Lithium-Ion Battery Charger with

FEATURES

■

Complete Linear Charger for 1-Cell Lithium-Ion

Batteries

■

Thermal Regulation Maximizes Charging Rate

without Risk of Overheating*

■

No External MOSFET, Sense Resistor or Blocking

Diode Required

■

Up to 1.5A Charge Current

■

Preset Charge Voltage with 1% Accuracy

■

Programmable Charge Current with 7% Accuracy

■

Programmable Charge Termination Timer

■

Tiny Thermally Enhanced 10-Pin MSOP Package

■

Charge Current Monitor Useful for Gas Gauging*

■

C/10 Charge Current Detection Output

■

Automatic Recharge

■

Thermistor Input for Temperature Qualified Charging

■

AC Present Logic Output

■

4.1V/4.2V Pin Selectable Output Voltage

U

APPLICATIO S

LTC1733

Monolithic Linear

Thermal Regulation

U

DESCRIPTIO

The LTC®1733 is a standalone constant-current/

constant-voltage linear charger for lithium-ion batteries

with an on-chip power MOSFET. Internal thermal feedback

regulates the charge current to limit die temperature

during high power operation or high ambient temperature

conditions. This feature allows the user to program a high

charge current without risk of damaging the LTC1733 or

the handheld product.

No external current sense resistor is needed and no

blocking diode is required due to the internal MOSFET

architecture. The charge current and charge time can be

set externally with a single resistor and capacitor, respectively. When the input supply (wall adapter) is removed,

the LTC1733 automatically enters a low current sleep

mode, dropping the battery drain current to less than 5µA.

The LTC1733 also includes NTC temperature sensing,

C/10 detection circuitry, AC present logic, 4.1V/4.2V pin

selectability and low battery charge conditioning (trickle

charging).

■

Cellular Telephones

■

Handheld Computers

■

Digital Still Cameras

■

Charging Docks and Cradles

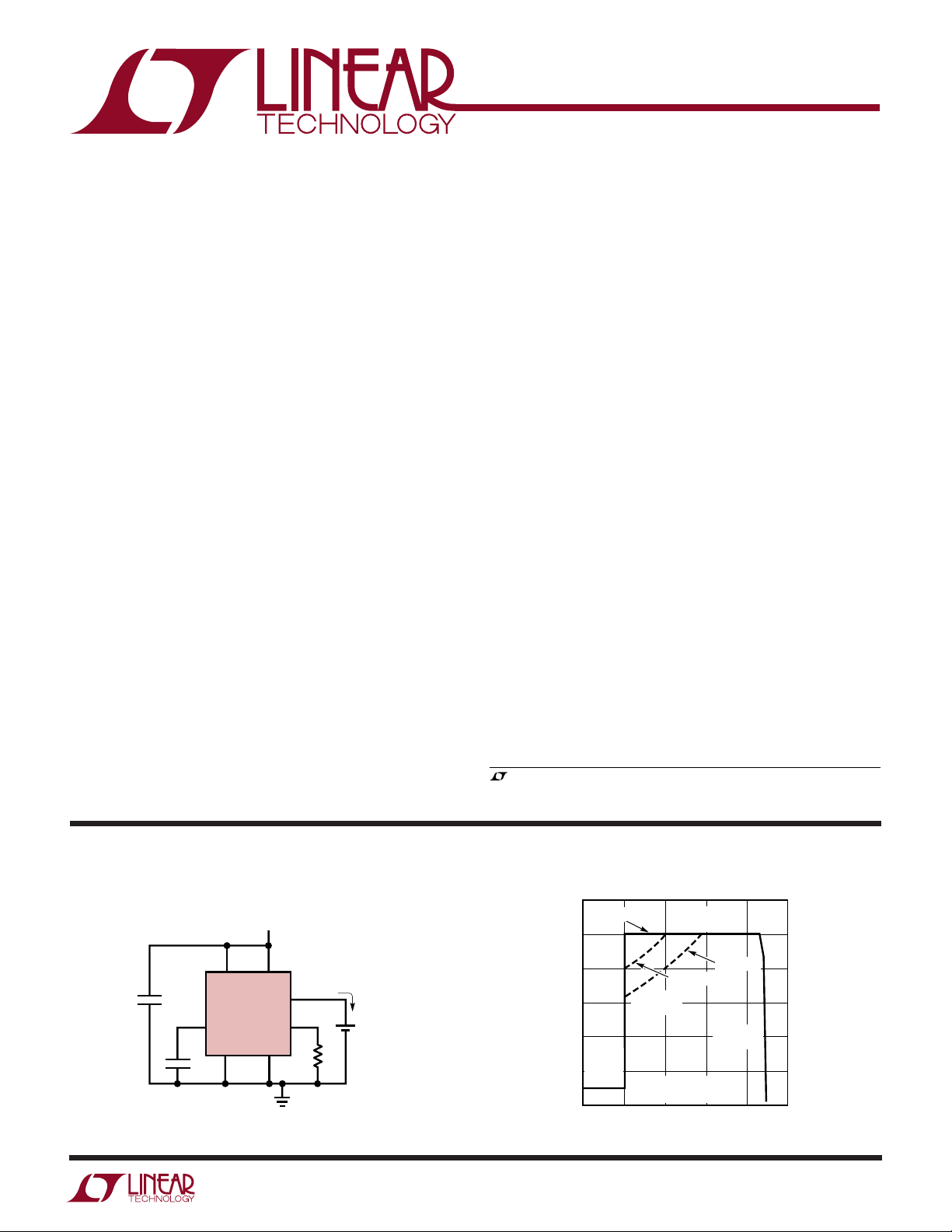

TYPICAL APPLICATIO

Standalone Li-Ion Battery Charger

V

= 5V

IN

28

V

SEL

4.7µF

4

TIMER

GND

0.1µF

*AN OUTPUT CAPACITOR MAY BE REQUIRED

DEPENDING ON BATTERY LEAD LENGTH

LTC1733

5

CC

BAT

PROG

NTC

6

The LTC1733 is available in a 10-pin thermally enhanced

MSOP package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

*Patent Pending

U

Charge Current vs Battery Voltage

1200

1000

I

= 1A

BAT

9

1.5k

1%

1733TA01

4.2V

1-CELL

Li-Ion

BATTERY*

CHARGE CURRENT (mA)

7

800

600

400

200

TA = 0°C

TA = 25°C

CONSTANT

POWER

TRICKLE

0

2

CHARGE

VIN = 5V

= 40°C/W

θ

JA

2.5 3 4 4.5

BATTERY VOLTAGE (V)

CONSTANT

CURRENT

TA = 40°C

CONSTANT

VOLTAGE

3.5

1733 TA01b

sn1733 1733fs

1

LTC1733

WW

W

ABSOLUTE AXI U RATI GS

U

UUW

PACKAGE/ORDER I FOR ATIO

(Note 1)

