Final Electrical Specifications

查询LT1745供应商

LTC1745

Low Noise,12-Bit, 25Msps ADC

FEATURES

■

Sample Rate: 25Msps

■

72.5dB SNR and 96dB SFDR (3.2V Range)

■

71dB SNR and 96dB SFDR (2V Range)

■

No Missing Codes

■

Single 5V Supply

■

Low Power Dissipation: 380mW

■

Selectable Input Ranges: ±1V or ±1.6V

■

240MHz Full Power Bandwidth S/H

■

Output Enable

■

Two’s Complement or Offset Binary Outputs

■

Out-of-Range Indicator

■

Data Ready Output Clock

■

48-Pin TSSOP Package

■

50Msps Pin-for-Pin Upgrade (LTC1743)

■

14-Bit Plug Compatible Upgrade (LTC1746)

U

APPLICATIO S

■

Telecommunications

■

Medical Imaging

■

Receivers

■

Cellular Base Stations

■

Spectrum Analysis

■

Imaging Systems

, LTC and LT are registered trademarks of Linear Technology Corporation.

U

January 2003

DESCRIPTION

The LTC®1745 is a 25Msps, sampling 12-bit A/D converter designed for digitizing high frequency, wide dynamic range signals. Pin selectable input ranges of ±1V

and ±1.6V along with a resistor programmable mode

allow the LTC1745’s input range to be optimized for a wide

variety of applications.

The LTC1745 is perfect for demanding communications

applications with AC performance that includes 72.5dB

SNR and 96dB spurious free dynamic range. Ultralow jitter

of 0.3ps

to 70MHz with excellent noise performance. DC specs

include ±1LSB INL and ±0.75LSB DNL over temperature.

The digital interface is compatible with 5V, 3V and 2V logic

systems. The ENC and ENC inputs may be driven differentially from PECL, GTL and other low swing logic families or

from single-ended TTL or CMOS. The low noise, high gain

ENC and ENC inputs may also be driven by a sinusoidal

signal without degrading performance. A separate output

power supply can be operated from 0.5V to 5V, making it

easy to connect directly to any low voltage DSPs or FIFOs.

The TSSOP package with a flow-through pinout simplifies

the board layout.

allows undersampling of IF frequencies of up

RMS

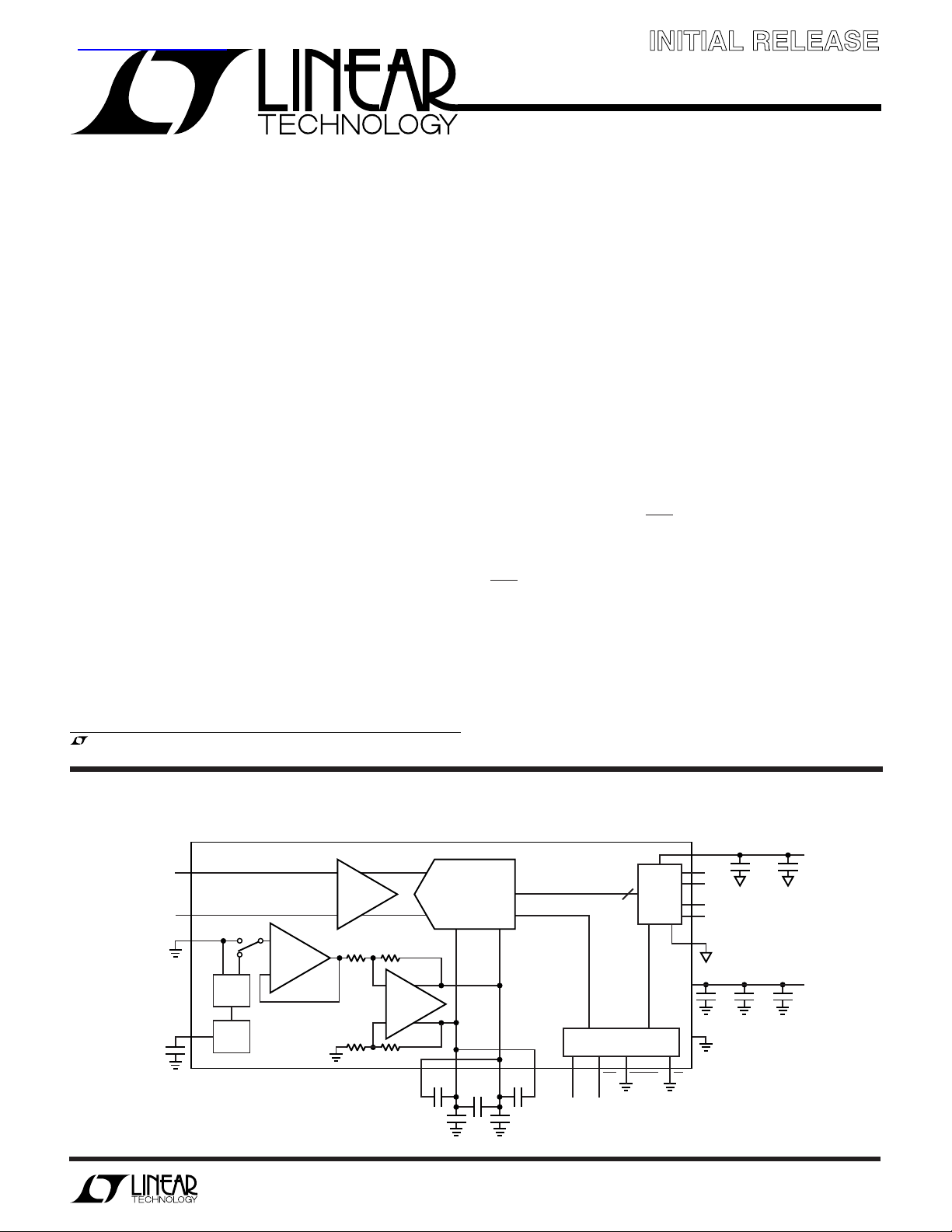

BLOCK DIAGRA

+

A

IN

±1V

DIFFERENTIAL

ANALOG INPUT

4.7µF

A

SENSE

V

–

IN

CM

2.35V

RANGE

SELECT

W

25Msps, 12-Bit ADC with a ±1V Differential Input Range

S/H

AMP

BUFFER

DIFF AMP

REF

0.1µF0.1µF

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

12-BIT

PIPELINED ADC

REFHAREFLB

REFLA REFHB

4.7µF

1µF1µF

CONTROL LOGIC

ENC

DIFFERENTIAL

ENCODE INPUT

ENC

12

OUTPUT

LATCHES

OV

DD

OF

D11

•

•

•

D0

CLKOUT

OGND

V

DD

GND

1745 BD

OEMSBINV

0.1µF

1µF 1µF 1µF

0.5V TO 5V

0.1µF

5V

1745i

1

LTC1745

WW

W

U

ABSOLUTE MAXIMUM RATINGS

OVDD = VDD (Notes 1, 2)

Supply Voltage (VDD)............................................. 5.5V

Analog Input Voltage (Note 3) .... –0.3V to (VDD + 0.3V)

Digital Input Voltage (Note 4) ..... –0.3V to (VDD + 0.3V)

Digital Output Voltage................. –0.3V to (VDD + 0.3V)

OGND Voltage...........................................–0.3V to 0.3V

Power Dissipation............................................ 2000mW

Operating Temperature Range

LTC1745C ............................................... 0°C to 70°C

LTC1745I............................................ – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

