FEATURES

LTC1704/LTC1704B

550kHz Synchronous

Switching Regulator Controller

Plus Linear Regulator Controller

U

DESCRIPTIO

■

Dual Regulated Outputs: One Switching Regulator

and One Linear Regulator

■

Excellent DC Accuracy: ±1.5% for Switcher

and ±2% for Linear Regulator

■

External N-Channel MOSFET Architecture

■

No External Current Sense Resistor Required

■

Burst Mode® Operation at Light Load (LTC1704)

■

Continuous Switching at Light Load (LTC1704B)

■

Linear Regulator with Programmable Current Limit

■

Linear Regulator with Programmable Start-Up Delay

■

Low Shutdown Current: <150µA

■

High Efficiency Over Wide Load Current Range

■

PGOOD Flag Monitors Both Outputs

■

Small 16-Pin Narrow SSOP Package

U

APPLICATIO S

■

Multiple Logic Supply Generator

■

Distributed Power Applications

■

High Efficiency Power Conversion

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a registered trademark of Linear Technology Corporation.

The LTC®1704/LTC1704B include a high power synchronous switching regulator controller plus a linear regulator

controller. The switching regulator controller is designed

to drive a pair of N-channel MOSFETs in a voltage mode,

synchronous buck configuration to provide the main supply. The constant frequency, true PWM architecture

switches at 550kHz, minimizing external component size,

cost and optimizing load transient performance. The

LTC1704 features automatic transition to power saving

Burst Mode operation at light loads. The LTC1704B does

not shift into Burst Mode operation at light loads, eliminating low frequency output ripple at the expense of light load

efficiency. The linear regulator controller is designed to

drive an external NPN power transistor to provide up to 2A

of current to an auxiliary load.

The LTC1704/LTC1704B deliver better than ±1.5% DC

accuracy at the switcher outputs and ±2% at the linear

regulator outputs. High performance feedback loops allow

the circuit to keep total output regulation within ±5%

under all transient conditions. An open-drain PGOOD

output indicates when both outputs are within ±10% of

their regulated values.

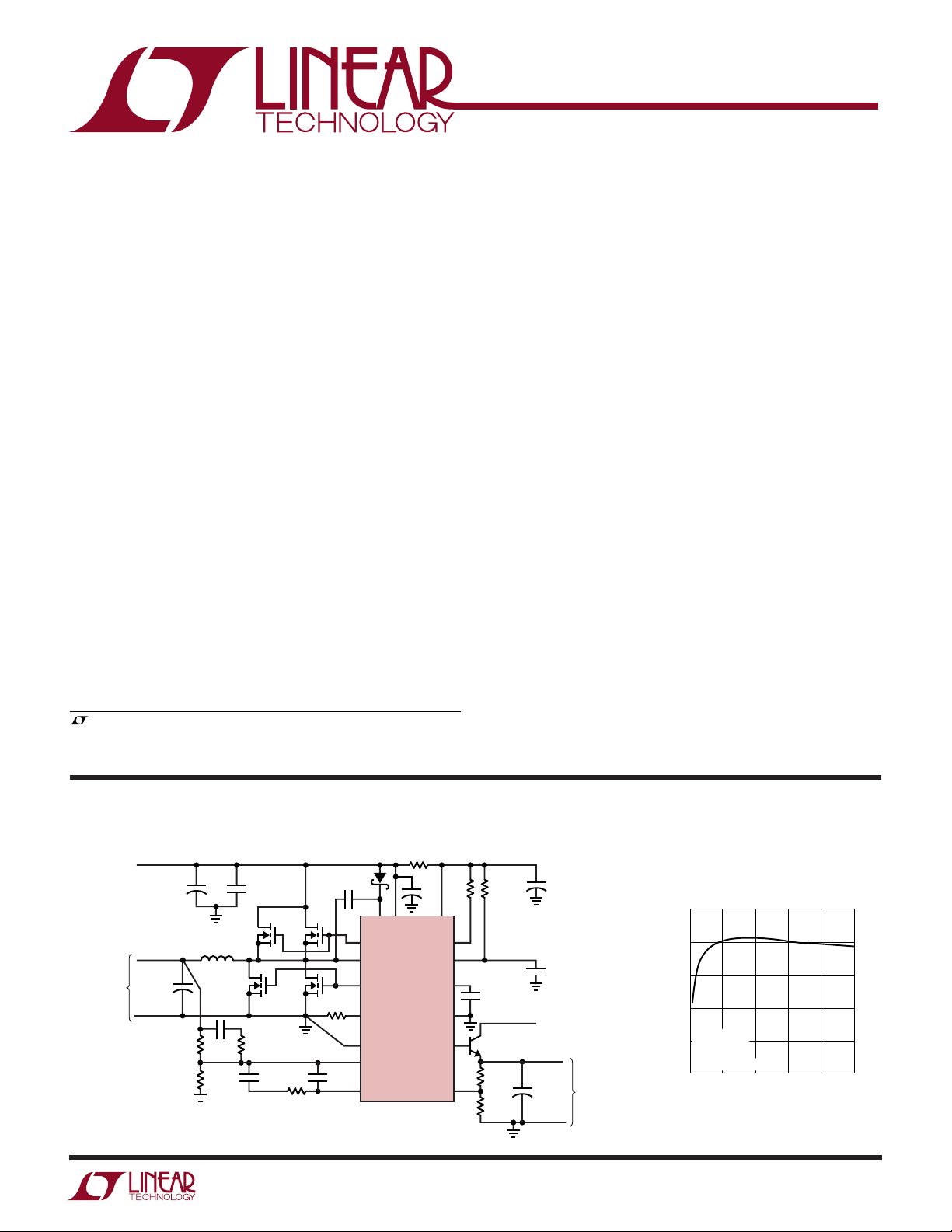

TYPICAL APPLICATIO

5V to 1.8V/15A and 1.5V/2A Application

V

IN

V

OUTSW

1.8V

15A

5V

C

OUTSW

180µF

330µF

10V

4V

×6

C

×3

+

IN

10k

8.06k

+

1µF

QTA

L1

0.68µH

1800pF

C

: KEMET T510X337K010AS

IN

C

OUTSW

L: SUMIDA CEP125-4712-T007

QTA, QTB, QBA, QBB: FAIRCHILD FDS6670A

QTB

QBAQBB

1.8k

1800pF

11k

: PANASONIC EEFUE0G181R

U

MBR0520LT1

C

CP

1µF

14

13.7k

13

330pF

1

2

3

6

5

BOOST

TG

SW

BG

I

MAX

PGND

FB

COMP

16

PV

LTC1704

10Ω

+

15

CC

10µF

V

CC

PGOOD

REGILM

RUN/SS

GND

REGDR

REGFB

5k

11

12

10

4

8

7

9

470k

0.1µF

ON SEMI

D44H11

698Ω

806Ω

+

10µF

1000pF

V

OUTSW

100µF

TANT

1704 TA01

V

OUTREG

1.5V

2A

+

EFFICIENCY (%)

Switcher Efficiency

100

90

80

70

VIN = 5V

60

= 1.8V

V

OUTSW

= 25°C

T

A

QT = QB = 2xFDS6670A

50

3

0

9

12

6

I

(A)

LOAD

15

1704 G04

1704bfa

1

LTC1704/LTC1704B

WW

W

ABSOLUTE AXI U RATI GS

U

UUW

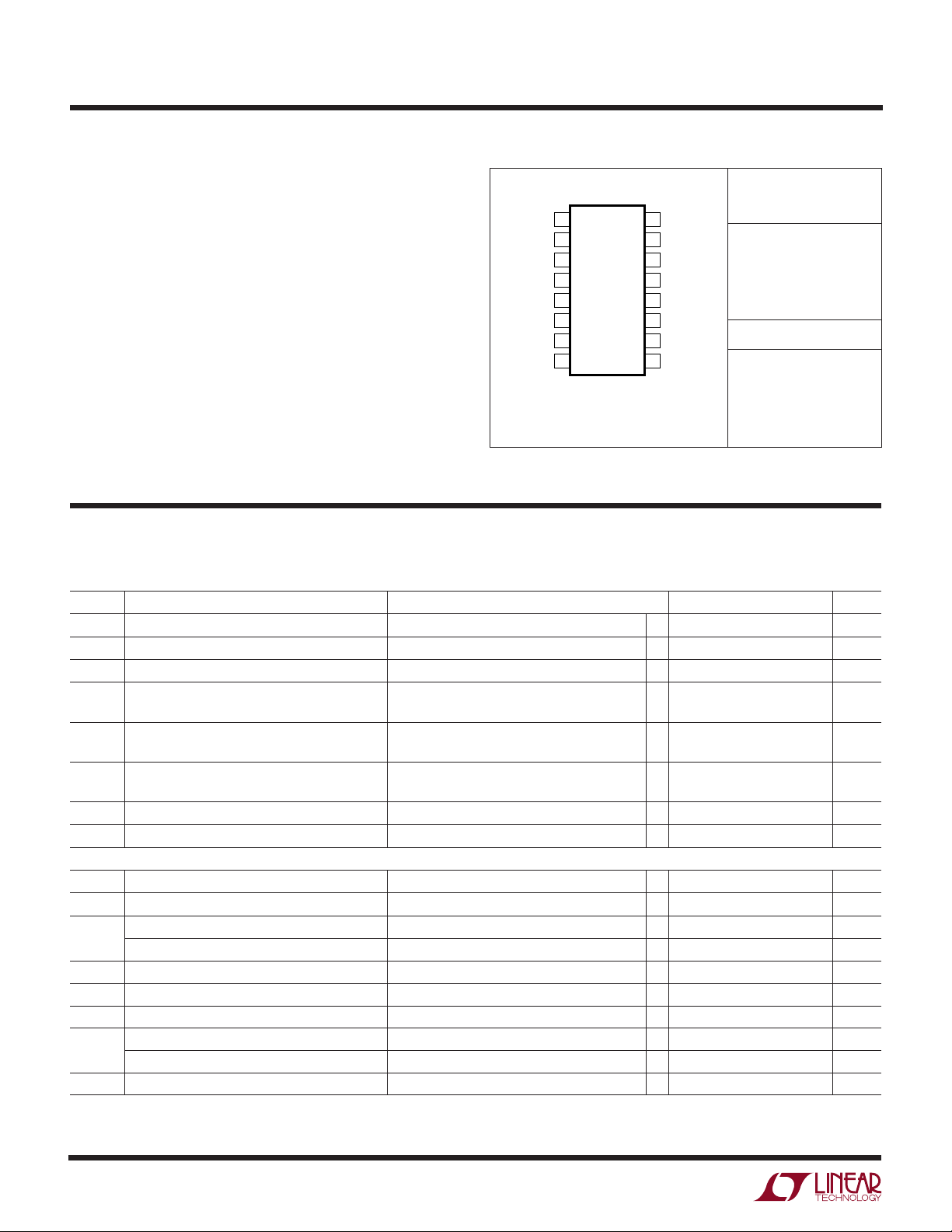

PACKAGE/ORDER I FOR ATIO

(Note 1)

Supply Voltage

VCC, PVCC.............................................................. 6V

BOOST................................................................. 12V

BOOST – SW ......................................................... 6V

Input Voltage

SW ............................................................. –1V to 6V

FB, REGFB, REGILM,

RUN/SS, I

.......................... –0.3V to (VCC + 0.3V)

MAX

Peak Output Current <10µs

TG, BG (Note 7) ..................................................... 5A

Operating Temperature Range (Note 2) .. –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