Input Supply Voltage (VCC) ........................................ 7V

BAT............................................................................ 7V

NTC, SEL, TIMER, PROG ................ –0.3V to VCC + 0.3V

CHRG, FAULT, ACPR ...................................–0.3V to 7V

BAT Short-Circuit Duration ...........................Continuous

BAT Current (Note 2) .............................................. 1.6A

PROG Current (Note 2) ........................................ 1.6mA

Junction Temperature........................................... 125°C

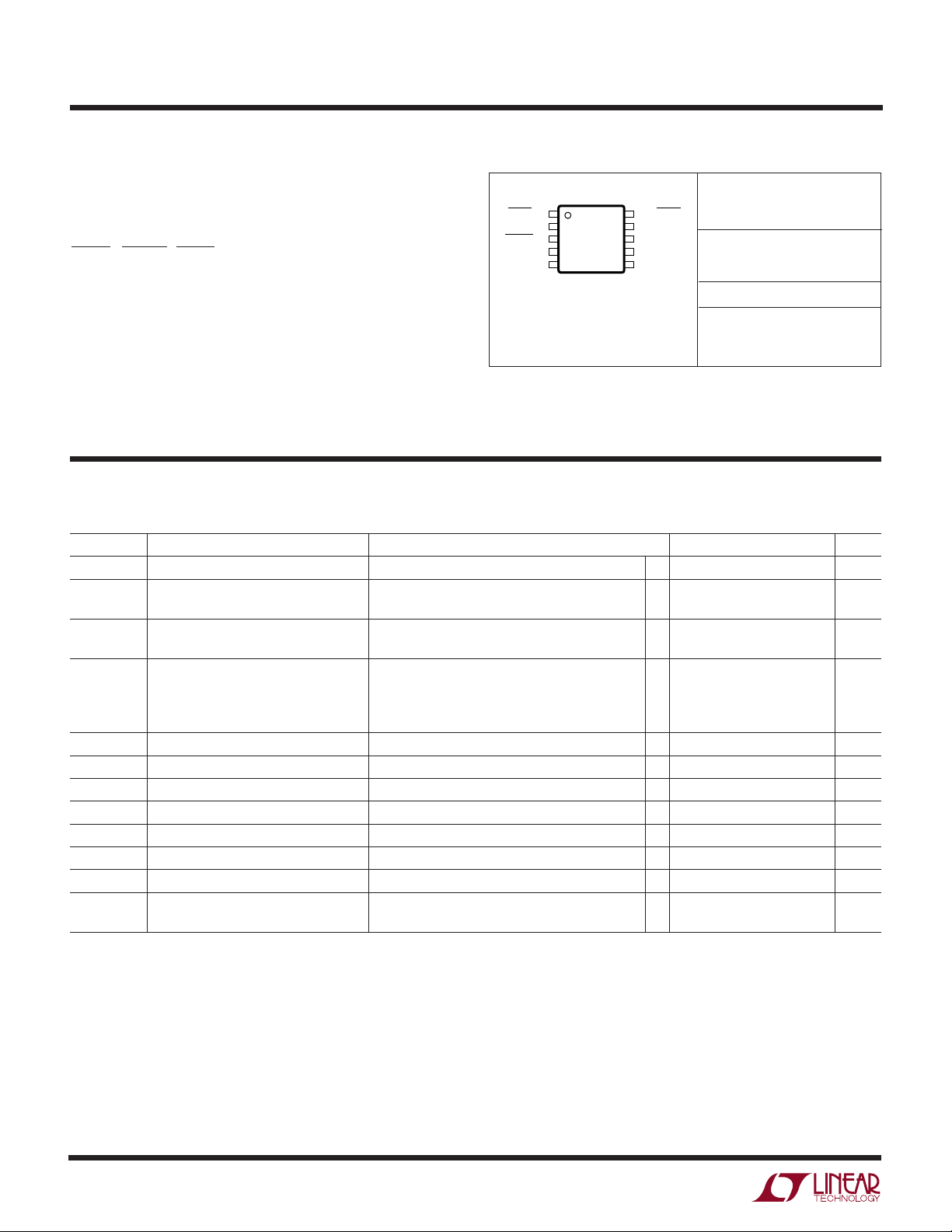

TOP VIEW

1

CHRG

2

V

CC

FAULT

3

TIMER

4

GND

5

MSE EXPOSED PAD PACKAGE

10-LEAD PLASTIC MSOP

T

= 125°C, θJA = 40°C/W (Note 4)

JMAX

EXPOSED PAD IS GROUND.

(MUST BE SOLDERED TO PCB

FOR MAXIMUM HEAT TRANSFER).

10

ACPR

9

BAT

8

SEL

7

PROG

6

NTC

ORDER PART

NUMBER

LTC1733EMSE

MSE PART MARKING

LTLX

Operating Temperature Range (Note 3) ...–40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