U

W

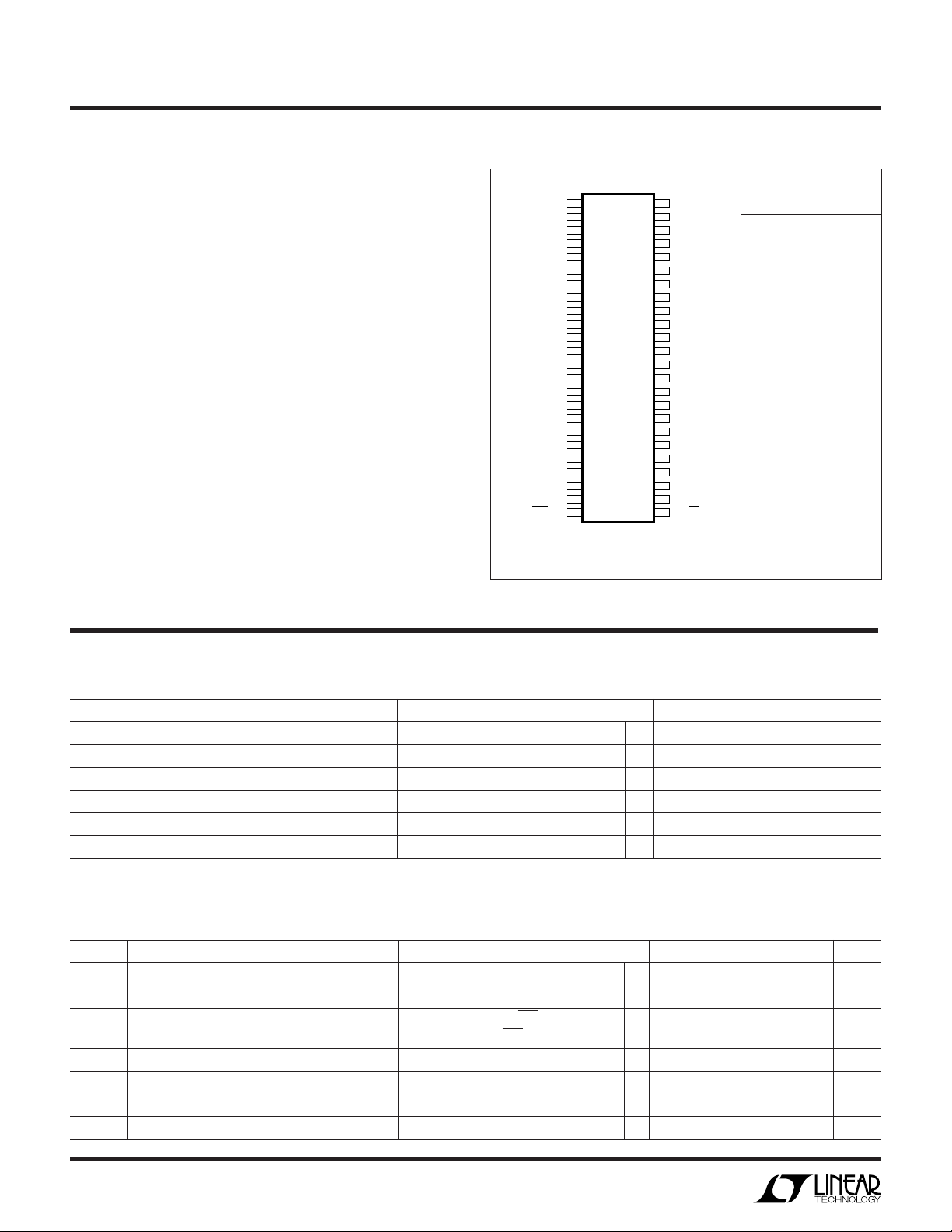

PACKAGE/ORDER INFORMATION

SENSE

V

GND

A

A

GND

V

V

GND

REFLB

REFHA

GND

GND

REFLA

REFHB

GND

V

V

GND

V

GND

MSBINV

ENC

ENC

TOP VIEW

1

2

CM

3

+

4

IN

–

5

IN

6

7

DD

8

DD

9

10

11

12

13

14

15

16

17

DD

18

DD

19

20

DD

21

22

23

24

FW PACKAGE

48-LEAD PLASTIC TSSOP

T

= 150°C, θJA = 35°C/W

JMAX

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

OF

OGND

D11

D10

D9

OV

DD

D8

D7

D6

D5

OGND

GND

GND

D4

D3

D2

OV

DD

D1

D0

NC

NC

OGND

CLKOUT

OE

ORDER PART

NUMBER

LTC1745CFW

LTC1745IFW

U

Consult LTC Marketing for parts specified with wider operating temperature ranges.

U

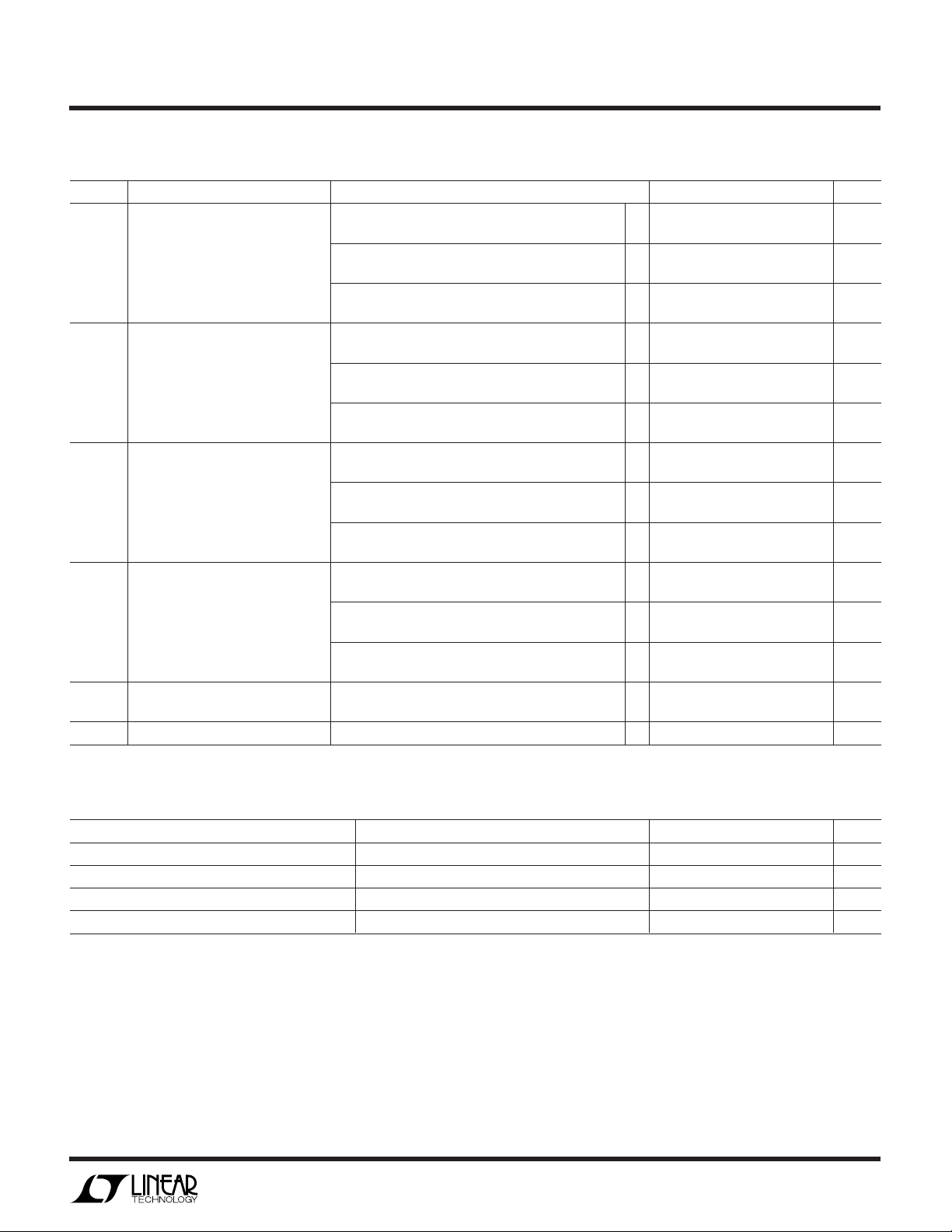

CO VERTER CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. (Note 5)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) ● 12 Bits

Integral Linearity Error (Note 6) ● –1 ±0.4 1 LSB

Differential Linearity Error ● –0.75 ±0.2 0.75 LSB

Offset Error (Note 7) ● –30 ±530 mV

Gain Error External Reference (SENSE = 1.6V) ● –2.5 ±1 2.5 %FS

Full-Scale Tempco I

The ● indicates specifications which apply over the full operating

= 0 ±40 ppm/°C

OUT(REF)

UU

A ALOG I PUT

specifications are at TA = 25°C. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

I

IN

C

IN

t

ACQ

t

AP

t

JITTER

CMRR Analog Input Common Mode Rejection Ratio 1.0V < (A

Analog Input Range (Note 8) 4.75V ≤ VDD ≤ 5.25V ● ±1 to ±1.6 V

Analog Input Leakage Current ● –1 1 µA

Analog Input Capacitance Sample Mode ENC < ENC 8 pF

Sample-and-Hold Acquisition Time ● 15 18 ns

Sample-and-Hold Acquisition Delay Time 0 ns

Sample-and-Hold Acquisition Delay Time Jitter 0.3 ps

The ● indicates specifications which apply over the full operating temperature range, otherwise

