Application Note 106

February 2007

Instrumentation Circuitry Using RMS-to-DC Converters

RMS Converters Rectify Average Results

Jim Williams

INTRODUCTION

It is widely acknowledged that RMS (Root of the Mean

of the Square) measurement of waveforms furnishes

1

the most accurate amplitude information.

Rectify-andaverage schemes, usually calibrated to a sine wave, are

only accurate for one waveshape. Departures from this

waveshape result in pronounced errors. Although accurate,

RMS conversion often entails limited bandwidth, restricted

range, complexity and diffi cult to characterize dynamic

and static errors. Recent developments address these

issues while simultaneously improving accuracy. Figure 1

®

shows the LTC

1966/LTC1967/LTC1968 device family. Low

frequency accuracy, including linearity and gain error, is

inside 0.5% with 1% error at bandwidths extending to

500kHz. These converters employ a sigma-delta based

computational scheme to achieve their performance.

2

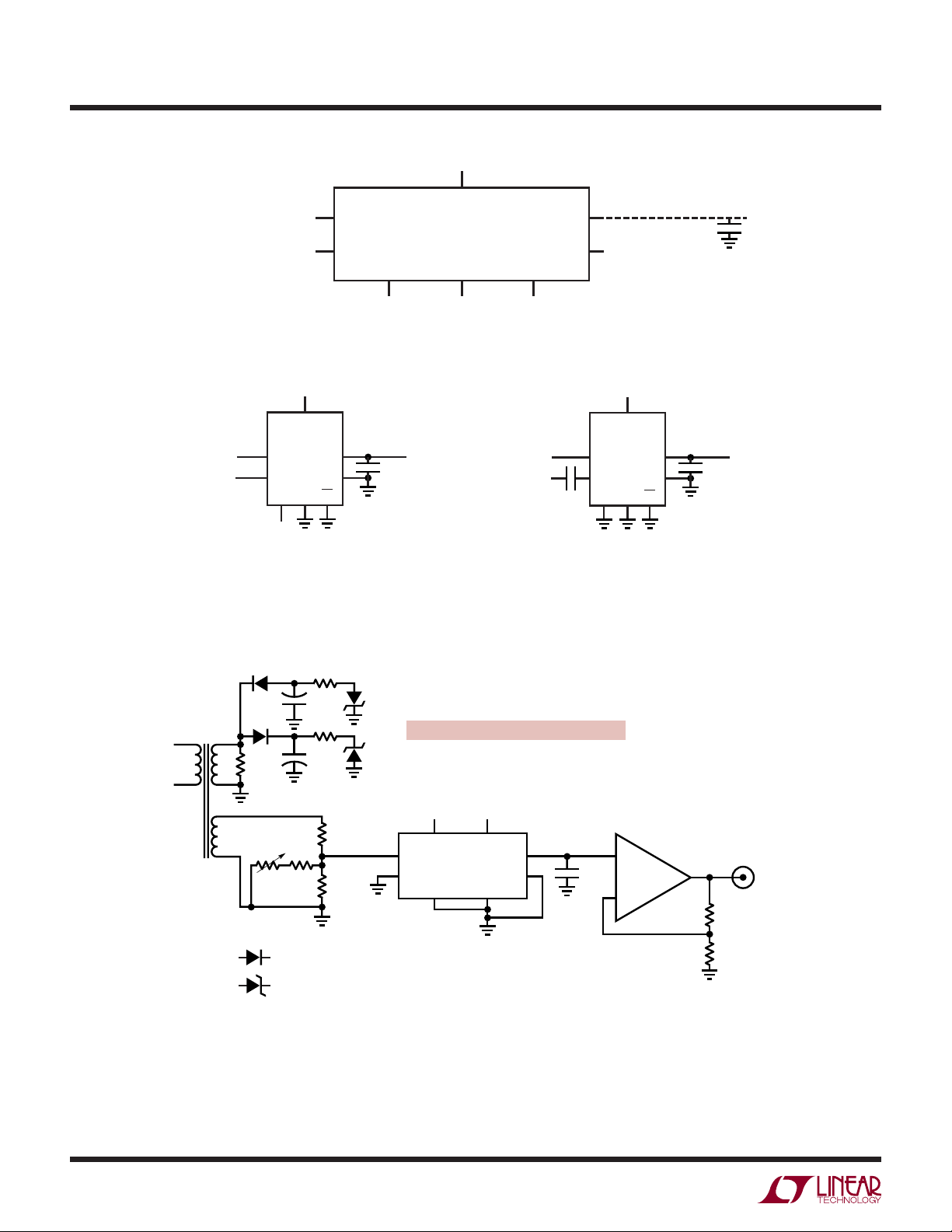

Figure 2’s pinout descriptions and basic circuits reveal an

easily applied device. An output fi lter capacitor is all that is

required to form a functional RMS-to-DC converter. Split

and single supply powered variants are shown. Such ease

of implementation invites a broad range of application;

examples begin with Figure 3.

Isolated Power Line Monitor

BEFORE PROCEEDING ANY FURTHER, THE READER

IS WARNED THAT CAUTION MUST BE USED IN THE

CONSTRUCTION, TESTING AND USE OF THIS CIRCUIT.

HIGH VOLTAGE, LETHAL POTENTIALS ARE PRESENT IN

THIS CIRCUIT. EXTREME CAUTION MUST BE USED IN

WORKING WITH, AND MAKING CONNECTIONS TO, THIS

CIRCUIT. REPEAT: THIS CIRCUIT CONTAINS DANGEROUS, HIGH VOLTAGE POTENTIALS. USE CAUTION.

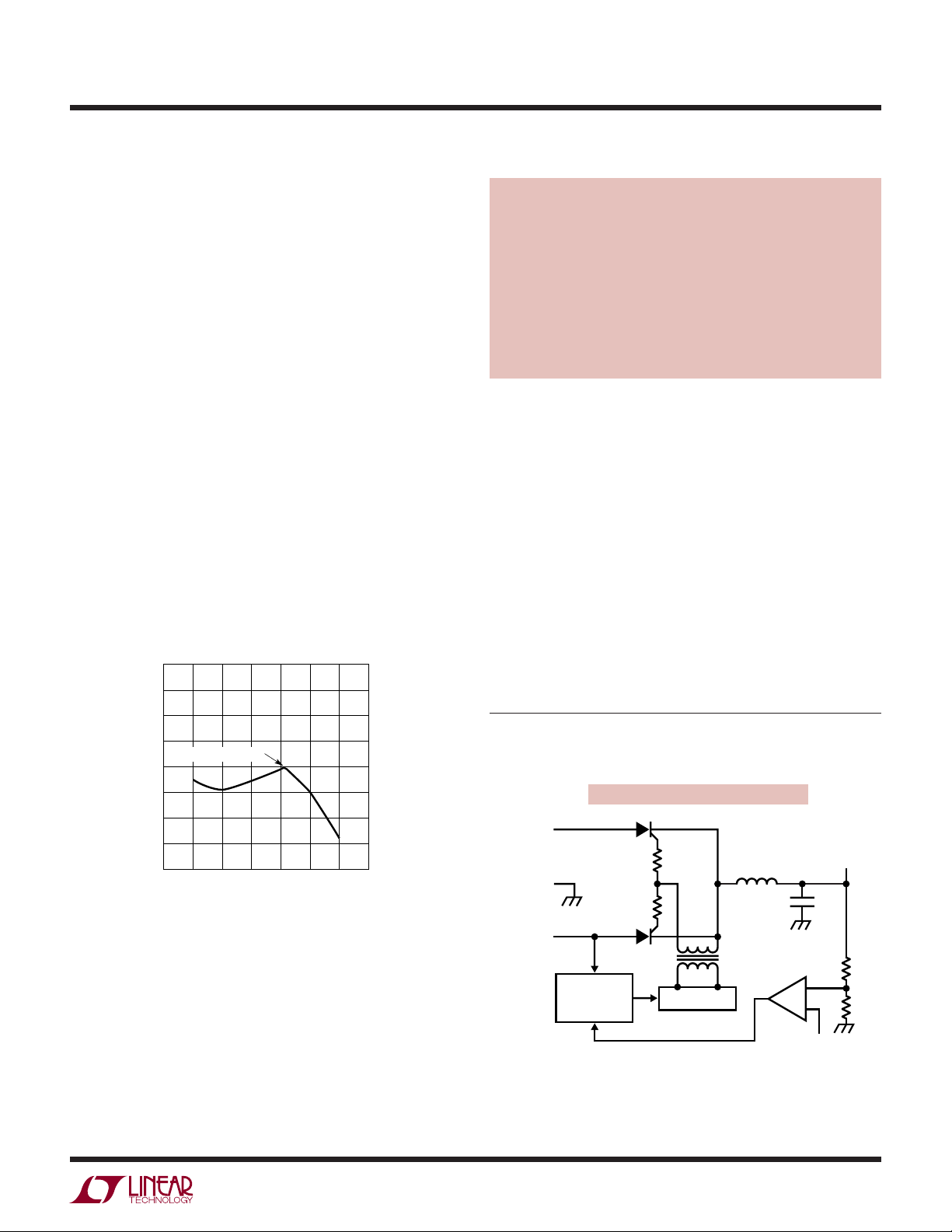

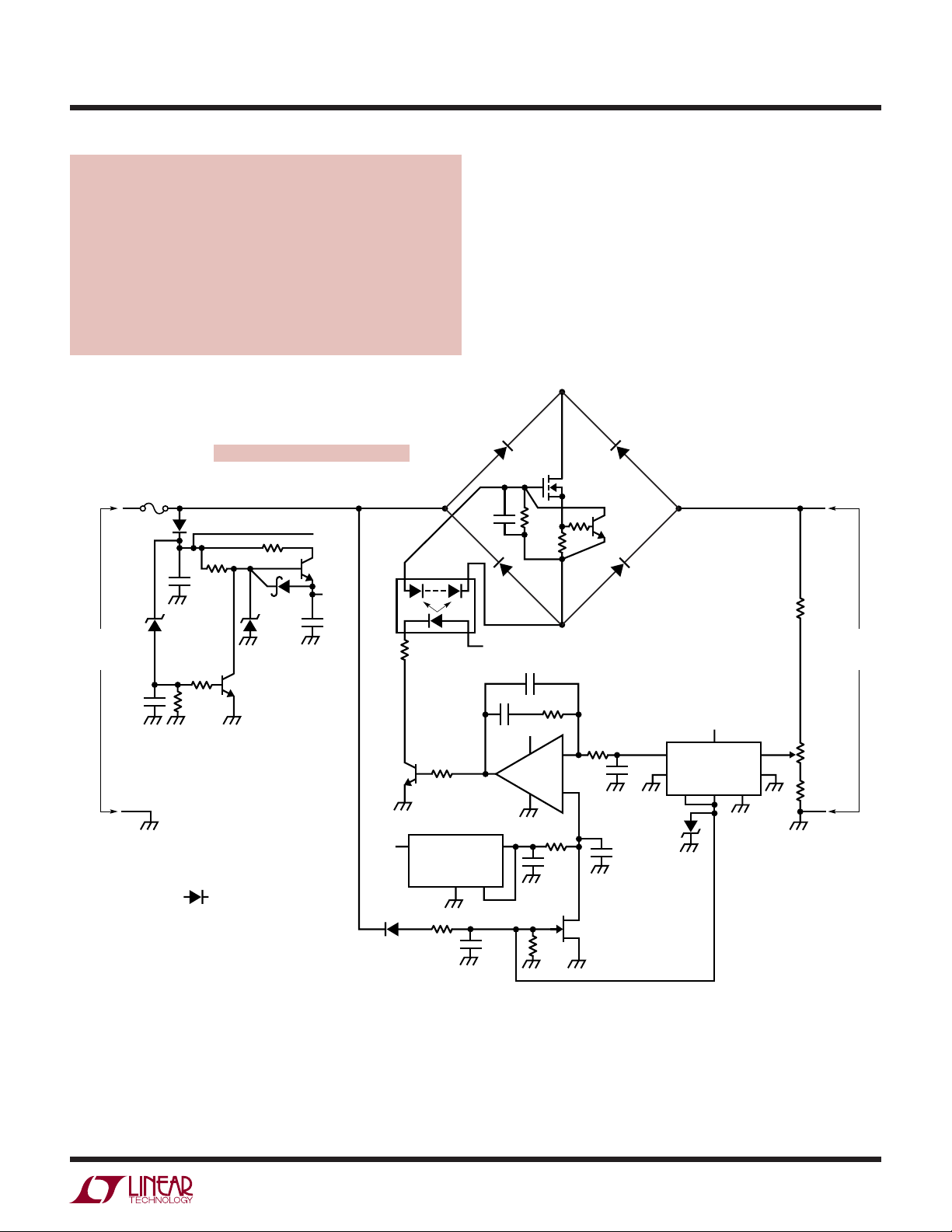

Figure 3’s AC power line monitor has 0.5% accuracy over

a sensed 90VAC to 130VAC input and provides a safe, fully

isolated output. RMS conversion provides accurate reporting of AC line voltage regardless of waveform distortion,

which is common.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

1

See Appendix A, “RMS-to-DC Conversion” for complete discussion of

RMS measurement.