Lead Temperature (Soldering, 10 sec).................. 300°C

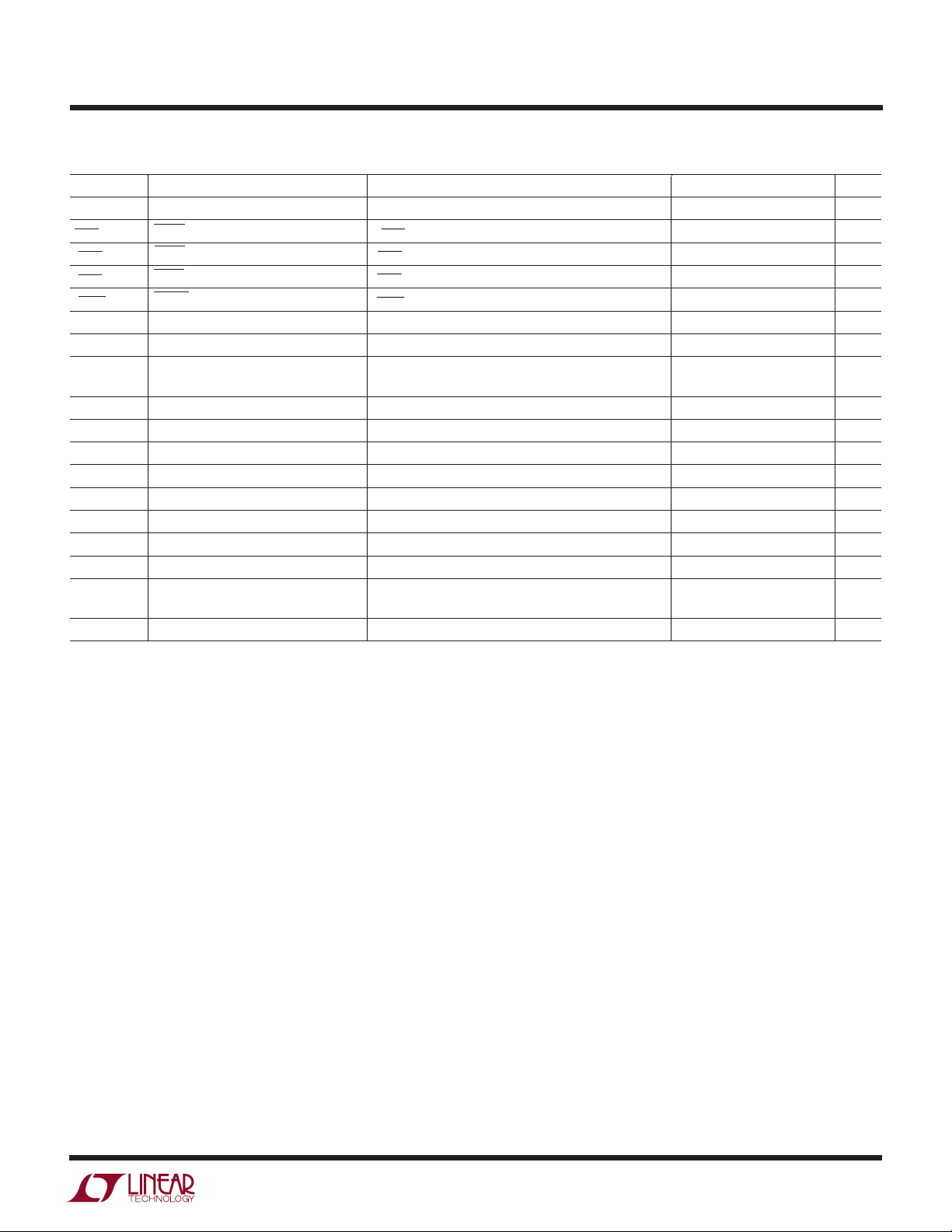

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

V

BAT

I

BAT

I

TRIKL

V

TRIKL

∆V

TRIKL

V

UV

∆V

UV

V

MSD

V

MSD-HYS

V

ASD

VCC Supply Voltage ● 4.5 6.5 V

VCC Supply Current Charger On; Current Mode; R

Shutdown Mode; V

V

Regulated Output Voltage SEL = 0V ● 4.059 4.1 4.141 V

BAT

Battery Pin Current R

Trickle Charge Current V

Trickle Charge Trip Threshold V

Trickle Charge Trip Hysteresis 100 mV

VCC Undervoltage Lockout Voltage VCC Rising ● 4.2 4.5 V

VCC Undervoltage Lockout Hysteresis 150 mV

Manual Shutdown Threshold Voltage PROG Pin Voltage Rising 2.15 V

Manual Shutdown Hysteresis Voltage 100 mV

Automatic Shutdown Threshold Voltage (VCC - V

SEL = V

R

Shutdown Mode; V

Sleep Mode V

(V

The ● denotes the specifications which apply over the full operating

= 30k (Note 5) ● 13 mA

PROG

= 3V ● 0.9 2 mA

PROG

CC

= 3k; Current Mode ● 465 500 535 mA

PROG

= 1k; Current Mode 1.395 1.5 1.605 A

PROG

CC

< 2V; R

BAT

BAT

CC

PROG

Rising 2.48 V

) Voltage Falling 30 mV

BAT

- V

) Voltage Rising 60 mV

BAT

= 3V ±1 ±5 µA

PROG

< V

or VCC < (VUV – ∆VUV) ±1 ±5 µA

BAT

= 3k ● 35 50 65 mA

● 4.158 4.2 4.242 V

2

sn1733 1733fs

LTC1733

ELECTRICAL CHARACTERISTICS

TA = 25°C. VCC = 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

PROG

I

CHRG

V

CHRG

V

ACPR

V

FAULT

I

C/10

t

TIMER

V

RECHRG

PROG Pin Voltage R

CHRG Pin Weak Pulldown Current V

CHRG Pin Output Low Voltage I

ACPR Pin Output Low Voltage I

FAULT Pin Output Low Voltage I

End of Charge Indication Current Level R

TIMER Accuracy C

= 3k, I

PROG

= 1V 25 µA

CHRG

= 5mA 0.35 V

CHRG

= 5mA 0.35 V

ACPR

= 5mA 0.35 V

FAULT

= 3k 35 50 65 mA

PROG

= 0.1µF ±10 %

TIMER

= 500µA; Current Mode 1.5 V

PROG

Recharge Battery Voltage Threshold Battery Voltage Falling, SEL = 0V 3.9 V

Battery Voltage Falling, SEL = 5V 4.0 V

V

NTC-HOT

V

HOT-HYS

V

NTC-COLD

V

COLD-HYS

V

NTC-DIS

V

DIS-HYS

V

SEL-IL

V

SEL-IH

T

LIM

NTC Pin Hot Threshold Voltage V

Falling 2.5 V

NTC

NTC Pin Hot Hysteresis Voltage 70 mV

NTC Pin Cold Threshold Voltage V

Rising 4.375 V

NTC

NTC Pin Cold Hystersis Voltage 70 mV

NTC Pin Disable Threshold Voltage V

Rising 100 mV

NTC

NTC Pin Disable Hystersis Voltage 10 mV

SEL Pin Threshold Input Low 0.3 V

SEL Pin Threshold Input High 1V

Junction Temperature in 105 °C

Constant-Temperature Mode

R

ON

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The Absolute Maximum BAT Current Rating of 1.6A is guaranteed

by design and current density calculations. The Absolute Maximum PROG

Current Rating is guaranteed to be 1/1000 of BAT current rating by design.

Note 3: The LTC1733E is guaranteed to meet performance specifications

Power MOSFET “ON” Resistance 375 mΩ

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 4: Failure to solder the exposed backside of the package to the PC

board will result in a thermal resistance much higher than 40°C/W.

Note 5: Supply current includes PROG pin current but does not include

any current delivered to the battery through the BAT pin.

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

sn1733 1733fs

3

LTC1733

VCC (V)

4.24

4.22

4.20

4.18

4.16

4.14

4.12

4.10

4.08

4.06

V

BAT

(V)

