LVDS.

LVDS is only terminated differentially,

which does not reject any common

mode signal that may appear on the

transmission line—another limiting

factor in LVDS signaling.

CML Power Consumption

With a constant 16mA of bias current

and a voltage swing of 800mV differential, CML logic consumes a moderate

amount of power. For an equal data

rate, CML logic consumes less total

power than PECL and LVPECL. A

single CML driver uses more power

than a single LVDS driver, but only

marginally more that the three pairs

of LVDS drivers required for a typical

LVDS serial bus.

8B/10B Encoding Makes for

Simple Connection

The 8B/10B encoding process results

in an average DC offset of zero, allowing

the data to be routed through transformers or fiber channel transceivers

that can provide isolation between

the digital and analog realm. 8B/10B

encoding also does not require a framing signal or a data clock, whereas

both are required in traditional serial

communication. 8B/10B encoding

transmits data over a single pair of

data lines, whereas a typical serial

ADC requires three or more pairs,

and a typical parallel ADC can require

more than 16 pairs.

The complexity of decoding 8B/10B

lies in the receiver. Fortunately Xilinx,

Altera and Lattice have solutions to

receive data from the LTC2274 and

decode the 8B/10B data, simplifying

the collection of 8B/10B data. Other

8B/10B decoding solutions may be

available. The FPGA required to receive

data from the LTC2274 must be able

to receive high speed serial transmissions of 2GHz or more.

Conclusion

Without sacrificing resolution or

sample rate, the LTC2274 delivers full

16-bit performance at 105Msps over

a single pair of transmission lines,

greatly simplifying layout and saving

valuable board space. This mitigates

interaction with other circuitry in

software defined radio, base station or

industrial applications which involve

many channels of an ADC routed to

one FPGA.

L

LTC35xx, continued from page 6

power synchronous boost converter

(Figure 5).

The fully integrated boost in the

LTC3586 can regulate up to a 5V output with up to 800mA from a battery

voltage as low as 3V. The regulator has

built in output disconnect making it

well-suited for USB OTG supplies or

for powering motors in printer and

camera applications. The current

mode synchronous boost is internally

compensated and operates at a fixed

2.25MHz switching frequency. Pulseskipping at low loads achieves low

noise output for driving high power

audio circuits.

I2C, Programmable

Sequencing and Easy I/O

Despite the progress in new cutting

edge features and design, one old

problem does not go away: power

supply control. Power supplies require

startup and power down sequencing,

fault detection/reporting/handling

and voltage and operating mode adjustments. Getting it all right can be

a system control nightmare depending

on the complexity and limitations of

the power supply circuits.

The LTC35xx family provides very

simple and flexible control of all essential power supply functions. The

LTC3566 and LTC3586 employ dedicated I/O control pins for enabling,

disabling and changing DC/DC

operating modes. Voltages on these

parts are fixed and set with external resistor dividers. The LTC3555,

LTC3556 and LTC3567 accommodate

either I2C control or simple I/O pins

to control the supplies. The LTC3556

provides a three-state SEQ pin to allow the power up sequence of its three

DC/DC converters to be programmed

via pin-strapping. Those parts with

I2C V

maximum V

control power-up at their

OUT

(as determined by the

OUT

FB servo point and external dividers)

when enabled via simple I/O, and

can independently reduce V

OUT

by as

much as 50% in equal 16-step increments via I2C.

All DC/DC converters in all the

PMICs discussed here can survive

an indefinite output fault. The parts

all provide a RST output and all converters are actively pulled down in

shutdown to ensure proper power-up

sequencing. The LTC3586 contains an

additional fault handing feature that

automatically powers down all DC/DC

converters whenever a valid fault is

detected. In short, the entire family

is designed for simple, flexible and

trouble-free control and operation.

Conclusion

Linear Technology’s latest PMIC

products improve the performance

and simplify the design of a wide variety of portable power management

applications. Instead of kitchen sink

alternatives with large packages,

Linear Technology offers a number of

devices with various feature mixes in

small packages. These new PMICs are

simple to use, highly integrated and

high performance, allowing for shorter

design times, greater PCB flexibility,

and better power/thermal management than traditional solutions.

L

Linear Technology Magazine • September 2008

15

Loading...

Loading...