Hold Mode ENC > ENC 4 pF

–

+

= A

IN

) < 3.5V 80 dB

IN

RMS

1745i

2

LTC1745

UW

DY A IC ACCURACY

otherwise specifications are at TA = 25°C. AIN = –1dBFS. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SNR Signal-to-Noise Ratio 5MHz Input Signal (2V Range) 71 dB

SFDR Spurious Free Dynamic Range 5MHz Input Signal (2V Range) 96.5 dB

S/(N + D) Signal-to-(Noise + Distortion) Ratio 5MHz Input Signal (2V Range) 71 dB

THD Total Harmonic Distortion 5MHz Input Signal, First 5 Harmonics (2V Range) –95 dB

IMD Intermodulation Distortion f

Sample-and-Hold Bandwidth R

The ● indicates specifications which apply over the full operating temperature range,

5MHz Input Signal (3.2V Range)

30MHz Input Signal (2V Range) 71 dB

30MHz Input Signal (3.2V Range) 72 dB

70MHz Input Signal (2V Range) 70 dB

70MHz Input Signal (3.2V Range) 71.5 dB

5MHz Input Signal (3.2V Range)

30MHz Input Signal (2V Range) 93.5 dB

30MHz Input Signal (3.2V Range) 87.5 dB

70MHz Input Signal (2V Range) 78.5 dB

70MHz Input Signal (3.2V Range) 70.5 dB

5MHz Input Signal (3.2V Range)

30MHz Input Signal (2V Range) 71 dB

30MHz Input Signal (3.2V Range) 72 dB

70MHz Input Signal (2V Range) 69.5 dB

70MHz Input Signal (3.2V Range) 68.5 dB

5MHz Input Signal, First 5 Harmonics (3.2V Range) –93 dB

30MHz Input Signal, First 5 Harmonics (2V Range) –92 dB

30MHz Input Signal, First 5 Harmonics (3.2V Range) –87 dB

70MHz Input Signal, First 5 Harmonics (2V Range) –77.5 dB

70MHz Input Signal, First 5 Harmonics (3.2V Range) –70 dB

= 4MHz, f

IN1

= 4MHz, f

f

IN1

SOURCE

= 5.1MHz (2V Range) 97 dBc

IN2

= 5.1MHz (3.2V Range) 93 dBc

IN2

= 50Ω 240 MHz

● 71 72.5 dB

● 78 96.5 dB

● 71 72.5 dB

UU U

I TER AL REFERE CE CHARACTERISTICS

PARAMETER CONDITIONS MIN TYP MAX UNITS

VCM Output Voltage I

VCM Output Tempco I

VCM Line Regulation 4.75V ≤ VDD ≤ 5.25V 3 mV/V

VCM Output Resistance 1mA ≤ I

= 0 2.29 2.35 2.41 V

OUT

= 0 ±30 ppm/°C

OUT

≤ 1mA 4 Ω

OUT

(Note 5)

1745i

3

LTC1745

UU

DIGITAL I PUTS A D DIGITAL OUTPUTS

operating temperature range, otherwise specifications are at TA = 25°C. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

I

IN

C

IN

V

OH

V

OL

I

OZ

C

OZ

I

SOURCE

I

SINK

High Level Input Voltage VDD = 5.25V ● 2.4 V

Low Level Input Voltage VDD = 4.75V ● 0.8 V

Digital Input Current VIN = 0V to V

Digital Input Capacitance MSBINV and OE Only 1.5 pF

High Level Output Voltage OVDD = 4.75V IO = –10µA 4.74 V

Low Level Output Voltage OVDD = 4.75V IO = 160µA 0.05 V

Hi-Z Output Leakage D11 to D0 V

Hi-Z Output Capacitance D11 to D0 OE = High (Note 8) ● 15 pF

Output Source Current V

Output Sink Current V

OUT

OUT

OUT

DD

= 0V to VDD, OE = High ● ±10 µA

= 0V –50 mA

= 5V 50 mA

The ● indicates specifications which apply over the full

● ±10 µA

IO = –200µA ● 4V

IO = 1.6mA ● 0.1 0.4 V

WU

POWER REQUIRE E TS

range, otherwise specifications are at TA = 25°C. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

I

DD

P

OV

DD

DIS

DD

Positive Supply Voltage 4.75 5.25 V

Positive Supply Current 2V Range, Full-Scale Input ● 76 91 mA

Power Dissipation 2V Range, Full-Scale Input 380 455 mW

Digital Output Supply Voltage 0.5 V

The ● indicates specifications which apply over the full operating temperature

DD

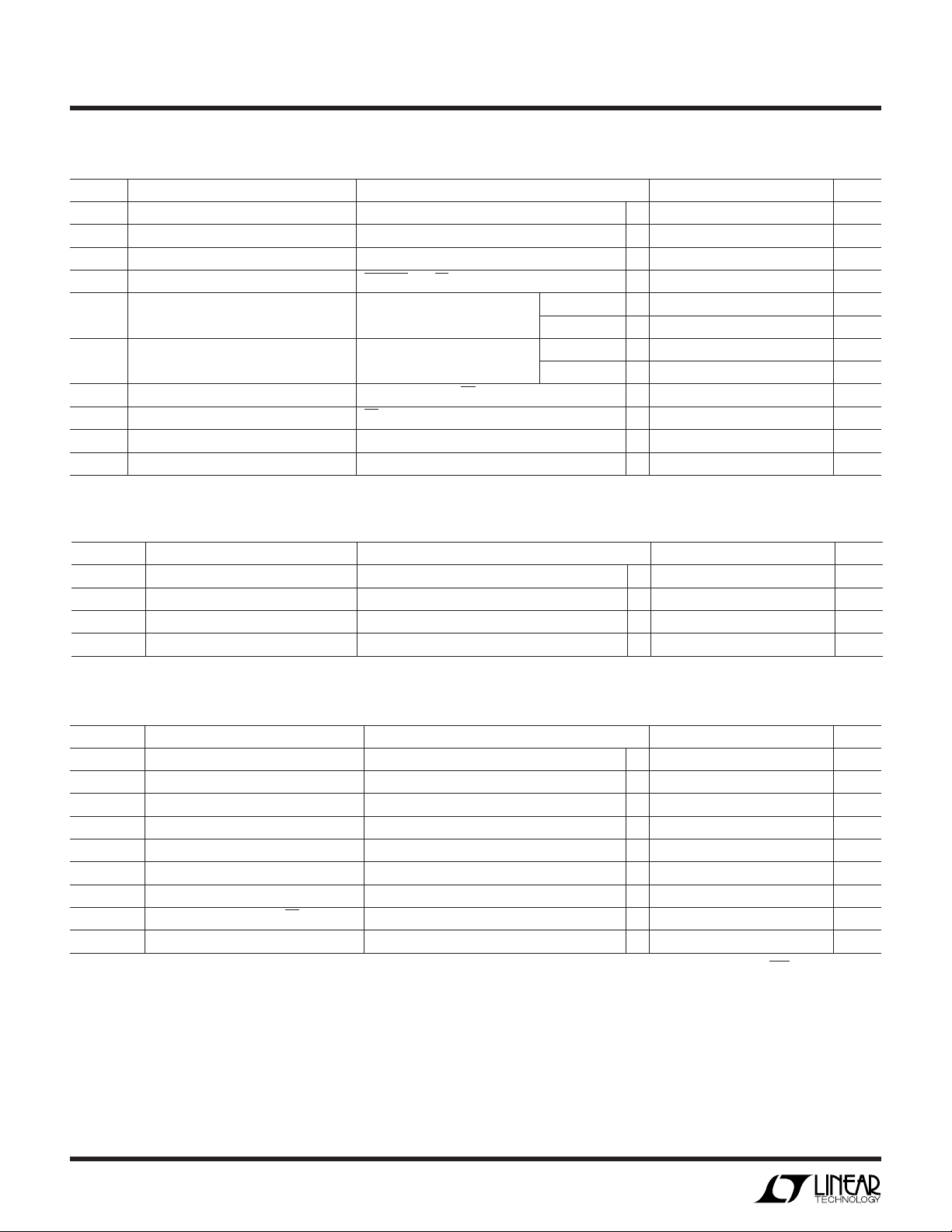

UW

TI I G CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. (Note 5)

The ● indicates specifications which apply over the full operating temperature

V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

SAMPLE(MAX)

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All voltage values are with respect to ground with GND

(unless otherwise noted).