1733 G03

4.0 4.5 5.0

5.5

6.0 6.5 7.0

V

SEL

= V

CC

V

SEL

= 0V

TA = 25°C

I

BAT

= 10mA

R

PROG

= 1.5k

UW

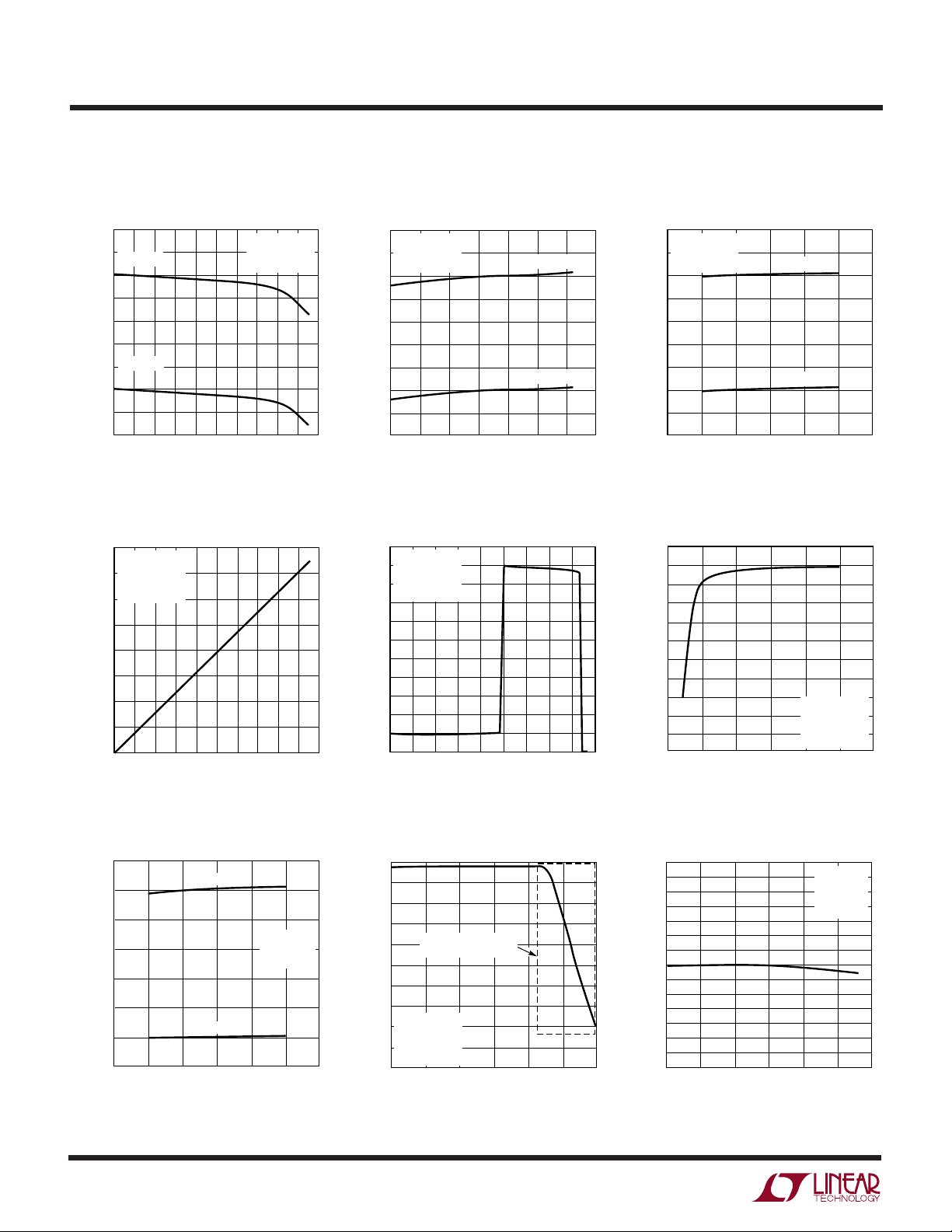

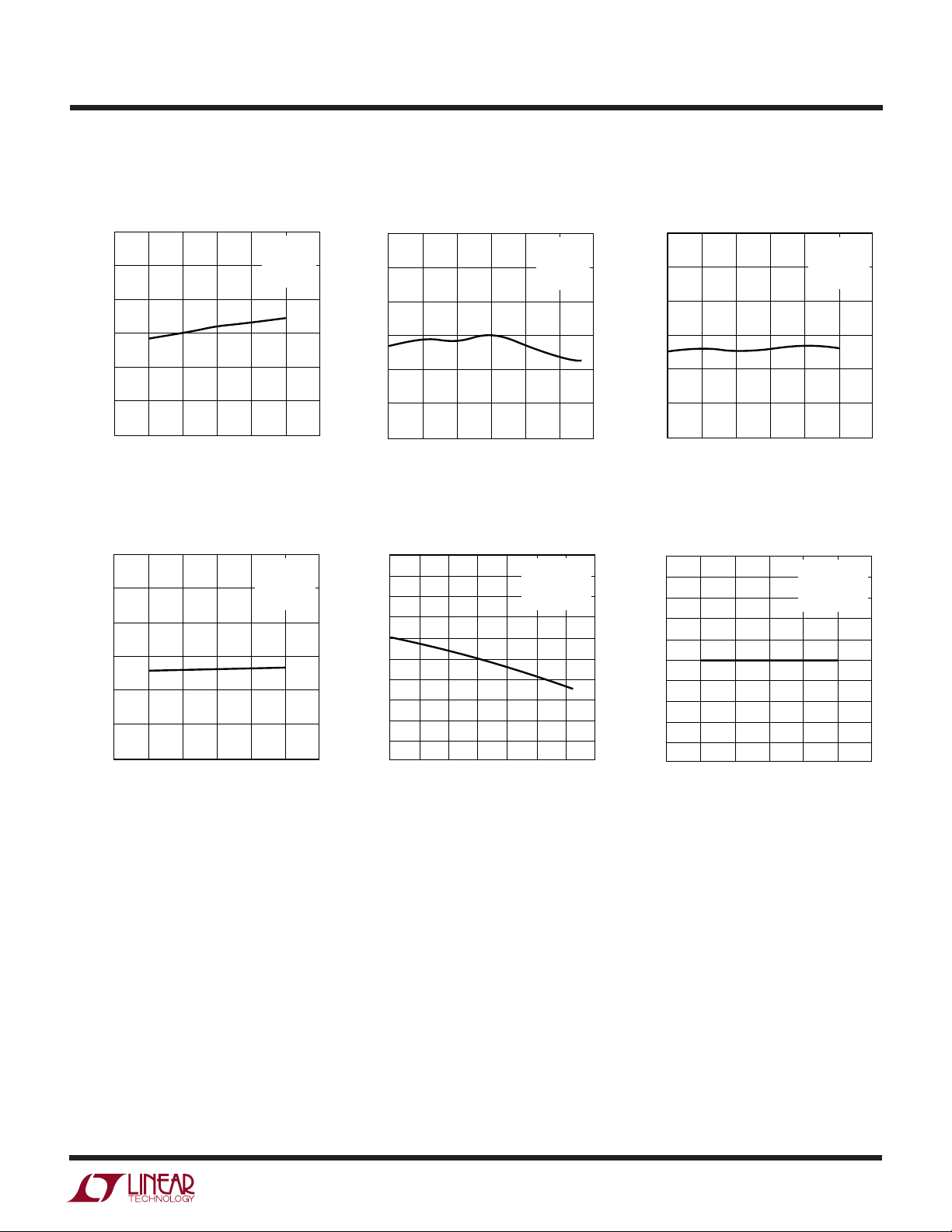

TYPICAL PERFOR A CE CHARACTERISTICS

Battery Regulation Voltage vs

Battery Charge Current

4.24

4.22

V

= 5V

SEL

4.20

4.18

4.16

(V)

BAT

4.14

V

V

= 0V

SEL

4.12

4.10

4.08

4.06

0 100 200 300

400

500

I

(mA)

BAT

PROG Pin Voltage vs Charge

Current

1.6

VCC = 5V

= 25°C

T

A

1.4

R

= 1.5k

PROG

V

= 5V

SEL

1.2

1.0

(V)

0.8

PROG

V

0.6

0.4

0.2

0

0 100 200 300

400

500

CHARGE CURRENT (mA)

VCC = 5V

= 25°C

T

A

= 1.5k

R

PROG

600 700 800 900 1000

1733 G01

600 700 800 900 1000

1733 G04

Battery Regulation Voltage vs

Temperature

4.24

VCC = 5V

= 10mA

I

4.22

BAT

= 1.5k

R

PROG

4.20

4.18

4.16

(V)

BAT

4.14

V

4.12

4.10

4.08

4.06

–50 –25 0

25

50 75 100 125

TEMPERATURE(°C)

Charge Current vs Battery Voltage

1100

VCC = 5V

1000

= 25°C

T

A

= 1.5k

R

PROG

900

800

700

600

(mA)

500

BAT

I

400

300

200

100

V

0

0

= 5V

SEL

0.5 1.5

1.0

2.5 4.5

BAT

3.0

(V)

2.0

V

Battery Regulation Voltage vs V

V

= 5V

SEL

V

= 0V

SEL

1733 G02

CC

Charge Current vs Input Voltage

1100

1000

900

800

700

600

(mA)

500

BAT

I

400

3.5

4.0

1733 G05

300

200

100

0

4.0

4.5 5.5

5.0

VCC (V)

6.0

V

T

R

V

BAT

A

PROG

SEL

= 4.1V

= 25°C

= 5V

= 1.5k

6.5

1733 G06

7.0

Charge Current vs V

1100

1000

900

800

(mA)

700

BAT

I

600

500

400

4.0

4

R

PROG

R

PROG

4.5 5.5

5.0

VCC (V)

CC

= 1.5k

= 3k

6.0

V

BAT

T

A

V

SEL

= 3.5V

= 25°C

= V

6.5

1733 G07

Charge Current vs Temperature

with Thermal Regulation

1000

900

800

700

600

CC

7.0

500

(mA)

BAT

I

400

300

200

100

0

–50

VCC = 5V

= 3.5V

V

BAT

R

PROG

= 5V

V

SEL

THERMAL CONTROL

LOOP IN OPERATION

= 1.5k

–25 25

0

TEMPERATURE (°C)

75

50

100

1733 G08

Charge Current vs Temperature

535

530

525

520

515

510

505

(mA)

500

BAT

495

I

490

485

480

475

470

465

–50 25 75

–25 0

TEMPERATURE (°C)

VCC = 5V

= 4V

V

BAT

R

= 3k

PROG

V

= 5V

SEL

50 100

1733 G09

sn1733 1733fs

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1733

PROG Pin Voltage vs V

Constant Current Mode

1.515

1.510

1.505

(V)