2

Appendix A details sigma-delta based RMS-to-DC converter operation.

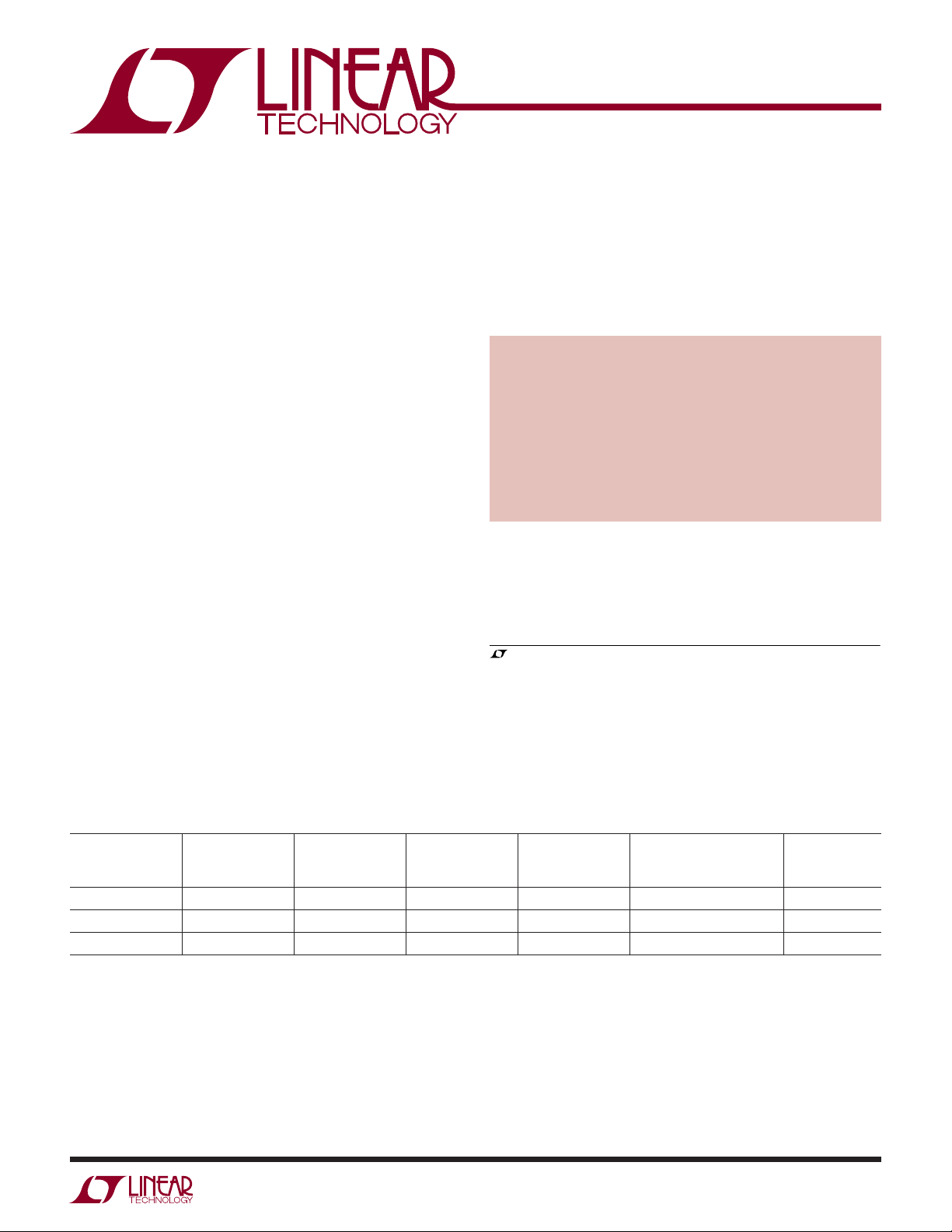

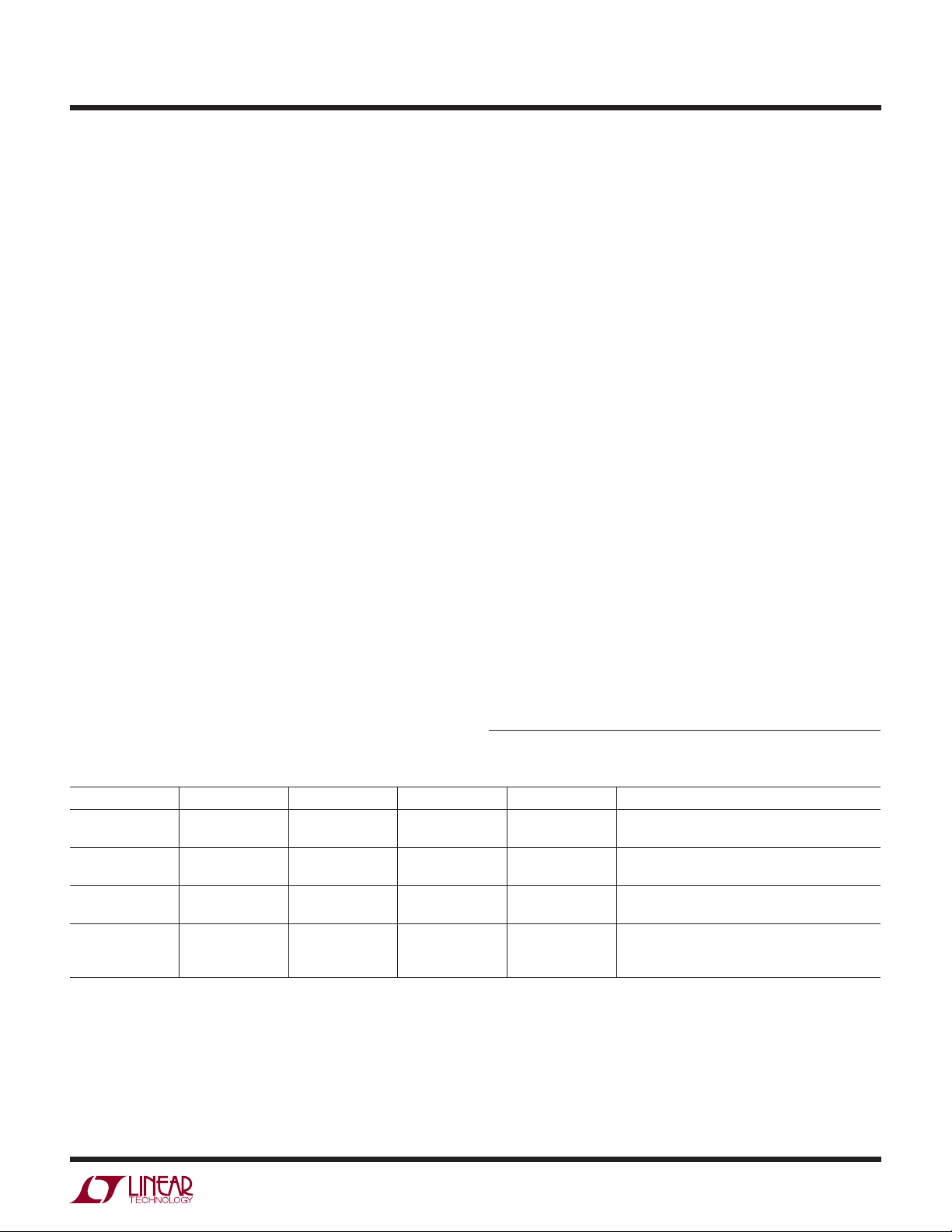

LINEARITY

PART NUMBER

LTC1966 0.02/0.15 0.1/0.3 6 800 2.7 ±5 170

LTC1967 0.02/0.15 0.1/0.3 200 4MHz 4.5 5.5 390

LTC1968 0.02/0.15 0.1/0.3 500 15MHz 4.5 5.5 2.3mA

Figure 1. Primary Differences in RMS to DC Converter Family are Bandwidth and Supply Requirements.

All Devices Have Rail-to-Rail Differential Inputs and Output

ERROR

TYP/MAX (%)

CONVERSION

GAIN ERROR

TYP/MAX (%)

1% ERROR

BANDWIDTH

(kHz)

3dB ERROR

BANDWIDTH

(kHz)

SUPPLY VOLTAGE I

MIN(V) MAX(V)

AN106-1

SUPPLY

MAX (µA)

an106f

Application Note 106

POSITIVE SUPPLY

2.7V TO 5.5V

DEPENDING ON DEVICE CHOICE

DIFFERENTIAL

MAX COMMON MODE

INPUTS.

RANGE = ±V SUPPLY.

MAX DIFFERENTIAL = 1V.

MINIMUM INPUT = 5mV

INPUT 1

INPUT 2

±5V Supplies, Differential, DC-Coupled

RMS-to-DC Converter

5V

V

DD

DC + AC

INPUTS

(1V

DIFFERENTIAL)

PEAK

LTC1966

IN1

IN2

SS

–5V

V

OUT RTN

GND ENV

OUT

Figure 2. RMS Converter Pin Functions (Top) and Basic Circuits (Bottom).

Pin Descriptions are Common to All Devices, with Minor Differences

SET HIGH TO

SHUT DOWN

C

AVE

1µF

LTC1966

LTC1967

LTC1968

LTC1966 ONLY.

0V TO –5V

SUPPLY

DC OUTPUT

= 85kΩ

Z

O

+V

–V*ENABLE

DIFFERENTIAL)

OUTPUT OUTPUT

OUTPUT RETURN

GND

POWER

GROUND

OUTPUT TO FILTER CAPACITOR

OUTPUT REFERRED

TO THIS PIN.

NORMALLY GROUNDED

*NO –V PIN ON THE LTC1967/LTC1968

5V Single Supply, Differential, AC-Coupled

RMS-to-DC Converter

5V

V

DD

AC INPUTS

(1V

PEAK

0.1µF

LTC1966

V

IN1

IN2

C

C

SS

OUT RTN

GND ENV

OUT

AN106 F02

C

1µF

AVE

DC OUTPUT

= 85kΩ

Z

O

LINE INPUT

90VAC

TO 140VAC

T1

145

BIAS SUPPLY

100Ω

A

1W

6

ISOLATED LINE SENSE

7

B

1k

8

120VAC

TRIM

T1 = TAMURA-PAN MAG 3FS-212

*1% METAL FILM RESISTOR

1µF = WIMA MKS-2

1k

100µF

+

1k

+

100µF

100Ω

1W

0.25%

100Ω

10Ω

0.25%

= 1N4148

= 1N4689 5.1V

–5V

5V

DANGER! Lethal Potentials Present—See Text

5V –5V

+V –V

IN1 OUT

IN2

EN GND

C1

LTC1966

OUT RTN

RMS CONVERTER

1µF

+

A1

®

1006

LT

–

RMS OUT

0.9V TO 1.4V =

90VAC TO 140VAC

100k*

100k*

AN106 F03

Figure 3. Isolated Power Line Monitor Senses Via Transformer with 0.5% Accuracy Over 90VAC to 130VAC Input.

Secondary Loading Optimizes Transformer Voltage Conversion Linearity

AN106-2

an106f

Application Note 106

The AC line voltage is divided down by T1’s ratio. An isolated

and reduced potential appears across T1’s secondary B,

where it is resistively scaled and presented to C1’s input.

Power for C1 comes from T1’s secondary A, which is

rectifi ed, fi ltered and zener regulated to DC. A1 takes gain

and provides a numerically convenient output. Accuracy

is increased by biasing T1 to an optimal loading point,

facilitated by the relatively low resistance divider values.

Similarly, although C1 and A1 are capable of single supply

operation, split supplies maintain symmetrical T1 loading.

The circuit is calibrated by adjusting the 1k trim for 1.20V

output with the AC line set at 120VAC. This adjustment is

made using a variable AC line transformer and a well fl oated

(use a line isolation transformer) RMS voltmeter.