1

TG

2

SW

3

I

MAX

RUN/SS

4

5

COMP

6

FB

7

REGDR

8

GND

16-LEAD PLASTIC SSOP

T

JMAX

TOP VIEW

16

15

14

13

12

11

10

9

GN PACKAGE

= 125°C, θJA = 130°C/W

BOOST

PV

CC

BG

PGND

PGOOD

V

CC

REGILM

REGFB

ORDER PART

NUMBER

LTC1704EGN

LTC1704BEGN

GN PART MARKING

1704

1704B

Lead Temperature (Soldering, 10 sec)..................300°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= PVCC = BOOST = 5V, unless otherwise specified. (Note 3)

CC

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

PV

BV

I

VCC

I

PVCC

I

BOOST

V

SHDN

I

SS

Switcher Control Loop

V

FB

I

FB

dV

A

FB

GBW Feedback Amplifier Gain Bandwidth Product f = 100kHz (Note 7) 20 MHz

I

COMP

V

PGOOD

I

IMAX

VCC Supply Voltage ● 3.15 5 5.5 V

PVCC Supply Voltage (Note 4) ● 3.15 5 5.5 V

CC

BOOST Pin Voltage V

CC

VCC Supply Current Test Circuit ● 4.5 8 mA

PVCC Supply Current Test Circuit, No Load at Drivers ● 36 mA

BOOST Pin Current Test Circuit ● 26 mA

RUN/SS Shutdown Threshold V

RUN/SS Source Current V

Feedback Voltage ● 0.788 0.800 0.812 V

Feedback Input Current ● ±1 µA

Feedback Voltage Line Regulation VCC = 3.3V to 5.5V ● ±0.01 ±0.1 %/V

FB

Output Voltage Load Regulation (Note 7) ● –0.2 –0.1 %

Feedback Amplifier DC Gain ● 74 85 dB

Feedback Amplifier Output Sink/Source Current ● ±3 ±10 mA

Negative Power Good Threshold ● –15 –10 –6 %

Positive Power Good Threshold ● 61015 %

I

Source Current V

MAX

– VSW (Note 4) ● 3.15 5 5.5 V

BOOST

V

= 0V, V

RUN/SS

= 0V (Notes 5, 6) ● 50 µA

V

RUN/SS

= 0V (Notes 5, 6) ● 50 µA

V

RUN/SS

↑ ● 0.2 0.5 V

RUN/SS

= 0V –3 µA

RUN/SS

= 0V ● –11.5 –10 –8.5 µA

IMAX

= 0V ● 75 150 µA

REGILM

2

1704bfa

LTC1704/LTC1704B

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= PVCC = BOOST = 5V, unless otherwise specified. (Note 3)

CC

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Switcher Switching Characteristics

f

OSC

DC

MAX

t

NOV

tr, t

f

Linear Regulator Controller

V

REGFB

I

REGFB

dV

REGFB

I

REGDR

V

DROPOUT

V

REGILM

I

REGILMINT

V

PGOOD

PGOOD

I

PGOOD

V

OLPG

t

PGOOD

Oscillator Frequency Test Circuit ● 460 550 650 kHz

Maximum Duty Cycle ● 87 90 93 %

Driver Nonoverlap Test Circuit (Note 8) ● 10 25 120 ns

Driver Rise/Fall Time Test Circuit (Note 8) ● 15 100 ns

Feedback Voltage Test Circuit, R

= 680k 0.784 0.800 0.816 V

REGILM

● 0.780 0.800 0.820 V

REGFB Input Current ● ±1 µA

Feedback Voltage Line Regulation Test Circuit, VCC = 4.5V to 5.5V ● ±0.05 ±0.2 %/V

Feedback Voltage Load Regulation Test Circuit, I

= 0mA to 30mA ● –0.2 –0.05 %

REGDR

Driver Output Current Test Circuit ● 30 mA

= 680k, V

R

REGILM

R

= 680k, V

REGILM

Driver Dropout Voltage Test Circuit, I

dV

= –1% (Note 9)

REGFB

REGILM Threshold Test Circuit, R

REGILM Internal Pull-Up Current V

= 0V –1.9 µA

REGILM

REGDR

REGILM

= 0.76V, V

REGFB

= 0V, V

REGFB

= 30mA, V

REGDR

REGDR

= 3.3V 20 mA

REGDR

= 1V 6 mA

= 3.3V, ● 0.65 1.1 V

= 680k 0.8 V

Negative REGFB Power Good Threshold ● –15 –10 –6 %

Positive REGFB Power Good Threshold ● 61015 %

V

Sink Current Power Good ● 10 µA

PGOOD

Power Bad

V

Output Low Voltage I

PGOOD

V

Falling Edge Delay (Note 8) ● 0.5 1 4 µs

PGOOD

V

Rising Edge Delay (Note 8) ● 10 20 40 µs

PGOOD

= 1mA ● 0.03 0.1 V

PGOOD

● 10 mA

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1704E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Note 4: PV

and BVCC (V

CC

– VSW) must be greater than V

BOOST

GS(ON)

of

the external MOSFETs to ensure proper operation.

Note 5: Supply current in normal operation is dominated by the current

needed to charge and discharge the external MOSFET gates. This current

will vary with supply voltage and the external MOSFETs used.

Note 6: Supply current in shutdown is dominated by external MOSFET

leakage and may be significantly higher than the quiescent current drawn

by the LTC1704, especially at elevated temperature.

Note 7: Guaranteed by design, not subject to test.

Note 8: Rise and fall times are measured using 10% and 90% levels. Delay

and nonoverlap times are measured using 50% levels.

Note 9: Dropout voltage is the minimum V

CC

to V

voltage differential

REGDR

required to maintain regulation at the specified driver output current.

1704bfa

3

LTC1704/LTC1704B

UW

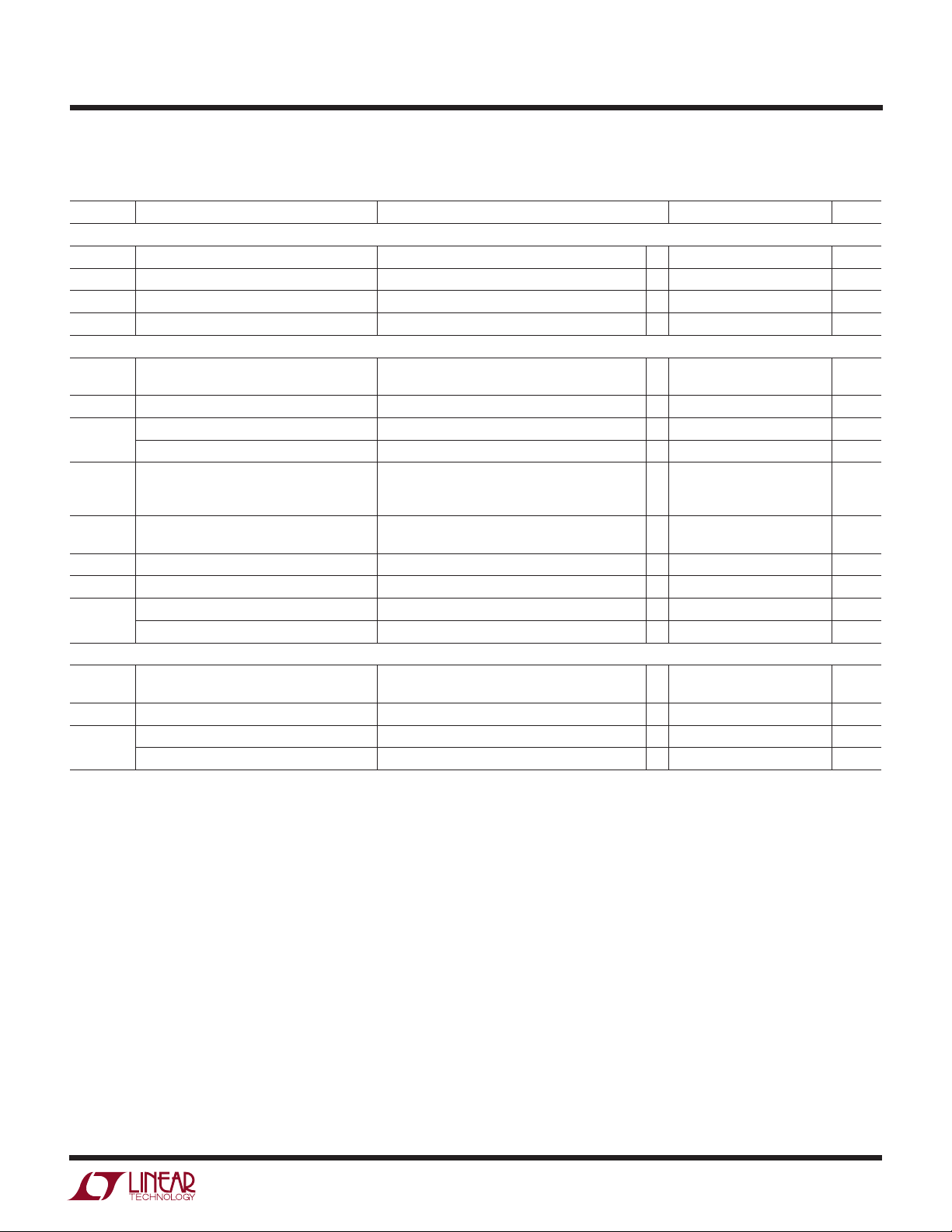

TYPICAL PERFOR A CE CHARACTERISTICS

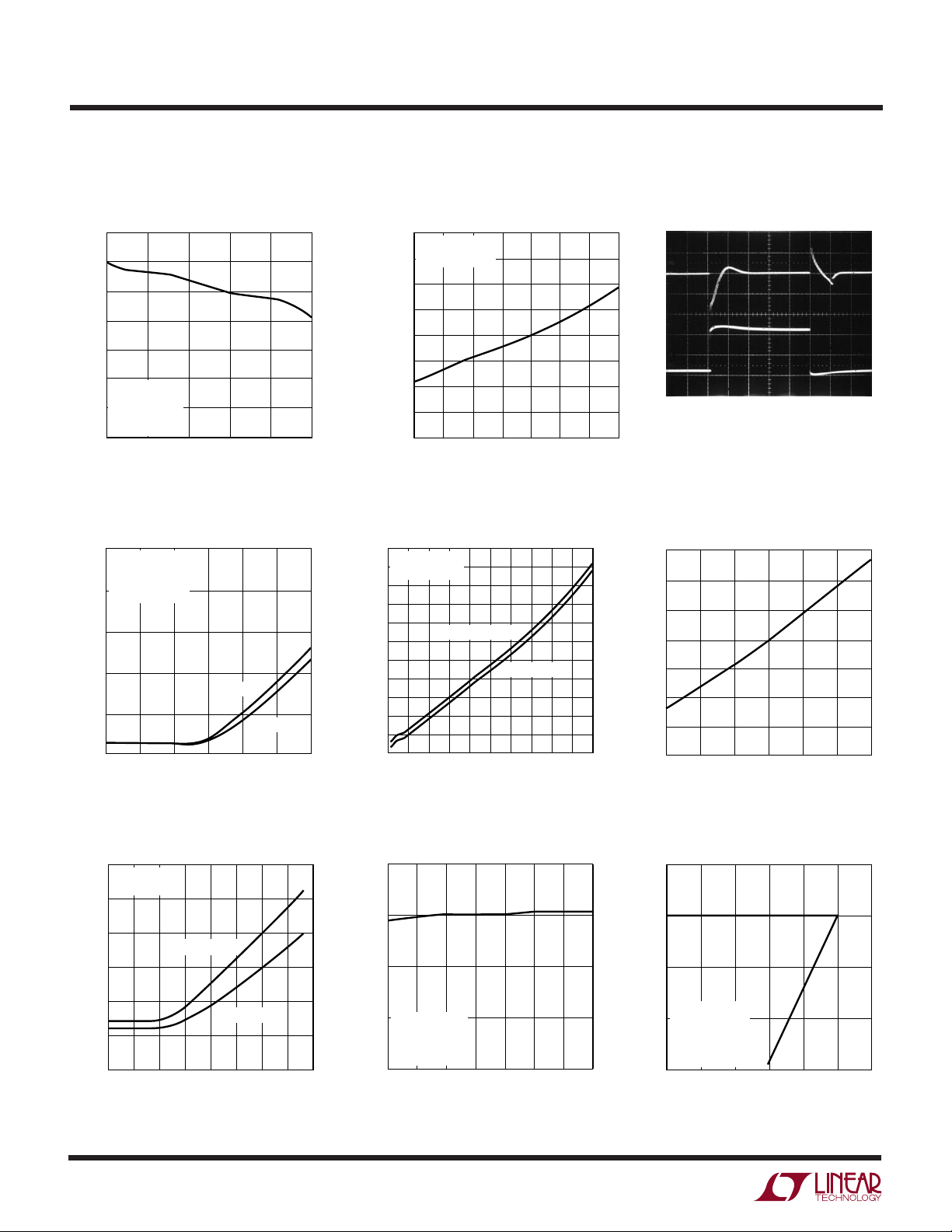

VFB vs Temperature

0.812

VCC = 5V

0.808

0.804

(V)

