查询LTC1983-3供应商

FEATURES

■

Fixed Output Voltages: –3V, –5V or Low Noise V

to –VIN Inverted Output

■

±4% Output Voltage Accuracy

■

Low Quiesient Current: 25µA

■

100mA Output Current Capability

■

3V to 5.5V Operating Voltage Range (LTC1983-3)

■

2.3V to 5.5V Operating Voltage Range (LTC1983-5)

■

Internal 900kHz Oscillator

■

“Zero Current” Shutdown

■

Short-Circuit and Over-Temperature Protected

■

Low Profile (1mm) ThinSOTTM Package

U

APPLICATIO S

■

–3V Generation in Single-Supply Systems

■

Portable Equipment

■

LCD Bias Supplies

■

GaAs FET Bias Supplies

IN

LTC1983-3/LTC1983-5

100mA Regulated

Charge-Pump Inverters

in ThinSOT

U

DESCRIPTIO

The LTC®1983-3 and LTC1983-5 are inverting charge

pump DC/DC converters that produce negative regulated

outputs. The parts require only three tiny external capacitors and can provide up to 100mA of output current. The

devices can operate in open loop mode (creating a –V

supply) or regulated output mode depending on the input

supply voltage and the output current.

The LTC1983-3/LTC1983-5 have many useful features for

portable applications including very low quiescent current

(25µA typical) and a zero current shutdown mode pro-

grammed through the SHDN pin.

The LTC1983-3/LTC1983-5 are over-temperature and

short-circuit protected. The parts are available in a 6-pin

low profile (1mm) ThinSOT package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

IN

TYPICAL APPLICATIO

–3V at 100mA DC/DC Converter

V

3V TO 5.5V

10µF

OFF ON

IN

C

IN

: TAIYO YUDEN LMK212BJ105

C

FLY

, C

: TAIYO YUDEN JMK316BJ106ML

C

IN

OUT

V

IN

LTC1983-3

SHDN

+

C

C

FLY

1µF

V

GND

OUT

C

–

1983-3 TA01

U

= –3V

V

OUT

= UP TO 100mA

I

OUT

C

OUT

10µF

(V)

OUT

V

–3.3

–3.2

–3.1

–3.0

–2.9

–2.8

–2.7

V

OUT

0

20 40 60 80

I

OUT

vs I

OUT

VIN = 5V

VIN = 3.3V

(mA)