Note 3: When these pin voltages are taken below GND or above V

will be clamped by internal diodes. This product can handle input currents

of greater than 100mA below GND or above V

Note 4: When these pin voltages are taken below GND, they will be

clamped by internal diodes. This product can handle input currents of

>100mA below GND without latchup. These pins are not clamped to V

Maximum Sampling Frequency (Note 9) ● 25 MHz

ENC Low Time (Note 9) ● 19 20 1000 ns

ENC High Time (Note 9) ● 19 20 1000 ns

Aperture Delay of Sample-and-Hold 0 ns

Delay to Data Output CL = 10pF (Note 8) ● 0.5 1.5 5 ns

ENC to CLKOUT Delay (Note 8) ● 013ns

CLKOUT to Data Delay (Note 8) ● 0 0.5 ns

DATA Access Time After OE ↓ CL = 5pF (Note 8) 10 25 ns

BUS Relinquish Time (Note 8) 10 25 ns

without latchup.

DD

DD

, they

DD

Note 5: V

sine wave, input range = ±1.6V differential, unless otherwise specified.

Note 6: Integral nonlinearity is defined as the deviation of a code from a

straight line passing through the actual endpoints of the transfer curve.

The deviation is measured from the center of the quantization band.

Note 7: Bipolar offset is the offset voltage measured from –0.5 LSB

when the output code flickers between 0000 0000 0000 and

1111 1111 1111.

Note 8: Guaranteed by design, not subject to test.

.

Note 9: Recommended operating conditions.

= 5V, f

DD

= 25MHz, differential ENC/ENC = 2V

SAMPLE

P-P

25MHz

1745i

4

UW

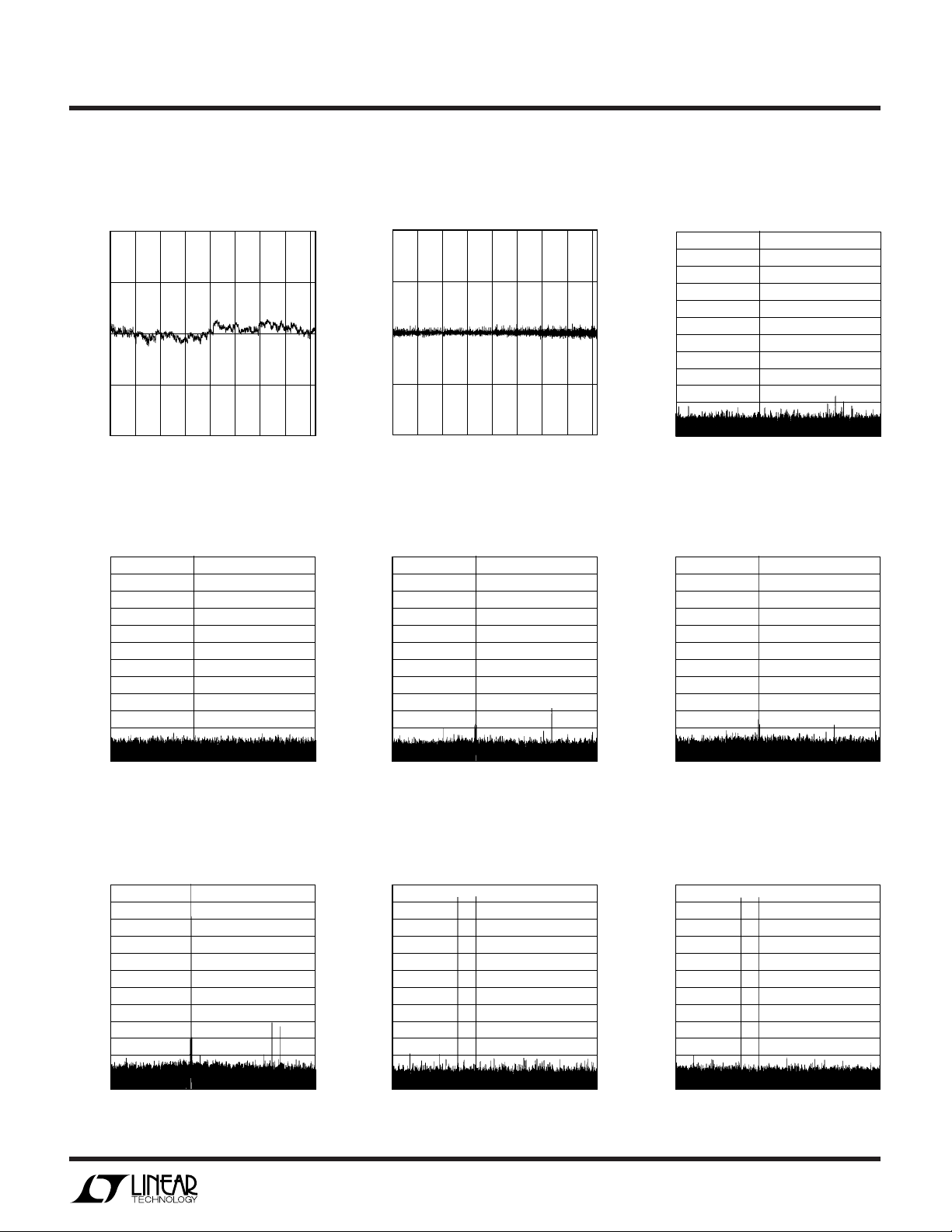

TYPICAL PERFOR A CE CHARACTERISTICS

1.0

0.5

0

INL ERROR (LSB)

–0.5

–1.0

0

1000 2000

CODE

Nonaveraged, 32768 Point FFT,

Input Frequency = 5MHz,

2V Range

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

4

2

FREQUENCY (MHz)

6

Nonaveraged, 32768 Point FFT,

Input Frequency = 70MHz,

2V Range

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

4

2

FREQUENCY (MHz)

6

3000 4000

1745 G01

10

812

1745 G04

10

812

1745 G07

1.0

0.5

0

DNL ERROR (LSB)

–0.5

–1.0

0

1000 2000

CODE

Nonaveraged, 32768 Point FFT,

Input Frequency = 30MHz,

3.2V Range

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

4

2

FREQUENCY (MHz)

6

Nonaveraged, 32768 Point

2-Tone FFT, Input Frequency =

4MHz and 5.1MHz, 3.2V Range

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

4

2

FREQUENCY (MHz)

6

3000 4000

10

812

10

812

1745 G02

1745 G05

1745 G08

LTC1745

Nonaveraged, 32768 Point FFT,

Input Frequency = 5MHz,

3.2V RangeTypical INL Typical DNL

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

Nonaveraged, 32768 Point FFT,

Input Frequency = 30MHz,

2V Range

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

Nonaveraged, 32768 Point

2-Tone FFT, Input Frequency =

4MHz and 5.1MHz, 2V Range

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

4

2

FREQUENCY (MHz)

4

2

FREQUENCY (MHz)

4

2

FREQUENCY (MHz)