0.800

FB

V

0.796

0.792

0.788

–50

–25 0

V

OUTSW

0.6

0

–0.6

(mV)

–1.2

–1.8

OUTSW

∆V

–2.4

–3.0

50 100 125

25 75

TEMPERATURE (°C)

Load Regulation

TA = 25°C

V

OUTSW

1704 G01

= 1.8V

0.03

0

–0.03

–0.07

–0.10

–0.13

–0.17

∆V

OUTSW

(%)

VFB Line Regulation

0.80

TA = 25°C

0.64

0.48

0.32

0.16

(mV)

0

FB

∆V

–0.16

–0.32

–0.48

–0.64

–0.80

3.5

3

4

4.5 5

VCC (V)

Switcher Current Limit Threshold

vs Temperature

24

22

20

18

16

14

CURRENT LIMIT THRESHOLD (A)

12

VIN = 5V

V

OUTSW

∆V

OUTSW

= 13.7k

R

IMAX

QT = QB = 2xFDS6670A

= 1.8V

= –1%

5.5

1704 G02

6

0.10

0.08

0.06

0.04

0.02

0

–0.02

–0.04

–0.06

–0.08

–0.10

FB

∆V

(%)

–3.6

V

0.5A to 5.5A Load Step

OUTSW

369 15

0

(Burst Mode Operation)

CH1: V

OUTSW

CH2: 0.5A to 5.5A LOAD, 5A DIV

100µs/DIV 1704 G05

= 1.8V, AC 50mV/DIV

I

LOAD

(A)

12

–0.20

1704 G03

V

5A to 10A Load Step

OUTSW

CH1: V

OUTSW

CH2: 5A to 10A LOAD, 5A DIV

50µs/DIV 1704 G06

= 1.8V, AC 50mV/DIV

10

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

V

OUTSW

1704 G08

Burst Mode Operation

at 1A Load

CH1: V

CH2: V

OUTSW

TG

20µs/DIV 1704 G07

= 1.8V, AC 20mV/DIV

, 5V DIV

1704bfa

4

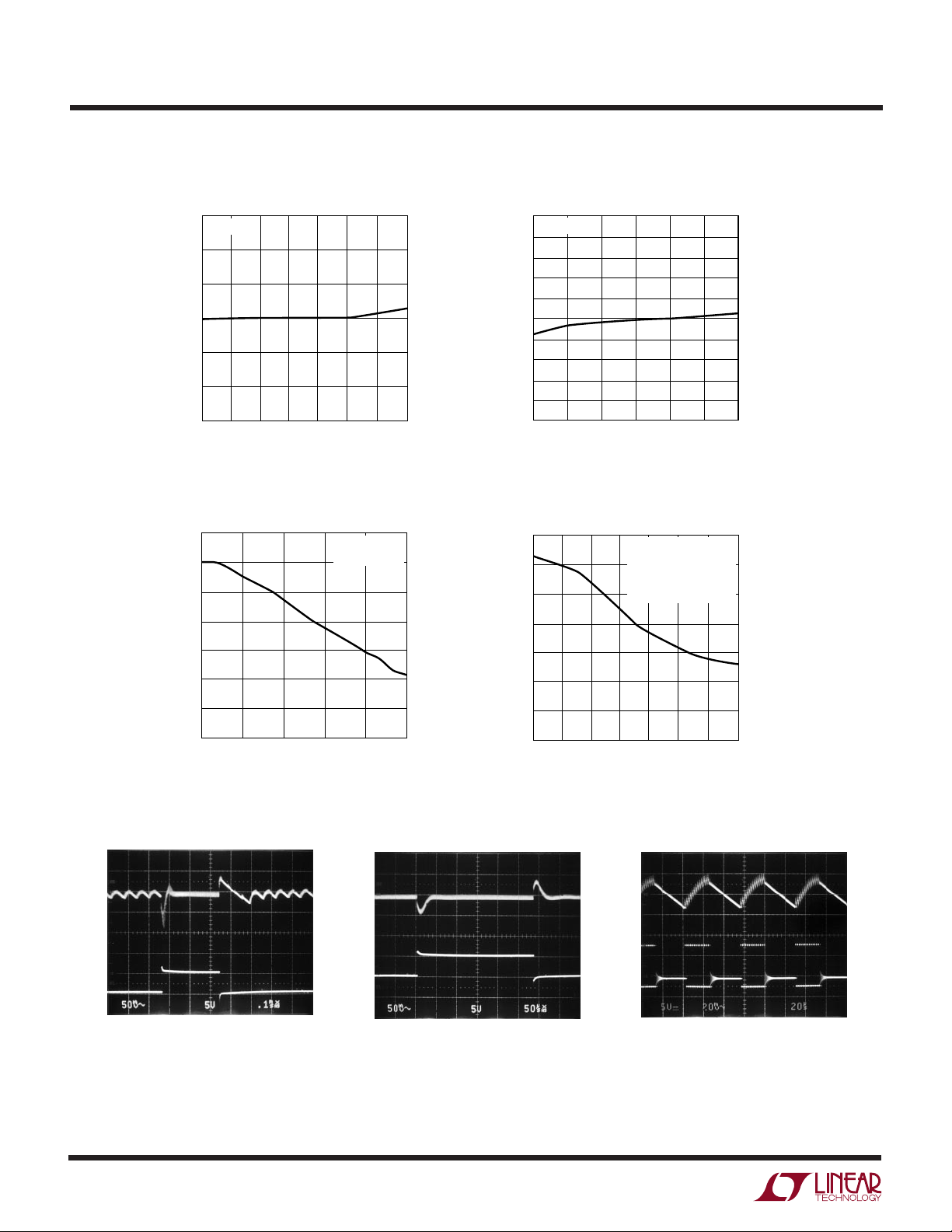

UW

TEMPERATURE (°C)

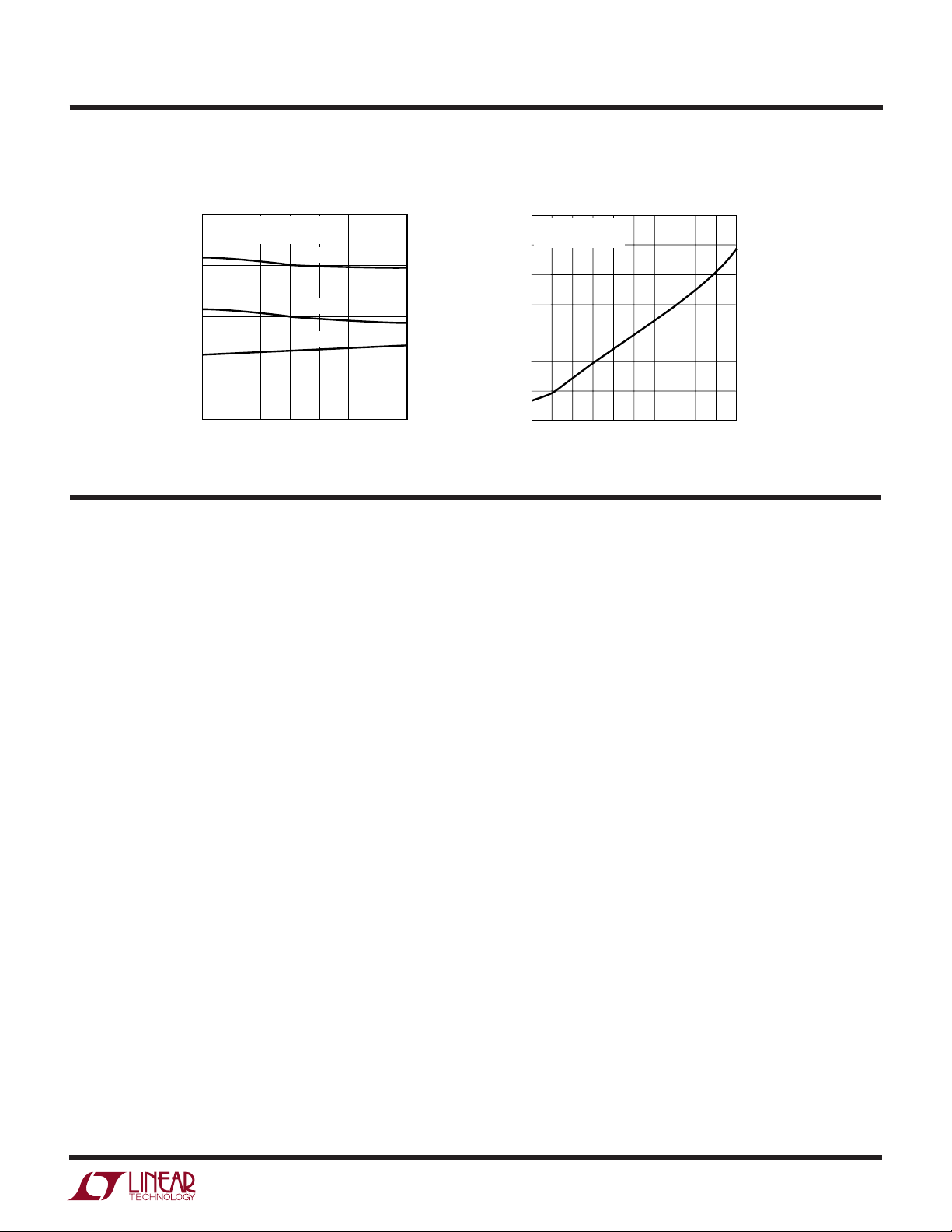

–50

DC

MAX

(%)

91

92

93

25 75

1704 G10

90

89

–25 0

50 100 125

88

87

VCC = 5V

TG, BG FLOAT

TYPICAL PERFOR A CE CHARACTERISTICS

V

OUTSW

2.0

1.5

(V)

1.0

OUTSW

V

VIN = 5V

0.5

V

OUTSW

T

= 25°C

A

R

IMAX

QT = QB = 2xFDS6670A

0

0

f

OSC

640

VCC = 5V

620

600

580

560

(kHz)

540

OSC

f

520

500

480

460

–25

–50

vs Load Current

= 1.8V

= 13.7k

4

8

LOAD CURRENT (A)

vs Temperature

0

25 125

TEMPERATURE (°C)

50

12

16

75 100

20

1704 G09

1704 G12

(µA)

IMAX

I

–8.5

–9.0

–9.5

–10.0

–10.5

–11.0

–11.5

650

610

570

(kHz)

OSC

f

530

490

450

I

vs Temperature I

IMAX

VCC = 5V

50 100 125

–50

f

3

OSC

–25 0

vs V

TA = 25°C

3.5

25 75

TEMPERATURE (°C)

CC

4 4.5 5

VCC (V)

1704 G10

5.5 6

1704 G13

LTC1704/LTC1704B

vs V

IMAX

–8.5

TA = 25°C

–9.0

–9.5

(µA)