100

1983 TA02

sn1983 1983fs

1

LTC1983-3/LTC1983-5

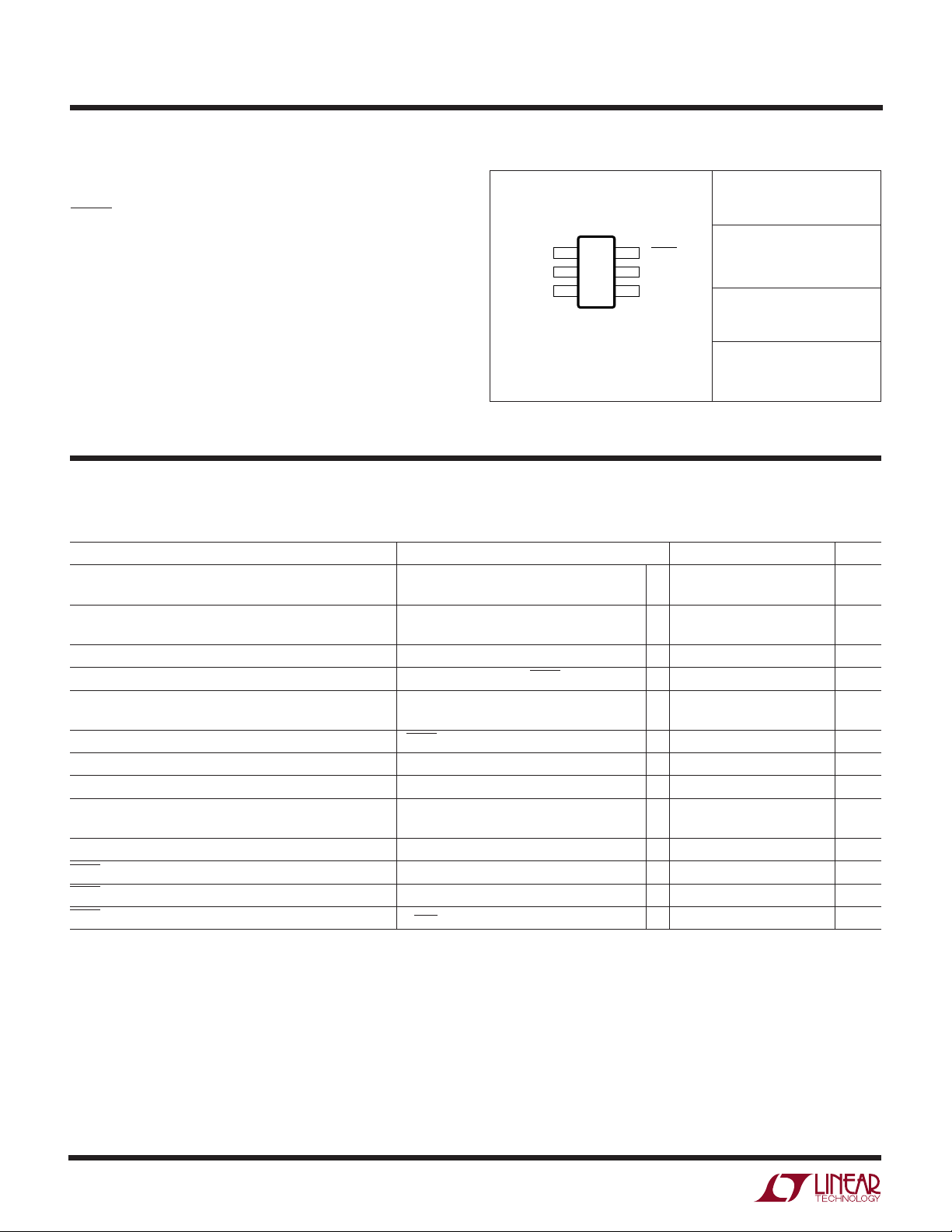

VCC 1

V

OUT

2

C

+

3

6 SHDN

5 GND

4 C

–

TOP VIEW

S6 PACKAGE

6-LEAD PLASTIC SOT-23

WW

W

ABSOLUTE AXI U RATI GS

U

UUW

PACKAGE/ORDER I FOR ATIO

(Note 1)

VIN to GND................................................... –0.3V to 6V

SHDN Voltage ..............................................–0.3V to 6V

V

to GND (LTC1983-3)..................0.2V to V

OUT

V

to GND (LTC1983-5)..................0.2V to V

OUT

I

Max ............................................................. 125mA

OUT

OUT

OUT

Max

Max

Output Short-Circuit Duration..........................Indefinite

Operating Temperature Range (Note 2) ...–40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

Lead Temperature (Soldering, 10 sec).................. 300°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 5V, C

The ● denotes the specifications which apply over the full operating

T

= 1µF, C

FLY

JMAX

= 125°C, θJA = 256°C/W

= 10µF

OUT

ORDER PART

NUMBER

LTC1983ES6-3

LTC1983ES6-5

S6 PART

MARKING

LTPC

LTYB

unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Operating Voltage (Regulated Output Mode) (LTC1983-3) ● 3.0 5.5 V

Min Startup Voltage 2.3 V

V

IN

V

(LTC1983-3) VIN ≥ 3.3V, I

OUT

V

(LTC1983-5) VIN ≥ 5V, VIN –5V ≥ I

OUT

VIN Operating Current V

VIN Operating Current (Open-Loop Mode) (LTC1983-5) VIN = 3.3V 2.5 mA

VIN Shutdown Current SHDN = 0V, VIN ≤ 5.5V ● 0.1 1 µA

Output Ripple 3.3 ≤ VIN ≤ 5.5 60 mV

Open-Loop Output Impedance (LTC1983-3): R

Open-Loop Output Impedance (LTC1983-5): R

Oscillator Frequency (Non-Burst Mode® Operation) 900 kHz

SHDN Input High ● 1.1 V

SHDN Input Low ● 0.3 V

SHDN Input Current V

OUT

OUT

V

≥ 5V, I

IN

≤ 5.5V, I

IN

V

= 4.75V 4 mA

IN

VIN = 3.3V, V

VIN = 3.3V, I

V

= 5V, I

IN

= 5.5V ● 2.2 4 µA

SHDN

≤ 25mA ● –2.88 –3 –3.12 V

OUT

≤ 100mA ● –2.88 –3 –3.12 V

OUT

• R

OUT

OUT

= 0µA, SHDN = V

OUT

= –3V 11 Ω

OUT

≈ 50mA 11 Ω

OUT

≈ 60mA 8.5 Ω

OUT

IN

● – 4.8 –5 –5.2 V

● 25 60 µA

P-P

Burst Mode is a registered trademark of Linear Technology

Corporation.

Note 1: Absolute Maximum Ratings are those values beyond

which the life of a device may be impaired.

2

Note 2: The LTC1983E-3/LTC1983E-5 are guaranteed to meet

performance specifications from 0°C to 70°C. Specifications over the

–40°C to 85°C operating temperature range are assured by design,

characterization and correlation with statistical process controls.