6

6

6

10

812

1745 G03

10

812

1745 G06

10

812

1745 G09

1745i

5

LTC1745

UW

TYPICAL PERFOR A CE CHARACTERISTICS

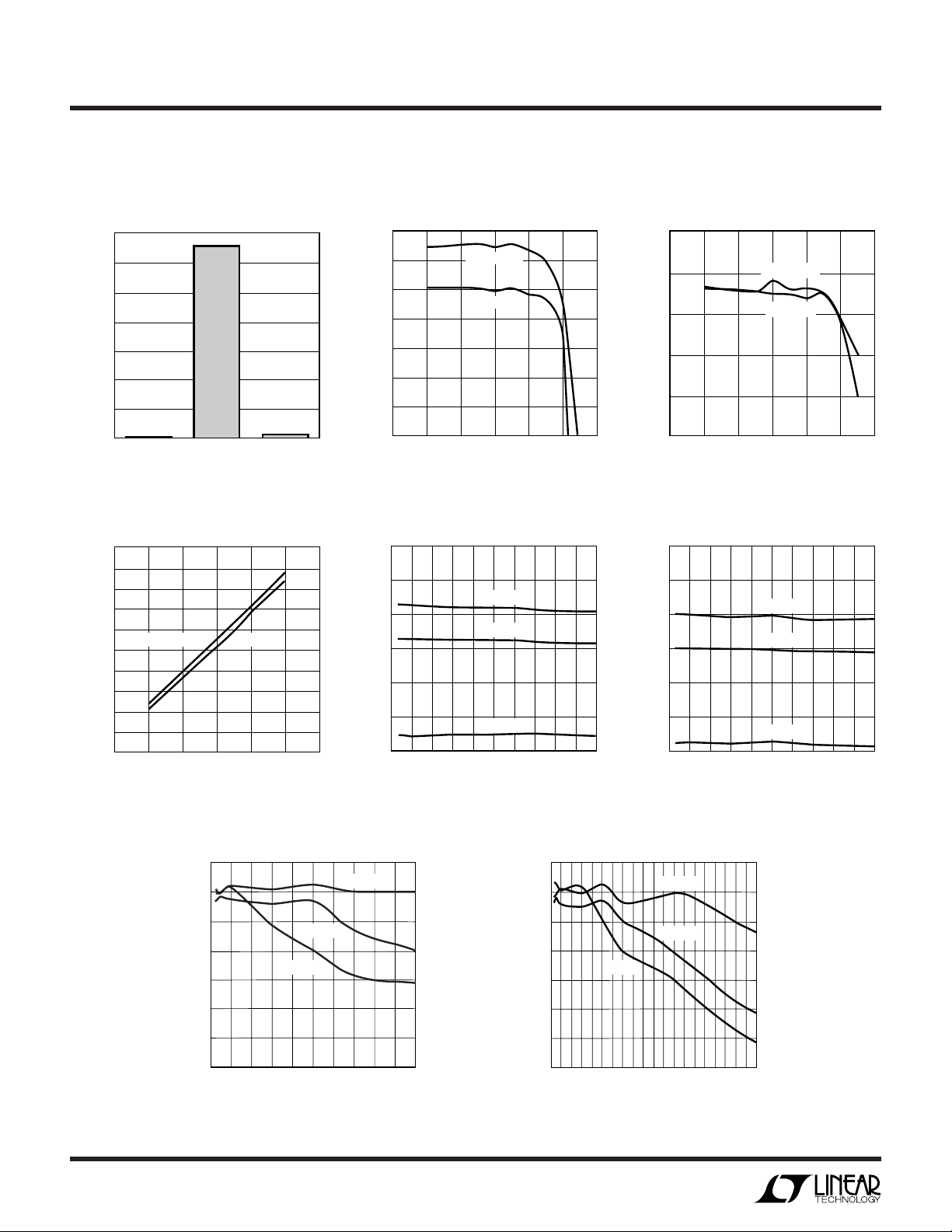

Grounded Input Histogram

35000

30000

25000

20000

COUNT

15000

10000

5000

0

2041

Power vs Sample Rate,

Input Frequency = 5MHz

500

480

460

440

420

400

380

POWER (mW)

360

340

320

300

0

10

20

SAMPLE RATE (Msps)

2042 2043

CODE

2V RANGE3.2V RANGE

30 40

SNR vs Sample Rate,

Input Frequency = 5MHz, –1dB

73

3.2V RANGE

2V RANGE

20 30 40

10

SAMPLE RATE (Msps)

50 60

1745 G11

1745 G10

72

71

70

69

SNR (dBFS)

68

67

66

0

SNR vs Input Frequency

3.2V Range

80

75

–1dBFS

70

65

SNR (dB)

60

55

60

50

1745 G13

50

20 40 60 80

INPUT FREQUENCY (MHz)

–6dBFS

–20dBFS

10010030507090

1745 G14

SFDR vs Sample Rate,

Input Frequency = 5MHz, –1dB

110

100

90

SFDR (dB)

80

70

60

0

10

3.2V RANGE

2V RANGE

20 30 40

SAMPLE RATE (Msps)

SNR vs Input Frequency

2V Range

80

75

70

65

SNR (dB)

60

55

50

20 40 60 80

INPUT FREQUENCY (MHz)

–1dBFS

–6dBFS

–20dBFS

50 60

1745 G12

10010030507090

1745 G15

6

SFDR vs Input Frequency

and Amplitude, 3.2V Range

110

100

90

80

70

SFDR (dBFS)

60

50

40

0

10

20

INPUT FREQUENCY (MHz)

–6dBFS

–1dBFS

30

50

40

–20dBFS

70

60 80

90

1746 G16

100

SFDR vs Input Frequency

and Amplitude, 2V Range

110

100

90

80

70

SFDR (dBFS)

60

50

40

0

–1dBFS

50

INPUT FREQUENCY (MHz)

100

–20dBFS

–6dBFS

150

200

1745 G17

1745i

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1745

2nd and 3rd Harmonic vs Input

Frequency, 3.2V Range, –1dB

–30

–50

–70

–90

DISTORTION (dB)

–110

–130

3RD HARMONIC

10 20 30

0

2ND HARMONIC

60 70 90

40 50

INPUT FREQUENCY (MHz)

Worst Harmonic 4th or Higher vs

Input Frequency, 2V Range, –1dB

–60

–70

–80

2nd and 3rd Harmonic vs Input

Frequency, 2V Range, –1dB

–30

–50

–70

–90

DISTORTION (dB)

–110

80

100

1745 G18

–130

0

2ND HARMONIC

3ND HARMONIC

30 30 50

INPUT FREQUENCY (MHz)

40

1745 G19

Worst Harmonic 4th or Higher vs

Input Frequency, 3.2V Range, –1dB

–60

–70

–80

–90

DISTORTION (dB)

–100

–110

10 20 30

0

INPUT FREQUENCY (MHz)

40 50

60 70 90

80

100

1746 G20

SFDR vs Input Amplitude,

2V Range, 5MHz Input Frequency

110

100

SFDR dBFS

90

–90

DISTORTION (dB)

–100

–110

0

50 150 200

INPUT FREQUENCY (MHz)

100

1745 G21

80

SFDR (dBc AND dBFS)

70

60

–60

INPUT AMPLITUDE (dBFS)

–40

SFDR dBc

–20

0

1745 G22

1745i

7

LTC1745

UUU

PI FU CTIO S

SENSE (Pin 1): Reference Sense Pin. Ground selects

±1V. VDD selects ±1.6V. Greater than 1V and less than

1.6V applied to the SENSE pin selects an input range of

±V

VCM (Pin 2): 2.35V Output and Input Common Mode Bias.

Bypass to ground with 4.7µF ceramic chip capacitor.

GND (Pins 3, 6, 9, 12, 13, 16, 19, 21, 36, 37): ADC

Power Ground.

A

IN

A

IN

VDD (Pins 7, 8, 17, 18, 20): 5V Supply. Bypass to AGND

with 1µF ceramic chip capacitor.

REFLB (Pin 10): ADC Low Reference. Bypass to Pin 11

with 0.1µF ceramic chip capacitor. Do not connect to

Pin␣ 14.

REFHA (Pin 11): ADC High Reference. Bypass to Pin 10

with 0.1µF ceramic chip capacitor, to Pin 14 with a 4.7µF

ceramic capacitor and to ground with 1µF ceramic

capacitor.

REFLA (Pin 14): ADC Low Reference. Bypass to Pin 15

with 0.1µF ceramic chip capacitor, to Pin 11 with a 4.7µF

ceramic capacitor and to ground with 1µF ceramic

capacitor.

REFHB (Pin 15): ADC High Reference. Bypass to Pin 14

with 0.1µF ceramic chip capacitor. Do not connect to

Pin␣ 11.

, ±1.6V is the largest valid input range.

SENSE

+

(Pin 4): Positive Differential Analog Input.

–

(Pin 5): Negative Differential Analog Input.

MSBINV (Pin 22): MSB Inversion Control. Low inverts

the MSB, 2’s complement output format. High does not

invert the MSB, offset binary output format.

ENC (Pin 23): Encode Input. The input sample starts on

the positive edge.

ENC (Pin 24): Encode Complement Input. Conversion

starts on the negative edge. Bypass to ground with 0.1µF

ceramic for single-ended ENCODE signal.

OE (Pin 25): Output Enable. Low enables outputs. Logic

high makes outputs Hi-Z.

CLKOUT (Pin 26): Data Valid Output. Latch data on the

rising edge of CLKOUT.

OGND (Pins 27, 38, 47): Output Driver Ground.

NC (Pins 28, 29): Do Not Connect These Pins.

D0-D1 (Pins 30, 31): Digital Outputs. D0 is the LSB.

OVDD (Pins 32, 43): Positive Supply for the Output Driv-

ers. Bypass to ground with 0.1µF ceramic chip capacitor.

D2-D4 (Pins 33 to 35): Digital Outputs.

D5-D8 (Pins 39 to 42): Digital Outputs.

D9-D11 (Pins 44 to 46): Digital Outputs. D11 is the MSB.

OF (Pin 48): Over/Under Flow Output. High when an over

or under flow has occurred.