–10.0

IMAX

I

–10.5

–11.0

–11.5

3

Maximum TG Duty Cycle

vs Temperature

3.5

CC

4 4.5 5

VCC (V)

5.5 6

1704 G11

Drivers Rise and Fall Time

vs Load

100

TA = 25°C

90

PV

= BOOST = 5V

CC

80

70

60

(ns)

f

50

, t

r

t

40

30

20

10

0

2000

0

4000

TG, BG LOAD (pF)

6000

8000

10000

1704 G15

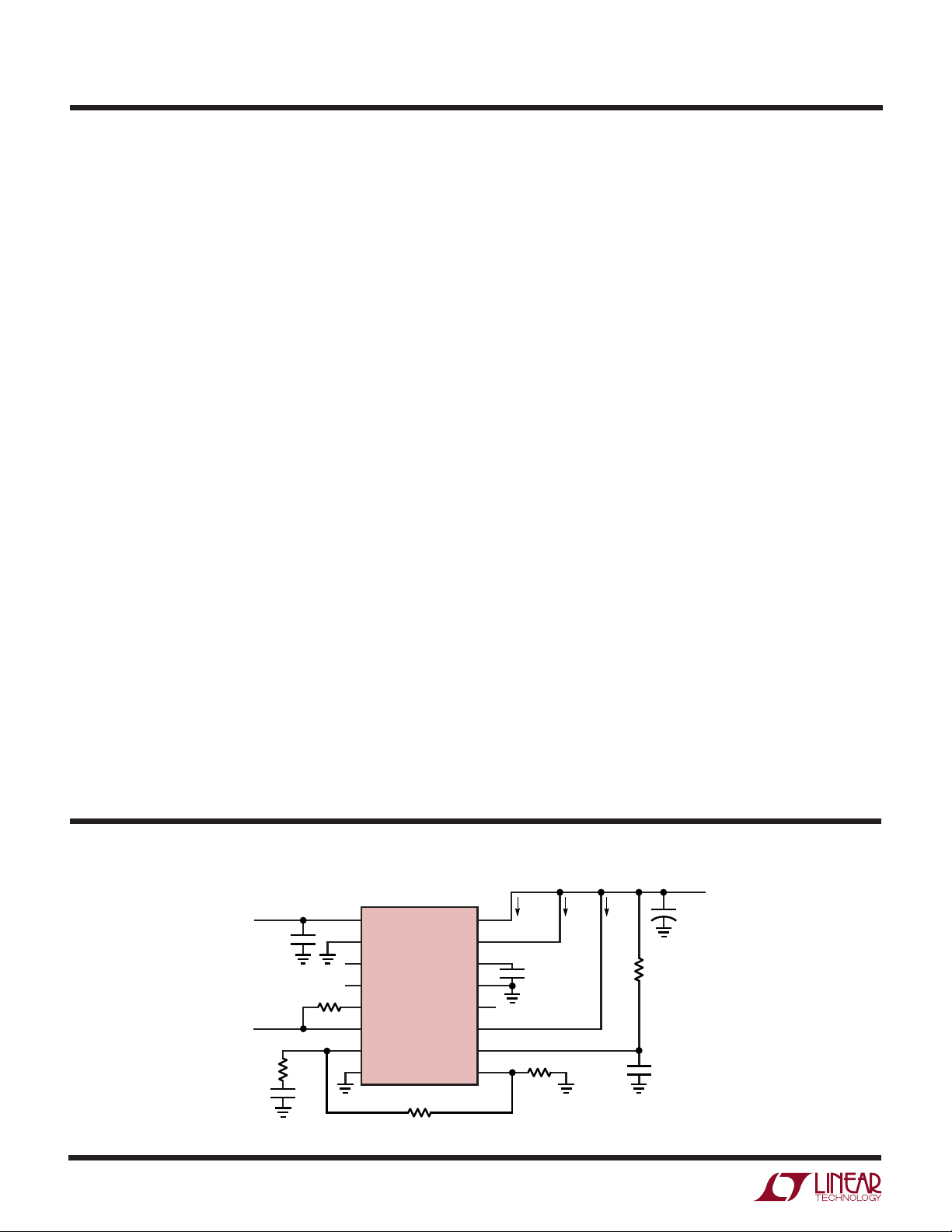

0.820

0.815

0.810

0.805

(V)

0.800

REGFB

V

0.795

0.790

0.785

0.780

V

vs Temperature

REGFB

V

= 3.3V

REGDR

–25 0 50

–50

25

TEMPERATURE (°C)

75 100 125

LTXXX • TPCXX

1.6

1.2

0.8

0.4

(mV)

REGFB

–0.4

∆V

–0.8

–1.2

–1.6

V

Line Regulation

REGFB

TA = 25°C

= 0.8V

V

REGDR

0

3.5 4 5

3

4.5

VCC (V)

5.5

1704 G17

6

0.20

0.15

0.10

0.05

0

–0.05

–0.10

–0.15

–0.20

1704bfa

5

∆V

REGFB

(%)

LTC1704/LTC1704B

I

REGILM

(µA)

0

35

30

25

20

15

10

5

0

610

1704 G23

24

812

I

REGDR

(mA)

I

OUTREG

(A)

0

0

V

OUTREG

(V)

0.5

1.0

1.5

2.0

0.5 1 1.5 2

1704 G25

2.5 3

TA = 25°C

V

INREG

= 1.8V

V

OUTREG

= 1.5V

I

REGILM

= 9µA

QEXT = D44H11

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Linear Regulator Dropout Voltage

V

0.5

0

–0.5

(mV)

–1.0

–1.5

OUTREG

∆V

–2.0

–2.5

–3.0

0

Minimum VCC vs V

5.5

5.0

(V)

4.5

CC

4.0

MINIMUM V

3.5

3.0

0.9

Load Regulation

OUTREG

TA = 25°C

= 1.5V

V

OUTREG

I

= 9µA

REGILM

QEXT = D44H11

0.4 0.8 1.2 2

I

(A)

OUTREG

OUTREG

I

= 9µA

REGILM

= 2A

I

OUTREG

= –1%

∆V

OUTREG

QEXT = D44H11

TA = –40°C

1.7 2.1 2.5

1.3

V

(V)

OUTREG

T

A

1.6

= 25°C

1704 G18

2.9 3.3

1704 G21

0.03

0

–0.03

–0.07

–0.10

–0.13

–0.17

–0.20

vs Temperature

1.1

I

= –30mA

REGDR

= 3.3V

V

REGDR

1.0

0.9

∆V

0.8

OUTREG

(V)

0.7

(%)

DROPOUT

V

0.6

0.5

0.4

0.3

–25 0 50

–50

TEMPERATURE (°C)

Linear Regulator Start-Up Time

vs C

0

0

DELAY

TA = 25°C

V

OUTREG

2000

= 1.5V

I

REGILM

4000

C

DELAY

= 6.2µA

(pF)

1100

1000

900

800

700

600

500

400

START-UP TIME (µs)

300

200

100

25

6000

I

REGILM

= 9µA

8000

75 100 125

1704 G19

10000

1704 G22

V

V

OUT

I

LOAD

CH1: V

CH2: 0.1A to 2.1A LOAD, 1A DIV

I

0.1A to 2.1A Load Step

OUTREG

= 1.5V, AC 50mV/DIV

OUTREG

vs I

REGDR

REGILM

50µs/DIV 1704 G20

30

25

20

(mA)

15

REGDR

I

10

5

0

6

I

vs V

REGDR

TA = 25°C

V

REGDR

0

REGFB

= 0V

I

REGILM

0.1 0.3

0.2 0.4

V

REGFB

= 9µA

I

REGILM

0.5

(V)

= 6.2µA

0.6

0.7

1704 G28

0.8

Linear Regulator Current Limit

Threshold vs Temperature

3.0

2.5

2.0

1.5

V

= 1.8V

INREG

= 1.5V

V

OUTREG

CURRENT LIMIT THRESHOLD (A)

1.0

–50

= 9µA

I

REGILM

QEXT = D44H11

–25 0 25 50

TEMPERATURE (°C)

75 100 125

1704 G24

V

OUTREG

vs Load Current

1704bfa

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1704/LTC1704B

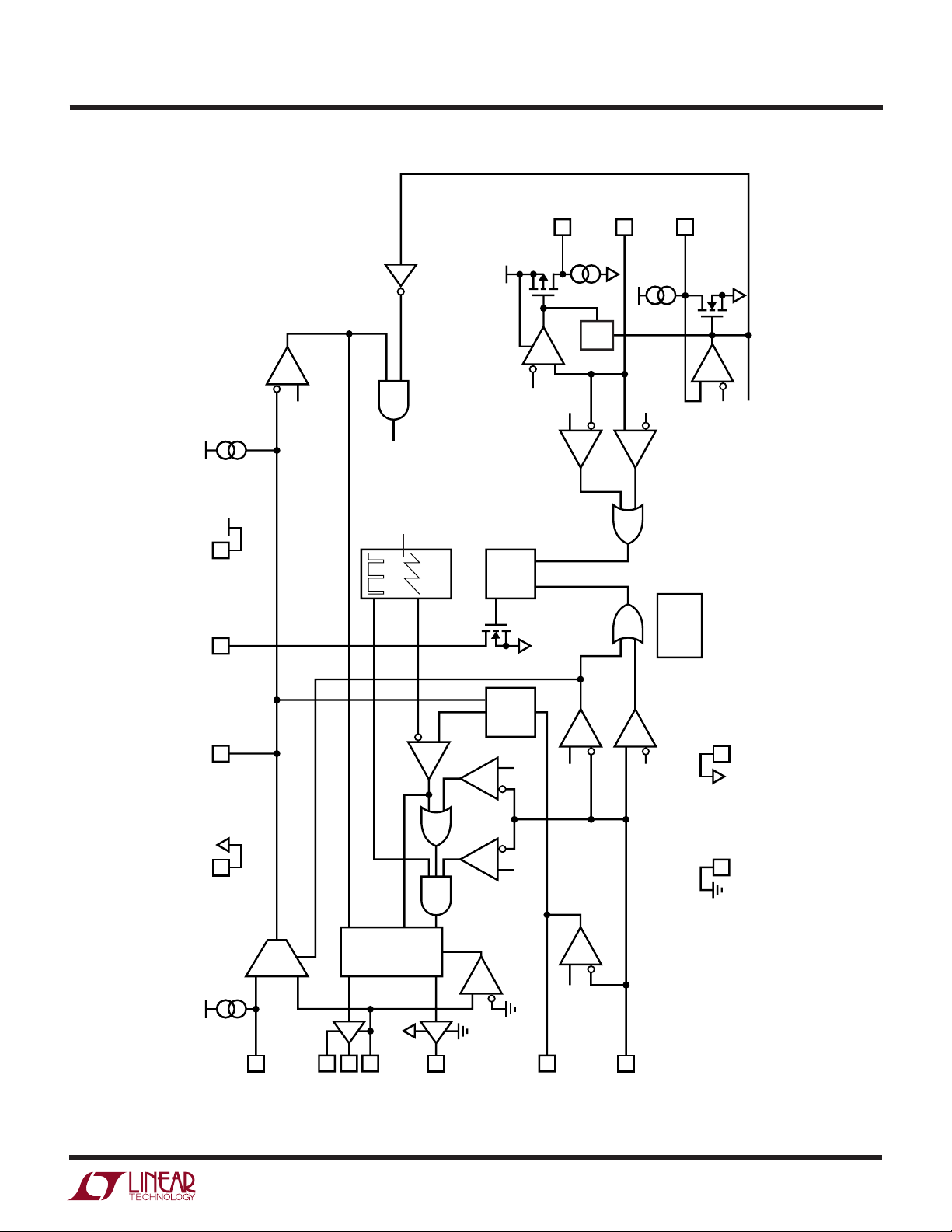

Supply Current vs Temperature I

6.0

VCC = PVCC = BOOST = 5V

TG, BG FLOAT

I

4.5

3.0

SUPPLY CURRENT (mA)

1.5

0

–50

–25 0 25 50

TEMPERATURE (°C)

VCC

I

PVCC

I

BOOST

75 100 125

1704 G26

UUU

PI FU CTIO S

TG (Pin 1): Switcher Controller Top Gate Drive. The TG pin

drives the gate of the top N-channel MOSFET, QT. The TG

driver draws power from the BOOST pin and returns it to

the SW pin, providing true floating drive to QT. TG is designed to typically drive up to 10,000pF of gate capacitance.