sn1983 1983fs

UW

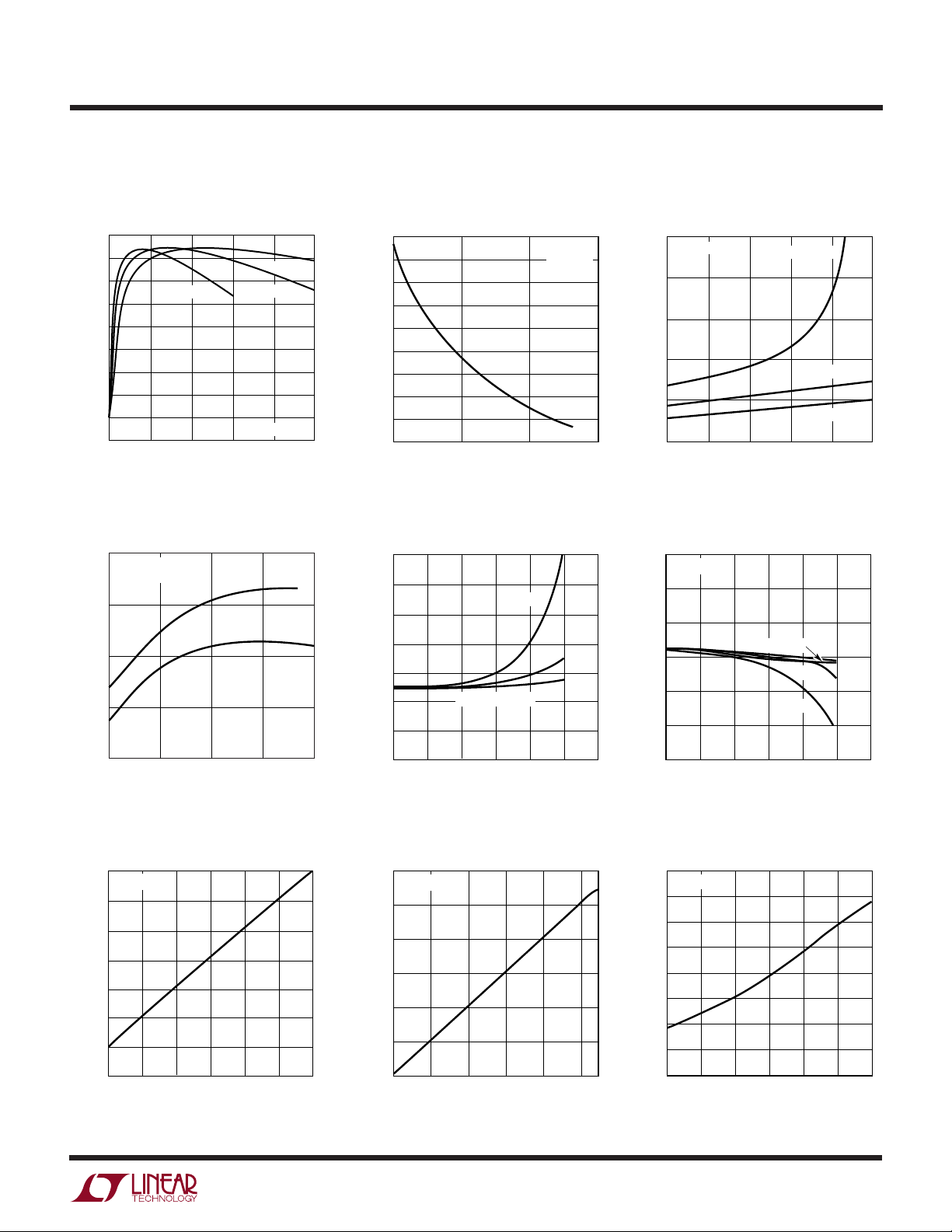

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1983-3/LTC1983-5

Efficiency vs I

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0

Efficiency vs I

100

V

OUT

= 25°C

T

A

75

50

EFFICIENCY (%)

25

OUT

VIN = 2.3V

20 60

40

I

(mA)

OUT

OUT

= –3V

(LTC1983-5)

VIN = 5V

VIN = 3.3V

TA = 25°C

80

= 3.3V

V

IN

VIN = 5V

1983 G01

100

Output Impedance vs

Input Voltage

12.5

12.0

11.5

11.0

10.5

(Ω)

OUT

10.0

R

9.5

9.0

8.5

8.0

2.35

–3V

vs I

OUT

–2.1

–2.3

–2.5

–2.7

(V)

OUT

V

–2.9

–3.1

–3.3

I

= 25mA

OUT

= 25°C

T

A

R

OUT

3.35 5.35

OUT

–40°C, 0°C, 40°C

4.35

VIN (V)

1983 TA02

Over Temperature

120°C

80°C

Output Impedance

vs I

(LTC1983-5)

OUT

30

TA = 25°C

25

20

(Ω)

OUT

R

15

10

5

0

20 60

–3V

vs I

OUT

(VIN = 5V)

3.3

VIN = 5V

3.2

3.1

(–V)

3.0

OUT

V

2.9

2.8

VIN = 2.3V

VIN = 3.3V

40

I

(mA)

OUT

Over Temperature

OUT

–40°C

0°C

40°C

80°C

VIN = 5V

80

1983 G03

100

0

0.01

0.1 1 100

I

(mA)

OUT

Open-Loop Current

vs Temperature (LTC1983-5)

4.9

VIN = 5V

4.7

4.5

4.3

(mA)

IN

I

4.1

3.9

3.7

3.5

–40

10

TEMPERATURE (°C)