8

1745i

UWW

TI I G DIAGRA

LTC1745

ANALOG

INPUT

ENCODE

DATA

CLKOUT

OE

DATA

UU

N

t

3

t

6

t

5

t

7

t

2

DATA (N – 5)

D11 TO D0

DATA N

D11 TO D0, OF AND CLKOUT

W

FU CTIO AL BLOCK DIAGRA

t

1

t

4

DATA (N – 4)

D11 TO D0

t

8

DATA (N – 3)

D11 TO D0

1745 TD

±1V

DIFFERENTIAL

ANALOG INPUT

SENSE

4.7µF

OV

DD

+

A

IN

S/H

–

A

IN

BUFFER

RANGE

SELECT

V

CM

2.35V

REF

AMP

DIFF AMP

0.1µF 0.1µF

12-BIT

PIPELINED ADC

REFHAREFLB

1µF1µF

REFLA REFHB

4.7µF

ENC

DIFFERENTIAL

ENCODE INPUT

12

OUTPUT

LATCHES

CONTROL LOGIC

ENC

OF

D11

•

•

•

D0

CLKOUT

OGND

V

DD

GND

1745 BD

OEMSBINV

0.1µF

1µF 1µF 1µF

0.5V TO 5V

0.1µF

5V

1745i

9

LTC1745

WUUU

APPLICATIO S I FOR ATIO

DYNAMIC PERFORMANCE

Signal-to-Noise Plus Distortion Ratio

The signal-to-noise plus distortion ratio [S / (N + D)] is the

ratio between the RMS amplitude of the fundamental input

frequency and the RMS amplitude of all other frequency

components at the ADC output. The output is band limited

to frequencies above DC to below half the sampling

frequency.

Signal-to-Noise Ratio

The signal-to-noise ratio (SNR) is the ratio between the

RMS amplitude of the fundamental input frequency and

the RMS amplitude of all other frequency components

except the first five harmonics and DC.

Total Harmonic Distortion

Total harmonic distortion is the ratio of the RMS sum of all

harmonics of the input signal to the fundamental itself. The

out-of-band harmonics alias into the frequency band

between DC and half the sampling frequency. THD is

expressed as:

If two pure sine waves of frequencies fa and fb are applied

to the ADC input, nonlinearities in the ADC transfer function can create distortion products at the sum and difference frequencies of mfa ± nfb, where m and n = 0, 1, 2, 3,

etc. The 3rd order intermodulation products are 2fa + fb,

2fb + fa, 2fa – fb and 2fb – fa. The intermodulation

distortion is defined as the ratio of the RMS value of either

input tone to the RMS value of the largest 3rd order

intermodulation product.

Spurious Free Dynamic Range (SFDR)

Spurious free dynamic range is the peak harmonic or

spurious noise that is the largest spectral component

excluding the input signal and DC. This value is expressed

in decibels relative to the RMS value of a full scale input

signal.

Input Bandwidth

The input bandwidth is that input frequency at which the

amplitude of the reconstructed fundamental is reduced by

3dB for a full scale input signal.

Aperture Delay Time

222 2

VVV Vn

+++

THD Log

=

20

where V1 is the RMS amplitude of the fundamental frequency and V2 through Vn are the amplitudes of the

second through nth harmonics. The THD calculated in this

data sheet uses all the harmonics up to the fifth.

Intermodulation Distortion

If the ADC input signal consists of more than one spectral

component, the ADC transfer function nonlinearity can

produce intermodulation distortion (IMD) in addition to

THD. IMD is the change in one sinusoidal input caused by

the presence of another sinusoidal input at a different

frequency.

234

V

1

...

The time from when a rising ENC equals the ENC voltage

to the instant that the input signal is held by the sample and

hold circuit.

Aperture Delay Jitter

The variation in the aperture delay time from conversion to

conversion. This random variation will result in noise

when sampling an AC input. The signal to noise ratio due

to the jitter alone will be:

SNR

= –20log (2π) • FIN • T

JITTER

JITTER

10

1745i

WUUU

APPLICATIO S I FOR ATIO

LTC1745

CONVERTER OPERATION

As shown in Figure 1, the LTC1745 is a CMOS pipelined

multistep converter. The converter has four pipelined ADC

stages; a sampled analog input will result in a digitized

value five cycles later, see the Timing Diagram section.

The analog input is differential for improved common

mode noise immunity and to maximize the input range.

Additionally, the differential input drive will reduce even

order harmonics of the sample-and-hold circuit. The encode input is also differential for improved common mode

noise immunity.

The LTC1745 has two phases of operation, determined by

the state of the differential ENC/ENC input pins. For

+

A

IN

INPUT

S/H

–

A

IN

FIRST STAGE

5-BIT

PIPELINED

ADC STAGE

SECOND STAGE THIRD STAGE FOURTH STAGE

4-BIT

PIPELINED

ADC STAGE

brevity, the text will refer to ENC greater than ENC as ENC

high and ENC less than ENC as ENC low.

Each pipelined stage shown in Figure 1 contains an ADC,

a reconstruction DAC and an interstage residue amplifier.

In operation, the ADC quantizes the input to the stage and

the quantized value is subtracted from the input by the

DAC to produce a residue. The residue is amplified and

output by the residue amplifier. Successive stages operate

out of phase so that when the odd stages are outputting

their residue, the even stages are acquiring that residue

and visa versa.

4-BIT

PIPELINED

ADC STAGE

4-BIT

FLASH

ADC

V

4.7µF

SENSE

CM

2.35V

REFERENCE

RANGE

SELECT

REF

BUF

INTERNAL

REFERENCES TO ADC

DIFF

REF

AMP

REFHAREFLB

0.1µF 0.1µF

1µF1µF

REFLA REFHB

4.7µF

INTERNAL

CLOCK SIGNALS

DIFFERENTIAL

INPUT

LOW JITTER

CLOCK

DRIVER

ENC ENC

CONTROL

MSBINV

LOGIC

SHIFT REGISTER AND CORRECTION

OUTPUT

DRIVERS

OE

OGND

OV

DD

0.5V TO

5V

OF

D11

•

•

•

D0

CLKOUT

1745 F01

Figure 1. Functional Block Diagram

1745i

11

LTC1745

WUUU

APPLICATIO S I FOR ATIO

When ENC is low, the analog input is sampled differentially

directly onto the input sample-and-hold capacitors, inside

the “Input S/H” shown in the block diagram. At the instant

that ENC transitions from low to high, the sampled input

is held. While ENC is high, the held input voltage is

buffered by the S/H amplifier which drives the first pipelined

ADC stage. The first stage acquires the output of the S/H

during this high phase of ENC. When ENC goes back low,

the first stage produces its residue which is acquired by

the second stage. At the same time, the input S/H goes

back to acquiring the analog input. When ENC goes back

high, the second stage produces its residue which is

acquired by the third stage. An identical process is repeated for the third stage, resulting in a third stage residue

that is sent to the fourth stage ADC for final evaluation.

Each ADC stage following the first has additional range to

accommodate flash and amplifier offset errors. Results

from all of the ADC stages are digitally delayed such that

the results can be properly combined in the correction

logic before being sent to the output buffer.

acquire a new sample. Since the sampling capacitors still

hold the previous sample, a charging glitch proportional to

the change in voltage between samples will be seen at this

time. If the change between the last sample and the new

sample is small the charging glitch seen at the input will be

small. If the input change is large, such as the change seen

with input frequencies near Nyquist, then a larger charging

glitch will be seen.

Common Mode Bias

The ADC sample-and-hold circuit requires differential drive

to achieve specified performance. Each input should swing

±0.8V for the 3.2V range or ±0.5V for the 2V range, around

a common mode voltage of 2.35V. The VCM output pin

(Pin␣ 2) may be used to provide the common mode bias

level. VCM can be tied directly to the center tap of a transformer to set the DC input level or as a reference level to

an op amp differential driver circuit. The VCM pin must be

bypassed to ground close to the ADC with 4.7µF or greater

capacitor.

SAMPLE/HOLD OPERATION AND INPUT DRIVE

Sample Hold Operation

Figure 2 shows an equivalent circuit for the LTC1745

CMOS differential sample-and-hold. The differential analog inputs are sampled directly onto sampling capacitors

(C

SAMPLE

) through CMOS transmission gates. This direct

capacitor sampling results in lowest possible noise for a

given sampling capacitor size. The capacitors shown

attached to each input (C

PARASITIC

) are the summation of

all other capacitance associated with each input.