F

igure 4’s error plot shows 0.5% accuracy from 90VAC

3

to 130VAC, degrading to 1.4% at 140VAC. The benefi cial

effect of trimming at 120VAC is clearly evident; trimming at full scale would result in larger overall error,

primarily due to non-ideal transformer behavior. Note

that the data is specifi c to the transformer specifi ed.

Substitution for T1 necessitates circuit value changes

and recharacterization.

2.0

1.5

1.0

0.5

120VAC TRIM POINT

0

–0.5

–1.0

RMS OUTPUT READING ERROR (%)

–1.5

–2.0

90 100 120

Figure 4. Error Plot for Isolated Line Monitor Shows 0.5%

Accuracy from 90VAC to 130VAC, Degrading to 1.4% at 140VAC.

Transformer Parasitics Account for Almost All Error

110

RMS INPUT VOLTAGE (V)

130 140

AN106 F04

Fully Isolated 2500V Breakdown,

Wideband RMS-to-DC Converter

NOTE: BEFORE PROCEEDING ANY FURTHER, THE

READER IS WARNED THAT CAUTION MUST BE USED

IN THE CONSTRUCTION, TESTING AND USE OF THIS

CIRCUIT. HIGH VOLTAGE, LETHAL POTENTIALS ARE

PRESENT IN THIS CIRCUIT. EXTREME CAUTION MUST

BE USED IN WORKING WITH, AND MAKING CONNECTIONS TO, THIS CIRCUIT. REPEAT: THIS CIRCUIT

CONTAINS DANGEROUS, HIGH VOLTAGE POTENTIALS.

USE CAUTION.

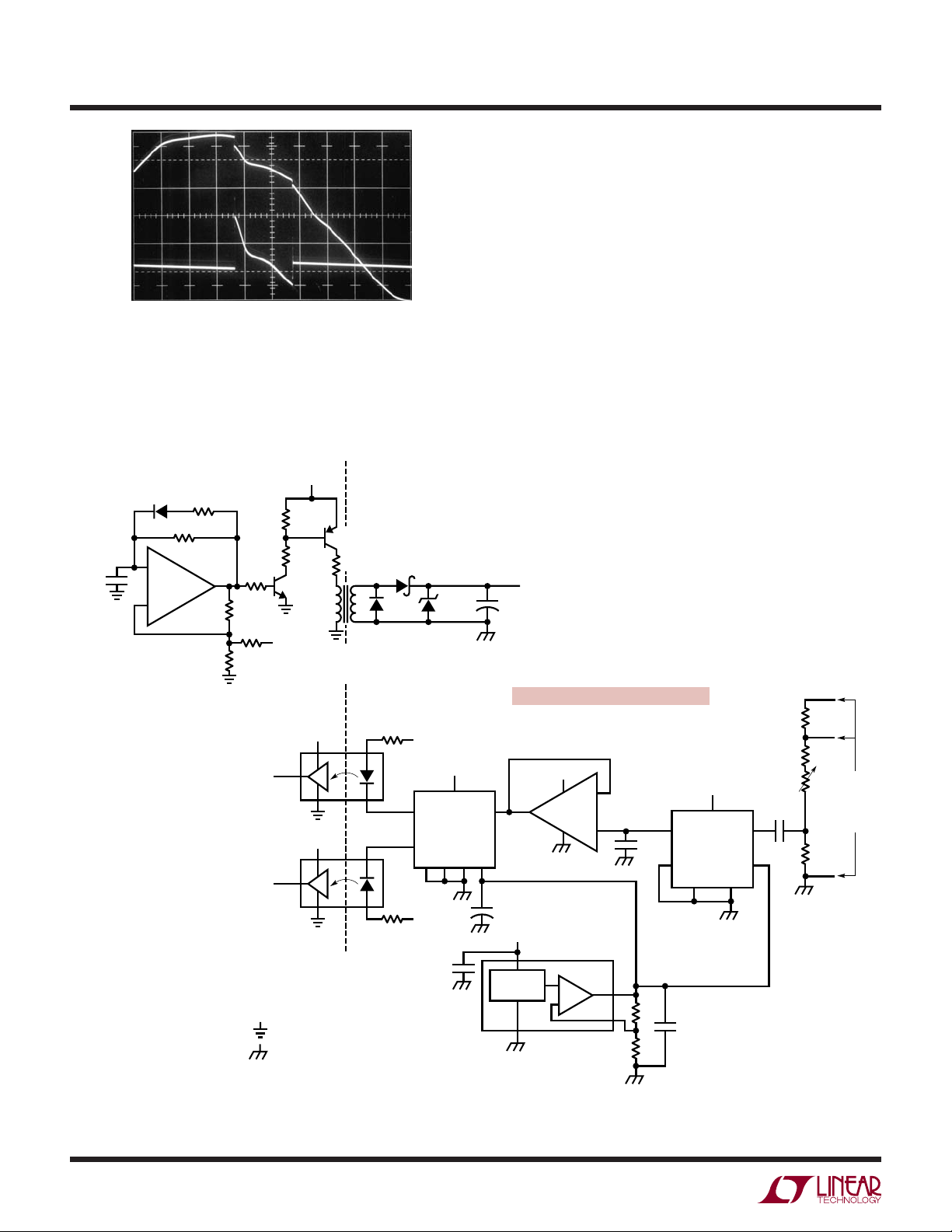

Accurate RMS amplitude measurement of SCR chopped

AC line related waveforms is a common requirement. This

measurement is complicated by the SCR’s fast switching

of a sine wave, introducing odd waveshapes with high

frequency harmonic content. Figure 5’s conceptual SCRbased AC/DC converter is typical. The SCRs alternately

chop the 220VAC line, responding to a loop enforced,

phase modulated trigger to maintain a DC output. Figure

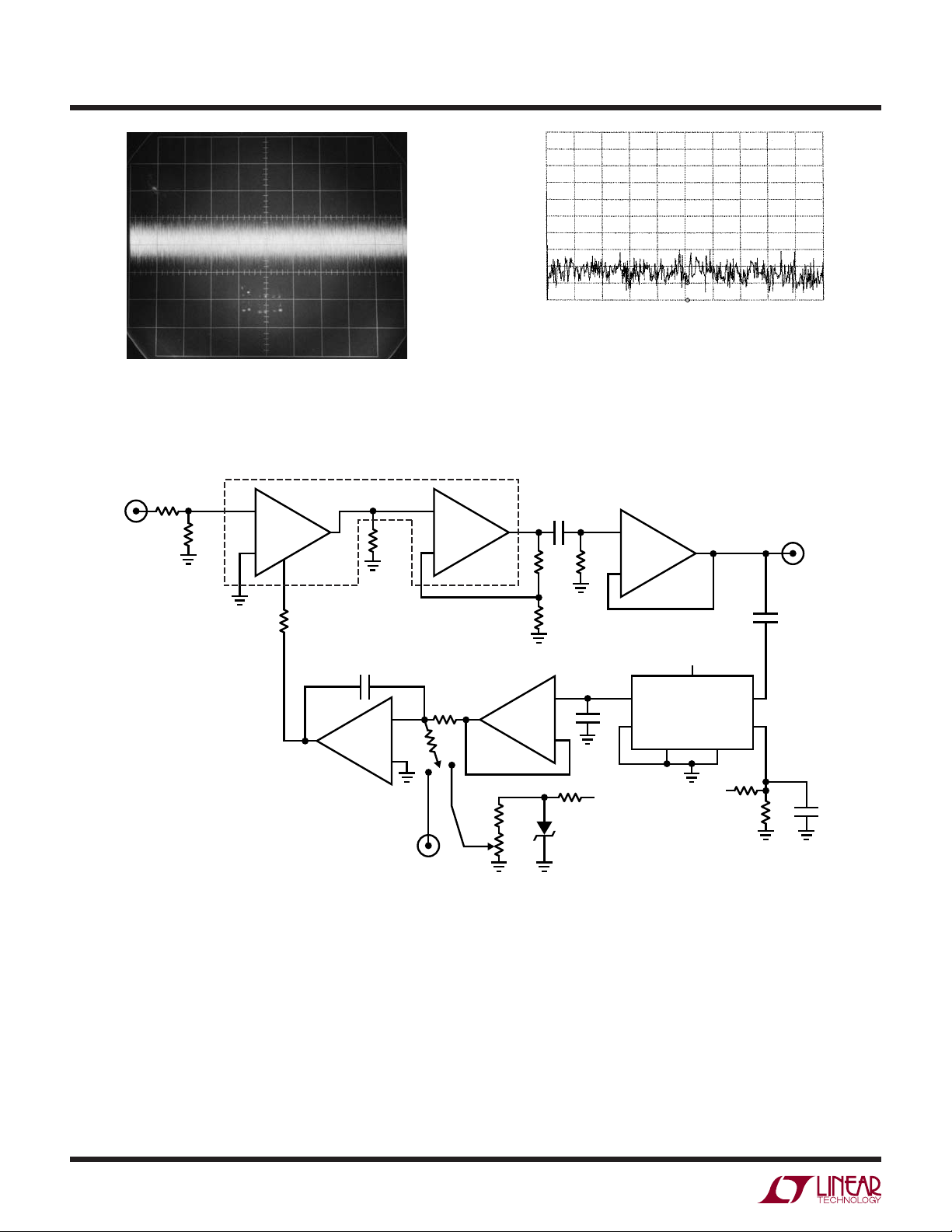

6’s waveforms are representative of operation. Trace A is

one AC line phase, trace B the SCR cathodes. The SCR’s

irregularly shaped waveform contains DC and high frequency harmonic, requiring wideband RMS conversion

for measurement. Additionally, for safety and system

interface considerations, the measurement must be fully

isolated.

3

See Appendix B, “AC Measurement and Signal Handling Practice,” for

recommendations on RMS voltmeters and other AC measurement related

gossip.

DANGER! Lethal Potentials Present—See Text

220VAC

INPUT

NEUTRAL

220VAC

AC LINE SYNC

AND PHASE

MODULATION

TRIGGER

DC

OUTPUT

AN106 F05

REF

Figure 5. Conceptual AC/DC Converter is Typical of SCR-Based

Confi gurations. Feedback Directed, AC Line Synchronized

Trigger Phase Modulates SCR Turn-On, Controlling DC Output

an106f

AN106-3

Application Note 106

A = 100V/DIV

B = 50V/DIV

ON 170 VDC

LEVEL

1ms/DIV

Figure 6. Typical SCR-Based Converter Waveforms Taken at AC

Line (Trace A) and SCR Cathodes (Trace B). SCR’s Irregularly

Shaped Waveform Contains DC and High Frequency Harmonic,

Requiring Wideband RMS Converter for Measurement

AN106 F06

Figure 7 provides isolated power and data output paths to

an RMS-to-DC converter, permitting safe, wideband, digital

output RMS measurement. A pulse generator confi gured

comparator combines with Q1 and Q2 to drive T1, resulting

in isolated 5V power at T1’s rectifi ed, fi ltered and zener

regulated output. The RMS-to-DC converter senses either

135VAC or 270VAC full-scale inputs via a resistive divider.

The converter’s DC output feeds a self-clocked, serially

interfaced A/D converter; optocouplers convey output data

across the isolation barrier. The LTC6650 provides a 1V

reference to the A/D and biases the RMS-to-DC converter’s

inputs to accommodate the voltage divider’s AC swing.

Calibration is accomplished by adjusting the 20k trim while

noting output data agreement with the input AC voltage.

Circuit accuracy is within 1% in a 200kHz bandwidth.