SW (Pin 2): Switcher Controller Switching Node. Connect

SW to the switching node of the main converter. The TG

driver ground returns to SW, providing floating gate drive

to the top N-channel MOSFET, QT. The voltage at SW is

compared to I

the bottom MOSFET, QB is on. The Burst comparator

(BURST, see Block Diagram) monitors the potential at SW

and switches to Burst Mode operation under light load

conditions.

I

(Pin 3): Switcher Controller Current Limit Set. The

MAX

I

pin sets the current limit comparator threshold for

MAX

the switcher controller. If the voltage drop across the

bottom MOSFET, QB, exceeds the magnitude of the voltage at I

The I

MAX

pin has an internal 10µA current source pull-up,

MAX

allowing the current threshold to be set with a single

external resistor to PGND. Kelvin connect this current

setting resistor to the source of QB. Refer to the Current

Limit Programming section for more information on choosing R

IMAX

.

by the current limit comparator while

MAX

, the switcher controller enters current limit.

35

30

25

(mA)

20

BOOST

, I

15

PVCC

I

10

PVCC

TA = 25°C

PV

5

0

0

, I

= BOOST = 5V

CC

2000

vs Driver Load

BOOST

4000

TG, BG LOAD (pF)

6000 8000

10000

1704 G27

RUN/SS (Pin 4): Switcher Controller Soft-Start. A capacitor from RUN/SS to GND controls the turn-on time and

rate of rise of the switcher output voltage at power up. An

internal 3µA current source pull-up at RUN/SS sets the

turn-on time at approximately 300ms/µF. If both RUN/SS

and REGILM are pulled low, the LTC1704 enters shutdown

mode.

COMP (Pin 5): Switcher Controller Loop Compensation.

The COMP pin is connected directly to the output of the

switcher controller’s error amplifier and the input to the

PWM comparator. Use an RC network between the COMP

pin and the FB pin to compensate the feedback loop for

optimum transient response.

FB (Pin 6): Switcher Controller Feedback Input. FB should

be connected through a resistor divider network to V

OUTSW

to set the switcher output voltage. Also, connect the

switcher loop compensation network to FB.

REGDR (Pin 7): Linear Regulator Controller Driver Output.

Connect REGDR to the base of the external NPN Pass

transistor. The REGILM pin input current controls the

linear regulator controller maximum driving capability.

GND (Pin 8): Signal Ground. All internal low power circuitry returns to the GND pin. Connect to a low impedance

ground, separated from the PGND node. All feedback,

1704bfa

7

LTC1704/LTC1704B

UUU

PI FU CTIO S

compensation and soft-start connections should return to

GND. GND and PGND should connect only at a single

point, near the PGND pin and the negative plate of the V

IN

bypass capacitor.

REGFB (Pin 9): Linear Regulator Controller Feedback

Input. REGFB should be connected through a resistor

divider network to V

OUTREG

to set the output voltage of the

linear regulator.

REGILM (Pin 10): Linear Regulator Controller Current

Limit Setting cum ON/OFF Control. This pin is internally

servoed to 0.8V. An external resistor R

REGILM

between V

CC

and REGILM programs the REGILM pin input current. This

current determines the maximum pass transistor base

current and directly controls the linear regulator current

sourcing capabilitiy. An external capacitor, C

DELAY

is added

to this pin to control the turn-on time of the linear regulator, the minimum value for this capacitor is 100pF. Refer

to the Linear Regulator Current Limit Programming section for more information on choosing R

REGILM

and C

DELAY

.

Pulling REGILM to GND turns off the linear regulator. If

both RUN/SS and REGILM are pulled low, the LTC1704

enters shutdown mode.

VCC (Pin 11): Power Supply Input. All internal circuits

except the switcher output drivers are powered from this

pin. VCC should be connected to a low noise 5V supply, and

should be bypassed to GND with at least a 10µF capacitor

in close proximity to the LTC1704.

PGOOD (Pin 12): Power Good. PGOOD is an open-drain

logic output. PGOOD pulls low if any of the two supply

outputs are outside ±10% of their nominal levels. An

external pull-up resistor is required at PGOOD to allow it

to swing positive.

PGND (Pin 13): Power Ground. The BG driver returns to

this pin. Connect PGND to a high current ground node in

close proximity to the sources of external MOSFET QB,

and the VIN and V

bypass capacitors.

OUTSW

BG (Pin 14): Switcher Controller Bottom Gate Drive. The

BG pin drives the gate of the bottom N-channel synchronous switch MOSFET, QB. BG is designed to typically drive

up to 10,000pF of gate capacitance.

PVCC (Pin 15): Switcher Controller Bottom Gate Driver Supply. PVCC provides power to the BG output driver. PV

CC

must be connected to a voltage high enough to fully turn

on the external MOSFET, QB. PV

nected directly to VIN, the main system 5V supply. PV

should generally be con-

CC

CC

requires at least a 10µF bypass capacitor directly to PGND.

BOOST (Pin 16): Switcher Controller Top Gate Driver

Supply. The BOOST pin supplies power to the floating TG

driver. Bypass BOOST to SW with a 1µF capacitor. An

external Schottky diode from VIN to BOOST creates a

complete floating charge-pumped supply at BOOST. No

other external supplies are required.

TEST CIRCUIT

8

BOOST

2000pF

80k

I

PVCCIVCC

1

f

OSC

2000pF

V

FB

100Ω

1µF

TG

2

SW

3

I

MAX

4

RUN/SS

2k

5

COMP

6

FB

7

REGDR

8

GND

LTC1704

250k

BOOST

PV

BG

PGND

PGOOD

V

REGILM

REGFB

CC

CC

I

16

15

14

13

12

11

10

9

+

R

REGILM

100k

100pF

1704 TC

5V

10µF

1704bfa

BLOCK DIAGRA

PWRGD

DELAY

OSC

550kHz

0.720V

0.8V

0.8V

POWER-UP LINEAR REGULATOR

REGFB

0.880V

SOFT-

START

BURST

AND

DRIVER

LOGIC

0.720V

0.880V

0.760V0.840V

0.800V

MPG

PWRBAD

REG

PWRBAD

SWITCHER

0.5V

POWER

DOWN

SHUTDOWN

SWITCHER DRIVER

10µA

MAX

BURST

MIN

PPGREG

NPGREG

PPG

NPG

SSCMP

PWM

ILM

I

MAX

BOOST

PGOODRUN/SS

TG

SW

COMP

FB

1704 BD

PV

CC

PGND

GND

V

CC

3µA

15

11

4

12

8

13

6

5

2

BG

PV

CC

14

1

16

3

0.8V

BANDGAP

REFERENCE

REG

ILM

2mA

REGDR

MREG

1.9µA

7

REGFB

9

REGILM

MREGILM

AMP

FB

10

V

B

= 2V TYP

V

A

= 1V TYP

W

LTC1704/LTC1704B

1704bfa

9

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

OVERVIEW

The LTC1704 includes a step-down (buck), voltage mode

feedback switching regulator controller and a linear regulator controller. The switching regulator controller employs a synchronous switching architecture with two

external N-channel MOSFETs. The chip operates from a

low voltage input supply (6V maximum) and provides high

power, high efficiency, precisely regulated output voltage.

The switcher output regulation is extremely tight, with

initial accuracy and DC line and load regulation and better

than 1.5%. Total regulation, including transient response,

is inside of 3.5% with a properly designed circuit. The

550kHz switching frequency allows the use of physically

small, low value external components without compromising performance.

The LTC1704’s internal feedback amplifier is a 20MHz gain

bandwidth op amp, allowing the use of complex multipole/

zero compensation networks. This allows the feedback

loop to maintain acceptable phase margin at higher frequencies than traditional switching regulator controllers,

improving stability and maximizing transient response.

The 800mV internal reference allows regulated output

voltages as low as 800mV without external level shifting

amplifiers. The LTC1704’s synchronous switching logic

transitions automatically into Burst Mode operation, maximizing efficiency with light loads.

The linear regulator controller drives an external NPN pass

transistor to provide a programmable output voltage up to

2A of current. An external pull-up resistor programs the

current limit threshold for the linear regulator. Under

short-circuit condition, the foldback current limit circuitry

prevents excessive pass transistor heating. The switcher

and the linear regulator can be individually disabled. When

both controllers are disabled, the LTC1704 enters shutdown mode and the supply current reduces to 75µA. An

onboard power good (PGOOD) flag goes high when both

outputs are regulating.

Small Footprint

The LTC1704 switcher supply operates at a 550kHz switching frequency, allowing it to use low value inductors

without generating excessive ripple currents. Because the

inductor stores less energy per cycle, the physical size of

the inductor can be reduced without risking core saturation, saving PCB board space. The high operating frequency also means less energy is stored in the output

capacitors between cycles, minimizing their required value

and size. The remaining components, including the

LTC1704, are tiny, allowing an entire power convertor to

be constructed in 1.5in2 of PCB space.

Fast Transient Response

The LTC1704 switcher supply uses a fast 20MHz GBW op

amp as an error amplifier. This allows the compensation

network to be designed with several poles and zeros in a

more flexible configuration than with a typical gm feedback

amplifier. The high bandwidth of the amplifier, coupled

with the high switching frequency and the low values of the

external inductor and output capacitor, allow very high

loop crossover frequencies. The low inductor value is the

other half of the equation—with a typical value on the

order of 1µH, the inductor allows very fast di/dt slew rates.

The result is superior transient response compared with

conventional solutions.

High Efficiency

The LTC1704 switcher supply uses a synchronous stepdown (buck) architecture, with two external N-channel

MOSFETs. A floating topside driver and a simple external

charge pump provide full gate drive to the upper MOSFET.

The voltage mode feedback loop and MOSFET VDS current

limit sensing remove the need for an external current

sense resistor, eliminating an external component and a

source of power loss in the high current path. Properly

designed circuits using low gate charge MOSFETs are

capable of efficiencies exceeding 90% over a wide range

of output voltages.

Linear Regulator Controller

The LTC1704 linear regulator controller drives an external NPN pass transistor in emitter-follower configuration

to provide an externally adjustable output voltage. The controller senses the output voltage via the REGFB pin, drives

the base of the NPN through the REGDR pin to regulate

the REGFB pin to 0.8V. REGDR is capable of sourcing more

than 30mA of base current to the external NPN.

1704bfa

10

LTC1704/LTC1704B

TG

C

CP

D

CP

BOOST

SW

BG

PGND

PV

CC

LTC1704

QT

C

IN

QB

L

+

C

OUTSW

1704 F02

V

OUTSW

V

IN

+

U

WUU

APPLICATIO S I FOR ATIO

Overcurrent protection is achieved by limiting the drive

current. The input current at the REGILM pin programs the

current limit threshold. Refer to the Linear Regulator

Supply Current Limit Programming section for more

information on choosing R

REGILM

controller employs a foldback current limit scheme for

overcurrent protection. Under a short-circuit condition,

the external NPN transistor is subjected to the full input

voltage across its collector-emitter terminal. This increases

the power dissipation of the NPN and may eventually

cause damage to the transistor. LTC1704 overcomes this

problem by using a foldback current limit scheme whereby

the available drive current is reduced as the output voltage

at REGFB pin drops. This limits the power dissipation and

prevents catastrophic damage to the external NPN.