1.500

PROG

V

1.495

1.490

1.485

4.0 5.5 6.5

4.5 5.0

VCC (V)

Trickle Charge Current vs V

13

12

11

10

9

(% OF PROGRAMMED CURRENT)

8

BAT

I

7

4.0 5.5 6.5

4.5 5.0

VCC (V)

CC

TA = 25°C

= 3.5V

V

BAT

R

= 3k

PROG

= 5V

V

SEL

6.0 7.0

1733 G10

CC

TA = 25°C

= 2V

V

BAT

= 1.5k

R

PROG

= 5V

V

SEL

6.0 7.0

1733 G13

PROG Pin Voltage vs Temperature

Constant Current Mode

1.515

1.510

1.505

(V)

1.500

PROG

V

1.495

1.490

1.485

–50 25 75

–25 0

TEMPERATURE (°C)

50 100

Timer Accuracy vs Temperature

105

104

103

102

101

(%)

100

TIMER

t

99

98

97

96

95

–50 –25 0

25

TEMPERATURE(°C)

VCC = 5V

I

V

C

50 75 100 125

VCC = 5V

V

R

V

BAT

SEL

TIMER

BAT

PROG

= 5V

SEL

= 0mA

= 5V

= 0.1µF

= 4V

= 3k

1733 G11

1733 G14

Trickle Charge Current vs

Temperature

130

120

110

(mA)

100

BAT

I

90

80

70

–50 25 75

–25 0

TEMPERATURE (°C)

Timer Accuracy vs V

105

104

103

102

101

(%)

100

TIMER

t

99

98

97

96

95

4.0 5.5 6.5

4.5 5.0

V

(V)

CC

VCC = 5V

= 2V

V

BAT

= 1.5k

R

PROG

= 5V

V

SEL

50 100

1733 G12

CC

TA = 25°C

= 0mA

I

BAT

= 5V

V

SEL

= 0.1µF

C

TIMER

6.0 7.0

1733 G15

sn1733 1733fs

5

LTC1733

U

UU

PI FU CTIO S

CHRG: Open-Drain Charge Status Output. When the

battery is being charged, the CHRG pin is pulled low by an

internal N-channel MOSFET. When the charge current

drops to 10% of the full-scale current, the N-channel

MOSFET latches off and a 25µA current source is con-

nected from the CHRG pin to ground. The C/10 latch can

be cleared by momentarily pulling the PROG pin above the

2.15V shutdown threshold, or by toggling VCC. When the

timer runs out or the input supply is removed, the current

source is disconnected and the CHRG pin is forced to a

high impedance state.

VCC: Positive Input Supply Voltage. When VCC is within

30mV of V

threshold, the LTC1733 enters sleep mode, dropping I

to less than 5µA. VCC can range from 4.5V to 6.5V. Bypass

this pin with at least a 4.7µF ceramic capacitor to ground.

FAULT: Open-Drain Fault Status Output. The FAULT opendrain logic signal indicates that the charger has timed out

under trickle charge conditions (1/4 of total time period) or

the NTC comparator is indicating an out-of-range battery

temperature condition. When V

trickle charging activates whereby the charge current

drops to one tenth of its programmed value and the timer

period is reduced by a factor of four. When one fourth of

the timing period has elapsed, if V

2.48V, trickle charging stops and the FAULT pin latches to

ground. The fault can be cleared by toggling VCC, momentarily pulling the PROG pin above the 2.15V shutdown

threshold, or pulling the BAT pin above 2.48V. If the NTC

comparator is indicating an out-of-range battery temperature condition, then the FAULT pin will pull to ground until

the temperature returns to the acceptable range.

TIMER: Timer Capacitor. The timer period is set by placing

a capacitor, C

Time (Hours) = (C

Short the TIMER pin to ground to disable the internal timer

function.

or less than the undervoltage lockout

BAT

is less that 2.48V,

BAT

is still less than

BAT

, to ground. The timer period is:

TIMER

• 3 hr)/(0.1µF)

TIMER

BAT

GND: Ground. Connect exposed back package to ground.

NTC: Input to the NTC (Negative Temperature Coefficient)

Thermistor Temperature Monitoring Circuit. With an external 10kΩ NTC thermistor to ground and a 1% resistor

to VCC, this pin can sense the temperature of the battery

pack and stop charging when it is out of range. When the

voltage at this pin drops below (0.5)•(VCC) at hot temperatures or rises above (0.875)•(VCC) at cold, charging is

suspended and the internal timer is frozen. The CHRG pin

output status is not affected in this hold state. The FAULT

pin is pulled to ground, but not latched. When the temperature returns to an acceptable range, charging will resume

and the FAULT pin is released. The NTC feature can be

disabled by grounding the NTC pin.

PROG: Charge Current Program, Shutdown Input and

Charge Current Monitor Pin. The charge current is programmed by connecting a resistor, R

When in constant-current mode, the LTC1733 servos the

PROG pin voltage to 1.5V. In all modes the voltage on the

PROG pin can be used to measure the charge current as

follows:

I

= (V

CHG

The IC can be forced into shutdown by pulling the PROG

pin above the 2.15V shutdown threshold voltage (note: it

will not be pulled up when allowed to float).

SEL: 4.1V/4.2V Battery Selection Input. Grounding this

pin sets the battery float voltage to 4.1V, while connecting

to VCC sets the voltage to 4.2V.

BAT: Charge Current Output. A bypass capacitor of at least

1µF with a 1Ω series resistor is required to minimize ripple

voltage when the battery is not present. A precision

internal resistor divider sets the final float potential on this

pin. The internal resistor divider is disconnected in sleep

and shutdown modes.

ACPR: Open-Drain Power Supply Status Output. When

VCC is greater than the undervoltage lockout threshold

and at least 30mV above V

ground. Otherwise, the pin is forced to a high impedance

state.

PROG/RPROG

) • 1000.

, the ACPR pin will pull to

BAT

to ground.

PROG

6

sn1733 1733fs

SI PLIFIEDWBLOCK DIAGRA

W

LTC1733

V

CC

2

NTC

CHRG

ACPR

FAULT

105°C

T

DIE

6

1

10

3

–

+

HOT COLD DISABLE

STOP

C/10

25µA

ACPR

FAULT

TA

NTC

LOGIC

SHDN

D1

D2

M2

×1

D3

+

–

MA

30µA

MP

CA

+

–

2.485V

–

C1

C2

2.15V

+

1.5V

0.15V

+

REF

R4

R5

R6

R7

+

VA

–

M1

×1000

R1

R2

R3

2.5µA

BAT

9

8

SEL

–

CHARGE

COUNTER

OSCILLATOR

TIMER

C

TIMER

2.485V

475

C3

+

–

TO BAT

PROG

R

PROG

GND

1733 F01

Figure 1.

sn1733 1733fs

7

LTC1733

OPERATIO

U

The LTC1733 is a linear battery charger designed primarily

for charging single cell lithium-ion batteries. Featuring an

internal P-channel power MOSFET, the charger uses a

constant-current/constant-voltage charge algorithm with

programmable current and a programmable timer for

charge termination. Charge current can be programmed

up to 1.5A with a final float voltage accuracy of ±1%. No

blocking diode or sense resistor is required thus dropping

the external component count to three for the basic

charger circuit. The CHRG, ACPR, and FAULT open-drain

status outputs provide information regarding the status of

the LTC1733 at all times. An NTC thermistor input

provides the option of charge qualification using battery

temperature.