10

1983 GO4

60 110

1983 G07

–3.5

0

20 40

OUTPUT CURRENT (mA)

Open-Loop Input Current

vs VIN (LTC1983-5)

4.5

TA = 25°C

4.0

3.5

3.0

(mA)

IN

I

2.5

2.0

1.5

2.3

2.8

3.3 3.3 4.3

80 120

60 100

VIN (V)

1983 G05

4.8

1983 G09

2.7

0

40 60 80

20

OUTPUT CURRENT (mA)

Burst Mode Current

vs Temperature (LTC1983-3)

50

VIN = 5V

45

40

35

30

(µA)

IN

I

25

20

15

10

–40

10 60

TEMPERATURE (°C)

100 120

1983 G06

110

1983 G08

sn1983 1983fs

3

LTC1983-3/LTC1983-5

TEMPERATURE (°C)

–50

0

V

THRESHOLD

(V)

0.1

0.3

0.4

0.5

1.0

0.7

0

50

1983 G12

0.2

0.8

0.9

0.6

100

150

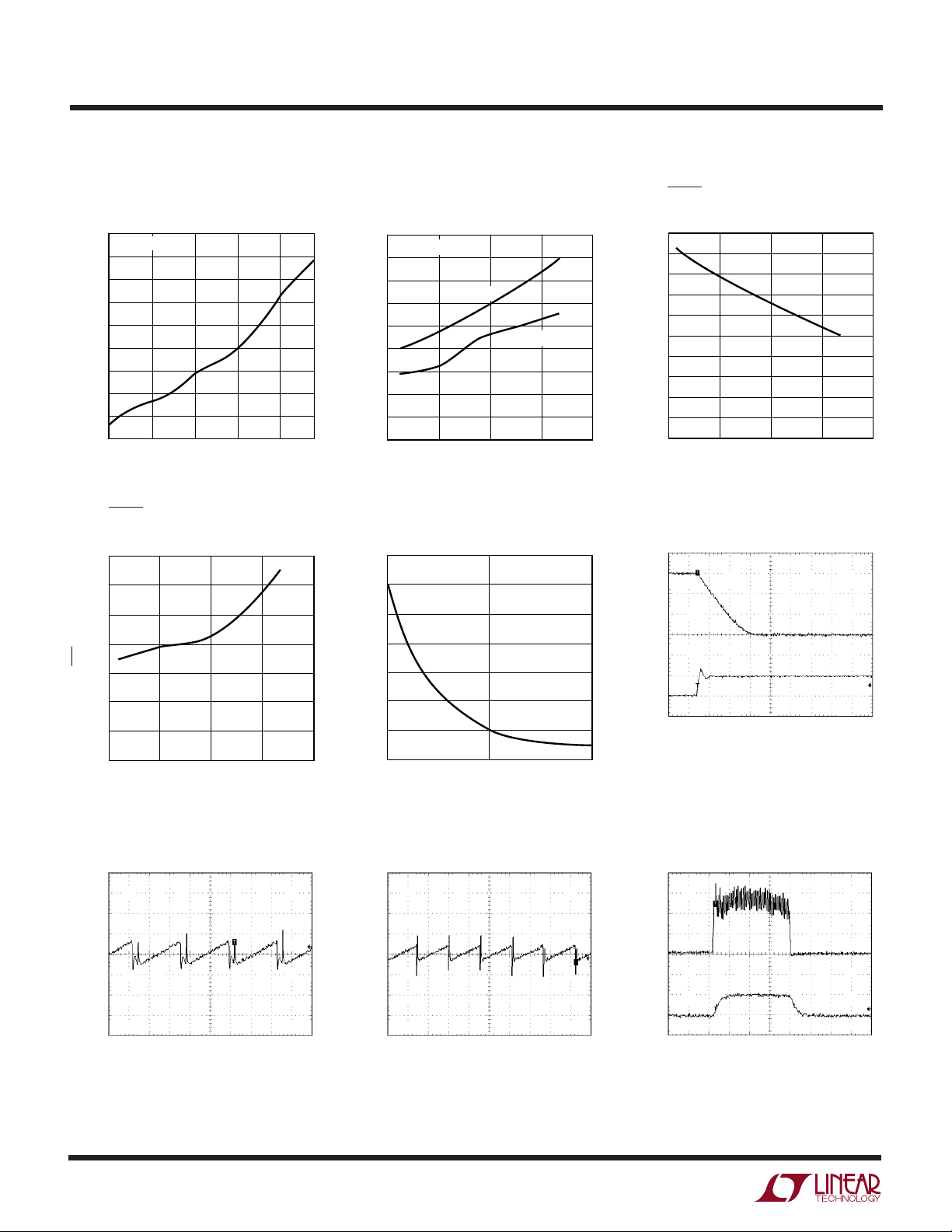

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Burst Mode Input Current

vs VIN (LTC1983-3)

31.0

TA = 25°C

30.5

30.0

29.5

29.0

28.5

28.0

INPUT CURRENT (µA)

27.5

27.0

26.5

3.1

3.6 4.6

4.1

VIN (V)