0.001µF

PULSE GENERATOR

1N4148

1k

220k

–

LT1671

+

DRIVER

1k

750k

750k

750k

DATA

ISOLATORS

SCK

DATA

OUTPUTS

SDO

5VPOWER

1k

100Ω

Q1

2N2369

5V

ISOLATION/POWER

Q2

ZTX-749

2Ω

3

1

6

4

T1

TRANSFORMER

2500V BREAKDOWN

ISOLATION BARRIER

5V

5V

ISOLATED POWER SUPPLY

1N5817

1N4148

4.7k

4.7k

1N4689

5.1V

5V ISO

A/D RMS CONVERTER

5V ISO

+V

SCK V

LTC2400

SDO

FOGND CS

5V ISO

+

5V ISO

+

100µF

DANGER! Lethal Potentials Present—See Text

5V ISO

–

IN

REF

10µF

5V ISO

LT1006

+

1µF

†

5V ISO

+V

OUT IN1

LTC1967

OUT RTN IN2

GND

EN

CALIBRATE

20k

0.1µF

182k*

182k*

1k*

INPUT

135VAC

OR

270VAC

FULL SCALE

ISOLATORS = AGILENT-HCPL-2300-010

T1 = BI TECHNOLOGIES HM-41-11510

* = 1% METAL FILM RESISTOR

† = WIMA MKS-2

= CIRCUIT COMMON

= AC LINE GROUND

1µF

400mV

REFERENCE

LT6650

+

OUT

–

15k*

FB

10k*

1µF

1VDC

AN106 F07

Figure 7. Isolated RMS Converter Permits Safe, Digital Output, Wideband RMS Measurement. T1-Based Circuitry Supplies Isolated

Power. RMS-to-DC Converter Senses High Voltage Input via Resistive Divider. A/D Converter Provides Digital Output Through

Optoisolators. Accuracy is 1% in 200kHz Bandwidth

AN106-4

an106f

Application Note 106

Low Distortion AC Line RMS Voltage Regulator

NOTE: BEFORE PROCEEDING ANY FURTHER, THE

READER IS WARNED THAT CAUTION MUST BE USED

IN THE CONSTRUCTION, TESTING AND USE OF THIS

CIRCUIT. HIGH VOLTAGE, LETHAL POTENTIALS ARE

PRESENT IN THIS CIRCUIT. EXTREME CAUTION MUST

BE USED IN WORKING WITH, AND MAKING CONNECTIONS TO, THIS CIRCUIT. REPEAT: THIS CIRCUIT

CONTAINS DANGEROUS, HIGH VOLTAGE POTENTIALS.

USE CAUTION.

DANGER! Lethal Potentials Present—See Text

1.5A

AC

SB

HIGH

UNREGULATED

AC LINE

INPUT

0.22µF

AC

LOW

+V REGULATORS

470k

0.47µF

1N5281B

200V

200k

200k

HEAT SINK IRF-840

*1% METAL FILM RESISTOR

OPTODRIVER = TOSHIBA TLP190B

= 1N4005

Q3

2N5210

100k

1N4690

5.6V

BAT85

OVERVOLTAGE

PROTECTION

170V

Q4

MPSA42

5V

0.1µF

2N3440

10k

2W

ISOLATED

GATE BIAS

5.6k

Q1

REFERENCE

0.4V OUT5V IN

LT6650

GND

1M

Almost all AC line voltage regulators rely on some form of

waveform chopping, clipping or interruption to function.

This is effi cient, but introduces waveform distortion, which

is unacceptable in some applications. Figure 8 regulates

the AC line’s RMS value within 0.25% over wide input

swings and does not introduce distortion. It does this by

continuously controlling the conductivity of a series pass

MOSFET in the AC lines path. Enclosing the MOSFET in

a diode bridge permits it to operate during both AC line

polarities.

AC SERIES PASS

AND CURRENT LIMIT

0.03µF

FB

170V

1µF

0.22µF

0.1µF

5V

LT1077

430k

0.7Ω

A1

100k

Q2

IRF-840

10k

CONTROL

AMPLIFIER

22k

–

+

330k

1µF

10k

Q5

2N4393

Q6

2N3904

2.2µF

MYLAR

RMS-TO-DC CONVERTER

C1

OUT

1µF

OUT RTN

1N4689

5.1V

5V

+V

LTC1966

–VEN

GND

FEEDBACK

IN1

IN2

SENSE

AC HIGH

1k

AC LOW

2.2M*

REGULATED

105VAC

TO 120VAC

ADJUST

7.32k*

OUTPUT

VAC

AN106 F08

SOFT-START/–V

BIAS

Figure 8. Adjustable AC Line Voltage Regulator Introduces No Waveform Distortion. Line Voltage RMS Value is Sensed and

Compared to a Reference by A1. A1 Biases Photovoltaic Optocoupler via Q1, Setting Q2-Diode Bridge Conductivity and Closing a

Control Loop. VIN Must be ≥2V Above V

to Maintain Regulation

OUT

an106f

AN106-5

Application Note 106

The AC line voltage is applied to the Q2-diode bridge. The

Q2-diode bridge output is sensed by a calibrated variable

voltage divider which feeds C1. C1’s output, representing

the regulated lines RMS value, is routed to control amplifi er A1 and compared to a reference. A1’s output biases

Q1, controlling drive to a photovoltaic optoisolator. The

optoisolator’s output voltage provides level-shifted bias

to diode bridge enclosed Q2, closing a control loop which

regulates the output’s RMS voltage against AC line and

load shifts. RC components in A1’s local feedback path

stabilize the control loop. The loop operates Q2 in its

linear region, much like a common low voltage DC linear

regulator. The result is absence of introduced distortion

at the expense of lost power. Available output power is

constrained by heat dissipation. For example, with the

output adjustment set to regulate 10V below the normal

input, Q2 dissipates about 10W at 100W output. This fi gure

can be improved upon. The circuit regulates for V

above V

dropout as V

, but operation in this region risks regulation

OUT

varies.

IN

≥ 2V

IN

Circuit details include JFET Q5 and associated components.

The passive components associated with Q5’s gate form

a slow turn-on negative supply for C1. They also provide

gate bias for Q5. Q5, a soft-start, prevents abrupt AC power

application to the output at start-up. When power is off,

Q5 conducts, holding A1’s “+” input low. When power

is applied, A1 initially has a zero volt reference, causing

the control loop to set the output at zero. As the 1MΩ

0.22µF combination charges, Q5’s gate moves negative,

causing its channel conductivity to gradually decay. Q5

ramps off, A1’s positive input moves smoothly towards

the LT6650’s 400mV reference, and the AC output similarly

ascends towards its regulation point. Current sensor Q6,

measuring across the 0.7Ω shunt, limits output current

to about 1A. At normal line inputs (90VAC to 135VAC) Q4

supplies 5V operating bias to the circuit. If line voltage

rises beyond this point, Q3 comes on, turning off Q4 and

shutting down the circuit.

X1000 DC Stabilized Millivolt Preamplifi er

The preceding circuits furnish high level inputs to the RMS

converter. Many applications lack this advantage and some

form of preamplifi er is required. High gain pre-amplifi cation

for the RMS converter requires more attention than might

be supposed. The preamplifi er must have low offset error

because the RMS converter (desirably) processes DC as

legitimate input. More subtly, the preamplifi er must have

far more bandwidth than is immediately apparent. The

amplifi ers –3db bandwidth is of interest, but its closed

loop 1% amplitude error bandwidth must be high enough

to maintain accuracy over the RMS converter’s 1% error

passband. This is not trivial, as very high open-loop gain

at the maximum frequency of interest is required to avoid

inaccurate closed-loop gain.

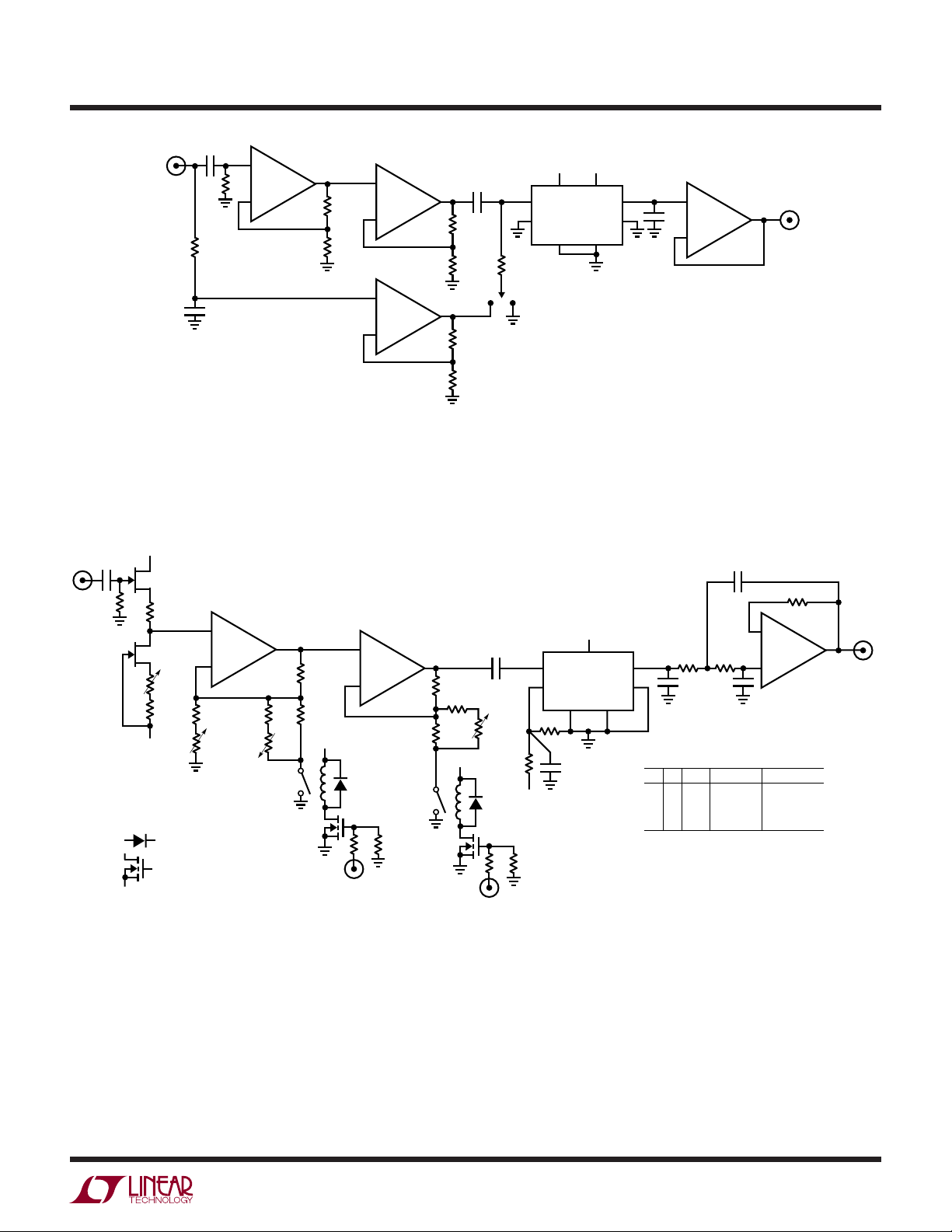

Figure 9 shows an x1000 preamplifi er which preserves the

LTC1966’s DC-6kHz 1% accuracy. The amplifi er may be

either AC or DC coupled to the RMS converter. The 1mV

full-scale input is split into high and low frequency paths.

AC coupled A1 and A2 take a cascaded, high frequency

gain of 1000. DC coupled, chopper stabilized A3 also has

X1000 gain, but is restricted to DC and low frequency by

its RC input fi lter. Assuming the switch is set to “DC + AC,”

high and low frequency path information recombine at the

RMS converter. The high frequency paths 650kHz –3db

response combines with the low frequency sections microvolt level offset to preserve the RMS converters DC-6kHz

1% error. If only AC response is desired, the switch is set

to the appropriate position. The minimum processable

input, set by the circuits noise fl oor, is 15µV.

Wideband Decade Ranged X1000 Preamplifi er

The LTC1968, with a 500kHz, 1% error bandwidth, poses

a signifi cant challenge for an accurate preamplifi er, but

Figure 10 meets the requirement. This design features

decade ranged gain to X1000 with a 1% error bandwidth

beyond 500kHz, preserving the RMS converters 1% error bandwidth. Its 20µV noise fl oor maintains wideband

performance at microvolt level inputs.

Q1A and Q1B form a low noise buffer, permitting high

impedance inputs. A1 and A2, both gain switchable, take

cascaded gain in accordance with the fi gure’s table. The

gains are settable via reed relays controlled by a 2-bit code.