An internal thermal limit reduces the programmed charge

current if the die temperature attempts to rise above a

preset value of approximately 105°C. This feature protects

the LTC1733 from excessive temperature, and allows the

user to push the limits of the power handling capability of

a given circuit board without risk of damaging the LTC1733

or the external components. Another benefit of the LTC1733

thermal limit is that charge current can be set according to

typical, not worst-case, ambient temperatures for a given

application with the assurance that the charger will automatically reduce the current in worst-case conditions.

into the fast charge constant-current mode once the

voltage on the BAT pin rises above 2.48V. In constantcurrent mode, the charge current is set by R

When the battery approaches the final float voltage, the

charge current begins to decrease as the LTC1733 switches

to constant-voltage mode. When the current drops to 10%

of the full-scale charge current, an internal comparator

latches off the MOSFET at the CHRG pin and connects a

weak current source to ground to indicate a near end-ofcharge (C/10) condition. The C/10 latch can be cleared by

momentarily pulling the PROG pin above the 2.15V

shutdown threshold, or momentarily removing and reapplying VCC.

An external capacitor on the TIMER pin sets the total

charge time. When this time elapses the charge cycle

terminates and the CHRG pin assumes a high impedance

state. To restart the charge cycle, simply remove the input

voltage and reapply it, or force the PROG pin above the

2.15V shutdown threshold (note: simply floating the PROG

pin will not restart the charging cycle.

For lithium-ion and similar batteries that require accurate

final float potential, the internal reference, voltage amplifier and the resistor divider provide regulation with ±1%

(max) accuracy.

PROG

.

The charge cycle begins when the voltage at the V

rises above the UVLO level and a program resistor is

connected from the PROG pin to ground. At the beginning

of the charge cycle, if the battery voltage is below 2.48V,

the charger goes into trickle charge mode to bring the cell

voltage up to a safe level for charging. The charger goes

CC

pin

When the input voltage is not present, the charger goes

into a sleep mode, dropping battery drain current, I

less than 5µA. This greatly reduces the current drain on the

battery and increases the standby time. The charger can be

shut down (ICC = 0.9mA) by forcing the PROG pin above

2.15V.

, to

BAT

sn1733 1733fs

8

LTC1733

U

WUU

APPLICATIO S I FOR ATIO

Undervoltage Lockout (UVLO)

An internal undervoltage lockout circuit monitors the input

voltage and keeps the charger in shutdown mode until V

rises above the undervoltage lockout threshold. The UVLO

circuit has a built-in hysteresis of 150mV. Furthermore, to

protect against reverse current in the power MOSFET, the

UVLO circuit keeps the charger in shutdown mode if V

falls to within 30mV of the battery voltage. If the UVLO

comparator is tripped, the charger will not come out of

shutdown until VCC rises 60mV above the battery voltage.

Trickle Charge and Defective Battery Detection

At the beginning of a charge cycle, if the battery voltage is

low (below 2.48V) the charger goes into trickle charge

reducing the charge current to 10% of the full-scale

current. If the low battery voltage persists for one quarter

of the total charge time, the battery is assumed to be

defective, the charge cycle is terminated, the CHRG pin

output assumes a high impedance state, and the FAULT

pin latches low. The fault can be cleared by toggling VCC,

temporarily forcing the PROG pin above 2.15V, or temporarily forcing the BAT pin voltage above 2.48V.

Shutdown

The LTC1733 can be shutdown (ICC = 0.9mA) by pulling

the PROG pin above the 2.15V shutdown threshold voltage. In shutdown the internal linear regulator is turned off,

and the internal timer is reset.

CC

CC

recharge comparator is disabled and a new charge cycle

will not begin unless the input voltage is toggled, the PROG

pin is pulled above the 2.15V shutdown threshold, or the

BAT pin is pulled above the 2.48V trickle charge threshold.

Programming Charge Current

The formula for the battery charge current (see Figure 1)

is:

I

= (I

CHG

= (1.5V / R

R

= 1500/I

PROG

where R

ground. Under trickle charge conditions, this current is

reduced to 10% of the full-scale value.

For example, if 500mA charge current is required,

calculate:

For best stability over temperature and time, 1% metalfilm resistors are recommended.

If the charger is in constant-temperature or constantvoltage mode, the battery current can be monitored by

measuring the PROG pin voltage as follows:

Programming the Timer

PROG

R

= 1500/0.5A = 3kΩ

PROG

I

= (V

CHG

) • 1000

PROG

) • 1000 or

PROG

CHG

is the total resistance from the PROG pin to

PROG

/ R

PROG

) • 1000

Recharge

The LTC1733 has the ability to recharge a battery

assuming that the battery voltage has been charged above

4.05V (SEL = 5V) or 3.95V (SEL = 0V). Once above these

thresholds, a new charge cycle will begin if the battery

voltage drops below 4V (SEL = 5V) or 3.9V (SEL = 0V) due

to either a load on the battery or self-discharge. The

recharge circuit integrates the BAT pin voltage for a few

milliseconds to prevent a transient from restarting the

charge cycle.

If the battery voltage remains below 2.48V during trickle

charge for 1/4 of the programmed time, the battery may be

defective and the charge cycle will end. In addition, the

The programmable timer is used to terminate the charge

cycle. The timer duration is programmed by an external

capacitor at the TIMER pin. The total charge time is:

Time (Hours) = (3 Hours) • (C

C

The timer starts when an input voltage greater than the

undervoltage lockout threshold level is applied and the

program resistor is connected to ground. After a time-out

occurs, the charge current stops, and the CHRG output

assumes a high impedance state to indicate that the

charging has stopped. Connecting the TIMER pin to ground

disables the timer function.

= 0.1µF • Time (Hours)/3 (Hours)

TIMER

TIMER

/ 0.1µF) or

sn1733 1733fs

9

LTC1733

WUUU

APPLICATIO S I FOR ATIO

Open-Drain Status Outputs

The LTC1733 has three open-drain status outputs: ACPR,

CHRG and FAULT. The ACPR pin pulls low when an input

voltage greater than the undervoltage lockout threshold is

applied and goes high impedance when power (VIN < VUV)

is removed. CHRG and FAULT work together to indicate

the status of the charge cycle. Table 1 describes the status

of the charge cycle based on the CHRG and FAULT

outputs.

Table 1.

FAULT CHRG Description

High Low Charge cycle has started, C/10 has not been

reached and charging is proceeding normally.

Low Low Charge cycle has started, C/10 has not been

reached, but the charge current and timer

have been paused due to an NTC out-oftemperature condition.

High 25µA C/10 has been reached and charging is

pulldown proceeding normally.

Low 25µA C/10 has been reached but the charge current

pulldown and timer have paused due to an

NTC out-of-temperature condition.

High High Normal timeout (charging has terminated).

Low High If FAULT goes low and CHRG goes high

impedance simultaneously, then the LTC1733

has timed out due to a bad cell (V

after one-quarter the programmed charge time).

If CHRG goes high impedance first, then

the LTC1733 has timed out normally (charging

has terminated), but NTC is indicating an out-

of-temperature condition.

BAT

<2.48V

CHRG Status Output Pin

When the charge cycle starts, the CHRG pin is pulled to

ground by an internal N-channel MOSFET capable of

driving an LED. When the charge current drops to 10% of

the full-scale current (C/10), the N-channel MOSFET is

latched off and a weak 25µA current source to ground is

connected to the CHRG pin. After a time-out occurs, the

pin assumes a high impedance state. By using two different value pull-up resistors a microprocessor can detect

three states from this pin (charging, C/10, and time-out).

See Figure 2.