ARCHITECTURE DETAILS

Switcher Supply Architecture

The LTC1704 switcher supply is designed to operate as a

synchronous buck converter (Figure 1). The controller

includes two high power MOSFET gate drivers to control

the external N-channel MOSFETs QT and QB. The drivers

have 0.5Ω output impedances and can carry over an amp

of continuous current with peak currents up to 5A to slew

large MOSFET gates quickly. The drain of QT is connected

to the input supply and the source of QT connected to the

switching node SW. QB is the synchronous rectifier with

its drain at SW and its source at PGND. SW is connected

to one end of the inductor, with the other end connected

to V

. The output capacitor is connected from V

OUTSW

to PGND.

. The linear regulator

OUTSW

When a switching cycle begins, QB is turned off and QT is

turned on. SW rises almost immediately to VIN and the

inductor current begins to increase. When the PWM pulse

completes, QT turns off and one nonoverlap interval later,

QB turns on. Now SW drops to PGND and the inductor

current decreases. The cycle repeats with the next tick of

the master clock. The percentage of time spent in each

mode is controlled by the duty cycle of the PWM signal,

which in turn is controlled by the feedback amplifier. The

master clock runs at a 550kHz rate and turns QT once

every 1.8µs. In a typical application with a 5V input and a

1.5V output, the duty cycle will be set at 1.5/5 • 100% or

30% by the feedback loop. This will give roughly a 540ns

on-time for QT and a 1.26µs on-time for QB.

This constant frequency operation brings with it a couple

of benefits. Inductor and capacitor values can be chosen

with a precise operating frequency in mind and the feedback loop components can be similarly tightly specified.

Noise generated by the circuit will always be in a known

frequency band with the 550kHz frequency designed to

leave the 455kHz IF band free of interference. Subharmonic

oscillation and slope compensation, common headaches

with constant frequency current mode switchers, are

absent in voltage mode designs like the LTC1704. During

the time that QT is on, its source (the SW pin) is at VIN. V

IN

is also the power supply for the LTC1704. However, QT

requires VIN + V

at its gate to achieve minimum RON.

GS(ON)

The LTC1704, needs to generate a gate drive signal at TG

higher than its highest supply voltage. To accomplish this,

the TG driver runs from floating supplies, with its negative

supply attached to SW and its power supply at BOOST.

This allows it to slew up and down with the source of QT.

V

IN

+

C

+

1704 F01

IN

V

OUTSW

C

OUTSW

Figure 2. Floating TG Driver Supply

1704bfa

TG

SW

LTC1704

BG

PGND

Figure 1. Synchronous Buck Architecture

QT

QB

L

11

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

In combination with a simple external charge pump (Figure 2), this allows the LTC1704 to completely enhance the

gate of QT without requiring an additional, higher supply

voltage.

Switcher Supply Feedback Amplifier

The LTC1704 senses the switcher output voltage at V

with an internal feedback op amp (see Block Diagram).

This is a real op amp with a low impedance output, 85dB

open-loop gain and 20MHz gain bandwidth product. The

positive input is connected internally to an 800mV reference, while the negative input is connected to the FB pin.

The output is connected to COMP, which is in turn connected to the soft-start circuitry and from there to the

PWM generator. The switching regulator output voltage

can be obtained using the following equation:

R

1

VV

OUTSW

=+

08 1

.•

R

2

Unlike many regulators that use a resistor divider connected to a high impedance feedback input, the LTC1704

switcher supply is designed to use an inverting summing

amplifier topology with the FB pin configured as a virtual

ground. This allows flexibility in choosing pole and zero

locations not available with simple gm configurations. In

particular, it allows the use of “Type 3” compensation,

which provides a phase boost at the LC pole frequency

and significantly improves loop phase margin (refer to

Figure␣ 3).

C3

+

COMP

LTC1704

R4

FB

C2

Figure 3. "Type 3" Feedback Loop

0.8V

FB

–

C1

R3

R1

R2

1704 F03

V

OUTSW

OUTSW

Switcher Supply MIN/MAX Comparators

Two additional feedback loops in the switcher supply keep

an eye on the primary feedback amplifier and step in if the

feedback node moves ±5% from its nominal 800mV value.

The MAX comparator (see Block Diagram) activates whenever FB rises more than 5% above 800mV. It immediately

turns the top MOSFET (QT) off and the bottom MOSFET

(QB) on and keeps them that way until FB falls back within

5% of its nominal value. This pulls the output down as fast

as possible, preventing damage to the (often expensive)

load. If FB rises because the output is shorted to a higher

supply, QB will stay on until the short goes away, the

higher supply current limits or QB dies trying to save the

load. This behavior provides maximum protection against

overvoltage faults at the output, while allowing the circuit

to resume normal operation when the fault is removed.

The MIN comparator (see Block Diagram) trips whenever

FB is more than 5% below 800mV and immediately forces

the switch duty cycle to 90% to bring the output voltage

back into range. It releases when FB is within the 5%

window. MIN is disabled when the soft-start or current

limit circuits are active—the only two times that the output

should legitimately be below its regulated value.

Notice that the FB pin is the virtual ground node of the

feedback amplifier. A typical compensation network does

not include local DC feedback around the amplifier, so that

the DC level at FB will be an accurate replica of the output

voltage, divided down by R1 and R2 (Figure 3). However,

the compensation capacitors will tend to attenuate AC

signals at FB, especially with low bandwidth Type 1 feedback loops. This creates a situation where the MIN and

MAX comparators do not respond immediately to shifts in

the output voltage, since they monitor the output at FB.

PGOOD Flag

The LTC1704 comes with a power good pin (PGOOD).

PGOOD is an open-drain output, and requires an external

pull-up resistor. If both the regulators are within ±10%

from their nominal value, the transistor MPG shuts off (see

Block Diagram), and PGOOD is pulled high by the external

pull-up resistor. If any of the two outputs is more than 10%

outside the nominal value for more than 1µs, PGOOD pulls

12

1704bfa

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

low, indicating that the output is out of regulation. For

PGOOD to go high, both the outputs must be in regulation

for more than 20µs. PGOOD remains active during soft-

start and current limit. Upon power-up, PGOOD is forced

low. As soon as the RUN/SS and REGILM pins rise above

the shutdown thresholds, the two pairs of power good

comparators take over and control the transistor MPG

directly. The 1µs and 20µs delay ensures that short output

transient glitches that are successfully “caught” by the

power good comparators don’t cause momentary glitches

at the PGOOD pin.

Shutdown/Soft-Start

The RUN/SS pin performs two functions: when pulled to

ground, it shuts down the switcher drivers, and acts as a

conventional soft-start pin, enforcing a maximum duty

cycle limit proportional to the voltage at RUN/SS. An

internal 3µA current source pull-up is connected to the

RUN/SS pin, allowing a soft-start ramp to be generated

with a single external capacitor to ground. The 3µA current

source is active even when the LTC1704 is shut down,

ensuring the device will start when any external pull-down

at RUN/SS is released.

The RUN/SS pin shuts down the switcher drivers when it

falls below 0.5V (Figure 4). Between 0.5V and about 1V,

the LTC1704 wakes up and the duty cycle is kept to

minimum. As the potential at RUN/SS goes higher, the

duty cycle increases linearly between 1V and 2V, reaching

its final value of 90% when RUN/SS is above 2V. Somewhere before this point, the feedback amplifier will assume control of the loop and the output will come into

regulation. When RUN/SS rises to 1V below VCC , the MIN

feedback comparator is enabled, and the LTC1704 voltage

feedback loop is in full operation.

Switcher Supply Current Limit

The LTC1704 switcher supply includes an onboard current limit circuit that limits the maximum output current to

a user-programmed level. It works by sensing the voltage

drop across QB during the time that QB is on and comparing that voltage to a user-programmed voltage at I

Since QB looks like a low value resistor during its on-time,

the voltage drop across it is proportional to the current

MAX

.

flowing in it. In a buck converter, the average current in the

inductor is equal to the output current. This current also

flows through QB during its on-time. Thus, by watching

the voltage across QB, the LTC1704 can monitor the

output current.

Any time QB is on and the current flowing to the output is

reasonably large, the SW node at the drain of QB will be

somewhat negative with respect to PGND. The LTC1704

senses this voltage and inverts it to allow it to compare the

sensed voltage with a positive voltage at the I

I

pin includes a trimmed 10µA pull-up, enabling the

MAX

user to set the voltage at I

with a single resistor, R

MAX

MAX

pin. The

IMAX

,

to ground. The LTC1704 compares the two inputs and

begins limiting the output current when the magnitude of

the negative voltage at the SW pin is greater than the

voltage at I

MAX

.

The current limit detector is connected to an internal gm

amplifier that pulls a current from the RUN/SS pin proportional to the difference in voltage magnitudes between the

SW and I

pins. This current begins to discharge the

MAX

soft-start capacitor at RUN/SS, reducing the duty cycle

and controlling the output voltage until the current drops

below the limit. The soft-start capacitor needs to move a

fair amount before it has any effect on the duty cycle,

adding a delay until the current limit takes effect (Figure 4).

This allows the LTC1704 to experience brief overload

conditions without affecting the output voltage regulation.

V

OUT

CURRENT

0V

5V

4V

2V

1V

0.5V

0V

Figure 4. Soft-Start Operation in Start Up and Current Limit

START-UP

MINIMUM DUTY CYCLE

DRIVER DISABLE MODE

LTC1704 ENABLE

OPERATION

COMP CONTROLS

DUTY CYCLE

RUN/SS CONTROLS

DUTY CYCLE

LIMIT

NORMAL

COMPARATOR

ENABLE

MIN

HARD

CURRENT

LIMIT

1704 F04

1704bfa

13

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

The delay also acts as a pole in the current limit loop to

enhance loop stability. Prolonged overload conditions will

allow the RUN/SS pin to reach a steady state, and the

output will remain at a reduced voltage until the overload

is removed. Under current limit condition, if the output

voltage is less than 10% of its normal value, the soft-start

capacitor will be forced low immediately and the LTC1704

will rerun a complete soft-start cycle. The soft-start capacitor must be selected such that during power-up the

current through QB will not exceed the current limit value.

Power MOSFET R

limiting the accuracy obtainable from the LTC1704 current

limit loop. Additionally, ringing on the SW node due to

parasitics can add to the apparent current, causing the

loop to engage early. When the load current increases

abruptly, the voltage feedback loop forces the duty cycle

to increase rapidly and the on-time of QB will be small

momentarily. The R

ensure that the SW node is pulled low within the QB ontime for proper current sensing. The LTC1704 current limit

is designed primarily as a disaster prevention, “no blowup” circuit, and is not useful as a precision current regulator. It should typically be set around 50% above the

maximum expected normal output current to prevent component tolerances from encroaching on the normal current range. See the Switching Supply Current Limit Programming section for advice on choosing a valve for R

varies from MOSFET to MOSFET,

DS(ON)

of QB must be low enough to

DS(ON)

IMAX

.

Continuous mode works efficiently when the load current

is greater than half of the ripple current in the inductor. In

a buck converter like the LTC1704, the average current in

the inductor (averaged over one switching cycle) is equal

to the load current. The ripple current is the difference

between the maximum and the minimum current during

a switching cycle (see Figure 5a). The ripple current

depends on inductor value, clock frequency and output

voltage, but is constant regardless of load as long as the

LTC1704 remains in Continuous mode. See the Inductor

Selection section for a detailed description of ripple

current.