5.1 5.5

1983 G10

SHDN Pin Input Current

vs Temperature R

3.5

3.0

2.5

2.0

SHDN

I

1.5

1.0

(Ω)

OUT

R

1400

1200

1000

800

(Ω)

OUT

600

R

400

R

vs Temperature

OUT

(I

= 10mA)

OUT

18

I

= 10mA

OUT

16

14

12

10

8

6

4

2

0

–50

vs C

OUT

= 5V

V

IN

= 25°C

T

A

VIN = 3V

0

50

TEMPERATURE (

(V

FLY

IN

VIN = 5V

= 5V)

°C)

100

1983 G11

150

SHDN Pin Threshold Voltage

vs Temperature

V

Start-Up into 100mA

OUT

Resistive Load

V

OUT

1V

V

IN

5V

0.5

0

–50

V

OUT

V

OUT

20mV

4

0 50 150

TEMPERATURE (°C)

100

Ripple at 100mA Load

1µs/DIV 1983 G16

1983 G13

200

V

OUT

20mV

0

0.01

V

Ripple at 30mA Load

OUT

0.1 1

C

(µF)

FLY

2.5µs/DIV

1983 G14

1983 G17

V

OUT

20mV

I

OUT

100mA

50µs/DIV 1983 G15

V

Load Step Reponse from

OUT

I

OUT

= 0 to I

= 100mA

OUT

100µs/DIV

1983 G18

sn1983 1983fs

LTC1983-3/LTC1983-5

U

UU

PI FU CTIO S

V

(Pin 1): Charge Pump Input Voltage. May be between

IN

2.3V and 5.5V. VIN should be bypassed with a ≥4.7µF low

ESR capacitor as close as possible to the pin for best

performance.

V

(Pin 2): Regulated Output Voltage for the IC. V

OUT

OUT

should be bypassed with a ≥4.7µF low ESR capacitor as

close as possible to the pin for best performance.

C+ (Pin 3): Charge Pump Flying Capacitor Positive Terminal. This node is switched between VIN and GND (It is

connected to VCC during shutdown).

W

BLOCK DIAGRA

LTC1983-X

+

C

S1A

C– (Pin 4): Charge Pump Flying Capacitor Negative Terminal. This node is switched between GND and V

OUT

(It is

connected to GND during shutdown).

GND (Pin 5): Signal and Power Ground for the 6-Pin

SOT-23 package. This pin should be tied to a ground plane

for best performance.

SHDN (Pin 6): Shutdown. Grounding this pin shuts down

the IC. Tie to VIN to enable. This pin should not be pulled

above the VIN voltage or below GND.

V

IN

C

IN

10µF

C

FLY

1µF

V

OUT

C

OUT

10µF

S2A

–

C

S1B

S2B

CHARGE PUMP

CLOCK1

CLOCK2

CONTROL

LOGIC

COMP1

SHDN

V

REF

+

–

1µA

1983 BD

sn1983 1983fs

5

LTC1983-3/LTC1983-5

U

OPERATIO

(Refer to Block Diagram)

The LTC1983-3/LTC1983-5 use a switched capacitor

charge pump to invert a positive input voltage to a regulated –3V ±4% (LTC1983-3) or –5 ±4% (LTC1983-5)

output voltage. Regulation is achieved by sensing the

output voltage through an internal resistor divider and

enabling the charge pump when the output voltage droops

above the upper trip point of COMP1. When the charge

pump is enabled, a 2-phase, nonoverlapping clock controls the charge pump switches. Clock 1 closes the S1

switches which enables the flying capacitor to charge up

to the VIN voltage. Clock 2 closes the S2 switches that

invert the VIN voltage and connect the bottom plate of C

to the output capacitor at V

. This sequence of charging

OUT

FLY

and discharging continues at a free-running frequency of

900kHz (typ) until the output voltage has been pumped

down to the lower trip point of COMP1 and the charge

pump is disabled. When the charge pump is disabled, the

LTC1983 draws only 25µA (typ) from VIN which provides

high efficiency at low load conditions.

In shutdown mode, all circuitry is turned off and the part

draws less than 1µA from the VIN supply. V

disconnected from VIN and C

. The SHDN pin has a

FLY

OUT

is also

threshold of approximately 0.7V. The part enters shutdown when a low is applied to the SHDN pin . The SHDN

pin should not be floated; it must be driven with a logic

high or low.

Open-Loop Operation

The LTC1983-3/LTC1983-5 inverting charge pumps regulate at –3V/–5V respectively, unless the input voltage is too

low or the output current is too high. The equations for

output voltage regulation are as follows:

VIN –5.06V > I

VIN –3.06V > I

OUT

OUT

• R

• R

(LTC1983-5)

OUT

(LTC1983-3)

OUT

If this condition is not met, then the part will run in open

loop mode and act as a low output impedance inverter for

which the output voltage will be:

V

= –[VIN –(I

OUT

OUT

• R

OUT

)]

For all R

values, check the corresponding curves in

OUT

the Typical Performance Characteristics section (Note:

C

= 1µF for all R

FLY

curves). The R

OUT

value will be

OUT

different for different flying caps, as shown in the following equation:

=Ω+

OUT OUT

()–.