+

V

8

V

CC

LTC1733

CHRG

Figure 2. Microprocessor Interface

400k

2k

3

V

DD

µPROCESSOR

OUT

IN

1733 F02

When the LTC1733 is in charge mode, the CHRG pin is

pulled low by the internal N-channel MOSFET. To detect

this mode, force the digital output pin, OUT, high and

measure the voltage at the CHRG pin. The N-channel

MOSFET will pull the pin low even with the 2k pull-up

resistor. Once the charge current drops to 10% of the fullscale current (C/10), the N-channel MOSFET is turned off

and a 25µA current source is connected to the CHRG pin.

The IN pin will then be pulled high by the 2k pull-up. By

forcing the OUT pin to a high impedance state, the current

source will pull the pin low through the 400k resistor.

When the internal timer has expired, the CHRG pin will

assume a high impedance state and the 400k resistor will

then pull the pin high to indicate that charging has terminated.

NTC Thermistor

The battery temperature is measured by placing a negative

temperature coefficient (NTC) thermistor close to the

battery pack. The NTC circuitry is shown in Figure 3. To use

this feature, connect a 10k NTC thermistor between the

NTC pin and ground and a resistor (R

to VCC. R

should be a 1% resistor with a value equal to

HOT

) from the NTC pin

HOT

the value of the chosen NTC thermistor at 50°C (this value

is 4.1k for a Vishay NTHS0603N02N1002J thermistor).

The LTC1733 goes into hold mode when the resistance of

the NTC thermistor drops below 4.1k which should be

at 50°C. The hold mode freezes the timer and stops

the charge cycle until the thermistor indicates a return

to a valid temperature. As the temperature drops, the

10

sn1733 1733fs

WUUU

APPLICATIO S I FOR ATIO

LTC1733

resistance of the NTC thermistor rises. The LTC1733 is

designed to go into hold mode when the value of the NTC

thermistor increases to seven times the value of R

HOT

. For

a Vishay NTHS0603N02N1002J thermistor, this value is

28.2k which corresponds to approximately 0°C. The hot

and cold comparators each have approximately 2°C of

hysteresis to prevent oscillation about the trip point. The

NTC function can be disabled by grounding the NTC pin.

V

CC

7/8 V

1/2 V

3/160 V

LTC1733

CC

CC

CC

R

HOT

1%

NTC

R

NTC

10k

–

TOO COLD

+

+

TOO HOT

–

+

DISABLE NTC

–

1733 F03

Figure 3.

Thermistors

The LTC1733 NTC trip points were designed to work with

thermistors whose resistance-temperature characteristics follow Vishay Dale’s “R-T Curve 2”. The Vishay

NTHS0603N02N1002J is an example of such a thermistor. However, Vishay Dale has many thermistor products that follow the “R-T Curve 2” characteristic in a variety

of sizes. Futhermore, any thermistor whose ratio of R

to R

2 shows a ratio of R

is about 7.0 will also work (Vishay Dale R-T Curve

HOT

COLD

to R

of 2.816/0.4086 = 6.9).

HOT

COLD

NTC Layout Considerations

It is important that the NTC thermistor not be in close

thermal contact with the LTC1733. Because the LTC1733

package can reach temperatures in excess of the 50°C trip

point, the NTC function can cause a hysteretic oscillation

which turns the charge current on and off according to the

package temperature rather than the battery temperature.

This problem can be eliminated by thermally coupling the

NTC thermistor to the battery and not to the LTC1733.

Furthermore, it is essential that the VCC connection to

R

is made according to standard Kelvin sense tech-

HOT

niques. Since VCC is a high current path into the LTC1733,

it is essential to minimize voltage drops between the V

input pin and the top of R

HOT

.

CC

NTC Trip Point Errors

When a 1% resistor is used for R

, the major error in

HOT

the 50°C trip point is determined by the tolerance of the

NTC thermistor. A typical 10k NTC thermistor has a ±10%

tolerance. By looking up the temperature coefficient of the

thermistor at 50°C, the tolerance error can be calculated

in degrees centigrade. Consider the Vishay

NTHS0603N02N1002J thermistor which has a temperature coefficient of –3.3%/°C at 50°C. Dividing the tolerance by the temperature coefficient, ±10%/(–3.3%/°C) =

±3°C, gives the temperature error of the hot trip point.

The cold trip point is a little more complicated because its

error depends on the tolerance of the NTC thermistor and

the degree to which the ratio of its value at 0°C and its value

at 50°C varies from 7 to 1. Therefore, the cold trip point

error can be calculated using the tolerance, TOL, the

temperature coefficient of the thermistor at 0°C, TC

(in %/°C), the value of the thermistor at 0°C, R

the value of the thermistor at 50°C, R

1

+

TOL R

7

Temperature Error (°C) =

. The formula is:

HOT

COLD

•–•

R

HOT

COLD

1 100

, and

TC

For example, the Vishay NTHS0603N02N1002J thermistor

with a tolerance of ±10%, TC of –4.5%/°C, and R

R

of 6.89, has a cold trip point error of:

HOT

Temperature Error (°C) =

±

.

1010

7

•. – •

6 89 1 100

–.

45

COLD

/

= –1.8°C, +2.5°C

sn1733 1733fs

11

LTC1733

I

CT

VV

BAT

A

CC BAT JA

=

°105 –

(– )•θ

WUUU

APPLICATIO S I FOR ATIO

If a thermistor with a tolerance less than ±10% is used, the

trip point errors begin to depend on errors other than

thermistor tolerance including the input offset voltage of

the internal comparators of the LTC1733 and the effects of

internal voltage drops due to high charging currents.

Constant-Current/Constant-Voltage/

Constant-Temperature

The LTC1733 uses a unique architecture to charge a

battery in a constant-current, constant-voltage, constanttemperature fashion. Figure 1 shows a simplified block

diagram of the LTC1733. Three of the amplifier feedback

loops shown control the constant-current, CA, constantvoltage, VA, and constant-temperature, TA modes. A

fourth amplifier feedback loop, MA, is used to increase the

output impedance of the current source pair, M1 and M2

(note that M1 is the internal P-channel power MOSFET). It

ensures that the drain current of M1 is exactly 1000 times

greater than the drain current of M2.

Amplifiers CA, TA, and VA are used in three separate

feedback loops to force the charger into constant-current,

temperature, or voltage mode, respectively. Diodes, D1,

D2, and D3 provide priority to whichever loop is trying to

reduce the charging current the most. The outputs of the

other two amplifiers saturate low which effectively removes their loops from the system. When in constantcurrent mode, CA servos the voltage at the PROG pin to be

precisely 1.50V (or 0.15V when in trickle-charge mode).

TA limits the die temperature to approximately 105°C

when in constant-temperature mode and the PROG pin

voltage gives an indication of the charge current as discussed in “Programming Charge Current” . VA servos its

inverting input to precisely 2.485V when in constantvoltage mode and the internal resistor divider made up of

R1 and R2 ensures that the battery voltage is maintained

at either 4.1V or 4.2V. Again, the PROG pin voltage gives

an indication of the charge current.

105°C. As the battery voltage rises, the LTC1733 either

returns to constant-current mode or it enters constantvoltage mode straight from constant-temperature mode.

Regardless of mode, the voltage at the PROG pin is

proportional to the current being delivered to the battery.