A2’s output feeds the RMS converter and the converter’s

output is smoothed by a Sallen-Keys active fi lter. The

circuit maintains 1% error over a 10Hz to 500kHz bandwidth at all gains due to the preamplifi ers –3db, 10MHz

bandwidth. The 10Hz low frequency restriction could be

eliminated with a DC stabilization path similar to Figure

9’s but its gain would have to be switched in concert with

the A1-A2 path.

an106f

AN106-6

Application Note 106

INPUT

0mV TO 1mV

1µF

100pF

HIGH FREQUENCY PATH AC/DC SUMMATION RMS CONVERTER

+

A1

1M

LT1122

–

LOW FREQUENCY/DC PATH

*1% METAL FILM RESISTOR

1µF = WIMA MKS-2

10k*

536Ω*1M

+

A2

LT1222

–

+

A3

LTC1050

–

1µF

10k*

200Ω*

DC + AC

1M*

1k*

100k

5V –5V

+V –V

IN1

EN GND

AC

RMS STAGE INPUT COUPLING

LTC1966

OUT

OUT RTNIN2

1µF

+

LT1077

–

OUTPUT

A4

0V TO 1V

AN106 F09

Figure 9. X1000 Preamplifi er Allows 1mV Full-Scale Sensitivity RMS-to-DC Conversion. Input Splits Into High and Low Frequency

Amplifi er Paths, Recombining at RMS Converter. Amplifi er’s –3dB, 650kHz Bandwidth Preserves RMS-to-DC Converter’s 6kHz, 1%

Error Bandwidth. Noise Floor is 15µV

INPUT BUFFER OUTPUT FILTER

5V

1µF

INPUT

Q1A

1M

100Ω

SWITCHED GAIN AMP

A = 1, 100

+

10k

200k

–

A1

LT1227

A = 100

TRIM

Q1B

ZERO

100Ω

50Ω

A = 1

–5V

TRIM

Q1 = 2N6485. GROUND CASE

*1% METAL FILM RESISTOR

RELAYS = COTO-COIL 800-05-001

10µF, 1µF = WIMA MKS-2

= 1N4148

= VN2222L

22Ω

100Ω

499Ω*

5.62Ω*

5V

SWITCHED GAIN AMP

+

A2

LT1227

–

1M20k

S1

A = 1, 10

750Ω*

470Ω

90.9Ω*

5V

1k

1µF

A = 10

TRIM

S2

20k

10k

5V

1M

RMS CONVERTER

5V

+V

IN1

LTC1968

EN GND

10k

0.1µF

OUT

OUT RTNIN2

5.62k* 24.9k*

S1

S2

LO

LO

LO

HI

HI

LO

HI

HI

*SET ZERO ADJUSTMENT FOR A2

OUTPUT = 0 VDC WITH INPUT GROUNDED

AND S1, S2 HIGH BEFORE TRIMMING

GAIN

10

100

1000

1

10µF

1µF10µF

FS OUTPUT

1V

0.1V

0.01V

0.001V

43k

–

A3

LT1077

+

TRIM NOTES*

TRIM A = 1

TRIM A = 10

TRIM A = 100

NO TRIM

OUTPUT

AN106 F10

Figure 10. Switched Gain 10MHz (–3dB) Preamplifi er Preserves LTC1968’s 500kHz, 1% Error Bandwidth. Decade Ranged Gains

(See Table) Allow 1mV Full Scale with 20µV Noise Floor. JFET Input Stage Presents High Input Impedance. AC Coupling, 3rd Order

Sallen-Key Filter Maintains 1% Accuracy Down to 10Hz

an106f

AN106-7

Application Note 106

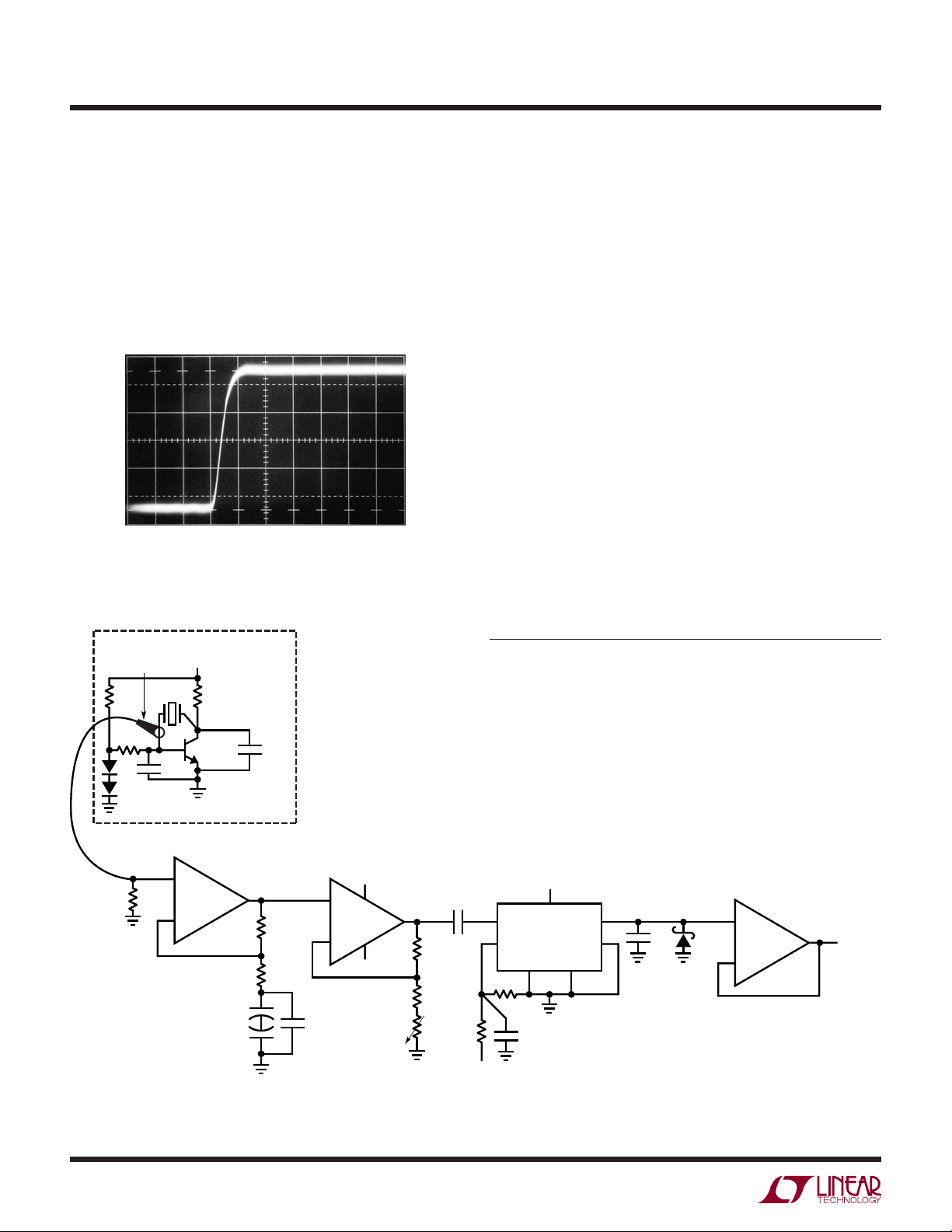

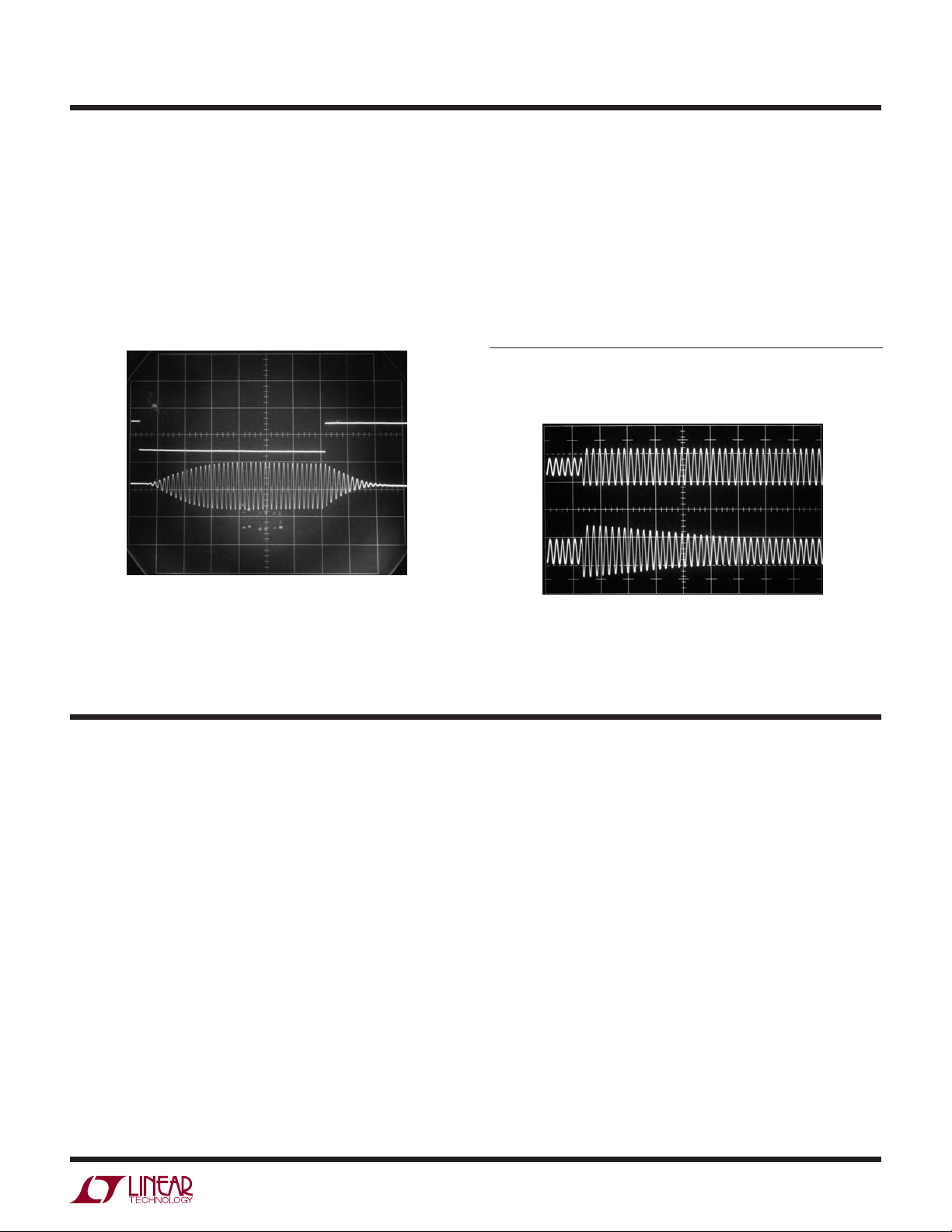

Figure 11 shows preamplifi er response to a 1mV input

step at a gain of X1000. A2’s output is singularly clean,

with trace thickening in the pulse fl at portions due to the

20µV noise fl oor. The 35ns risetime indicates a 10MHz

bandwidth.

To calibrate this circuit fi rst set S1 and S2 high, ground

the input and trim the “zero” adjustment for zero VDC at

A2’s output. Next, set S1 and S2 low, apply a 1V, 100kHz

input, and trim “A = 1” for unity gain, measured at the

200mV/DIV

50ns/DIV

Figure 11. Figure 10’s A2 Output Responds to a 1mV Input Step

at X1000 Gain. 35ns Risetime Indicates 10MHz Bandwidth. Trace

Thickening in Pulse Flat Portions Represents Noise Floor

TEKTRONIX CT-2

CURRENT PROBE

1mV/mA

1.5V

AN106 F11

circuit output, in accordance with the table in the fi gure.

Continue this procedure for the remaining three gains

given in the table. A good way to generate the accurate

low level inputs required is to set a 1.00VAC level and

divide it down with a high grade 50Ω attenuator such

as the Hewlett Packard 350D or the Tektronix 2701. It is

prudent to verify the attenuator’s output with a precision

RMS voltmeter.

4

Wideband, Isolated, Quartz Crystal RMS Current

Measurement

Quartz crystal RMS operating current is critical to longterm stability, temperature coeffi cient and reliability. Accurate determination of RMS crystal current, especially

in low power types, is complicated by the necessity to

minimize introduced parasitics, particularly capacitance,

which corrupt crystal operation. Figure 12, a form of

Figure 10’s wideband amplifi er, combines with a commercially available closed core current probe to permit

the measurement. An RMS-to-DC converter supplies

the RMS value. The quartz crystal test circuit shown in

dashed lines exemplifi es a typical measurement situation. The Tektronix CT-2 current probe monitors crystal

4

See Appendix B for recommendations on RMS voltmeters.