111

fC

OSC FLY

R R curve

1

•

Short-Circuit/Thermal Protection

During short-circuit conditions, the LTC1983 will draw

several hundred milliamps from VIN causing a rise in the

junction temperature. On-chip thermal shutdown circuitry disables the charge pump once the junction temperature exceeds ≈155°C, and reenables the charge pump

once the junction temperature falls back to ≈145°C. The

LTC1983 will cycle in and out of thermal shutdown

indefinitely without latchup or damage until the V

OUT

short is removed.

Capacitor Selection

For best performance, it is recommended that low ESR

capacitors be used for both CIN and C

and ripple. The CIN and C

capacitors should be either

OUT

to reduce noise

OUT

ceramic or tantalum and should be 4.7µF or greater.

Aluminum electrolytic are not recommended because of

their high equivalent series resistance (ESR). If the source

impedance is very low, CIN may not be needed. Increasing

the size of C

voltage ripple. The flying capacitor and C

to 10µF or greater will reduce output

OUT

should also

OUT

have low equivalent series inductance (ESL). The board

layout is critical as well for inductance for the same reason

(the suggested board layout should be used).

A ceramic capacitor is recommended for the flying capacitor with a value in the range of 0.1µF to 4.7µF. Note that

a large value flying cap (>1µF) will increase output ripple

unless C

is also increased. For very low load applica-

OUT

tions, C1 may be reduced to 0.01µF to 0.047µF. This will

reduce output ripple at the expense of efficiency and

maximum output current.

6

sn1983 1983fs

V

OUT

V

OUT

LTC1983-X

10µF

TANTALUM

10µF

TANTALUM

V

OUT

V

OUT

LTC1983-X

15µF

TANTALUM

1µF

CERAMIC

3.9Ω

1983 F01

OPERATIO

LTC1983-3/LTC1983-5

U

(Refer to Block Diagram)

There are many aspects of the capacitors that must be

taken into account. First, the temperature stability of the

dielectric is a main concern. For ceramic capacitors, a

three character code specifies the temperature stability

(e.g. X7R, Y5V, etc.). The first two characters represent

the temperature range that the capacitor is specified and

the third represents the absolute tolerance that the capacitor is specified to over that temperature range. The

ceramic capacitor used for the flying and output capacitors should be X5R or better. Second, the voltage coef-

ficient of capacitance for the capacitor must be checked

and the actual value usually needs to be derated for the

operating voltage (the actual value has to be larger than

the value needed to take into account the loss of capacitance due to voltage bias across the capacitor). Third, the

frequency characteristics need to be taken into account

because capacitance goes down as the frequency of

oscillation goes up. Typically, the manufacturers have

capacitance vs frequency curves for their products. This

curve must be referenced to be sure the capacitance will

not be too small for the application. Finally, the capacitor

ESR and ESL must be low for reasons mentioned in the

following section.

Output Ripple

Normal LTC1983 operation produces voltage ripple on the

V

pin. Output voltage ripple is required for the LTC1983

OUT

to regulate. Low frequency ripple exists due to the hysteresis in the sense comparator and propagation delays in the

charge pump enable/disable circuits. High frequency ripple

is also present mainly due to ESR of the output capacitor.

Typical output ripple under maximum load is 60mV

with a low ESR 10µF output capacitor. The magnitude of

the ripple voltage depends on several factors. High input

voltage to negative output voltage differentials [(VIN +

V

) >1V] increase the output ripple since more charge

OUT

is delivered to C

per clock cycle. A large flying capacitor

OUT

(>1µF) also increases ripple for the same reason. Large

output current load and/or a small output capacitor (<10µF)

P-P

results in higher ripple due to higher output voltage dV/dt.

High ESR capacitors (ESR > 0.1Ω) on the output pin cause

high frequency voltage spikes on V

with every clock

OUT

cycle.

There are several ways to reduce the output voltage ripple.

A larger C

the low and high frequency ripple due to the lower C

capacitor (22µF or greater) will reduce both

OUT

OUT

charging and discharging dV/dt and the lower ESR typically found with higher value (larger case size) capacitors.

A low ESR ceramic output capacitor will minimize the high

frequency ripple, but will not reduce the low frequency

ripple unless a high capacitance value is chosen. A reasonable compromise is to use a 10µF to 22µF tantalum

capacitor in parallel with a 1µF to 4.7µF ceramic capacitor

on V

to reduce both the low and high frequency ripple.

OUT

However, the best solution is to use 10µF to 22µF, X5R

ceramic capacitors which are available in 1206 package

sizes. An RC filter may also be used to reduce high

frequency voltage spikes (see Figure 1).

In low load or high VIN applications, smaller values for

C

may be used to reduce output ripple. A smaller flying

FLY

capacitor (0.01µF to 0.047µF) delivers less charge per

clock cycle to the output capacitor resulting in lower

output ripple. However, the smaller value flying caps also

reduce the maximum I

Figure 1. Output Ripple Reduction Techniques

capability as well as efficiency.