Power Dissipation

The conditions that cause the LTC1733 to reduce charge

current due to the thermal protection feedback can be

approximated by considering the power dissipated in the

IC. For high charge currents, the LTC1733 power dissipation is approximately:

PD = (VCC – V

where PD is the power dissipated, VCC is the input supply

voltage, V

charge current. It is not necessary to perform any worstcase power dissipation scenarios because the LTC1733

will automatically reduce the charge current to maintain

the die temperature at approximately 105°C. However, the

approximate ambient temperature at which the thermal

feedback begins to protect the IC is:

TA = 105°C – PDθ

TA = 105°C – (VCC – V

Example: Consider an LTC1733 operating from a 5V wall

adapter providing 1.2A to a 3.75V Li-Ion battery. The

ambient temperature above which the LTC1733 will begin

to reduce the 1.2A charge current is approximately:

TA = 105°C – (5V – 3.75V) • 1.2A • 40°C/W

TA = 105°C – 1.5W • 40°C/W = 105°C – 60°C = 45°C

The LTC1733 can be used above 45°C, but the charge

current will be reduced below 1.2A. The approximate

charge current at a given ambient temperature can be

approximated by:

BAT

) • I

BAT

is the battery voltage, and I

JA

BAT

BAT

) • I

BAT • θJA

is the battery

BAT

In typical operation, the charge cycle begins in constantcurrent mode with the current delivered to the battery

equal to 1500V/R

LTC1733 results in the junction temperature approaching

105°C, the amplifier (TA) will begin decreasing the charge

current to limit the die temperature to approximately

12

. If the power dissipation of the

PROG

Consider the above example with an ambient temperature

of 55°C. The charge current will be reduced to approximately:

sn1733 1733fs

WUUU

APPLICATIO S I FOR ATIO

LTC1733

I

BAT

°°

=

105 55

VVCWCCA

5 3 75 40

(–. )• / /

–

°

°

50

=

°

50

A

=

1

CC

Furthermore, the voltage at the PROG pin will change

proportionally with the charge current as discussed in the

Programming Charge Current section.

It is important to remember that LTC1733 applications do

not need to be designed for worst-case thermal conditions

since the IC will automatically reduce power dissipation

when the junction temperature reaches approximately

105°C. See Design Note 283 for additional information.

Board Layout Considerations

In order to be able to deliver maximum charge current

under all conditions, it is critical that the exposed pad on

the backside of the LTC1733 package is soldered to the

board. Correctly soldered to a 2500mm2 double-sided

1oz. copper board the LTC1733 has a thermal resistance

of approximately 40°C/W. Failure to make thermal contact

between the exposed pad on the backside of the package

and the copper board will result in thermal resistances far

greater than 40°C/W. As an example, a correctly soldered

LTC1733 can deliver over 1250mA to a battery from a 5V

supply at room temperature. Without a backside thermal

connection, this number could drop to less than 500mA.

VCC Bypass Capacitor

Many types of capacitors can be used for input bypassing.

However, caution must be exercised when using multilayer ceramic capacitors. Because of the self resonant and

high Q characteristics of some types of ceramic capacitors, high voltage transients can be generated under some

start-up conditions, such as connecting the charger input

to a hot power source. For more information refer to

Application Note 88.

Stability

The constant-voltage mode feedback loop is stable

without any compensation when a battery is connected.

However, a 1µF capacitor with a 1Ω series resistor to GND

is recommended at the BAT pin to keep ripple voltage low

when the battery is disconnected.

In the constant-current mode it is the PROG pin that is in

the feedback loop and not the battery. The constantcurrent mode stability is affected by the impedance at the

PROG pin. With no additional capacitance on the PROG

pin, stability is acceptable with program resistor values as

high as 50k. However, additional capacitance on this node

reduces the maximum allowed program resistor. The pole

frequency at the PROG pin should be kept above 500kHz.

Therefore, if the PROG pin is loaded with a capacitance, C,

the following equation should be used to calculate the

maximum resistance value for R

R

< 1/(6.283 • 500E3 • C)

PROG

PROG

:

Average, rather than instantaneous, battery current may

be of interest to the user. For example, if a switching power

supply operating in low-current mode is connected in

parallel with the battery the average current being pulled

out of the BAT pin is typically of more interest than the

instantaneous current pulses. In such a case, a simple RC

filter can be used on the PROG pin to measure the average

battery current as shown in Figure 4. A 10k resistor is

added between the PROG pin and the filter capacitor and

monitoring circuit to ensure stability.

LTC1733

PROG

GND

5

PROG

10k

C

FILTER

7

R

CHARGE

CURRENT

MONITOR

CIRCUITRY

1733 F04

Figure 4. Isolating Capacitive Load on PROG Pin and Filtering.

sn1733 1733fs

13

LTC1733

TYPICAL APPLICATIO

Basic Li-Ion Battery Charger with Reverse Polarity Input Protection

5V WALL

ADAPTER

U

4.7µF

0.1µF

2

8

4

V

CC

SEL

TIMER

GND

5

LTC1733

BAT

PROG

NTC

I

= 1A

1.5k

1%

BAT

1733 F06

+

4.2V Li-Ion

BATTERY

9

7

6

14

sn1733 1733fs

PACKAGE DESCRIPTIO

2.794 ± 0.102

(.110 ± .004)

U

MSE Package

10-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1663)

0.889

(.035 ± .005)

± 0.127

BOTTOM VIEW OF

EXPOSED PAD OPTION

1

2.06 ± 0.102

(.081 ± .004)

± 0.102

1.83

(.072 ± .004)

LTC1733

5.23

(.206)

MIN

0.305 ± 0.038

(.0120 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

0.254

(.010)

GAUGE PLANE

0.18

(.007)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

DETAIL “A”

DETAIL “A”

2.083 ± 0.102

(.082 ± .004)

0.50

(.0197)

BSC

° – 6° TYP

0

0.53 ± 0.01

(.021 ± .006)

3.2 – 3.45

(.126 – .136)

SEATING

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.88 ± 0.10

(.192 ± .004)

1.10

(.043)

MAX

0.17 – 0.27

(.007 – .011)

10

12

0.50

(.0197)

TYP

8910

3

7

6

45

0.497 ± 0.076

(.0196 ± .003)

REF

3.00 ± 0.102

(.118 ± .004)

NOTE 4

0.86

(.034)

REF

0.13 ± 0.05

(.005 ± .002)

MSOP (MSE) 1001

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

sn1733 1733fs

15

LTC1733

TYPICAL APPLICATIO

U

Full Featured Single Cell Li-Ion Charger

82

R

4.7µF

NTC

10k

1%

1k

4k

1

CHRG

6

NTC

4

TIMER

0.1µF

SEL

LTC1733

GND

FAULT

5

V

CC

ACPR

BAT

PROG

10

3

9

7

3k

1%

1k 1k

1µF

1Ω

I

BAT

= 5V

V

IN

= 500mA

+

4.2V Li-Ion

BATTERY

1733 F05

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1571 200kHz/500kHz Switching Battery Charger Up to 1.5A Charge Current; Preset and Adjustable Battery Voltages

LTC1729 Lithium-Ion Battery Charger Termination Controllers Time or Charge Current Termination, Preconditioning 8-Lead MSOP

LTC1730 Lithium-Ion Battery Pulse Charger No Blocking Diode Required, Current Limit for Maximum Safety

LTC1731 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

Charger Detection and Programmable Timer

LTC1732 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

Charger Detection and Programmable Timer, Input Power Good Indication

LTC1734 Lithium-Ion Linear Battery Charger in ThinSOT Simple ThinSOT Charger, No Blocking Diode, No Sense Resistor Needed

LTC1998 Lithium-Ion Low Battery Detector 1% Accurate 2.5µA Quiescent Current, SOT-23

LTC4050 Lithium-Ion Linear Battery Charger Controller Simple Charger uses External FET, Features Preset Voltages, C/10

Charger Detection and Programmable Timer, Input Power Good Indication,

Thermistor Interface

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

sn1733 1733fs

LT/TP 0602 2K • PRINTED IN USA

Loading...

Loading...