During the sample phase when ENC/ENC is low, the

transmission gate connects the analog inputs to the sampling capacitors and they charge to, and track the differential input voltage. When ENC/ENC transitions from low to

high the sampled input voltage is held on the sampling

capacitors. During the hold phase when ENC/ENC is high

the sampling capacitors are disconnected from the input

and the held voltage is passed to the ADC core for

processing. As ENC/ENC transitions from high to low the

inputs are reconnected to the sampling capacitors to

A

IN

A

IN

ENC

ENC

LTC1745

V

DD

+

C

PARASITIC

4pF

V

DD

–

C

PARASITIC

4pF

5V

BIAS

2V

6k

6k

2V

Figure 2. Equivalent Input Circuit

C

SAMPLE

4pF

C

SAMPLE

4pF

1745 F02

12

1745i

WUUU

APPLICATIO S I FOR ATIO

LTC1745

Input Drive Impedance

As with all high performance, high speed ADCs the dynamic performance of the LTC1745 can be influenced by

the input drive circuitry, particularly the second and third

harmonics. Source impedance and input reactance can

influence SFDR. At the falling edge of encode the sampleand-hold circuit will connect the 4pF sampling capacitor to

the input pin and start the sampling period. The sampling

period ends when encode rises, holding the sampled input

on the sampling capacitor. Ideally the input circuitry

should be fast enough to fully charge the sampling capacitor during the sampling period 1/(2F

ENCODE

); however,

this is not always possible and the incomplete settling may

degrade the SFDR. The sampling glitch has been designed

to be as linear as possible to minimize the effects of

incomplete settling.

For the best performance, it is recomended to have a

source impedence of 100Ω or less for each input. The S/H

circuit is optimized for a 50Ω source impedance. If the

source impedance is less than 50Ω, a series resistor

should be added to increase this impedance to 50Ω. The

source impedence should be matched for the differential

inputs. Poor matching will result in higher even order

harmonics, especially the second.

Input Drive Circuits

Figure 3 shows the LTC1745 being driven by an RF

transformer with a center tapped secondary. The secondary center tap is DC biased with VCM, setting the ADC input

signal at its optimum DC level. Figure 3 shows a 1:1 turns

ratio transformer. Other turns ratios can be used if the

source impedence seen by the ADC does not exceed

100Ω for each ADC input. A disadvantage of using a

transformer is the loss of low frequency response. Most

small RF transformers have poor performance at frequencies below 1MHz.

Figure 4 demonstrates the use of operational amplifiers to

convert a single ended input signal into a differential input

signal. The advantage of this method is that it provides low

frequency input response; however, the limited gain bandwidth of most op amps will limit the SFDR at high input

frequencies.

The 25Ω resistors and 12pF capacitors on the analog

inputs serve two purposes: isolating the drive circuitry

from the sample-and-hold charging glitches and limiting

the wideband noise at the converter input. For input

frequencies higher than 50MHz, the capacitors may need

to be decreased to prevent excessive signal loss.

ANALOG

INPUT

4.7µF

0.1µF

1:1

100Ω 100Ω 12pF

25Ω

25Ω

12pF

25Ω

25Ω

12pF

Figure 3. Single-Ended to Differential

Conversion Using a Transformer

V

CM

25Ω

12pF

4.7µF

12pF

12pF

+

A

IN

LTC1745

–

A

IN

1745 F04

5V

SINGLE-ENDED

V

CM

INPUT

2.35V ±1/2

RANGE

+

1/2 LT1810

25Ω

–

LTC1745

+

A

IN

–

A

IN

100Ω

+

1/2 LT1810

25Ω 25Ω

–

1745 F03

500Ω 500Ω

Figure 4. Differential Drive with Op Amps

1745i

13

LTC1745

V

CM

SENSE

2.35V

1.1V

4.7µF

12.5k

1µF

11k

1745 F06a

LTC1745

WUUU

APPLICATIO S I FOR ATIO

Reference Operation

Figure 5 shows the LTC1745 reference circuitry consisting

of a 2.35V bandgap reference, a difference amplifier and

switching and control circuit. The internal voltage reference can be configured for two pin selectable input ranges

of 2V(±1V differential) or 3.2V(±1.6V differential). Tying

the SENSE pin to ground selects the 2V range; tying the

SENSE pin to VDD selects the 3.2V range.

The 2.35V bandgap reference serves two functions: its

output provides a DC bias point for setting the common

mode voltage of any external input circuitry; additionally,

the reference is used with a difference amplifier to generate the differential reference levels needed by the internal

ADC circuitry.

An external bypass capacitor is required for the 2.35V

reference output, VCM. This provides a high frequency low

impedance path to ground for internal and external circuitry. This is also the compensation capacitor for the

reference. It will not be stable without this capacitor.

The difference amplifier generates the high and low reference for the ADC. High speed switching circuits are

connected to these outputs and they must be externally

bypassed. Each output has two pins: REFHA and REFHB

for the high reference and REFLA and REFLB for the low

reference. The doubled output pins are needed to reduce

package inductance. Bypass capacitors must be connected as shown in Figure 5.

Other voltage ranges in between the pin selectable ranges

can be programmed with two external resistors as shown

in Figure 6a. An external reference can be used by applying

its output directly or through a resistor divider to SENSE.

It is not recommended to drive the SENSE pin with a logic

device since the logic threshold is close to ground and

VDD. The SENSE pin should be tied high or low as close to

the converter as possible. If the SENSE pin is driven

externally, it should be bypassed to ground as close to the

device as possible with a 1µF ceramic capacitor.

FOR 3.2V RANGE;

TIE TO V

DD

TIE TO GND FOR 2V RANGE;

RANGE = 2 • V

1V < V

SENSE

SENSE

Figure 5. Equivalent Reference Circuit

14

2.35V

FOR

< 1.6V

1µF

1µF

0.1µF

4.7µF

4.7µF

SENSE

REFLB

REFHA

REFLA

0.1µF

REFHB

LTC1745

4Ω

V

CM

RANGE

DETECT

AND

CONTROL

2.35V BANDGAP

REFERENCE

1.6V

INTERNAL ADC

HIGH REFERENCE

DIFF AMP

INTERNAL ADC

LOW REFERENCE

1V

BUFFER

1745 F05

Figure 6a. 2.2V Range ADC

V

4.7µF

SENSE

1µF0.1µF

CM

LTC1745

1745 F06b

2.35V

5V

LT1790-1.25

1.25V64

1, 2

Figure 6b. 2.5V Range ADC with an External Reference

1745i

WUUU

APPLICATIO S I FOR ATIO

LTC1745

Input Range

The input range can be set based on the application. For

oversampled signal processing in which the input frequency is low (<10MHz), the largest input range will

provide the best signal-to-noise performance while maintaining excellent SFDR. For high input frequencies

(>10MHz), the 2V range will have the best SFDR performance but the SNR will degrade by 1.5dB. See the Typical

Performance Characteristics section.

LTC1745

2V BIAS

V

DD

CLOCK

INPUT

ANALOG INPUT

0.1µF

1:4

50Ω

ENC

ENC

2V BIAS

V

DD

Driving the Encode Inputs

The noise performance of the LTC1745 can depend on the

encode signal quality as much as on the analog input. The

ENC/ENC inputs are intended to be driven differentially,

primarily for noise immunity from common mode noise

sources. Each input is biased through a 6k resistor to a 2V

bias. The bias resistors set the DC operating point for

transformer coupled drive circuits and can set the logic

threshold for single-ended drive circuits.

5V

BIAS

TO INTERNAL

ADC CIRCUITS

6k

6k

Figure 7. Transformer Driven ENC/ENC with Equivalent Encode Input Circuit

V

THRESHOLD

= 2V

0.1µF

ENC

ENC2V

LTC1745

Figure 8a. Single-Ended ENC Drive,

Not Recommended for Low Jitter

1745 F08a

1745 F07

3.3V

MC100LVELT22

3.3V

130Ω

Q0

D0

Q0

130Ω

83Ω83Ω

ENC

ENC

LTC1745

1745 F08b

Figure 8b. ENC Drive Using a CMOS-to-PECL Translator

1745i

15

LTC1745

WUUU

APPLICATIO S I FOR ATIO

Any noise present on the encode signal will result in

additional aperture jitter that will be RMS summed with the

inherent ADC aperture jitter.

In applications where jitter is critical (high input frequencies) take the following into consideration:

1. Differential drive should be used.

2. Use as large an amplitude as possible; if transformer

coupled use a higher turns ratio to increase the

amplitude.

3. If the ADC is clocked with a sinusoidal signal, filter the

encode signal to reduce wideband noise.

4. Balance the capacitance and series resistance at both

encode inputs so that any coupled noise will appear at

both inputs as common mode noise.

The encode inputs have a common mode range of 1.8V to

VDD. Each input may be driven from ground to VDD for

single-ended drive.