OUT

sn1983 1983fs

7

LTC1983-3/LTC1983-5

U

OPERATIO

(Refer to Block Diagram)

Inrush Currents

During normal operation, VIN will experience current transients in the several hundred milliamp range whenever the

charge pump is enabled. During start-up, these inrush

currents may approach 1 to 2 amps. For this reason, it is

important to minimize the source resistance between the

input supply and the V

pin. Too much source resistance

IN

may result in regulation problems or even prevent startup. One way that this can be avoided (especially when the

source impedance can’t be lowered due to system constraints) is to use a large VIN capacitor with low ESR right

at the VIN pin. If ceramic capacitors are used, you may

need to add 1µF to 10µF tantalum capacitor in parallel to

limit input voltage transients. Input voltage transients will

occur if V

is applied via a switch or a plug. One example

IN

of this situation is in USB applications.

Ultralow Quiescent Current Regulated Supply

The LTC1983 contains an internal resistor divider (refer to

the Block Diagram) that draws only 1µA (typ for the 3V

version) from V

during normal operation. During shut-

OUT

down, the resistor divider is disconnected from the output

and the part draws only leakage current from the output.

During no-load conditions, applying a 1Hz to 100Hz, 2%

to 5% duty cycle signal to the SHDN pin ensures that the

circuit of Figure 2 comes out of shutdown frequently

enough to maintain regulation even under low-load conditions. Since the part spends nearly all of its time in

shutdown, the no-load quiescent current is essentially

zero. However, the part will still be in operation during the

time the SHDN pin is high, so the current will not be zero

and can be calculated using the following equations to

determine the approximate maximum current: I

IN(MAX)

=

[(Time out of shutdown) • (Burst Mode operation quiescent current) + (Normal operating IIN) • (Time output is

being charged before the LTC1983 enters Burst Mode

operation)]/(Period of SHDN signal). This number will be

highly dependent on the amount of board leakage current

and how many devices are connected to V

(each will

OUT

draw some leakage current) and must be calculated and

verified for each different board design.

V

IN

TANTALUM

Figure 2. Ultralow Quiescent Current Regulated Supply

3.3V TO 5.5V

C

IN

10µF

SHDN PIN WAVEFORMS:

LOW IQ MODE

≤ 100µA)

(I

OUT

(1Hz TO 100Hz, 2% TO 5% DUTY CYCLE)

LTC1983-3

V

SHDN

IN

GND

V

OUT

+

C

C

FLY

1µF

CERAMIC

V

LOAD ENABLE MODE

OUT

= 100µA TO 100mA)

(I

OUT

–

C

FROM MPU

SHDN

–3V ± 4%

C

OUT

10µF

CERAMIC

1983 F02

The LTC1983 must be out of shutdown for a minimum

duration of 200µs to allow enough time to sense the output

and keep it in regulation. A 1Hz, 2% duty cycle signal will

keep V

in regulation under no-load conditions. Even

OUT

though the term no-load is used, there will always be board

leakage current and leakage current drawn by anything

connected to V

. This is why it is necessary to wake the

OUT

part up every once in a while to verify regulation. As the

V

load current increases, the frequency with which the

OUT

part is taken out of shutdown must also be increased to

prevent V

from drooping below the – 2.88V (for the 3V

OUT

version) during the OFF phase (see Figure 3). A 100Hz, 2%

duty cycle signal on the SHDN pin ensures proper regulation with load currents as high as 100µA. When load

current greater than 100µA is needed, the SHDN pin must

be forced high as in normal operation.

Each time the LTC1983 comes out of shutdown, the part

delivers a minimum of one clock cycle worth of charge to

the output. Under high VIN (>4V) and/or low I

(<10µA)

OUT

conditions, this behavior may cause a net excess of charge

to be delivered to the output capacitor if a high frequency

signal is used on the SHDN pin (e.g., 50Hz to 100Hz).

Under such conditions, V

will slowly drift positive and

OUT

may even go out of regulation. To avoid this potential

8

sn1983 1983fs

OUTPUT CURRENT (µA)

1

10

100

1000

MAXIMUM SHDN OFF TIME (ms)

1000

1983 F03b

1 10 100

SHDN ON PULSE WIDTH = 200µs

C

OUT

= 10µF

U

OPERATIO

problem in the low IQ mode, it is necessary to switch the

part in and out of shutdown at the minimum allowable

frequency (refer to Figure 3) for a given output load.

General Layout Considerations

Due to the high switching frequency and high transient

currents produced by the LTC1983, careful board layout is

a must. A clean board layout using a ground plane and

short connections to all capacitors will improve performance and ensure proper regulation under all conditions

(refer to Figures 4a and 4b). You will not get advertised

performance with careless layout.