4.3k

330k

1N4148s

100kHz

50Ω*

680pF

+

LT1227

–

10k

Q1

2N3904

A1

PRE-AMPLIFIER

+

47µF

47µF

150pF

A = 1000

499Ω*

5.62Ω*

+

CRYSTAL

OSCILLATOR

TEST CIRCUIT

+

A2

LT1227

–

0.1µF

5V

–5V

750Ω*

64.9Ω*

20Ω

1mA

TRIM

1µF

10k

IN1

10k

5V

RMS CONVERTER

5V

+V

LTC1968

OUT RTNIN2

EN GND

0.1µF

OUT

1µF 1N5712

*0.25% METAL FILM RESISTOR

+

LT1077

–

AN106 F12

OUTPUT

0 – 1V =

0 – 1mA

A3

Figure 12. Figure 10’s Wideband Amplifi er Adapted for Isolated RMS Current Measurement of Quartz Crystal Current. FET Input Buffer

is Deleted; Current Probe’s 50Ω Impedance Allows Direct Connection to A1. Current Probe Provides Minimal Crystal Loading

in Oscillator Test Circuit

an106f

AN106-8

Application Note 106

current while introducing minimal parasitic loading (see

Figure 14). The probe’s 50Ω termination allows direct

connection to A1—Figure 10’s FET buffer is deleted. Additionally, because quartz crystals are not common below

4kHz, A1’s gain does not extend to low frequency.

Figure 13 shows results. Crystal drive, taken at Q1’s collector (trace A), causes a 25µA RMS crystal current which

is represented at the RMS-to-DC converter input (trace B).

The trace enlargement is due to the preamplifi er’s 5µA

RMS equivalent noise contribution.

A = 0.5V/DIV

B = 50mA/DIV

2ms/DIV

Figure 13. Crystal Voltage (Trace A) and Current (Trace B) for

Figure 12’s Test Circuit. 25µA RMS Crystal Current Measurement

Includes Preamplifi er 5µA RMS Noise Floor Contribution

PARAMETER CT-1 CT-2

Sensitivity 5mV/mA 1mV/mA

Accuracy 3% 3%

Low Frequency Additional

1% Error BW*

–3dB Bandwidth 25kHz to 1GHz 1.2kHz to 200MHz

Noise Floor with Amplifi er

Shown*

Capacitive Loading 1.5pF 1.8pF

Insertion Impedance at

10MHz

*As measured. Not vendor specifi ed

Figure 14. Relevant Specifi cations of Two Tektronix Current

Probes. Primary Trade-Off is Low Frequency Error and

Sensitivity. Noise Floor is Due to Amplifi er Limitations

98kHz 6.4kHz

1µA RMS 5µA RMS

1Ω 0.1Ω

AN106 F13

Figure 14 details characteristics of two Tektronix closed

core current probes. The primary trade-off is low frequency

error versus sensitivity. There is essentially no probe

noise contribution and capacitive loading is notably low.

Circuit calibration is achieved by putting 1mA RMS current

through the probe and adjusting the indicated trim for a

1V circuit output. To generate the 1mA, drive a 1k, 0.1%

5

resistor with 1V

RMS

.

AC Voltage Standard with Stable Frequency and Low

Distortion

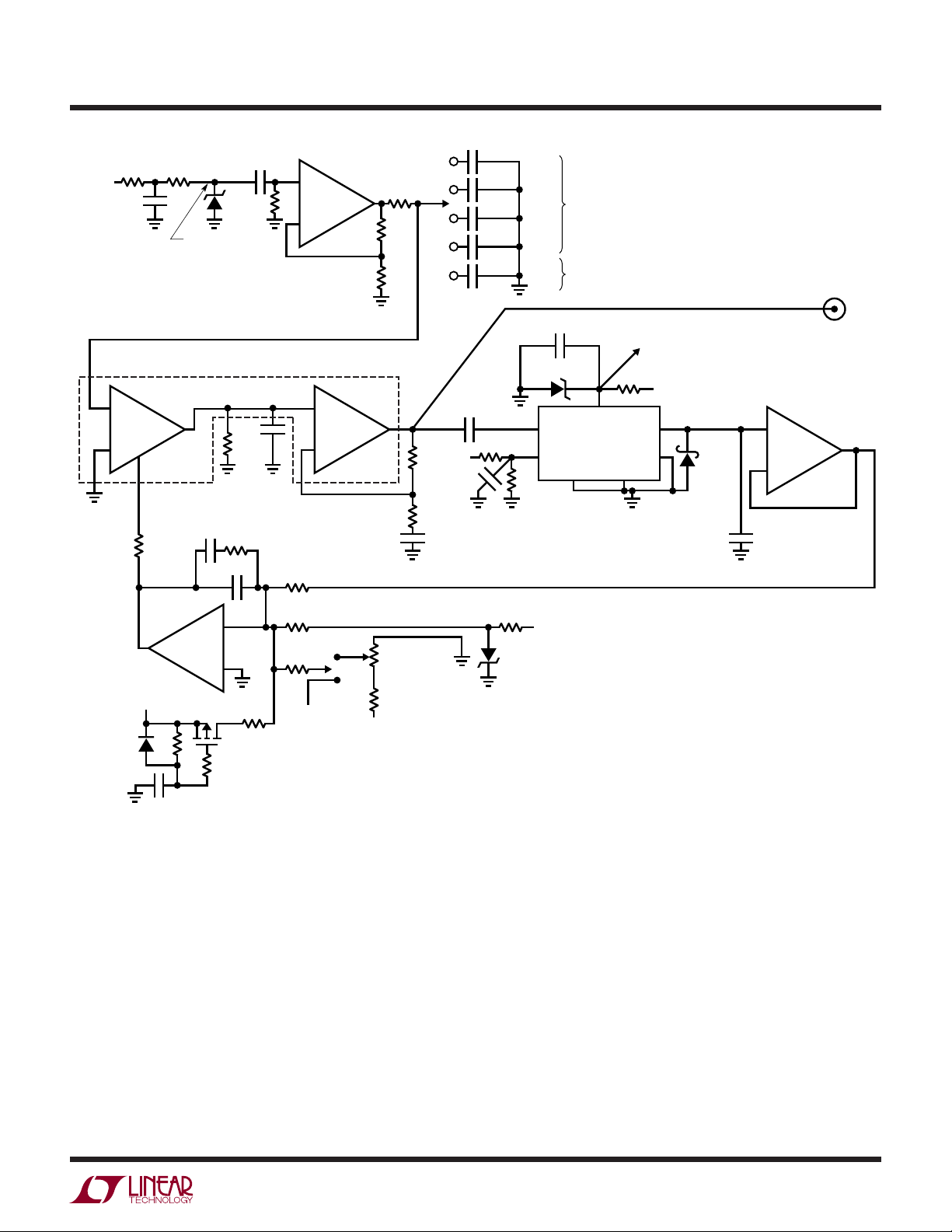

Figure 15 utilizes the RMS-to-DC converter’s stability in an

AC voltage standard. Initial circuit accuracy is 0.1% and

long-term (6 months at 20°C to 30°C) drift remains within

that fi gure. Additionally, the 4kHz operating frequency is

within 0.01% and distortion inside 30ppm.

A1 and its power buffer A3 sense across a bridge composed

of a 4kHz quartz crystal and an RC impedance in one arm;

resistors and an LED driven photocell comprise the other

arm. A1 sees positive feedback at the crystals 4kHz resonance, promoting oscillation. Negative feedback, stabilizing oscillation amplitude, occurs via a control path which

includes an RMS-to-DC converter and amplitude control

amplifi er, A5. A5 acts on the difference between A3’s RMS

converted output and the LT1009 voltage reference. Its

output controls the LED driven photocell to set A1’s negative

feedback. RC components in A5’s feedback path stabilize the

control loop. The 50k trim sets the optically driven resistor’s

value to the point where lowest A3 output distortion occurs

while maintaining adequate loop stability.

Normally the bridge’s “bottom” would be grounded. While

this connection will work, it subjects A1 to common mode

swings, increasing distortion due to A1’s fi nite common

mode rejection versus frequency. A2 eliminates this concern by forcing the bridges mid-points, and hence common

mode voltage, to zero while not infl uencing desired circuit

operation. It does this by driving the bridge “bottom” to

force its input differential to zero. A2’s output swing is

180° out of phase with A3’s circuit output. This action

eliminates common mode swing at A1, reducing circuit

output distortion by more than an order of magnitude. Figure 16 shows the circuits 1.414V

RMS

(2.000V

PEAK

) output

in trace A while trace B’s distortion constituents include

noise, fundamental related residue and 2F components.

The 4kHz crystal is a relatively large structure with very

high Q factor. Normally, it would require more than 30

seconds to start and arrive at full regulated amplitude.

This is avoided by inclusion of the Q1-LTC201 switch

circuitry. At start-up A5’s output goes high, biasing Q1.

Q1’s collector goes low, turning on the LTC201. This sets

A1’s gain abnormally high, increasing bridge drive and

5

This measurement technique has been extended to monitor 32.768kHz

“watch crystal” sub-microampere operating currents. Contact the author

for details.

an106f

AN106-9

Application Note 106

CRYSTAL BRIDGE BRIDGE AMPLIFIER

430pF

47k

50k

–5V

DISTORTION

TRIM

1k

1/4 LTC201

START-UP

+

LT1792

–

A1

1k

4kHz

J

–

A2

LT1792

+

CUT

560k

COMMON

MODE

SUPPRESSION

AMPLIFIER

5V

470Ω

2N3904

4kHz

OUTPUT

1.414V

39k

5V

A5

CONTROL

10µF

RMS

+

AN106 F15

–5V

2.5k*

LT1009

–

LT1077

+

2.5V

A4

RMS-TO-DC CONVERTER

A3

LT1010

5V

1M

Q1

510k

100k

1k*

909Ω*

200Ω

OUTPUT

SET

*IRC-CAR-6 1% RESISTOR

GROUND CRYSTAL CASE

5V

+

V

IN1 OUT

LTC1966

IN2

EN RTN GND V

= 1N4148

–

–5V

= SILONEX NSL-32SR3

1µF

28k*

100k*

–

LT1006

+

AMPLITUDE

AMPLIFIER

Figure 15. Quartz Stabilized Sine Wave Output AC Reference Has 0.1% Long-Term Amplitude Stability. Frequency Accuracy is 0.01%

with <30ppm Distortion. Positive Feedback Around A1 Causes Oscillation at Crystal’s Resonance. A5, Acting on A3’s RMS Amplitude,

Supplies Negative Feedback to A1 via Bridge Network, Stabilizing RMS Output Amplitude. Optocoupler Minimizes Feedback Induced

Distortion. Q1 Closes Switch During Start-Up, Ensuring Rapid Oscillation Build-Up

the trim for minimal output distortion as measured on a

distortion analyzer. Note that the absolute lowest level

A = 2V/DIV

of distortion coincides with the point where control loop

gain is just adequate to maintain oscillation. As such,

fi nd this point and retreat from it into the control loop’s

B = 30ppm

DISTORTION

active region. This necessitates giving up about 5ppm

distortion, but 30ppm is achievable with good control loop

stability. Output amplitude is trimmed with the indicated

100µs/DIV

Figure 16. A3’s 1.414V

RMS

(2.000V

), 4kHz Reference

PEAK

Output (Trace A) Shows 30ppm Distortion in Trace B. Distortion

Constituents Include Noise, Fundamental Related Residue and

2F Components

accelerating crystal start-up. When the bridge arrives at

its operating point A5’s output drops to a lower value, Q1

and the LTC201 switch go off, and the circuit transitions

into normal operation. Start-up time is several seconds.

The circuit requires trimming for amplitude accuracy and

lowest distortion. The distortion trim is made fi rst. Adjust

AN106 F16

adjustment for exactly 1.414V

RMS

(2.000V

PEAK

) at the

circuit output.

RMS Leveled Output Random Noise Generator

Figure 17 uses the RMS-to-DC converter in a leveled

output random noise generator. Noise diode D1 AC biases

6

A1, operating at a gain of 2.

A1’s output feeds a 1kHz to

500kHz switch selectable lowpass fi lter. The fi lter output

biases the variable gain amplifi er, A2-A3. A2-A3, contained

6

See Appendix C “Symmetrical White Gaussian Noise,” guest written by

Ben Hessen-Schmidt of Noise Com, Inc. for turorial on noise and noise

diodes.