As the output load current decreases in Continuous mode,

the average current in the inductor will reach a point where

it drops below half the ripple current. At this point, the

current in the inductor will reverse during a portion of the

switching cycle, or begin to flow from the output back to

the input. This does not adversely affect regulation, but

does cause additional losses as a portion of the inductor

current flows back and forth through the resistive power

switches, giving away a little more power each time and

lowering the efficiency. There are some benefits to allowing this reverse current flow: the circuit will maintain

regulation even if the load current drops below zero (the

load supplies current to the LTC1704) and the output

ripple voltage and frequency remain constant at all loads,

easing filtering requirements.

BURST MODE OPERATION

Theory of Operation

The LTC1704 (non-B part) switcher supply has two modes

of operation. Under heavy loads, it operates as a fully

synchronous, continuous conduction switching regulator. In this mode of operation (“Continuous” mode), the

current in the inductor flows in the positive direction

(toward the output) during the entire switching cycle,

constantly supplying current to the load. In this mode, the

synchronous switch (QB) is on whenever QT is off, so the

current always flows through a low impedance switch,

minimizing voltage drop and power loss. This is the most

efficient mode of operation at heavy loads, where the

resistive losses in the power devices are the dominant loss

term.

(For Non-B Parts Only)

14

Besides the reverse current loss, the LTC1704 drivers are

still switching QT and QB on and off once a cycle. Each time

an external MOSFET is turned on, the internal driver must

charge its gate to PVCC. Each time it is turned off, that

charge is lost to ground. At the high switching frequency

that the LTC1704 operates, the charge lost to the gates can

add up to tens of milliamps from PVCC. As the load current

continues to drop, this quickly becomes the dominant

power loss term, reducing efficiency once again.

To minimize the efficiency loss due to switching loss and

reverse current flow at light loads, the LTC1704 (non-B

part) switches to a second mode of operation: Burst Mode

operation (Figure 5b). In Burst Mode operation, the

LTC1704 detects when the inductor current approaches

zero and turns off both drivers. During this time, the

voltage at the SW pin will float around V

OUTSW

, the voltage

1704bfa

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

across the inductor will be zero, and the inductor current

remains zero. This prevents current from flowing backwards in QB, eliminating that power loss term. It also

reduces the ripple current in the inductor as the output

current approaches zero.

I

RIPPLE

I

AVERAGE

INDUCTOR CURRENT

Figure 5a. Continous Mode

INDUCTOR CURRENT

Figure 5b. Burst Mode Operation

I

RIPPLE

TIME

TIME

I

AVERAGE

1704 F05

The burst comparator is turned on only at the last 180ns

of the switching period, the propagation delay of the

comparator is designed to be fast so that a zero or low

positive voltage on the SW node can trip the comparator

within this 180ns. Low inductor ripple current coupled

with low MOSFET R

may prolong the delay of the

DS(ON)

burst comparator and prevent the comparator from tripping. To overcome this, reduce the inductor value to

increase the ripple current and the SW node voltage

change.

The moment LTC1704 (non-B parts) enters Burst Mode

operation, both drivers skip several switching cycles until

the output droops. Once the voltage feedback loop requests

for an additional 10% duty cycle, the LTC1704 enters Continuous mode operation again. To eliminate audible noise

from certain types of inductors when they are lightly loaded,

LTC1704 includes an internal timer that forces Continuous

mode operation every 15µs.

The LTC1704B does not shift into Burst Mode operation at

light loads, eliminating low frequency output ripple at the

expense of light load efficiency.

The LTC1704 detects when the inductor current has

reached zero by monitoring the voltage at the SW pin while

QB is on (see BURST in Block Diagram). Since QB acts like

a resistor, SW should ideally be right at 0V when the

inductor current reaches zero. In reality, the SW node will

ring to some degree immediately after it is switched to

ground by QB, causing some uncertainty as to the actual

moment the average current in QB goes to zero. The

LTC1704 minimizes this effect by turning on the Burst

Comparator only at the last 180ns of the switching period,

before QB turns off. In addition, the Burst Comparator is

disabled if QB turns on for less than 200ns. Despite this,

care must still be taken in the PCB layout to ensure that

proper kelvin sensing for the SW pin is provided. Connect

the SW pin of the LTC1704 as close to the drain of QB as

possible through a thick trace. The same applies to the

PGND pin of the LTC1704, which is the negative input of

the burst comparator and it should be connected close to

the source of QB through a thick trace. Ringing on the

PGND pin due to an insufficient PVCC bypass capacitor can

also cause the burst comparator to trip prematurely.

Connect at least a 10µF bypass capacitor directly from the

PVCC pin to PGND.

In Burst Mode operation, both resistive loss and switching

loss are minimized while keeping the output in regulation.

The total deviation from the regulated output is within the

1.5% regulation tolerance of the LTC1704. As the load

current falls to zero in Burst Mode operation, the most

significant loss term becomes the 4.5mA quiescent current drawn by the LTC1704—usually much less than the

minimum load current in a typical low voltage logic system. Burst Mode operation maximizes efficiency at low load

currents, but can cause low frequency ripple in the output

voltage as the cycle-skipping circuitry switches on and off.

V

SW

0V

5V

V

BG

0V

BURST

COMPARATOR

DISABLED IF QB

TURNS ON FOR

LESS THAN 200ns

Figure 6. Burst Comparator Turns On 180ns Before QB Turns Off

BURST

COMPARATOR

TURNS ON

180ns BEFORE

QB TURNS OFF

TIME

TIME

1704 F06

1704bfa

15

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

Maximizing High Load Current Efficiency

Efficiency at high load currents is primarily controlled by

the resistance of the components in the power path (QT,

QB, L) and power lost in the gate drive circuits due to

MOSFET gate charge. Maximizing efficiency in this region

of operation is as simple as minimizing these terms.

The behavior of the load over time affects the efficiency

strategy. Parasitic resistances in the MOSFETs and the

inductor set the maximum output current the circuit can

supply without burning up. A typical efficiency curve

shows that peak efficiency occurs near 30% of this maximum current. If the load current will vary around the

efficiency peak and spend relatively little time at the

maximum load, choosing components so that the average

load is at the efficiency peak is a good idea. This puts the

maximum load well beyond the efficiency peak, but usually gives the greatest system efficiency over time, which

translates to the longest run time in a battery-powered

system. If the load is expected to be relatively constant at

the maximum level, the components should be chosen so

that this load lands at the peak efficiency point, well below

the maximum possible output of the converter.

Maximizing Low Load Current Efficiency

Low load current efficiency depends strongly on proper

operation in Burst Mode operation. In an ideally optimized

system, when Burst Mode operation is activated, gate

drive is the dominant loss term. Burst Mode operation

turns off all output switching for several clock cycles in a

row, significantly cutting gate drive losses. As the load

current in Burst Mode operation falls toward zero, the

current drawn by the circuit falls to the LTC1704’s background quiescent level, about 4.5mA.

To maximize low load efficiency, make sure the LTC1704

(non-B part) is allowed to enter Burst Mode operation as

cleanly as possible. Minimize ringing at the SW node so

that the Burst comparator leaves as little residual current

in the inductor as possible when QB turns off. It helps to

connect the SW pin of the LTC1704 as close to the drain

of QB as possible. An RC snubber network can also be

added from SW to PGND.

SWITCHER SUPPLY EXTERNAL

COMPONENT SELECTION

Power MOSFETs Selection

Getting peak efficiency out of the LTC1704 switcher supply depends strongly on the external MOSFETs used. The

LTC1704 requires at least two external MOSFETs—more

if one or more of the MOSFETs are paralleled to lower onresistance. To work efficiently, these MOSFETs must

exhibit low R

loss while they are conducting current. They must also

have low gate charge to minimize transition losses during

switching. On the other hand, voltage breakdown requirements in a typical LTC1704 circuit are pretty tame; the 6V

maximum input voltage limits the VDS and VGS the MOSFETs

can see to safe levels for most devices.

Low R

DS(ON)

R

the resistance from the drain to the source of the MOSFET

when the gate is fully on. Many MOSFETs have R

specified at 4.5V gate drive—this is the right number to

use in LTC1704 circuits running from a 5V supply. As

current flows through this resistance while the MOSFET is

on, it generates I2R watts of heat, where I is the current

flowing (usually equal to the output current) and R is the

MOSFET R

MOSFET is on. When it is off, the current is zero and the

power lost is also zero (and the other MOSFET is busy

losing power).

This lost power does two things: it subtracts from the

power available at the output, costing efficiency, and it

makes the MOSFET hotter, both bad things. The effect is

worst at maximum load when the current in the MOSFETs

and thus the power lost, are at a maximum. Lowering

R

additional gate charge (usually) and more cost (usually).

Proper choice of MOSFET R

between tolerable efficiency loss, power dissipation and

cost. Note that while the lost power has a significant effect

on system efficiency, it only adds up to a watt or two in a

typical LTC1704 circuit, allowing the use of small, surface

mount MOSFETs without heat sinks.

calculations are pretty straightforward. R

DS(ON)

DS(ON)

improves heavy load efficiency at the expense of

DS(ON)

at 5V VGS to minimize resistive power

DS(ON)

. This heat is only generated when the

becomes a trade-off

DS(ON)

DS(ON)

DS(ON)

is

16

1704bfa

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

Gate Charge

Gate charge is amount of charge (essentially, the number

of electrons) that the LTC1704 needs to put into the gate

of an external MOSFET to turn it on. The easiest way to

visualize gate charge is to think of it as a capacitance from

the gate pin of the MOSFET to SW (for QT) or to PGND (for

QB). This capacitance is composed of MOSFET channel

charge, actual parasitic drain-source capacitance and

Miller-multiplied gate-drain capacitance, but can be approximated as a single capacitance from gate to source.

Regardless of where the charge is going, the fact remains

that it all has to come out of PVCC to turn the MOSFET gate

on, and when the MOSFET is turned back off, that charge

all ends up at ground. In the meanwhile, it travels through

the LTC1704’s gate drivers, heating them up. More power

lost!

In this case, the power is lost in little bite-sized chunks, one

chunk per switch per cycle, with the size of the chunk set

by the gate charge of the MOSFET. Every time the MOSFET

switches, another chunk is lost. Clearly, the faster the

clock runs, the more important gate charge becomes as a

loss term. Old fashioned switchers that ran at 20kHz could

pretty much ignore gate charge as a loss term. In the

550kHz LTC1704, gate charge loss can be a significant

efficiency penalty. Gate charge loss can be the dominant

loss term at medium load currents, especially with large

MOSFETs. Gate charge loss is also the primary cause of

power dissipation in the LTC1704 itself.

TG Charge Pump

There’s another nuance of MOSFET drive that the LTC1704

needs to get around. The LTC1704 is designed to use

N-channel MOSFETs for both QT and QB, primarily because N-channel MOSFETs generally cost less and have

lower R

QB on is no big deal since the source of QB is attached to

PGND; the LTC1704 just switches the BG pin between

PGND and PVCC . Driving QT is another matter. The source

of QT is connected to SW which rises to VIN when QT is on.

To keep QT on, the LTC1704 must get TG one MOSFET

V

GS(ON)

with the negative lead of the driver attached to SW (the

source of QT) and the PVCC lead of the driver coming out

than similar P-channel MOSFETs. Turning

DS(ON)

above VIN. It does this by utilizing a floating driver

separately at BOOST. An external 1µF capacitor (CCP)

connected between SW and BOOST (Figure 2) supplies

power to BOOST when SW is high, and recharges itself

through DCP when SW is low. This simple charge pump

keeps the TG driver alive even as it swings well above VIN.

The value of the bootstrap capacitor CCP needs to be at

least 100 times that of the total input capacitance of the

topside MOSFET(s). For very large external MOSFETs (or

multiple MOSFETs in parallel), CCP may need to be increased beyond the 1µF value.

Input Supply

The BiCMOS process that allows the LTC1704 switcher

supply to include large MOSFET drivers on-chip also limits

the maximum input voltage to 6V. This limits the practical

maximum input supply to a loosely regulated 5V or 6V rail.