(Refer to Block Diagram)

LTC1983-3/LTC1983-5

Figure 3

VIN: 2.3V TO 5.5V

1 V

IN

V

OUT

2 V

3 C

OUT

SHDN 6

GND 5

+

C

–

C

C

FLY

OUT

C

IN

4

1983 F04a

Figure 4a. Recommended Component

Placement for a Single Layer Board

BOTTOM LAYER TOP LAYER

1 V

IN

V

OUT

2 V

3 C

OUT

+

SHDN 6

GND 5

–

C

4

C

IN

C

OUT

C

FLY

1983 F04b

Figure 4b. Recommended Component

Placement for a Double Layer Board

sn1983 1983fs

9

LTC1983-3/LTC1983-5

U

TYPICAL APPLICATIO S

2.5V to –2.5V DC/DC Converter

2.5V

OFF ON

V

2.5V TO 5.5V

OFF ON

V

IN

4.7µF

CERAMIC

V

IN

LTC1983-5

SHDN

+

C

0.47µF

CERAMIC

V

GND

OUT

C

–

100mA Inverting DC/DC Converter

IN

10µF

CERAMIC

V

IN

LTC1983-5

SHDN

+

C

1µF

CERAMIC

V

OUT

GND

–

C

1983 TA03

1983 TA04

1µF

CERAMIC

10µF

V

OUT

–2.5V

V

OUT

–V

IN

10

sn1983 1983fs

PACKAGE DESCRIPTIO

0.754

U

S6 Package

6-Lead Plastic SOT-23

(Reference LTC DWG # 05-08-1636)

0.854 ±0.127

LTC1983-3/LTC1983-5

2.90 BSC

(NOTE 4)

3.254

0.95 BSC

1.9 BSC

RECOMMENDED SOLDER PAD LAYOUT

0.20 BSC

DATUM ‘A’

0.30 – 0.50 REF

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

0.09 – 0.20

(NOTE 3)

2.80 BSC

1.50 – 1.75

(NOTE 4)

1.00 MAX

0.95 BSC

0.80 – 0.90

PIN ONE ID

1.90 BSC

0.30 – 0.45 TYP

6 PLCS (NOTE 3)

0.01 – 0.10

S6 TSOT-23 0801

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

sn1983 1983fs

11

LTC1983-3/LTC1983-5

U

TYPICAL APPLICATIO

Combined Unregulated Doubler

and Regulated Inverter

OFF ON

V

IN

CERAMIC

D1

V

BOOST

C

IN

10µF

C

BOOST

1µF

= 2VIN –2(VD)

V

IN

LTC1983-3/

LTC1983-5

SHDN

+

C

D2

V

OUT

GND

–

C

C

10µF

CERAMIC

1983 TA05

OUT2

C

10µF

CERAMIC

C

1µF

CERAMIC

V

BOOST

V

OUT1

FLY

OUT

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1261 Switched-Capacitor Regulated Voltage Inverter Selectable Fixed Output Voltages

LTC1261L Switched-Capacitor Regulated Voltage Inverter Adjustable and Fixed Output Voltages, Up to 20mA I

LTC1429 Clock-Synchronized Switched-Capacitor Voltage Inverter Synchronizable Up to 2MHz System Clock

LTC1514/LTC1515 Step-Up/Step-Down Switched-Capacitor DC/DC Converters VIN 2V to 10V, Adjustable or Fixed V

LTC1516 Micropower Regulated 5V Charge Pump DC/DC Converter I

LTC1522 Micropower Regulated 5V Charge Pump DC/DC Converter I

LTC1550L/LTC1551L Low Noise, Switched-Capacitor Regulated Voltage Inverters 900kHz Charge Pump, 1mV

= 20mA (VIN ≥ 2V), I

OUT

= 10mA (VIN ≥ 2.7V), I

OUT

= 50mA (VIN ≥ 3V)

OUT

OUT

Ripple

P-P

, I

OUT

OUT

= 20mA (VIN ≥ 3V)

LT1611 1.4MHz Inverting Mode Switching Regulator –5V at 150mA from a 5V Input, 5-Lead ThinSOT

LT1617/LT1617-1 Micropower, Switched-Capacitor Voltage Inverter VIN 1.2V/1V to 15V; 350mA/100mA Current Limit

LTC1682/-3.3/-5 Doubler Charge Pumps with Low Noise LDO MS8 and SO-8 Packages, I

LTC1751/-3.3/-5 Doubler Charge Pumps V

=5V at 100mA; V

OUT

LTC1754/-3.3/-5 Doubler Charge Pumps with Shutdown ThinSOT Package; IQ = 13µA; I

LTC1928-5 Doubler Charge Pump with Low Noise LDO ThinSOT Output Noise = 60µV

= 80mA, Output Noise = 60µV

OUT

=3.3V at 80mA; ADJ; MSOP Packages

OUT

= 50mA

OUT

; V

RMS

= 5V; VIN = 2.7V to 4V

OUT

LTC3200 Constant Frequency Doubler Charge Pump Low Noise, 5V Output or Adjustable

OUT

to 50mA

, MSOP

RMS

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

sn1983 1983fs

LT/TP 0302 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2002

Loading...

Loading...