AN106-10

an106f

Application Note 106

15V

NOISE DIODE NOISE DIODE

75k

75k

1µF

7VDC TO 10VDC

+NOISE

VARIABLE GAIN AMPLIFIER

+

A2

I

SET

–

GAIN CONTROL AMPLIFIER

3k

A5

1/2 LT1013

1µF

–

+

LT1228

100pF

900Ω

150k

0.1µF

10µF

1kNC103

475k*

1.1M*

909k*

+

A1

LT1220

–

+

–

INTERNAL

PREAMP

A3

160Ω

1k

1k

AMPLITUDE

10k

ADJUST

510Ω

5Ω

10µF

0.01µF

+V

Z

0.1µF

1µF

0.1µF

0.01µF

0.002µF

500pF

10k

4.7k

FILTER

1kHz

10kHz

100kHz

500kHz

500kHz

1µF

1N4689 5.1V

IN1 OUT

IN2

10k

–15V

LT1004-1.2V

–3dB

FLAT

TO ALL +V

Z

POINTS

1.5k

15V

+V

RMS CONVERTER

+

LTC1968

OUT RTN

EN GND

*1% METAL FILM RESISTOR

CONNECTIONS INSIDE DASHED LINES WITHIN A SINGLE IC

NC103 = NOISE COM

10µF = WIMA MKS-2

1N5712

1/2 LT1013

–

1µF

RMS

AMPLITUDE

STABILIZED

NOISE OUTPUT

A4

AN106 F17

15V

1M1N4148

0.33µF

Q1

TPO610L

1M

510k

SOFT-START

EXTERNAL

0V TO 1V

+V

40.2k*

Z

Figure 17. An RMS Levelled Output Random Noise Generator. Amplifi ed (A1) Diode Noise Is Filtered, Variable Gain Amplifi ed (A2-A3)

and RMS Converted. Converter Output Feeds Back to A5 Gain Control Amplifi er, Closing RMS Stabilized Loop. Output Amplitude, Taken

at A3, is Settable

on one chip, include a current controlled transconductance

amplifi er (A2) and an output amplifi er (A3). This stage takes

AC gain, biases the LTC1968 RMS-to-DC converter and

is the circuit’s output. The RMS converter output at A4,

feeds back to gain control amplifi er A5, which compares

the RMS value to a variable portion of the 5.1V zener

potential. A5’s output sets A2’s gain via the 3k resistor,

completing a control loop to stabilize noise RMS output

stabilize this loop. Output amplitude is variable by the 10k

potentiometer; a switch permits external voltage control.

Q1 and associated components, a soft-start circuit, prevent

output overshoot at power turn-on.

Figure 18 shows circuit output noise in the 10kHz fi lter

position; Figure 19’s spectral plot reveals essentially fl at

RMS noise amplitude over a 500kHz bandwidth.

amplitude. The RC components in A5’s local feedback path

an106f

AN106-11

Application Note 106

2V/DIV

5ms/DIV

AN106 F18

Figure 18. Figure 17’s Output in the 10kHz Filter Position

0.4V

INPUT

RMS

5V

RMS

TO

10k

100Ω

VARIABLE GAIN AMPLIFIER

+

A1

1/2 LT1228

300Ω

–

1k

0.15µF

–

A5

1/2 LT1013

+

GAIN CONTROL

AMPLIFIER

EXT INPUT

0V TO –0.5V

TO 0.5V

0V

RMS

OUTPUT

+

A2

1/2 LT1228

–

100k*

100k*

RMS

–3dB/DIV

AMPLITUDE VARIANCE

0 50 100 150 200 250

FREQUENCY (kHz)

300 350 400 450 500

AN106 F19

Figure 19. Amplitude vs Frequency for the Random Noise

Generator is Essentially Flat to 500kHz. NC103 Diode Contributes

Even Noise Spectrum Distribution; RMS Converter and Loop

Stabilize Amplitude. Sweep Time is 2.8 Minutes, Resolution

Bandwidth, 100Hz

1µF

470Ω

10k

OUTPUT BUFFER

+

A3

LT1220

RMS LEVELLED

OUTPUT

TO 0.5V

0V

RMS

RMS

–

0V

RMS

A4

1/2 LT1013

13.3k*

10k

OUTPUT

LEVEL

TO 0.5V

10Ω

RMS CONVERTER

+

–

4.7k

–5V

LT1004

1.2V

REFERENCE

RMS

5V

+

OUT IN1

1µF

OUT RTN IN2

*0.1% METAL FILM RESISTOR

CONNECTIONS INSIDE DASHED

LINES ARE WITHIN A SINGLE IC

V

C1

LTC1968

GND EN

5V

1µF

10k

10k 0.1µF

AN106 F20

Figure 20. RMS Amplitude Level Control Uses Figure 17’s Gain Control Loop. A1-A3 Provide Variable Gain to Input. RMS Converter

Feeds Back to A5 Gain Control Amplifi er, Closing Amplitude Stabilization Loop. Variable Reference Permits Settable, Calibrated RMS

Output Amplitude Independent of Input Waveshape

RMS Amplitude Stabilized Level Controller

Figure 20 borrows the previous circuit’s gain control

loop to stabilize the RMS amplitude of an arbitrary input

waveform. The unregulated input is applied to variable gain

amplifi er A1-A2 which feeds A3. DC coupling at A1-A2

permits passage of low frequency inputs. A3’s output is

taken by RMS-to-DC converter C1-A4, which feeds the

A5 gain control amplifi er. A5 compares the RMS value to

a variable reference and biases A1, closing a gain control

loop. The 0.15µF feedback capacitor stabilizes this loop,

even for waveforms below 100Hz. This feedback action

stabilizes output RMS amplitude despite large variations

an106f

AN106-12

Application Note 106

in input amplitude while maintaining waveshape. Desired

output level is settable with the indicated potentiometer or

an external control voltage may be switched in.

Figure 21 shows output response (trace B) to abrupt reference level set point changes (trace A). The output settles

within 60 milliseconds for ascending and descending

transitions. Faster response is possible by decreasing A5’s

compensation capacitor, but low frequency waveforms

A = 0.5V/DIV

B = 1V/DIV

20ms/DIV

Figure 21. Amplitude Level Control Response (Trace B) to

Abrupt Reference Changes (Trace A). Settling Time is Set by

A5’s Compensation Capacitor, Which Must be Large Enough

to Stabilize Loop at Lowest Expected Input Frequency

AN106 F21

would not be processable. Similar considerations apply to

Figure 22’s response to an input waveform step change.

Trace A is the circuit’s input and trace B its output. The

output settles in 60 milliseconds due to A5’s compensation. Reducing compensation value speeds response at the

expense of low frequency waveform processing capability.

Specifi cations include 0.1% output amplitude stability

for inputs varying from 0.4V

RMS

to 5V

, 1% set point

RMS

accuracy, 0.1kHz to 500kHz passband and 0.1% stability

for 20% power supply deviation.

Note: This Application Note was derived from a manuscript originally

prepared for publication In EDN magazine.

A = 2V/DIV

B = 1V/DIV

10ms/DIV

Figure 22. Amplitude Level Control Output Reacts (Trace B) to

Input Step Change (Trace A). Slow Loop Compensation Allows

Overshoot But Output Settles Cleanly

AN106 F22

REFERENCES

1. Hewlett-Packard Company, “1968 Instrumentation.

Electronic—Analytical—Medical,” AC Voltage Measurement, Hewlett-Packard Company, 1968, pp. 197-198.

2. Sheingold, D. H. (editor), “Nonlinear Circuits Handbook,” 2nd Edition, Analog Devices, Inc., 1976.

3. Lambda Electronics, Model LK-343A-FM Manual.

4. Grafham, D. R., “Using Low Current SCRs,” General

Electric AN200.19. Jan. 1967.

5. Williams, J., “Performance Enhancement Techniques

for Three-Terminal Regulators,” Linear Technology Corp.

AN-2. August, 1984. “SCR Preregulator,” pp. 3-6.

6. Williams, J., “High Effi ciency Linear Regulators,”

Linear Technology Corporation, Application Note 32, “SCR

Preregulator.” March 1989, pp. 3-4.

7. Williams, J., “High Speed Amplifi er Techniques,” Linear

Technology Corporation, Application Note 47, “Parallel

Path Amplifi ers,” August 1991, pp. 35-37.

8. Williams, J., “Practical Circuitry for Measurement and

Control Problems,” Broadband Random Noise Generator,”

“Symmetrical White Gaussian Noise,” Appendix B, Linear

Technology Corporation, Application Note 61, August 1994,

pp.24-26, pp. 38-39.

9. Williams, J., “A Fourth Generation of LCD Backlight

Technology,” “RMS Voltmeters,” Linear Technology Corporation, Application Note 65, November 1995, pp. 82-83.

10. Meacham, L. A., “The Bridge Stabilized Oscillator,”

Bell System Technical Journal, Vol. 17, p. 574, October

1938.

11. Williams, Jim, “Bridge Circuits—Marrying Gain and

Balance,” Linear Technology Corporation, Application Note

43, June, 1990.

an106f

AN106-13

Application Note 106

APPENDIX A

RMS-TO-DC CONVERSION

Joseph Petrofsky

Defi nition of RMS

RMS amplitude is the consistent, fair and standard way to

measure and compare dynamic signals of all shapes and

sizes. Simply stated, the RMS amplitude is the heating

potential of a dynamic waveform. A 1V

AC waveform

RMS

will generate the same heat in a resistive load as will 1V

DC. See Figure A1.

Mathematically, RMS is the “Root of the Mean of the

Square”:

VV

RMS

2

=

+

R1V DC

–

1V AC

RMS

R

R1V (AC + DC) RMS

SAME

HEAT

AN106 FA1

The last two entries of Table A1 are chopped sine waves

as is commonly created with thyristors such as SCRs and

Triacs. Figure A2a shows a typical circuit and Figure A2b

shows the resulting load voltage, switch voltage and load

currents. The power delivered to the load depends on the

fi ring angle, as well as any parasitic losses such as switch

“ON” voltage drop. Real circuit waveforms will also typically have signifi cant ringing at the switching transition,

dependent on exact circuit parasitics. Here, “SCR Waveforms” refers to the ideal chopped sine wave, though the

LTC1966/LTC1967/LTC1968 will do faithful RMS-to-DC

conversion with real SCR waveforms as well.

The case shown is for Θ = 90°, which corresponds to 50%

of available power being delivered to the load. As noted

in Table A1, when Θ = 114°, only 25% of the available

power is being delivered to the load and the power drops

quickly as Θ approaches 180°.

With an average rectifi cation scheme and the typical

calibration to compensate for errors with sine waves, the

RMS level of an input sine wave is properly reported; it is

only with a non-sinusoidal waveform that errors occur.

Because of this calibration, and the output reading in V

RMS

,

the term True-RMS got coined to denote the use of an

actual RMS-to-DC converter as opposed to a calibrated

average rectifi er.

Figure A1

Alternatives to RMS

Other ways to quantify dynamic waveforms include peak

detection and average rectifi cation. In both cases, an average (DC) value results, but the value is only accurate at

the one chosen waveform type for which it is calibrated,

typically sine waves. The errors with average rectifi cation

are shown in Table A1. Peak detection is worse in all cases

and is rarely used.

Table A1. Errors with Average Rectifi cation vs True RMS

AVERAGE

RECTIFIED

WAVEFORM V

Square Wave 1.000 1.000 11%

Sine Wave 1.000 0.900 *Calibrate for 0% Error

Triangle Wave 1.000 0.866 –3.8%

SCR at 1/2 Power,

Θ = 90°

SCR at 1/4 Power,

Θ = 114°

RMS

1.000 0.637 –29.3%

1.000 0.536 –40.4%

(V) ERROR*

MAINS

V

LOAD

+

–

I

LOAD

+

AC

V

LINE

CONTROL

–

+

V

–

AN106 FA2a

THY

Figure A2a

V

LINE

Θ

V

LOAD

V

THY

I

LOAD

AN106 FA2b

Figure A2b

an106f

AN106-14

Application Note 106

How an RMS-to-DC Converter Works

Monolithic RMS-to-DC converters use an implicit computation to calculate the RMS value of an input signal. The

fundamental building block is an analog multiply/divide

used as shown in Figure A3. Analysis of this topology is

easy and starts by identifying the inputs and the output

of the lowpass fi lter. The input to the LPF is the calculation from the multiplier/divider; (V

IN

)2/V

. The lowpass

OUT

fi lter will take the average of this to create the output,

mathematically:

2

⎛

V

=

⎜

OUT

⎜

⎝

Because V is DC,

2

⎛

⎜

⎜

⎝

⎞

VV

()

IN

⎟

V

⎟

OUT

⎠

()

V

=

OUT

2

VVor

()

VV

OUT IN

Figure A3 RMS-to-DC Converter with Implicit Computation

=

OUT IN

=

V

⎞

V

()

IN

,

⎟

V

⎟

OUT

⎠

OUT

2

V

()

IN

()

so

V

OUT

2

,

2

2

,

and

,

=

RRMS V

()

IN

()

V

÷×

V

OUT

IN

LPF

2

AN106 FA3

=

V

(()

IN

V

OUT

()

()

IN

V

OUT

Unlike the prior generation RMS-to-DC converters, the

LTC1966/LTC1967/LTC1968 computation does NOT use

log/antilog circuits, which have all the same problems,

and more, of log/antilog multipliers/dividers, i.e., linearity

is poor, the bandwidth changes with the signal amplitude

and the gain drifts with temperature.