At the same time, the input supply needs to supply several

amps of current without excessive voltage drop. The input

supply must have regulation adequate to prevent sudden

load changes from causing the LTC1704 input voltage to

dip. In most typical applications where the LTC1704 is

generating a secondary low voltage logic supply, all of

these input conditions are met by the main system logic

supply when fortified with an input bypass capacitor.

Input Bypass Capacitor Selection

A typical LTC1704 circuit running from a 5V logic supply

might provide 1.6V at 10A at its switcher output. 5V to

1.6V implies a duty cycle of 32%, which means QT is on

32% of each switching cycle. During QT’s on-time, the

current drawn from the input equals the load current and

during the rest of the cycle, the current drawn from the

input is near zero. This 0A to 10A, 32% duty cycle pulse

train results in 4.66A

ing cycles last about 1.8µs; most system logic supplies

have no hope of regulating output current with that kind of

speed. A local input bypass capacitor is required to make

up the difference and prevent the input supply from

dropping drastically when QT kicks on. This capacitor is

usually chosen for RMS ripple current capability and ESR

as well as value.

Consider our 10A example. The input bypass capacitor

gets exercised in three ways: its ESR must be low enough

ripple current. At 550kHz, switch-

RMS

1704bfa

17

LTC1704/LTC1704B

I

tV

L

RIPPLE

ON QB OUT

=

()

()

U

WUU

APPLICATIO S I FOR ATIO

to keep the initial drop as QT turns on within reason

(100mV or so); its RMS current capability must be adequate to withstand the 4.66A capacitor ripple current is

not the same as input RMS current at the input and the

capacitance must be large enough to maintain the input

voltage until the input supply can make up the difference.

Generally, a capacitor that meets the first two parameters

will have far more capacitance than is required to keep

capacitance-based droop under control. In our example,

we need 0.01Ω ESR to keep the input drop under 100mV

with a 10A current step and 5.65A

capacity to avoid overheating the capacitor. These requirements can be met with multiple low ESR tantalum or

electrolytic capacitors in parallel, or with a large monolithic ceramic capacitor.

I

RMSIN

IA

DCIN

IA

RIPP RMS

Tantalum capacitors are a popular choice as input capacitors for LTC1704 applications, but they deserve a special

caution here. Generic tantalum capacitors have a destructive failure mechanism when they are subjected to large

RMS currents (like those seen at the input of an LTC1704).

At some random time after they are turned on, they can

blow up for no apparent reason. The capacitor manufacturers are aware of this and sell special “surge tested”

tantalum capacitors specifically designed for use with

switching regulators. When choosing a tantalum input

capacitor, make sure that it is rated to carry the RMS

current that the LTC1704 will draw. If the data sheet

doesn’t give an RMS current rating, chances are the

capacitor isn’t surge tested. Don’t use it!

Output Bypass Capacitor Selection

The output bypass capacitor has quite different requirements from the input capacitor. The ripple current at the

output of a buck regulator, like the LTC1704’s switcher

controller, is much lower than at the input because the

inductor current is constantly flowing at the output whenever the LTC1704 is operating in Continuous mode. The

primary concern at the output is capacitor ESR. Fast load

current transitions at the output will appear as voltage

=

565

.

=

32

.

==

22

565 32 466

(. ) –(.) .

ripple current

RMS

across the ESR of the output bypass capacitor until the

feedback loop in the LTC1704 can change the inductor

current to match the new load current value. This ESR step

at the output is often the single largest budget item in the

load regulation calculation. As an example, our hypothetical 1.6V, 10A switcher with a 0.01Ω ESR output capacitor

would experience a 100mV step at the output with a 0A to

10A load step—a 6.3% output change!

Usually the solution is to parallel several capacitors at the

output. For example, to keep the transient response inside

of 3% with the previous design, we’d need an output ESR

better than 0.0048Ω. This can be met with three 0.014Ω,

470µF tantalum capacitors in parallel.

Inductor Selection

The inductor in a typical LTC1704 circuit is chosen primarily for value and saturation current. The inductor value

sets the ripple current, which is commonly chosen at

around 40% of the anticipated full load current. Ripple

current is set by:

In our hypothetical 1.6V, 10A example, we’d set the ripple

to 40% of 10A or 4A, and the inductor value would be:

The inductor must not saturate at the expected peak

current. In this case, if the current limit was set to 15A, the

inductor should be rated to withstand 15A + 1/2I

17A without saturating.

FEEDBACK LOOP/COMPENSATION

Feedback Loop Types

In a typical LTC1704 switcher circuit, the feedback loop

consists of the modulator, the external inductor and

output capacitor, and the feedback amplifier and its com-

tV

L

==µ=µ

with t

()

ON QB OUT

()

I

RIPPLE

()

=−

ON QB

(. )(. )

12 16

V

.

16

1

V

5

sV

A

4

/.

550 1 2

.

05

kHz s

=µ

H

RIPPLE

, or

1704bfa

18

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

pensation network. All of these components affect loop

behavior and need to be accounted for in the loop compensation. The modulator consists of the internal PWM generator, the output MOSFET drivers and the external

MOSFETs themselves. From a feedback loop point of view,

it looks like a linear voltage transfer function from COMP

to SW and has a gain roughly equal to the input voltage. It

has fairly benign AC behavior at typical loop compensation

frequencies with significant phase shift appearing at half

the switching frequency.

The external inductor/output capacitor combination makes

a more significant contribution to loop behavior. These

components cause a second order LC roll-off at the

output, with the attendant 180° phase shift. This roll-off is

what filters the PWM waveform, resulting in the desired

DC output voltage, but the phase shift complicates the

loop compensation if the gain is still higher than unity at

the pole frequency. Eventually (usually well above the LC

pole frequency), the reactance of the output capacitor will

approach its ESR, and the roll-off due to the capacitor will

stop, leaving 6dB/octave and 90° of phase shift (Figure 7).

So far, the AC response of the loop is pretty well out of the

user’s control. The modulator is a fundamental piece of

the LTC1704 design, and the external L and C are usually

chosen based on the regulation and load current requirements without considering the AC loop response. The

feedback amplifier, on the other hand, gives us a handle

with which to adjust the AC response. The goal is to have

180° phase shift at DC (so the loop regulates) and

some

thing less than 360° phase shift at the point that the

loop gain falls to 0dB. The simplest strategy is to set up the

feedback amplifier as an inverting integrator, with the 0dB

frequency lower than the LC pole (Figure 8). This “Type 1”

configuration is stable but transient response will be less

than exceptional if the LC pole is at a low frequency.

Figure 9 shows an improved “Type 2” circuit that uses an

additional pole-zero pair to temporarily remove 90° of phase

shift. This allows the loop to remain stable with 90° more

phase shift in the LC section, provided the loop reaches 0dB

gain near the center of the phase “bump.” Type 2 loops work

well in systems where the ESR zero in the LC roll-off happens close to the LC pole, limiting the total phase shift due

to the LC. The additional phase compensation in the feedback amplifier allows the 0dB point to be at or above the

LC pole frequency, improving loop bandwidth substantially

over a simple Type 1 loop. It has limited ability to compensate for LC combinations where low capacitor ESR keeps

the phase shift near 180° for an extended frequency range.

LTC1704 circuits using conventional switching grade electrolytic output capacitors can often get acceptable phase

margin with Type 2 compensation.

“Type 3” loops (Figure 10), use two poles and two zeros

to obtain a 180° phase boost in the middle of the frequency

band. A properly designed Type 3 circuit can maintain

acceptable loop stability even when low output capacitor

ESR causes the LC section to approach 180° phase shift

well above the initial LC roll-off. As with a Type 2 circuit,

the loop should cross through 0dB in the middle of the

phase bump to maximize phase margin. Many LTC1704

circuits use low ESR tantalum or OS-CON output capacitors need Type 3 compensation to obtain acceptable phase

margin with a high bandwidth feedback loop.

PHASE (DEG)

GAIN (dB)

GAIN

A

V

0

PHASE

Figure 7. Transfer Function of Buck Modulator

–12dB/OCT

–6dB/OCT

FREQ

–90

–180

–270

–360

1704 F05

IN

R1

FB

R2

V

REF

C1

–

0

COMP

+

Figure 8. Type 1 Schematic and Transfer Function

GAIN

GAIN (dB)

PHASE

PHASE (DEG)

–6dB/OCT

FREQ

–90

–180

–270

–360

1704 F06

1704bfa

19

LTC1704/LTC1704B

U

WUU

APPLICATIO S I FOR ATIO

C2

IN

R1

FB

–

R2

V

+

REF

C1

R4

COMP

GAIN (dB)

GAIN

0

PHASE

–6dB/OCT

–6dB/OCT

Figure 9. Type 2 Schematic and Transfer Function

IN

C3

R1

R3

FB

R2

V

REF

C2

C1

R4

–

COMP

GAIN (dB)

GAIN

0

–6dB/OCT

+6dB/OCT –6dB/OCT

+

PHASE

Figure 10. Type 3 Schematic and Transfer Function

Feedback Component Selection

Selecting the R and C values for a typical Type 2 or Type

3 loop is a nontrivial task. The applications shown in this

data sheet show typical values, optimized for the power

components shown. They should give acceptable performance with similar power components, but can be way

off if even one major power component is changed

significantly. Applications that require optimized transient response will need to recalculate the compensation

values specifically for the circuit in question. The underlying mathematics are complex, but the component

values can be calculated in a straightforward manner if

we know the gain and phase of the modulator at the

crossover frequency.

Modulator gain and phase can be measured directly from

a breadboard, or can be simulated if the appropriate parasitic values are known. Measurement will give more accu-

PHASE (DEG)

FREQ

–90

–180

–270

–360

1704 F09

PHASE (DEG)

FREQ

–90

–180

–270

–360

1704 F10

rate results, but simulation can often get close enough to

give a working system. To measure the modulator gain and

phase directly, wire up a breadboard with an LTC1704 and

the actual MOSFETs, inductor, and input and output capacitors that the final design will use. This breadboard should

use appropriate construction techniques for high speed

analog circuitry: bypass capacitors located close to the

LTC1704, no long wires connecting components, appropriately sized ground returns, etc. Wire the feedback amplifier as a simple Type 1 loop, with a 10k resistor from

V

to FB and a 0.1µF feedback capacitor from COMP

OUTSW

to FB. Choose the bias resistor (R2) as required to set the

desired output voltage. Disconnect R2 from ground and

connect it to a signal generator or to the source output of

a network analyzer (Figure 11) to inject a test signal into the

loop. Measure the gain and phase from the COMP pin to

the output node at the positive terminal of the output capacitor. Make sure the analyzer’s input is AC coupled so that

the DC voltages present at both the COMP and V

OUTSW

nodes don’t corrupt the measurements or damage the

analyzer.

5V

10Ω

+

V

COMP

ANALYZER

AC SOURCE

FROM

ANALYZER

0.1µF

R2

TO

10µF

V

COMP

FB

10k

GND

PV

CC

BOOST

LTC1704

RUN/SS NC

PGND

MBR0530T

CC

TG

1µF

SW

BG

QT

QB

L

V

TO

OUTSW

ANALYZER

+

C

OUT

1704 F11

Figure 11. Modulator Gain/Phase Measurement Setup

If breadboard measurement is not practical, a SPICE

simulation can be used to generate approximate gain/

phase curves. Plug the expected capacitor, inductor and

MOSFET values into the following SPICE deck and generate an AC plot of V(V

)/V(COMP) in dB and phase of

OUTSW

V(OUTSW) in degrees. Refer to your SPICE manual for

details of how to generate this plot.

20

1704bfa

LTC1704/LTC1704B

K Tan

BOOST

C

fGKR

CCK

R

K

fC

R

VR

VV

REF

OUTSW REF

=+°

=

=−

()

=

=

−

2

45

2

1

21

12 1

4

21

2

1