Maximum and Minimum Encode Rates

The maximum encode rate for the LTC1745 is 25Msps. For

the ADC to operate properly the encode signal should have

a 50% (±5%) duty cycle. Each half cycle must have at least

19ns for the ADC internal circuitry to have enough settling

time for proper operation. Achieving a precise 50% duty

cycle is easy with differential sinusoidal drive using a

transformer or using symmetric differential logic such as

PECL or LVDS. When using a single-ended encode signal

asymmetric rise and fall times can result in duty cycles that

are far from 50%.

At sample rates slower than 25Msps the duty cycle can

vary from 50% as long as each half cycle is at least 19ns.

The lower limit of the LTC1745 sample rate is determined

by the droop of the sample-and-hold circuits. The pipelined

architecture of this ADC relies on storing analog signals

on small valued capacitors. Junction leakage will discharge the capacitors. The specified minimum operating

frequency for the LTC1745 is 1Msps.

DIGITAL OUTPUTS

Digital Output Buffers

Figure 9 shows an equivalent circuit for a single output

buffer. Each buffer is powered by OVDD and OGND, isolated from the ADC power and ground. The additional

N-channel transistor in the output driver allows operation

down to low voltages. The internal resistor in series with

the output makes the output appear as 50Ω to external

circuitry and may eliminate the need for external damping

resistors.

16

DATA

FROM

LATCH

OE

LTC1745

V

DD

PREDRIVER

LOGIC

Figure 9. Equivalent Circuit for a Digital Output Buffer

V

DD

OV

DD

43Ω

1745 F09

OV

DD

OGND

0.5V TO

V

DD

0.1µF

TYPICAL

DATA

OUTPUT

1745i

WUUU

APPLICATIO S I FOR ATIO

LTC1745

Output Loading

As with all high speed/high resolution converters the

digital output loading can affect the performance. The

digital outputs of the LTC1745 should drive a minimal

capacitive load to avoid possible interaction between the

digital outputs and sensitive input circuitry. The output

should be buffered with a device such as an ALVCH16373

CMOS latch. For full speed operation the capacitive load

should be kept under 10pF. A resistor in series with the

output may be used but is not required since the ADC has

a series resistor of 43Ω on chip.

Lower OVDD voltages will also help reduce interference

from the digital outputs.

Format

The LTC1745 parallel digital output can be selected for

offset binary or 2’s complement format. The format is

selected with the MSBINV pin; high selects offset binary.

Overflow Bit

An overflow output bit indicates when the converter is

overranged or underranged. When OF outputs a logic high

the converter is either overranged or underranged.

Output Clock

The ADC has a delayed version of the ENC input available

as a digital output, CLKOUT. The CLKOUT pin can be used

to synchronize the converter data to the digital system.

This is necessary when using a sinusoidal encode. Data

will be updated just after CLKOUT falls and can be latched

on the rising edge of CLKOUT.

Output Driver Power

Separate output power and ground pins allow the output

drivers to be isolated from the analog circuitry. The power

supply for the digital output buffers, OVDD, should be tied

to the same power supply as for the logic being driven. For

example if the converter is driving a DSP powered by a 3V

supply then OVDD should be tied to that same 3V supply.

OVDD can be powered with any voltage up to 5V. The logic

outputs will swing between OGND and OVDD.

Output Enable

The outputs may be disabled with the output enable pin,

OE. OE low disables all data outputs including OF and

CLKOUT. The data access and bus relinquish times are too

slow to allow the outputs to be enabled and disabled

during full speed operation. The output Hi-Z state is

intended for use during long periods of inactivity.

GROUNDING AND BYPASSING

The LTC1745 requires a printed circuit board with a clean

unbroken ground plane. A multilayer board with an internal ground plane is recommended. The pinout of the

LTC1745 has been optimized for a flowthrough layout so

that the interaction between inputs and digital outputs is

minimized. Layout for the printed circuit board should

ensure that digital and analog signal lines are separated as

much as possible. In particular, care should be taken not

to run any digital track alongside an analog signal track or

underneath the ADC.

1745i

17

LTC1745

WUUU

APPLICATIO S I FOR ATIO

High quality ceramic bypass capacitors should be used at

the V

DD, VCM

shown in the block diagram on the front page of this data

sheet. Bypass capacitors must be located as close to the

pins as possible. Of particular importance are the capacitors between REFHA and REFLB and between REFHB and

REFLA. These capacitors should be as close to the device

as possible (1.5mm or less). Size 0402 ceramic capacitors

are recomended. The large 4.7µF capacitor between REFHA

and REFLA can be somewhat further away. The traces

connecting the pins and bypass capacitors must be kept

short and should be made as wide as possible.

The LTC1745 differential inputs should run parallel and

close to each other. The input traces should be as short as

possible to minimize capacitance and to minimize noise

pickup.

, REFHA, REFHB, REFLA and REFLB pins as

An analog ground plane separate from the digital processing system ground should be used. All ADC ground pins

labeled GND should connect to this plane. All ADC V

bypass capacitors, reference bypass capacitors and input

filter capacitors should connect to this analog plane. The

LTC1745 has three output driver ground pins, labeled

OGND (Pins 27, 38 and 47). These grounds should connect to the digital processing system ground. The output

driver supply, OVDD should be connected to the digital

processing system supply. OVDD bypass capacitors should

bypass to the digital system ground. The digital processing system ground should be connected to the analog

plane at ADC OGND (Pin 38).

DD

18

1745i

PACKAGE DESCRIPTIO

0.95 ±0.10

U

FW Package

48-Lead Plastic TSSOP (6.1mm)

(Reference LTC DWG # 05-08-1651)

48 46 4544434241 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 2547

12.4 – 12.6*

(.488 – .496)

LTC1745

8.1 ±0.10

0.32 ±0.05 0.50 TYP

RECOMMENDED SOLDER PAD LAYOUT

6.0 – 6.2**

(.236 – .244)

0.09 – 0.20

(.0035 – .008)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*

DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED .152mm (.006") PER SIDE

**

DIMENSIONS DO NOT INCLUDE INTERLEAD FLASH. INTERLEAD FLASH SHALL NOT EXCEED .254mm (.010") PER SIDE

0.45 – 0.75

(.018 – .029)

MILLIMETERS

(INCHES)

6.2 ±0.10

° – 8°

0

1345678 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

2

-C-

0.50

(.0197)

BSC

0.17 – 0.27

(.0067 – .0106)

(.311 – .327)

1.20

(.0473)

MAX

0.05 – 0.15

(.002 – .006)

7.9 – 8.3

FW48 TSSOP 0502

-TC.10

1745i

19

LTC1745

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1019 Precision Bandgap Reference 0.05% Max Initial Accuracy, 5ppm/°C Max Drift

LTC1196 8-Bit, 1Msps Serial ADC 3V to 5V, SO-8

LTC1405 12-Bit, 5Msps, Sampling ADC 5V or ±5V Pin Compatible with the LTC1420

LTC1406 8-Bit, 20Msps ADC Undersampling Capability Up to 70MHz Input

LTC1410 12-Bit, 1.25Msps ADC ±5V, 71dB SINAD

LTC1411 14-Bit, 2.5Msps ADC 5V, No Pipeline Delay, 80dB SINAD

LTC1412 12-Bit, 3Msps, Sampling ADC ±5V, No Pipeline Delay, 72dB SINAD

LTC1414 14-Bit, 2.2Msps ADC ±5V, 81dB SINAD and 95dB SFDR

LTC1415 Single 5V, 12-Bit, 1.25Msps 55mW Power Dissipation, 72dB SINAD

LTC1419 14-Bit, 800ksps ADC ±5V, 95dB SFDR

LTC1420 12-Bit, 10Msps ADC 71dB SINAD and 83dB SFDR at Nyquist

LT1460 Micropower Precision Series Reference 0.075% Accuracy, 10ppm/°C Drift

LTC1604/LTC1608 16-Bit, 333ksps/500ksps ADCs 16-Bit, No Missing Codes, 90dB SINAD, –100dB THD

LTC1668 16-Bit, 50Msps DAC 87dB SFDR at 1MHz f

LTC1740 14-Bit, 6Msps ADC Low Power, 79dB SINAD, 91dB SFDR

LTC1743 12-Bit, 50Msps ADC 72.5dB SNR, 87dB SFDR, Pin Compatible with LTC1744, LTC1745, LTC1746

LTC1744 14-Bit, 50Msps ADC 77dB SNR, Undersampling to 70MHz, Pin Compatible with LTC1743, LTC1745, LTC1746

LTC1746 14-Bit, 25Msps ADC Low Power, 77.5dB SNR, 99dB SFDR Pin Compatible with Family

, Low Power, Low Cost

OUT

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

1745i

LT/TP 0103 1.5K • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPORATION 2003

Loading...

Loading...