How the LTC1966/LTC1967/LTC1968 RMS-to-DC

Converters Work

The LTC1966/LTC1967/LTC1968 use a completely new

topology for RMS-to-DC conversion, in which a ΔΣ modulator acts as the divider, and a simple polarity switch is

used as the multiplier as shown in Figure A4.

V

IN

D

α

V

OUT

∆-Σ

REF

V

IN

±1

LPF

AN106 FA4

Figure A4. Topology of the LTC1966/LTC1967/LTC1968

V

OUT

The ΔΣ modulator has a single-bit output whose average

⎯

duty cycle (

D) will be proportional to the ratio of the input

signal divided by the output. The ΔΣ is a 2nd order modulator with excellent linearity. The single-bit output is used to

selectively buffer or invert the input signal. Again, this is a

circuit with excellent linearity, because it operates at only

two points: ±1 gain; the average effective multiplication over

time will be on the straight line between these two points.

The combination of these two elements again creates a

lowpass fi lter input signal equal to (V

IN

)2/V

, which, as

OUT

shown above, results in RMS-to-DC conversion.

The lowpass fi lter performs the averaging of the RMS func-

tion and must be a lower corner frequency than the lowest

frequency of interest. For line frequency measurements,

this fi lter is simply too large to implement on-chip, but

the LTC1966/LTC1967/LTC1968 need only one capacitor

on the output to implement the lowpass fi lter. The user

can select this capacitor depending on frequency range

and settling time requirements.

This topology is inherently more stable and linear than

log/antilog implementations primarily because all of the

signal processing occurs in circuits with high gain op

amps operating closed loop.

Note that the internal scalings are such that the ΔΣ output duty cycle is limited to 0% or 100% only when V

exceeds ±4 • V

OUT

.

IN

an106f

AN106-15

Application Note 106

Linearity of an RMS-to-DC Converter

Linearity may seem like an odd property for a device that

implements a function that includes two very nonlinear

processes: squaring and square rooting.

However, an RMS-to-DC converter has a transfer function,

RMS volts in to DC volts out, that should ideally have a

1:1 transfer function. To the extent that the input to output

transfer function does not lie on a straight line, the part

is nonlinear.

A more complete look at linearity uses the simple model

shown in Figure A5. Here an ideal RMS core is corrupted by

both input circuitry and output circuitry that have imperfect

transfer functions. As noted, input offset is introduced in

the input circuitry, while output offset is introduced in the

output circuitry.

Any nonlinearity that occurs in the output circuity will corrupt the RMS in to DC out transfer function. A nonlinearity

in the input circuitry will typically corrupt that transfer

function far less simply because with an AC input, the

RMS-to-DC conversion will average the nonlinearity from

a whole range of input values together.

But the input nonlinearity will still cause problems in

an RMS-to-DC converter because it will corrupt the accuracy as the input signal shape changes. Although an

RMS-to-DC converter will convert any input waveform to

a DC output, the accuracy is not necessarily as good for

all waveforms as it is with sine waves. A common way

to describe dynamic signal wave shapes is Crest Factor.

The crest factor is the ratio of the peak value relative to

the RMS value of a waveform. A signal with a crest factor

of 4, for instance, has a peak that is four times its RMS

value. Because this peak has energy (proportional to volt-

2

age squared) that is 16 times (4

) the energy of the RMS

value, the peak is necessarily present for at most 6.25%

(1/16) of the time.

The LTC1966/LTC1967/LTC1968 perform very well with

crest factors of 4 or less and will respond with reduced

accuracy to signals with higher crest factors. The high

performance with crest factors less than 4 is directly

attributable to the high linearity throughout the LTC1966/

LTC1967/LTC1968.

INPUT CIRCUITRY

INPUT OUTPUT

• V

IOS

• INPUT NONLINEARITY

Figure A5. Linearity Model of an RMS-to-DC Converter

IDEAL

RMS-TO-DC

CONVERTER

OUTPUT CIRCUITRY

• V

OOS

• OUTPUT NONLINEARITY

AN106 FA5

an106f

AN106-16

Application Note 106

APPENDIX B

AC Measurement and Signal Handling Practice

Accurate AC measurement requires trustworthy instrumentation, proper signal routing technique, parasitic

minimization, attention to layout and care in component

selection. The text circuits DC-500kHz, 1% error bandwidth seems benign, but unpleasant surprises await the

unwary.

An accurate RMS voltmeter is required for serious AC

work. Figure B1 lists types used in our laboratory. These

are high grade, specialized instruments specifi cally intended for precise RMS measurement. All are thermally

1

based

. The fi rst three entries, general purpose instruments with many ranges and features, are easily used and

meet almost all AC measurement needs. The last entry is

more of a component than an instrument. The A55 series

of “thermal converters” provide millivolt level outputs

for various inputs. Typical input ranges are 0.5V

1V

RMS

, 2V

RMS

and 5V

and each converter is sup-

RMS

RMS

,

plied with individual calibration data. They are somewhat

cumbersome to use and easily destroyed but are highly

accurate. Their primary use is as reference standards to

check other instrument’s performance.

AC signal handling for high accuracy is a broad topic,

involving a considerable degree of depth. This forum

must suffer brevity, but some gossip is possible.

Layout is critical. The most prevalent parasitic in AC

measurement is stray capacitance. Keep signal path

connections short and small area. A few picofarrads of

coupling into a high impedance node can upset a 500kHz,

1% accuracy signal path. To the extent possible, keep

impedances low to minimize parasitic capacitive effects.

Consider individual component parasitics and plan to

accommodate them. Examine effects of component

placement and orientation on the circuit board. If a

ground plane is in use it may be necessary to relieve it

in the vicinity of critical circuit nodes or even individual

components.

Passive components have parasitics that must be kept in

mind. Resistors suffer shunt capacitance whose effects

vary with frequency and resistor value. It is worth noting

that different brands of resistors, although nominally

similar, may exhibit markedly different parasitic behavior. Capacitors in the signal path should be used so that

their outer foil is connected to the less sensitive node,

affording some relief from pick-up and stray capacitance

induced effects. Some capacitors are marked to indicate

the outer foil terminal, others require consulting the

data sheet or vendor contact. Avoid ceramic capacitors

in the signal path. Their piezoelectric responses make

them unsuitable for precision AC circuitry. In general,

any component in the signal path should be examined

in terms of its potential parasitic contribution.

1

See references 1 and 2 for details on thermally based RMS-to-DC

conversion.

MODEL MANUFACTURER 1V RANGE INPUT BANDWIDTH COMMENTS

3400A/3400B Hewlett-Packard 1% AC 10MHz/20MHz Metered Instrument. Most Common RMS

3403C Hewlett-Packard 0.2% AC, AC + DC 100MHz Digital Display, 1µV Sensitivity (2MHz BW),

8920/8921A Fluke 0.7% AC, AC + DC 20MHz Digital Display, 10µV Sensitivity (2MHz BW),

A55 Fluke 0.05% AC + DC 50MHz Set of Individually Calibrated Thermal

Figure B1. Precision Wideband RMS Voltmeters Useful for AC Measurement. All are Thermally Based, Permitting High Accuracy

and Wide Bandwidth Independent of Input Waveshape. A55 Reference Standards, Although Unsuitable for General Purpose

Measurement, Have Best Accuracy

Voltmeter

dB Ranges, Relative dB

dB Ranges, Relative dB

Converters. Reference Standards. Not for

General Purpose Measurement

an106f

AN106-17

Application Note 106

Active components, such as amplifi ers, must be treated

as potential error sources. In particular, as stated in the

text, ensure that there is enough open loop gain at the

frequency of interest to assure needed closed loop gain

accuracy. Margins of 100:1 are not unreasonable. Keep

feedback values as low as possible to minimize parasitic

effects.

Route signals to and from the circuit board coaxially and

at low impedance, preferably 50Ω, for best results. In

50Ω systems, remember that terminators and attenuators

APPENDIX C

Symmetrical White Gaussian Noise

by Ben Hessen-Schmidt,

NOISE COM, INC.

White noise provides instantaneous coverage of all frequencies within a band of interest with a very fl at output

spectrum. This makes it useful both as a broadband

stimulus and as a power-level reference.

Symmetrical white Gaussian noise is naturally generated in

resistors. The noise in resistors is due to vibrations of the

conducting electrons and holes, as described by Johnson

and Nyquist.

metrically Gaussian, and the average noise voltage is:

VkT

n

where:

k = 1.38E–23 J/K (Boltzmann’s constant)

T = temperature of the resistor in Kelvin

f = frequency in Hz

h = 6.62E–34 Js (Planck’s constant)

R(f) = resistance in ohms as a function of frequency

1

The distribution of the noise voltage is sym-

=∫2 R(f) p(f) df

(1)

have tolerances that can corrupt a 1% amplitude accuracy

measurement. Verify such terminator and attenuator

tolerances by measurement and account for them when

interpreting measurement results. Similarly, verify the

accuracy of any associated instruments 50Ω input or

output impedance and account for deviations.

This all seems painful but is an essential part of achieving

1% accurate, 500kHz signal integrity. Failure to observe

the precautions listed above risks degrading the RMSto-DC converters system level performance.

p(f) is close to unity for frequencies below 40GHz when T

is equal to 290°K. The resistance is often assumed to be

independent of frequency, and Údf is equal to the noise

bandwidth (B). The available noise power is obtained when

the load is a conjugate match to the resistor, and it is:

2

V

n

N

==

where the “4” results from the fact that only half of the

noise voltage and hence only 1/4 of the noise power is

delivered to a matched load.

Equation 3 shows that the available noise power is proportional to the temperature of the resistor; thus it is often

called thermal noise power, Equation 3 also shows that

white noise power is proportional to the bandwidth.

An important source of symmetrical white Gaussian noise

is the noise diode. A good noise diode generates a high

level of symmetrical white Gaussian noise. The level is

often specifi ed in terms of excess noise ratio (ENR).

ENR in Log

kTB

R

4

dB

()

Te

−

=

10

()

290

290

(3)

(4)

pf

()=

exp(hf/kT) 1

kT

[]

AN106-18

hf

(2)

−

Te is the physical temperature that a load (with the same

impedance as the noise diode) must be at to generate the

same amount of noise.

1

See “Additional Reading” at the end of this section.

an106f

Application Note 106

The ENR expresses how many times the effective noise

power delivered to a non-emitting, nonrefl ecting load

exceeds the noise power available from a load held at the

reference temperature of 290°K (16.8°C or 62.3°F).

The importance of high ENR becomes obvious when the

noise is amplifi ed, because the noise contributions of the

amplifi er may be disregarded when the ENR is 17dB larger

than the noise fi gure of the amplifi er (the difference in

total noise power is then less than 0.1dB). The ENR can

easily be converted to noise spectral density in dBm/Hz

or µV/√Hz by use of the white noise conversion formulas

in Table 1.

Table 1. Useful White Noise Conversion

dBm

dBm

dBm

dBm/Hz

dBm/Hz

=

dBm/Hz + 10log (BW)

=

20log (Vn) – 10log(R) + 30dB

=

20log(Vn) + 13dB for R = 50Ω

=

20log(µVn√

=

–174dBm/Hz + ENR for ENR > 17dB

Hz

) – 10log(R) – 90dB

When amplifying noise it is important to remember that

the noise voltage has a Gaussian distribution. The peak

voltages of noise are therefore much larger than the average

or RMS voltage. The ratio of peak voltage to RMS voltage

is called crest factor, and a good crest factor for Gaussian

noise is between 5:1 and 10:1 (14 to 20dB). An amplifi er’s

1dB gain-compression point should therefore be typically

20dB larger than the desired average noise-output power

to avoid clipping of the noise.

For more information about noise diodes, please contact

NOISE COM, INC. at (973) 386-9696.

Additional Reading

1. Johnson, J.B, “Thermal Agitation of Electricity in Conductors,” Physical Review, July 1928, pp. 97-109.

2. Nyquist, H. “Thermal Agitation of Electric Charge in Conductors,” Physical Review, July 1928, pp. 110-113.

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

an106f

AN106-19

Application Note 106

AN106-20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

an106f

LT 0207 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...